A Combined Pyro- and Hydrometallurgical Approach to Recycle Pyrolyzed Lithium-Ion Battery Black Mass Part 2: Lithium Recovery from Li Enriched Slag—Thermodynamic Study, Kinetic Study, and Dry Digestion

Abstract

1. Introduction

2. Materials and Methods

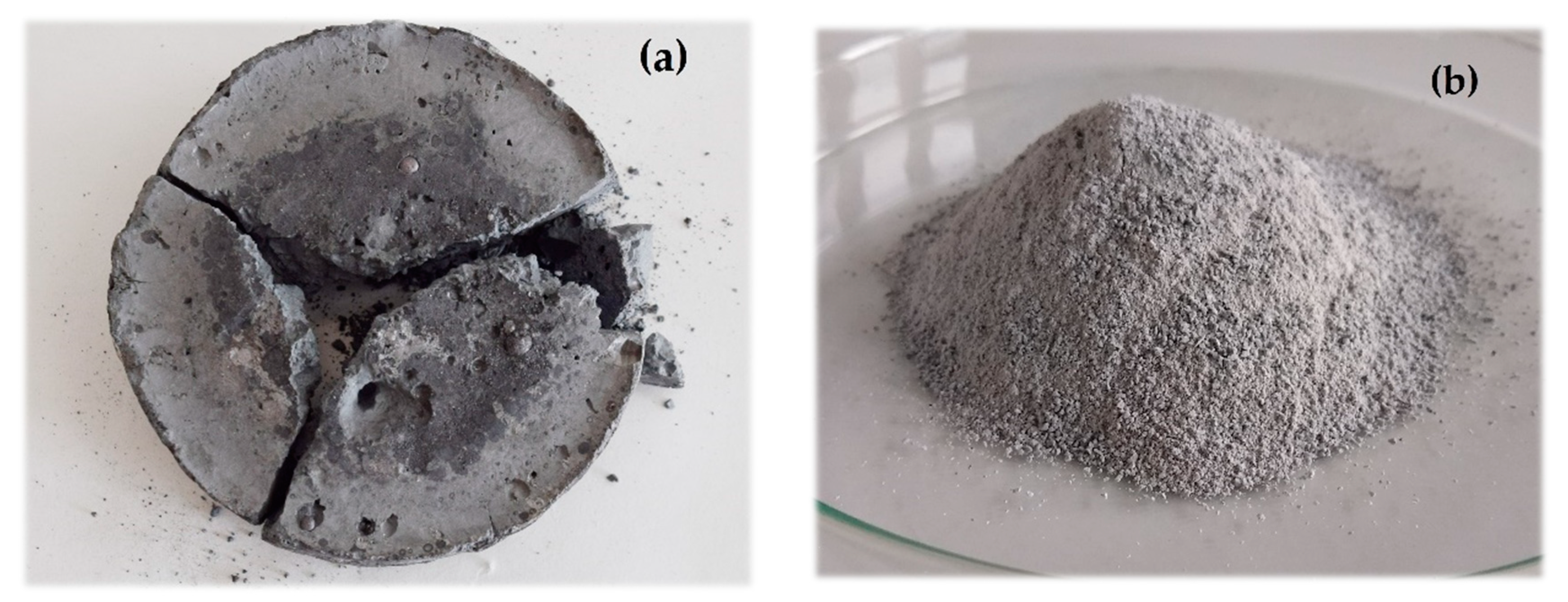

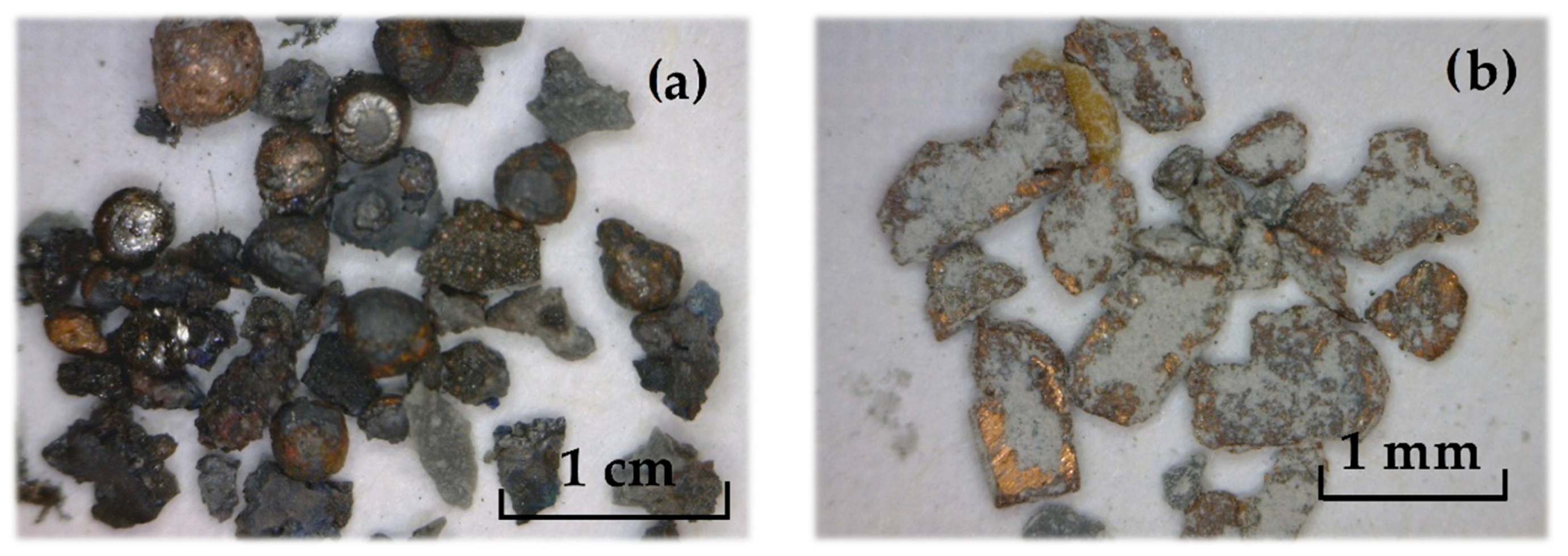

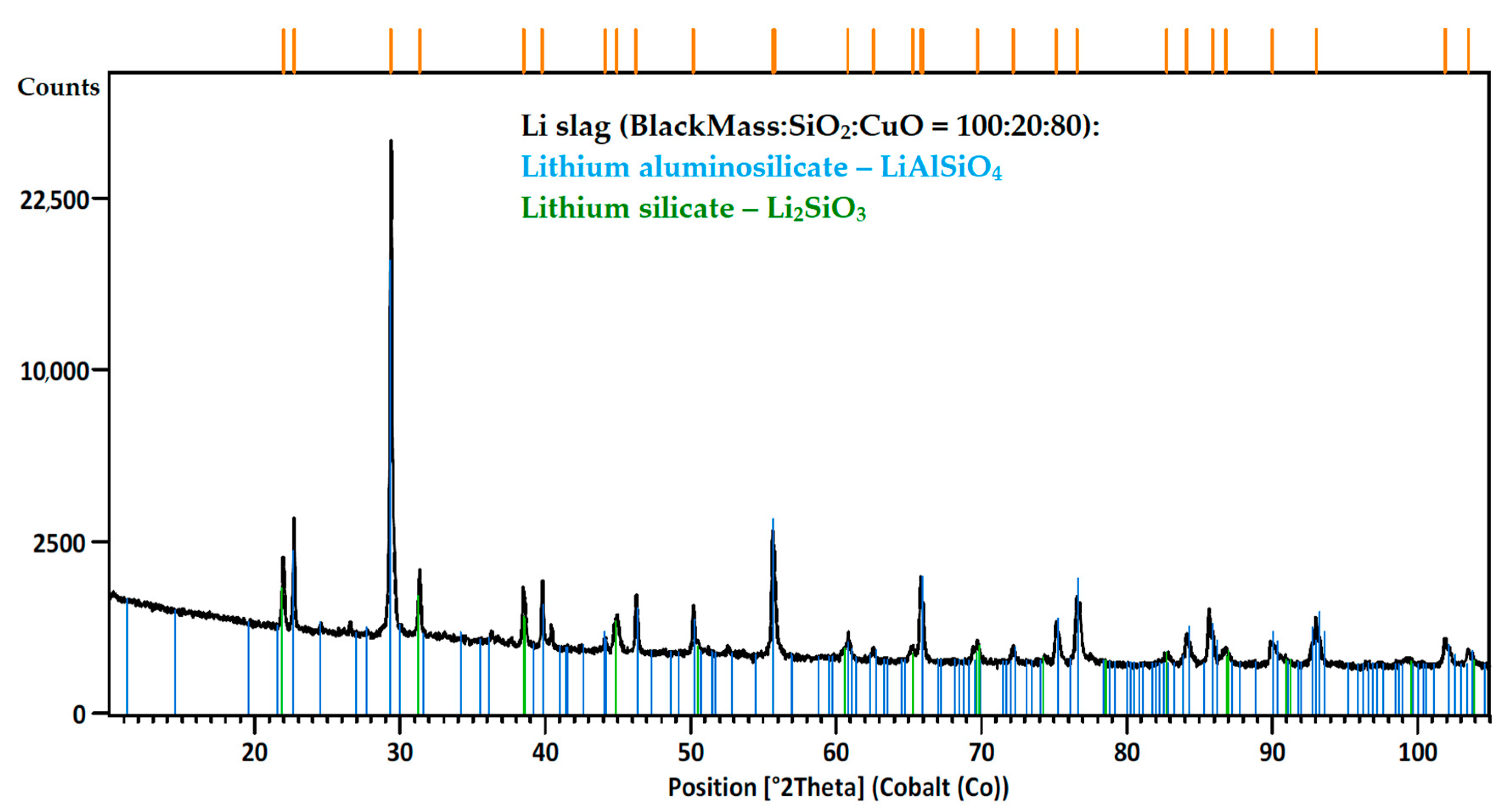

2.1. Sample Preparation and Characterization

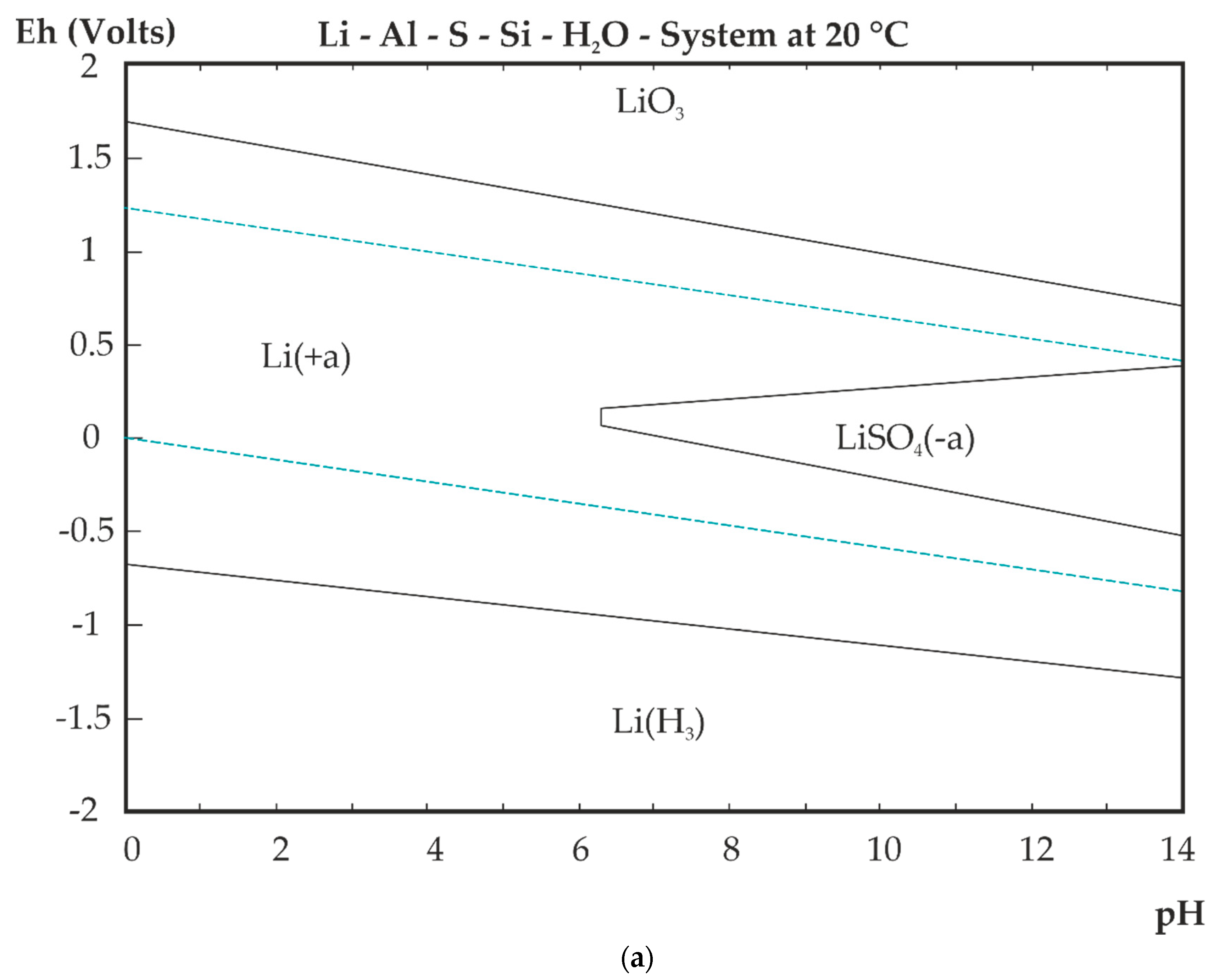

2.2. Thermodynamic Study of Lithium Slag Leaching

2.3. Methodology of Direct Li-Slag Leaching

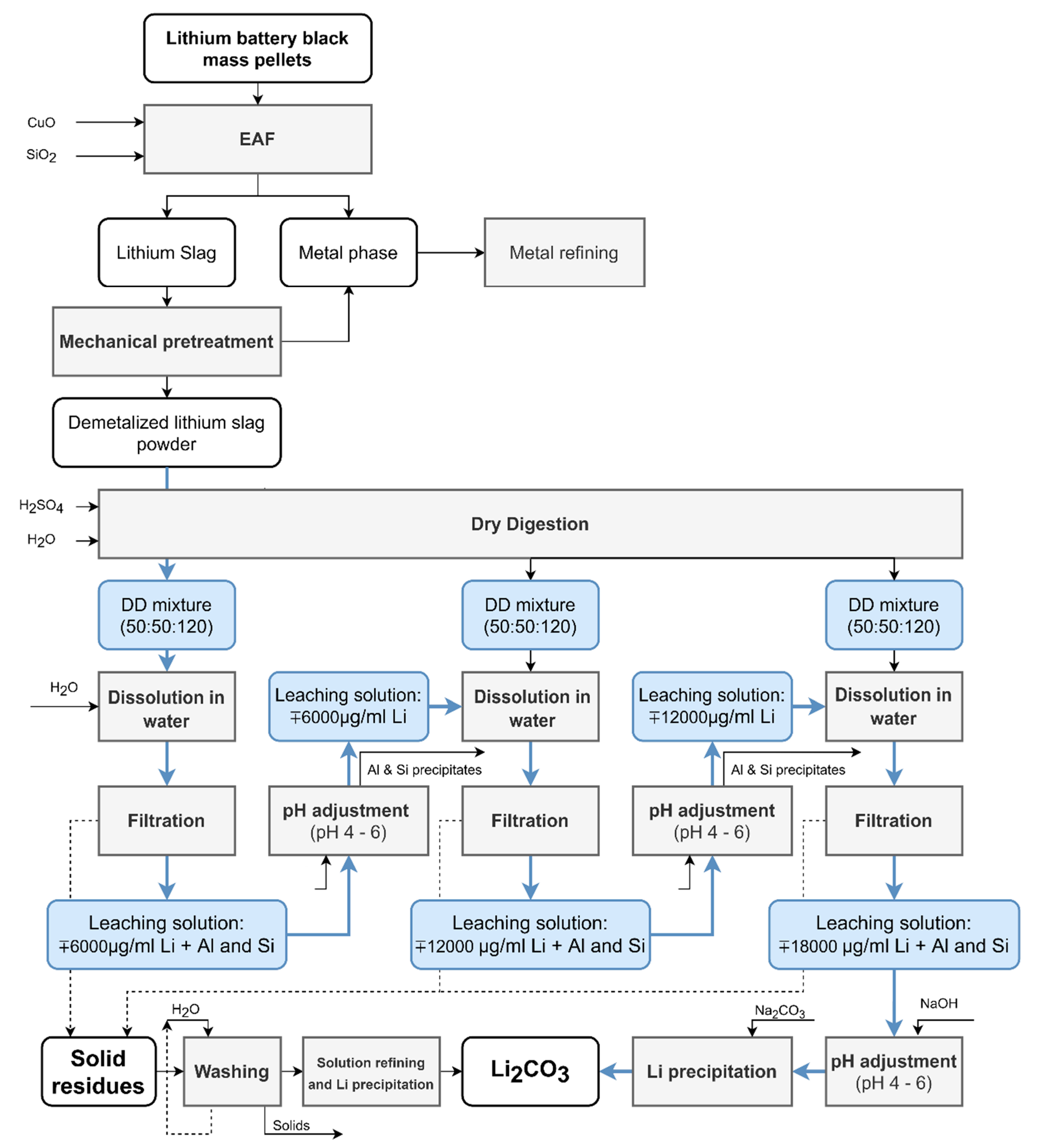

2.4. Methodology of Dry Digestion Followed by Dissolution in Water

3. Results and Discussion

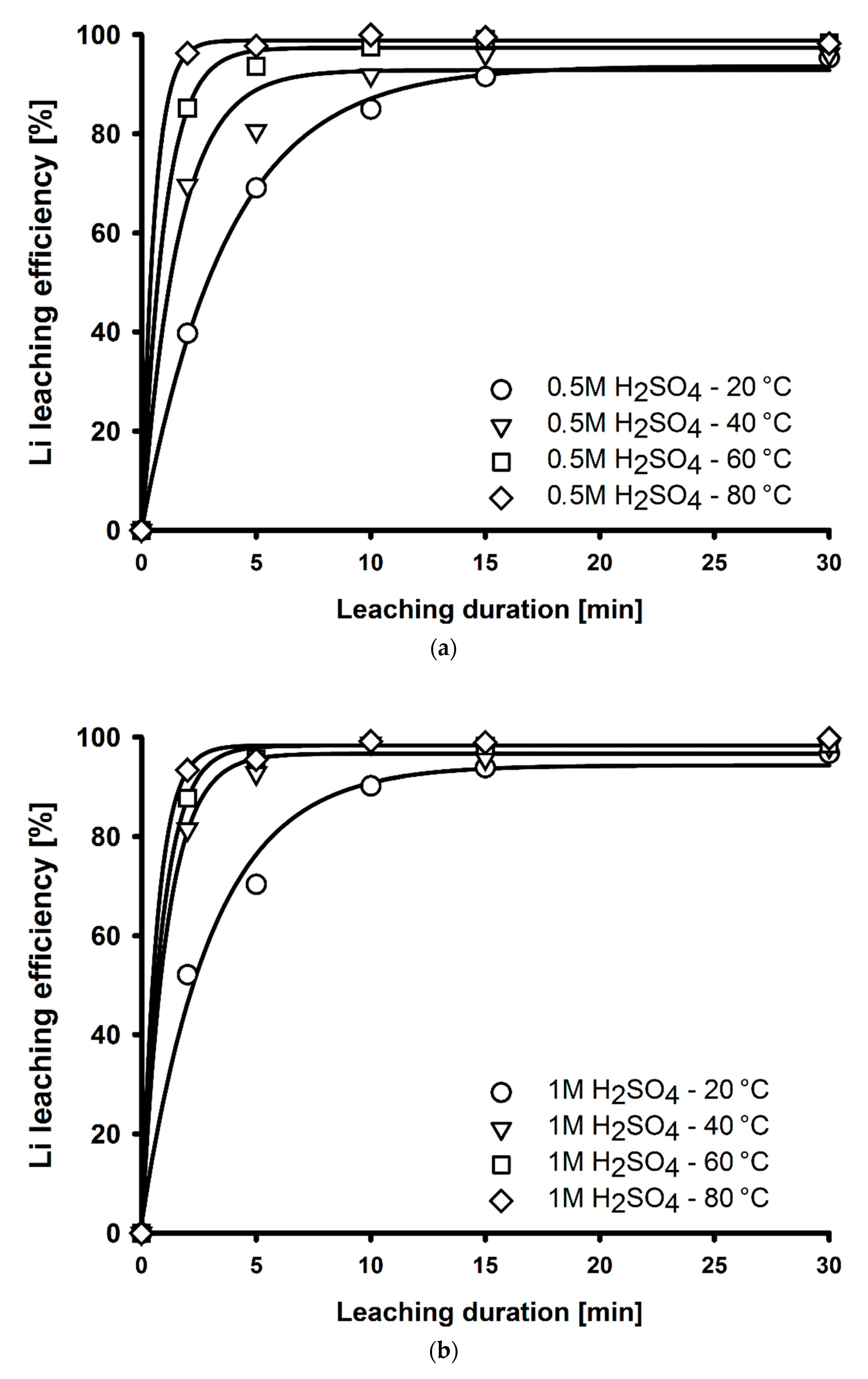

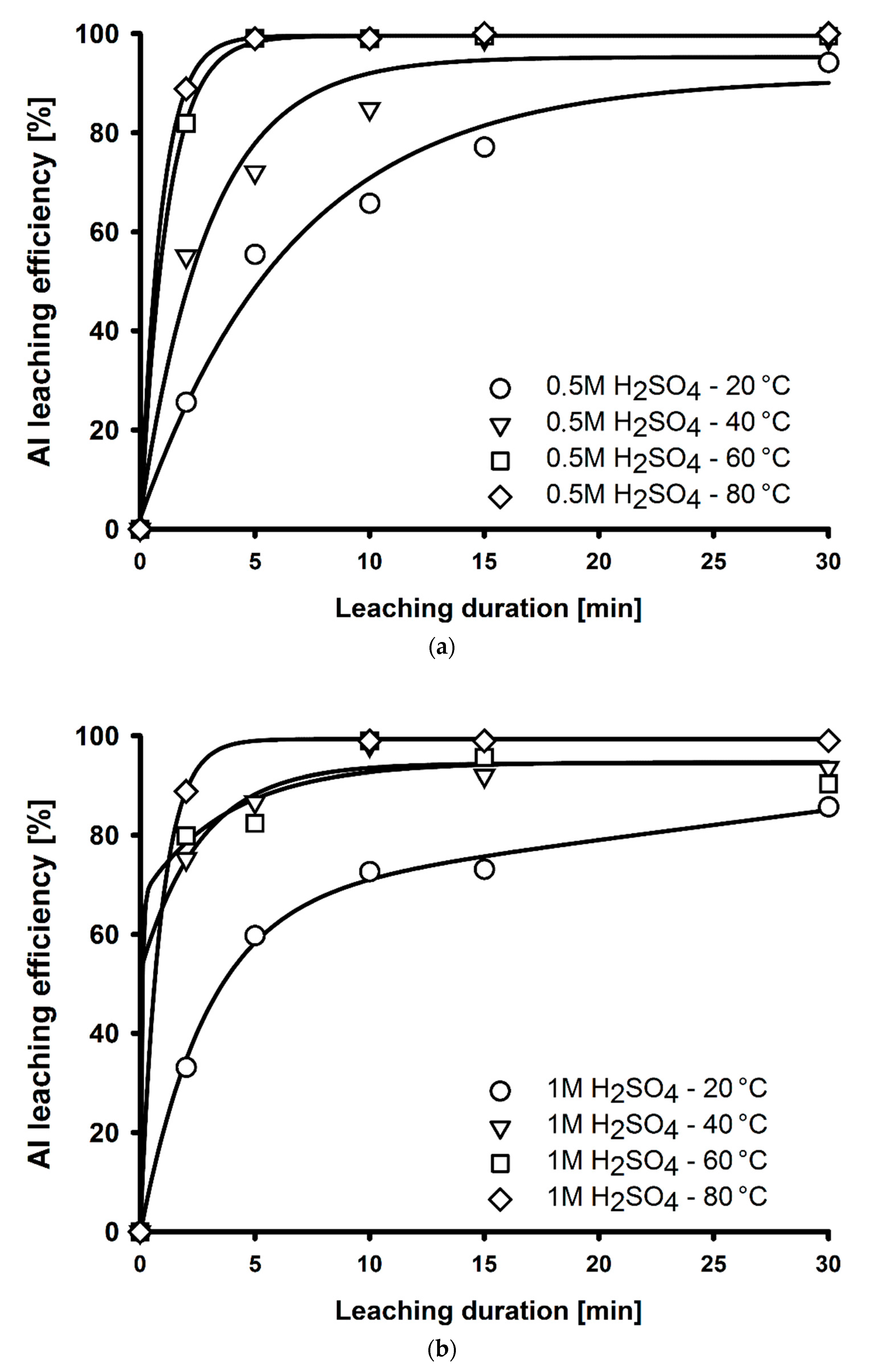

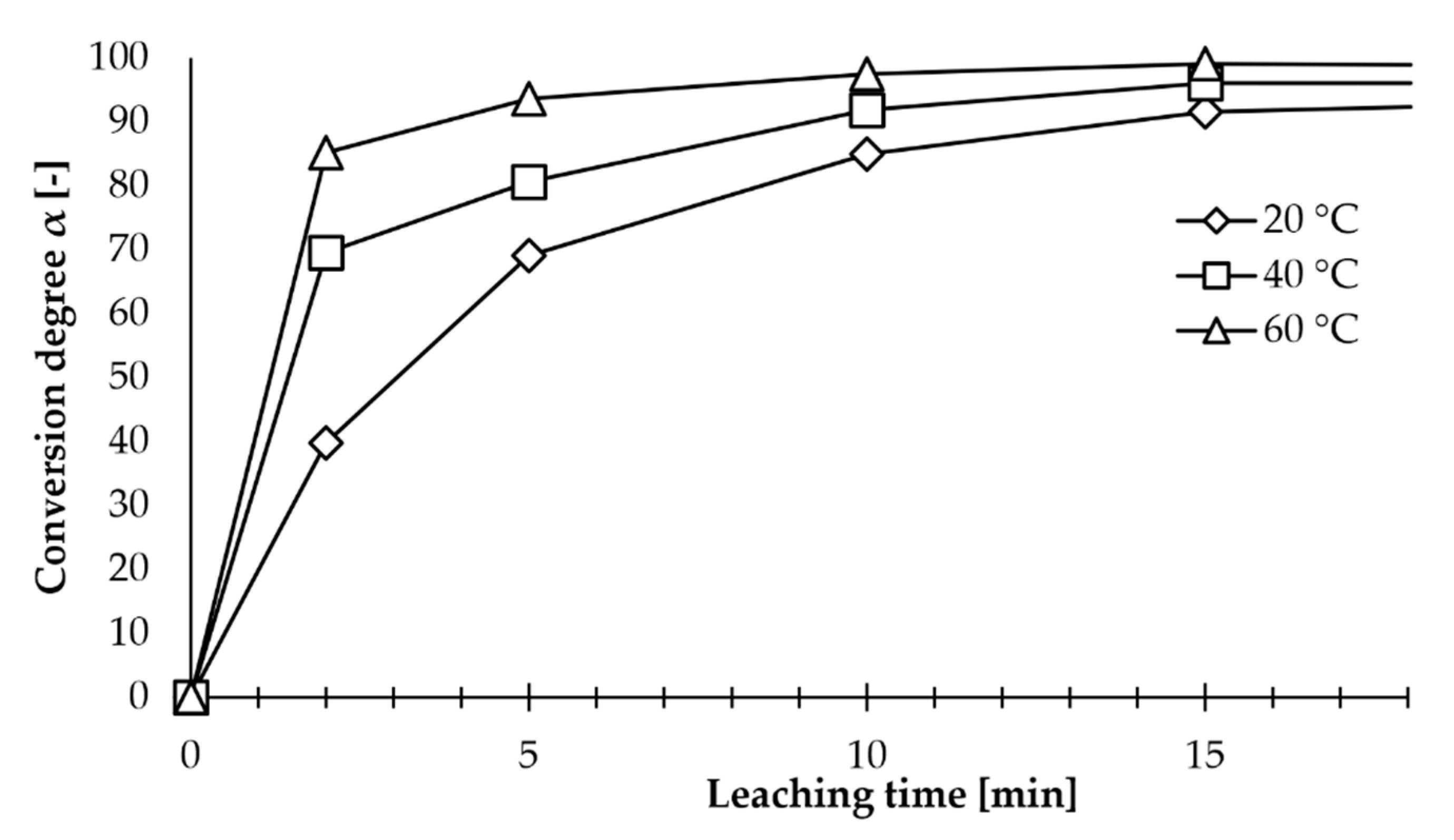

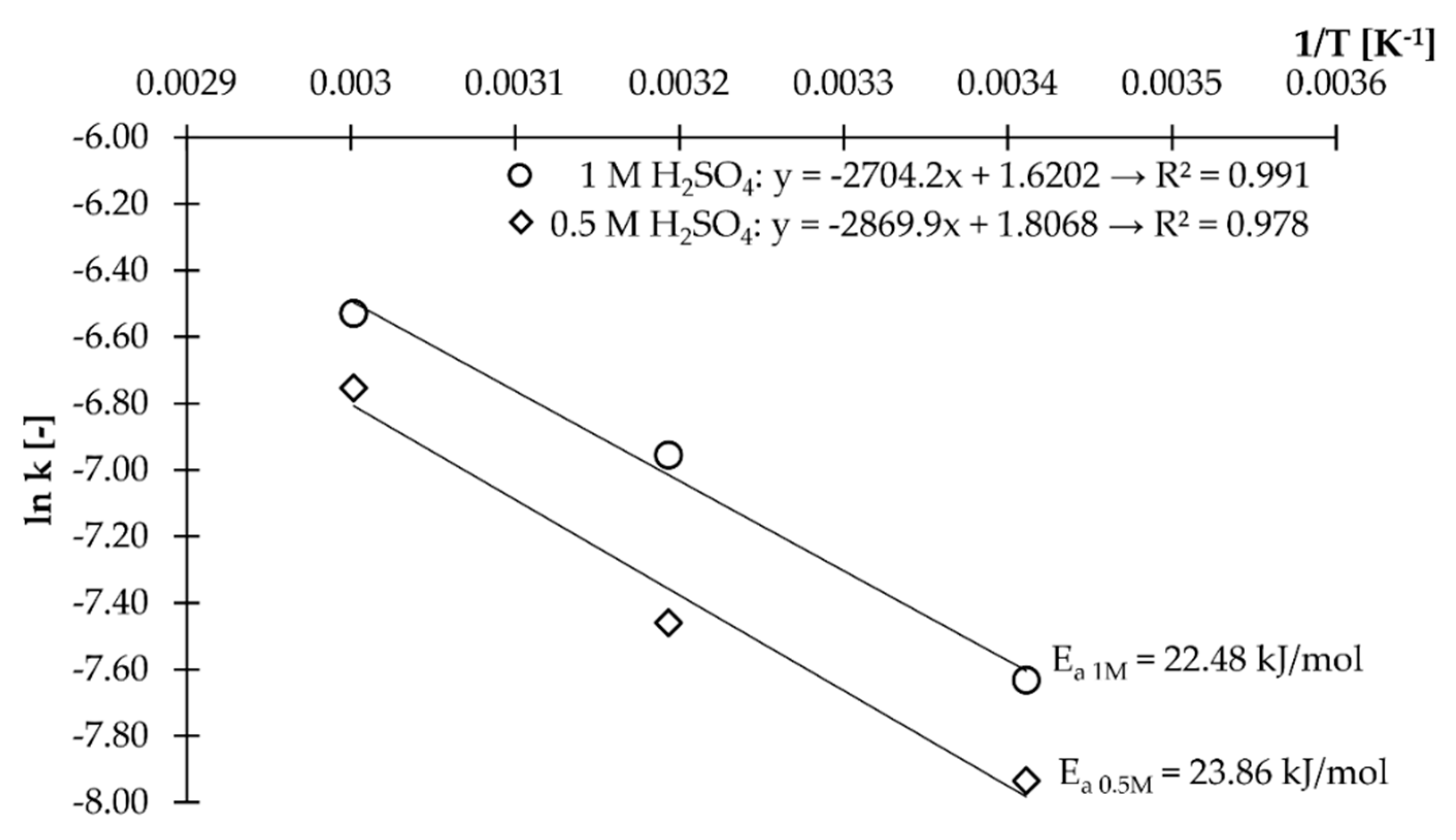

3.1. Direct Li Slag Leaching and Kinetic Study

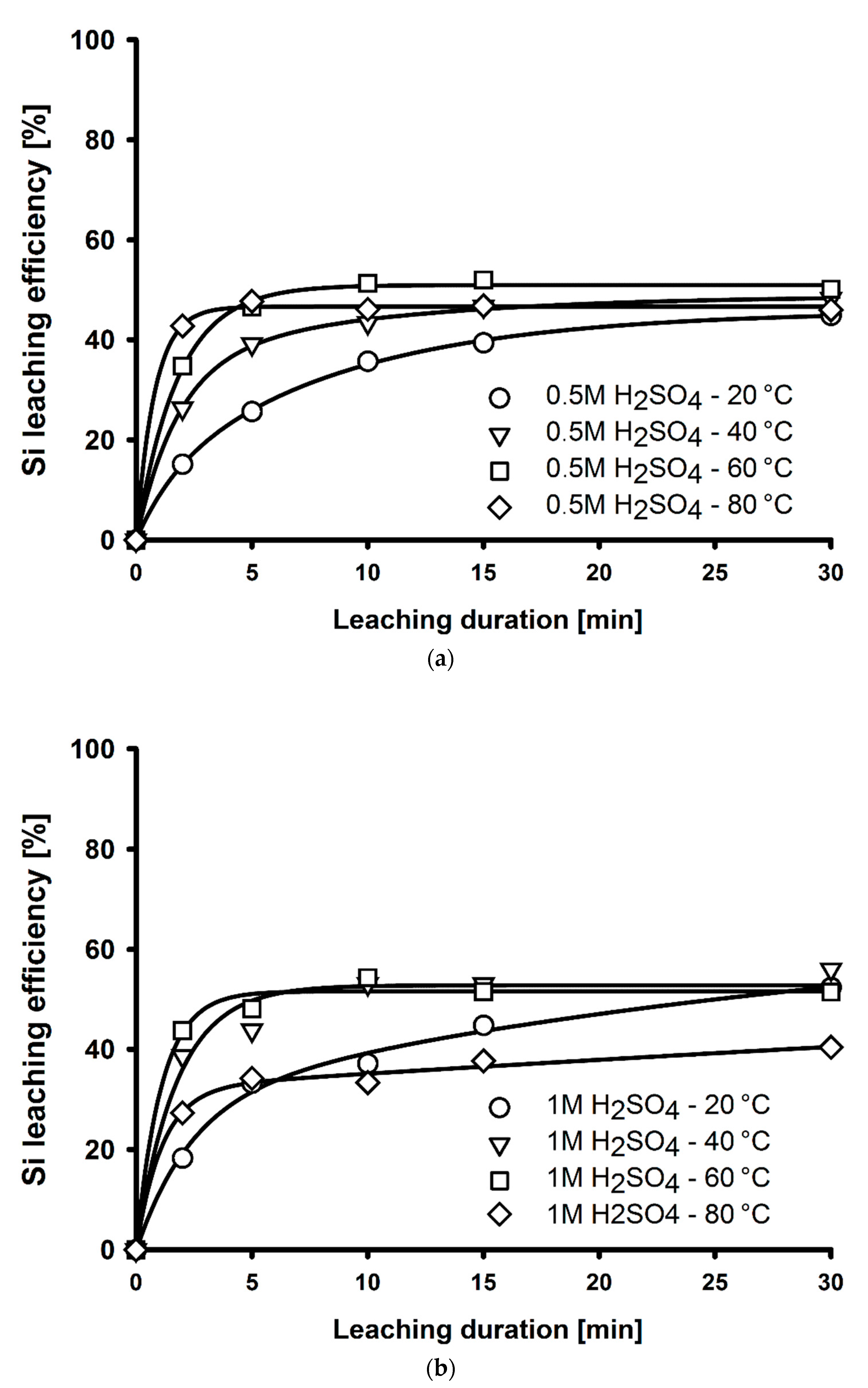

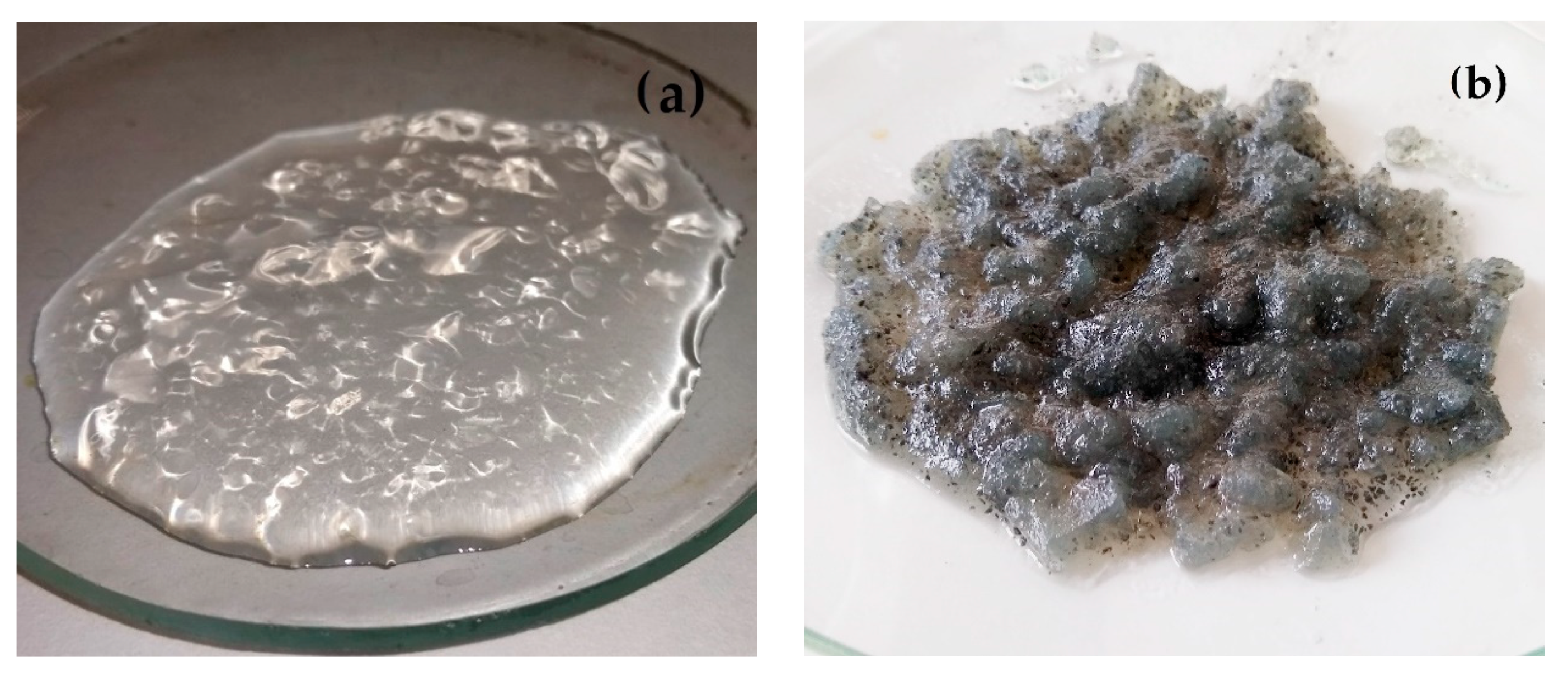

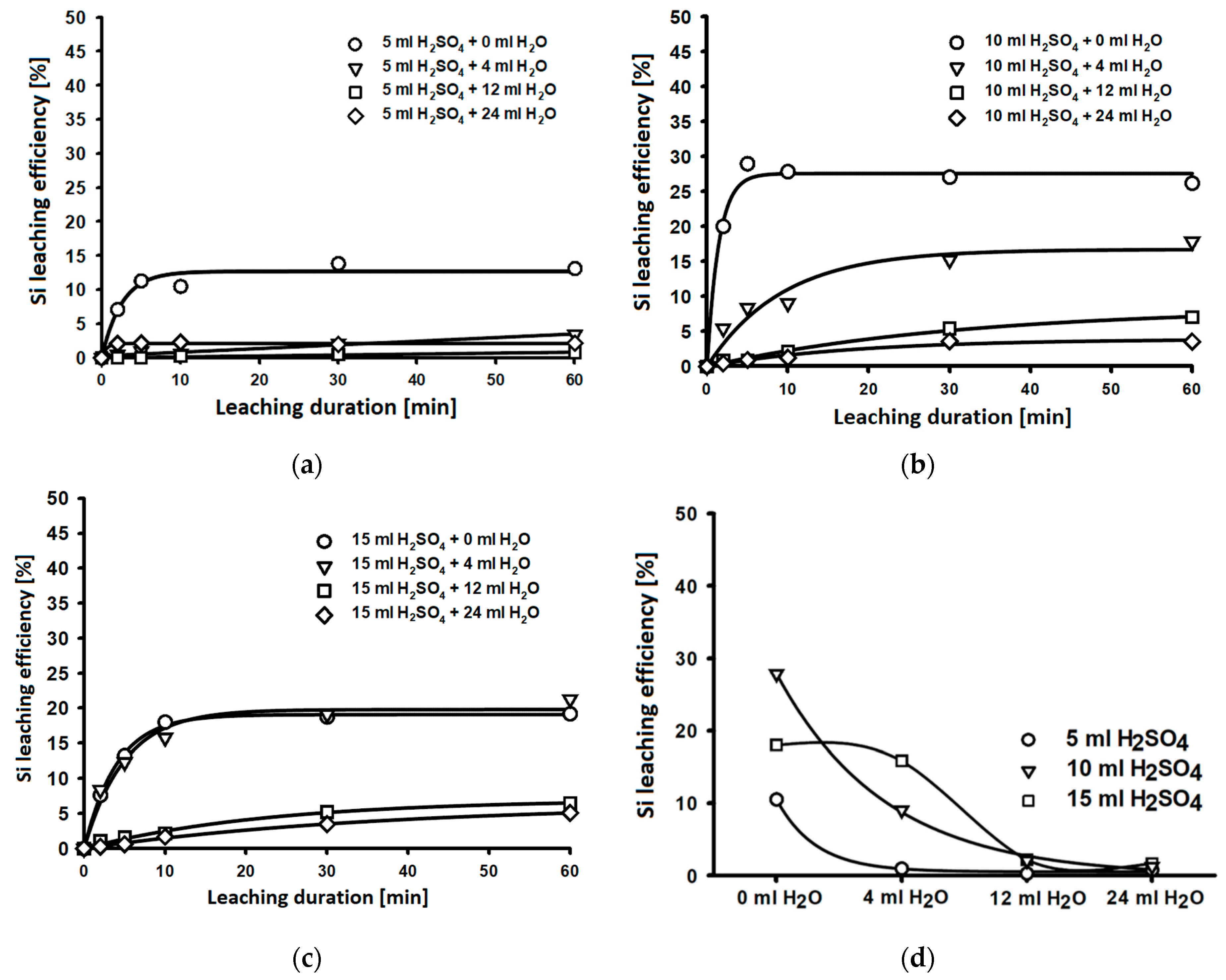

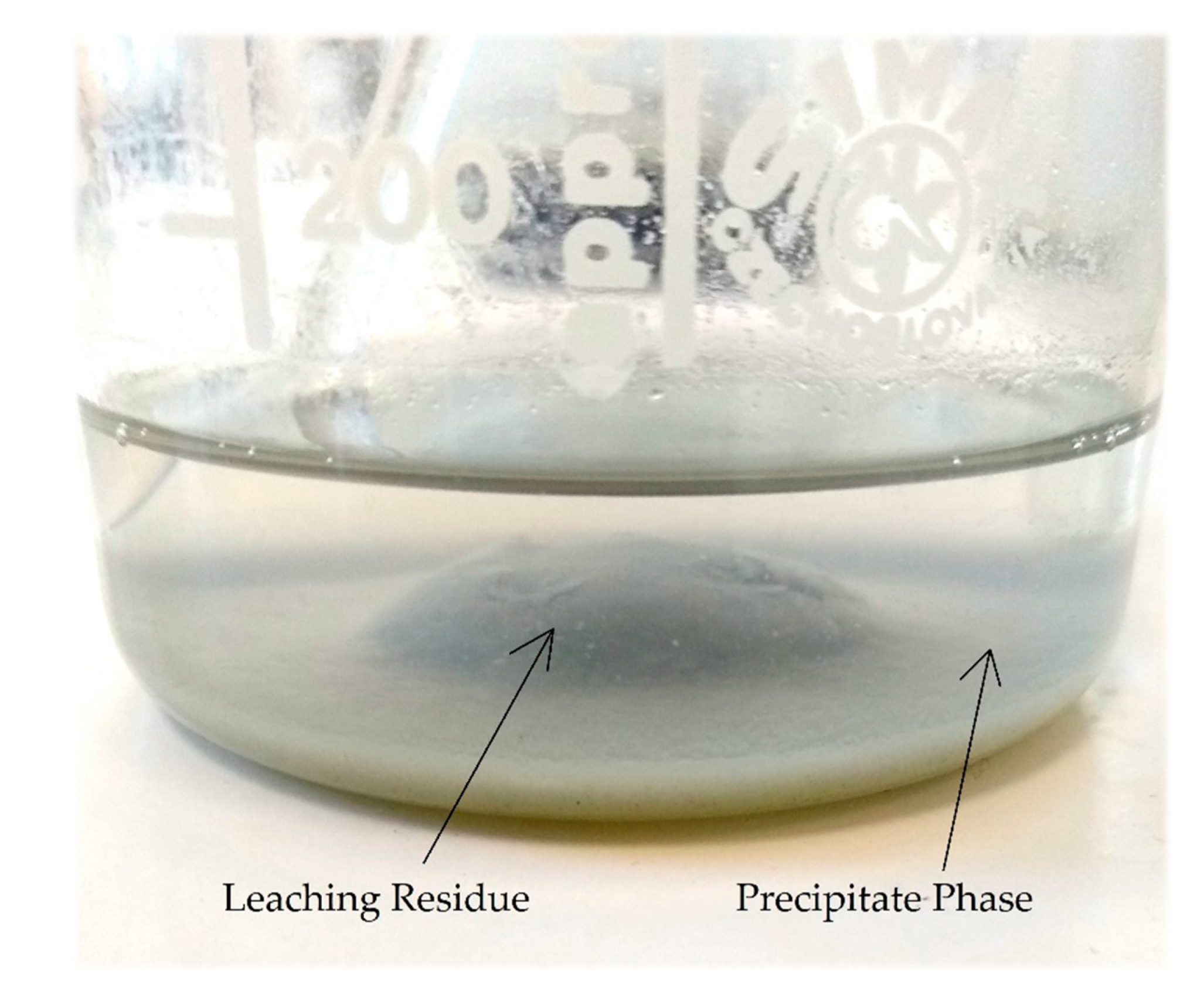

3.2. Investigation of the Silica Gel Formation

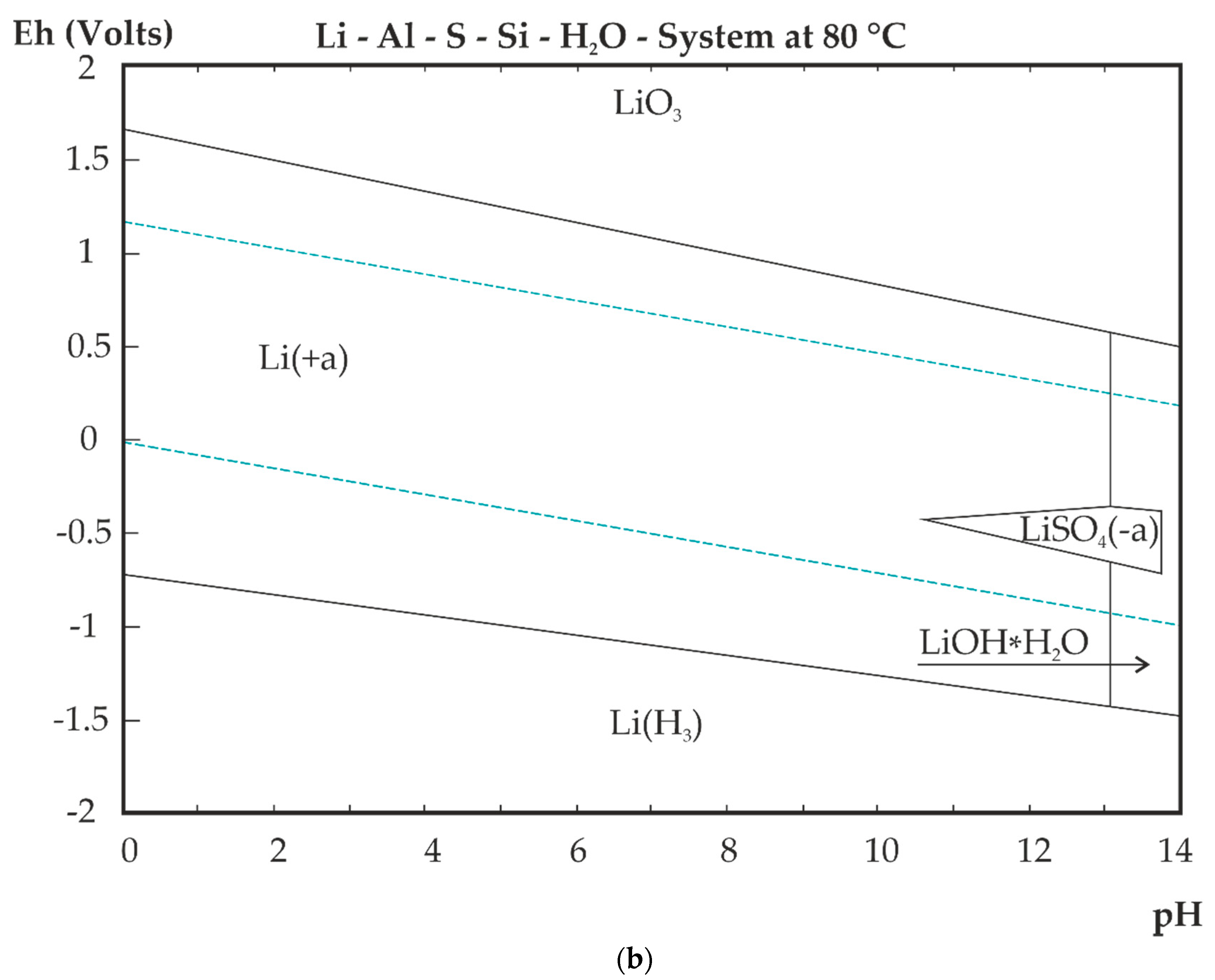

