Evolution in Microstructure and Mechanical Properties of Inconel 783 Alloy Bolts after Long Term High-Temperature Aging at 700 °C

Abstract

:1. Introduction

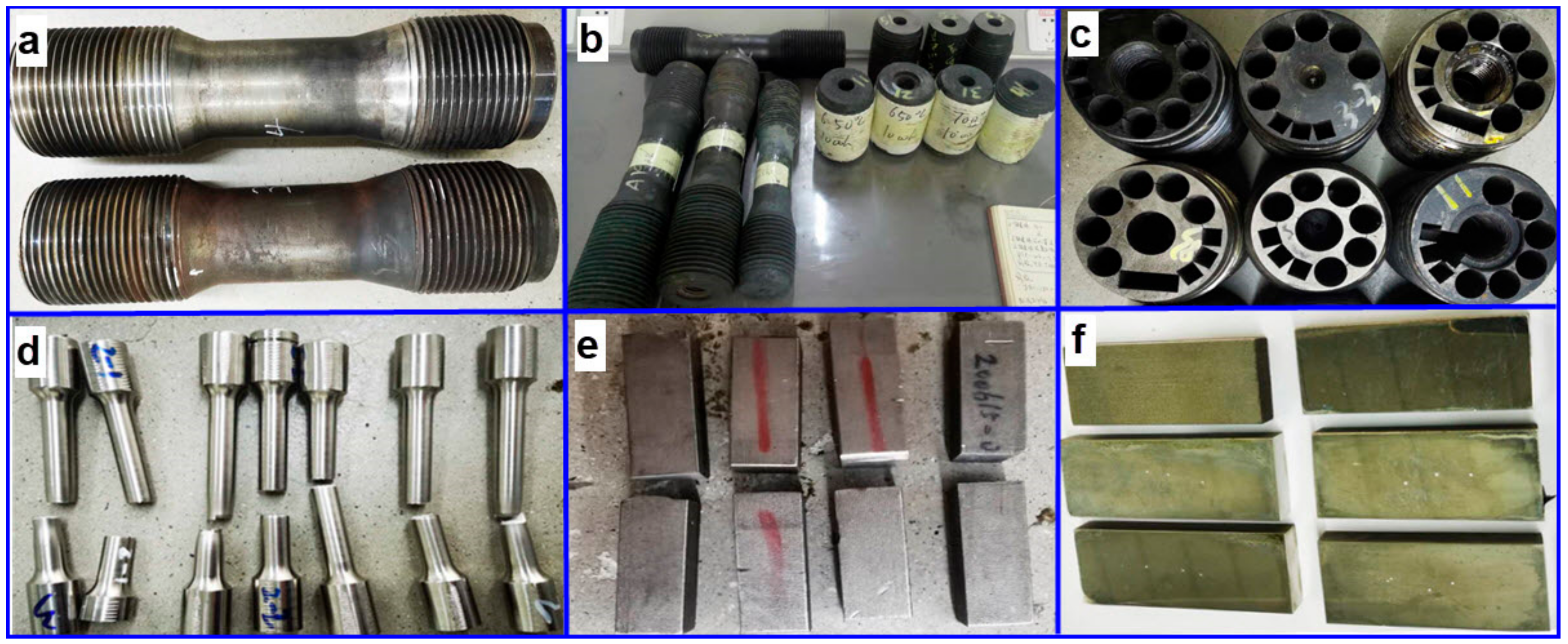

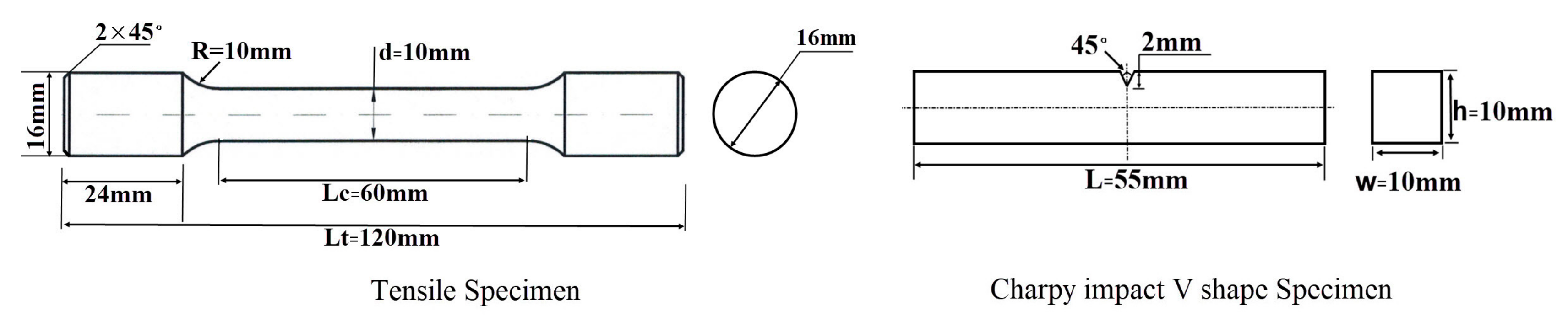

2. Experiment

2.1. Materials and Heat Treatment

2.2. Characterization

3. Results and Discussion

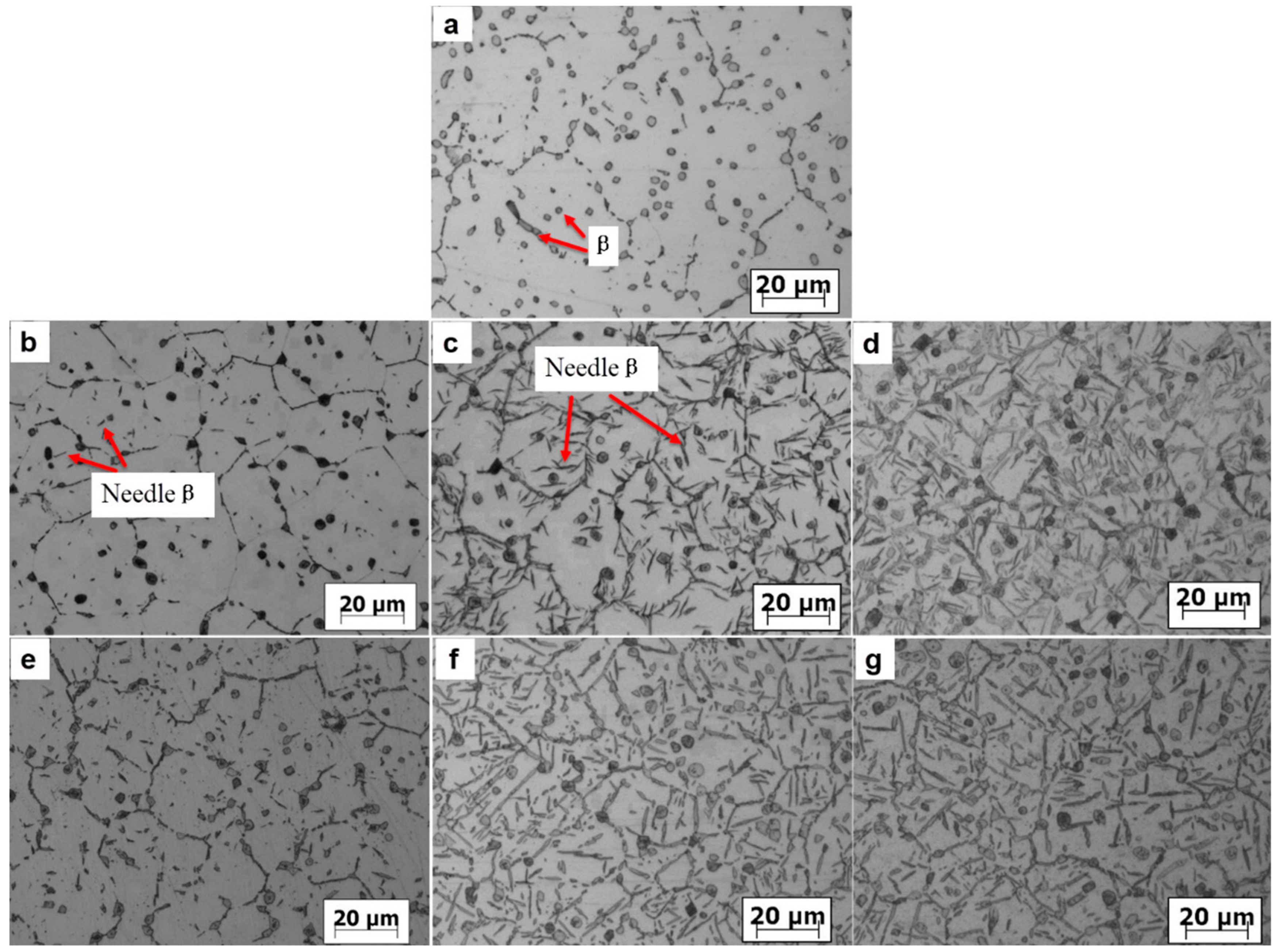

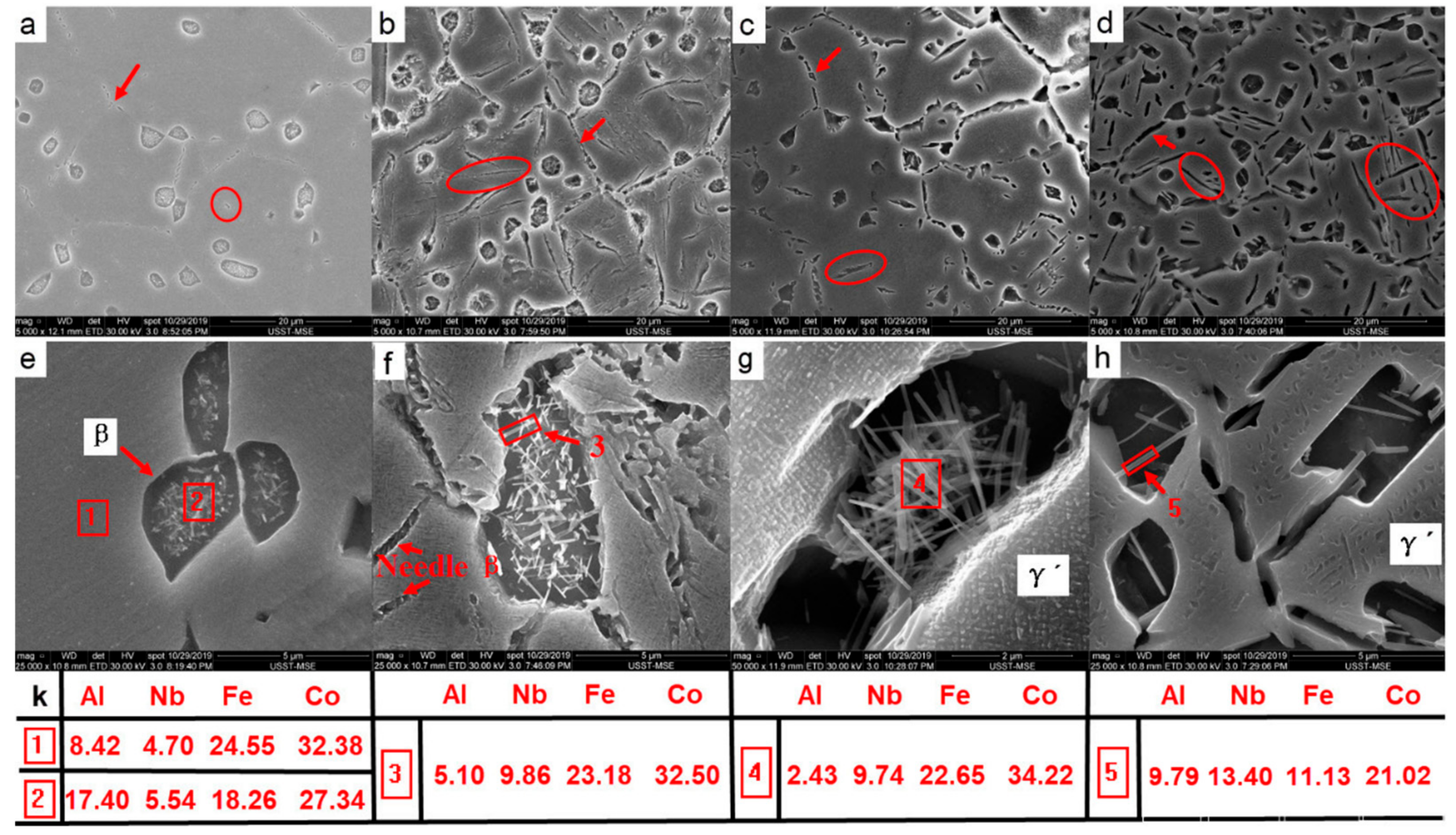

