Possibilities for Renovation of Functional Surfaces of Backup Rolls Used during Steel Making

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Cladding Technology and Used Equipment

2.2. Cladding Parameters

2.3. Filler Materials

2.4. Methodology of Chemical Composition Assessment and Structural Analysis of Clad Layers

2.5. Methodology of the Hardness Test

2.6. Methodology of the Evaluation of Welds by Static Tensile Testing

2.7. Methodology of the Impact Bending Test

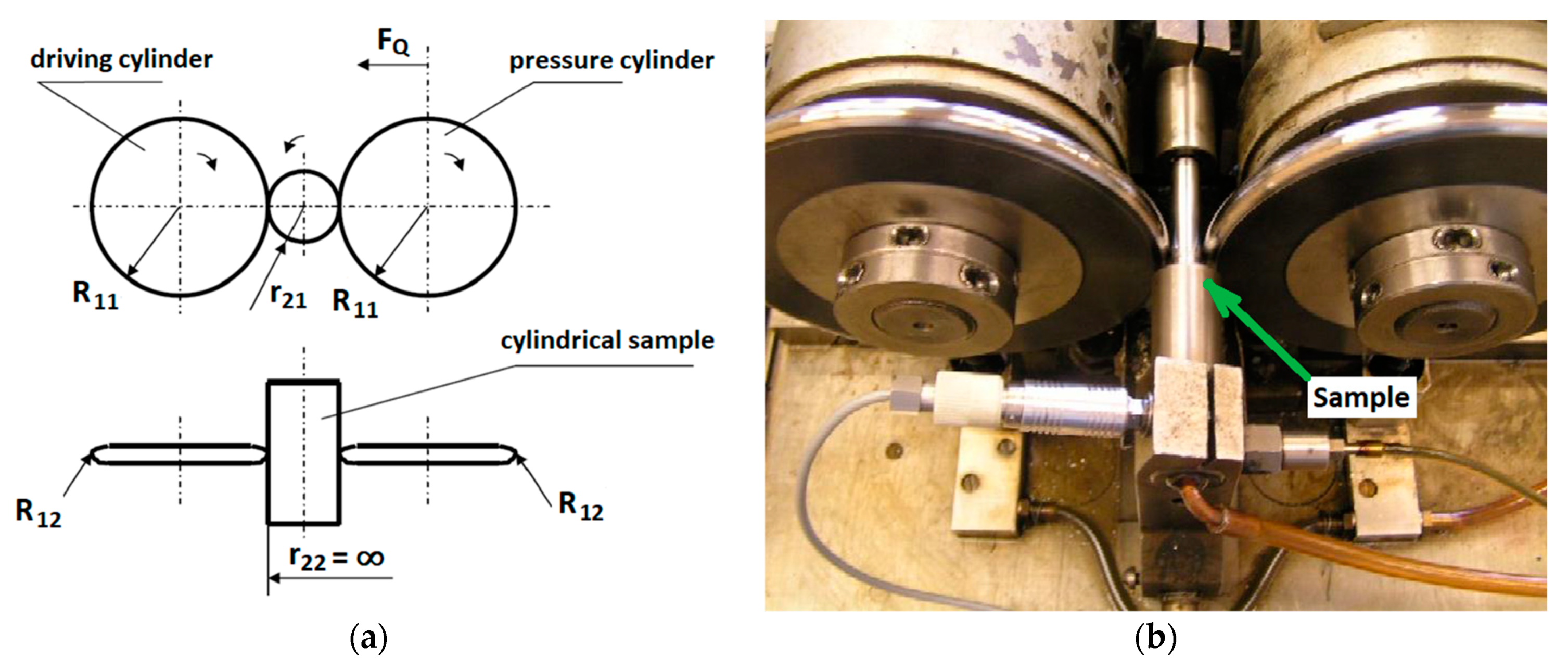

2.8. Methodology of the Evaluation of the Fatigue Wear of Clad Layers

3. Results and Discussion

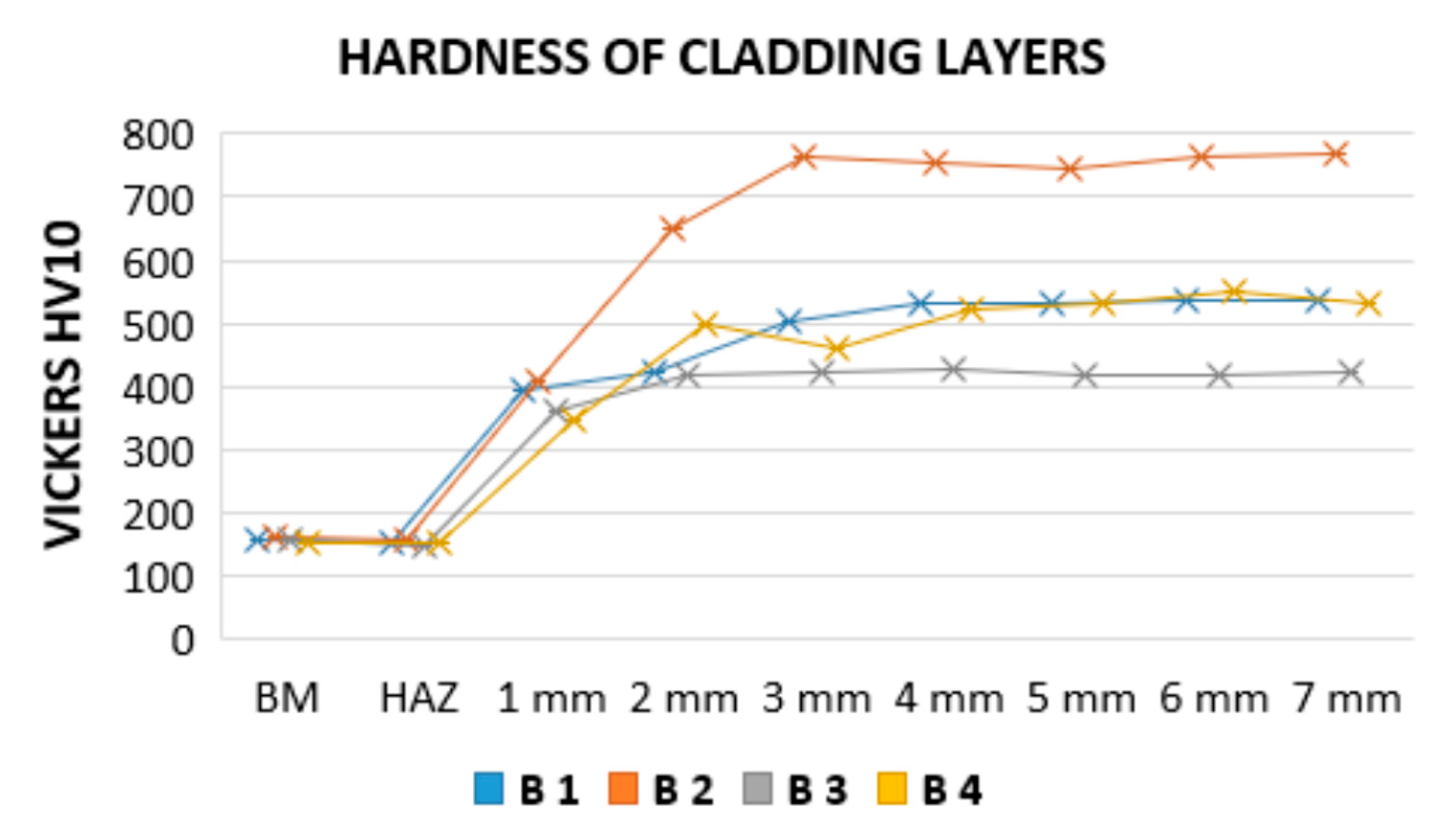

