A Study on Cross-Shaped Structure of Invar Material Using Cold Wire Laser Fillet Welding (PART I: Feasibility Study for Weldability)

Abstract

1. Introduction

2. Experiment

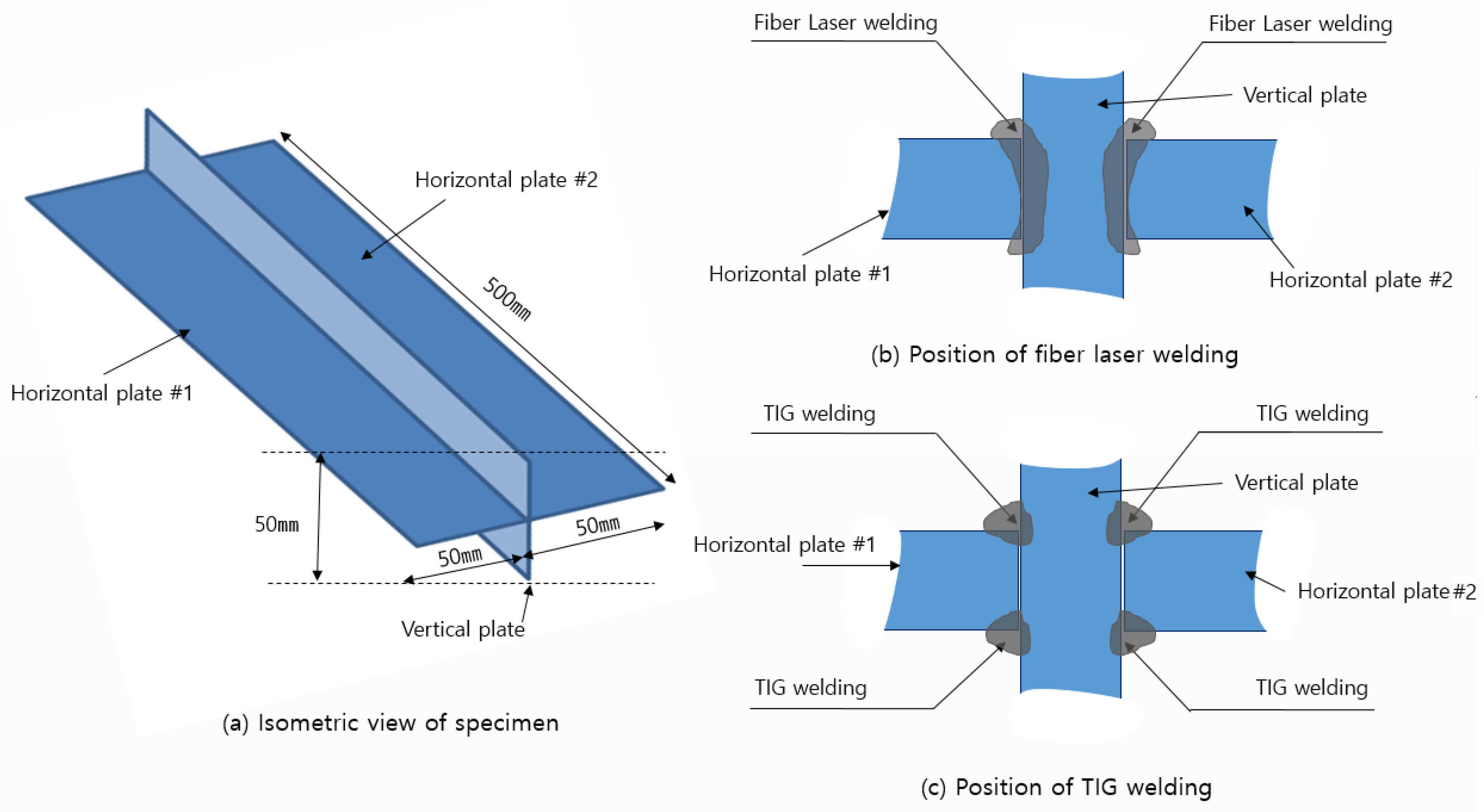