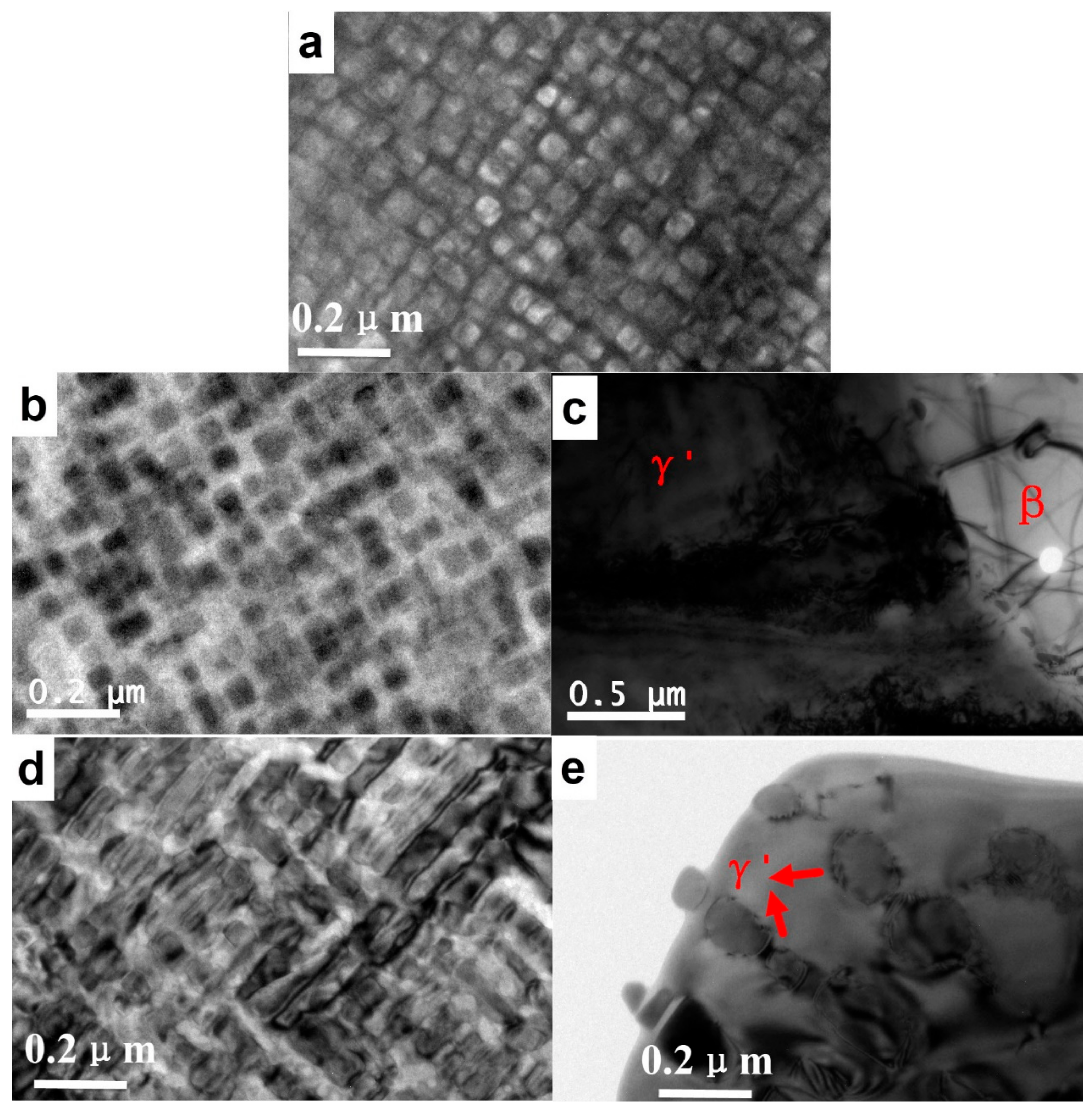

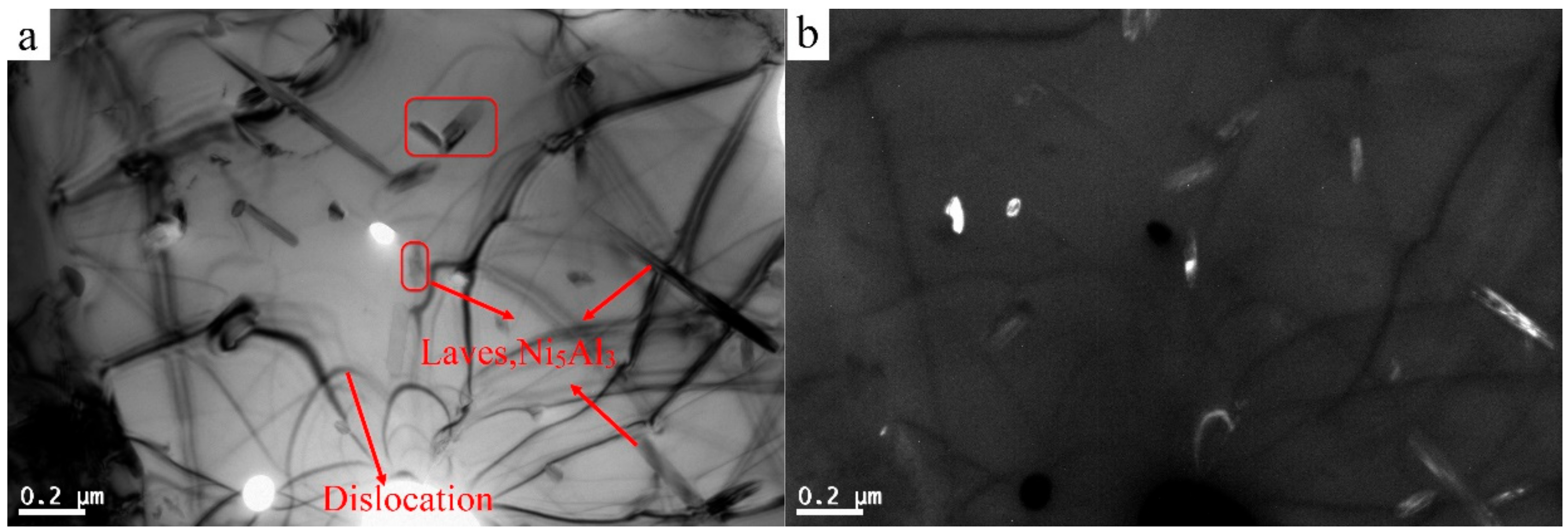

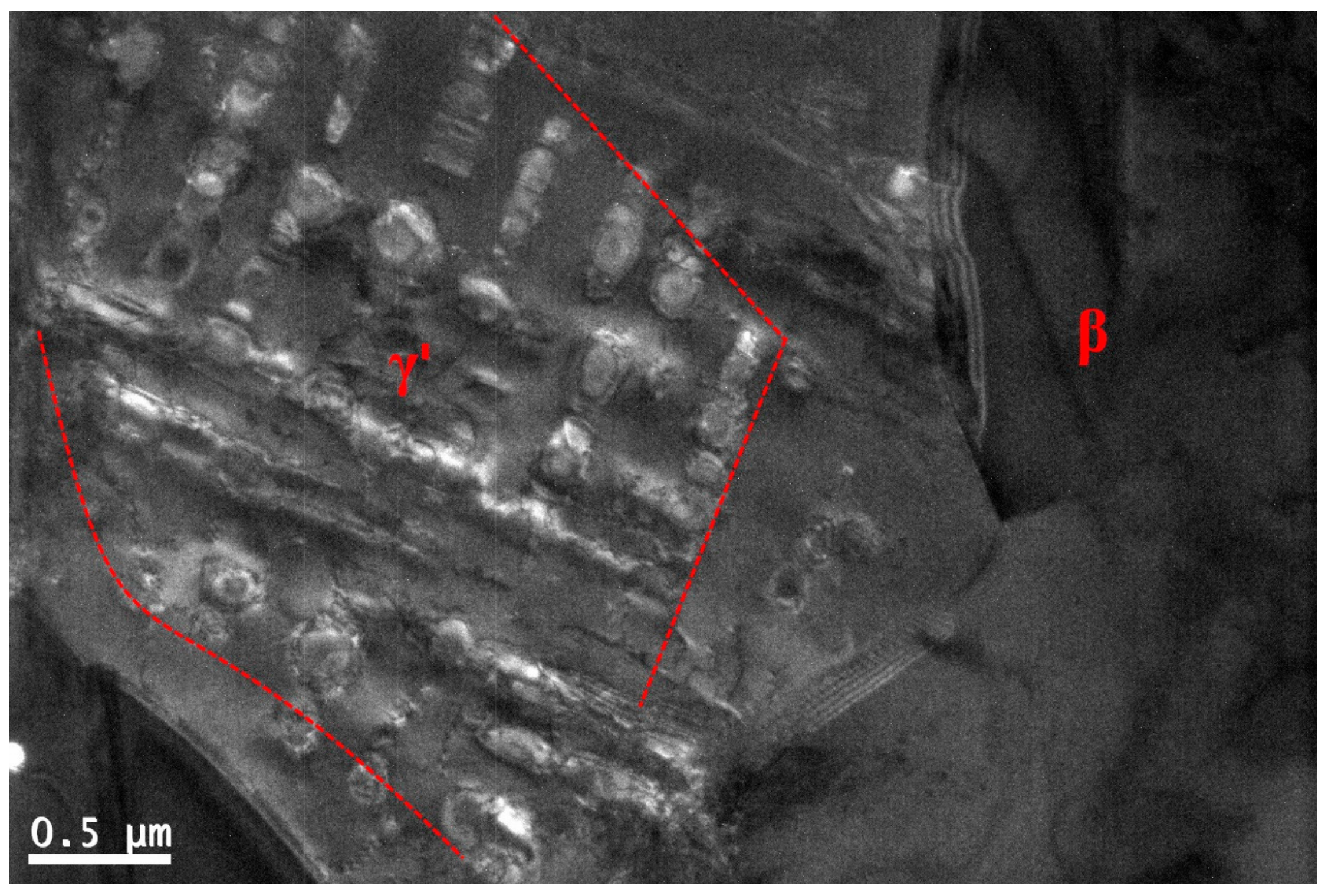

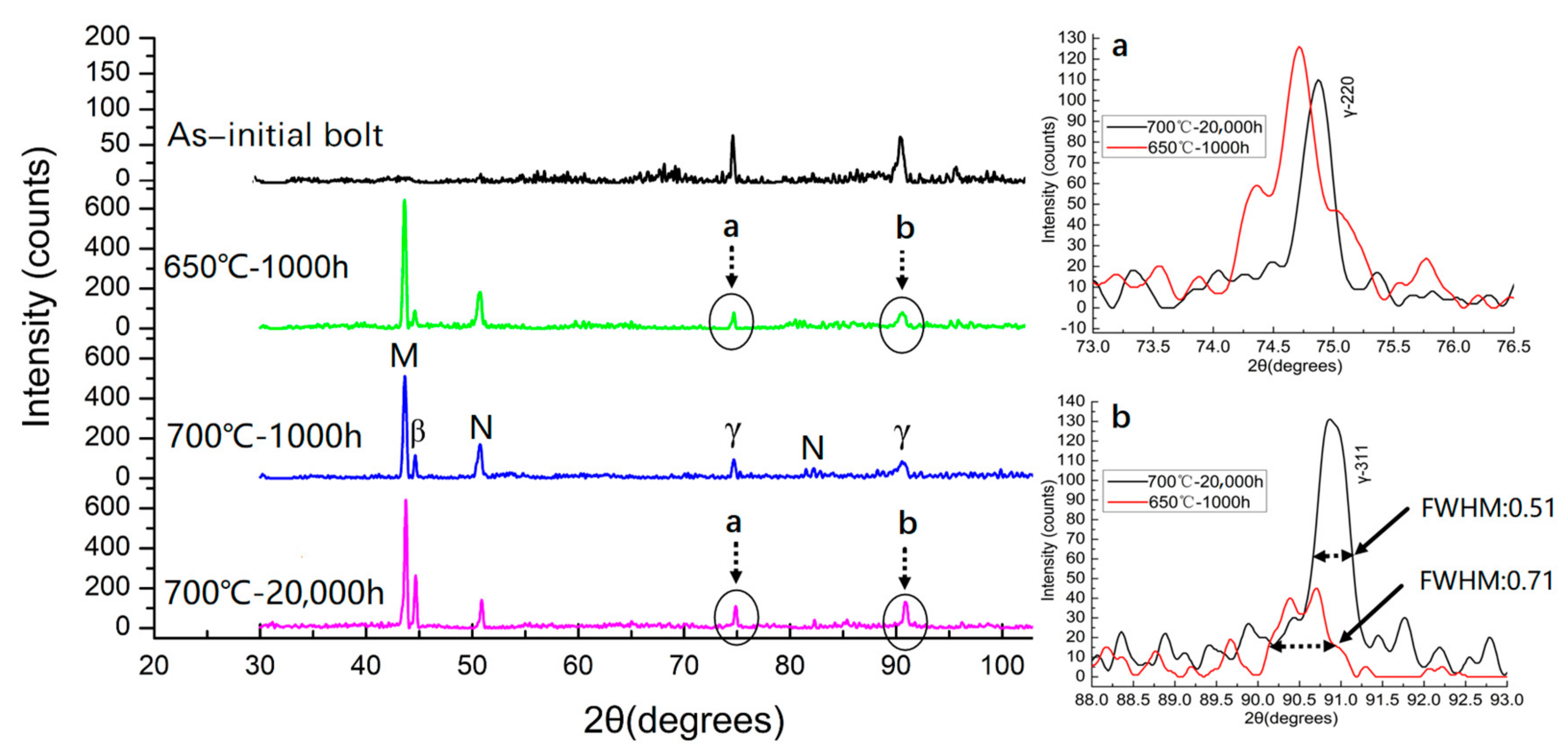

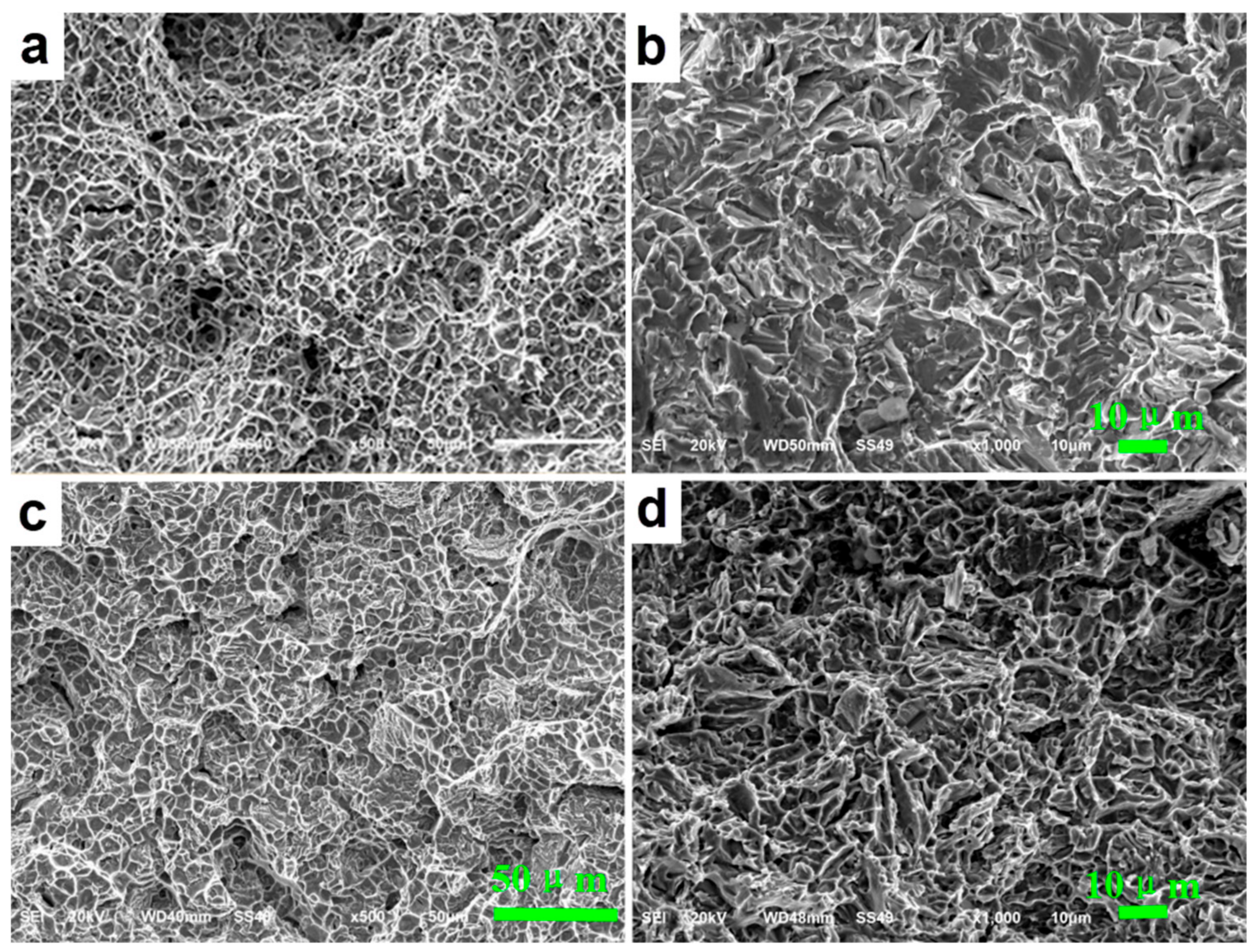

3.1. Morphology and Microstructure

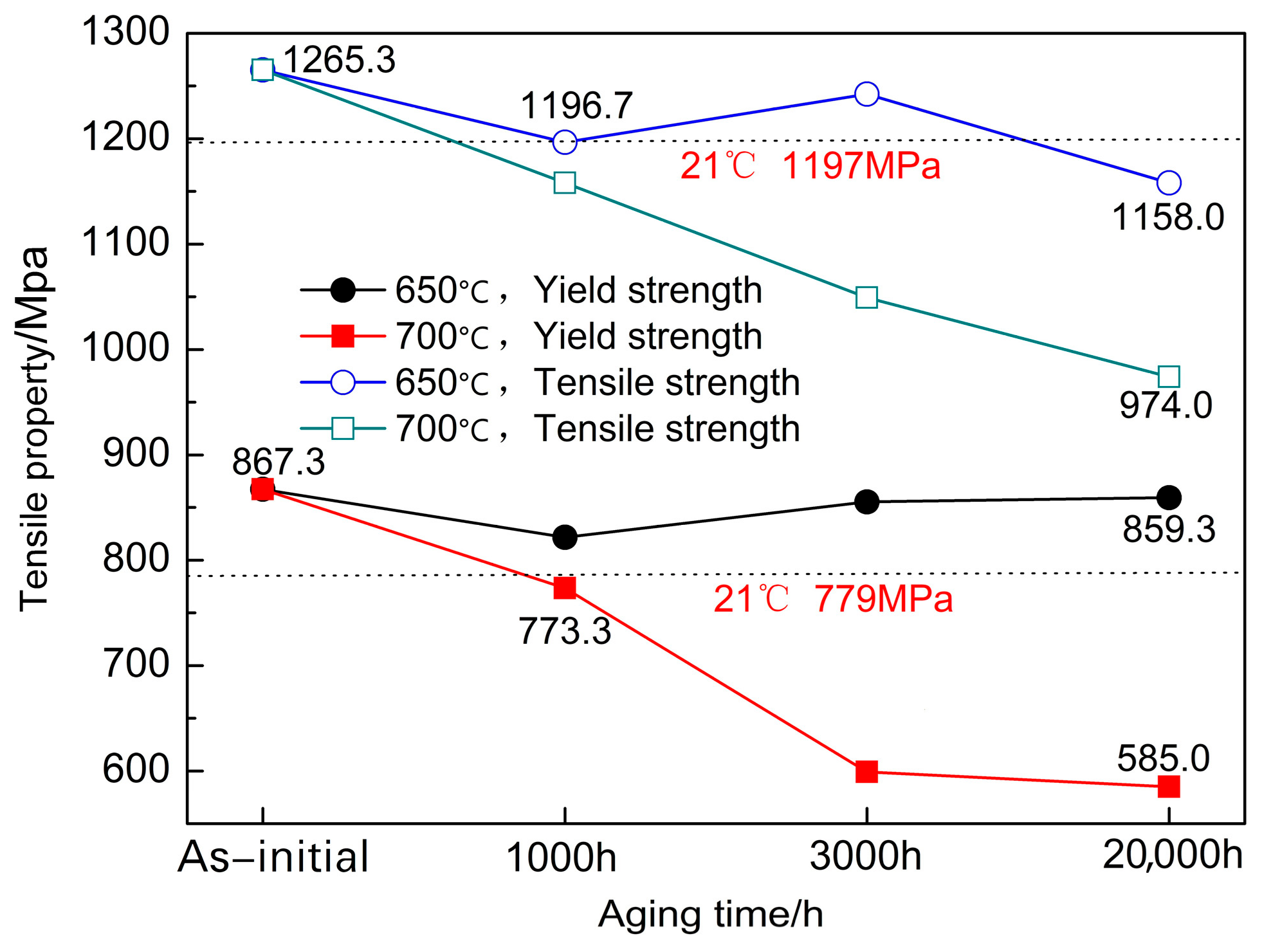

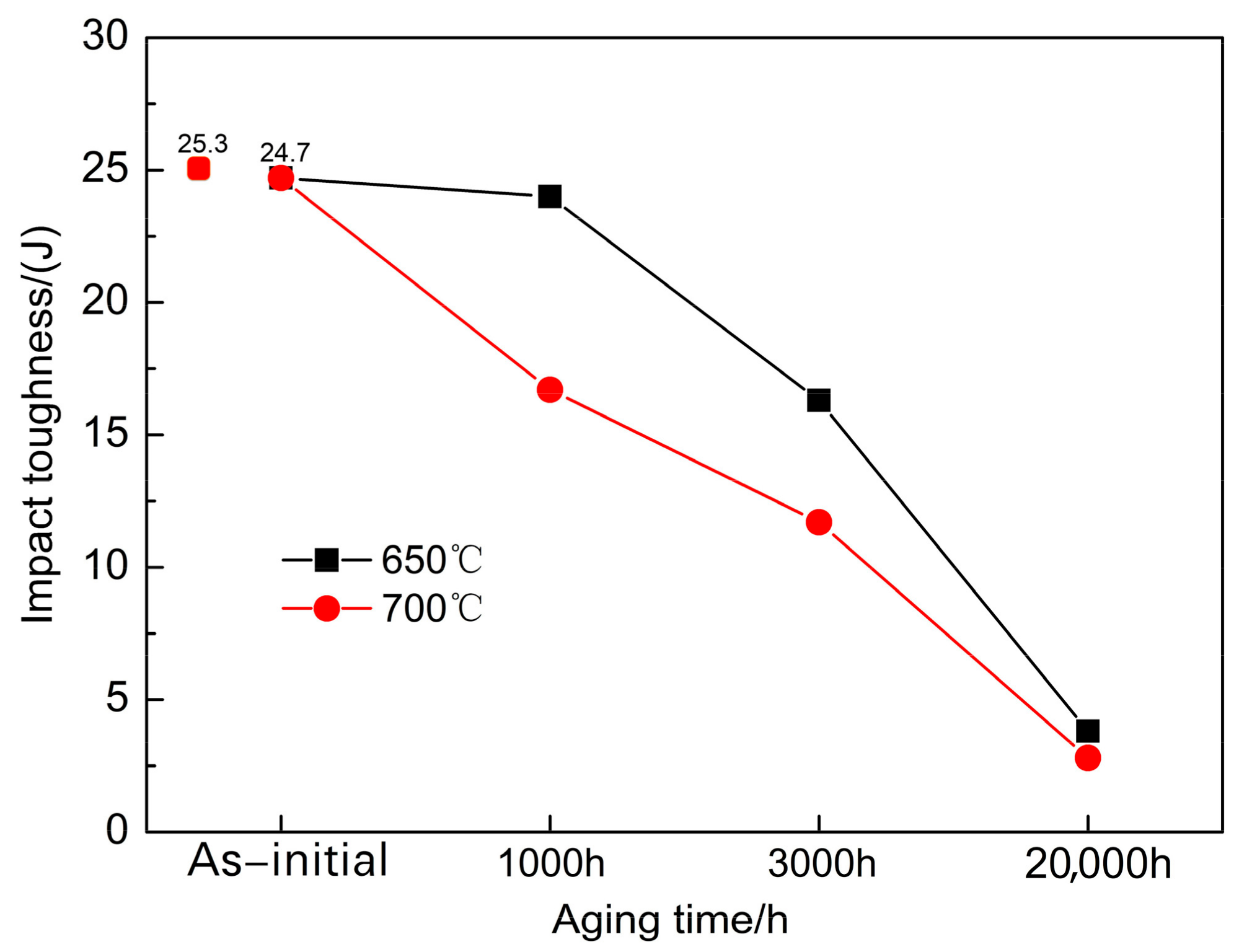

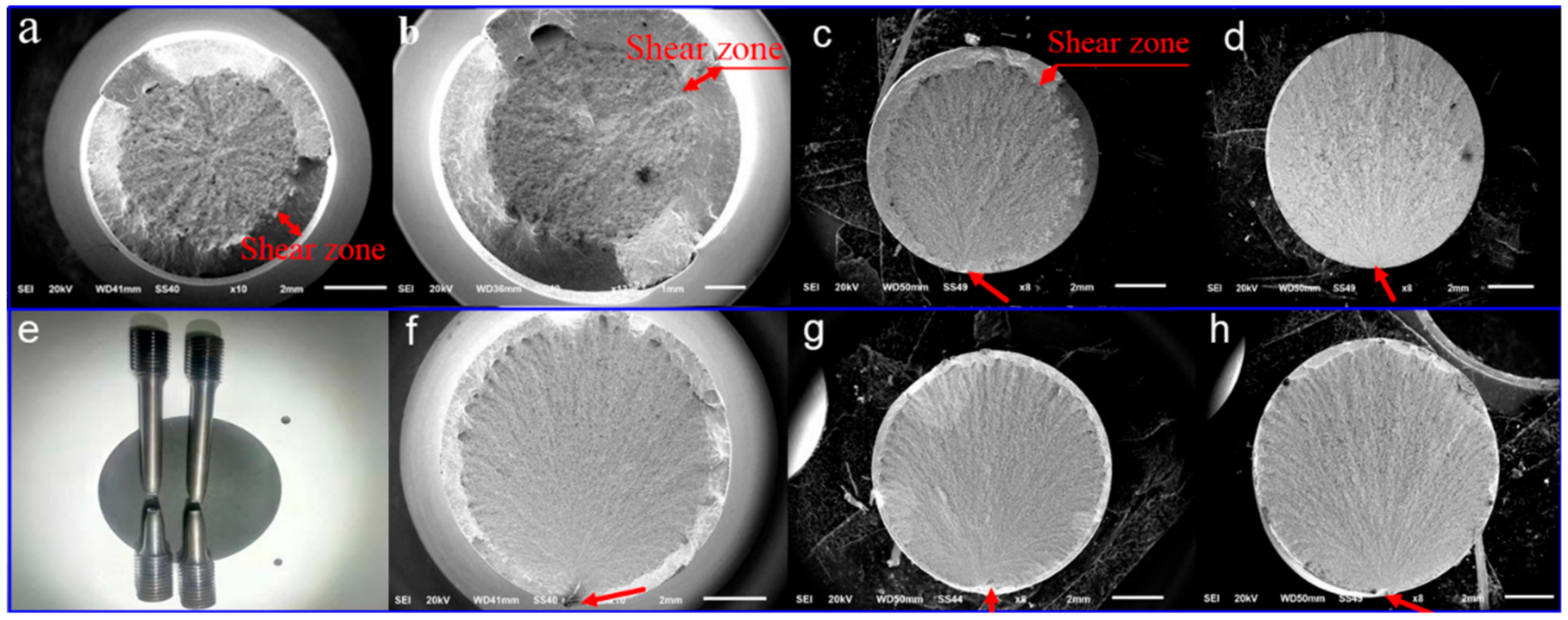