3.1. Non-Destructive Testing of the Cladded Layers

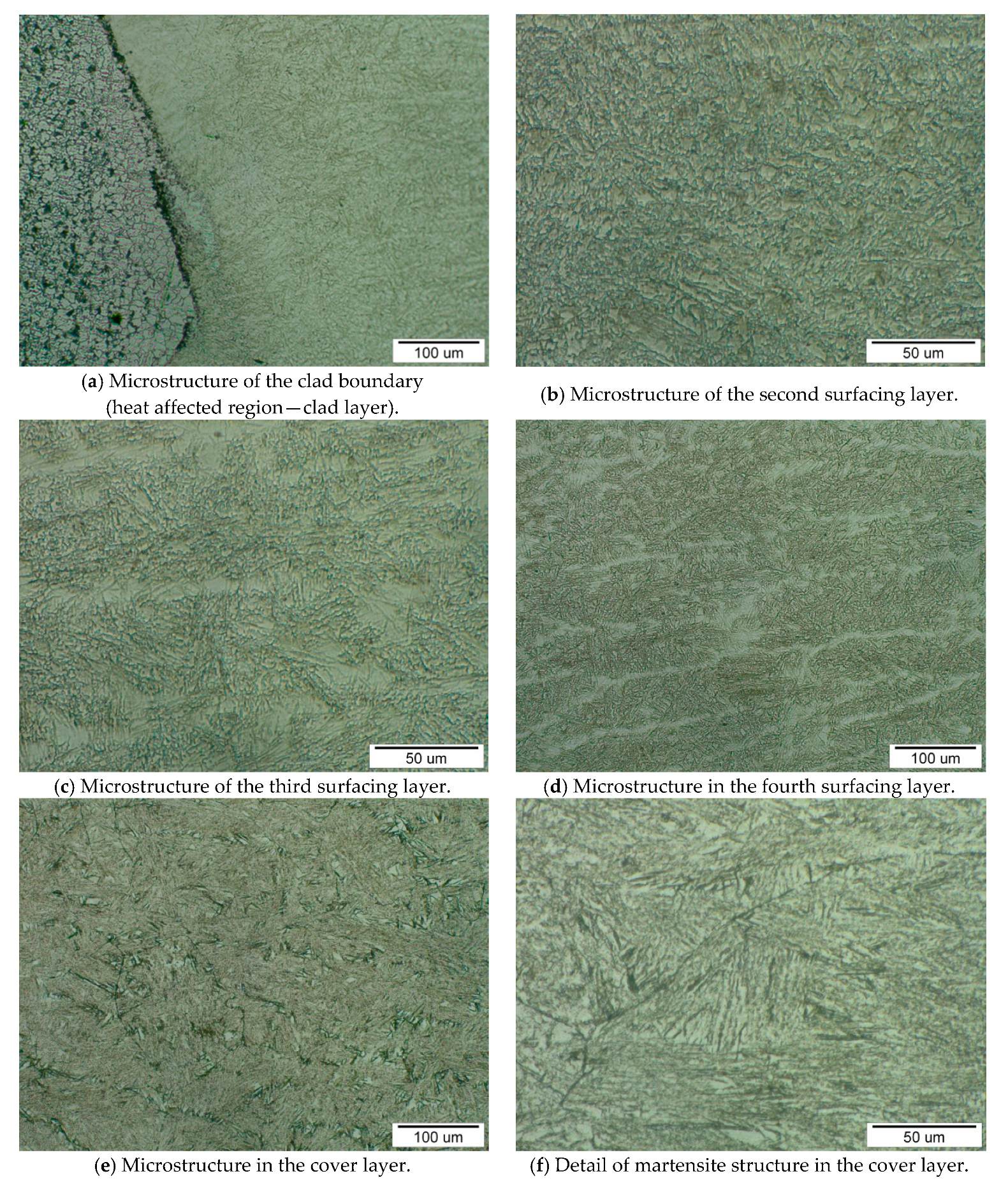

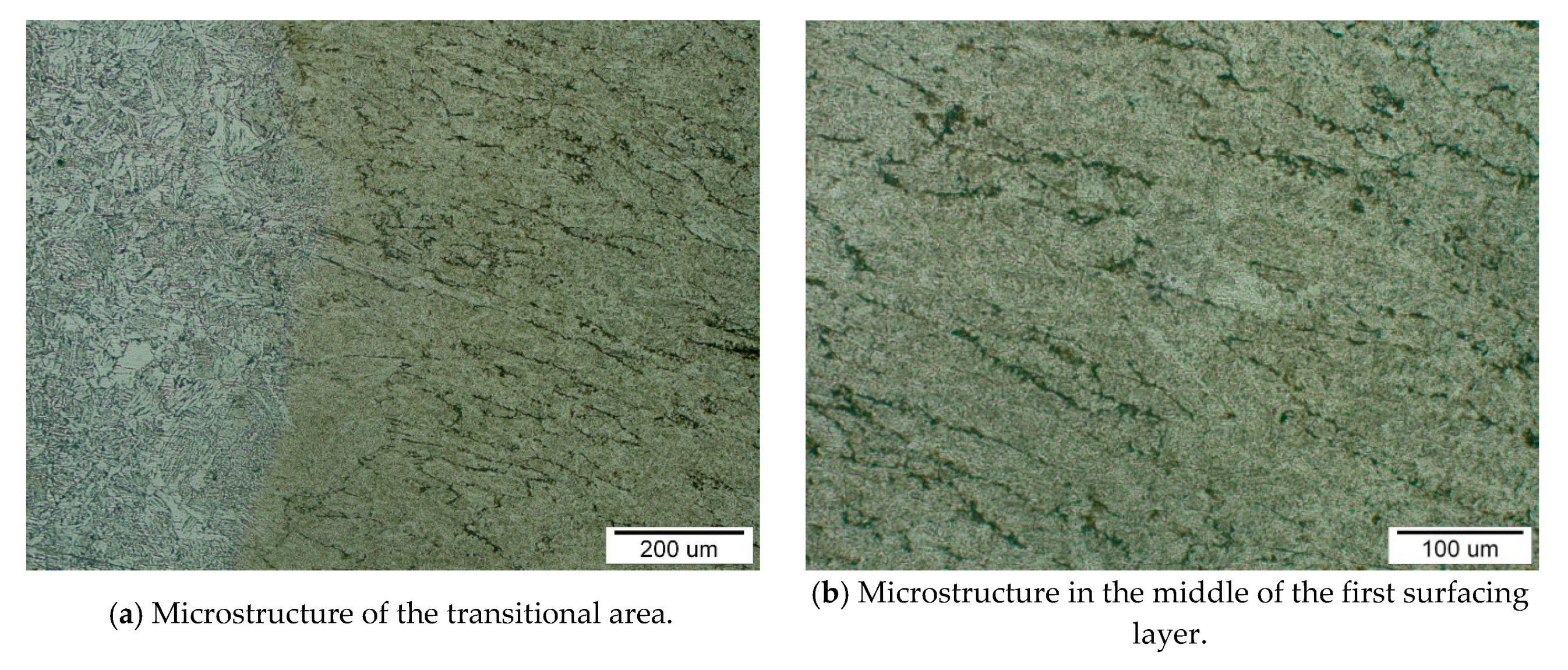

3.2. Structural Analysis of Clad Deposit B1

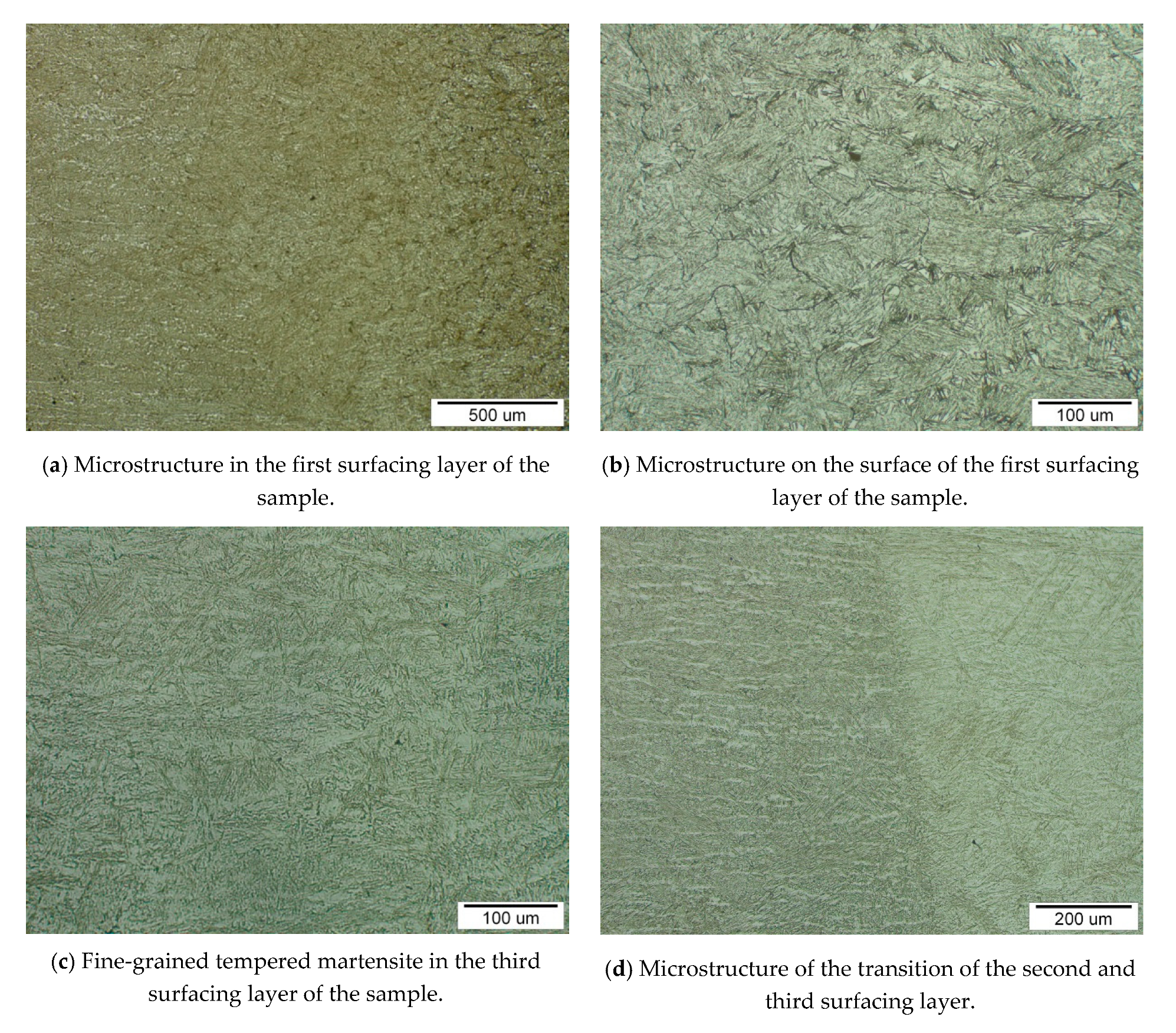

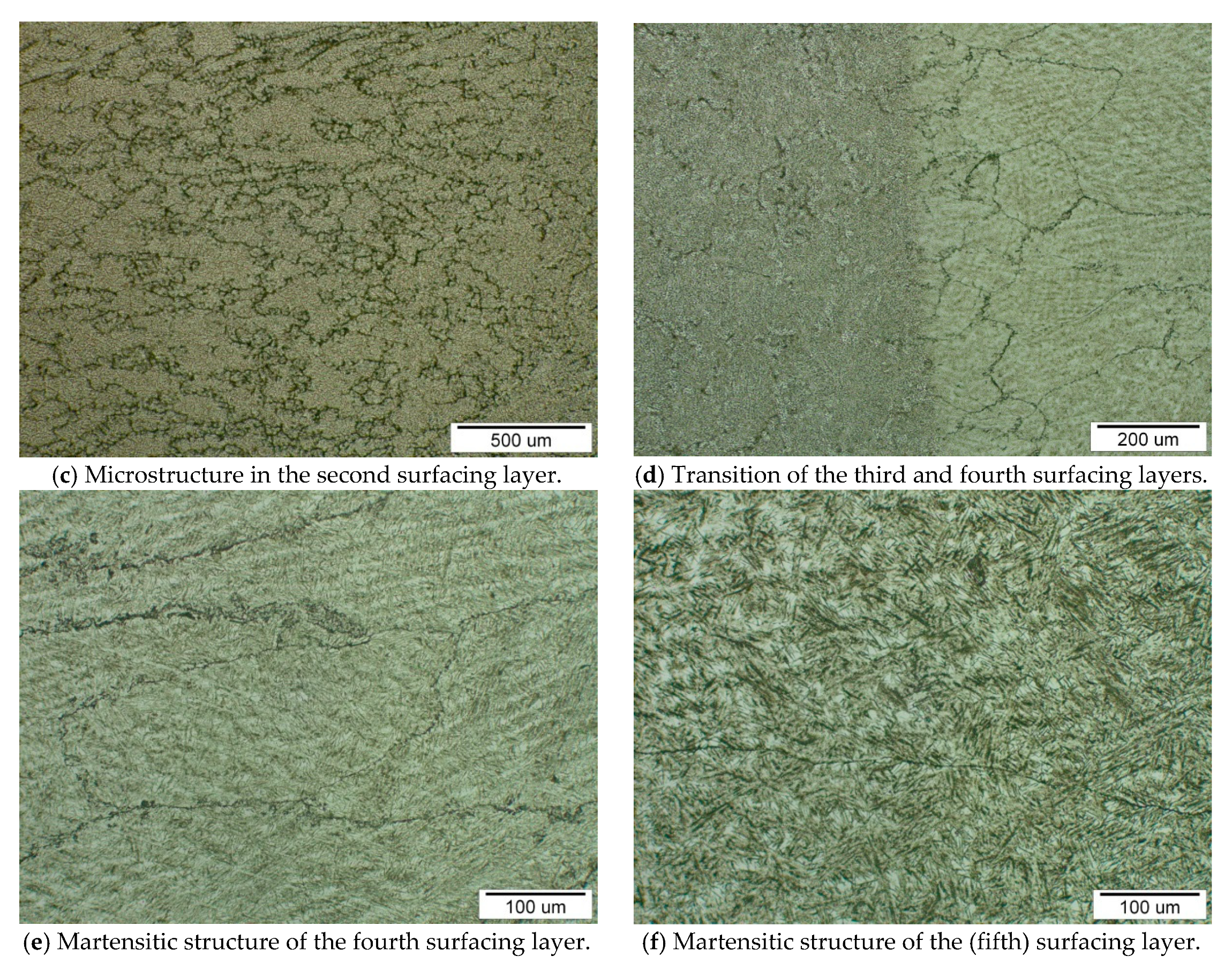

3.3. Structural Analysis of Clad Deposit B2

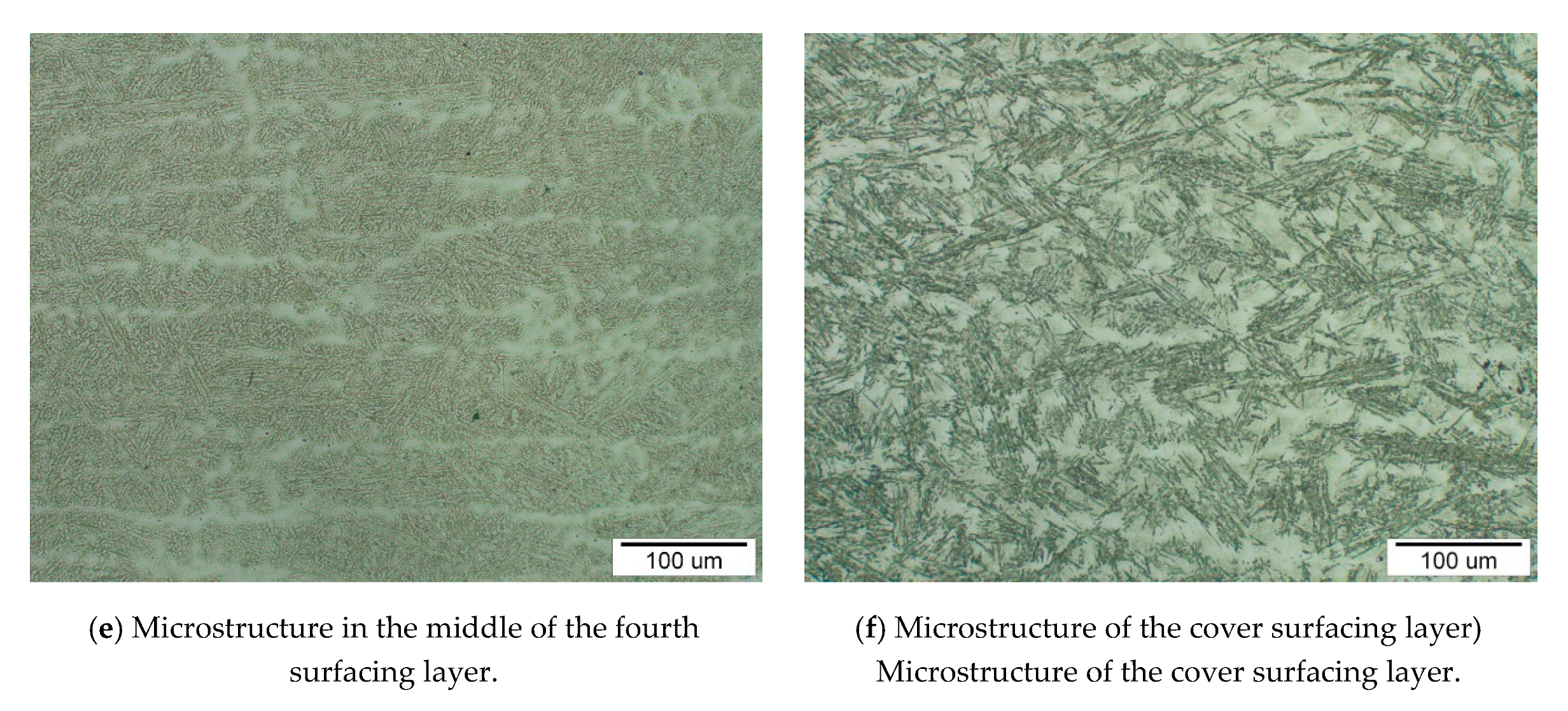

3.4. Structural Analysis of Clad Deposit B3

3.5. Structural Analysis of Clad Deposit B4

3.6. Results of Static Tensile Test Measurements

3.7. Results of Impact Bending Test Measurements