2.1. Specimen for Experiment

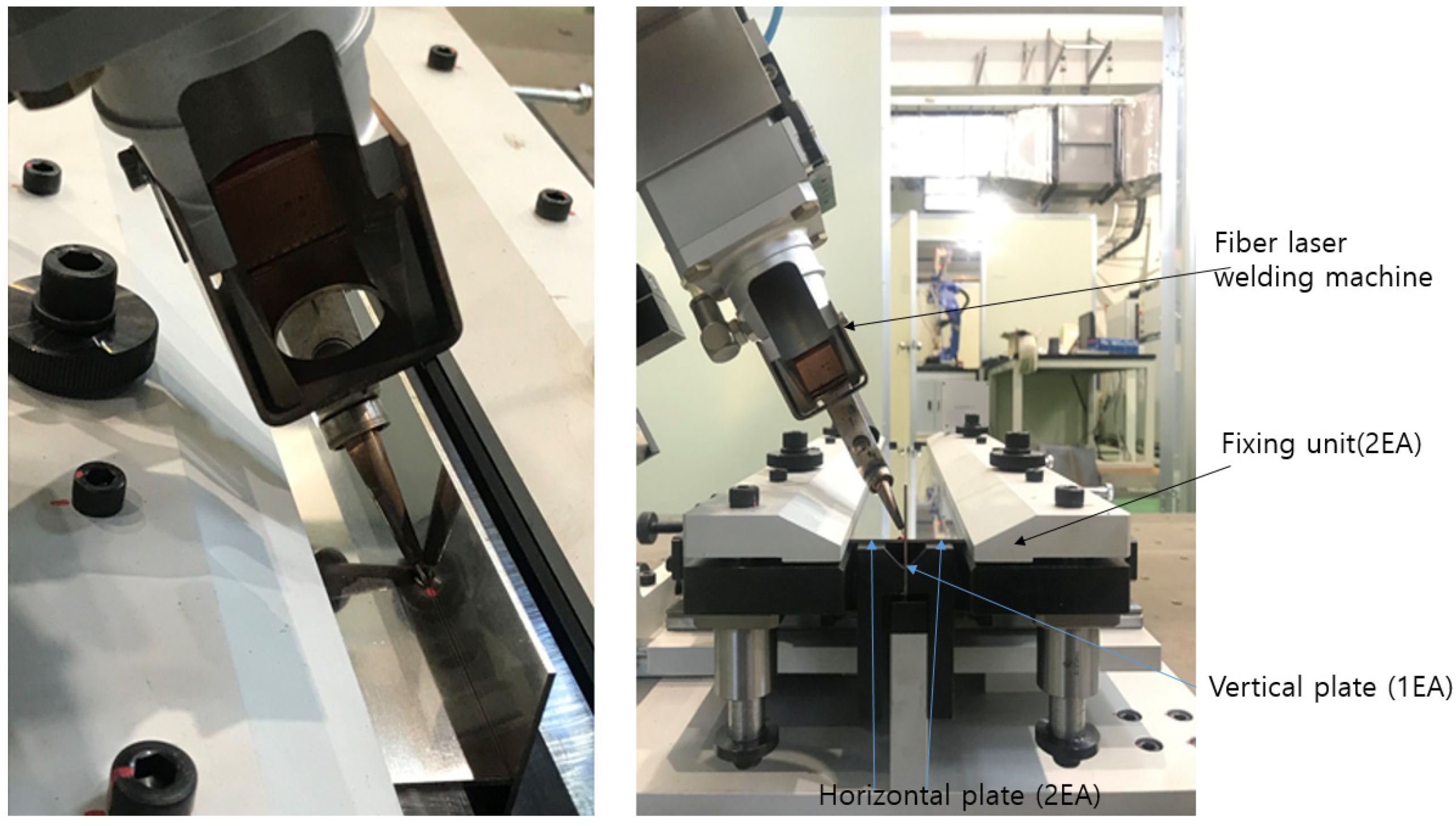

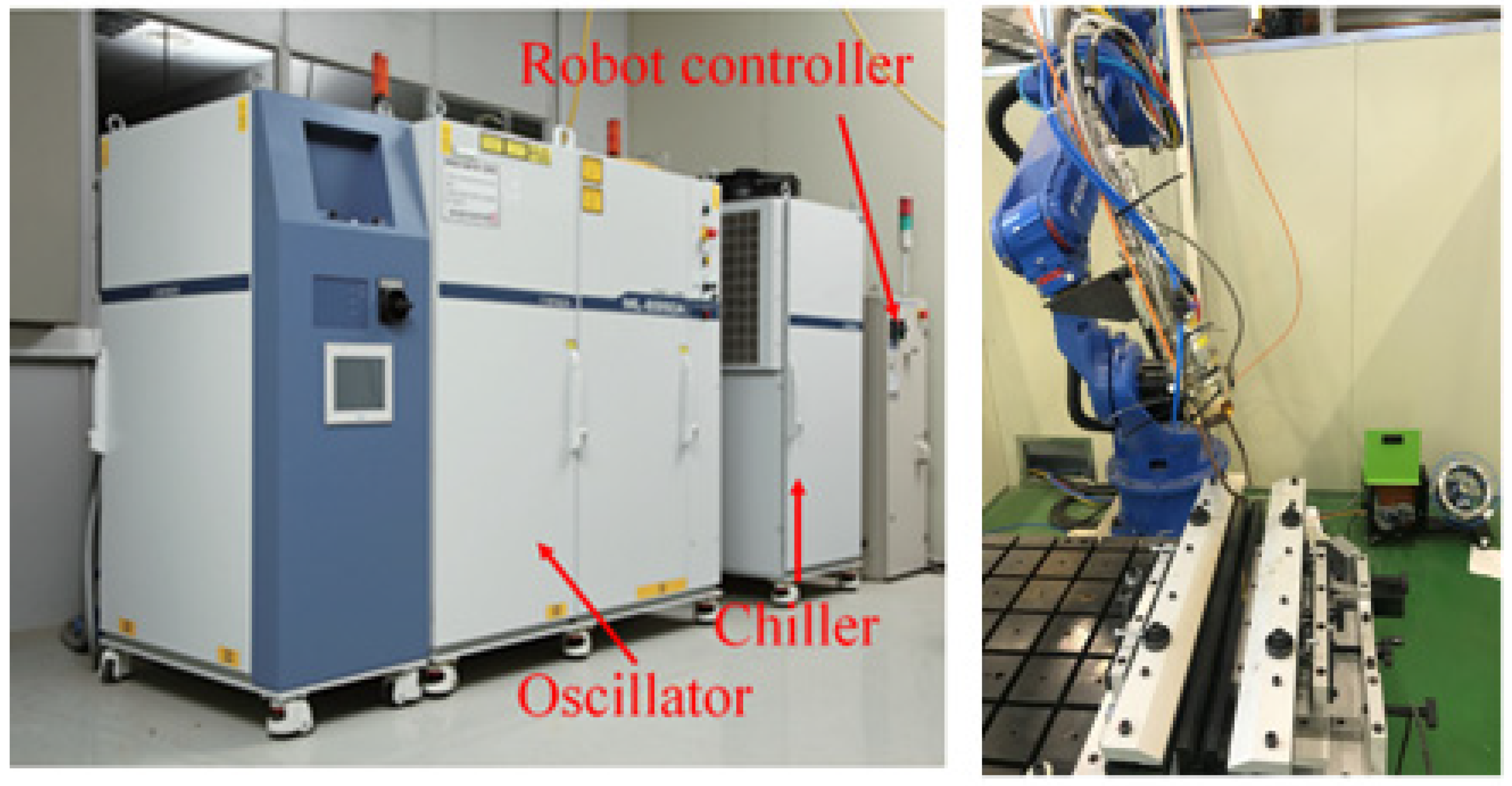

2.2. Laser Welding Using Fiber Laser System

2.3. Examination of Cross-Section

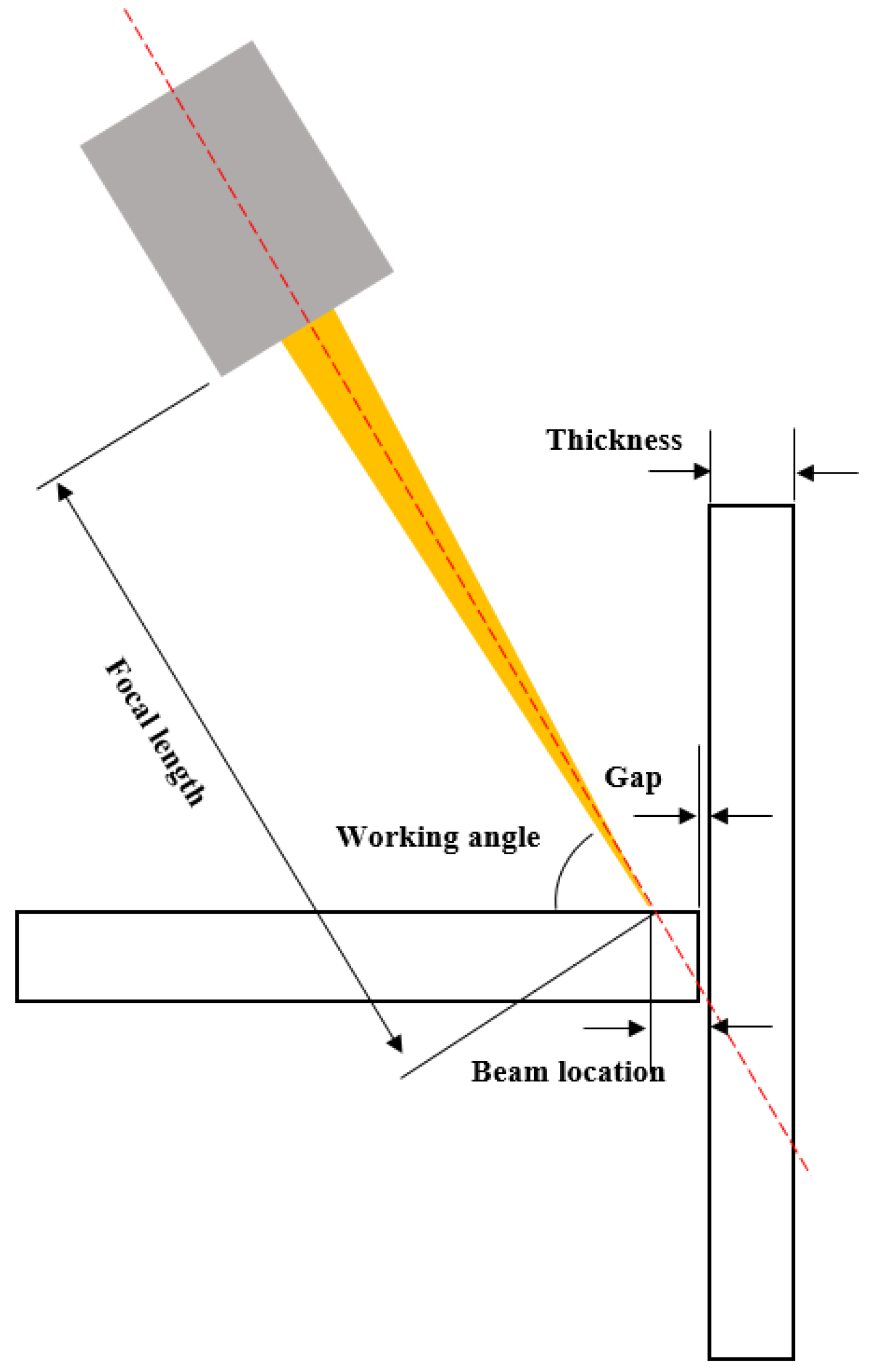

2.4. Experimental Conditions of Cold Wire Laser Welding Using Fiber Laser

3. Results

3.1. 1.5 mm Thickness of Invar Experiment

3.2. 3.0 mm Thickness of Invar Experiment

4. Discussion

5. Conclusions

- (1)

