The Effect of Hydrogen on the Nanoindentation Behavior of Heat Treated 718 Alloy

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

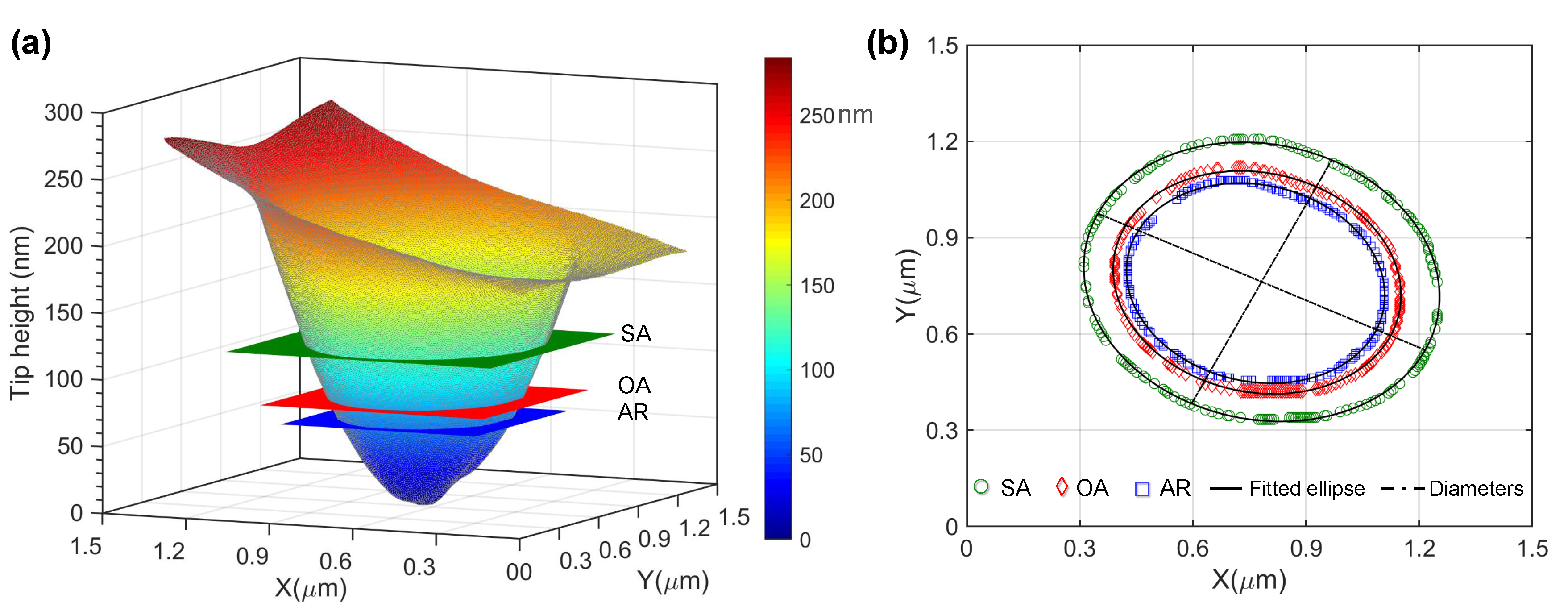

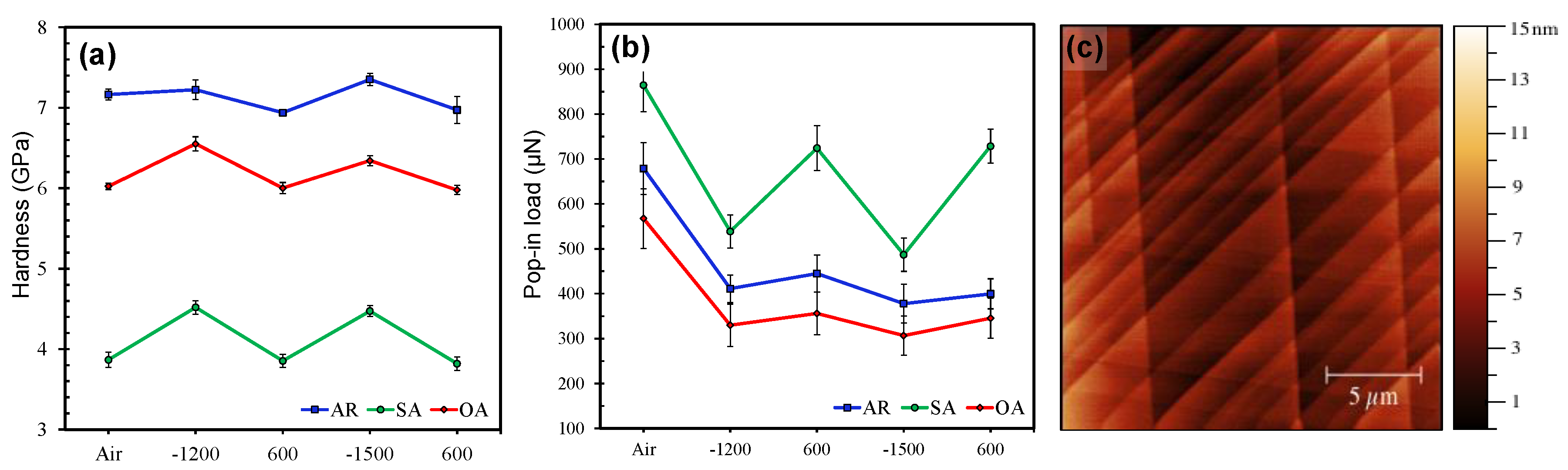

3.1. Hardness Measurement

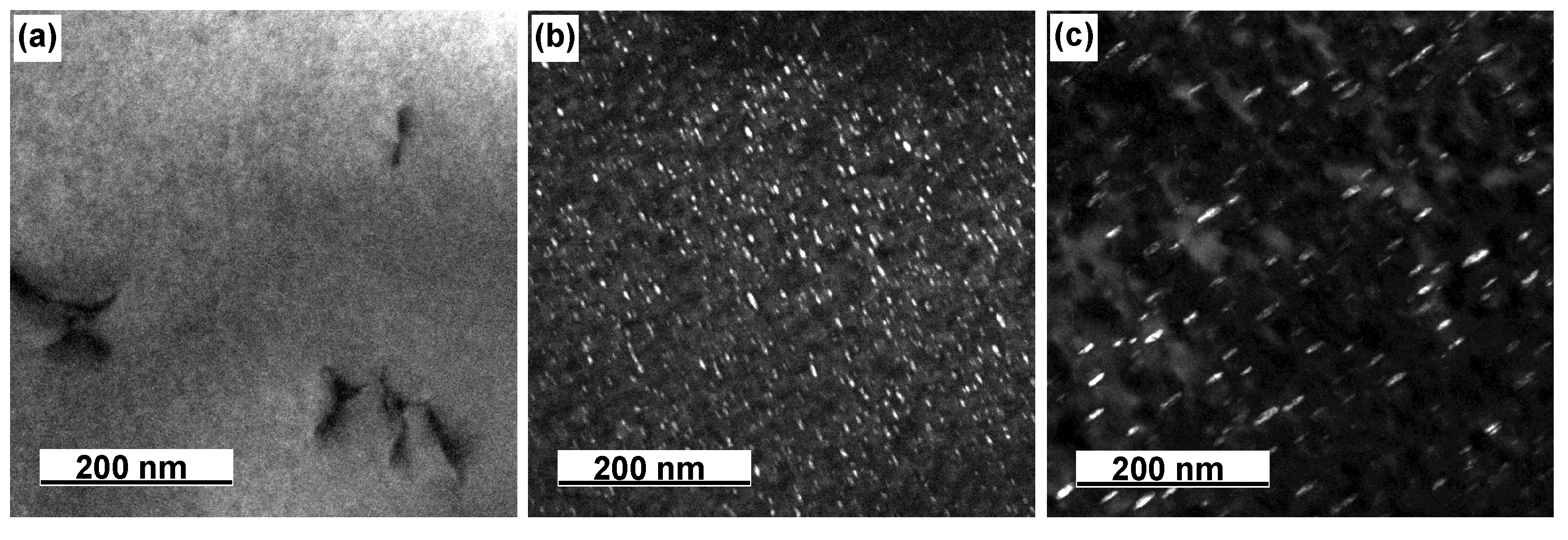

3.2. Precipitation Effect on Hardness and Plasticity Onset

4. Conclusions

- A new method is employed to obtain the of the nanoindentation directly from the tip image to calculate the hardness value.

- While the precipitates in the matrix increase the hardness significantly, compared to the SA sample, aged samples are less affected by H charging.

- Hardness enhancement of the OA sample is higher at , whereas the cathodic polarization is more effective for the hardness increase of the AR sample. The possible reasons are explained based on the interaction of H, the matrix, and precipitations.

- Cathodic polarization decreases the pop-in load, which cannot be fully recovered under the anodic H egression.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| H | Hydrogen |

| SA | Solution annealed |

| AR | As-received |

| OA | Over-aged |

| Projected contact area | |

| L-D | Load-displacement |

References

- Mignanelli, P.M.; Jones, N.G.; Pickering, E.J.; Messé, O.M.D.M.; Rae, C.M.F.; Hardy, M.C.; Stone, H.J. Gamma-gamma prime-gamma double prime dual-superlattice superalloys. Scr. Mater. 2017, 136, 136–140. [Google Scholar] [CrossRef]

- Slama, C.; Abdellaoui, M. Structural characterization of the aged Inconel 718. J. Alloys Compd. 2000, 306, 277–284. [Google Scholar] [CrossRef]

- Yoo, Y.; Yoon, D.; Henry, M. The effect of elastic misfit strain on the morphological evolution of γ′-precipitates in a model Ni-base superalloy. Met. Mater. 1995, 1, 47–61. [Google Scholar]