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Viňáš, J.; Brezinová, J.; Guzanová, A.; Balog, P. Evaluation of the quality of cladding deposited on continuous steel casting rolls. Int. J. Mater. Res. 2013, 104, 183–191. [Google Scholar] [CrossRef]

- Viňáš, J.; Brezinová, J.; Guzanová, A. Analysis of the quality renovated continuous steel casting roller. Sadhana-Acad. Proc. Eng. Sci. 2013, 38, 477–490. [Google Scholar] [CrossRef]

- Viňáš, J.; Brezinová, J.; Guzanová, A.; Svetlík, J. Degradation of renovation layers deposited on continuous steel casting rollers by submerged arc welding. Proc. Inst. Mech. Eng. B J. Eng. 2013, 227, 1841–1848. [Google Scholar] [CrossRef]

- Viňáš, J.; Vrabeľ, M.; Greš, M.; Brezina, J.; Sabadka, D.; Fedorko, G.; Molnár, V. Restoration of worn movable bridge props with use of bronze claddings. Materials 2018, 11, 459. [Google Scholar] [CrossRef]

- Chen, J.; Young, B.; Uy, B. Behavior of high strength structural steel at elevated temperatures. J. Struct. Eng. 2006, 132, 1948–1954. [Google Scholar] [CrossRef]

- Montmitonnet, P. Hot and cold strip rolling processes. Comput. Methods. Appl. Mech. Eng. Comput. Met. Form. 2006, 195, 6604–6625. [Google Scholar] [CrossRef]

- Scandella, F.; Atamert, S.; Knowles, D.M. Evaluation of hot strip mill backup roll cladding. Mater. Sci. Tech.-Lond. 2000, 16, 491–500. [Google Scholar] [CrossRef]

