Microstructure and Wear Behavior of In Situ ZA27/TiB2 Composites

Abstract

:1. Introduction

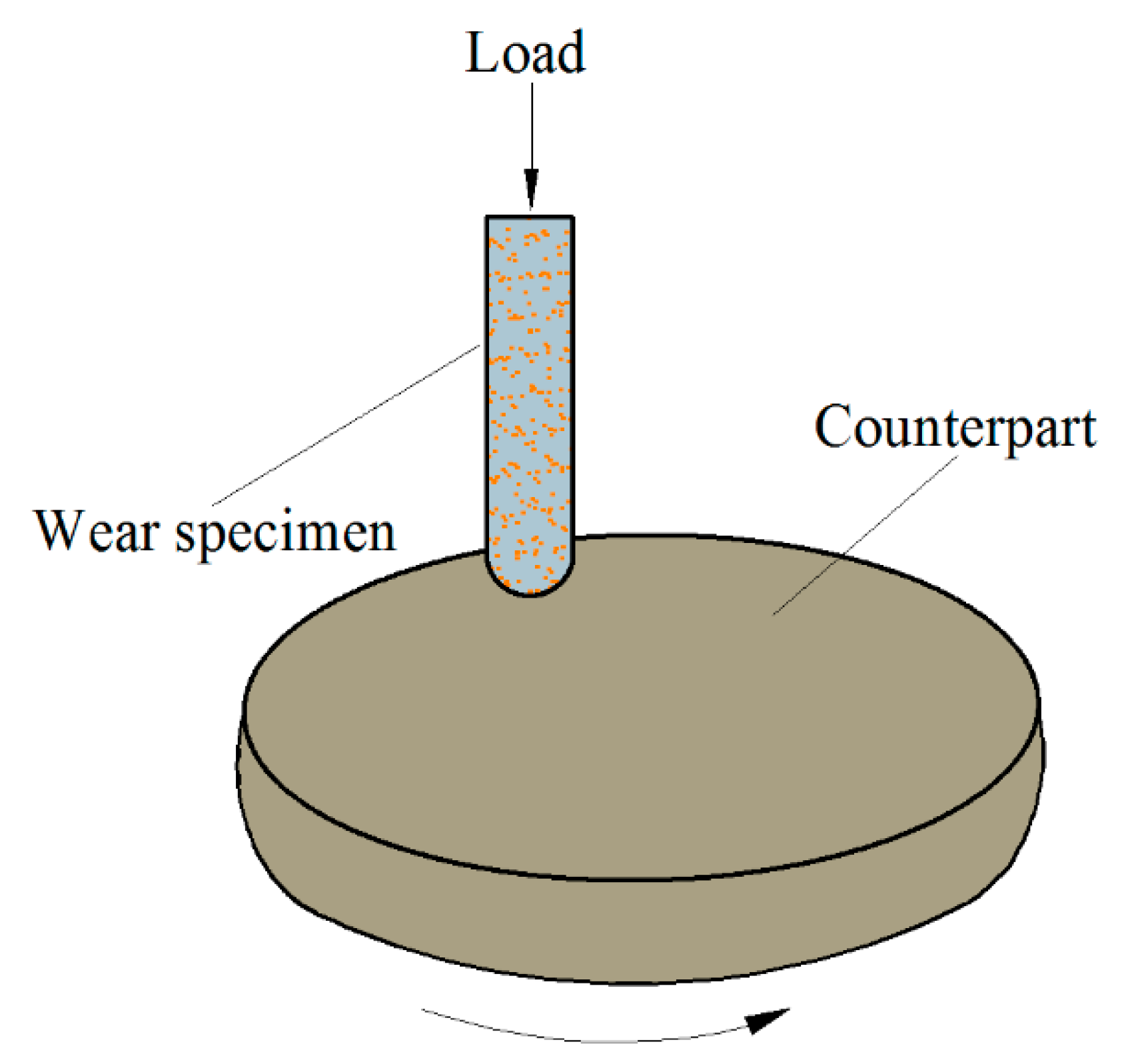

2. Experimental Procedure

3. Results and Discussion

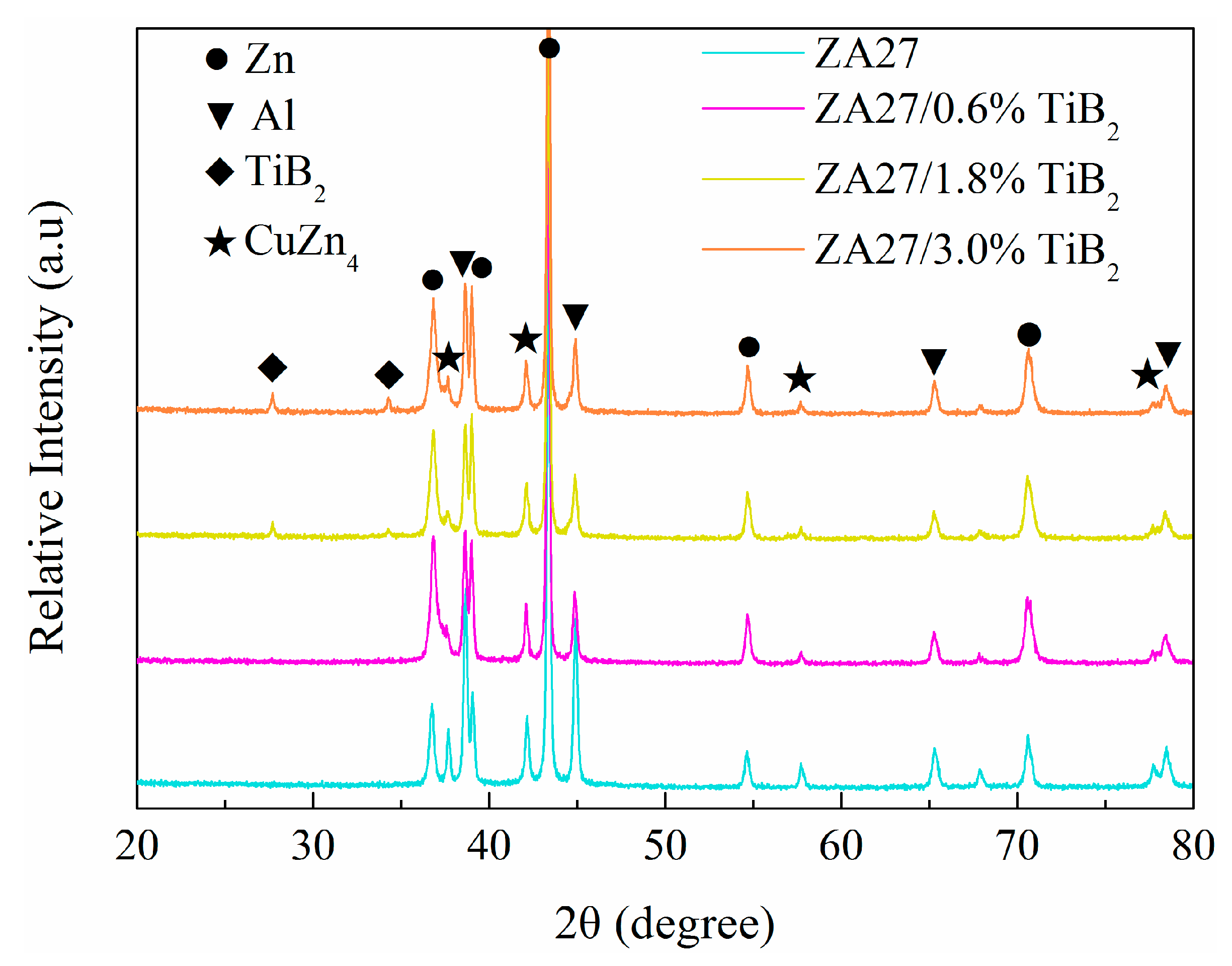

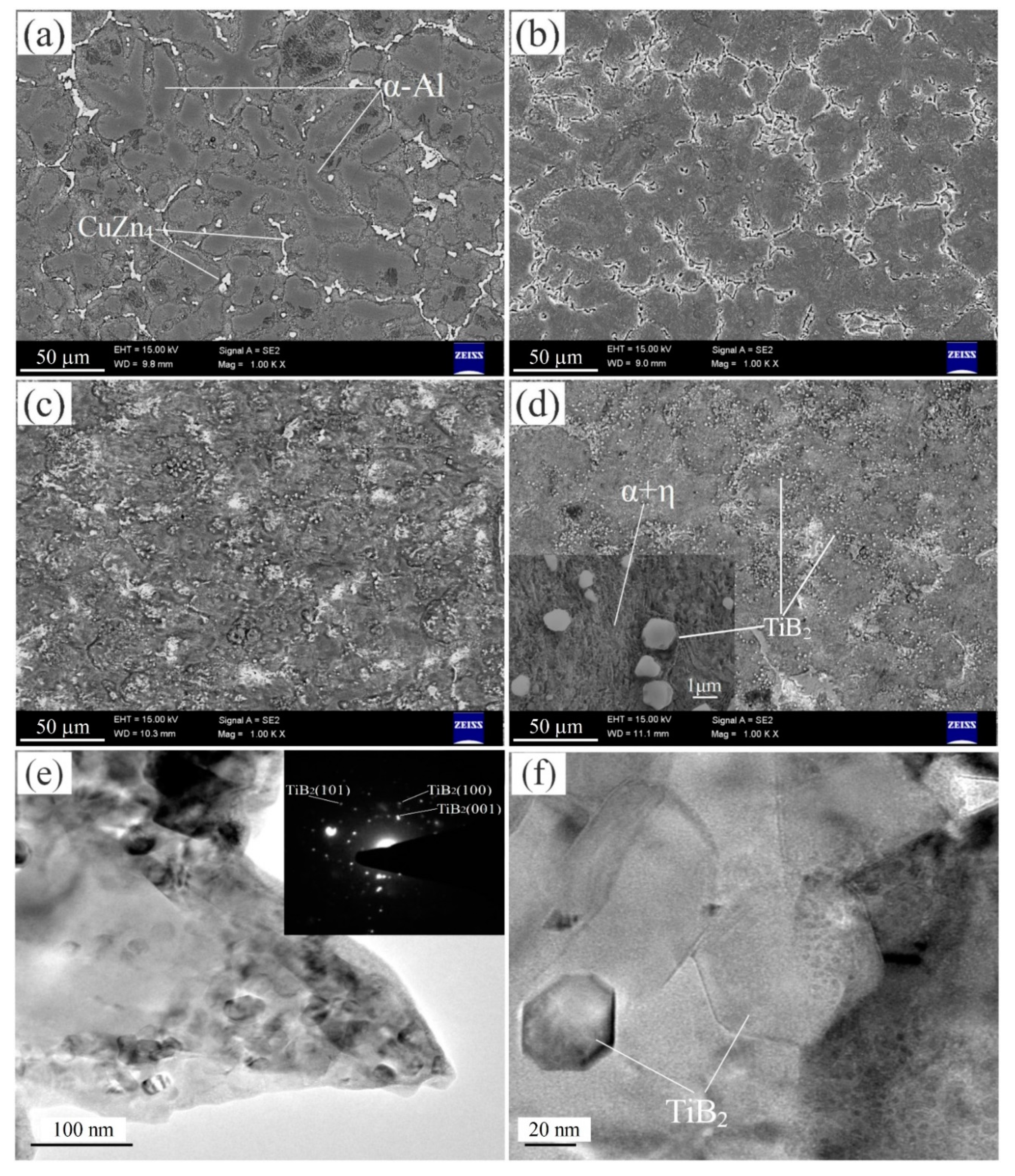

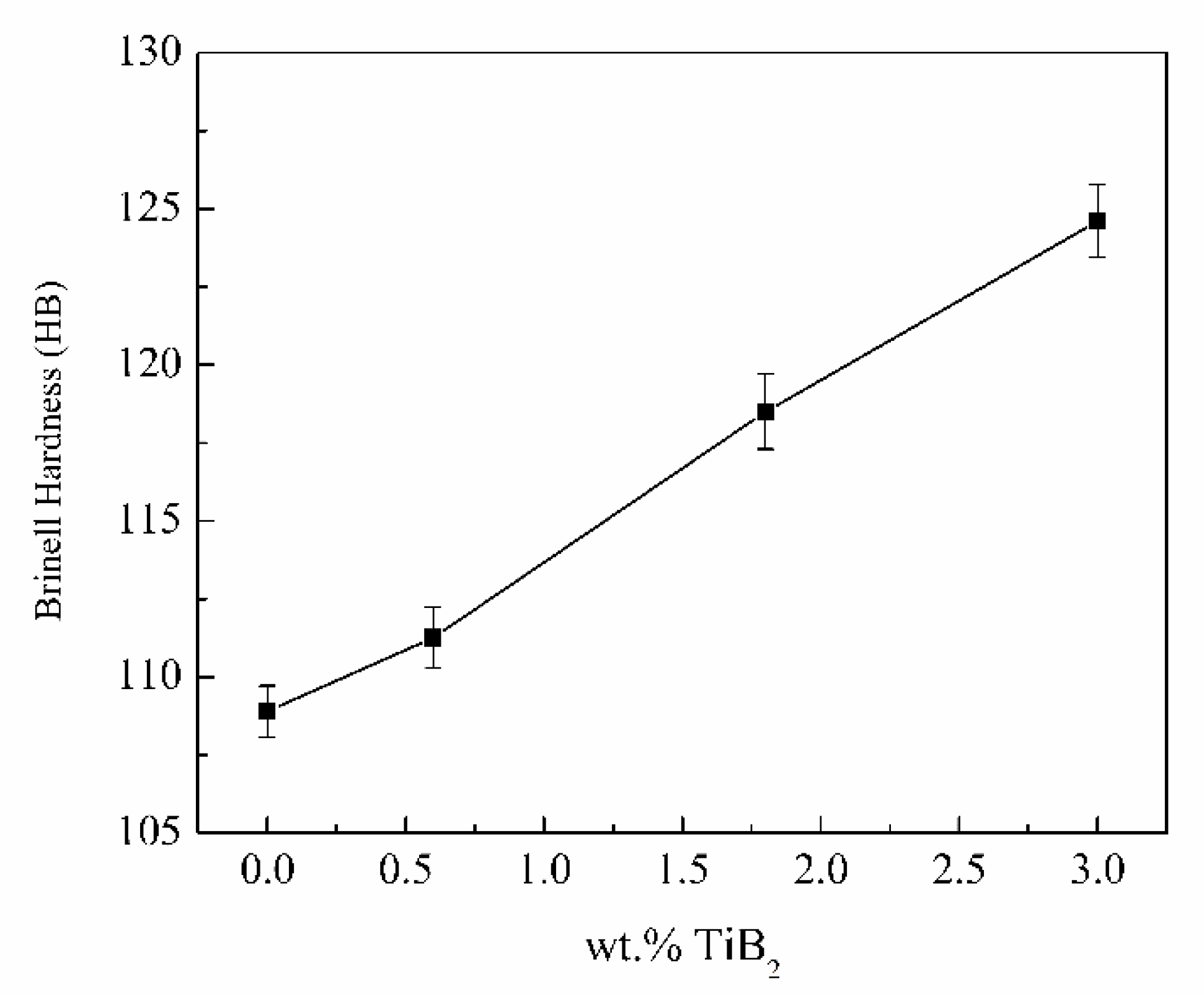

