1. Introduction

Ferrite rolling has been extensively studied with different kinds of steels, such as interstitial-free (IF) steel [

1,

2,

3,

4], ultra-low carbon steel [

5], low carbon steel [

6,

7,

8], and stainless steel [

9]. Many difficulties in these studies arise during hot rolling due to the phase transformation from austenite to ferrite, such as a detrimental shear texture appearing throughout the rolled strip thickness during the rolling process [

10]. The formation of rolling texture is dominated by factors such as chemical compositions and processing parameters [

11]. Normally, a ferrite rolled specimen shows a shear gradient from the rolled surface to the interior of the strip. The sheared surface layer is subject to up to 2.5 times the strain compared to the specimen as a whole [

10]. Oil-based lubricants applied during hot and ferrite rolling reduce the strain gradient, improve the surface quality, and reduce the cost of production [

12,

13]. Such lubrication can also reduce the rolling force and torque, save energy, and extend the roll service life. The shear action is responsible for developing the <100> texture in the sheared layers of the ferrite rolled strips while preventing the formation of compression textures with a {111} component [

14].

Since the application of lubrication during ferrite rolling of IF steel can improve significantly the material drawability, many investigations have been focused on this research area [

10,

15,

16]. Barrett [

10] reported application of mineral and ester based oil during the ferrite rolling of IF steel and pointed out that the ester-based oil showed a better lubrication performance by suppressing the detrimental shear texture throughout the rolled strip thickness. He also addressed the economic benefits derived from a proper use of lubricants in the industry. Zhao et al. [

15] concluded that a large reduction and higher rolling temperature combined with lubrication during ferrite rolling can yield a better drawability. The lubrication is responsible for improving the microstructure in terms of reducing the number of in-grain shear bands and producing more favorable texture during ferrite rolling of IF steel [

16]. Moreover, new data processing techniques are required in order to reduce the time taken to perform microstructural analysis, reduce human error, and give repeatable results. Digital image processing theoretically offers a solution to explore microstructural aspects in metallographic terms. Some works [

17,

18] have reported methods to extract microstructural information and understand process evolution from the polished and etched surfaces of metal materials obtained through quantitative microscopy.

Proper use of lubricant affects both the ferrite rolling process and the quality of the final product. The lubricants conducted in these related works mainly involve liquid lubricating oils (ester and mineral oils). However, at a higher temperature, the oil is burnt, and the oil film between the roll and strip is destroyed, so that lubrication performance is reduced. It is uncertain if an effective lubrication of liquid mediums can be achieved on the sliding interfaces since a number of oil-based lubricants may degrade seriously due to their high sensitivity to temperature [

19]. At the same time, replacing oil with more environmental-friendly water-based lubricant results in a reduction of hazardous waste by-products [

20]. The polyphosphate based lubricant described here, which can form a tribochemical film with steel, is a potential candidate for ferrite rolling of IF steels at high temperature and load [

21]. It is a water-based inorganic-polymer lubricant. It melts at high temperature and is able to form a continuous lubrication film with a glassy state, which can stabilize the contact conditions. The chemical production from the reaction between lubricant and steel improves the tribological property as well. On the consideration of other lubricants such as glass powder or nano-powder, it improves the contact conditions from the lubrication mechanism of the rolling/ball-bearing effect, protective film/tribofilm, mending effect, polishing effect, synergistic effect, third-body effect, etc. However, it is mainly on a physical level instead of chemical/physical actions. The microstructural evolution effects of polyphosphate lubricants on IF steel rolling have received little attention in the literature to date. The microstructural evolution mechanisms during ferrite rolling with polyphosphate based lubricants need to be investigated further.

In this paper, the influence of a polyphosphate lubricant on the microstructural evolution of IF steel after ferrite rolling was studied as a function of different rolling and lubrication conditions. The evolution of macrotexture and shear bands, as well as information on individual grain orientation were measured and analyzed by means of X-ray diffraction (XRD) and electron backscatter diffraction (EBSD) measurements.

4. Discussion

Compared with other lubricant such as synthetic oil, the polyphosphate lubricant is proposed for high temperature applications, such as hot/warm rolling, forging, and extrusion. The lubrication mechanism is that the polyphosphate lubricant melts at high temperature and acts on the interfaces between the tool and workpiece to improve the contact conditions. It also shows a potential to prolong the tool life and improve the surface quality due to its excellent lubrication performance. Ray and colleagues [

5,

14,

27,

28] investigated the texture obtained from hot and ferrite rolling. Their work summarized the important orientation for rolling texture and provided a good reference for further study of the rolling texture. The Goss texture is responsible for the deterioration of drawability [