- Schröder, K.H. A Basic Understanding of the Mechanics of Rolling Mill Rolls; ESW-Handbook; Eisenwerk Sulzau-Werfen: Bremerhaven, Germany, 2003. [Google Scholar]

- Lu, H.T.; Cao, J.G.; Zhang, J.; Jia, S.H.; Zeng, W. Shape control with varying contact backup rolls on tandem cold rolling mill. Iron Steel. 2007, 42, 42–46. [Google Scholar]

- Hertz, H. On contact of solid elastic bodies and on hardness. J. Math. 1881, 92, 156–171. [Google Scholar]

- Belyaev, N.M. Local stresses by compressing elastic solids. Eng. Struct. Struct. Mech. 1924, 27–108. (In Russian) [Google Scholar]

- Fischer, F.D.; Friedi, N.; Noe, A.; Rammerstorfer, F.G. A study on the buckling behaviour of strips and plates with residual stresses. Steel Res. Int. 2005, 76, 327–335. [Google Scholar] [CrossRef]

- Hao, J.W.; Cao, J.G.; Zhang, J.; Wei, G.C.; Zhou, Y.Z.; Chen, G. Backup roll contour of 2250 CVC hot strip mill. J. Cent. South. Univ. Technol. 2007, 38, 734–738. [Google Scholar]

- Frolisch, M.F. Design Criteria for Rolling Contact Fatigue Resistance in Back-up Rolls. Ph.D. Thesis, University of Sheffield, Sheffield, UK, 2002; p. 227. [Google Scholar]

- Gagg, C.; Lewis, P. Wear as a product failure mechanism—Overview and case studies. Eng. Fail. Anal. 2017, 14, 1618–1640. [Google Scholar] [CrossRef]

