Fatigue Examination of HSLA Steel with Yield Strength of 960 MPa and Its Welded Joints under Strain Mode

Abstract

1. Introduction

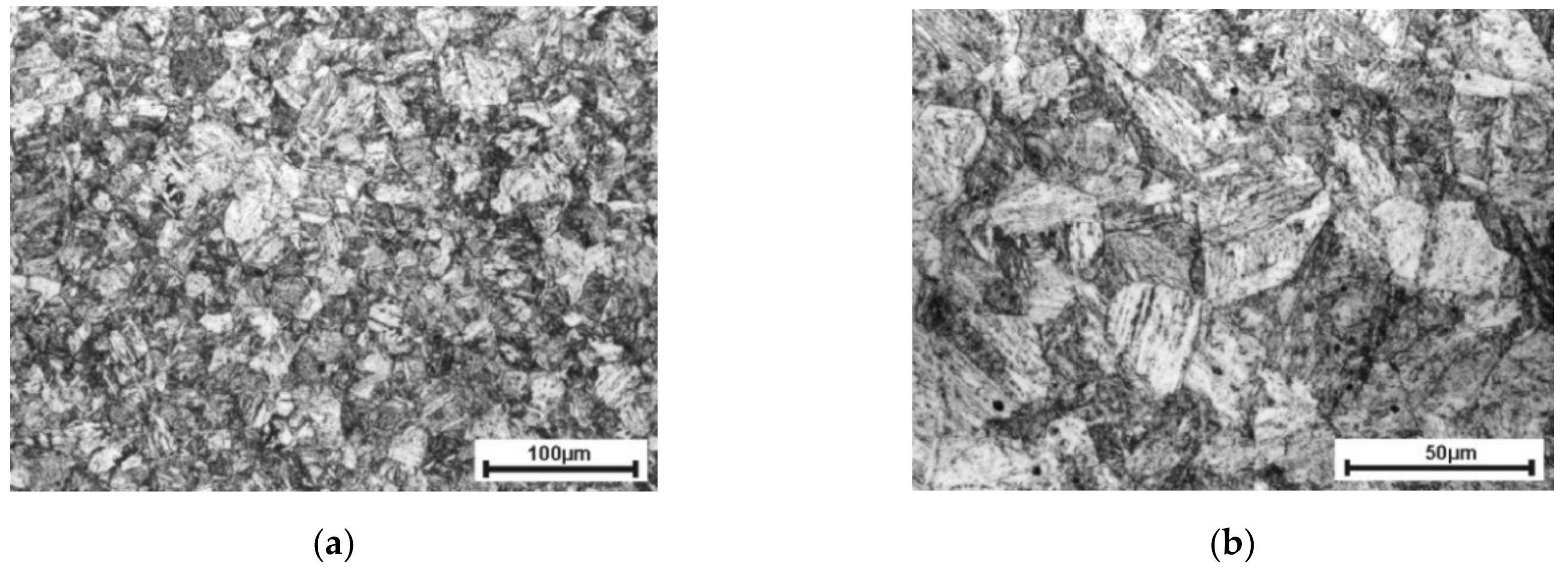

2. Materials and Methods

3. Results

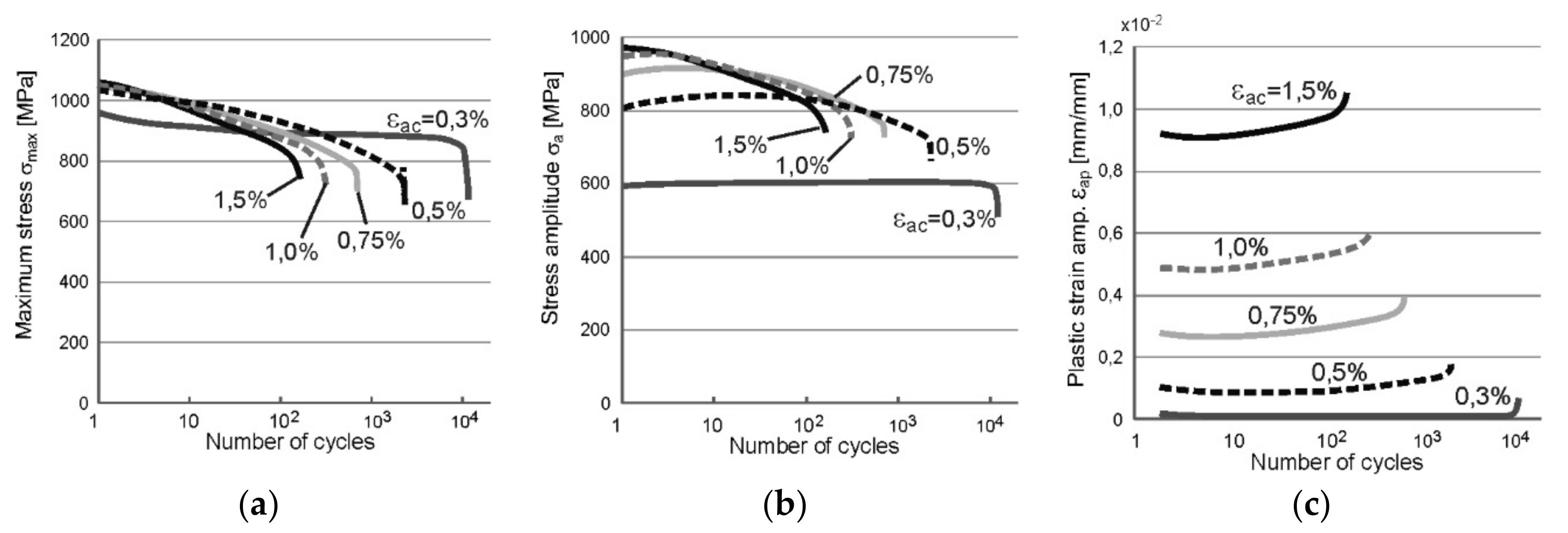

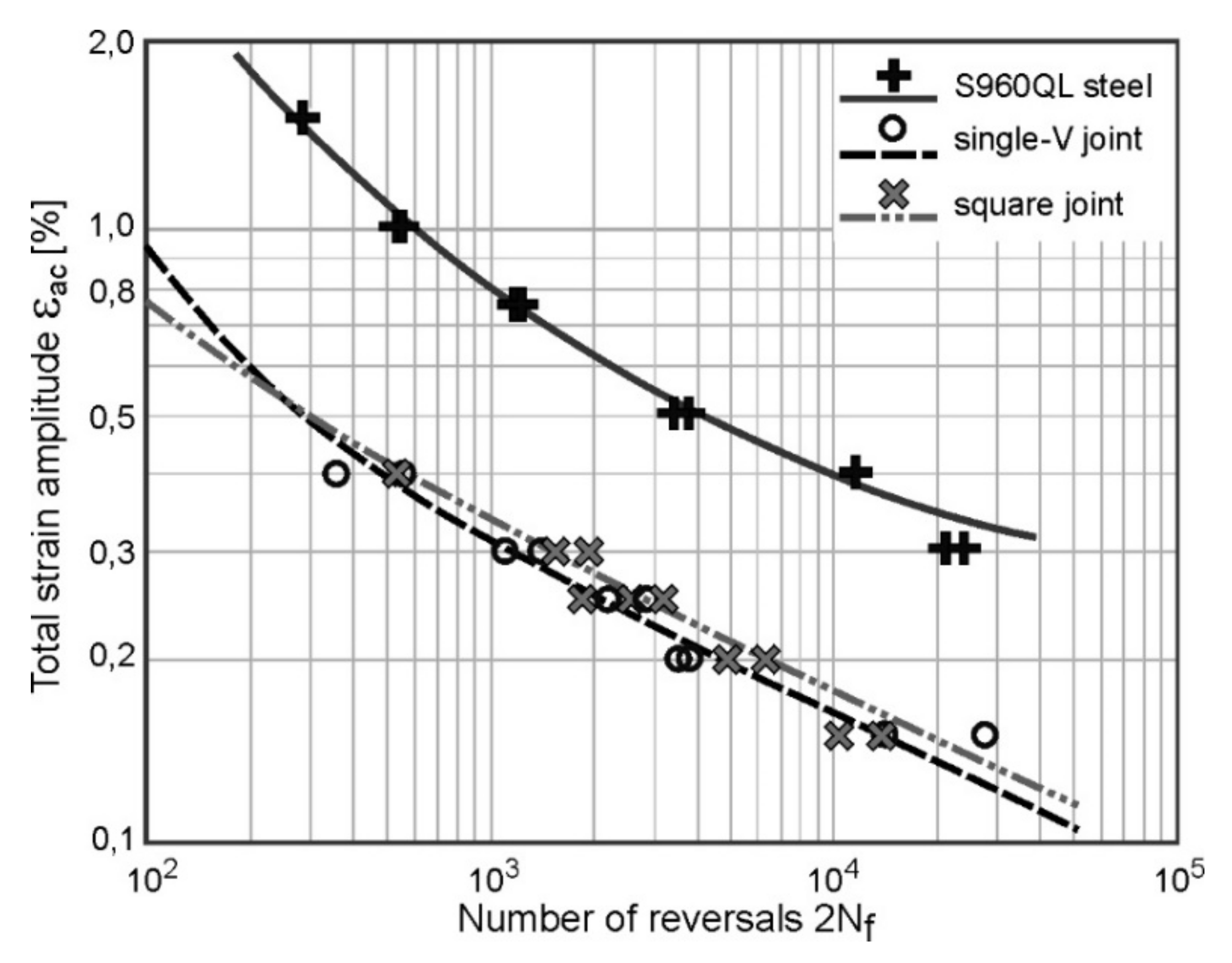

3.1. LCF Tests for S960QL Steel and Its Welded Joints

- εac—a total strain amplitude;

- εae—an elastic component of total strain;

- εap—a plastic component of total strain;

- σ’f—a fatigue strength coefficient;

- ε’f—a fatigue ductility coefficient;

- Nf—a number of cycles to failure;

- 2Nf—a number of reversals to failure;

- b—a fatigue strength exponent;

- c—a fatigue ductility exponent.