- When fabricating a cross-shaped structure through general TIG welding, fillet welding should be performed for each of the four corners with PJP. However, fillet welding is performed for two corners only to reduce the number of weld passes if the fiber laser fillet welding method proposed in this study is used because of the deep keyhole of CJP. In addition, the overall welding time can be reduced to less than one quarter of the time required for TIG welding, because laser welding using fiber laser speed is two times faster.

- (2)

- Using laser power, wire feeding speed, working angle, and beam location as variables, the welding conditions for two corner fillet welding were determined. At this time, welding was performed using a trial and error method, in which each variable was changed and its feasibility was verified through cross-section examination.

- (3)

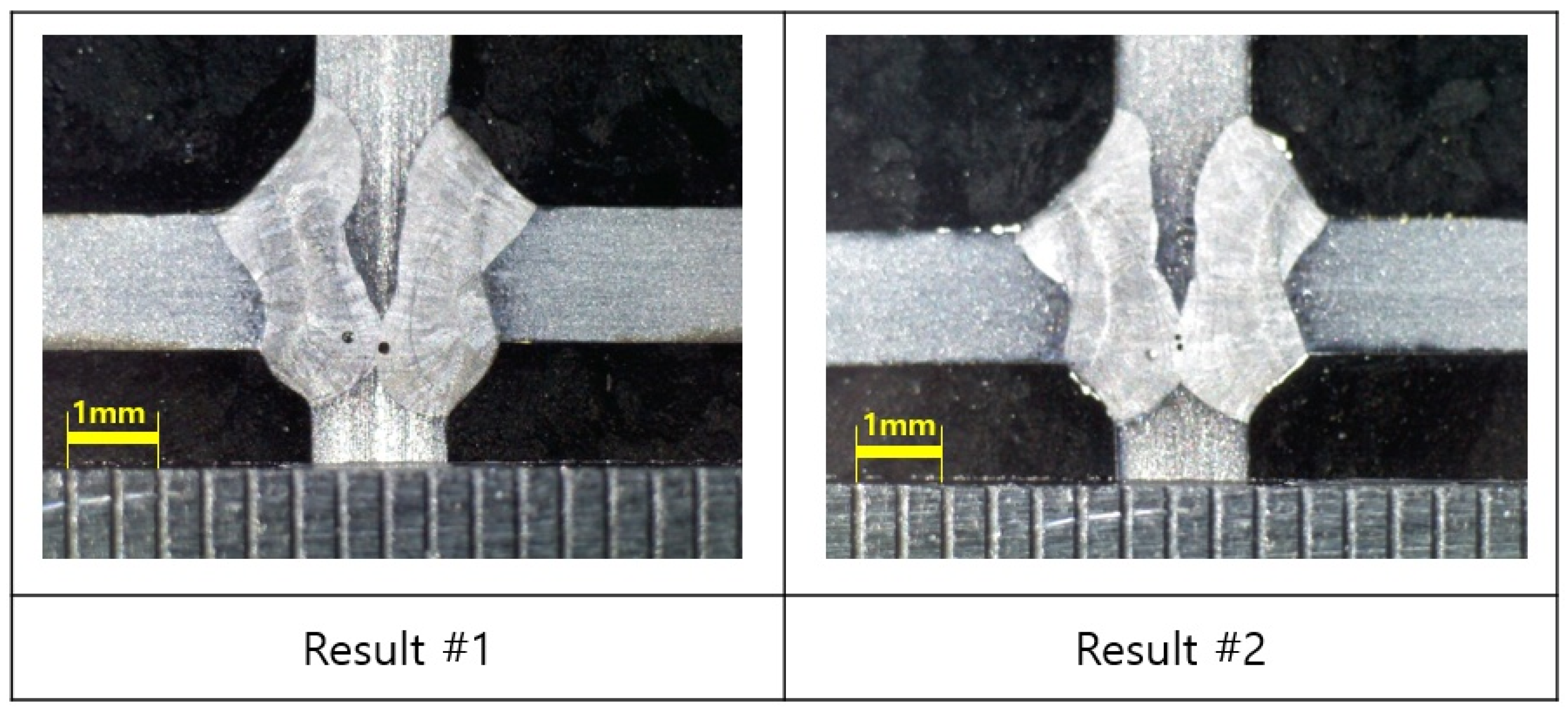

- To fabricate a cross-shaped Invar structure with 1.5 mm thickness, welding feasibility was achieved under the conditions of laser power of 1.75 kW, wire feeding speed of 1.5 m/min, working angle of 70°, and beam location of 0 mm. For the 3.0 mm Invar structure, welding feasibility was achieved under the conditions of laser power of 3.0 kW, wire feeding speed of 3.5 m/min, working angle of 70°, and beam location of 0.5 mm. Although those conditions are the best trials of this research, there could be other conditions for the feasibility for weldability.