3.1. Microstructure and Hardness Characterization

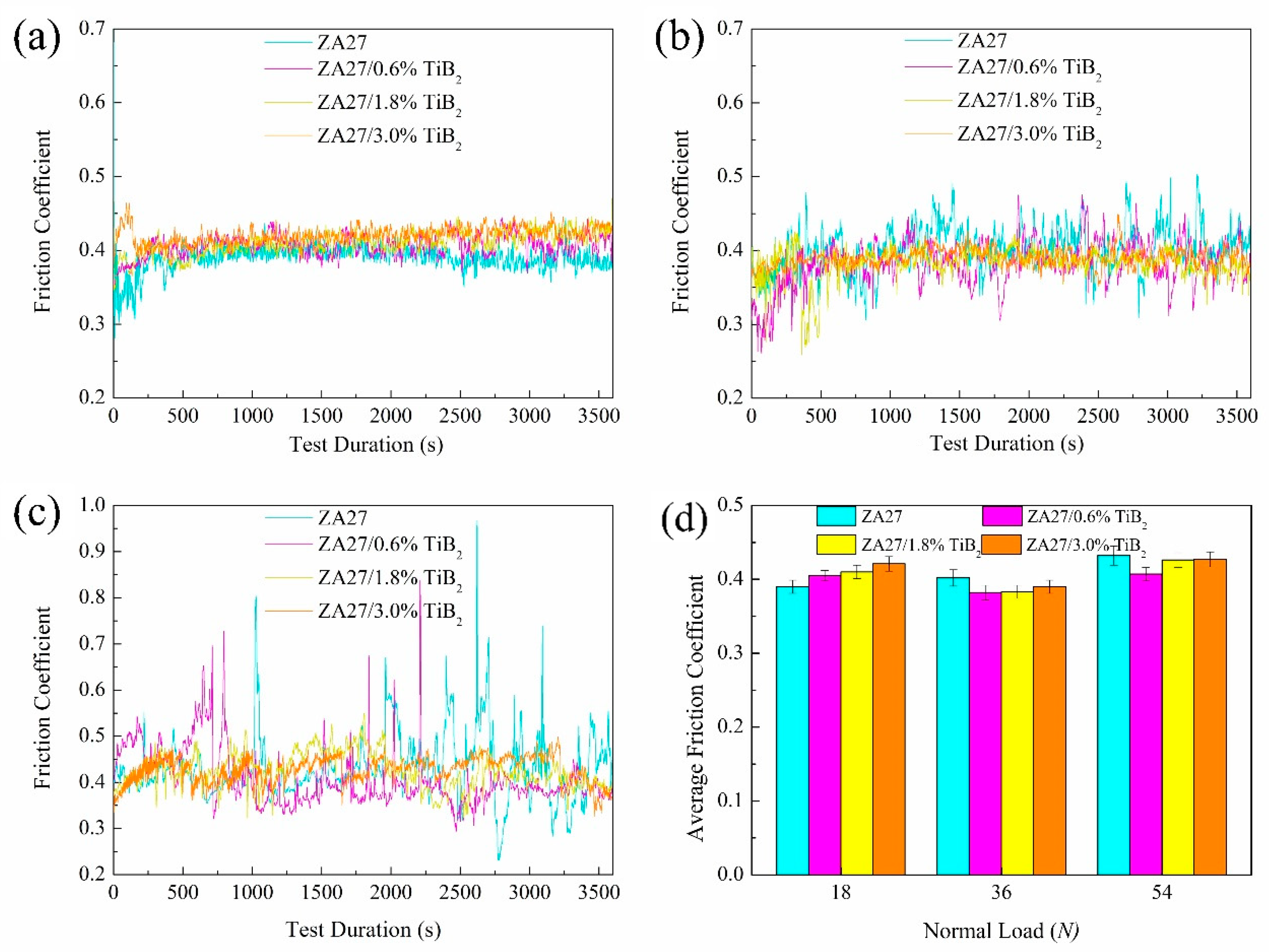

3.2. Coefficient of Friction

3.3. Sample Temperature

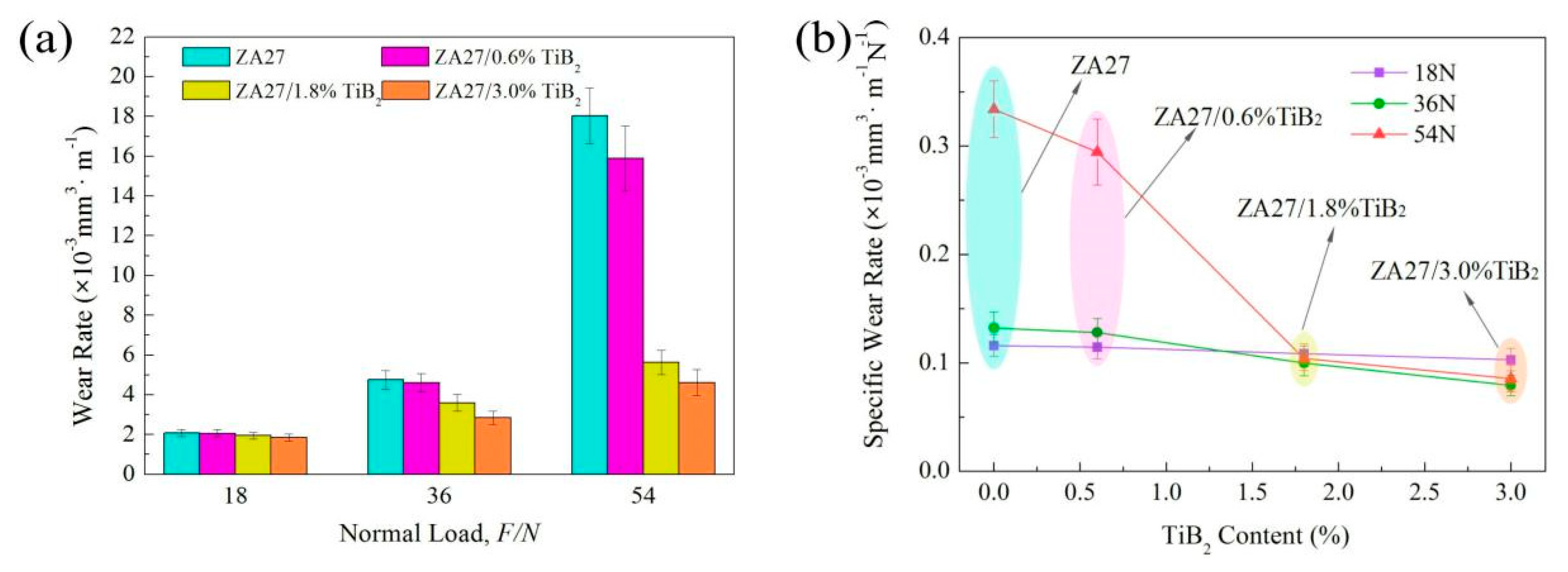

3.4. Wear Rate

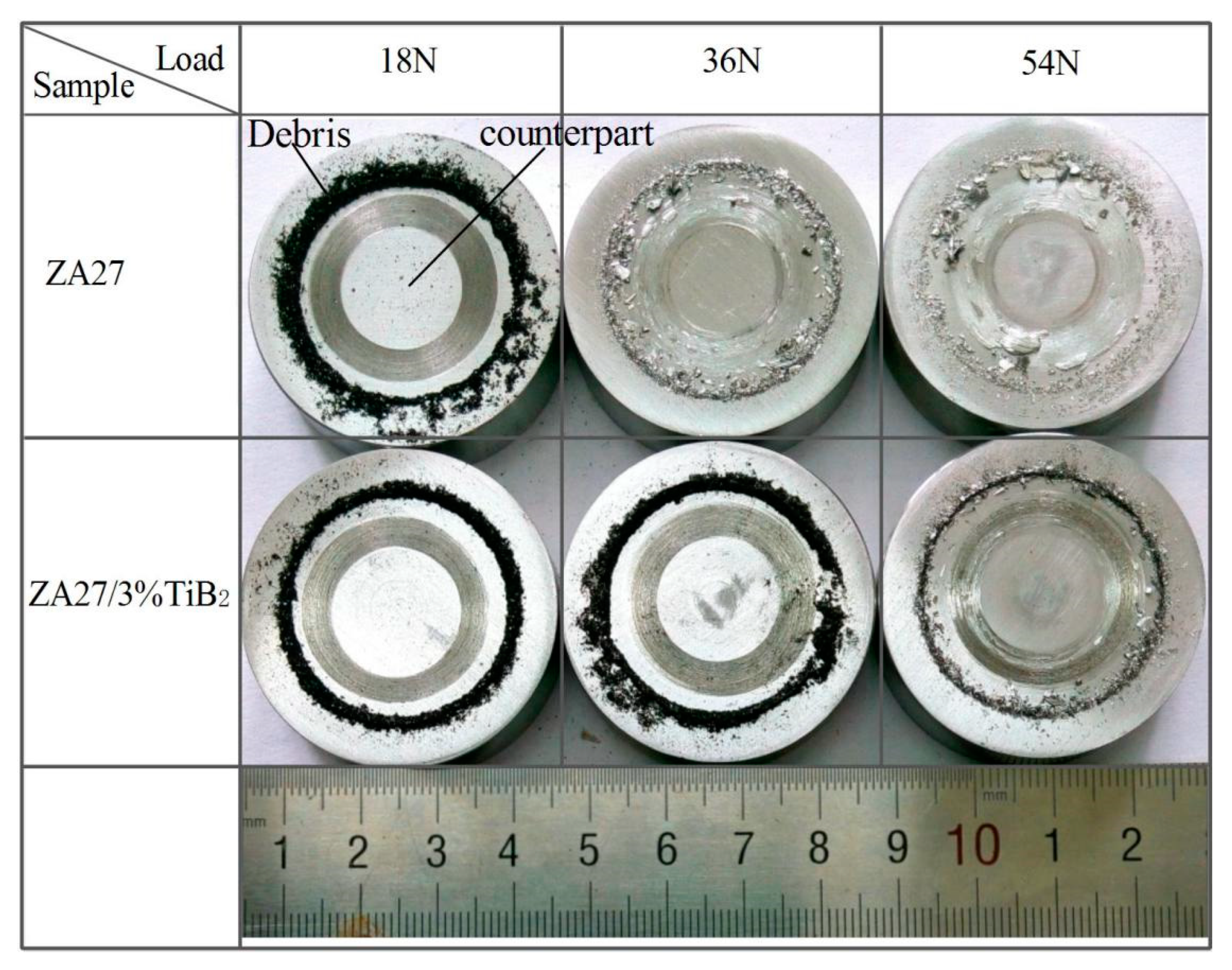

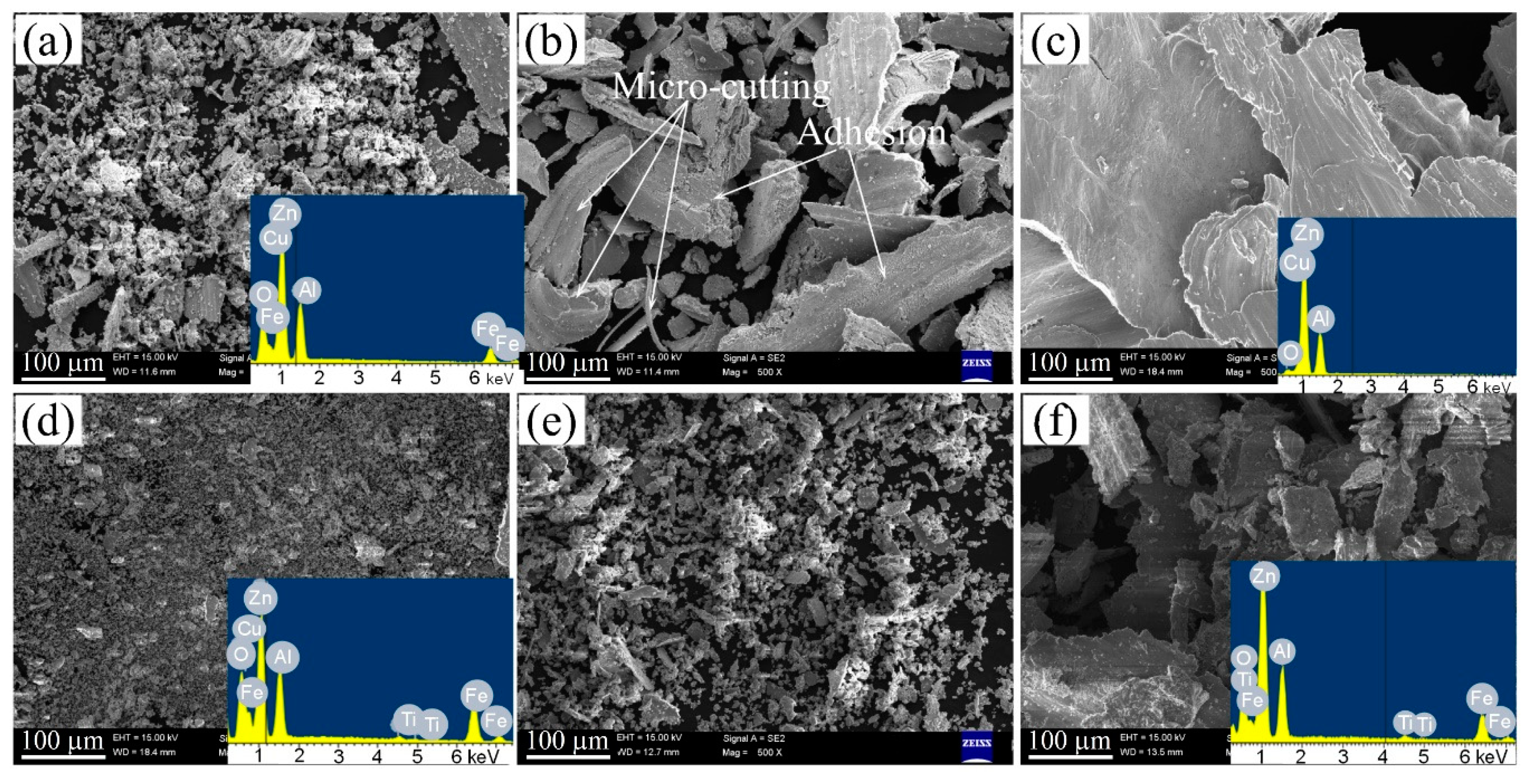

3.5. Wear Debris Morphology

3.6. Worn Surface of the Counterpart