- Zhang, R.Y.; Qin, H.L.; Bi, Z.N.; Li, J.; Paul, S.; Lee, T.L.; Zhang, S.Y.; Zhang, J.; Dong, H.B. Temperature-Dependent Misfit Stress in Gamma Double Prime Strengthened Ni-Base Superalloys. Metall. Mater. Trans. A 2020, 51, 1860–1873. [Google Scholar] [CrossRef]

- Zhang, Z.; Moore, K.L.; McMahon, G.; Morana, R.; Preuss, M. On the role of precipitates in hydrogen trapping and hydrogen embrittlement of a nickel-based superalloy. Corros. Sci. 2018, 146, 58–69. [Google Scholar] [CrossRef]

- Hajilou, T.; Deng, Y.; Kheradmand, N.; Barnoush, A. Hydrogen enhanced cracking studies on Fe–3wt%Si single and bi-crystal microcantilevers. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2017, 375, 20160410. [Google Scholar] [CrossRef] [PubMed]

- Jakob, S.; Leitner, A.; Lorich, A.; Eidenberger-Schober, M.; Knabl, W.; Pippan, R.; Clemens, H.; Maier-Kiener, V. Influence of crystal orientation and Berkovich tip rotation on the mechanical characterization of grain boundaries in molybdenum. Mater. Des. 2019, 182, 107998. [Google Scholar] [CrossRef]

- Barnoush, A.; Vehoff, H. In situ electrochemical nanoindentation: A technique for local examination of hydrogen embrittlement. Corros. Sci. 2008, 50, 259–267. [Google Scholar] [CrossRef]

- Kirchheim, R. Reducing grain boundary, dislocation line and vacancy formation energies by solute segregation. I. Theoretical background. Acta Mater. 2007, 55, 5129–5138. [Google Scholar] [CrossRef]

- Wan, D.; Deng, Y.; Meling, J.I.H.; Alvaro, A.; Barnoush, A. Hydrogen-enhanced fatigue crack growth in a single-edge notched tensile specimen under in situ hydrogen charging inside an environmental scanning electron microscope. Acta Mater. 2019, 170, 87–99. [Google Scholar] [CrossRef]

- Ogawa, Y.; Birenis, D.; Matsunaga, H.; Thøgersen, A.; Prytz, Ø.; Takakuwa, O.; Yamabe, J. Multi-scale observation of hydrogen-induced, localized plastic deformation in fatigue-crack propagation in a pure iron. Scr. Mater. 2017, 140, 13–17. [Google Scholar] [CrossRef]

- Metsue, A.; Oudriss, A.; Feaugas, X. Trapping/detrapping kinetic rates of hydrogen around a vacancy in nickel and some consequences on the hydrogen-vacancy clusters thermodynamic equilibrium. Comput. Mater. Sci. 2018, 151, 144–152. [Google Scholar] [CrossRef]

- Yashiro, K.; Naito, M.; Tomita, Y. Molecular dynamics simulation of dislocation nucleation and motion at γ/γ′ interface in Ni-based superalloy. Int. J. Mech. Sci. 2002, 44, 1845–1860. [Google Scholar] [CrossRef]

| Material Condition | Heat Treatment |

|---|---|

| Solution annealed (SA) | Solution annealing at 1200 , 2 h/water quenching |

| As received (AR) | Solution annealing at 1200 , 2 h/water quenching, thermomechanical treatment and age-hardening at 720 and 620 , 8 + 8 h/air cooling |

| Over-aged (OA) | Solution annealing at 1200 , 2 h/water quenching, over-aging at 800 , 8 h/water quenching |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stenerud, G.; Hajilou, T.; Olsen, J.S.; Taji, I.; Barnoush, A.; Johnsen, R. The Effect of Hydrogen on the Nanoindentation Behavior of Heat Treated 718 Alloy. Metals 2020, 10, 1451. https://doi.org/10.3390/met10111451

Stenerud G, Hajilou T, Olsen JS, Taji I, Barnoush A, Johnsen R. The Effect of Hydrogen on the Nanoindentation Behavior of Heat Treated 718 Alloy. Metals. 2020; 10(11):1451. https://doi.org/10.3390/met10111451

Chicago/Turabian StyleStenerud, Gaute, Tarlan Hajilou, Jim Stian Olsen, Iman Taji, Afrooz Barnoush, and Roy Johnsen. 2020. "The Effect of Hydrogen on the Nanoindentation Behavior of Heat Treated 718 Alloy" Metals 10, no. 11: 1451. https://doi.org/10.3390/met10111451

APA StyleStenerud, G., Hajilou, T., Olsen, J. S., Taji, I., Barnoush, A., & Johnsen, R. (2020). The Effect of Hydrogen on the Nanoindentation Behavior of Heat Treated 718 Alloy. Metals, 10(11), 1451. https://doi.org/10.3390/met10111451