Abstract

Advanced SA508-4N RPV steel samples, unadded, P-added, and P+Ce-added, are investigated on their hot ductility behavior. Hot tensile tests are carried out in the temperature range of 750 to 1000 °C through a Gleeble 1500D machine. It is demonstrated that the deformation temperatures of all the three steels are located in the austenite single-phase region. There is no ductility trough present for the P+Ce-added steel, but the unadded one exhibits a deep ductility trough. The reduction of area (RA) of the former is always higher than 75% and increases with rising temperature until reaching ~95% at 900 °C or above, whereas the lowest RA value of the latter is only ~50% at 850 °C. Microanalysis indicates that the grain boundary segregation of P and Ce takes place in the tested P+Ce-added steel. This may restrain the boundary sliding so as to improve the hot ductility behavior of the steel. Furthermore, the addition of P and Ce is able to facilitate the occurrence of the dynamic recrystallization (DR) of the steel, lowering the initial temperature of DR from ~900 to ~850 °C and thereby enhancing the hot ductility performance. Consequently, the combined addition of P and Ce can significantly improve the hot ductility of SA508-4N RPV steel, thereby improving its continuous casting performance and hot workability.

1. Introduction

The reactor pressure vessel (RPV) is a critical component in nuclear power plants, relating to the whole life of the plant due to its irreplaceability [1,2]. Due to its severe service condition, some superior performances of the RPV steel are attracting more and more attention [2,3]. SA508-3 steel mainly alloyed with Mn and Mo has been widely used in the nuclear industry for more than 30 years. However, this steel is unable to satisfy future applications due to its insufficient hardenability and irradiation embrittlement [4]. Nowadays, plenty of research studies focus on a new generation of RPV steel (i.e., SA508-4N steel mainly alloyed with Ni, Cr, and Mo). According to ASTM (American Society for Testing and Materials), advanced SA508-4N steel has higher strength, better fracture toughness, and outstanding hardenability as compared with SA508-3 steel [5,6,7]. As reported by Lee et al. [5], the Charpy impact toughness and fracture toughness of SA508-4N steel were evidently improved because of the addition of Ni and Cr. They also found that the yield strength and upper shelf energy of the steel were enhanced by increasing the tempered martensite phase fraction controlled by the cooling rate [6].

The process of continuous casting and rolling, which has the advantage of uncomplicatedness and cost-effectiveness, is widely employed in the manufacture of many steel products [8]. However, if the hot ductility (HD) of a steel is not high enough (less than 60% reduction of area), transverse cracking could take place during continuous casting, causing severe damage in the quality of products [9]. The poor HD of a steel also affects its hot working performance, such as hot rolling or forging. Moreover, the accumulation of some residual impurity elements during the recycling of steel scraps would severely deteriorate the HD of steel [9,10]. As demonstrated in [11], SA508-4N steel exhibits a relatively poor HD performance between 750 and 900 °C, especially at around 850 °C, where the reduction of area (RA) is much lower than 60%. As a result, for this RPV steel, the straightening operation of continuous casting must be conducted above 900 °C, and the hot working must also be carried out above this temperature. No doubt, it would be difficult to conduct these operations in fact as the temperature window is narrow. In order to improve the quality and productivity of continuous casting and hot working of this steel, it is necessary to raise its hot ductility, especially between 800 and 900 °C.

Recent studies demonstrated [9,11,12,13,14,15,16] that phosphorus segregated at grain boundaries (GBs) had a positive influence on the HD of some steels through restraining carbide precipitation along the boundaries. Usually, the carbide precipitation is very likely to form at high temperatures in steels containing some strong carbide-forming alloying elements, such as V, Ti, and Nb. Mintz et al. [12] reported that P could enhance the HD of Nb-bearing steels by suppressing the precipitation of NbC and thus restraining the GB sliding. Besides, a study by Jiang et al. [13] indicated that the HD of 1Cr0.5Mo steel could be significantly enhanced by adding 0.054 wt.% P. Further study suggested that P tended to strengthen the thin ferrite layers formed at austenite grain boundaries so that the difference in strength between the austenite matrix and ferrite layer could be reduced, and consequently, the hot deformation could occur more uniformly, enhancing the HD accordingly. Recently, Guo et al. [11] found that P could effectively enhance the HD of SA508-4N RPV steel through grain boundary segregation (GBS). It is proposed that the P atoms segregated at the GBs might suppress the GB sliding by occupying the vacant sites at the boundaries. As a result, the RA of the P-doped steel is considerably raised, making the HD trough much shallower. However, it is acknowledged that P could also seriously deteriorate some other properties of the steel, especially toughness [17,18,19]. The GBS of P could raise the ductile-to-brittle transition temperature (DBTT) by weakening the boundary, which significantly affects the applicability of steel. Therefore, it is not recommended to improve the HD of a steel by the addition of P.

In many cases, rare earths (REs) have beneficial influences on the mechanical properties of steels, such as toughness and hot ductility [20,21,22,23,24,25,26]. The enhancement mechanisms of toughness and hot ductility are mainly grain refinement and GBS of REs. Liu et al. [21] found that Ce could considerably improve the impact toughness of an industrial low-carbon steel in three ways: reducing pearlite, refining microstructure, and cleaning GBs. Meanwhile, the GBS of Ce is conducive to lowering the DBTT of the welding heat-affected zone in SA508-3 RPV steel [22]. A study by Jiang and Song [23] indicated that Ce played an important role in the HD performance of 1Cr-0.5Mo steel. The trace addition of Ce caused a remarkable rise in the RA of the steel due to the GBS of Ce by restraining the GB sliding and facilitating the dynamic recrystallization (DR). Ma et al. [24] found that RE (Ce or La) could enhance the hot workability behavior of duplex stainless steel mainly by reducing the difference of hardness between ferrite and austenite and promoting DR. Guo et al. [25] also demonstrated that the HD of SA508-3 RPV steel could be significantly improved by the GBS of Ce. In addition, the theoretical calculations [27,28] also showed that the addition of RE elements in the steel could increase the intergranular cohesion, thus strengthening the GB.