15,

29,

30]. As reported by Lee [

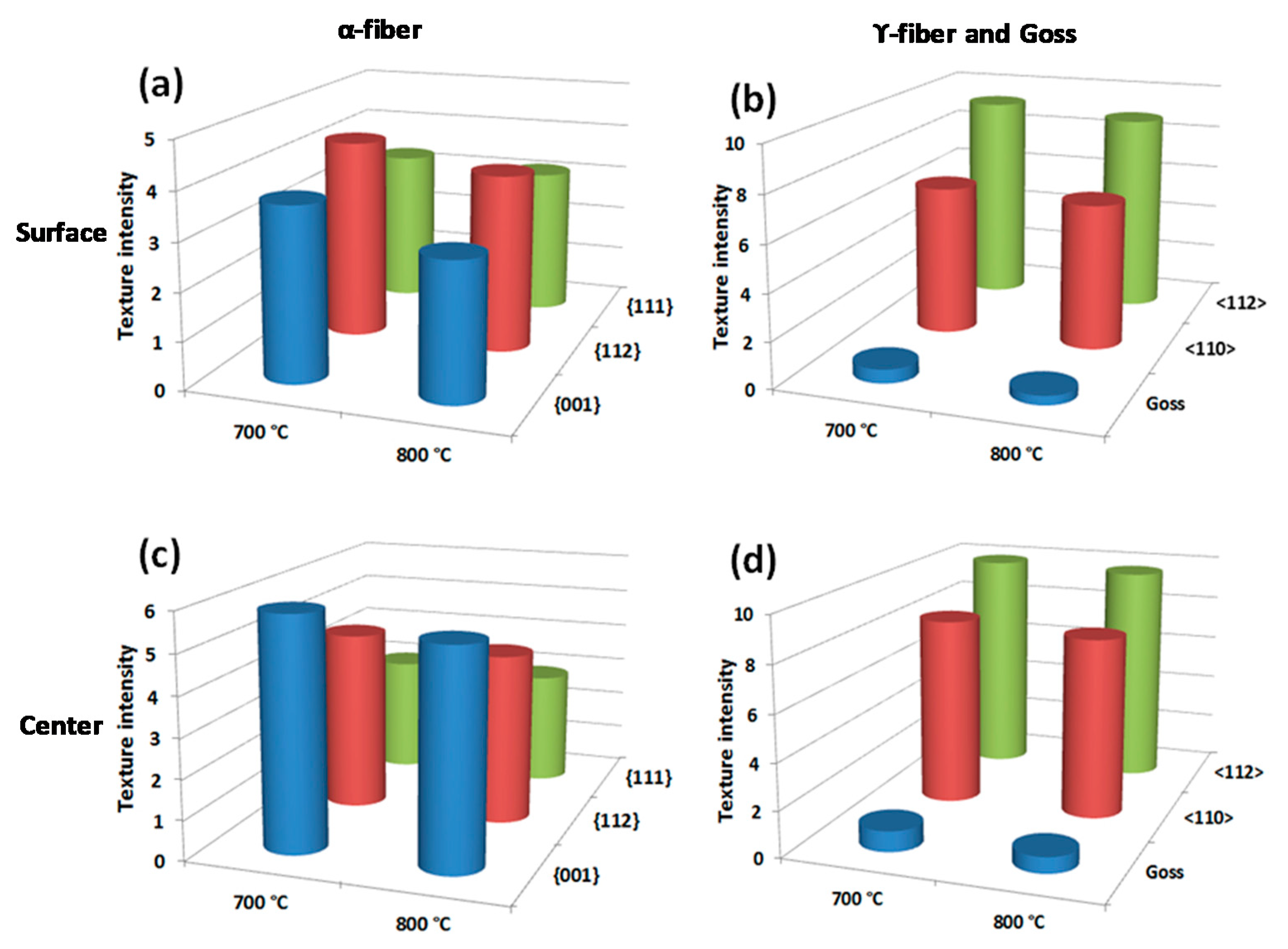

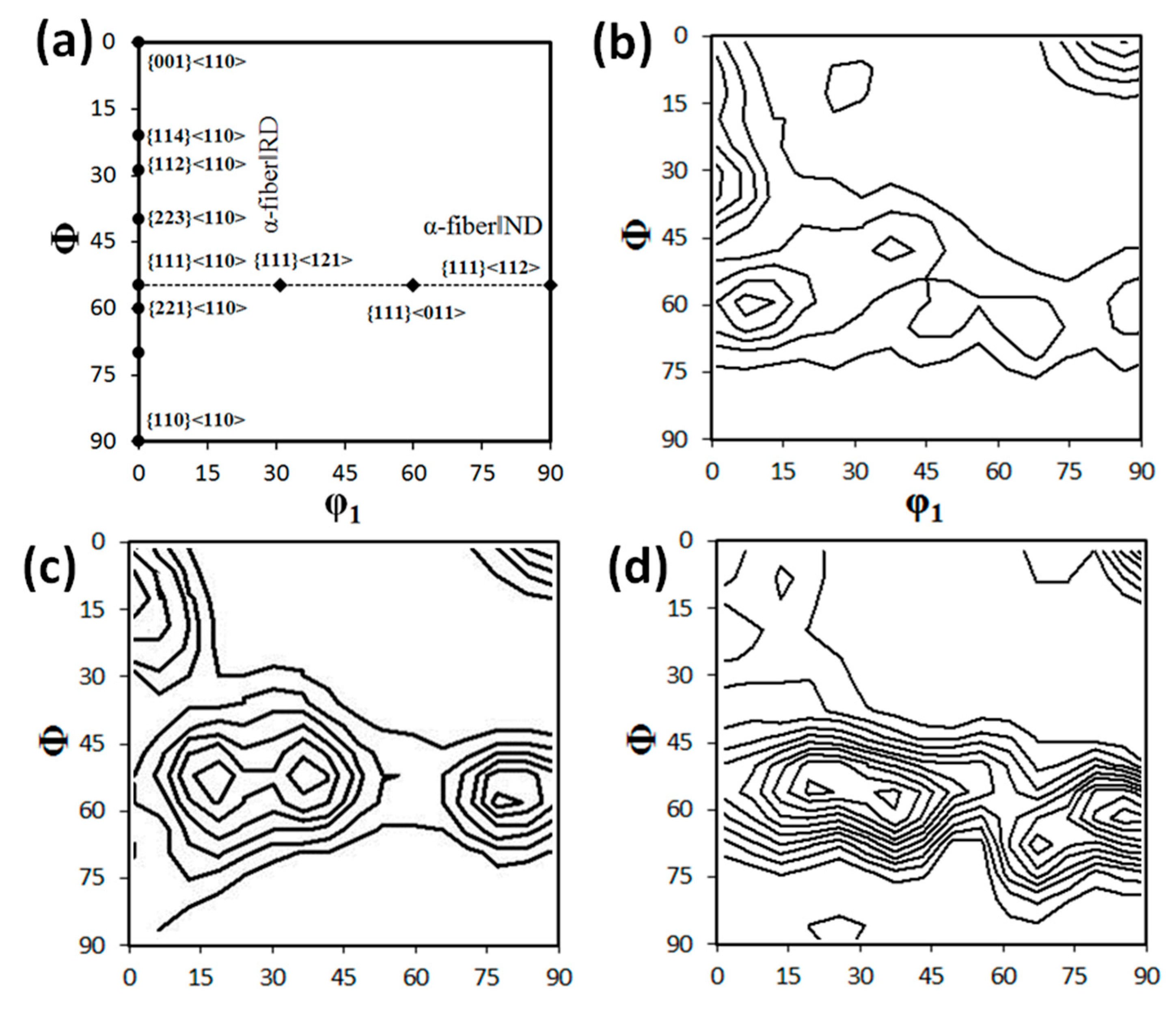

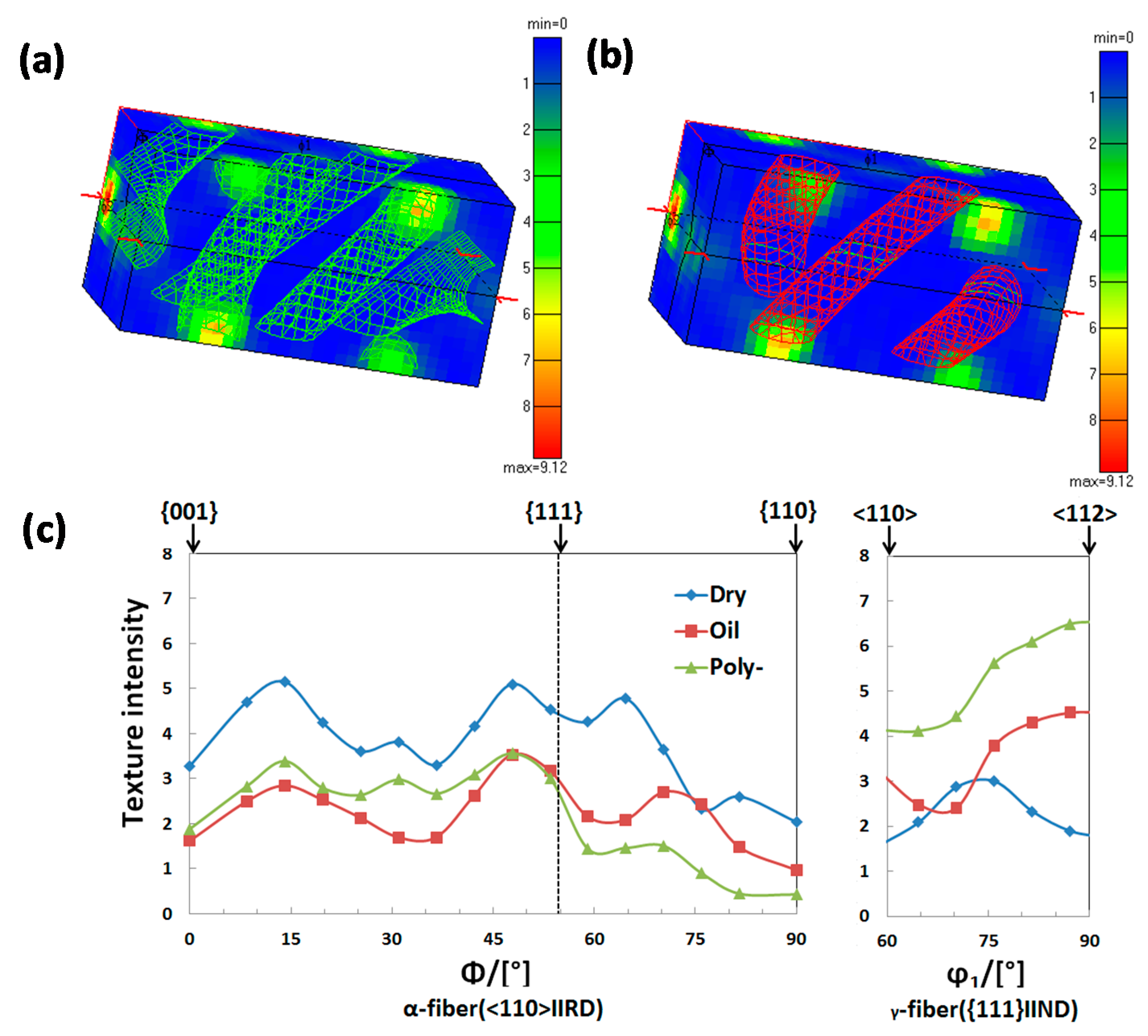

31], the Goss texture remained even after annealing. However, it can be effectively eliminated when lubrication is applied. The control of Goss texture during ferrite rolling is critical for the deep drawability of the final rolled product. The texture intensity on the surface and central layers was totally different under various lubrication conditions in the present work. On the surface layer, a strong shear texture of {111}, {112}, and {001} on the α-fiber could be observed under dry conditions, while both oil and polyphosphate lubricants showed some effect on the reduction of α-fiber texture. The lubrication influence on this texture was minor. The corresponding texture on the γ-fiber did change significantly under different lubrication conditions. The texture intensity of Goss orientation was significantly reduced by lubricating oil, as shown in

Figure 1b. The polyphosphate lubricant enhanced the texture on the γ-fiber texture and reduced the Goss orientation. As reported in reference [

10], shear texture can be avoided if the friction coefficient is less than 0.15. This indicates that a uniform texture throughout the thickness would not be achieved until the friction decreased to a certain level, and that lubrication would have a great impact on the texture formation. As for the texture of the center layer, the polyphosphate lubricant and lubricating oil did not exert notable influence. The typical ferrite rolling texture could be observed under all lubricating conditions. It was clear that shear deformation was the dominant factor in the texture formation during ferrite rolling.