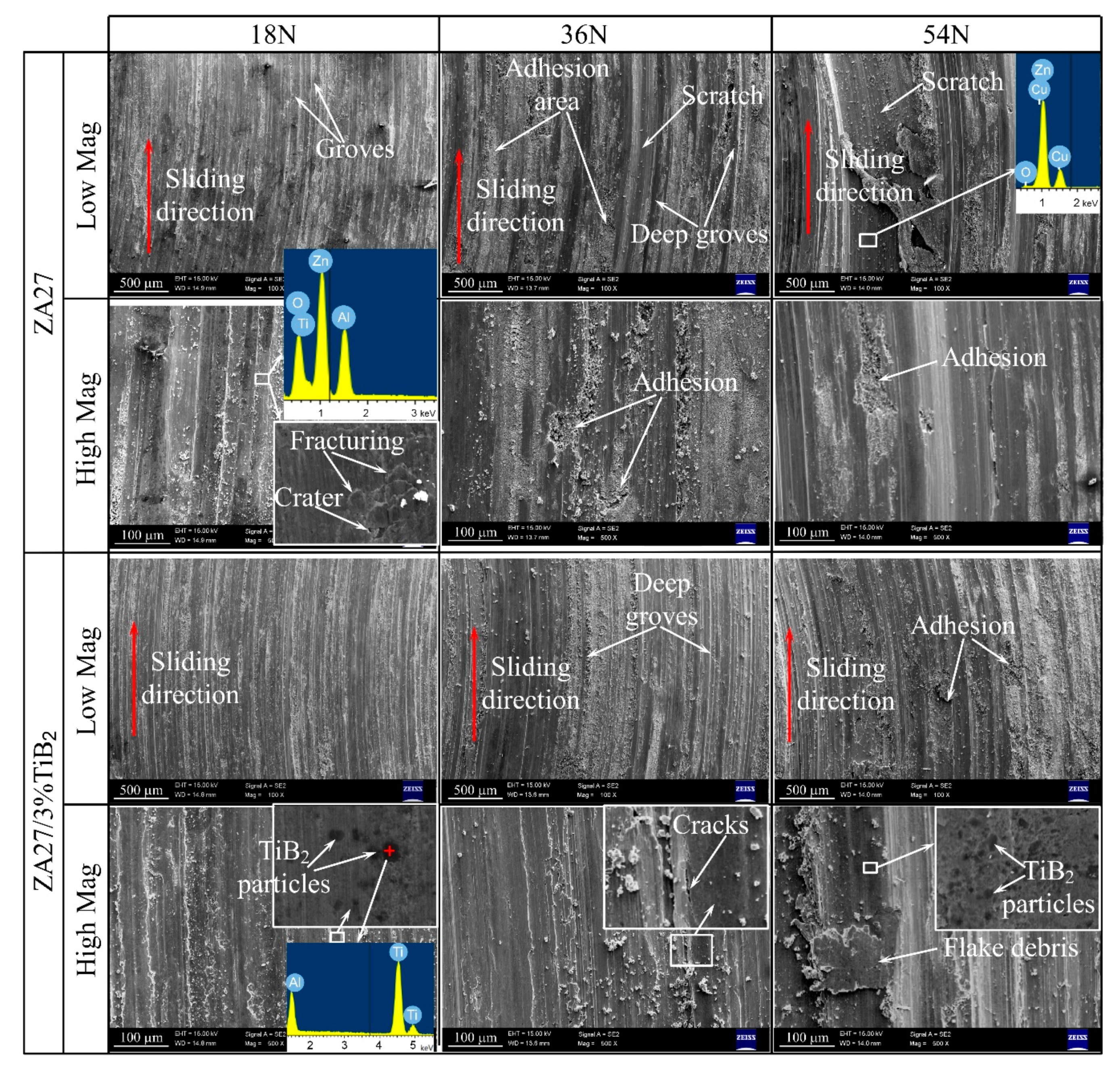

3.7. Worn Surface of the Samples

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Data Availability

References

- Liu, Y.; Li, H.; Jiang, H.-F.; Lu, X.-C. Effects of heat treatment on microstructure and mechanical properties of ZA27 alloy. Trans. Nonferr. Met. Soc. China 2013, 23, 642–649. [Google Scholar] [CrossRef]