According to the above-mentioned information, it is envisaged that the combined addition of P and Ce in the SA508-4N RPV steel could improve the HD behavior of the steel, and at the same time, the P-induced low-temperature embrittlement might be suppressed. In this study, a Gleeble machine together with various characterization techniques was employed to investigate in detail the combined impact of P and Ce on the HD behavior of SA508-4N RPV steel, demonstrating that the HD performance of the RPV steel could be highly ameliorated, thus eliminating the HD trough exhibited by the unadded steel. In order to better explore the combined effect of P and Ce, the results for the P-added SA508-4N steel reported in our previous work [11] were also incorporated into the present study for comparison.

2. Materials and Methods

Three heats of experimental SA508-4N RPV steel were melted by vacuum induction, cast into a sand mold, and finally hot-forged into plates after homogenization annealing (China Iron and Steel Research Institute Group, Beijing, China). The chemical composition of the steels is listed in Table 1. Clearly, they are unadded, added with 0.043 wt.% P, and added with 0.052 wt.% P and 0.030 wt.% Ce. In short, the three steels are hereafter called “unadded steel”, “P-added steel”, and “P + Ce-added steel”.

Table 1.

Chemical Composition of Experimental Steels (wt.%).

A Gleeble 1500D machine (Data Sciences International, Saint Paul, MN, USA) was employed to carry out the hot tensile tests. The tests were operated under a vacuum of 20–30 Pa. The size of specimens was cylindrical with 10 mm diameter and 120 mm gage length (uniform heating region). The specimens were heated up to 1300 °C and held there for 180 s, followed by cooling down to different temperatures (750–1000 °C) at a cooling speed of 5 °C s−1 [13]. After holding for 10 s at each temperature, the specimens were deformed until fracture with a rate of 10−3 s−1 [29], cooled to 300 °C under the same vacuum condition, and subsequently air-cooled to room temperature. In order to estimate the possibility of transverse cracking during continuous casting, the RA is usually used [30]. If the RA is less than 60%, the transverse cracking could occur during the straightening operation of continuous casting [31]. Hence, the RA was measured to evaluate the HD of the steel. Besides, the fracture surfaces were examined using scanning electron microscopy (SEM, Hitachi S-4700, Hitachi, Tokyo, Japan). Optical metallography (OM, HOMA2000, XPK, Shenzhen, China) and electron backscatter diffraction (EBSD, Hikarui, EDAX, Mahwah, NJ, USA) were used to characterize microstructural features.

Field-emission scanning transmission electron microscopy (FE-STEM, JEM-2100F, JEOL, Tokyo, Japan) coupled with energy dispersive X-ray spectroscopy (EDS, Oxford INCA, Oxford, UK) was adopted to further investigate microstructural characteristics and microchemistry at the GBs [11]. The field emission gun in the FE-STEM system may provide a large beam current in a probe with a size of only 0.5–1 nm [32]. The disc samples for transmission electron microscopy were 3 mm in diameter, prepared by mechanically polishing and dual-jet electropolishing. For microanalysis, five GBs were chosen, and more than five positions on each GB were analyzed. The mean value of data points gained was used as the observed result. Further description of GB microanalysis by FE-STEM can be seen elsewhere [33].

3. Results

3.1. Hot Ductility

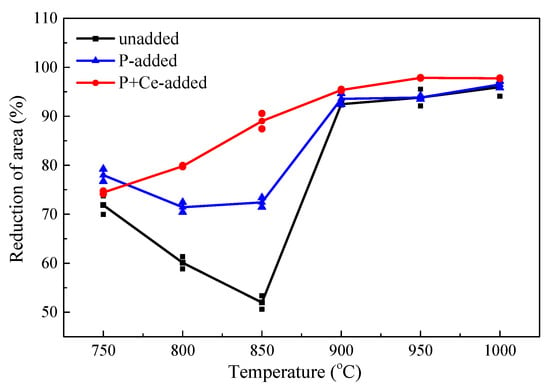

The HD curves of the steels are shown in Figure 1. It is clear that there are ductility troughs in the temperature range of 750–900 °C for both the unadded and P-added steels, but the trough is apparently shallower for the P-added steel. As a whole, the RA values of the P-added steel are all more than 70%, which are always higher than those of the unadded steel. The RA of the P-added steel is about 75% at 750 °C and then goes down to about 70% at 800 and 850 °C. Nevertheless, the RA value of the unadded steel deformed at 750–850 °C is 70–50%, attaining the lowest RA of ~50% at 850 °C. From 850 to 900 °C, the RA value for both the unadded and P-added steels increases rapidly to higher than 90%. On the other hand, there is no ductility trough present for the P+Ce-added steel so that it exhibits an outstanding HD behavior at all deforming temperatures. It is obvious that the RA of the P+Ce-added steel increases continuously with increasing temperature. Starting from ~75% at 750 °C, it rises up to ~90% at 850 °C, where it is just approximately 70% and 50%, respectively, for the P-added and unadded steels. Above 900 °C, the HD has no obvious difference between these steels, whose RA values are all higher than 90%. Therefore, the combined addition of P and Ce in the SA508Gr.4N RPV steel is able to achieve a superior HD performance.

Figure 1.

Hot ductility curves for the unadded, P-added, and P+Ce-added steels.