As discussed in the previous publication from our research group [

32,

33], molten polyphosphate lubricant reacts with the iron surface to form a hierarchical tribofilm. The polar molecules bond to the steel surface with different chain lengths. The boundary film with a thickness of around 100 nm not only reduces the friction and wear on the surface during the ferrite rolling, but also eliminates the shear strain of the ferrite rolled IF steels. Barrett et al. [

10,

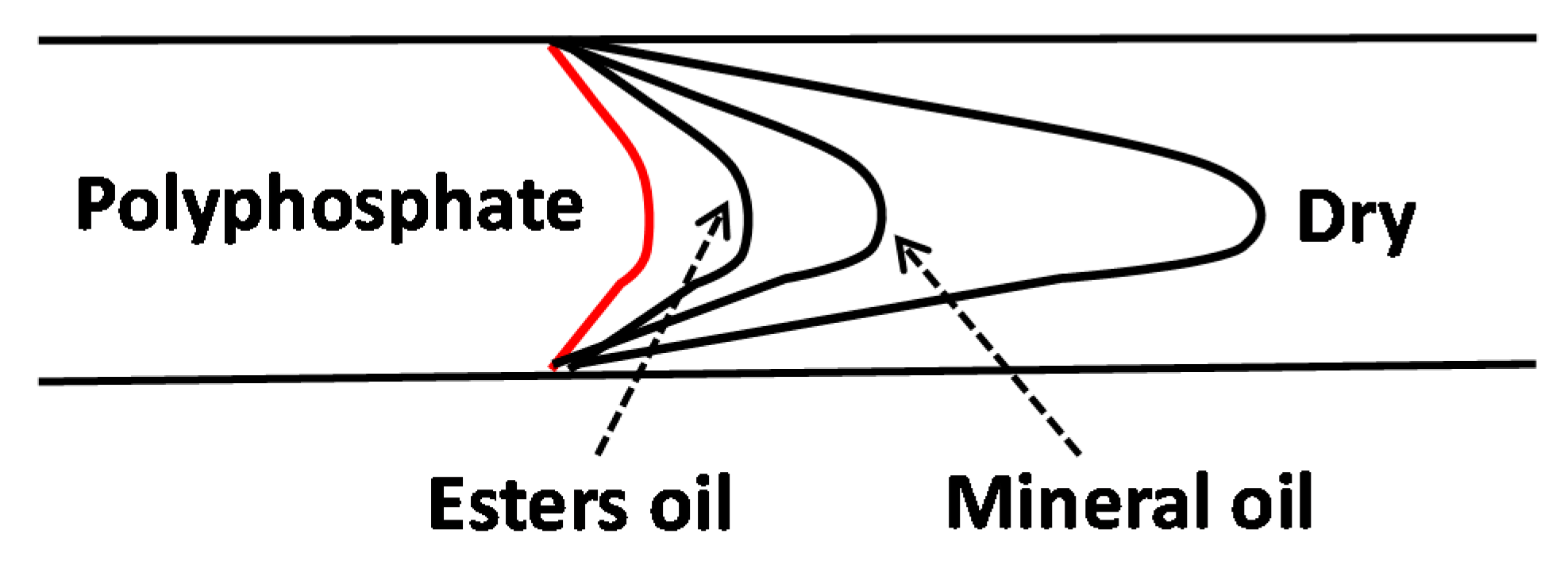

34] developed a schematic showing the influence of different liquid lubricants on the shear strain through-thickness. Without lubrication (dry condition), very severe shearing occurs, with only a small central region experiencing plane strain conditions. In contrast, the specimens rolled with lubrication shows only slight shearing, with the ester oil giving better results than the mineral oil. After the study of polyphosphate lubricant effect on the through thickness shear texture, a new curve can be added into the schematic to show the polyphosphate lubricant performance (

Figure 8). The polyphosphate lubricant showed better shearing resistance than the liquid lubricants.

Engler et al. [

30] reported that a lower finishing temperature developed more deformation, strengthened the hot-band texture, and enhanced the texture gradient [

35]. The results indicate that polyphosphate lubricant can maintain good lubrication performance suppressing the shear texture at high temperatures. Barrett [

10] reported that the lubricating effect of mineral oil was greatly reduced at 800 °C, resulting in a serious shear texture below the surface of the strip. Four times amount of lubricating oil was required on the rolls to equivalent lubrication to that achieved at 700 °C. In contract, the polyphosphate lubricant is quite stable at such high temperatures, since it produces a molten glassy state with a high viscosity, which provides a good lubrication performance in the ferrite temperature range [

21,

32].

Shear bands often associate with the formation of texture [

36]. The in-grain shear bands are responsible for the formation of Goss texture [

37]. Barnett [

38] pointed out that the shear bands affect the internal structure of most deformed ND fiber grains during the ferrite rolling of IF steels. In the ferrite temperature range, the in-grain shear bands in the IF steel seems unaffected by the rolling temperature [

25]. However, the local flow tendency of IF steel during ferrite rolling depends on the strain rate sensitivity [

39]. When lubrication is applied, the strain rate sensitivity can be eased as a result of the boundary film formation between contact surfaces. A reduction of strain rate sensitivity will decrease the fraction of in-grain shear bands within the ferrite rolled IF steel.