- Ranganath, G.; Sharma, S.; Krishna, M. Dry sliding wear of garnet reinforced zinc/aluminium metal matrix composites. Wear 2001, 251, 1408–1413. [Google Scholar] [CrossRef]

- Jianhua, W.; Jianfeng, H.; Xuping, S.; Changjun, W. Effect of reverse modification of Al–5Ti–B master alloy on hypoeutectic ZnAl4Y alloy. Mater. Des. 2012, 38, 133–138. [Google Scholar] [CrossRef]

- Türk, A.; Kurnaz, C.; Şevik, H. Comparison of the wear properties of modified ZA-8 alloys and conventional bearing bronze. Mater. Des. 2007, 28, 1889–1897. [Google Scholar] [CrossRef]

- Savaşkan, T.; Azaklı, Z. An investigation of lubricated friction and wear properties of Zn–40Al–2Cu–2Si alloy in comparison with SAE 65 bearing bronze. Wear 2008, 264, 920–928. [Google Scholar] [CrossRef]

- Modi, O.; Rathod, S.; Prasad, B.K.; Jha, A.; Dixit, G. The influence of alumina particle dispersion and test parameters on dry sliding wear behaviour of zinc-based alloy. Tribol. Int. 2007, 40, 1137–1146. [Google Scholar] [CrossRef]