3.2. Fractographic Analysis

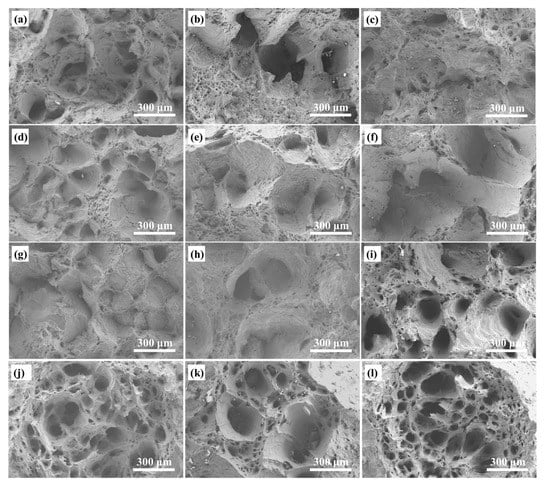

SEM micrographs of the fracture surfaces for the unadded, P-added, and P+Ce-added samples are represented in Figure 2. When deformed at 750 °C, three types of samples all exhibit similar ductile fracture with a number of small dimples (Figure 2a–c). This is well in agreement with their similar high RA values (Figure 1). When deformed at 800 °C, the fracture morphology for the unadded sample is ductile with some brittle characteristics demonstrated seemingly by some intergranular facets (Figure 2d). During the tensile test, some cracks could initiate and propagate along austenite grain boundaries. This is in agreement with its low RA value (~60%). However, the fracture morphologies for the P-added and P+Ce-added samples are fully ductile (Figure 2e,f), being well corresponding to their much higher RA values as shown in Figure 1. In addition, it is clear that the P+Ce-added sample exhibits bigger and deeper dimples than the P-added one, which is also well consistent with the difference between their RA values (P-added: ~70%; P+Ce-added: ~80%). At 850 °C, there are distinct differences in RA (Figure 1) and fracture morphology (Figure 2g–i) between the three steels. The unadded sample displays mainly an intergranular fracture characterized by intergranular facets accompanied with somewhat ductile characteristics, where the RA is only ~50%. However, the P-added and P+Ce-added samples still present ductile rupture. Compared with the P-added sample, the P+Ce-added one exhibits more visible and bigger dimples. This is well reflected in their RA values, being about 70% and 90%, respectively. When deformed at 1000 °C, all the samples exhibit a completely ductile fracture (Figure 2j–l), corresponding well to their high RA values (Figure 1). Consequently, the results of fracture characteristics further confirm that the combined addition of P and Ce has a positive effect on the HD behavior of SA508-4N RPV steel.

Figure 2.

SEM fractographs of the specimens tested at different temperatures: (a) unadded steel at 750 °C; (b) P-added steel at 750 °C; (c) P+Ce-added steel at 750 °C; (d) unadded steel at 800 °C; (e) P-added steel at 800 °C; (f) P+Ce-added steel at 800 °C; (g) unadded steel at 850 °C; (h) P-added steel at 850 °C; (i) P+Ce-added steel at 850 °C; (j) unadded steel at 1000 °C; (k) P-added steel at 1000 °C; and (l) P+Ce-added steel at 1000 °C.

3.3. Microstructural Observation

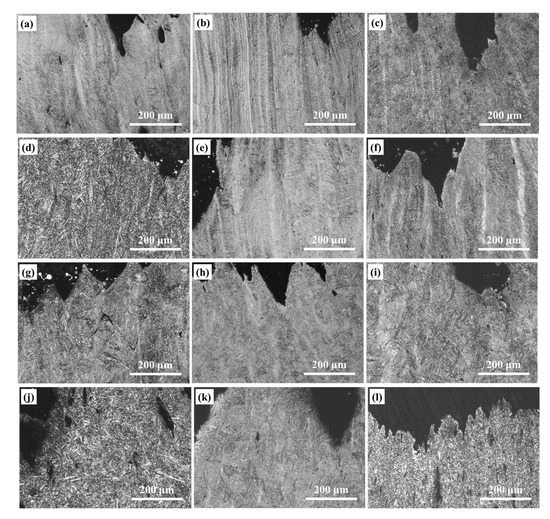

The longitudinal microstructural observations near the fracture tip are presented in Figure 3. As shown, no visible proeutectoid ferrite is precipitated along prior austenite GBs for any type of the ruptured samples after the tensile test. This indicates that the HD behavior of the three steels is merely related to the deformation of austenite. If the DR and GB sliding do not take place during hot deformation, the deformation bands will be formed along the tensile direction. The finer the bands, the stronger the deformation ability, and thus the better is the HD behavior. When deformed at 750 °C, there is no obvious difference in the band-shaped structure between different steels (Figure 3a–c). This is in accord with their similar RA values (Figure 1). However, when deformed at 800 °C, there is an apparent difference in morphology (Figure 3d–f). The band-shaped structure becomes more evident from the unadded to P-added to P+Ce-added samples, implying that the deformation capability increases in the same order, as demonstrated in Figure 1. When deformed at 850 °C, the band-shaped structure is still seemingly visible in the unadded and P-added samples and more clear in the latter (Figure 3g,h), being coincident with their RA values (~50% and 70%, respectively). Nevertheless, there is no band-shaped structure formed in the P+Ce-added sample (Figure 3i). Owing to the fact that the P+Ce-added sample exhibits a very high RA at this temperature (~90%), the DR should have occurred during hot deformation. It is worth noting that the microstructural morphology of the unadded sample (Figure 3g) clearly indicates that some cracks are initiated and propagated along austenite grain boundaries, thereby causing intergranular fracture characterized by the sawtooth-shaped fracture tip. This is well in accordance with the fracture morphology as shown above. When deformed at 900 °C or above, there are no band-shaped structures in all deformed samples, but with a high HD performance (Figure 3j–l). Under these circumstances, it can be inferred that the DR has took place in the course of hot deformation at these temperatures. Therefore, the combined addition of trace P and Ce in the SA508-4N RPV steel may be able to lower the starting temperature of DR from ~900 to ~850 °C.

Figure 3.

Optical microstructures near fracture tips of the specimens tested at different temperatures: (a) unadded steel at 750 °C; (b) P-added steel at 750 °C; (c) P+Ce-added steel at 750 °C; (d) unadded steel at 800 °C; (e) P-added steel at 800 °C; (f) P+Ce-added steel at 800 °C; (g) unadded steel at 850 °C; (h) P-added steel at 850 °C; (i) P+Ce-added steel at 850 °C; (j) unadded steel at 900 °C; (k) P-added steel at 900 °C; and (l) P+Ce-added steel at 900 °C.