- Zhao, X.L.; An, W.J.; Lu, Z.H.; Xu, J.Z.; Zhang, D.H. Research on work roll contour of conventional hot strip mill. Steel. Rolling 2008, 25, 10–12. [Google Scholar]

- Ohkomori, Y.; Kaku, K. High wear resistance and toughness backup roll for hot strip mill. SEAISI Q. 1997, 26, 47–53. [Google Scholar]

- Allison, F.H.; Peterson, C.E. Modern Manufacture and Use of Cast-Iron Rolling-Mill Rolls. Iron Steel Eng. 1954, 952–961. [Google Scholar]

- Stone, M.D. Benefits, Improvements and Ideas from Roll Research Program. Iron Steel Eng. 1966, 143–163. [Google Scholar]

- Senne, J.M. An Overview of Coiler Pinch Roll Technology. In Proceedings of the 39th Mechanical Working and Steel Processing Conference Proceedings, Indianapolis, Indiana, 19–22 October 1997; Volume XXXV, pp. 496–497. [Google Scholar]

- Gonzales, J.; Liano, J.; Garcia, J. Metallurgical application to work and back up rolls for hot & cold rolling of flat products. In Proceedings of the International Workshop on “Rolls for Flat Rolling of Steel” at JSW Steel, Ballari, Italy, 26–27 February 2007; pp. 1–20. [Google Scholar]

- Yang, Q.; Chen, X.; Xu, Y.; Xu, L. Applying varying-contact-length back-up roll to improve strip shape control. Iron Steel. 1995, 30, 48–51. [Google Scholar]

- Janovec, J.; Svoboda, M.; Kroupa, A.; Výrostkova, A. Thermal-induced evolution of secondary phases in Cr–Mo–V low alloy steels. J. Mater. Sci. 2006, 41, 3425–3433. [Google Scholar] [CrossRef]

- Janovec, J.; Výrostkova, A.; Holý, A. Effect of tempering on development of carbide particles in 2.7Cr-0.6Mo-0.3V steel. J. Mater. Sci. 1992, 27, 6564–6572. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Design of Ferritic Creep-resistant Steels. ISIJ Int. 2001, 41, 626–640. [Google Scholar] [CrossRef]

- Pigrova, G.D. Effect of Long-Term Operation on Carbide Phases in Cr–Mo–V Steels. Met. Sci. Heat Treat. 2003, 45, 84–87. [Google Scholar] [CrossRef]

- Yokota, T.; Shiraga, T. Evaluation of Hydrogen Content Trapped by Vanadium Precipitates in a Steel. ISIJ Int. 2003, 43, 534–538. [Google Scholar] [CrossRef]

- Maruyama, K.; Sawada, K.; Koike, J. Strengthening Mechanisms of Creep Resistant Tempered Martensitic. Steel. ISIJ Int. 2001, 41, 641–653. [Google Scholar] [CrossRef]

- Abe, F. Bainitic and martesitic creep-resistant steels. Curr. Opin. Solid. State. Mater. Sci. 2008, 8, 305–311. [Google Scholar] [CrossRef]

- Schlögl, S.M.; Svoboda, J.; Van der Giessen, E. Evolution of the methane pressure in a standard 2.25Cr–1Mo steel during hydrogen attack. Acta Mater. 2001, 49, 2227–2238. [Google Scholar] [CrossRef]

- Yongtao, Z.; Lede, M.; Xiaojun, W.; Hanqian, Z.; Jinfu, L. Evolution Behaviour of Carbides in 2.25Cr-1Mo-0.25V Steel. Mater. Trans. 2009, 50, 2507–2511. [Google Scholar] [CrossRef]

- Song, G.; Wang, X.; Yang, Q. Study on mathematical model of work roll wear in skin-pass rolling of hot steel strip. Int. J. Adv. Manuf. Tech. 2018, 97, 2675–2686. [Google Scholar] [CrossRef]

- Mohyla, P.; Kuboň, Z.; Čep, R.; Janásek, A.; Samardzic, I. Secondary Hardening of Low-Alloyed Creep-Resistant Steel Welds. Metallurgija 2014, 53, 25–28. [Google Scholar]

- Mohyla, P.; Foldynová, K. Influence of Post Weld Heat Treatment on Mechanical Properties of P92 Welds Made by Submerged Arc Welding. Met. Sci. Heat. Treat. 2014, 56, 206–209. [Google Scholar] [CrossRef]

- Yoon, D.J.; Kwon, O.J.; Chung, M.H.; Kim, K.W. Early detection of damages in journal bearings by acoustic emission monitoring. J. Aco. Emiss. 1995, 13, 1–10. [Google Scholar]

- Rowland, C.H.; Callaghan, T.; Coy, J. Condition Monitoring Using Acoustic Emission on Multiple Roller Bearings in Consignia’s Letter Sorting Machines; EWGAE: Prague, Czech Republic, 2002; Volume 2, p. 131. ISBN 80-214-2174-6. [Google Scholar]