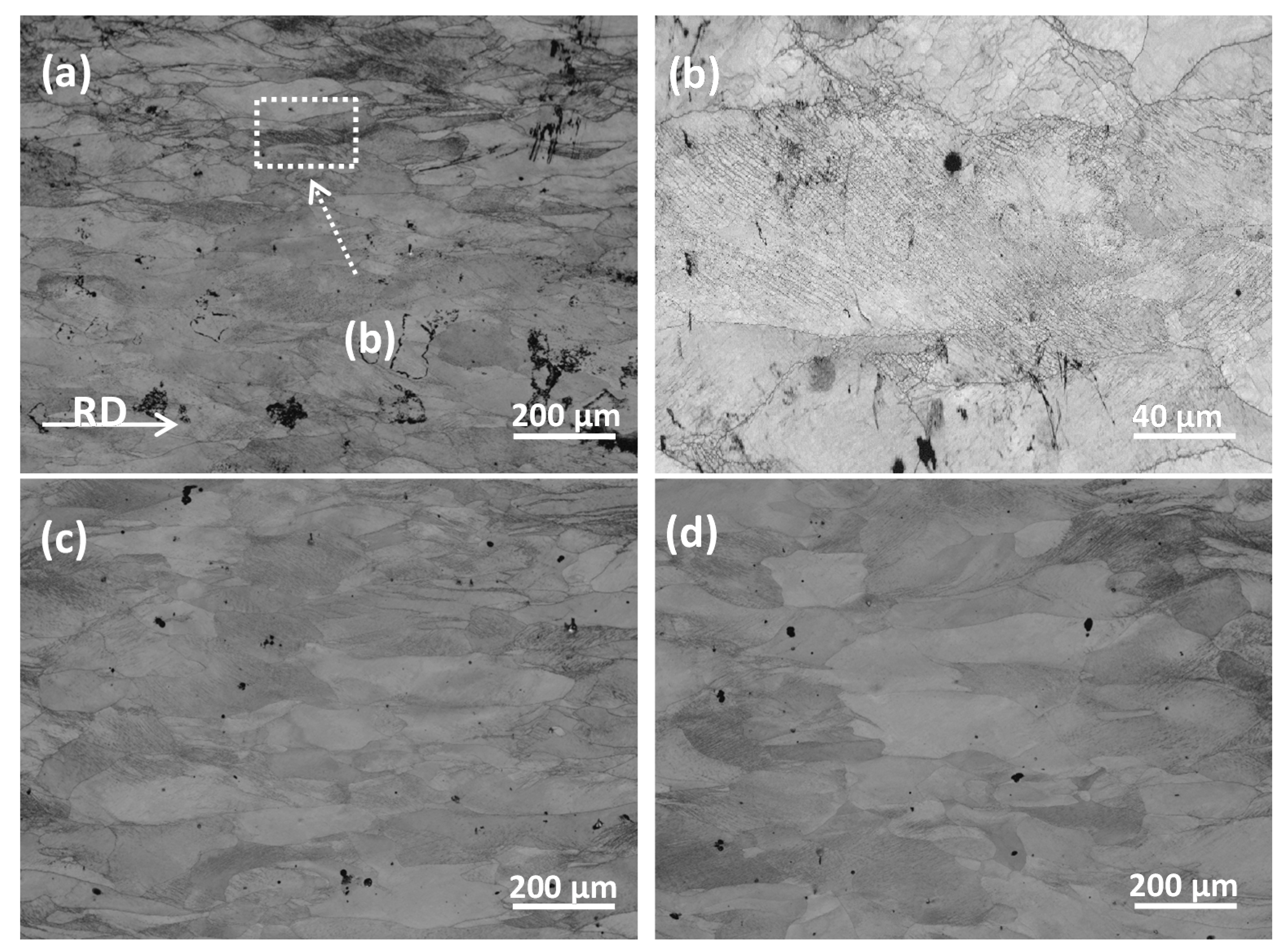

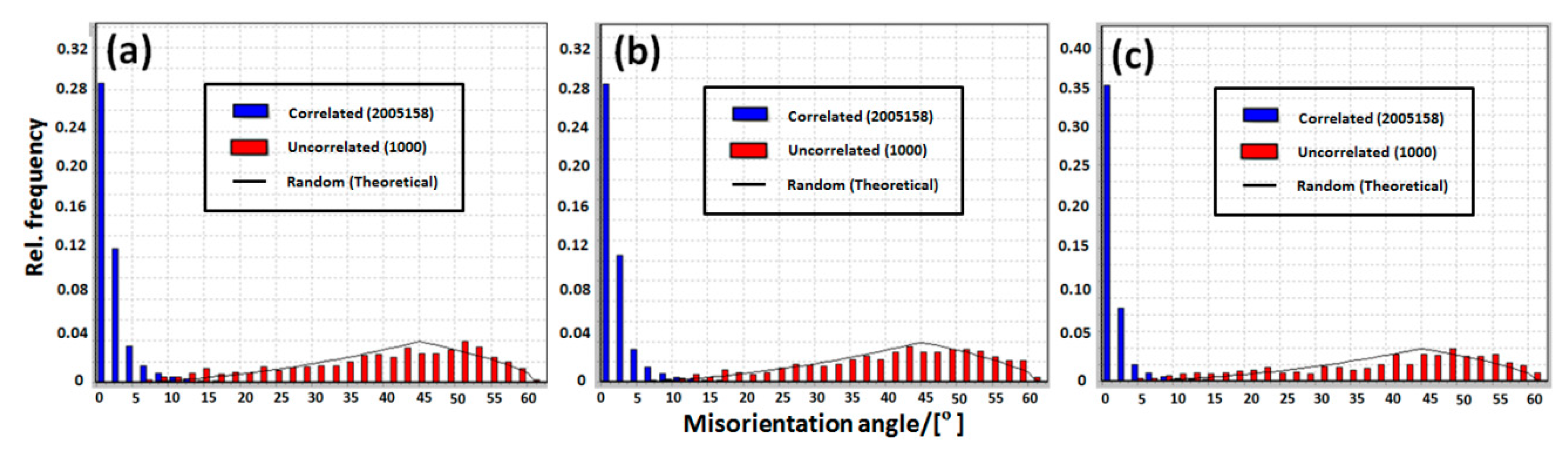

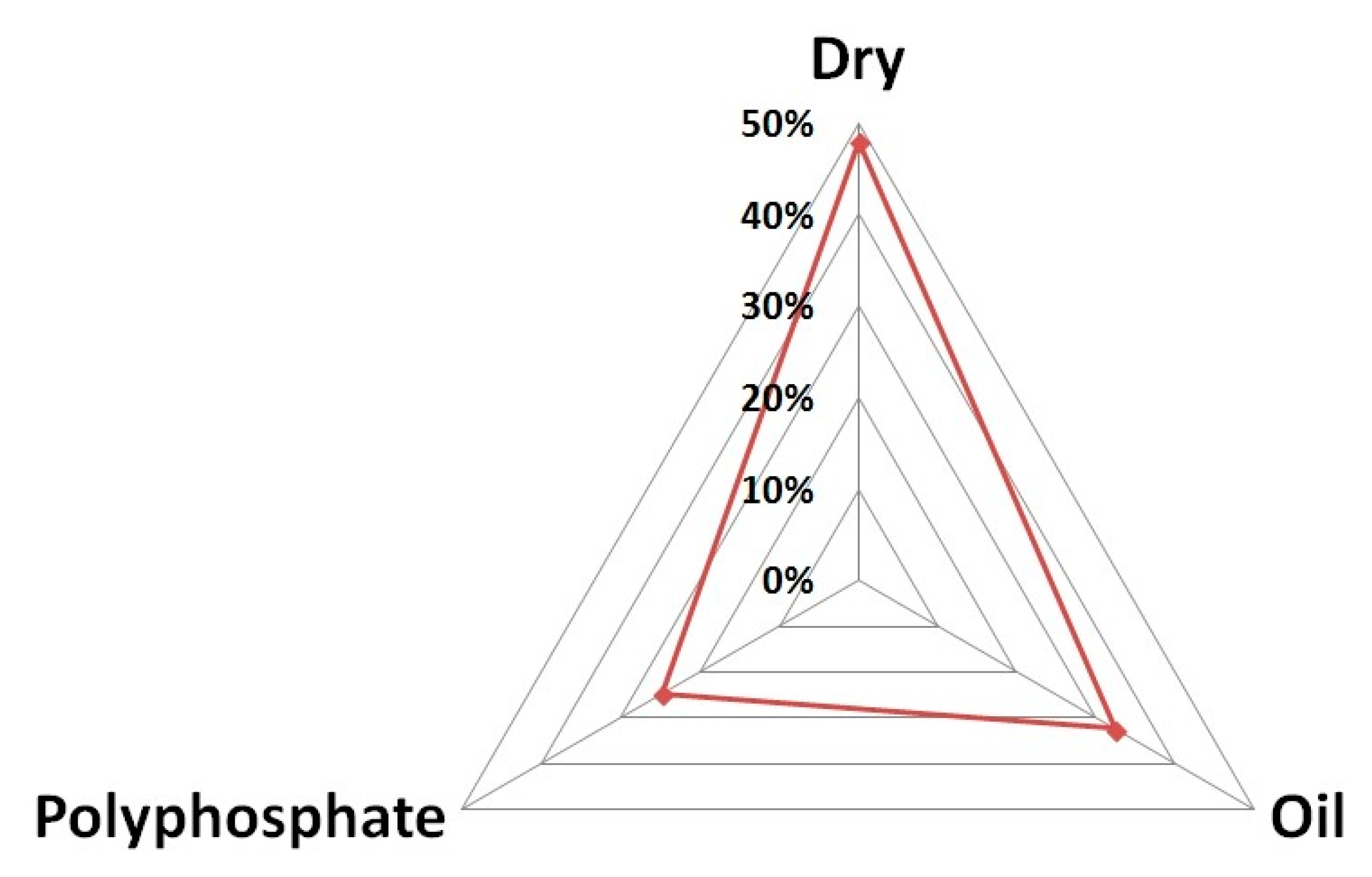

The lubrication effect on the reduction of shear bands is shown in

Figure 9. The severe shear stress in the roll bite is produced by the intense friction between the roll and strip. A pronounced direction transition can be found for the deformed micro-structure through the strip thickness. Moreover, the microstructure of the strip surface is quite similar to that at the strip center for the rolled strips with polyphosphate lubricant. Compared to the unlubricated condition, both oil and polyphosphate lubricants showed pronounced influence on the reduction of the in-grain shear bands during ferrite rolling. The polyphosphate reduced the fraction of in-grain shear bands by 48.5%, which was 16.2% more than the ester oil. These results also confirmed that the polyphosphate lubricant enhanced the deep drawability of IF steel after ferrite rolling. The characteristics of misorientation angle distribution showed a slight difference for different lubrication conditions. Interestingly, compared to the unlubricated condition, the misorientation angle between 3 and 10° was slightly reduced after applying polyphosphate lubricant. However, the lubricant had no significant effect on the misorientation angle during ferrite rolling. It can be concluded that the application of polyphosphate lubricant had little effect on the small misorientation angle below 10° during ferrite rolling.