- (4)

- This study is a preliminary study for improving the fabrication method of cross-shaped Invar structures using fiber laser fillet welding. Subsequent studies should aim to verify the soundness of such welded structures through tests of mechanical properties such as hardness, strength, and fatigue, in addition to checking for welding defects using ultrasonic and X-ray testing. Moreover, for obtaining the metallurgical soundness, a follow-up study will be performed including finding the condition for the removal of the porosity after welding.

Author Contributions

Funding

Conflicts of Interest

References

- Schinas, O.; Butler, M. Feasibility and commercial considerations of LNG-fueled ships. Ocean Eng. 2016, 122, 84–96. [Google Scholar] [CrossRef]

- Yoo, B. Economic assessment of liquefied natural gas (LNG) as a marine fuel for CO2 carriers compared to marine gas oil (MGO). Energy 2017, 121, 772–780. [Google Scholar] [CrossRef]

- Thomson, H.; Corbett, J.; Winebrake, J. Natural gas as a marine fuel. Energy Policy 2015, 87, 153–167. [Google Scholar] [CrossRef]

- Lee, J.; Yoo, W.; Yoo, C.; Kim, K.; Kim, Y. An experimental study on fatigue performance of cryogenic metallic materials for IMO type B tank. Int. J. Nav. Arch. Ocean 2013, 5, 580–597. [Google Scholar] [CrossRef]

- IMO. Sub-Committee on Carriage of Cargoes and Containers (CCC), 5th session 10–14 September 2018. Available online: http://www.imo.org/en/MediaCentre/MeetingSummaries/CCC/Pages/CCC-5-5th-session.aspx (accessed on 17 September 2020).

- Kim, B.; Park, J.; Lee, J.; Kim, M. Study on the initial design of an LNG fuel tank using 9 wt. % Nickel steel for ships and performance evaluation of the welded joint. J. Weld. Join. 2019, 37, 555–563. [Google Scholar] [CrossRef]

- Na, K.; Lee, C.; Park, J.; Cho, S. A comparison of hot cracking in GTAW and FCAW by applying alloy 525 filler materials of 9% Ni Steel. J. Weld. Join. 2019, 37, 357–362. [Google Scholar] [CrossRef]

- Matweb Material Property Data. Available online: http://matweb.com (accessed on 29 September 2020).

- Wei, K.; Yang, Q.; Ling, B.; Yang, X.; Xie, H.; Qu, Z.; Fang, D. Mechanical propertied of Invar 36 alloy additively manufactured by selective laser melting. Mater. Sci. Eng. A 2020, 772, 138799. [Google Scholar] [CrossRef]

- Nohara, K.; Ejima, A. Fe-36% Ni Invar type alloy KLN 36 for LNG Facilities. Kawasaki Steel Tech. Rep. 1985, 13, 97–108. [Google Scholar]

- Hwang, S.; Lee, J. Comparative Study on the thermal insulation of membrane LNG CCS by heat transfer analysis. J. Comput. Struct. Eng. Inst. Korea 2016, 29, 53–60. [Google Scholar] [CrossRef][Green Version]

- Han, J. A study on application of corrugated Invar strake edge in the membrane cargo containment of LNG carriers. J. KWJS 2009, 27, 544–550. [Google Scholar]

- Han, K.; Kim, D.; Yun, K.; Shin, Y.; Lee, H. Effect of Al and Zn coated layer of scaffolding on weldability of cryogenic material in LNG Carrier. J. Weld. Join. 2019, 37, 9–14. [Google Scholar] [CrossRef]

- LNG Shipping Knowledge, 2nd ed.; Witherby Publishing Group Ltd.: Edinburgh, UK, 2011; pp. 74–97.

- OSAKA GAS. Available online: https://gps.osakagas.co.jp/daigas_gps/en/businessdomain/terminal/invar_alloy (accessed on 7 September 2020).

- Kim, J.; Kim, J. Laser Welding of ASTM A553-1 (9% Nickel Steel) (PART II: Comparison of Mechanical Properties with FCAW). Metals 2020, 10, 999. [Google Scholar] [CrossRef]

- Shibata, K.; Sakamoto, H.; Iwase, T. Laser-MIG Hybrid Welding of Aluminum Alloys. Weld. World 2006, 50, 28–34. [Google Scholar] [CrossRef]

- Mirakhorli, F.; Nadeau, F.; Guillemette, C. Single pass laser cold wire welding of thick section AA6061-T6 aluminum alloy. J. Laser Appl. 2018, 30, 032421. [Google Scholar] [CrossRef]

- Nasstrom, J.; Frostwvarg, J.; Silver, T. Hot wire laser welding of deep and wide gaps. Phys. Procedia 2015, 78, 247–254. [Google Scholar] [CrossRef]