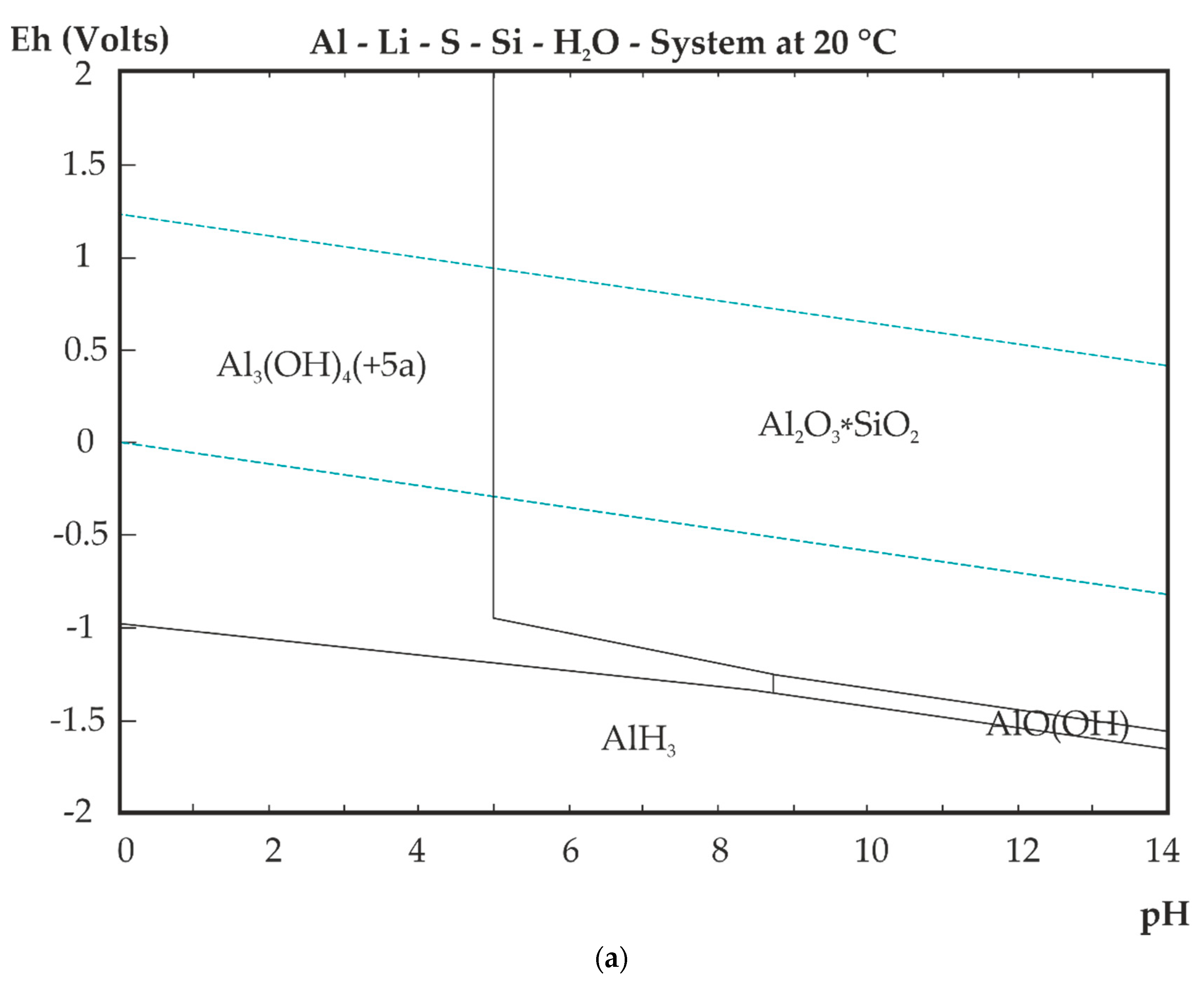

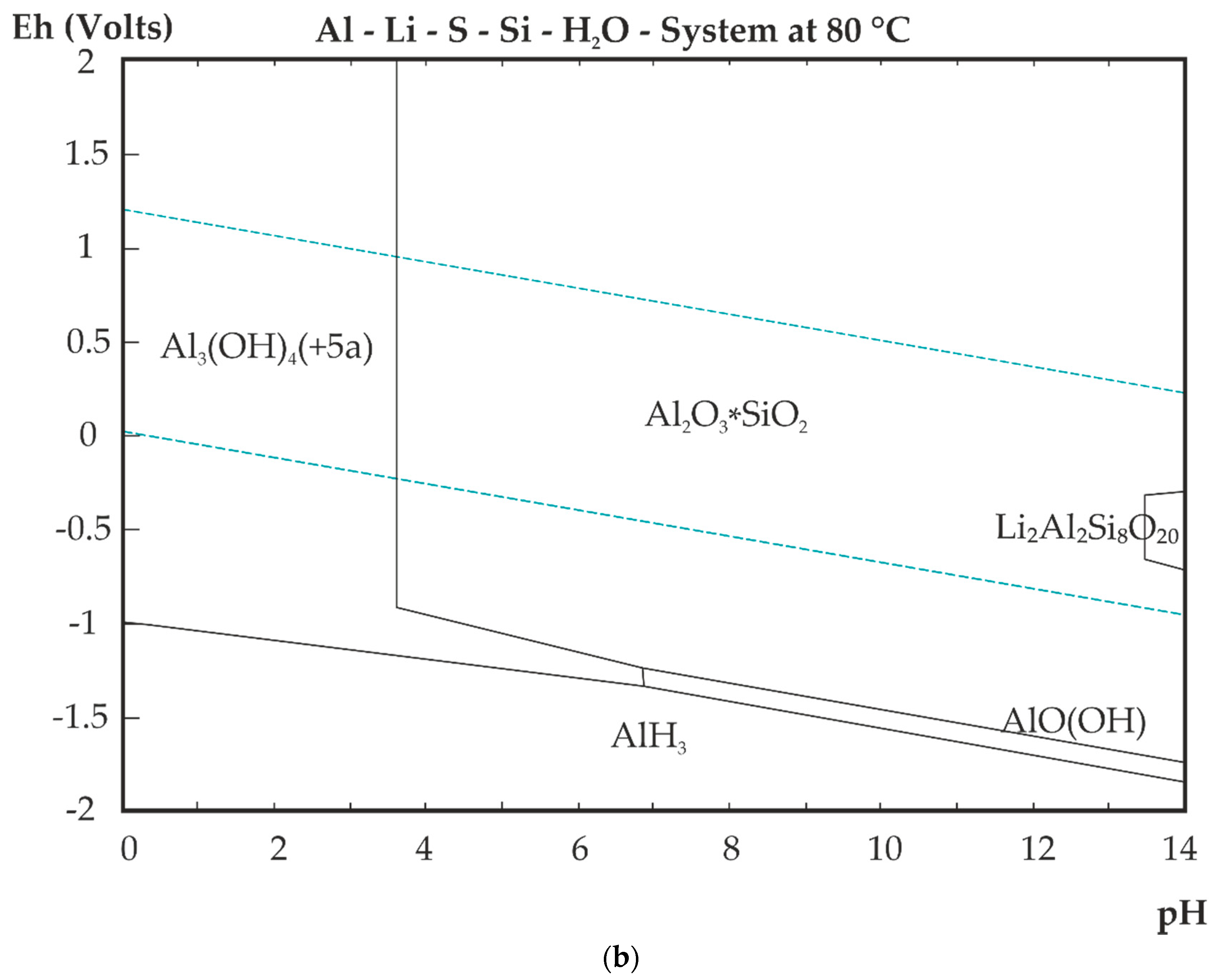

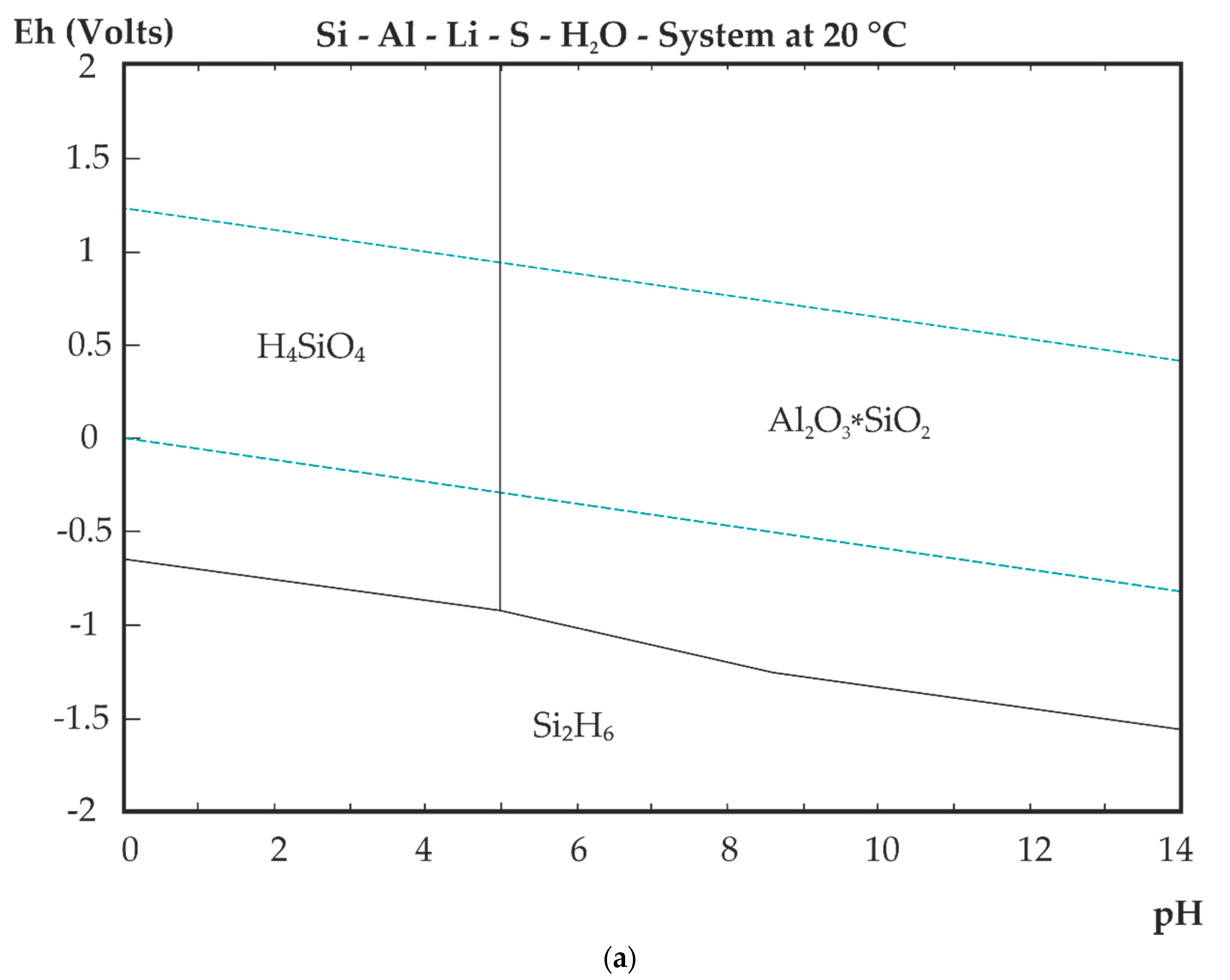

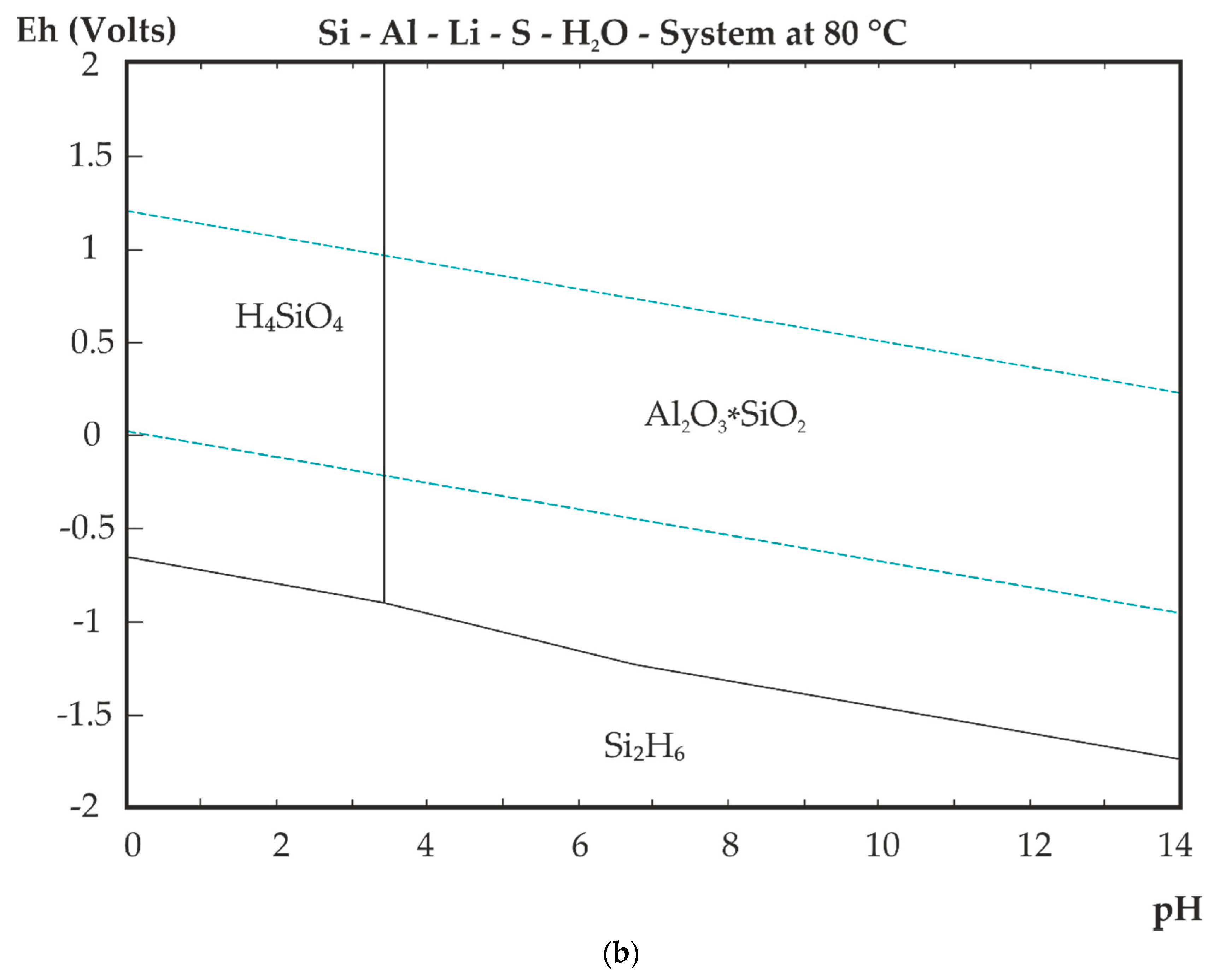

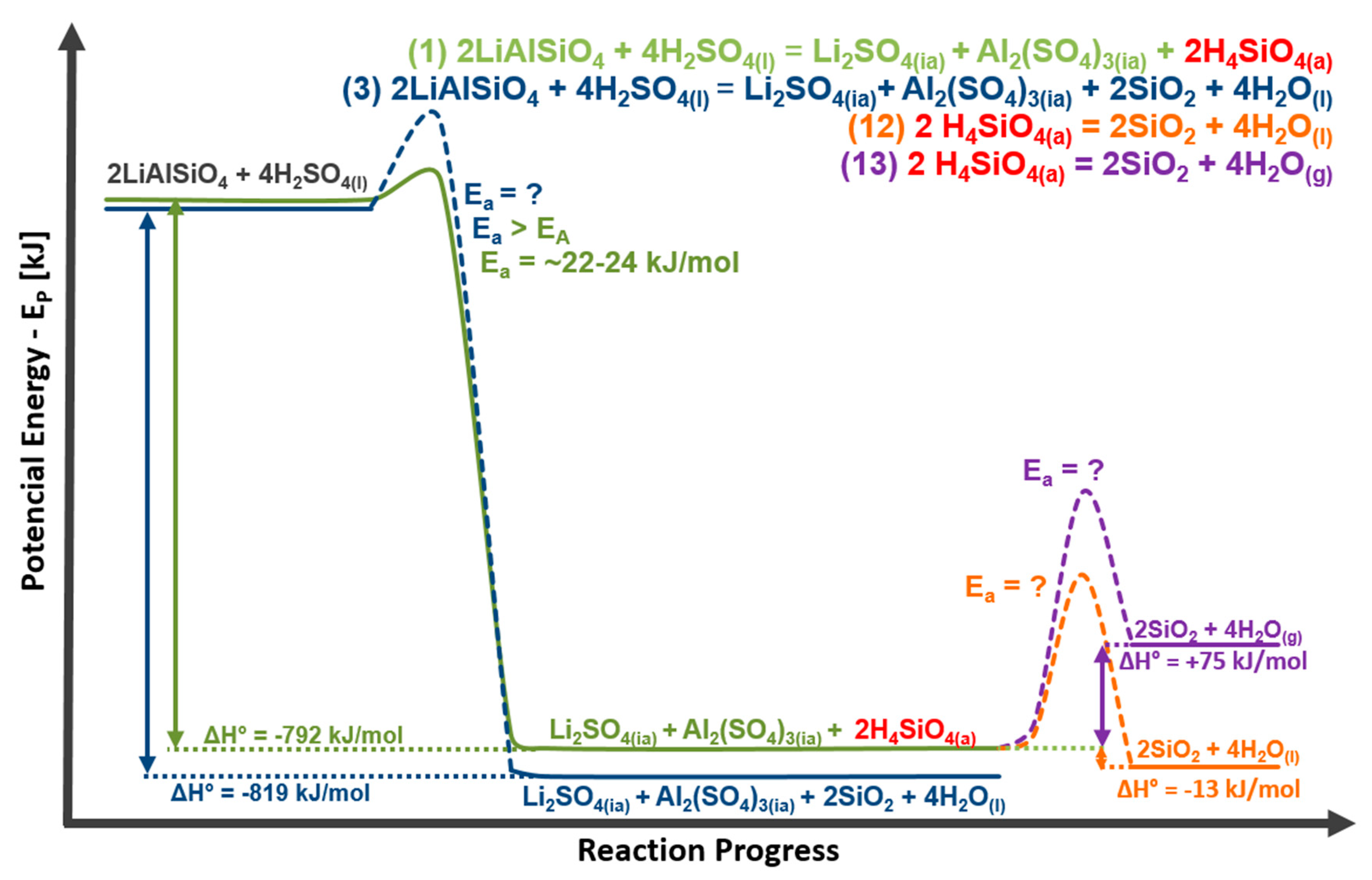

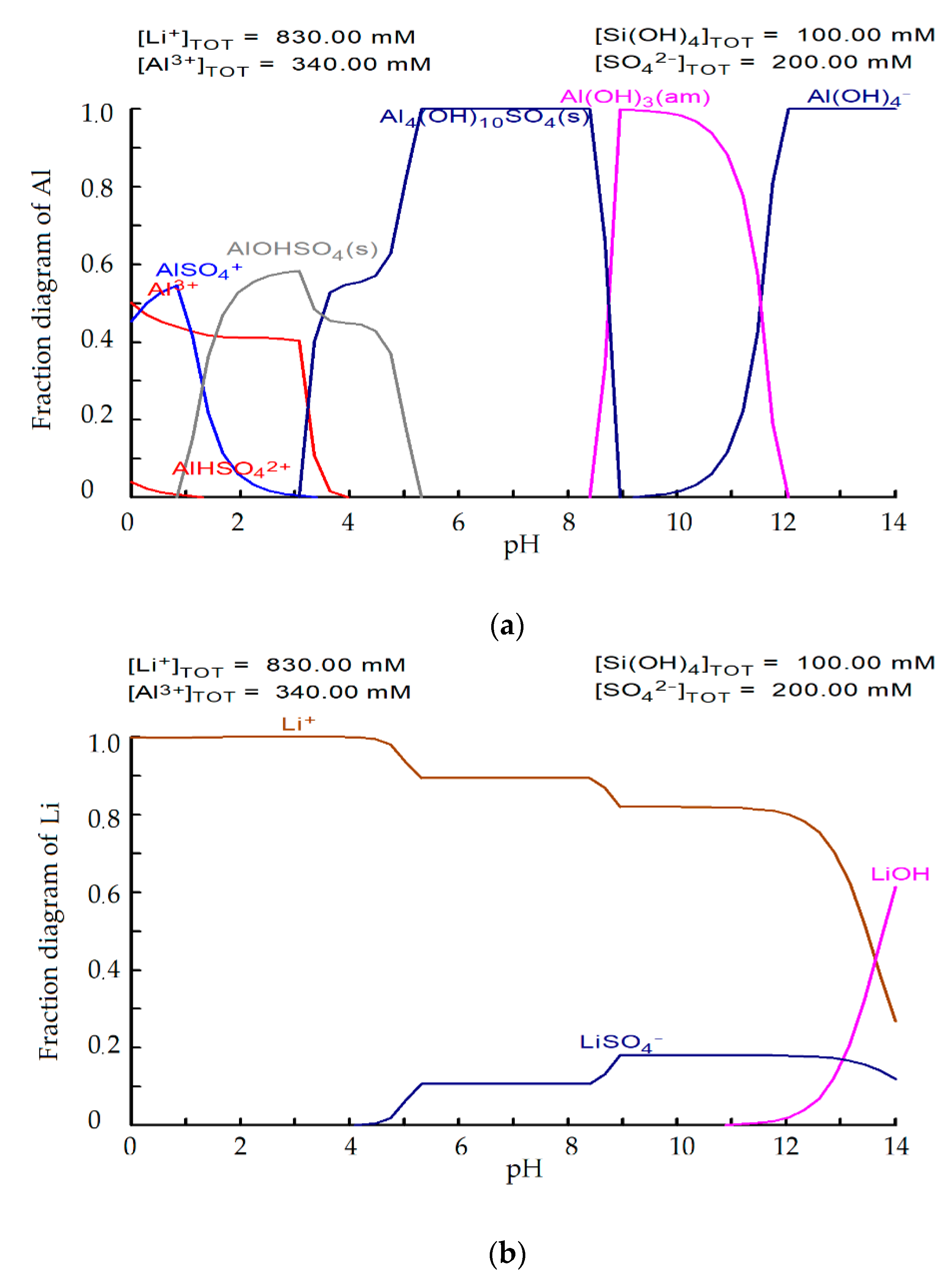

3.3. Suppression of Gel Formation—Thermodynamic Analysis

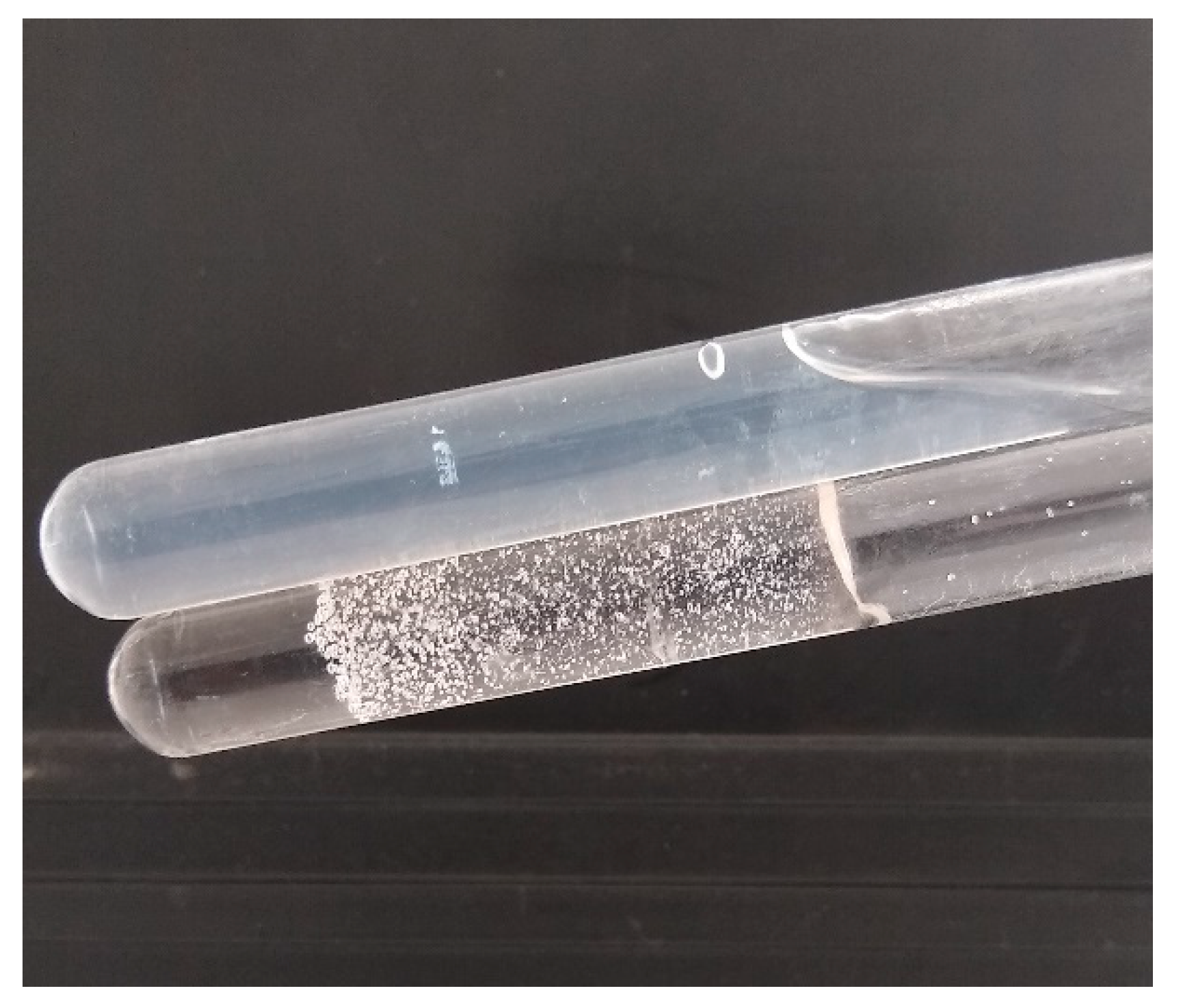

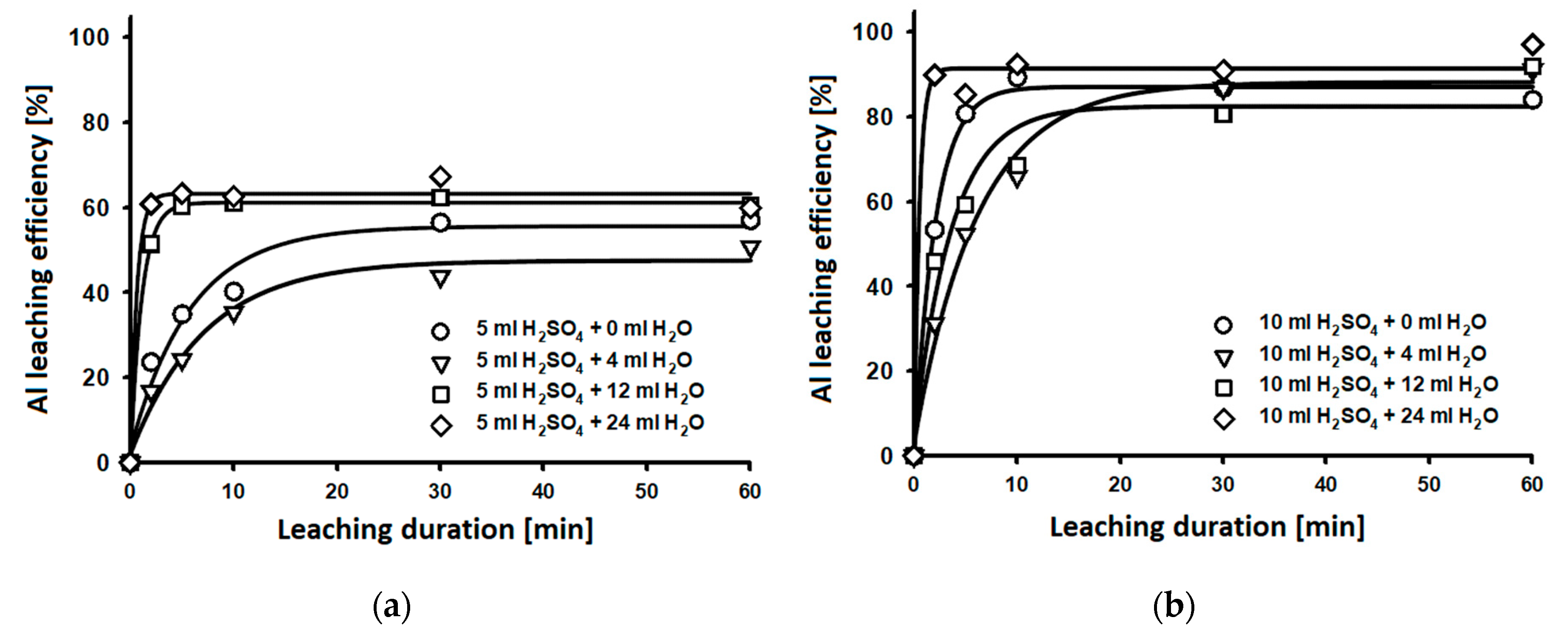

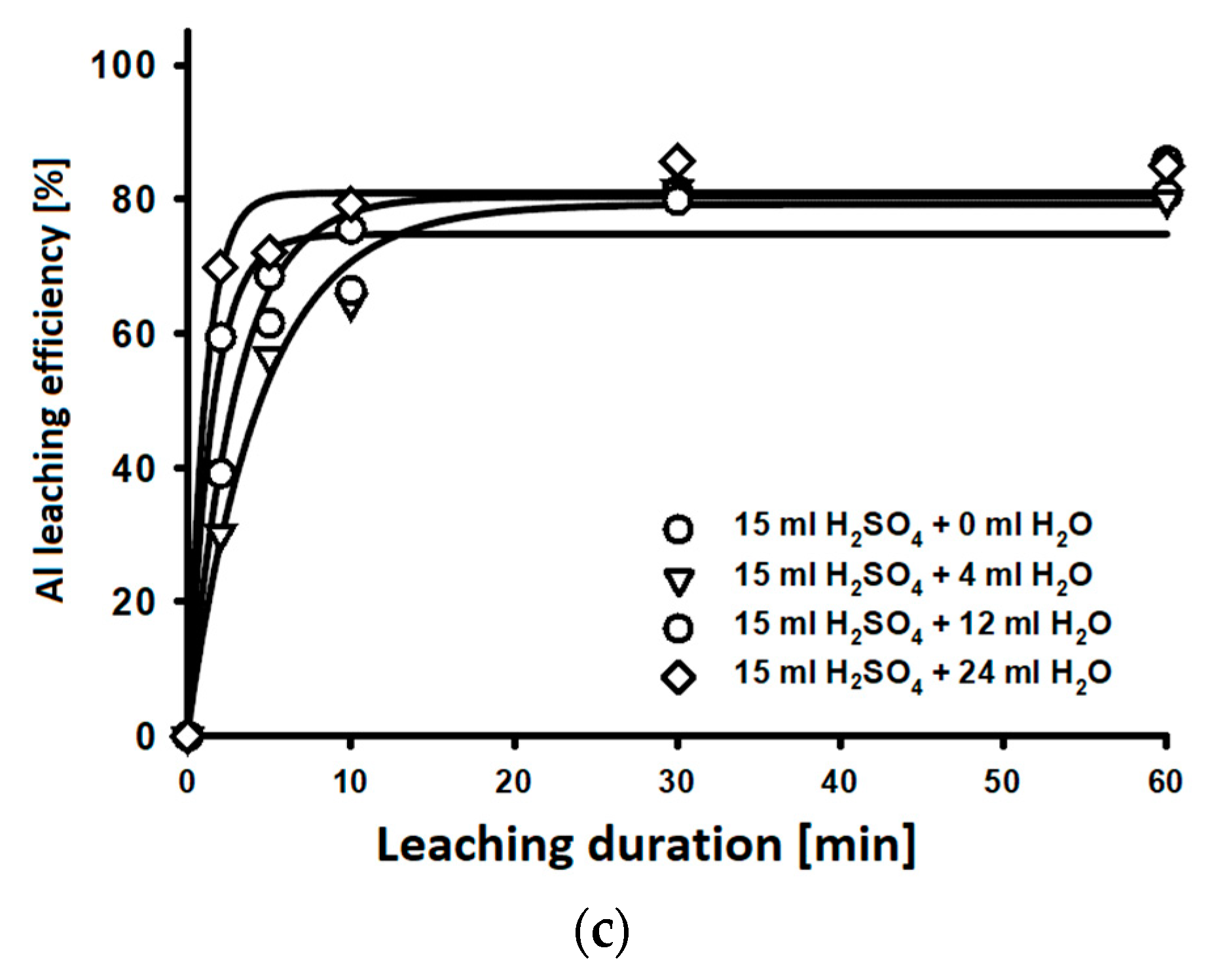

3.4. Dry Digestion—the Optimal Ratio of Li Slag Sample, Acid, and Water

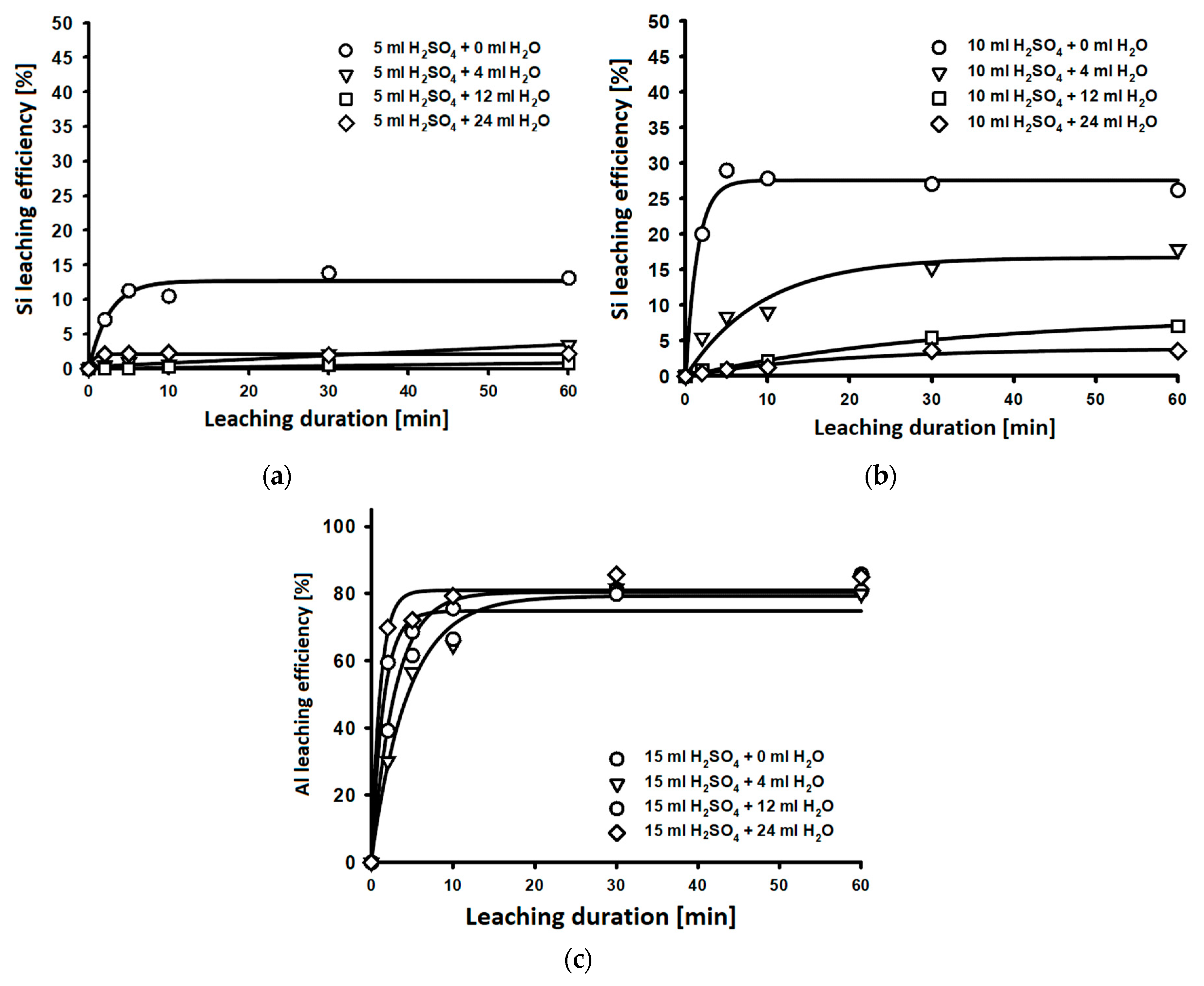

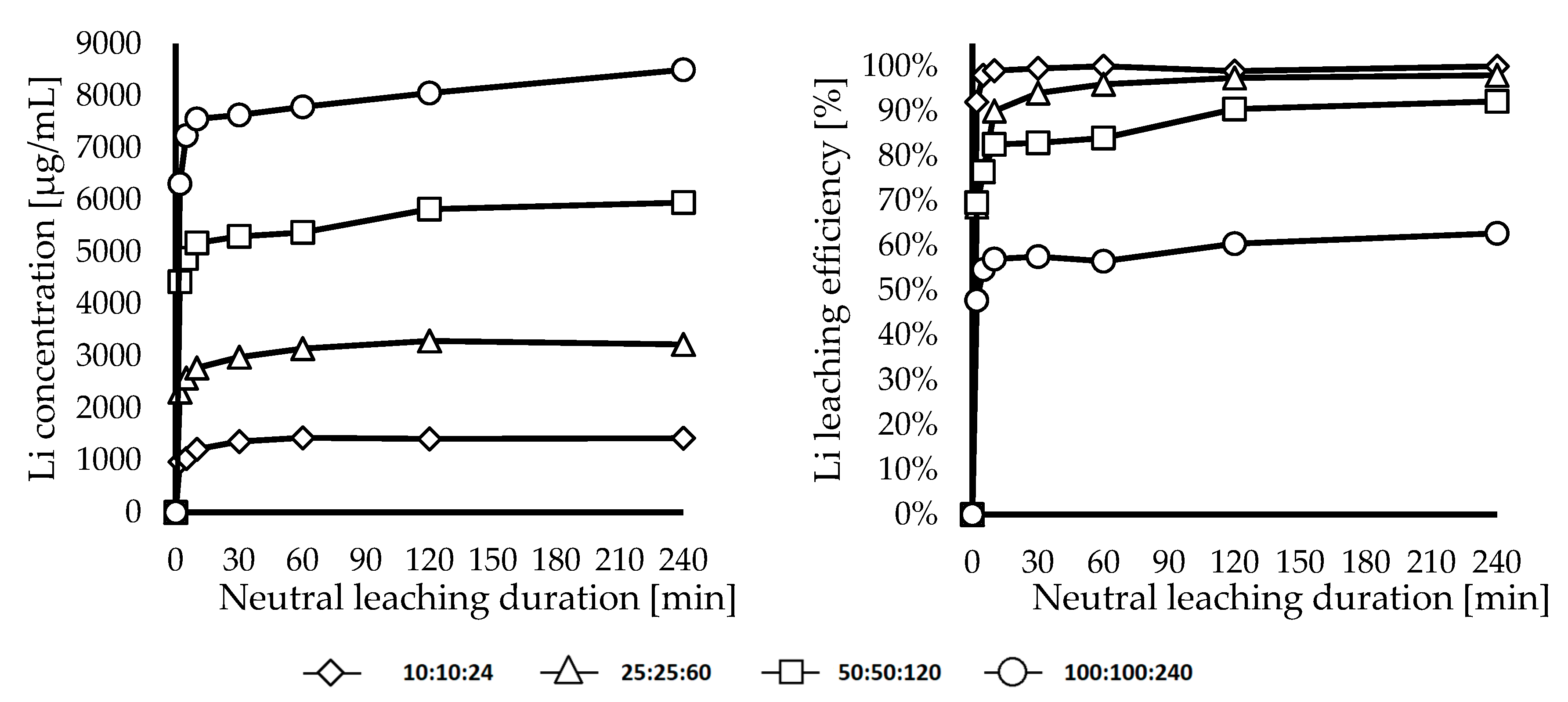

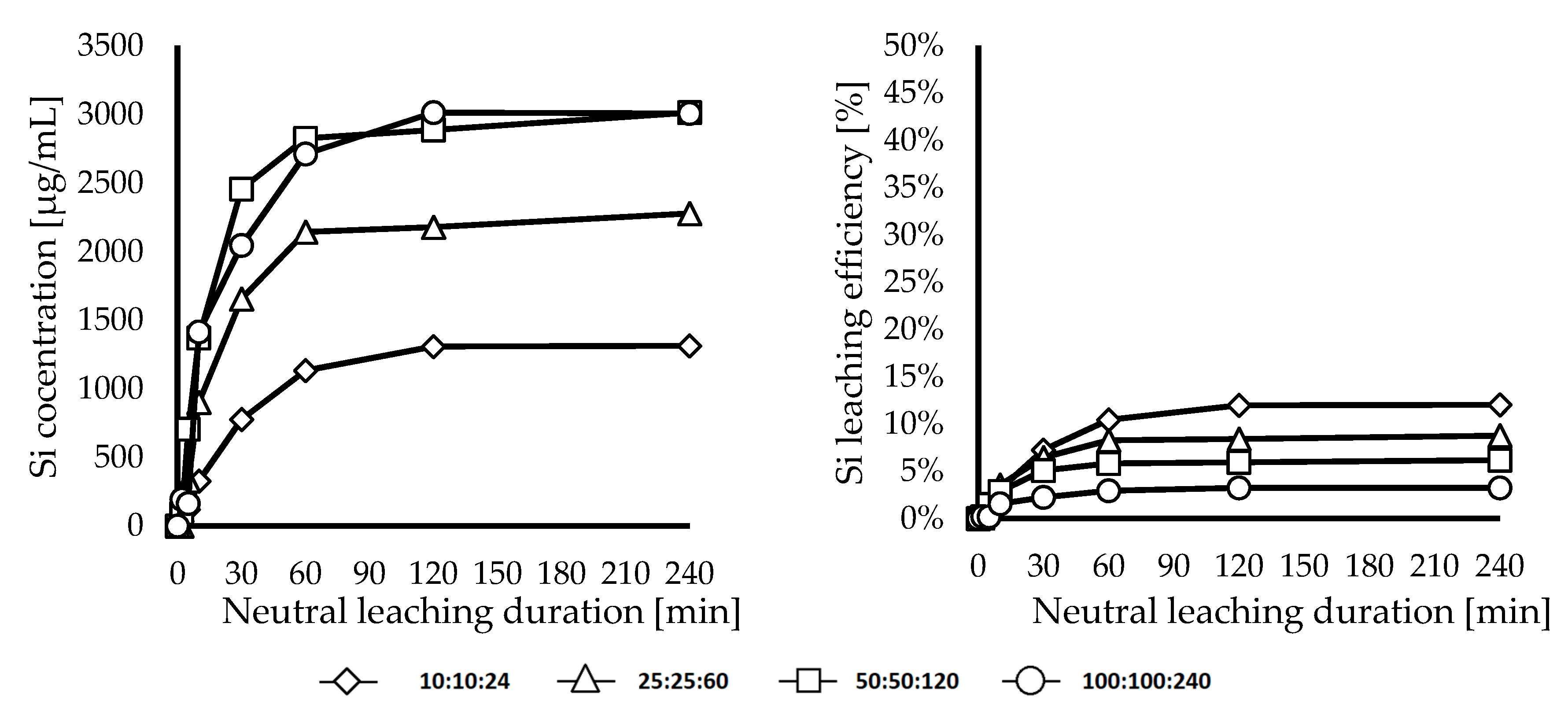

3.5. Dry Digestion—Increase of Dry Digested Mixture Used per Constant Volume of Water in Dissolution Step

3.6. Further Lithium Concentration Increase and Precipitation of Products (Theoretical Analysis)

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dańczak, A.; Klemettinen, L.; Kurhila, M.; Taskinen, P.; Lindberg, D.; Jokilaakso, A. Behavior of Battery Metals Lithium, Cobalt, Manganese and Lanthanum in Black Copper Smelting. Batteries 2020, 6, 16. [Google Scholar] [CrossRef]