4. Discussion

The following factors usually affect the HD of a steel. In the austenite–ferrite dual-phase region, the HD may be degenerated by a thin ferrite layer precipitated along the austenite GB since the hot deformation can be concentrated in this thin ferrite area, resulting in failure with a small overall deformation [9,13,14,34]. In the austenite single-phase region, the HD can be deteriorated by the GB sliding or substantially enhanced by the DR [9,12,14,35,36,37,38]. As the GB strength decreases with the increase of temperature, the GB sliding will become more serious at a higher temperature (i.e., the GB sliding increases with the increase of temperature), thereby reducing the HD of the steel. Generally, the GB sliding is affected by the GBS of solute or impurity atoms and the GB precipitation of carbides [15,39,40,41]. However, the DR would occur during hot deformation if the deformation temperature is sufficiently high, resulting in a dramatic enhancement of HD. Accordingly, the HD trough of a steel in the austenite single-phase range is caused by a combination of GB sliding and DR. Besides, the austenite grain size is another factor influencing the HD of a steel. Normally, the samples with finer grains would exhibit higher RA values as compared with the coarse-grained samples.

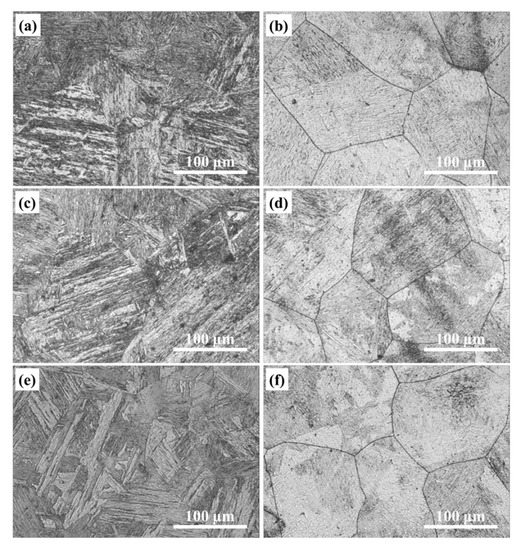

Optical microscopy, as shown in Figure 3, indicates that all the three steels have no evident proeutectoid ferrite precipitation at prior austenite GBs after hot deformation, even at 750 °C. This implies that the Ar3 of this RPV steel is lower than 750 °C; that is, the deformation between 750 and 1000 °C was proceeded in the austenite single-phase range. Since the microstructural characteristics are not very clear because of the deformation bands near the fracture tip as displayed in Figure 3, it is necessary to further confirm that the Ar3 of the steel is definitely lower than 750 °C. For this, the samples were heated to 1300 °C for 180 s, then furnace-cooled to 750 °C and maintained there for 1 h, followed by water quenching. Evidently, the optical microstructure revealed by etching with nital, as shown in Figure 4a,c,e, is a typical quenched martensite with no proeutectoid ferrite formation. Consequently, the Ar3 of the steel is lower than 750 °C indeed, which is well consistent with thermodynamic calculations where the A3 (or Ae3) of this RPV steel is forecasted as ~750 °C [11,42,43]. To reveal the prior austenite grain boundaries, the samples were etched with a supersaturated picric acid aqueous solution. As shown in Figure 4b,d,f, the average austenite grain size has no noticeable difference between different steels, which are about 178, 191, and 186 μm for the unadded, P-added, and P+Ce-added steels, respectively, determined by the linear intercept method. Based on these results, it could be inferred that before hot deformation at each temperature, the average grain size of austenite had no apparent difference between different steels. Therefore, the difference in HD behavior between these steels may not be related to grain size. It is worth mentioning that since the HD measurements were all performed in the austenite single-phase region, the microstructural constituents after hot tensile testing and subsequent cooling are not concerned with the above HD behavior. Accordingly, it is unnecessary to take into account their details in the present research.

Figure 4.

Optical micrographs of the specimens heated at 1300 °C for 180 s, furnace-cooled to 750 °C and held there for 1 h, followed by water quenching: (a,b) unadded steel; (c,d) P-added steel; (e,f) P+Ce-added steel; (a,c,e) etched with nital; (b,d,f) etched with supersaturated picric acid aqueous solution.

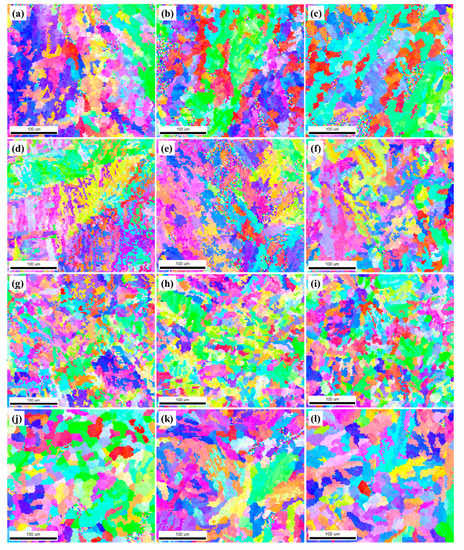

Many investigations [20,36,44] have demonstrated that the DR can relieve the concentrations of stress and dislocations so that the HD behavior can be significantly improved by restraining the microcrack formation. In other words, the starting temperature at which the DR may occur during hot deformation has a great impact on the HD performance of a steel. As inferred previously from Figure 1 and Figure 3, the DR occurred during hot deformation at 850 °C for the P+Ce-added sample and at 900 °C or above for all the three types of samples. This will be further discussed tentatively on the basis of EBSD images. The EBSD images in the regions near the fracture tip of the samples tested at 800, 850, 900, and 1000 °C are illustrated in Figure 5. As observed in Figure 5a–c, there are the distinct oriented big blocks in all samples deformed at 800 °C, and within each big block, the colors for different small constituents have no large difference. With reference to Figure 1 and Figure 3, it could be believed that the DR did not occur during hot deformation. It is also seen that the distinct oriented big blocks exist in both the unadded and P-added samples deformed at 850 °C (Figure 5d,e). For the P+Ce-added sample deformed at 850 °C, a mixture of oriented big blocks and equiaxed small blocks is mainly formed (Figure 5f), while the equiaxed small blocks present primarily in the other cases. This demonstrates that when deformed at 850 °C, the DR should have happened to some degree in the P+Ce-added sample, but it should have not in the unadded and P-added samples. When deformed at 900 °C or above, all EBSD images exhibit a similar morphology mainly with equiaxed small blocks. Accordingly, the DR should have fully occurred in these samples, leading to an excellent HD behavior as shown Figure 1.

Figure 5.