- Casalino, G. Statistical analysis of MIG-laser CO2 hybrid welding of Al–Mg alloy. J. Mater. Process. Technol. 2007, 191, 106–110. [Google Scholar] [CrossRef]

| Materials | CTE (mm/mmK) | Young’s Modulus (GPa) | Density (kg/m3) |

|---|---|---|---|

| Invar | 1.2 × 10−6 | 148 | 8100 |

| A240-304L | 17.3 × 10−6 | 193 | 8000 |

| AL5083-O | 23.8 × 10−6 | 71 | 2660 |

| Material | Composition (%) | ||||

|---|---|---|---|---|---|

| Invar (ASTM F1684) | Ni | Mo | C | Mn | Fe |

| 36 | ~0.5 | ~0.1 | ~0.06 | bal. | |

| P | S | Si | Cr | - | |

| ~0.025 | ~0.025 | ~0.35 | ~0.5 | - | |

| Variables | Cases |

|---|---|

| Laser Power (kW) | 1.25, 1.75, 2.00, 2.25 |

| Wire Feeding Speed (m/min) | 1.00, 1.25, 1.50, 1.75 |

| Working Angle (°) | 60, 70, 80 |

| Welding Speed (m/min) | 1.0 |

| Beam Location (mm) | 0 |

| Variables | Cases |

|---|---|

| Laser Power (kW) | 1.75, 2.25, 2.75, 3.25 |

| Wire Feeding Speed (m/min) | 1.75, 2.00, 2.25, 2.50, 3.00, 3.50 |

| Working Angle (°) | 70, 75, 80, 85 |

| Welding Speed (m/min) | 1.0 |

| Beam Location (mm) | 0.25, 0.5, 1.0 |

| Variable | Value | Variable | Value |

|---|---|---|---|

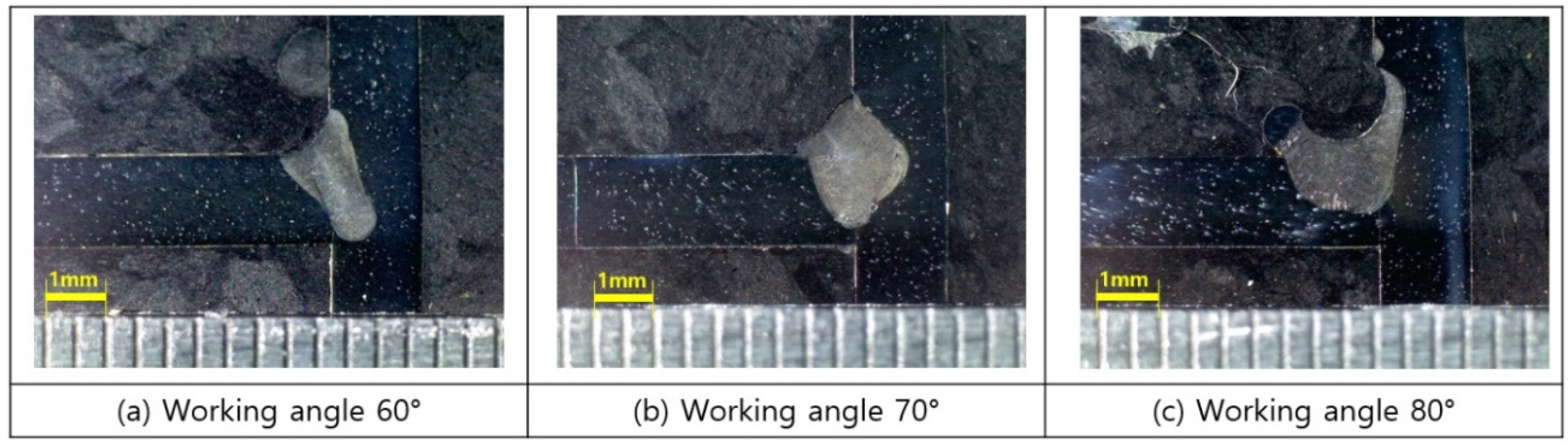

| Laser Power (kW) | 1.25 | Working Angle (°) | 60, 70, 80 |

| Wire Feeding Speed (m/min) | 1.0 | Beam Location (mm) | 0.0 |

| Variable | Value | Variable | Value |

|---|---|---|---|

| Laser Power (kW) | 1.75, 2.0, 2.25 | Working Angle (°) | 70 |

| Wire Feeding Speed (m/min) | 1.0 | Beam Location (mm) | 0.0 |

| Variable | Value | Variable | Value |

|---|---|---|---|

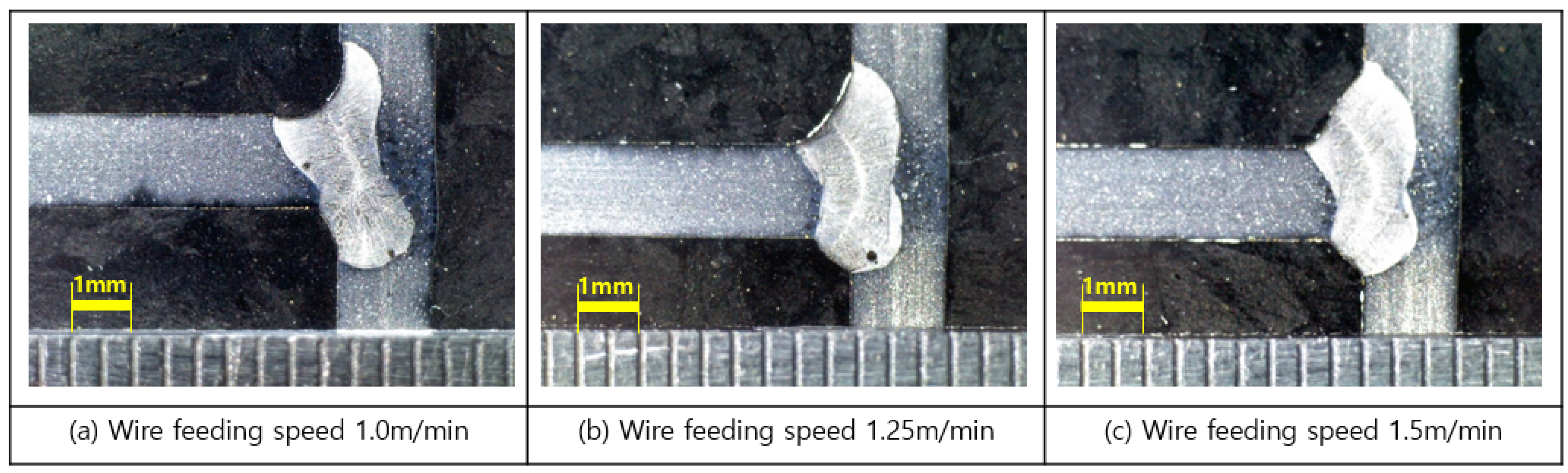

| Laser Power (kW) | 1.75, 2.0 | Working Angle (°) | 70 |

| Wire Feeding Speed (m/min) | 1.0, 1.25, 1.50, 1.75 | Beam Location (mm) | 0.0 |