- Helbig, C.; Bradshaw, A.M.; Wietschel, L.; Thorenz, A.; Tuma, A. Supply Risks Associated with Lithium-Ion Battery Materials. J. Clean. Prod. 2018, 172, 274–286. [Google Scholar] [CrossRef]

- Nitta, N.; Wu, F.; Lee, J.T.; Yushin, G. Li-Ion Battery Materials: Present and Future. Mater. Today 2015, 18, 252–264. [Google Scholar] [CrossRef]

- Gu, F.; Guo, J.; Yao, X.; Summers, P.A.; Widijatmoko, S.D.; Hall, P. An Investigation of the Current Status of Recycling Spent Lithium-Ion Batteries from Consumer Electronics in China. J. Clean. Prod. 2017, 161, 765–780. [Google Scholar] [CrossRef]

- Contestabile, M.; Panero, S.; Scrosati, B. A Laboratory-Scale Lithium-Ion Battery Recycling Process. J. Power Sources 2001, 92, 65–69. [Google Scholar] [CrossRef]

- Pinegar, H.; Smith, Y.R. Recycling of End-of-Life Lithium-Ion Batteries, Part II: Laboratory-Scale Research Developments in Mechanical, Thermal, and Leaching Treatments. J. Sustain. Metall. 2020, 6, 142–160. [Google Scholar] [CrossRef]

- Porvali, A.; Aaltonen, M.; Ojanen, S.; Velazquez-Martinez, O.; Eronen, E.; Liu, F.; Wilson, B.P.; Serna-Guerrero, R.; Lundström, M. Mechanical and Hydrometallurgical Processes in HCl Media for the Recycling of Valuable Metals from Li-Ion Battery Waste. Resour. Conserv. Recycl. 2019, 142, 257–266. [Google Scholar] [CrossRef]