Jia et al. [

16] pointed out that friction played a great role in affecting through-thickness texture gradients due to the variation of shear strain along the thickness direction. The polyphosphate lubricant, which had good thermal stability, reduced the shear strain and the texture gradient from the surface to the center layer at elevated temperatures. The polyphosphate lubricant can effectively prevent the formation of shear texture and therefore likely improve the deep drawability of IF steel. In summary, the polyphosphate lubricant not only improves the surface quality and antiwear properties [

21], but also suppresses the shear strain between contact surfaces, shown by the enhanced γ-fibers with less shear texture. Finally, it achieves an overall improvement on the ferrite rolled IF steel with a good surface quality as well as the rolling texture with potentially improved drawability.

Author Contributions

All authors have read and agree to the published version of the manuscript. Conceptualization, N.K. and J.Z.; methodology, N.K. and J.Z.; formal analysis, N.K.; investigation, B.W. and D.R.G.M.; data curation, N.K.; writing—original draft preparation, N.K.; writing—review and editing, N.K., J.Z., and H.L.; project administration, J.Z. and H.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China, grant number 51605026 and the China Postdoctoral Science Foundation, grant number 2016M600916.

Acknowledgments

This project is supported by the National Natural Science Foundation of China (Grant No. 51605026). The authors also acknowledge the support from the China Postdoctoral Science Foundation (Grant No. 2016M600916). This research used equipment funded by the Australian Research Council (ARC)—JEOL JSM-7001F (#LE0882613) located at the UOW Electron Microscopy Centre.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jeong, W.C. Strength and formability of ultra-low-carbon Ti-IF steels. Metall. Mater. Trans. A 2000, 31, 1305–1307. [Google Scholar] [CrossRef]

- Um, K.K.; Jeong, H.T.; An, J.K.; Lee, D.N.; Kim, G.; Kwon, O. Effect of initial sheet thickness on shear deformation in ferritic rolling of IF-steel sheets. ISIJ Int. 2000, 40, 58–64. [Google Scholar] [CrossRef]

- Martı́nez, V.J.; Verdeja, J.I.; Pero Sanz, J.A. Interstitial free steel: Influence of α-phase hot-rolling and cold-rolling reduction to obtain extra-deep drawing quality. Mater. Charact. 2001, 46, 45–53. [Google Scholar] [CrossRef]

- Jin, Y.H.; Huh, M.Y.; Chung, Y.H. Evolution of textures and microstructures in IF-steel sheets during continuous confined strip shearing and subsequent recrystallization annealing. J. Mater. Sci. 2004, 39, 5311–5314. [Google Scholar] [CrossRef]

- Ray, R.K.; Haldar, A. Texture development in extra low carbon (ELC) and interstitial free (IF) steels during warm rolling. Mater. Manuf. Processes 2002, 17, 715–729. [Google Scholar] [CrossRef]

- Yu, H.; Kang, Y.; Zhao, Z.; Wang, X.; Chen, L. Microstructural characteristics and texture of hot strip low carbon steel produced by flexible thin slab rolling with warm rolling technology. Mater. Charact. 2006, 56, 158–164. [Google Scholar] [CrossRef]

- Tsuchida, N.; Masuda, H.; Harada, Y.; Fukaura, K.; Tomota, Y.; Nagai, K. Effect of ferrite grain size on tensile deformation behavior of a ferrite-cementite low carbon steel. Mater. Sci. Eng. A 2008, 488, 446–452. [Google Scholar] [CrossRef]

- Park, H.-W.; Yanagimoto, J. Effect of carbon content on formation of bimodal microstructure and mechanical properties of low-carbon steels subjected to heavy-reduction single-pass hot/warm deformation. Mater. Sci. Eng. A 2014, 607, 542–550. [Google Scholar] [CrossRef]

- Raabe, D.; Hölscher, M.; Dubke, M.; Reher, F.; Lücke, K. Texture development of strip cast ferritic stainless steel. Mater. Sci. Forum 1994, 157–162, 1917–1928. [Google Scholar] [CrossRef]

- Barrett, C.J. Influence of lubrication on through thickness texture of ferritically hot rolled interstitial free steel. Ironmaking Steelmaking 1999, 26, 393–397. [Google Scholar] [CrossRef]

- Lins, J.F.C.; Sandim, H.R.Z.; Kestenbach, H.-J. Microstructural and textural characterization of a hot-rolled IF steel. J. Mater. Sci. 2007, 42, 6572–6577. [Google Scholar] [CrossRef]

- Akira, A. Lubrication in steel strip rolling in Japan. Tribol. Int. 1987, 20, 316–321. [Google Scholar]

- Shirizly, A.; Lenard, J.G. The effect of lubrication on mill loads during hot rolling of low carbon steel strips. J. Mater. Process. Technol. 2000, 97, 61–68. [Google Scholar] [CrossRef]

- Ray, R.K.; Jonas, J.J.; Hook, R.E. Cold rolling and annealing textures in low carbon and extra low carbon steels. Int. Mater. Rev. 1994, 39, 129–172. [Google Scholar] [CrossRef]

- Zhao, H.; Rama, S.C.; Barber, G.C.; Wang, Z.; Wang, X. Experimental study of deep drawability of hot rolled IF steel. J. Mater. Process. Technol. 2002, 128, 73–79. [Google Scholar] [CrossRef]