- Falat, L.; Dzupon, M.; Tavodova, M.; Hnilica, R.; Luptacikova, V.; Ciripova, L.; Homolova, V.; Durisinova, K. Microstructure and Abrasive Wear Resistance of Various Alloy Hardfacings for Application on Heavy-Duty Chipper Tools in Forestry Shredding and Mulching Operations. Materials 2019, 12, 2212. [Google Scholar] [CrossRef]

- Kovaříková, I.; Szewczyková, B.; Blaškovitš, P.; Hodúlová, E.; Lechovič, E. Study and characteristic of abrasive wear mechanisms. Mat. Sci. Tech. 2009, 9, 2009. [Google Scholar]

- Turňa, M.; Sahul, M.; Demianová, K. Laser cladding of metal powders. In Proceedings of the METAL 2011: 20 International Conference on Metallurgy and Materials, Brno, Czech Republic, 18–20 May 2011; Tanger Ltd.: Brno, Czech Republic, 2011; pp. 1–2, ISBN 978-80-87294-22-2. [Google Scholar]

- Viňáš, J.; Brezinová, J.; Guzanová, A.; Kotus, M. Application of hard surfacing for repairing of agricultural parts. Res. Agr. Eng. 2013, 59, 61–67. [Google Scholar] [CrossRef]

- Brezinová, J.; Viňáš, J.; Maruschak, P.; Guzanová, A.; Draganovská, D.; Vrabeľ, M. Sustainable Renovation within Metallurgical Production, 1st ed.; RAM–Verlag: Lüdenscheid, Germany, 2017; p. 215. ISBN 978-3-942303-58-3. [Google Scholar]

| C | Mn | Si | P | S | Cr | Ni | Cu | V | Mo | Al | Ti | Sn |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.30 | 0.49 | 0.23 | 0.015 | 0.028 | 2.40 | 0.11 | 0.18 | 0.12 | 0.20 | 0.032 | 0.017 | 0.012 |

| Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Contraction (%) |

|---|---|---|---|

| 802 | 939 | 19.6 | 65.8 |

| Flux | C | Mn | Si | Cr | P | Cr | Mo |

|---|---|---|---|---|---|---|---|

| WLDC 17 | 0.32 | 1.01 | 0.54 | 0.006 | 0.007 | 5.0 | 3.05 |

| Preheating | 280 °C |

| Roller rotation speed | 270 mm·min−1 |

| Spiral climb | 11 mm |

| Voltage | 29 V |

| Wire feed speed | 6 m·min−1 |

| Weld Deposit | C | Mn | Si | P | S | Al | Cu | Ni | Cr | Ti | V | Nb | Zr |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B1 | 0.27 | 1.01 | 0.55 | 0.02 | 0.01 | 0.02 | 0.05 | 0.21 | 5.2 | 0.02 | 0.02 | <0.01 | <0.005 |

| B2 | 0.46 | 1.05 | 0.54 | 0.02 | 0.01 | 0.03 | 0.04 | 0.2 | 4.81 | - | 0.26 | 0.003 | - |

| B3 | 0.24 | 0.95 | 0.49 | 0.02 | 0.01 | 0.02 | 0.05 | 0.19 | 2.88 | - | 0.01 | 0.002 | 1.174 |

| B4 | 0.41 | 1.00 | 0.23 | 0.01 | 0.01 | 0.04 | 0.04 | 0.02 | 2.89 | - | 0.01 | <0.002 | - |

| Sample | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Contraction (%) |

|---|---|---|---|---|

| B1 | 981 ± 4 | 1033 ± 6 | 0.9 ± 0.2 | 4.54 ± 0.2 |

| B2 | 744 ± 6 | 784 ± 8 | 1.0 ± 0.2 | 3.1 ± 0.2 |

| B3 | 767 ± 8 | 1155 ± 11 | 5.2 ± 0.4 | 9.06 ± 0.3 |

| B4 | 755 ± 4 | 888 ± 6 | 1.7 ± 0.2 | 3.8 ± 0.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brezinová, J.; Viňáš, J.; Brezina, J.; Guzanová, A.; Maruschak, P. Possibilities for Renovation of Functional Surfaces of Backup Rolls Used during Steel Making. Metals 2020, 10, 164. https://doi.org/10.3390/met10020164

Brezinová J, Viňáš J, Brezina J, Guzanová A, Maruschak P. Possibilities for Renovation of Functional Surfaces of Backup Rolls Used during Steel Making. Metals. 2020; 10(2):164. https://doi.org/10.3390/met10020164

Chicago/Turabian StyleBrezinová, Janette, Ján Viňáš, Jakub Brezina, Anna Guzanová, and Pavlo Maruschak. 2020. "Possibilities for Renovation of Functional Surfaces of Backup Rolls Used during Steel Making" Metals 10, no. 2: 164. https://doi.org/10.3390/met10020164

APA StyleBrezinová, J., Viňáš, J., Brezina, J., Guzanová, A., & Maruschak, P. (2020). Possibilities for Renovation of Functional Surfaces of Backup Rolls Used during Steel Making. Metals, 10(2), 164. https://doi.org/10.3390/met10020164