- European Commission. Report from the Commission to the European Parliament, the Council, the European Economic and Social Committee, the Committee of the Regions and the European Investment Bank: On the Implementation of the Strategic Action Plan on Batteries: Building a Strategic Battery Value Chain in Europe. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52019DC0176&from=EN (accessed on 16 June 2020).

- Pinegar, H.; Smith, Y.R. Recycling of End-of-Life Lithium Ion Batteries, Part I: Commercial Processes. J. Sustain. Metall. 2019, 5, 402–416. [Google Scholar] [CrossRef]

- Tarascon, J.; Armand, M. Issues and Challenges Facing Rechargeable Lithium Batteries. Nature 2001, 414, 359–367. [Google Scholar] [CrossRef]

- Huang, B.; Pan, Z.; Su, X.; An, L. Recycling of Lithium-Ion Batteries: Recent Advances and Perspectives. J. Power Sources 2018, 399, 274–286. [Google Scholar] [CrossRef]

- The European Parliament and the Council of the European Union. Directive 2006/66/EC of the European Parliament and of the Council on Batteries and Accumulators and Waste Batteries and Accumulators and Repealing Directive 91/157/EEC. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:02006L0066-20131230&rid=1 (accessed on 6 May 2020).

- European Commission. Report from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: Critical Raw Materials Resilience: Charting a Path towards greater Security and Sustainability. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52020DC0474 (accessed on 15 September 2020).

- Werner, D.; Peuker, U.A.; Mütze, T. Recycling Chain for Spent Lithium-Ion Batteries. Metals 2020, 10, 316. [Google Scholar] [CrossRef]

- Zhong, X.; Liu, W.; Han, J.; Jiao, F.; Qin, W.; Liu, T. Pretreatment for the Recovery of Spent Lithium Ion Batteries: Theoretical and Practical Aspects. J. Clean. Prod. 2020, 263, 121439. [Google Scholar] [CrossRef]

- Liu, J.; Wang, H.; Hu, T.; Bai, X.; Wang, S.; Xie, W.; Hao, J.; He, Y. Recovery of LiCoO2 and Graphite from Spent Lithium-Ion Batteries by Cryogenic Grinding and Froth Flotation. Miner. Eng. 2020, 148, 106223. [Google Scholar] [CrossRef]