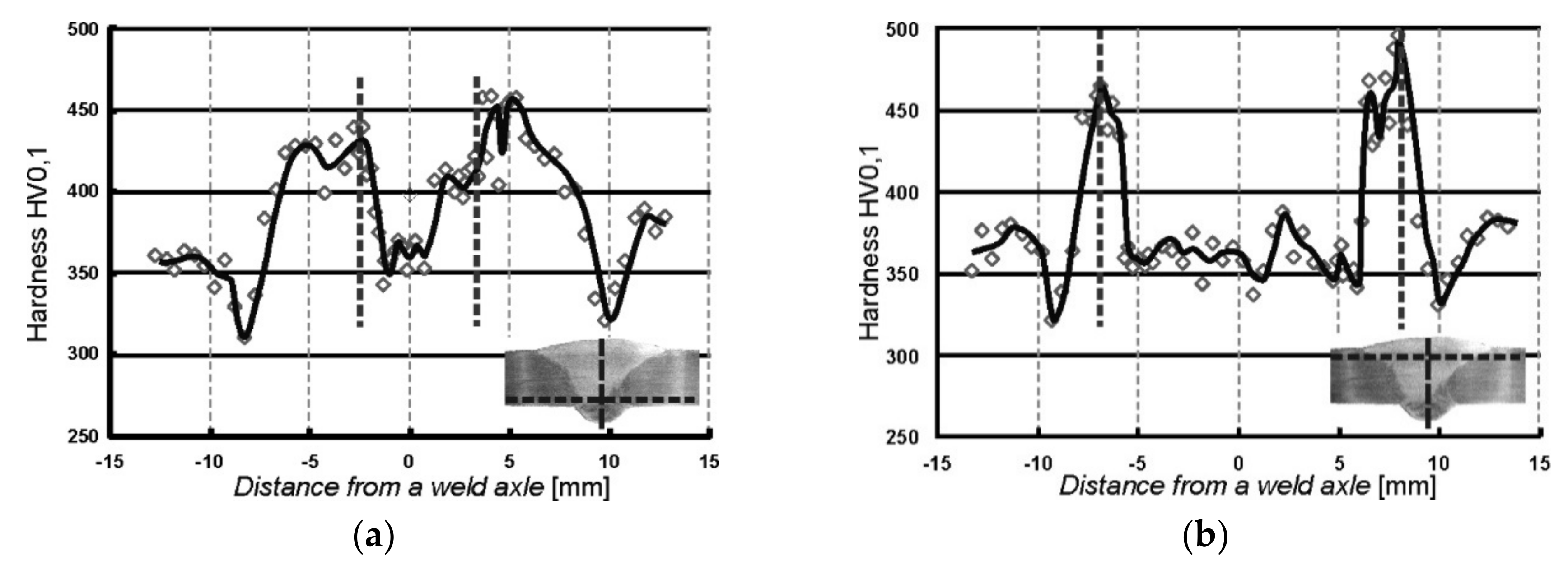

3.2. Measurement of Microhardness

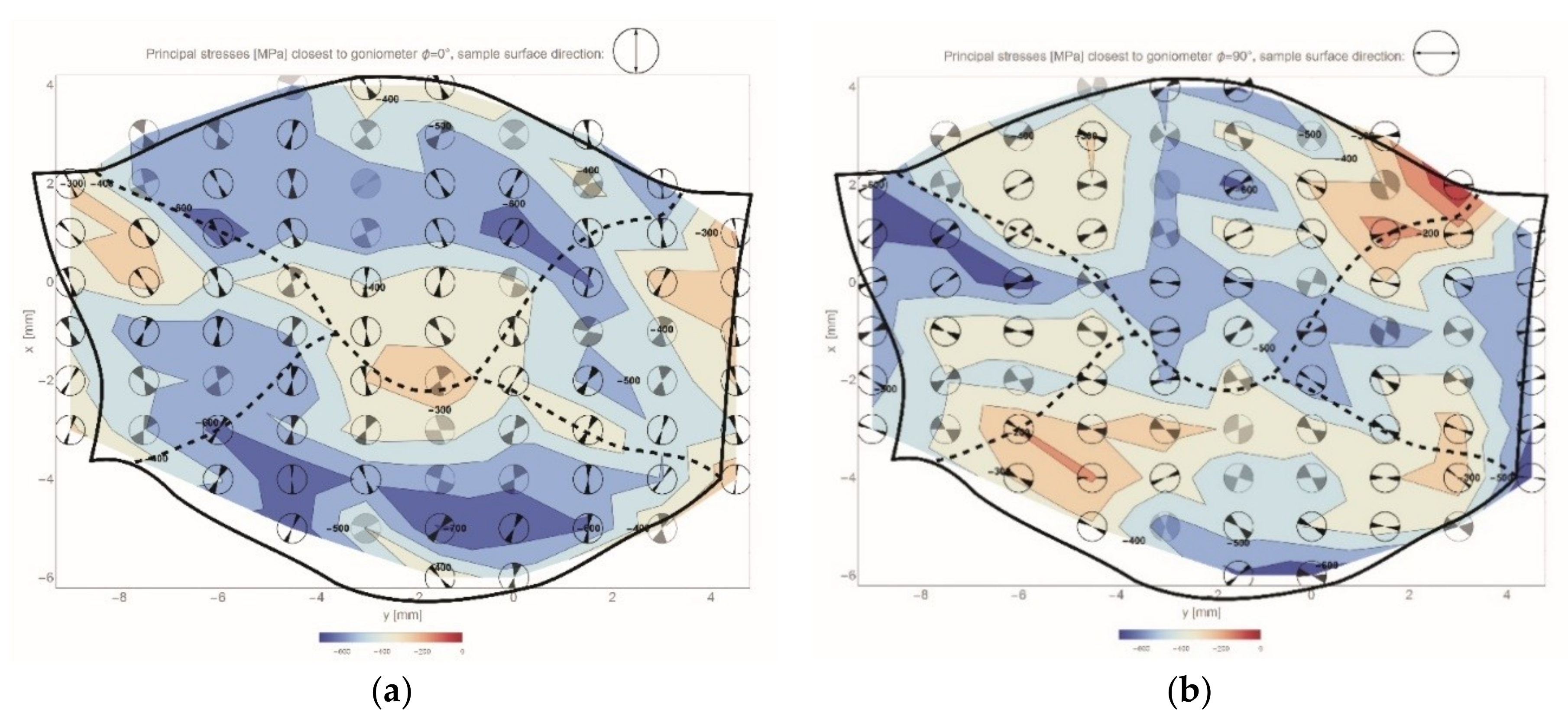

3.3. Residual Stresses Analysis

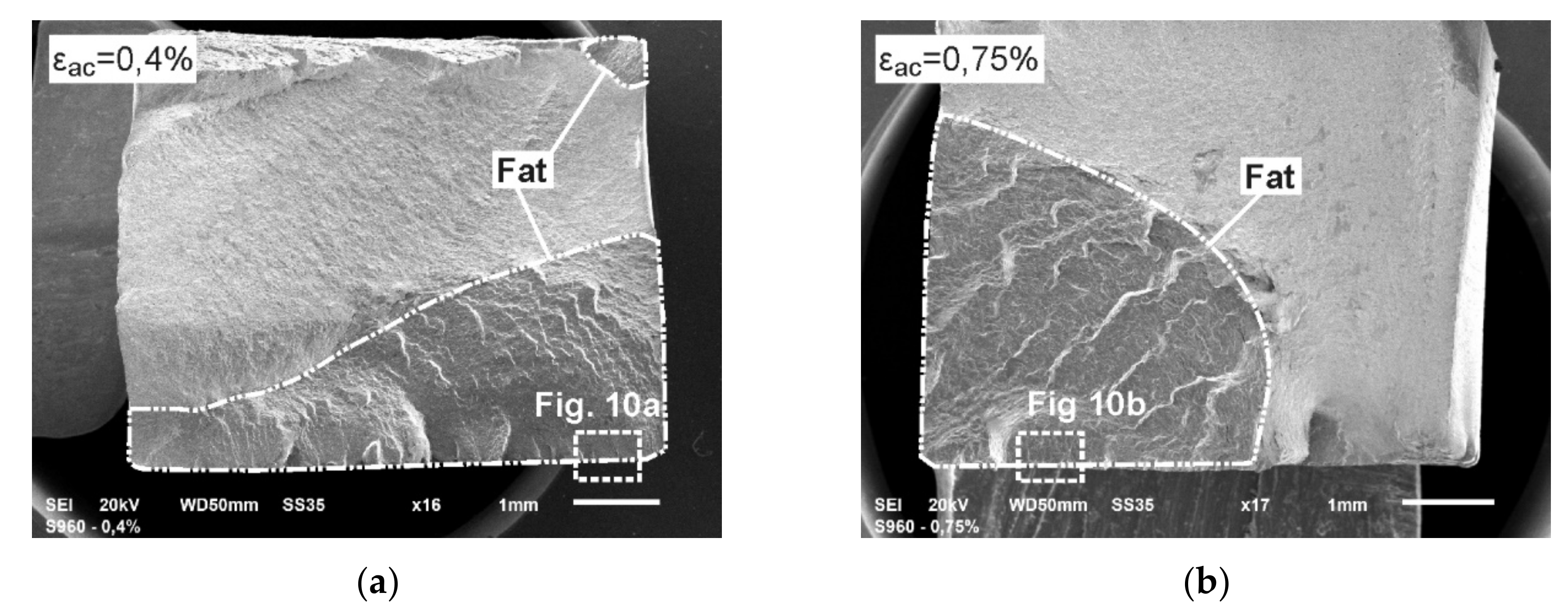

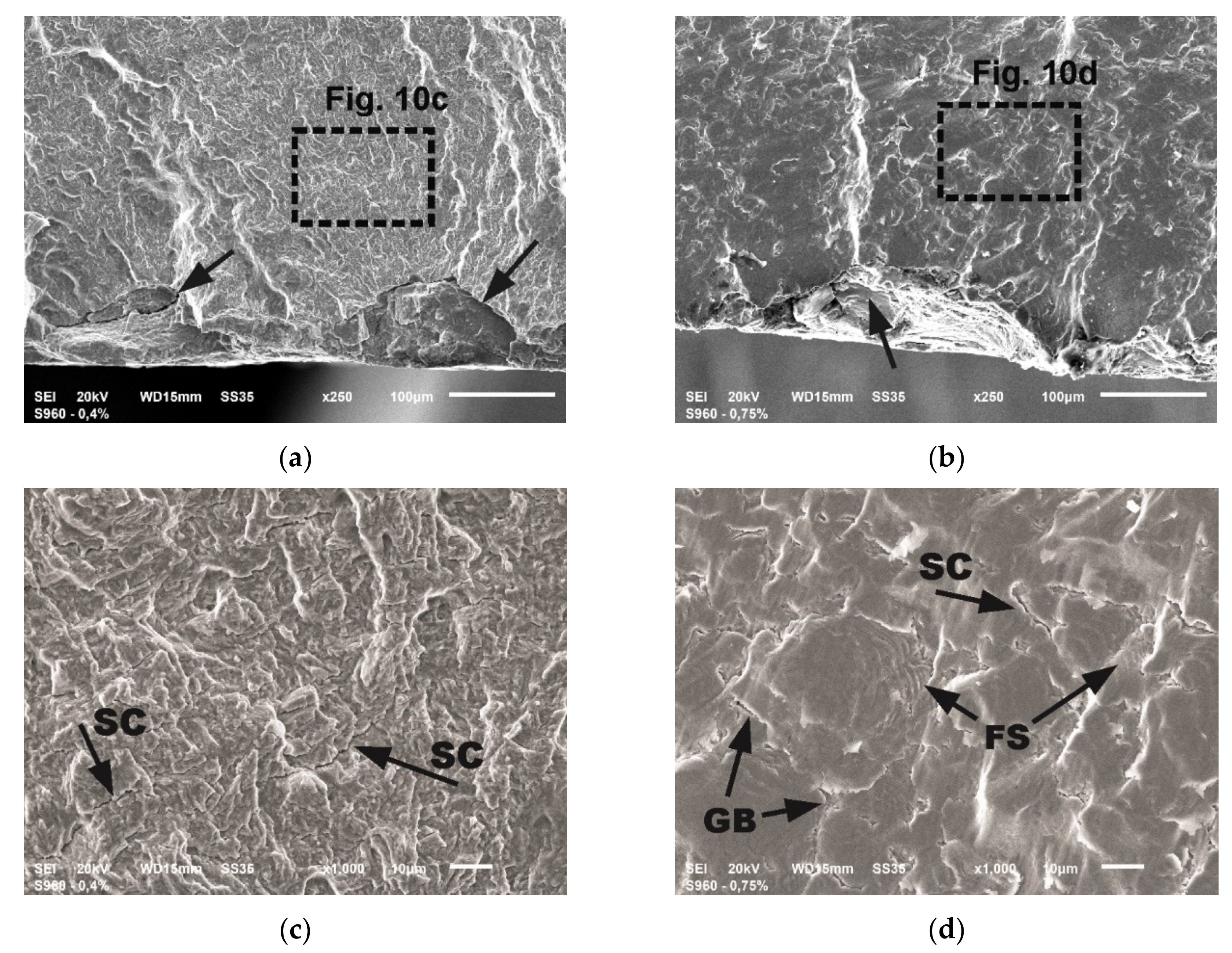

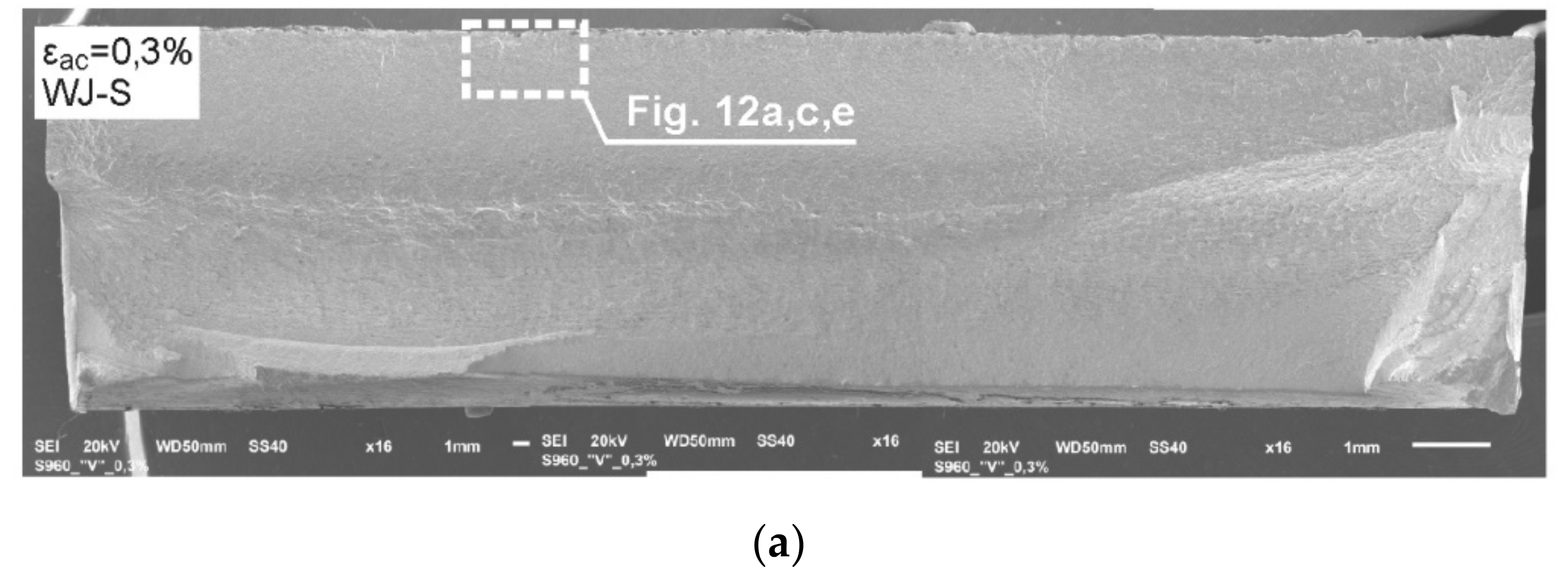

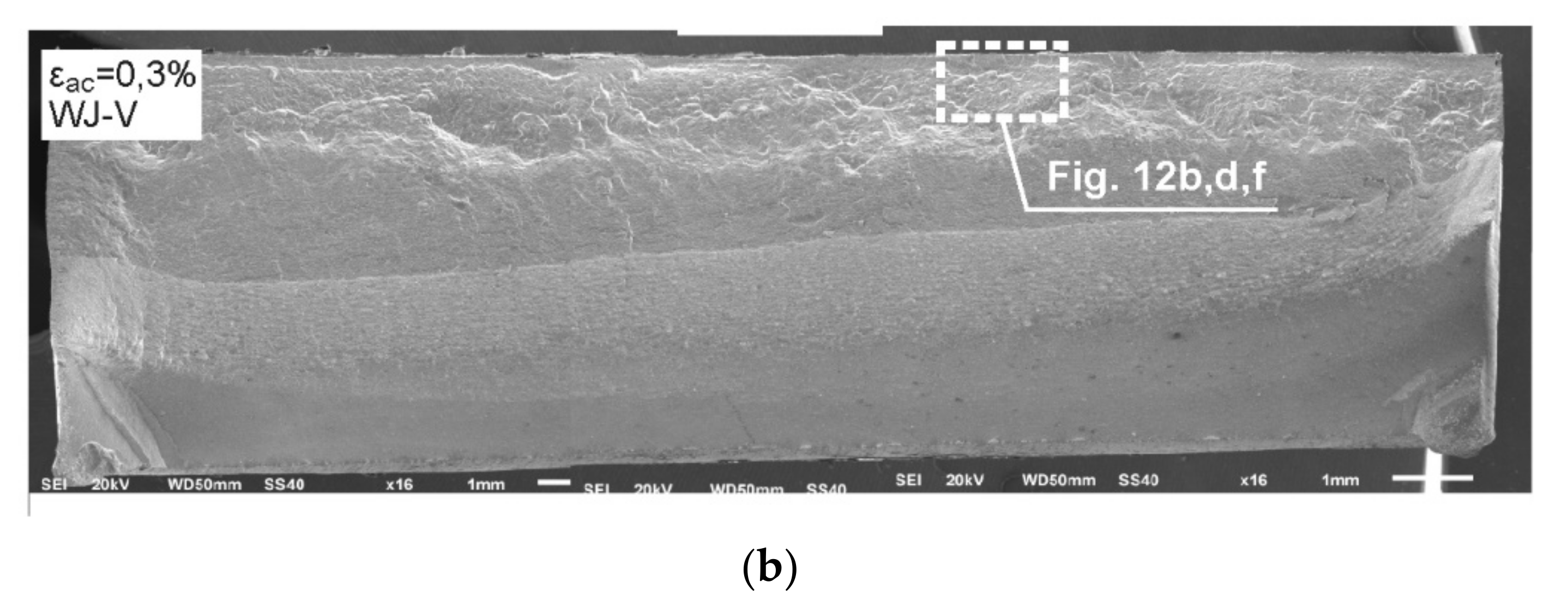

3.4. Fractographic Analysis of Fatigue Fractures

4. Discussion

5. Conclusions

- Increased resistance to fatigue cracks initiation of structural HSS steel is mishandled due to the presence of induced crack initiators in a form of rolled-in mill scale. Therefore fatigue behavior of S960QL steel in delivery state can be improved by refinement the production processes influencing the quality of surface.

- Concerning the microhardness distribution in examined welded joints, the square joints show more favorable courses than single-V. The maximum value of HV0.1 in HAZ is clearly lower what influence the ductility of this zone and their fatigue properties, especially crack resistance.

- In the low cycle fatigue regime, square joints show a higher fatigue life in comparison with single-V. The superior fatigue life corresponds to a more favorable microhardness distribution and less number of welding imperfections. Conducted fractographic investigation has revealed that the origins of crack initiation were the surface imperfections from the root side and the presence of gas pores additionally increase a cracking rate.