3.2. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Han, Z.S.; Du, J.F.; Liang, J.; Zhang, Z. Evolution of In783 alloy in microstructure and properties enduring different service times. Rare Met. 2018, 1–8. [Google Scholar] [CrossRef]

- Nagesha, A.; Goyal, S.; Valsan, M.; Rao, K.B.S.; Mannan, S.K. Low cycle fatigue behaviour of InconelR alloy 783. Trans. Indian Inst. Met. 2010, 63, 575–579. [Google Scholar] [CrossRef]

- Ma, L.; Chang, K.; Mannan, S.K. Oxide-induced crack closure: An explanation for abnormal time-dependent fatigue crack propagation behavior in Inconel alloy 783. Scr. Mater. 2003, 48, 583–588. [Google Scholar] [CrossRef]

- Heck, K.A.; Smith, J.S.; Smith, R. Inconel Alloy 783: An Oxidation Resistant, Low Expansion Superalloy for Gas Turbine Applications. J. Eng. Gas Turbines Power 1998, 120, 128–132. [Google Scholar] [CrossRef]

- Han, G.W.; Zhang, Y.Y. Variations in microstructure and properties of GH783 alloy after long term thermal exposure. Mater. Sci. Eng. A 2006, 441, 253–258. [Google Scholar] [CrossRef]

- Mannan, S.K.; Smith, G.D.; Patel, S.J. Thermal stability of Inconel alloy 783 at 593 °C and 704 °C. Superalloys 2004 2004, 627–635. [Google Scholar]

- Nagesha, A.; Goyal, S.; Nandagopal, M.; Parameswaran, P.; Sandhya, R.; Mathew, M.D.; Mannanc, S.K. Dynamic strain ageing in Inconel Alloy 783 under tension and low cycle fatigue. Mater. Sci. Eng. A 2012, 546, 34–39. [Google Scholar] [CrossRef]

- Sharghi-Moshatghin, R.; Asgari, S. The effect of thermal exposure on the γ’ characteristics in a Ni-base superalloy. J. Alloys Compd. 2004, 368, 144–151. [Google Scholar] [CrossRef]

- Ma, L.; Chang, K.M.; Mannan, S.K. Effects of NiAl-β precipitates on fatigue crack propagation of Inconel alloy 783 under time-dependent condition with various load ratios. Scr. Mater. 2003, 48, 551–557. [Google Scholar] [CrossRef]

- Kang, B.; Liu, X.; Cisloiu, C.; Chang, K.M. High temperature moiré interferometry investigation of creep crack growth of inconel 783-environment and β-phase effects. Mater. Sci. Eng. A 2003, 347, 205–213. [Google Scholar] [CrossRef]