- Zhang, G.; Du, Z.; He, Y.; Wang, H.; Xie, W.; Zhang, T. A Sustainable Process for the Recovery of Anode and Cathode Materials Derived from Spent Lithium-Ion Batteries. Sustainability 2019, 11, 2363. [Google Scholar] [CrossRef]

- Zhang, G.; He, Y.; Feng, Y.; Wang, H.; Zhang, T.; Xie, W.; Zhu, X. Enhancement in Liberation of Electrode Materials Derived from Spent Lithium-Ion Battery by Pyrolysis. J. Clean. Prod. 2018, 199, 62–68. [Google Scholar] [CrossRef]

- Li, J.; Lai, Y.; Zhu, X.; Liao, Q.; Xia, A.; Huang, Y.; Zhu, X. Pyrolysis Kinetics and Reaction Mechanism of the Electrode Materials During the Spent LiCoO2 Batteries Recovery Process. J. Hazard. Mater. 2020, 398, 122955. [Google Scholar] [CrossRef]

- Zhong, X.; Liu, W.; Han, J.; Jiao, F.; Qin, W.; Liu, T.; Zhao, C. Pyrolysis and Physical Separation for the Recovery of Spent LiFePO4 Batteries. Waste Manag. 2019, 89, 83–93. [Google Scholar] [CrossRef]

- Ruismäki, R.; Dańczak, A.; Klemettinen, L.; Taskinen, P.; Lindberg, D.; Jokilaakso, A. Integrated Battery Scrap Recycling and Nickel Slag Cleaning with Methane Reduction. Minerals 2020, 10, 435. [Google Scholar] [CrossRef]