- Prasad, B.; Patwardhan, A.; Yegneswaran, A. Dry sliding wear characteristics of some zinc-aluminium alloys: A comparative study with a conventional bearing bronze at a slow speed. Wear 1996, 199, 142–151. [Google Scholar] [CrossRef]

- Mishra, S.K.; Biswas, S.; Satapathy, A. A study on processing, characterization and erosion wear behavior of silicon carbide particle filled ZA-27 metal matrix composites. Mater. Des. 2014, 55, 958–965. [Google Scholar] [CrossRef]

- Babic, M.; Mitrović, S.; Zivic, F. Effects of Al2O3 particle reinforcement on the lubricated sliding wear behavior of ZA-27 alloy composites. J. Mater. Sci. 2011, 46, 6964–6974. [Google Scholar] [CrossRef]

- Pretreatment process of SiC particles and fabrication technology of SiC particulate reinforced Zn–Al alloy matrix composite. Mater. Sci. Technol. 2001, 17, 954–960. [CrossRef]

- BobiĆ, B.; Bajat, J.; BobiĆ, I.; JegdiĆ, B. Corrosion influence on surface appearance and microstructure of compo cast ZA27/SiCp composites in sodium chloride solution. Trans. Nonferr. Met. Soc. China 2016, 26, 1512–1521. [Google Scholar] [CrossRef]

- Sharma, S.C.; Sastry, S.; Krishna, M. Effect of aging parameters on the micro structure and properties of ZA-27/aluminite metal matrix composites. J. Alloys Compd. 2002, 346, 292–301. [Google Scholar] [CrossRef]

- El-Khair, M.A.; Lotfy, A.; Daoud, A.; El-Sheikh, A. Microstructure, thermal behavior and mechanical properties of squeeze cast SiC, ZrO2 or C reinforced ZA27 composites. Mater. Sci. Eng. A 2011, 528, 2353–2362. [Google Scholar] [CrossRef]

- Seah, K.; Sharma, S.; Girish, B. Mechanical properties of as-cast and heat-treated ZA-27/graphite particulate composites. Compos. Part A Appl. Sci. Manuf. 1997, 28, 251–256. [Google Scholar] [CrossRef]

- Ranganath, G.; Sharma, S.C.; Krishna, M.; Muruli, M.S. A Study of Mechanical Properties and Fractography of ZA-27/Titanium-Dioxide Metal Matrix Composites. J. Mater. Eng. Perform. 2002, 11, 408–413. [Google Scholar] [CrossRef]

- Chen, F.; Wang, T.-m.; Chen, Z.-n.; Mao, F.; Han, Q.; Cao, Z.-Q. Microstructure, mechanical properties and wear behaviour of Zn–Al–Cu–TiB2 in situ composites. Trans. Nonferr. Met. Soc. China 2015, 25, 103–111. [Google Scholar] [CrossRef]

- Kai, X.; Huang, S.; Wu, L.; Tao, R.; Peng, Y.; Mao, Z.; Chen, F.; Li, G.; Chen, G.; Zhao, Y. High strength and high creep resistant ZrB2/Al nanocomposites fabricated by ultrasonic-chemical in-situ reaction. J. Mater. Sci. Technol. 2019, 35, 2107–2114. [Google Scholar] [CrossRef]

- Hong, T.; Li, X.; Wang, H.; Chen, D.; Wang, K. Effects of TiB2 particles on aging behavior of in-situ TiB2/Al–Cu–Mg composites. Mater. Sci. Eng. A 2015, 624, 110–117. [Google Scholar] [CrossRef]

- Rajan, H.M.; Ramabalan, S.; Dinaharan, I.; Vijay, S. Effect of TiB2 content and temperature on sliding wear behavior of AA7075/TiB2 in situ aluminum cast composites. Arch. Civ. Mech. Eng. 2014, 14, 72–79. [Google Scholar] [CrossRef]

- Chen, F.; Chen, Z.; Mao, F.; Wang, T.; Cao, Z. TiB 2 reinforced aluminum based in situ composites fabricated by stir casting. Mater. Sci. Eng. A 2015, 625, 357–368. [Google Scholar] [CrossRef]

- Kumar, S.; Sarma, V.S.; Murty, B.S. High temperature wear behavior of Al–4Cu–TiB2 in situ composites. Wear 2010, 268, 1266–1274. [Google Scholar] [CrossRef]

- Li, P.; Wu, Y.; Liu, X. Controlled synthesis of different morphologies of TiB2 microcrystals by aluminum melt reaction method. Mater. Res. Bull. 2013, 48, 2044–2048. [Google Scholar] [CrossRef]

- Ramesh, C.S.; Ahamed, A.K.M.A. Friction and wear behaviour of cast Al 6063 based in situ metal matrix composites. Wear 2011, 271, 1928–1939. [Google Scholar] [CrossRef]

- Wang, T.; Chen, Z.; Zheng, Y.; Zhao, Y.; Kang, H.; Gao, L. Development of TiB2 reinforced aluminum foundry alloy based in situ composites—Part II: Enhancing the practical aluminum foundry alloys using the improved Al–5wt%TiB2 master composite upon dilution. Mater. Sci. Eng. A 2014, 605, 22–32. [Google Scholar] [CrossRef]

- Sahoo, B.N.; Panigrahi, S.K. Development of wear maps of in-situ TiC+TiB2 reinforced AZ91 Mg matrix composite with varying microstructural conditions. Tribol. Int. 2019, 135, 463–477. [Google Scholar] [CrossRef]

- Zou, J.; Lu, D.-P.; Fu, Q.-F.; Liu, K.-M.; Jiang, J. Microstructure and properties of Cu–Fe deformation processed in-situ composite. Vacuum 2019, 167, 54–58. [Google Scholar] [CrossRef]