EBSD images showing microstructural features for the specimens tested at different temperatures: (a) unadded steel at 800 °C; (b) P-added steel at 800 °C; (c) P+Ce-added steel at 800 °C; (d) unadded steel at 850 °C; (e) P-added steel at 850 °C; (f) P+Ce-added steel at 850 °C; (g) unadded steel at 900 °C; (h) P-added steel at 900 °C; (i) P+Ce-added steel at 900 °C; (j) unadded steel at 1000 °C; (k) P-added steel at 1000 °C; and (l) P+Ce-added steel at 1000 °C.

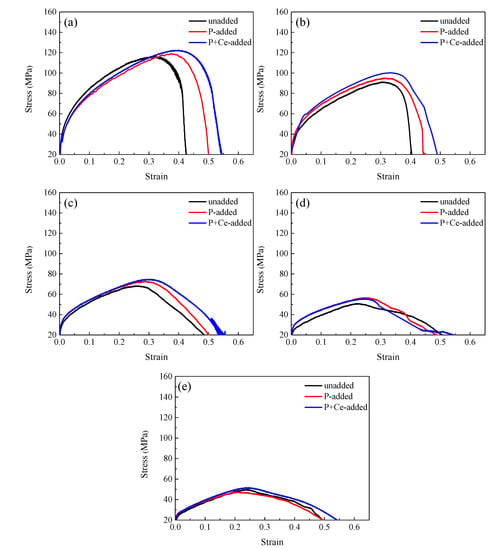

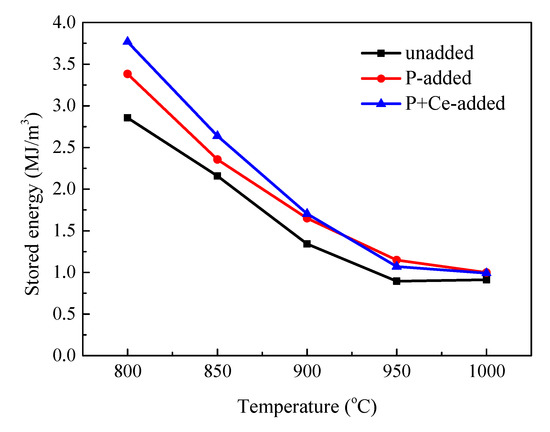

The stress–strain curves at different temperatures are shown in Figure 6. It is clear that the tensile strength is generally higher for the P-added and P+Ce-added samples than for the unadded ones, and the peak stress shifts to higher strains. As is well acknowledged [45,46], to initiate DR during hot deformation at a certain temperature, a critical stored energy is required. Since 90%–95% of the deformation energy is normally dissipated by heat generation and only 5%–10% is stored in the defects within the sample, it is assumed that the stored energy in the material during deformation is about 10% of the deformation energy, and the uniform deformation can reach the peak stress. The deformation energy may be estimated by the area under the stress–strain curve before the peak stress, and thus the stored energy can be obtained. The stored energies are represented in Figure 7 for the samples deformed at 800–1000 °C. Apparently, when deformed at 850 °C, the stored energy increases on going from the unadded to P-added to P+Ce-added samples. It can be conceived that at 850 °C, the stored energies in the unadded and P-added samples cannot attain their corresponding critical stored energies for the initiation of DR, while the critical stored energy can be reached in the P+Ce-added samples. As a consequence, the DR in the P+Ce-added samples took place to some extent during hot deformation at 850 °C, raising its RA to a high level of ~90% (Figure 1). Nevertheless, this did not happen in the unadded and P-added samples. When deformed at 900 °C or above, the stored energies for all the samples should have well surpassed their corresponding critical energies, and hence the evident DR should have occurred in the course of hot deformation, thereby significantly enhancing the HD performance as illustrated in Figure 1.

Figure 6.

Stress–strain curves for the unadded, P-added, and P+Ce-added steels at different temperatures: (a) 800 °C, (b) 850 °C, (c) 900 °C, (d) 950 °C, and (e) 1000 °C.

Figure 7.

The stored energies in different samples deformed at different temperatures.