- Han, G.W.; Dun, B.; Yang, Y.J. Investigation on Thermal Stability of Oxidation Resistant Low Thermal Expansion Superalloy Inconel 783 after Long Term Thermo-exposure. J. Iron Steel Res. 2011, 23, 278–281. [Google Scholar]

- Ma, L.; Chang, K. Effects of Different Metallurgical Processing on Microstructures and Mechanical Properties of Inconel Alloy 783. J. Mater. Eng. Perform. 2004, 12, 32–38. [Google Scholar] [CrossRef]

- Peng, Y.C.; Lou, Y.M.; Xu, S.P. Fracture failure analysis on Alloy783 bolts in medium-pressure valve bonnets of USC units. Therm. Power Gener. 2018, 47, 115–122. [Google Scholar]

- Jia, R.F.; Li, L.; Qin, C.P. Failure Analysis of IN783 Alloy Bolt Used on 1000MW Ultra Supercritical Steam Turbine. Turbine Technol. 2018, 61, 78–81. [Google Scholar]

- Luo, C.; Qian, Y.J.; Liu, J.J. Fracture Cause of Inconel783 Alloy Bolt in Medium-Pressure Contronl Valve of Ultra-supercritical Unit. Mater. Mech. Eng. 2019, 43, 71–79. [Google Scholar]

- Jiang, T.; Chen, L.; Jiang, F.; Cai, H.; Sun, J. Microstructural evolution and mechanical properties of a nickel-based superalloy through long-term service. Mater. Sci. Eng. A 2016, 656, 184–189. [Google Scholar] [CrossRef]

- Special Metals. INCONEL® Alloy 783. Publication Number SMC-064. 2004. Available online: www.specialmetals.com (accessed on 18 October 2020).

- Mannan, S.; Debarbadillo, J. Long Term Thermal Stability of Inconel Alloy 783. In Proceedings of the ASME 1998 International Gas Turbine and Aeroengine Congress and Exhibition, Stockholm, Sweden, 2–5 June 1998. [Google Scholar]

- Li, C.F.; Ren, Y.P.; Qin, G.W. Experimental confirmation of Ni5Al3 phase in Ni-Al binary system by diffusion couple technique. Adv. Mater. Res. 299–300, 224–227.

- Robertson, M.; Wayman, C.M. Ni5Al3 and the nickel-aluminum binary phase diagram. Metallography 1984, 17, 43–55. [Google Scholar] [CrossRef]

- Khadkikar, P.S.; Vedula, K. An investigation of the Ni5Al3 phase. J. Mater. Res. 1987, 2, 163–167. [Google Scholar] [CrossRef]

- Cheng, T. Ni5Al3 phase in heat cycled nickel-rich NiAl. J. Mater. Sci. Lett. 1996, 15, 285–289. [Google Scholar] [CrossRef]

- Duan, P.; Liu, Z.; Li, B.; Wang, Q.; Gu, S. Effect of aging at 650 °C on microstructure and mechanical properties of GH783 alloy bolts. Eng. Fail. Anal. 2020, 118, 104853. [Google Scholar] [CrossRef]

- Duan, Y.P.; Gu, S.C.; Zhang, Z.G.; Wen, M. Characterization of structures and novel magnetic response of Fe87.5Si7Al5.5 alloy processed by ball milling. J. Alloys Compd. 2012, 542, 90–96. [Google Scholar] [CrossRef]

- Duan, Y.P.; Zhang, Y.H.; Wang, T.G.; Gu, S.C.; Li, X.; Lv, X.J. Evolution study of microstructure and electromagnetic behaviors of Fe-Co-Ni alloy with mechanical alloying. Mater. Sci. Eng. B 2014, 185, 86–93. [Google Scholar]

- Robertson, J.H. Elem. of x-ray diffraction by BD Cullity. Acta Crystallogr. Sect. A Cryst. Phys. Diffr. Theor. Gen. Crystallogr. 1979, 35, 350. [Google Scholar]

- Burton, A.W.; Ong, K.; Rea, T.; Chan, I.Y. On the estimation of average crystallite size of zeolites from the scherrer equation: A critical evaluation of its application to zeolites with one dimensional pore systems. Microporous Mesoporous Mater. 2009, 117, 75–90. [Google Scholar] [CrossRef]

- Qi, H.Y.; Yang, J.S.; Yang, X.G.; Li, S.L. Low-cycle fatigue behavior of a directionally solidified Ni-based superalloy subjected to gas hot corrosion pre-exposure. Rare Met. 2019, 38, 227–232. [Google Scholar] [CrossRef]

- Yang, J.H.; Wayman, C.M. On the Ni5Al3 phase and yield strengthated phenomena in a NiAlFe alloy. Mater. Sci. Eng. A 1993, 160, 241–249. [Google Scholar] [CrossRef]

| Element | Ni | Fe | Co | Al | Nb | Ti | Cr |

|---|---|---|---|---|---|---|---|

| Bolts | 28.8 ± 0.4 | 26.2 ± 0.4 | Remainder | 5.36 ± 0.3 | 3.02 ± 0.3 | 0.20 ± 0.05 | 3.01 ± 0.3 |

| Special Metals [17] | 26.0–30.0 | 24.0–27.0 | Remainder | 5.0–6.0 | 2.5–3.5 | 0.1–0.4 | 2.5–3.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, P.; Liu, Z.; Gu, S.; Wang, S. Evolution in Microstructure and Mechanical Properties of Inconel 783 Alloy Bolts after Long Term High-Temperature Aging at 700 °C. Metals 2020, 10, 1440. https://doi.org/10.3390/met10111440

Duan P, Liu Z, Gu S, Wang S. Evolution in Microstructure and Mechanical Properties of Inconel 783 Alloy Bolts after Long Term High-Temperature Aging at 700 °C. Metals. 2020; 10(11):1440. https://doi.org/10.3390/met10111440

Chicago/Turabian StyleDuan, Peng, Zongde Liu, Shuchao Gu, and Song Wang. 2020. "Evolution in Microstructure and Mechanical Properties of Inconel 783 Alloy Bolts after Long Term High-Temperature Aging at 700 °C" Metals 10, no. 11: 1440. https://doi.org/10.3390/met10111440

APA StyleDuan, P., Liu, Z., Gu, S., & Wang, S. (2020). Evolution in Microstructure and Mechanical Properties of Inconel 783 Alloy Bolts after Long Term High-Temperature Aging at 700 °C. Metals, 10(11), 1440. https://doi.org/10.3390/met10111440