- Lee, J.; Lee, D.; Song, M.H.; Rhee, W.; Ryu, H.J.; Hong, S.H. In-situ synthesis of TiC/Fe alloy composites with high strength and hardness by reactive sintering. J. Mater. Sci. Technol. 2018, 34, 1397–1404. [Google Scholar] [CrossRef]

- Chen, F.; Mao, F.; Xuan, Z.; Yan, G.; Han, J.; Wang, T.; Cao, Z.; Fu, Y.; Xiao, T. Real time investigation of the grain refinement dynamics in zinc alloy by synchrotron microradiography. J. Alloys Compd. 2015, 630, 60–67. [Google Scholar] [CrossRef]

- Chen, T.J.; Yuan, C.R.; Fu, M.F.; Ma, Y.; Li, Y.D.; Hao, Y. In situ silicon particle reinforced ZA27 composites: Part 1—Microstructures and tensile properties. Mater. Sci. Technol. 2008, 24, 1321–1332. [Google Scholar] [CrossRef]

- Li, Z.Q.; Zhang, S.Y.; Wu, B.Y. Solidification and microstructure of ZA27/SiCp composite fabricated by mechanical-electromagnetic combination stirring process. Mater. Sci. Technol. 2001, 17, 465–471. [Google Scholar]

- Osório, W.R.; Freire, C.M.; Garcia, A. The effect of the dendritic microstructure on the corrosion resistance of Zn–Al alloys. J. Alloys Compd. 2005, 397, 179–191. [Google Scholar] [CrossRef]

- Prasad, B.; Modi, O.; Yegneswaran, A. Wear behaviour of zinc-based alloys as influenced by alloy composition, nature of the slurry and traversal distance. Wear 2008, 264, 990–1001. [Google Scholar] [CrossRef]

- Prasad, B.; Modi, O.; Khaira, H. High-stress abrasive wear behaviour of a zinc-based alloy and its composite compared with a cast iron under varying track radius and load conditions. Mater. Sci. Eng. A 2004, 381, 343–354. [Google Scholar] [CrossRef]

- Dinaharan, I.; Murugan, N. Dry sliding wear behavior of AA6061/ZrB2 in-situ composite. Trans. Nonferr. Met. Soc. China 2012, 22, 810–818. [Google Scholar] [CrossRef]

- Prasad, B. Sliding wear response of a zinc-based alloy and its composite and comparison with a gray cast iron: Influence of external lubrication and microstructural features. Mater. Sci. Eng. A 2005, 392, 427–439. [Google Scholar] [CrossRef]

- Savaskan, T.; Alemdağ, Y. Effects of pressure and sliding speed on the friction and wear properties of Al–40Zn–3Cu–2Si alloy: A comparative study with SAE 65 bronze. Mater. Sci. Eng. A 2008, 496, 517–523. [Google Scholar] [CrossRef]

- Mandal, A.; Chakraborty, M.; Murty, B. Effect of TiB2 particles on sliding wear behaviour of Al–4Cu alloy. Wear 2007, 262, 160–166. [Google Scholar] [CrossRef]

- Yadav, S.; Aggrawal, A.; Kumar, A.; Biswas, K. Effect of TiB2 addition on wear behavior of (AlCrFeMnV)90Bi10 high entropy alloy composite. Tribol. Int. 2019, 132, 62–74. [Google Scholar] [CrossRef]

- Kumar, N.; Gautam, G.; Gautam, G.; Mohan, A.; Mohan, S. Wear, friction and profilometer studies of insitu AA5052/ZrB2 composites. Tribol. Int. 2016, 97, 313–326. [Google Scholar] [CrossRef]

- Sharma, S.; Girish, B.; Somashekar, D.; Satish, B.; Kamath, R. Sliding wear behaviour of zircon particles reinforced ZA-27 alloy composite materials. Wear 1999, 224, 89–94. [Google Scholar] [CrossRef]

- Axe´n, N.; Jacobson, S. Transitions in the abrasive wear resistance of fibre- and particle-reinforced aluminium. Wear 1994, 178, 1–7. [Google Scholar] [CrossRef]

- Rabinowicz, E.; Mutis, A. Effect of abrasive particle size on wear. Wear 1965, 8, 381–390. [Google Scholar] [CrossRef]

- Gu, C.; Rong, W.; Guo, S.; Yang, Y. Dry sliding wear behavior of in situ Cu–TiB2 nanocomposites against medium carbon steel. Wear 2003, 255, 832–835. [Google Scholar] [CrossRef]

- Sivaprasad, K.; Babu, S.P.K.; Natarajan, S.; Narayanasamy, R.; Kumar, B.A.; Dinesh, G. Study on abrasive and erosive wear behaviour of Al 6063/TiB2 in situ composites. Mater. Sci. Eng. A 2008, 498, 495–500. [Google Scholar] [CrossRef]

- Zhang, Z.F.; Zhang, L.C.; Mai, Y.-W. Particle effects on friction and wear of aluminium matrix composites. J. Mater. Sci. 1995, 30, 5999–6004. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and Rubbing of Flat Surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

| Element | Al | Cu | Mg | Zn |

|---|---|---|---|---|

| % | 25.5–28.0 | 2.0–2.5 | 0.012–0.020 | Balance |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, F.; Wang, B.; Cao, Z. Microstructure and Wear Behavior of In Situ ZA27/TiB2 Composites. Metals 2020, 10, 1663. https://doi.org/10.3390/met10121663

Chen F, Wang B, Cao Z. Microstructure and Wear Behavior of In Situ ZA27/TiB2 Composites. Metals. 2020; 10(12):1663. https://doi.org/10.3390/met10121663

Chicago/Turabian StyleChen, Fei, Binbin Wang, and Zhiqiang Cao. 2020. "Microstructure and Wear Behavior of In Situ ZA27/TiB2 Composites" Metals 10, no. 12: 1663. https://doi.org/10.3390/met10121663

APA StyleChen, F., Wang, B., & Cao, Z. (2020). Microstructure and Wear Behavior of In Situ ZA27/TiB2 Composites. Metals, 10(12), 1663. https://doi.org/10.3390/met10121663