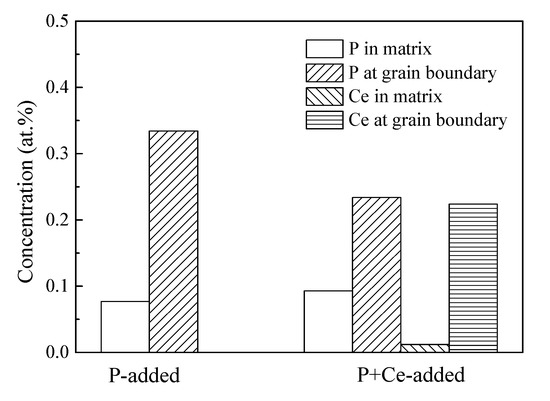

As clarified above, the trace addition of P and Ce can raise the HD of the steel in the case of no DR. This should be realized by restraining the GB sliding by their GBS. Since there is no occurrence of DR in the 800 °C-deformed samples and they have an apparent difference in RA, the boundary segregation of P and Ce in the P-added and P+Ce-added samples tested at this temperature was investigated using FE-STEM along with EDS, and the analyzed results are shown in Figure 8. As can be seen, the GB concentration of P is about 0.33 at.% for the P-added sample and 0.23 at.% for the P+Ce-added one, which are much higher than their respective matrix levels. The GB concentration of Ce is about 0.22 at.%, which is 18 times as high as its matrix level (approximately 0.012 at.%). Therefore, the GBS of P took place in the P-added and P+Ce-added samples, and that of Ce did in the P+Ce-added sample. As described in [11], the beneficial effect of P GBS on the HD of a steel might be explained as follows. The segregated P atoms could take up the boundary vacant sites like “cavities,” thereby lessening the GB sliding as the boundary cavities could be more effective in facilitating the boundary sliding than the segregation of P. As for the effect of Ce, many studies [26,27,28,29,37] have revealed that the GBS of Ce can raise the GB cohesion. Due to the augmentation of boundary cohesion, the GB sliding can be suppressed to a certain degree, thus enhancing the HD performance of the steel. Moreover, the suppression of the GB sliding may enable the uniform hot deformation to extend a higher strain with a higher flow stress. This may make the deformed material possess more stored energy, thereby lowering the initial temperature of DR as shown above. In addition, Ce can suppress the GBS of P to a certain extent, reducing the detrimental effect of P on the boundary cohesion. Therefore, the GBS of Ce can further raise the RA value of the steel, from ~70% for the P-added sample to ~90% for the P+Ce-added one, completely eliminating the HD trough. These results are in agreement with previous studies [23,29,37,47]. The GBS of rare earth Ce can considerably improve the HD of a 1Cr-0.5Mo low-alloy steel by enhancing the boundary cohesion and lowering the initial temperature of DR and suppressing the deleterious effect of impurity Sn [23,37]. The segregation of Ce can also enhance the HD of a Sn-doped C-Mn RPV steel by the same mechanisms [29]. The GBS of rare earth La is able to improve the HD of a low-carbon steel doped with As and Sn by reducing the GBS of harmful impurities As and Sn and lowering the starting temperature of DR [47]. The GBS of solute atoms in steel is divided into equilibrium segregation (ES) and nonequilibrium segregation (NES). The ES is produced during equilibration of the system. It is a function of temperature and decreases exponentially with rising temperature [48,49]. The NES of solute atoms counts on the formation of supersaturated vacancy–solute complexes since there is a binding energy between vacancy and solute atom [50], and the vacancies are supersaturated in the course of cooling from a high heating temperature [51,52,53]. During cooling, the complexes diffuse from the grain interior to the boundary, causing the solute boundary segregation. Furthermore, the NES may also be produced during hot plastic deformation as the deformation can create excess vacancies [54,55].

Figure 8.

Grain boundary concentrations of P and Ce in the P-added and P+Ce-added specimens tested at 800 °C, determined by FE-STEM microanalysis.

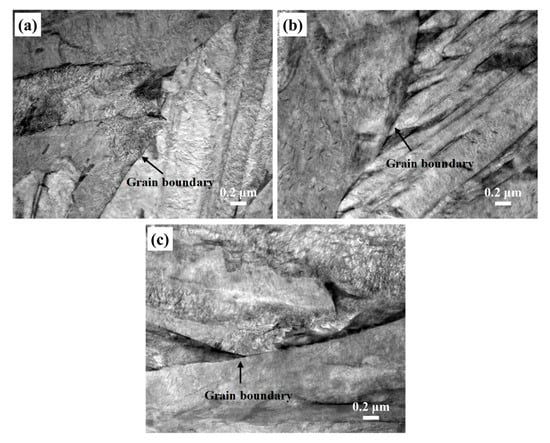

As described above [11,15,39], carbide precipitation along the GBs also plays an important role in the HD behavior. As seen from TEM micrographs in Figure 9, there is no apparent carbide precipitation formed along the GBs when deformed at 800 °C for all the three types of samples. This consists well with the results of Thermo-Calc calculations, which indicate that no apparent M23C6-type carbides are precipitated above 750 °C in the SA508-4N steel [11,42]. Accordingly, the HD performance in the austenite single-phase range should have nothing to do with the GB precipitation of carbides for this RPV steel.

Figure 9.

Transmission electron micrographs for the specimens tested at 800 °C: (a) unadded steel, (b) P-added steel, and (c) P+Ce-added.

5. Conclusions

The HD behaviors of three heats of SA508-4N RPV steel, unadded, P-added, and P+Ce-added, were investigated in detail over the range of 750–1000 °C. The testing temperatures are located in the austenite single-phase region. A deep HD trough exists for the unadded steel with the lowest RA value of ~50% at 850 °C, whereas there is no HD trough present for the P+Ce-added steel whose RA value is up to ~90% at this temperature, demonstrating that the trace addition of P and Ce can dramatically raise the HD of the steel, especially at temperatures between 800 and 900 °C. No doubt, the quality of continuous casting and hot working of the P+Ce-added steel can be improved considerably. The main mechanism for the above effect is suggested to be DR and GBS. The P+Ce addition in the steel may lower the initial temperature of DR from ~900 to ~850 °C. Meanwhile, the GBS of P and Ce may restrain the GB sliding by enhancing the GB cohesion. Consequently, the combined addition of minor P and Ce can significantly enhance the HD performance of SA508-4N RPV steel. No doubt, the highly enhanced HD performance of this steel can improve the quality and productivity of its continuous casting and hot working.

Author Contributions

Y.G.: investigation, analysis, and writing—original draft; Y.Z.: analysis and writing—review and editing; S.S.: conceptualization, supervision, and writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (Grant No. 51071060) and Natural Science Foundation of Anhui Province (Grant No. 2008085QE197).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Knott, J.F. Structural integrity of nuclear reactor pressure vessels. Philos. Mag. 2013, 93, 3835–3862. [Google Scholar] [CrossRef]

- Zinkle, S.J.; Was, G.S. Materials challenges in nuclear energy. Acta Mater. 2013, 61, 735–758. [Google Scholar] [CrossRef]

- Toribio, J.; Vergara, D.; Lorenzo, M. Role of in-service stress and strain fields on the hydrogen embrittlement of the pressure vessel constituent materials in a pressurized water reactor. Eng. Fail. Anal. 2017, 82, 458–465. [Google Scholar] [CrossRef]

- Kim, M.C.; Park, S.G.; Lee, K.H.; Lee, B.S. Comparison of fracture properties in SA508 Gr.3 and Gr.4N high strength low alloy steels for advanced pressure vessel materials. Int. J. Pres. Ves. Pip. 2015, 131, 60–66. [Google Scholar] [CrossRef]

- Lee, K.H.; Park, S.G.; Kim, M.C.; Lee, B.S.; Wee, D.M. Characterization of transition behavior in SA508 Gr.4N Ni-Cr-Mo low alloy steels with microstructural alteration by Ni and Cr contents. Mater. Sci. Eng. A 2011, 529, 156–163. [Google Scholar] [CrossRef]

- Lee, K.H.; Park, S.G.; Kim, M.C.; Lee, B.S. Cleavage fracture toughness of tempered martensitic Ni-Cr-Mo low alloy steel with different martensite fraction. Mater. Sci. Eng. A 2012, 534, 75–82. [Google Scholar] [CrossRef]