- Jia, M.X.; Lü, Y.P.; Xu, L.F.; Song, Y.P. The influence of friction on the texture formation of a IF steel during hot rolling in the ferrite region. Steel Res. Int. 2013, 84, 761–765. [Google Scholar] [CrossRef]

- Horovistiz, A.L.; Frade, J.R.; Hein, L.R.O. Comparison of fracture surface and plane section analysis for ceramic grain size characterisation. J. Eur. Ceram. Soc. 2004, 24, 619–626. [Google Scholar] [CrossRef]

- Campbell, A.; Murray, P.; Yakushina, E.; Marshall, S.; Ion, W. New methods for automatic quantification of microstructural features using digital image processing. Mater. Des. 2018, 141, 395–406. [Google Scholar] [CrossRef]

- Scharf, T.W.; Prasad, S.V. Solid lubricants: A review. J. Mater. Sci. 2013, 48, 511–531. [Google Scholar] [CrossRef]

- Crobu, M.; Rossi, A.; Mangolini, F.; Spencer, N.D. Tribochemistry of bulk zinc metaphosphate glasses. Tribol. Lett. 2010, 39, 121–134. [Google Scholar] [CrossRef]

- Tieu, A.K.; Kong, N.; Wan, S.; Zhu, H.; Zhu, Q.; Mitchell, D.R.G.; Kong, C. The Influence of Alkali Metal Polyphosphate on the Tribological Properties of Heavily Loaded Steel on Steel Contacts at Elevated Temperatures. Adv. Mater. Interfaces 2015, 2, 1–14. [Google Scholar] [CrossRef]

- Menezes, P.L.; Kishore; Kailas, S.V.; Lovell, M.R. Analysis of strain rates and microstructural evaluation during metal forming: Role of surface texture and friction. Tribol. Trans. 2012, 55, 582–589. [Google Scholar] [CrossRef]

- Booser, E.R. Tribology data handbook; CRC Press: Boca Raton, FL, USA, 1997. [Google Scholar]

- Saha, R.; Ray, R.K. Evolution of microstructure, texture and grain boundary character in a severely cold rolled Ti + Nb IF steel. J. Mater. Sci. 2007, 43, 207–211. [Google Scholar] [CrossRef]

- Barnett, M.R.; Jonas, J.J. Influence of ferrite rolling temperature on grain size and texture in annealed low C and IF steels. ISIJ Int. 1997, 37, 706–714. [Google Scholar] [CrossRef]

- Randle, V.; Davies, H.; Cross, I. Grain boundary misorientation distributions. Curr. Opin. Solid State Mater. Sci. 2001, 5, 3–8. [Google Scholar] [CrossRef]

- Ray, R.K.; Jonas, J.J. Transformation textures in steels. Int. Mater. Rev. 1990, 35, 1–36. [Google Scholar] [CrossRef]

- Ghosh, P.; Ghosh, C.; Ray, R.K. Thermodynamics of precipitation and textural development in batch-annealed interstitial-free high-strength steels. Acta Mater. 2010, 58, 3842–3850. [Google Scholar] [CrossRef]

- Gong, F.; Guo, B.; Wang, C.J.; Shan, D.B. Effects of lubrication conditions on micro deep drawing. Microsyst. Technol. 2010, 16, 1741–1747. [Google Scholar] [CrossRef]

- Engler, O.; Tomé, C.N.; Huh, M.Y. A study of through-thickness texture gradients in rolled sheets. Metall. Mater. Trans. A 2000, 31, 2299–2315. [Google Scholar] [CrossRef]

- Lee, S.H.; Lee, D.N. Shear rolling and recrystallization textures of interstitial-free steel sheet. Mater. Sci. Eng. A 1998, 249, 84–90. [Google Scholar] [CrossRef]

- Tieu, A.K.; Wan, S.; Kong, N.; Zhu, Q.; Zhu, H. Excellent melt lubrication of alkali metal polyphosphate glass for high temperature applications. RSC Adv. 2015, 5, 1796–1800. [Google Scholar] [CrossRef]

- Kong, N.; Tieu, A.K.; Zhu, Q.; Zhu, H.; Wan, S.; Kong, C. Tribofilms generated from bulk polyphosphate glasses at elevated temperatures. Wear 2015, 330–331, 230–238. [Google Scholar] [CrossRef]

- Barrett, C.J.; Wilshire, B. The production of ferritically hot rolled interstitial-free steel on a modern hot strip mill. J. Mater. Process. Technol. 2002, 122, 56–62. [Google Scholar] [CrossRef]

- Park, Y.B.; Lee, D.N.; Gottstein, G. Development of texture inhomogeneity during hot rolling in interstitial free steel. Acta Mater. 1996, 44, 3421–3427. [Google Scholar] [CrossRef]

- Krawczynska, A.T.; Gloc, M.; Lublinska, K. Intergranular corrosion resistance of nanostructured austenitic stainless steel. J. Mater. Sci. 2013, 48, 4517–4523. [Google Scholar] [CrossRef]

- Emren, F.; von Schlippenbach, U.; Lücke, K. Investigation of the development of the recrystallization textures in deep drawing steels by ODF analysis. Acta Mater. 1986, 34, 2105–2117. [Google Scholar] [CrossRef]

- Barnett, M.R. Role of in-grain shear bands in the nucleation of [111]/ND recrystallization textures in warm rolled steel. ISIJ Int. 1998, 38, 78–85. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Jonas, J.J. Formability and Workability of Metals: Plastic Instability and Flow Localization; American Society for Metals: Metals Park, OH, USA, 1984; Volume 2. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).