- Shi, J.; Peng, C.; Chen, M.; Li, Y.; Eric, H.; Klemettinen, L.; Lundström, M.; Taskinen, P.; Jokilaakso, A. Sulfation Roasting Mechanism for Spent Lithium-Ion Battery Metal Oxides Under SO2-O2-Ar Atmosphere. JOM 2019, 71, 4473–4482. [Google Scholar] [CrossRef]

- Peng, C.; Hamuyuni, J.; Wilson, B.P.; Lundström, M. Selective Reductive Leaching of Cobalt and Lithium from Industrially Crushed Waste Li-Ion Batteries in Sulfuric Acid System. Waste Manag. 2018, 76, 582–590. [Google Scholar] [CrossRef]

- Porvali, A.; Chernyaev, A.; Shukla, S.; Lundström, M. Lithium Ion Battery Active Material Dissolution Kinetics in Fe (II)/Fe (III) Catalyzed Cu-H2SO4 Leaching System. Sep. Purif. Technol. 2020, 236, 116305. [Google Scholar] [CrossRef]

- Dewulf, J.; van der Vorst, G.; Denturck, K.; van Langenhove, H.; Ghyoot, W.; Tytgat, J.; Vandeputte, K. Recycling Rechargeable Lithium Ion Batteries: Critical Analysis of Natural Resource Savings. Resour. Conserv. Recyl. 2010, 54, 229–234. [Google Scholar] [CrossRef]

- BRGM. Le Lithium (Li)—Éléments de Criticité; BRGM, the French Geological Survey: Orleans, France, 2017; pp. 1–8. Available online: http://www.mineralinfo.fr/page/fiches-criticite (accessed on 19 October 2020).