- Dai, X.; Yang, B. Hot deformation behavior and microstructural evolution of SA508-IV steel. Steel Res. Int. 2018, 89, 1800208. [Google Scholar] [CrossRef]

- Thomas, B.G.; Samarasekera, I.V.; Brimacombe, J.K. Mathematical model of the thermal processing of steel ingots: Part II. Stress model. Metall. Trans. B 1987, 18, 131–147. [Google Scholar] [CrossRef]

- Mintz, B.; Yue, S.; Jonas, J.J. Hot ductility of steels and its relationship to the problem of transverse cracking during continuous casting. Metall. Rev. 1991, 36, 187–217. [Google Scholar] [CrossRef]

- Abushosha, R.; Vipond, R.; Mintz, B. Influence of sulphur and niobium on hot ductility of as cast steels. Mater. Sci. Technol. 1991, 7, 1101–1107. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, K.; Song, S.H. Abnormal influence of impurity element phosphorus on the hot ductility of SA508Gr.4N reactor pressure vessel steel. Mater. Sci. Eng. A 2020, 79, 139837. [Google Scholar] [CrossRef]

- Mintz, B.; Cowley, A.; Talian, C.; Crowther, D.N.; Abushosha, R. Influence of P on hot ductility of high C, Al, and Nb containing steels. Mater. Sci. Technol. 2003, 19, 184–188. [Google Scholar] [CrossRef]

- Jiang, X.; Chen, X.M.; Song, S.H.; Shangguan, Y.J. Phosphorus-induced hot ductility enhancement of 1Cr–0.5Mo low alloy steel. Mater. Sci. Eng. A 2013, 574, 46–53. [Google Scholar] [CrossRef]

- Mintz, B.; Arrowsmith, J.M. Hot-ductility behaviour of C-Mn-Nb-Al steels and its relationship to crack propagation during the straightening of continuously cast strand. Met. Technol. 1979, 6, 24–32. [Google Scholar] [CrossRef]

- Maehara, Y.; Ohmori, Y. The precipitation of AlN and NbC and the hot ductility of low carbon steels. Mat. Sci. Eng. 1984, 62, 109–119. [Google Scholar] [CrossRef]

- Kang, S.E.; Banerjee, J.R.; Tuling, A.; Mintz, B. Influence of P and N on hot ductility of high Al, boron containing TWIP steels. Mater. Sci. Technol. 2014, 30, 1328–1335. [Google Scholar] [CrossRef]

- Zheng, L.; Song, S.H. Effect of thermal cycling induced phosphorus grain boundary segregation on embrittlement of welding heat affected zones in 2.25Cr-1Mo steel. Mater. Sci. Technol. 2014, 30, 1378–1385. [Google Scholar]

- Chen, X.M.; Song, S.H.; Weng, L.Q.; Liu, S.J.; Wang, K. Relation of ductile-to-brittle transition temperature to phosphorus grain boundary segregation for a Ti-stabilized interstitial free steel. Mater. Sci. Eng. A 2011, 528, 8299–9304. [Google Scholar] [CrossRef]

- Misra, R.D.K. Temperature-time dependence of grain boundary segregation of phosphorus in interstitial-free steels. J. Mater. Sci. Lett. 2002, 21, 1275–1279. [Google Scholar] [CrossRef]

- Yu, Y.C.; Chen, W.Q.; Zheng, H.G. Effects of Ti-Ce refiners on solidification structure and hot ductility of Fe-36Ni invar alloy. J. Rare Earth. 2013, 31, 927–932. [Google Scholar] [CrossRef]

- Liu, H.L.; Liu, C.J.; Jiang, M.F. Effect of rare earths on impact toughness of a low-carbon steel. Mater. Design 2012, 33, 306–312. [Google Scholar] [CrossRef]

- Song, S.H.; Sun, H.J.; Wang, M. Effect of rare earth cerium on brittleness of simulated welding heat-affected zones in a reactor pressure vessel steel. J. Rare Earth. 2015, 33, 1204–1211. [Google Scholar] [CrossRef]

- Jiang, X.; Song, S.H. Enhanced hot ductility of a Cr–Mo low alloy steel by rare earth cerium. Mater. Sci. Eng. A 2014, 613, 171–177. [Google Scholar] [CrossRef]

- Ma, X.C.; An, Z.J.; Chen, L.; Mao, T.Q.; Wang, J.F.; Long, H.J.; Xue, H.Y. The effect of rare earth alloying on the hot workability of duplex stainless steel-A study using processing map. Mater. Des. 2015, 86, 848–854. [Google Scholar] [CrossRef]

- Guo, Y.; Sun, S.F.; Song, S.H. Effect of minor rare earth cerium addition on the hot ductility of a reactor pressure vessel steel. Results Phys. 2019, 15, 102746. [Google Scholar] [CrossRef]

- Xin, W.B.; Zhang, J.; Luo, G.P.; Wang, R.; Meng, Q.Y.; Song, B. Improvement of hot ductility of C-Mn Steel containing arsenic by rare earth Ce. Metall. Res. Technol. 2018, 115, 419. [Google Scholar] [CrossRef]

- Wang, H.Y.; Gao, X.Y.; Ren, H.P.; Zhang, H.W.; Tan, H.J. First-principles characterization of lanthanum occupying tendency in α-Fe and effect on grain boundaries. Acta Phys. Sin-Ch. Ed. 2014, 63, 148101. [Google Scholar]

- Liu, G.L.; Zhang, G.Y.; Li, R.D. Electronic Theoretical Study of the Interaction between Rare Earth Elements and Impurities at Grain Boundaries in Steel. J. Rare Earth. 2003, 21, 372–374. [Google Scholar]

- Song, S.H.; Sun, S.F. Effect of Rare-Earth Cerium on Impurity Tin-Induced Hot Ductility Deterioration of SA508-III Reactor Pressure Vessel Steel. Steel Res. Int. 2016, 87, 1435–1443. [Google Scholar] [CrossRef]