| Variable | Value | Variable | Value |

|---|---|---|---|

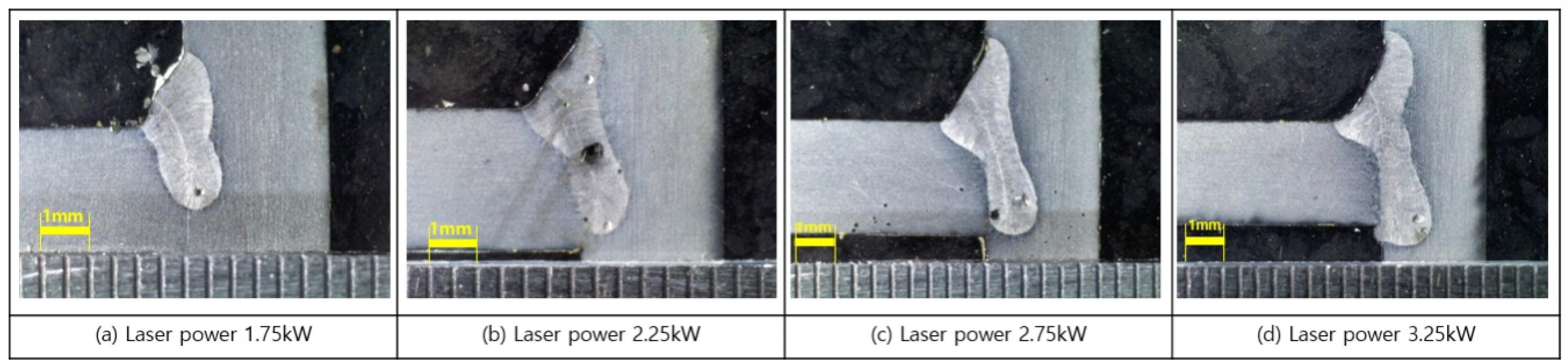

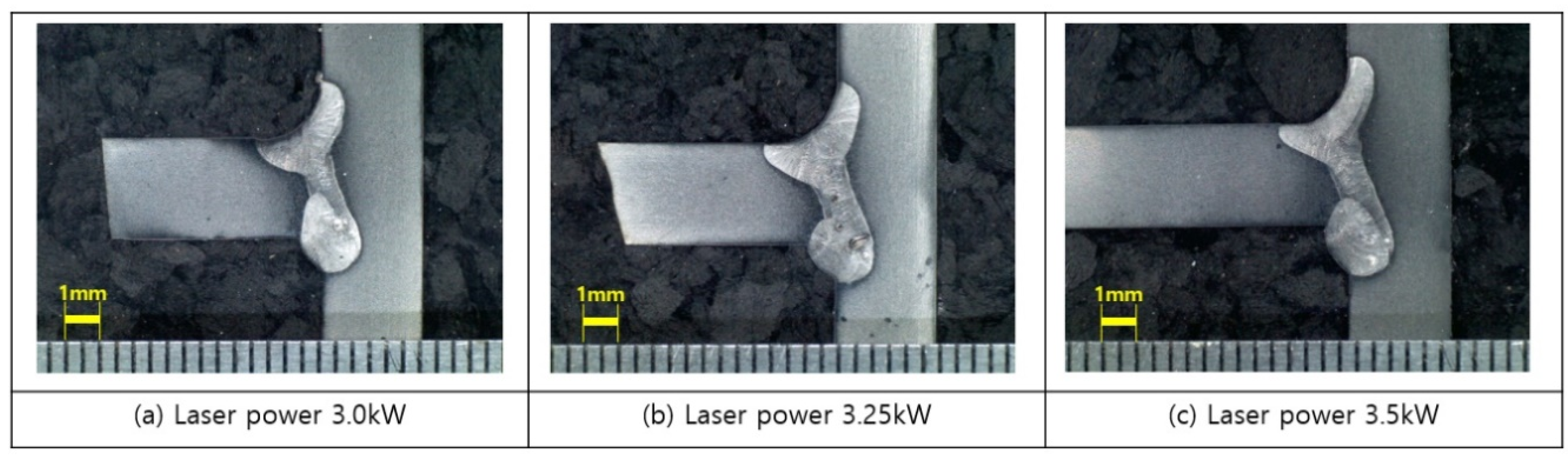

| Laser Power (kW) | 1.75, 2.25, 2.75, 3.25 | Working Angle (°) | 70 |

| Wire Feeding Speed (m/min) | 1.5 | Beam Location (mm) | 0.0 |

| Variable | Value | Variable | Value |

|---|---|---|---|

| Laser Power (kW) | 3.0, 3.25, 3.5 | Working Angle (°) | 70 |

| Wire Feeding Speed (m/min) | 1.5 | Beam Location (mm) | 0.5, 1.0 |

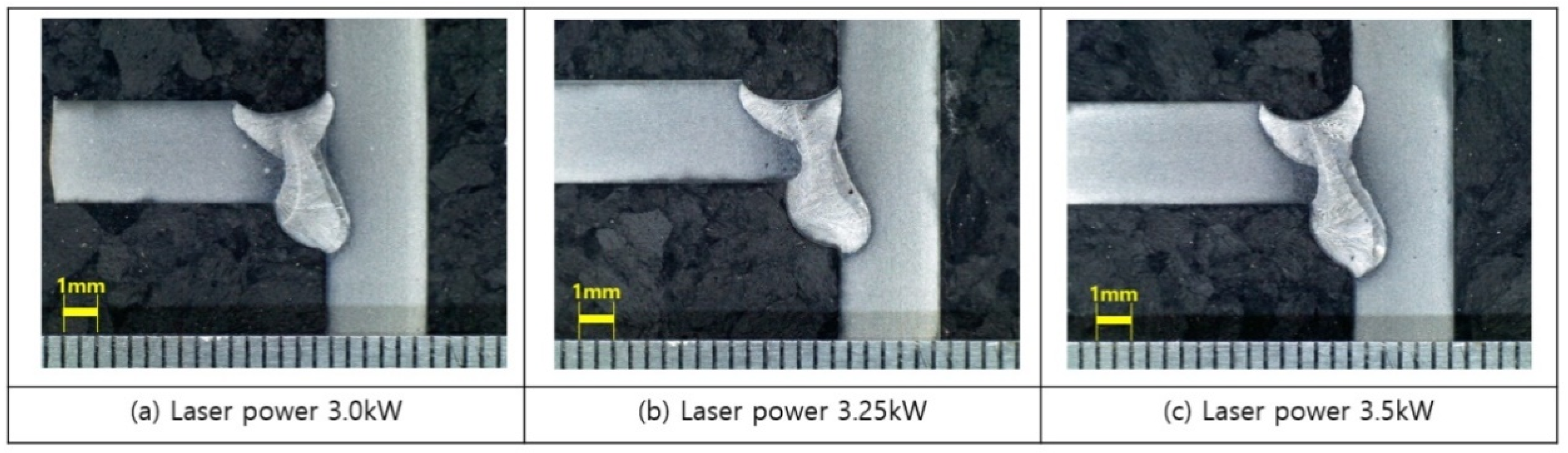

| Variable | Value | Variable | Value |

|---|---|---|---|

| Laser Power (kW) | 3.0 | Working Angle (°) | 70 |

| Wire Feeding Speed (m/min) | 1.75, 2.0, 2.25, 2.5, 3.0, 3.5 | Beam Location (mm) | 0.25, 0.5 |

| Welding Type | Welding Speed (m/min) | Number of Welding | Welding Time (s) (5 m Length Structure) |

|---|---|---|---|

| Fiber Laser Fillet Welding | 1.0 | 2 | 600 |