- Higher quality of square joints was caused primarily by fully-mechanized execution of welds in contrast to the second type of considered joint. Reduction of imperfections amount and its magnitude is especially important in high strength steels sensitive to notches.

Funding

Acknowledgments

Conflicts of Interest

References

- Kocanda, D.; Hutsaylyuk, V.; Slezak, T.; Torzewski, J.; Nykyforchyn, H.; Kyryliv, V. Fatigue crack growth rates of S235 and S355 steels after friction stir processing. Mater. Sci. Forum 2012, 726, 203–210. [Google Scholar] [CrossRef]

- Weglowski, M.S.; Kopyscianski, M.; Dymek, S. Friction stir processing multi-run modification of cast aluminum alloy. Key Eng. Mat. 2014, 611–612, 1595–1600. [Google Scholar] [CrossRef]

- Zasimchuk, E.; Markashova, L.; Baskova, O.; Turchak, T.; Chausov, N.; Hutsaylyuk, V.; Berezin, V. Influence of Combined Loading on Microstructure and Properties of Aluminum Alloy 2024-T3. J. Mater. Eng. Perform. 2013, 22, 3421–3429. [Google Scholar] [CrossRef]

- Ray, P.K.; Ganguly, R.I.; Panda, A.K. Optimization of mechanical properties of an HSLA-100 steel through control of heat treatment variables. Mat. Sci. Eng. A 2003, 346, 122–131. [Google Scholar] [CrossRef]

- Show, B.K.; Veerababu, R.; Balamuralikrishnan, R.; Malakondaiah, G. Effect of vanadium and titanium modification on the microstructure and mechanical properties of a microalloyed HSLA steel. Mat. Sci. Eng. A 2010, 527, 1595–1604. [Google Scholar] [CrossRef]

- Hildebrand, J.; Werner, F. Change of structural condition of welded joints between high-strength fine-grained steels and structural steels. J. Civ. Eng. Manag. 2004, X, 87–95. [Google Scholar] [CrossRef]

- Günther, H.P. Use and Application of High-Performance Steels for Steel Structures (Structural Engineering Documents 8); IABSE: Zurich, Switzerland, 2005. [Google Scholar]

- Muller, T.; Straetmans, B. High strength seamless tubes and steel hollow sections for cranes and machine building applications—Production and properties. Stahlbau 2015, 84, 650–654. [Google Scholar] [CrossRef]

- High-Strength and Ultra-High-Strength Heavy Plates. Available online: https://www.voestalpine.com/alform/en/content/download/4494/file/voestalpine_heavy_plate_TTD_ALFORM_620-1100_E_0319.pdf (accessed on 12 December 2019).

- Gogou, E. Use of High Strength Steel Grades for Economical Bridge Design. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, April 2012. Available online: https://www.scia.net/sites/default/files/thesis/reportgogou.pdf (accessed on 12 December 2019).

- Mosty. Available online: http://www.obrum.gliwice.pl/mosty (accessed on 12 December 2019).

- Lachowicz, M.; Nosko, W. Welding of Structural Steel Weldox 700. Prz. Spaw. 2010, 1, 13–18. (In Polish) [Google Scholar]

- Bjorhovde, R. Performance and Design Issues for High Strength Steel in Structures. Adv. Struct. Eng. 2010, 13, 403–411. [Google Scholar] [CrossRef]

- Shi, G.; Hu, F.; Shi, Y. Recent research advances of high strength steel structures and codification of design specification in China. Int. J. Steel Struct. 2014, 14, 873–887. [Google Scholar] [CrossRef]

- Björklund, O.; Larsson, R.; Nilsson, L. Failure of high strength steel sheets: Experiments and modelling. J. Mater. Process. Technol. 2013, 213, 1103–1117. [Google Scholar] [CrossRef]

- Branco, R.; Berto, F. Mechanical Behavior of High-Strength, Low-Alloy Steels. Metals 2018, 8, 610. [Google Scholar] [CrossRef]

- Wei, D.Y.; Gu, J.L.; Fang, H.S.; Bai, B.Z.; Yang, Z.G. Fatigue behavior of 1500 MPa bainite/martensite duplex-phase high strength steel. Int. J. Fatigue 2004, 26, 437–442. [Google Scholar] [CrossRef]

- Neimitz, A. Ductile Fracture Mechanisms in the High-strength Steel Hardox-400. Microscopic Observations and Numerical Stress-strain Analysis. Procedia Mater. Sci. 2014, 3, 270–275. [Google Scholar] [CrossRef]

- Simunek, D.; Leitner, M.; Grün, F. In-situ crack propagation measurement of high-strength steels including overload effects. Procedia Eng. 2018, 213, 335–345. [Google Scholar] [CrossRef]

- Dunder, M.; Vuherer, T.; Samardzic, I. Weldability of microalloyed high strength steels TStE 420 and S960QL. Metalurgija 2014, 53, 335–338. [Google Scholar]

- Gałkiewicz, J. Simulation of Tensile Test of The 1/2Y Welded Joint Made of Ultra-High Strength Steel. Mater. Sci. Forum 2012, 726, 110–117. [Google Scholar] [CrossRef]