- Hannerz, N.E. Critical hot plasticity and transverse cracking in continuous slab casting with particular reference to composition. ISIJ. Int. 1985, 25, 149–158. [Google Scholar] [CrossRef]

- Mintz, B.; Abushosha, R. Effectiveness of hot tensile test in simulating straightening in continuous-casting. Mater. Sci. Technol. 1992, 8, 171–177. [Google Scholar] [CrossRef]

- Song, S.H.; Weng, L.Q. An FEGSTEM study of grain boundary segregation of phosphorus during q-uenching in a 2.25Cr-1Mo steel. J. Mater. Sci. Technol. 2005, 21, 445–450. [Google Scholar]

- Chen, X.M.; Song, S.H.; Weng, L.Q.; Liu, S.J. Solute grain boundary segregation during high temperature plastic deformation in a Cr-Mo low alloy steel. Mater. Sci. Eng. A 2011, 528, 7663–7668. [Google Scholar] [CrossRef]

- Mintz, B.; Abushosha, R.; Shaker, M. Influence of deformation induced ferrite, grain boundary sliding, and dynamic recrystallisation on hot ductility of 0.1–0.75% C steels. Mater. Sci. Technol. 1993, 9, 907–914. [Google Scholar] [CrossRef]

- Mintz, B.; Cowley, A. Deformation induced ferrite and its influence on the elevated temperature tensile flow stress-elongation curves of plain C-Mn and Nb containing steels. Mater. Sci. Technol. 2006, 22, 279–292. [Google Scholar] [CrossRef]

- Mintz, B. The influence of composition on the hot ductility of steels and to the problem of transverse cracking. ISIJ. Int. 1999, 39, 833–855. [Google Scholar] [CrossRef]

- Song, S.H.; Xu, Y.W.; Chen, X.M.; Jiang, X. Effect of rare earth cerium and impurity tin on the hot ductility of a Cr-Mo low alloy steel. J. Rare Earth. 2016, 34, 1062–1068. [Google Scholar] [CrossRef]

- Wang, K.; Yang, C.; Si, H. Effect of non-equilibrium grain-boundary segregation of phosphorus on the intermediate-temperature ductility minimum of an Fe-17Cr alloy. Mater. Sci. Eng. A 2013, 587, 228–232. [Google Scholar] [CrossRef]

- Ouchi, C.; Matsumoto, K. Hot ductility in Nb-bearing high-strength low-alloy steels. ISIJ. Int. 2006, 22, 181–189. [Google Scholar] [CrossRef]

- Lv, B.; Zhang, F.C.; Li, M.; Hou, R.J.; Qian, L.H.; Wang, T.S. Effects of phosphorus and sulfur on the thermoplasticity of high manganese austenitic steel. Mater. Sci. Eng. A 2010, 527, 5648–5653. [Google Scholar] [CrossRef]

- Song, S.H.; Jiang, X.; Chen, X.M. Tin-induced hot ductility degradation and its suppression by phosphorus for a Cr-Mo low-alloy steel. Mater. Sci. Eng. A 2014, 595, 188–195. [Google Scholar] [CrossRef]

- Li, C.Y.; Liu, Z.D.; Lin, Z.J. Thermodynamic calculation and analysis on equilibrium phase in low alloy steel for reactor pressure vessel. Heat. Treat. Met. 2013, 38, 14–17. [Google Scholar]

- Liu, N.; Liu, Z.D.; He, X.K.; Yang, Z.Q. Austenite transformation of SA508Gr.4N steel for nuclear reactor pressure vessels during heating process. Heat. Treat. Met. 2017, 3, 88–92. [Google Scholar]

- Mintz, B.; Cowley, A.; Abushosha, R.; Crowther, D.N. Hot ductility curve of an austenitic stainless steel and importance of dynamic recrystallisation in determining ductility recovery at high temperatures. Mater. Sci. Technol. 1999, 15, 1179–1185. [Google Scholar] [CrossRef]

- Manda, D.; Baker, I. Determination of the stored energy and recrystallization temperature as a function of depth after rolling of polycrystalline copper. Scripta Mater. 1995, 33, 645–650. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, J.T.; Cheng, C.; Liu, J.Q. Stored energy and recrystallization temperature in high purity copper after equal channel angular pressing. J. Mater. Sci. 2008, 43, 7326–7330. [Google Scholar] [CrossRef]

- Huang, C.G.; Song, B.; Xin, W.B.; Jia, S.J.; Yang, Y.H. Influence of rare earth La on hot ductility of low carbon steel containing As and Sn. Heat Treat. Met. 2015, 40, 1–6. [Google Scholar]

- McLean, D. Grain Boundaries in Metals; Oxford University Press: London, UK, 1957; pp. 116–148. [Google Scholar]

- Lejcek, P. Grain Boundary Segregation in Metals; Springer: Berlin, Germany, 2010; pp. 50–102. [Google Scholar]

- Faulkner, R.G.; Song, S.H.; Flewitt, P.E.J. Determination of impurity-point defect binding energies in alloys. Mater. Sci. Technol. 1996, 12, 904–910. [Google Scholar] [CrossRef]

- Faulkner, R.G. Nonequilibrium grain boundary segregation in austenitic alloys. J. Mater. Sci. 1981, 16, 373–383. [Google Scholar] [CrossRef]

- Song, S.H.; Faulkner, R.G.; Flewitt, P.E.J. Effect of boron on phosphorus-induced temper embrittlement. J. Mater. Sci. 1999, 34, 5549–5556. [Google Scholar] [CrossRef]

- Xu, T.D.; Cheng, B.Y. Kinetics of non-equilibrium grain-boundary segregation. Prog. Mater. Sci. 2004, 49, 109–208. [Google Scholar] [CrossRef]

- Song, S.H.; Zhang, Q.; Weng, L.Q. Deformation-induced non-equilibrium grain boundary segregation in dilute alloys. Mater. Sci. Eng. A 2008, 473, 226–232. [Google Scholar] [CrossRef]

- Chen, X.M.; Song, S.H.; Weng, L.Q.; Wang, K. A study of deformation-induced phosphorus grain boundary segregation in an interstitial free steel. Mater. Sci. Eng. A 2012, 545, 86–90. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).