| TIG Welding | 0.5 | 4 | 2400 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, D.-S.; Pyo, C.; Kim, J.; Kim, J.; Lee, H.-K. A Study on Cross-Shaped Structure of Invar Material Using Cold Wire Laser Fillet Welding (PART I: Feasibility Study for Weldability). Metals 2020, 10, 1385. https://doi.org/10.3390/met10101385

Kim D-S, Pyo C, Kim J, Kim J, Lee H-K. A Study on Cross-Shaped Structure of Invar Material Using Cold Wire Laser Fillet Welding (PART I: Feasibility Study for Weldability). Metals. 2020; 10(10):1385. https://doi.org/10.3390/met10101385

Chicago/Turabian StyleKim, Du-Song, Changmin Pyo, Jaewoong Kim, Jisun Kim, and Hee-Keun Lee. 2020. "A Study on Cross-Shaped Structure of Invar Material Using Cold Wire Laser Fillet Welding (PART I: Feasibility Study for Weldability)" Metals 10, no. 10: 1385. https://doi.org/10.3390/met10101385

APA StyleKim, D.-S., Pyo, C., Kim, J., Kim, J., & Lee, H.-K. (2020). A Study on Cross-Shaped Structure of Invar Material Using Cold Wire Laser Fillet Welding (PART I: Feasibility Study for Weldability). Metals, 10(10), 1385. https://doi.org/10.3390/met10101385