- Mathieux, F.; Ardente, F.; Bobba, S.; Nuss, P.; Blengini, G.; Alves Dias, P.; Blagoeva, D.; Torres De Matos, C.; Wittmer, D.; Pavel, C.; et al. Critical Raw Materials and the Circular Economy—Background Report; JRC Science-for-policy report, EUR 28832 EN; Publications Office of the European Union: Luxembourg, 2017; ISBN 978-92-79-74282-8. [Google Scholar] [CrossRef]

- Harper, G.; Sommerville, R.; Kendrick, E.; Driscoll, L.; Slater, P.; Stolkin, R.; Walton, A.; Christensen, P.; Heidrich, O.; Lambert, S.; et al. Recycling Lithium-Ion Batteries from Electric Vehicles. Nature 2019, 575, 75–86. [Google Scholar] [CrossRef]

- Wang, H.; Friedrich, B. Development of a Highly Efficient Hydrometallurgical Recycling Process for Automotive Li–Ion Batteries. J. Sustain. Metall. 2015, 1, 168–178. [Google Scholar] [CrossRef]

- Sommerfeld, M.; Vonderstein, C.; Dertmann, C.; Klimko, J.; Oráč, D.; Miškufová, A.; Havlik, T.; Friedrich, B. A Combined Pyro- and Hydrometallurgical Approach to Recycle Pyrolyzed Lithium-Ion Battery Black Mass Part 1: Production of Lithium Concentrates in an Electric Arc Furnace. Metals 2020, 10, 1069. [Google Scholar] [CrossRef]

- Voßenkaul, D.; Birich, A.; Müller, N.; Stoltz, N.; Friedrich, B. Hydrometallurgical Processing of Eudialyte Bearing Concentrates to Recover Rare Earth Elements Via Low-Temperature Dry Digestion to Prevent the Silica Gel Formation. J. Sustain. Metall. 2017, 3, 79–89. [Google Scholar] [CrossRef]

- Ma, Y.; Stopic, S.; Gronen, L.; Friedrich, B. Recovery of Zr, Hf, Nb from eudialyte residue by sulfuric acid dry digestion and water leaching with H2O2 as a promoter. Hydrometallurgy 2018, 181, 206–214. [Google Scholar] [CrossRef]

- Ma, Y.; Stopic, S.; Gronen, L.; Milivojevic, M.; Obradovic, S.; Friedrich, B. Neural Network Modeling for the Extraction of Rare Earth Elements from Eudialyte Concentrate by Dry Digestion and Leaching. Metals 2018, 8, 267. [Google Scholar] [CrossRef]

- Davris, P.; Stopic, S.; Balomenos, E.; Panias, D.; Paspaliaris, I.; Friedrich, B. Leaching of rare earth elements from eudialyte concentrate by suppressing silica gel. Miner. Eng. 2017, 108, 115–122. [Google Scholar] [CrossRef]

- Alkan, G.; Yagmurlu, B.; Gronen, L.; Dittrich, C.; Ma, Y.; Stopic, S.; Friedrich, B. Selective silica gel free scandium extraction from Iron-depleted red mud slags by dry digestion. Hydrometallurgy 2019, 185, 266–272. [Google Scholar] [CrossRef]

- London Metal Exchange (LME). Available online: https://www.lme.com/Metals (accessed on 19 October 2020).

- Shanghai Metals Market (SMM). Available online: https://price.metal.com/ (accessed on 19 October 2020).

- Roine, A. HSC Chemistry Thermodynamic Software; Outotec: Pori, Finland, 2018. [Google Scholar]

- Hem Shanker Ray, H.; Saradindukumar, R. Analysis of Kinetic Data for Practical Applications. In Kinetics of Metallurgical Processes; Springer Nature: Singapore, 2018; Volume 1, pp. 315–340. [Google Scholar]

- Havlik, T. Hydrometallurgy—Principes and applications; Woodhead Publishing Limited: Cambridge, UK, 2008; p. 536. ISBN 978-1-84569-407-4. [Google Scholar]

- Takáčová, Z.; Havlik, T.; Kukurugya, F.; Orac, D. Cobalt and Lithium Recovery from Active Mass of Spent Li-ion Batteries: Theoretical and Experimental Approach. Hydrometallurgy 2016, 163, 9–17. [Google Scholar] [CrossRef]

- Iler, R.K. The Chemistry of Silica: Solubility, Polymerization, Colloid and Surface Properties, and Biochemistry; Wiley: New York, NY, USA, 1979. [Google Scholar]

- Icopini, G.A.; Brantley, S.L.; Heaney, P.J. Kinetics of silica oligomerization and nanocolloid formation as a function of pH and ionic strength at 25 °C. Geochimica Cosmochimica Acta 2005, 69, 293–303. [Google Scholar] [CrossRef]

| Sample | Li | Co | Cu | Al | Fe | Si | Ca | Ni | Mn |

|---|---|---|---|---|---|---|---|---|---|

| Li slag | 6.80 | 1.17 | 1.53 | 16.52 | 0.51 | 48.62 | 1.16 | 0.15 | 0.65 |

| De-metalized Li slag | 6.96 | 0.00 | 0.11 | 16.40 | 0.20 | 51.10 | 1.26 | 0.01 | 0.88 |

| Elements | Content | Marketable Products | Price of Marketable Products (US $/t) | Estimated Value of Marketable Products in 1 t of Li Slag (US $) |

|---|---|---|---|---|

| Li | 6.96% | Li2CO3 (Li = 18.79%) | 6750 | 2500.27 |

| Al | 16.40% | Al | 2243.86 | 367.99 |

| Si | 51.10% | SiO2 (Si= 46.74%) | 100–120 | 109–131 |

| Mn | 0.88% | Mn | 1525.83 | 13.43 |

| Cu | 0.11% | Cu | 7703.93 | 8.47 |

| Ca | 1.26% | CaO (Ca= 71.47%) | 80 | 1.41–1.76 |

| Ni | 0.01% | Ni | 17,935.94 | 1.79 |

| Fe | 0.20% | Fe | 285 | 0.57 |

| Co | 0.00% | Co | 32,985 | - |

| Equation | Reaction | ΔG°293.15 [kJ] | ΔG°353.15 [kJ] |

|---|---|---|---|

| (1) | 2LiAlSiO4 + 4H2SO4(l) = Li2SO4(ia) + Al2(SO4)3(ia) + 2H4SiO4(a) | −274.727 | −274.783 |

| (2) | 2LiAlSiO4 + 4H2SO4(l) = Li2SO4(ia) + Al2(SO4)3(ia) + 2H2SiO3(a) + 2H2O | −300.098 | −272.695 |

| (3) | 2LiAlSiO4 + 4H2SO4(l) = Li2SO4(ia) + Al2(SO4)3(ia) + 2SiO2 + 4H2O | −302.950 | −303.060 |

| (4) | 2LiAlSi2O6 + 4H2SO4(l) + 4H2O = Li2SO4(ia) + Al2(SO4)3(ia) + 4H4SiO4(a) | −216.581 | −218.504 |

| (5) | Li2SiO3 + H2SO4(l) = Li2SO4(ia) + H2SiO3(a) | −151.744 | −141.622 |

| (6) | Li2SiO3 + H2SO4(l) + H2O(l) = Li2SO4(ia) + H4SiO4(a) | −152.092 | −142.666 |

| Kinetic Models | Linear Relationship (R2) | |||

|---|---|---|---|---|

| 1. Linear α-t dependency | 20 °C | 40 °C | 60 °C | 80 °C |

| 0.80 | 0.59 | 0.45 | 0.37 | |

| 2. Deceleratory α–t curves | ||||

| 2.1. Based on geometrical models | ||||

| 0.90 | 0.77 | 0.63 | 0.47 | |

| 0.93 | 0.83 | 0.72 | 0.53 | |

| 2.2. Based on diffusion mechanism | ||||

| 0.93 | 0.78 | 0.56 | 0.40 | |

| 0.97 | 0.89 | 0.69 | 0.46 | |

| 1.00 | 0.99 | 0.92 | 0.64 | |

| 0.98 | 0.94 | 0.78 | 0.53 | |

| 2.3. Based on order of reaction | ||||

| 0.98 | 0.93 | 0.89 | 0.59 | |

| 0.99 | 0.95 | 0.90 | 0.17 | |

| 0.86 | 0.80 | 0.73 | 0.11 | |

| 3. Acceleratory α –t curves | ||||

| (n = 0.25) | 0.98 | 0.95 | 0.73 | 0.45 |

| (n = 0.5) | 0.93 | 0.78 | 0.56 | 0.40 |

| (n = 1) | 0.80 | 0.59 | 0.45 | 0.37 |

| (n = 2) | 0.62 | 0.47 | 0.40 | 0.36 |

| 0.13 | 0.12 | 0.15 | 0.14 | |

| 4. Sigmoidal α–t curves | ||||

| 0.83 | 0.73 | 0.68 | 0.54 | |

| 0.71 | 0.61 | 0.58 | 0.49 | |

| 0.63 | 0.55 | 0.52 | 0.46 | |

| 0.97 | 0.95 | 0.90 | 0.17 | |

| Equation | Reaction | ΔH°293.15 (kJ) | ΔH°353.15 (kJ) | ΔG°293.15 (kJ) | ΔG°353.15 (kJ) |

|---|---|---|---|---|---|

| (12) | H4SiO4(a) = SiO2 + 2H2O(l) | −13.642 | −14.203 | −14.112 | −14.139 |

| (13) | H4SiO4(a) = SiO2 + 2H2O(g) | 74.782 | 69.217 | 4.199 | −9.698 |

| Sample (Slag:H2SO4:H2O) | Leaching Residue Weight | Li | Al | ||

|---|---|---|---|---|---|

| Solid (AAS) | Solution (Calculated) | Solid (AAS) | Solution (Calculated) | ||

| Input sample | 100.00% | 100.00% | - | 100.00% | - |

| 10:10:24 | 54.16% (5.41 g) | 0.07% | 99.93% | 0.36% | 99.64% |

| 25:25:60 | 55.32% (13.83 g) | 0.07% | 99.93% | 0.57% | 99.43% |

| 50:50:120 | 45.03% (22.51 g) | 0.34% | 99.66% | 1.59% | 98.41% |

| 100:100:240 | 49.96% (49.96 g) | 2.76% | 97.24% | 3.81% | 96.19% |

| Trial (Slag:H2SO4:H2O) | Li | Al | Si | |||

|---|---|---|---|---|---|---|

| (µg/mL) | (%) | (µg/mL) | (%) | (µg/mL) | (%) | |

| 10:10:24 | 16.07 | 1.15% | 136 | 4.70% | 83 | 0.81% |

| 25:25:60 | 34.3 | 0.98% | 553 | 7.65% | 249 | 0.97% |

| 50:50:120 | 546 | 7.80% | 1548 | 10.71% | 289 | 0.57% |

| 100:100:240 | 3555 | 25.39% | 6460 | 22.34% | 311 | 0.30% |

| Slag:H2SO4:H2O | 10:10:24 | 25:25:60 | 50:50:120 | 100:100:240 |

|---|---|---|---|---|

| pH0 | 0.466 | 0.097 | −0.159 | −0.383 |

| pH1 | 1.322 | 1.033 | 0.752 | 0.494 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Klimko, J.; Oráč, D.; Miškufová, A.; Vonderstein, C.; Dertmann, C.; Sommerfeld, M.; Friedrich, B.; Havlík, T. A Combined Pyro- and Hydrometallurgical Approach to Recycle Pyrolyzed Lithium-Ion Battery Black Mass Part 2: Lithium Recovery from Li Enriched Slag—Thermodynamic Study, Kinetic Study, and Dry Digestion. Metals 2020, 10, 1558. https://doi.org/10.3390/met10111558

Klimko J, Oráč D, Miškufová A, Vonderstein C, Dertmann C, Sommerfeld M, Friedrich B, Havlík T. A Combined Pyro- and Hydrometallurgical Approach to Recycle Pyrolyzed Lithium-Ion Battery Black Mass Part 2: Lithium Recovery from Li Enriched Slag—Thermodynamic Study, Kinetic Study, and Dry Digestion. Metals. 2020; 10(11):1558. https://doi.org/10.3390/met10111558

Chicago/Turabian StyleKlimko, Jakub, Dušan Oráč, Andrea Miškufová, Claudia Vonderstein, Christian Dertmann, Marcus Sommerfeld, Bernd Friedrich, and Tomáš Havlík. 2020. "A Combined Pyro- and Hydrometallurgical Approach to Recycle Pyrolyzed Lithium-Ion Battery Black Mass Part 2: Lithium Recovery from Li Enriched Slag—Thermodynamic Study, Kinetic Study, and Dry Digestion" Metals 10, no. 11: 1558. https://doi.org/10.3390/met10111558

APA StyleKlimko, J., Oráč, D., Miškufová, A., Vonderstein, C., Dertmann, C., Sommerfeld, M., Friedrich, B., & Havlík, T. (2020). A Combined Pyro- and Hydrometallurgical Approach to Recycle Pyrolyzed Lithium-Ion Battery Black Mass Part 2: Lithium Recovery from Li Enriched Slag—Thermodynamic Study, Kinetic Study, and Dry Digestion. Metals, 10(11), 1558. https://doi.org/10.3390/met10111558