- Slezak, T.; Sniezek, L. Fatigue Properties and Cracking of High Strength Steel S1100QL Welded Joints. Key Eng. Mat. 2014, 598, 237–242. [Google Scholar] [CrossRef]

- Sołtysiak, R. Effect of Laser Welding Parameters of DUPLEX 2205 Steel Welds on Fatigue Life. Solid State Phenom. 2014, 223, 11–18. [Google Scholar] [CrossRef]

- Ślęzak, T.; Śnieżek, L. A Comparative LCF Study of S960QL High Strength Steel and S355J2 Mild Steel. Procedia Eng. 2015, 114, 78–85. [Google Scholar] [CrossRef]

- Ślęzak, T. Prediction of Fatigue Life of Welded Joints Made of Fine-Grained Martensite-Bainitic S960QL Steel and Determination of Crack Origins. Adv. Mater. Sci. Eng. 2019, 201, 9520801. [Google Scholar] [CrossRef]

- Lan, X.; Chan, T.-M. Recent research advances of high strength steel welded hollow section joints. Structures 2019, 17, 58–65. [Google Scholar] [CrossRef]

- Berdnikova, O.; Pozniakov, V.; Bernatskyi, A.; Alekseienko, T.; Sydorets, V. Effect of the structure on the mechanical properties and cracking resistance of welded joints of low-alloyed high-strength steels. Procedia Struct. Integr. 2019, 16, 89–96. [Google Scholar] [CrossRef]

- Ilić, A.; Ivanović, L.; Lazić, V.; Josifović, D. Welding method as influential factor of mechanical properties at high-strength low-alloyed steels. IOP Conf. Ser. Mater. Sci. Eng. 2019, 659, 012036. [Google Scholar] [CrossRef]

- Lahtinen, T.; Vilaça, P.; Peura, P.; Mehtonen, S. MAG Welding Tests of Modern High Strength Steels with Minimum Yield Strength of 700 MPa. Appl. Sci. 2019, 9, 1031. [Google Scholar] [CrossRef]

- Vimalraj, C.; Kah, P.; Layus, P.; Belinga, E.M.; Parshin, S. High-strength steel S960QC welded with rare earth nanoparticle coated filler wire. Int. J. Adv. Manuf. Technol. 2019, 102, 105–119. [Google Scholar] [CrossRef]

- ISO 6892-1. Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature; ISO: Geneva, Switzerland, 2019. [Google Scholar]

- SuperElso®960. A High Yield Strength Steel for Welded and Weight-Saving Structures. ArcelorMittal—Industeel. Available online: http://www.solid.cl (accessed on 3 July 2012).

- Ślęzak, T. Characteristics of MAG Welded Joints Made in Fine-Grained High-Strength Steel S960QL. Inst. Weld. Bull. 2018, 62, 45–53. [Google Scholar] [CrossRef][Green Version]

- ASTM E606-04. Standard Practice for Strain-Controlled Fatigue Testing; ASTM: Philadelphia, PA, USA, 2005. [Google Scholar]

| C | Si | Mn | Cr | Mo | Ni | Al | V | Cu | Ti | Nb | B | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Measurement | 0.18 | 0.36 | 1.19 | 0.23 | 0.66 | 0.052 | 0.11 | 0.032 | 0.19 | 0.012 | 0.002 | 0.0028 |

| Certificate | 0.18 | 0.28 | 1.13 | 0.22 | 0.67 | 0.077 | 0.08 | 0.027 | 0.18 | 0.004 | n.d. | n.d. |

| E [MPa] | σY [MPa] | σU [MPa] | EL 1 [%] | RA 2 [%] | |

|---|---|---|---|---|---|

| Measurement | 2.2 × 105 | 974 | 1070 | 14.2 | 45.6 |

| Certificate | - | 997 | 1069 | 13.0 | - |

| σ’f [MPa] | b [-] | ε’f [-] | c [-] | |

|---|---|---|---|---|

| PM | 1976 | −0.107 | 0.542 | −0.782 |

| R2 = 0.998 | R2 = 0.991 | |||

| WJ-V | 4326 | −0.263 | 0.264 | −1.073 |

| R2 = 0.979 | R2 = 0.992 | |||

| WJ-S | 4150 | −0.267 | 4.408 | −1.523 |

| R2 = 0.950 | R2 = 0.999 | |||

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ślęzak, T. Fatigue Examination of HSLA Steel with Yield Strength of 960 MPa and Its Welded Joints under Strain Mode. Metals 2020, 10, 228. https://doi.org/10.3390/met10020228

Ślęzak T. Fatigue Examination of HSLA Steel with Yield Strength of 960 MPa and Its Welded Joints under Strain Mode. Metals. 2020; 10(2):228. https://doi.org/10.3390/met10020228

Chicago/Turabian StyleŚlęzak, Tomasz. 2020. "Fatigue Examination of HSLA Steel with Yield Strength of 960 MPa and Its Welded Joints under Strain Mode" Metals 10, no. 2: 228. https://doi.org/10.3390/met10020228

APA StyleŚlęzak, T. (2020). Fatigue Examination of HSLA Steel with Yield Strength of 960 MPa and Its Welded Joints under Strain Mode. Metals, 10(2), 228. https://doi.org/10.3390/met10020228