Segregation of P and S Impurities to A Σ9 Grain Boundary in Cu

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lousada, C.M.; Korzhavyi, P.A. Hydrogen sorption capacity of crystal lattice defects and low Miller index surfaces of copper. J. Mater. Sci. 2020, 55, 6623–6636. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Korzhavyi, P.A.; Sandström, R.; Lilja, C. Impurity effects on the grain boundary cohesion in copper. Phys. Rev. Mater. 2017, 1, 070602. [Google Scholar] [CrossRef] [Green Version]

- Amelinckx, S.; Dekeyser, W. The Structure and Properties of Grain Boundaries. In Solid State Physics; Seitz, F., Turnbull, D., Eds.; Academic Press: New York, NY, USA, 1959; Volume 8, pp. 325–499. [Google Scholar]

- Uberuaga, B.P.; Vernon, L.J.; Martinez, E.; Voter, A.F. The relationship between grain boundary structure, defect mobility and grain boundary sink efficiency. Sci. Rep. 2015, 5, 9095. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Herbig, M.; Raabe, D. Atomic scale quantification of grain boundary segregation in nanocrystalline material. Phys. Rev. Lett. 2014, 112, 126103. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mishin, Y.; Asta, M.; Li, J. Atomistic modeling of interfaces and their impact on microstructure and properties. Acta Mater. 2010, 58, 1117–1151. [Google Scholar] [CrossRef] [Green Version]

- Sandström, R.; Lousada, C.M. The role of binding energies for phosphorus at grain boundaries in copper. J. Nucl. Mater. 2020. (under review). [Google Scholar]

- Rupert, T.J.; Trelewicz, J.R.; Schuh, C.A. Grain boundary relaxation strengthening of nanocrystalline Ni–W alloys. J. Mater. Res. 2012, 27, 1285–1294. [Google Scholar] [CrossRef]

- Rogers, H.C. Hydrogen Embrittlement of Metals. Science 1968, 159, 1057–1064. [Google Scholar] [CrossRef]

- King, A.; Johnson, G.; Engelberg, D.; Ludwig, W.; Marrow, J. Observations of intergranular stress corrosion cracking in a grain-mapped polycrystal. Science 2008, 321, 382–385. [Google Scholar] [CrossRef]

- Korzhavyi, P.A.; Sandström, R. First-principles evaluation of the effect of alloying elements on the lattice parameter of a 23Cr25NiWCuCo austenitic stainless steel to model solid solution hardening contribution to the creep strength. Mater. Sci. Eng. A 2015, 626, 213–219. [Google Scholar] [CrossRef]

- Sandström, R.; Wu, R. Influence of phosphorus on the creep ductility of copper. J. Nucl. Mater. 2013, 441, 364–371. [Google Scholar] [CrossRef]

- Henderson, P.J.; Sandström, R. Low temperature creep ductility of OFHC copper. Mater. Sci. Eng. A 1998, 246, 143–150. [Google Scholar] [CrossRef]

- Sandström, R.; Wu, R. Origin of the Extra Low Creep Ductility of Copper without Phosphorus; Swedish Nuclear Waste Management Company Report TR-07-02; Swedish Nuclear Waste Management Company: Stockholm, Sweden, 2007. [Google Scholar]

- Bowyer, W.H. The Effects of Impurities on the Properties of OFP Copper Specified for the Copper Iron Canister; SKI Report 99:44; SKI: Stockholm, Sweden, 1999. [Google Scholar]

- Hallberg, H.; Olsson, P.A.T. Investigation of microstructure evolution during self-annealing in thin Cu films by combining mesoscale level set and ab initio modeling. J. Mech. Phys. Solids 2016, 90, 160–178. [Google Scholar] [CrossRef] [Green Version]

- Mishin, O.V.; Gertsman, V.Y.; Gottstein, G. Distributions of orientations and misorientations in hot-rolled copper. Mater. Charact. 1997, 38, 39–48. [Google Scholar] [CrossRef]

- Korolev, V.V.; Kucherinenko, Y.V.; Makarevich, A.M.; Straumal, B.B.; Protsenko, P.V. Statistics of GB misorientations in 2D polycrystalline copper foil. Mater. Lett. 2017, 196, 377–380. [Google Scholar] [CrossRef]

- Kresse, G.; Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 1996, 54, 11169–11186. [Google Scholar]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 1997, 77, 3865–3868, Erratum in 1997, 78, 1396–1396. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Blöchl, P.E. Projector augmented-wave method. Phys. Rev. B 1994, 50, 17953–17979. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kresse, G.; Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 1999, 59, 1758–1775. [Google Scholar] [CrossRef]

- Lousada, C.M.; Johansson, A.J.; Korzhavyi, P.A. Molecular and dissociative adsorption of water and hydrogen sulfide at perfect and defective Cu(110) surfaces. Phys. Chem. Chem. Phys. 2017, 19, 8111–8120. [Google Scholar] [CrossRef]

- Lousada, C.M.; Johansson, A.J.; Korzhavyi, P.A. Molecular and dissociative adsorption of water at a defective Cu(110) surface. Surf. Sci. 2017, 658, 1–8. [Google Scholar] [CrossRef]

- Lousada, C.M.; Johansson, A.J.; Korzhavyi, P.A. Adsorption of Hydrogen Sulfide, Hydrosulfide and Sulfide at Cu(110)—Polarizability and Cooperativity Effects. First Stages of Formation of a Sulfide Layer. ChemPhysChem 2018, 19, 2159–2168. [Google Scholar] [CrossRef] [PubMed]

- Lousada, C.M.; Johansson, A.J.; Korzhavyi, P.A. Thermodynamics of H2O Splitting and H2 Formation at the Cu(110)–Water Interface. J. Phys. Chem. C 2015, 119, 14102–14113. [Google Scholar] [CrossRef]

- Methfessel, M.; Paxton, A.T. High-precision sampling for Brillouin-zone integration in metals. Phys. Rev. B 1989, 40, 3616–3621. [Google Scholar] [CrossRef] [Green Version]

- You, Y.-W.; Kong, X.-S.; Wu, X.-B.; Xu, Y.-C.; Fang, Q.F.; Chen, J.L.; Luo, G.-N.; Liu, C.S.; Pan, B.C.; Wang, Z. Dissolving, trapping and detrapping mechanisms of hydrogen in bcc and fcc transition metals. AIP Adv. 2013, 3, 012118. [Google Scholar] [CrossRef]

- Lousada, C.M.; Sophonrat, N.; Yang, W. Mechanisms of Formation of H, HO, and Water and of Water Desorption in the Early Stages of Cellulose Pyrolysis. J. Phys. Chem. C 2018, 122, 12168–12176. [Google Scholar] [CrossRef]

- Heinola, K.; Ahlgren, T.; Nordlund, K.; Keinonen, J. Hydrogen interaction with point defects in tungsten. Phys. Rev. B 2010, 82, 094102. [Google Scholar] [CrossRef] [Green Version]

- Randle, V. The coincidence site lattice and the ‘sigma enigma’. Mater. Charact. 2001, 47, 411–416. [Google Scholar] [CrossRef]

- Fortes, M.A. Coincidence Site Lattices. Phys. Status Solidi (b) 1972, 54, 311–319. [Google Scholar] [CrossRef]

- Wan, L.; Wang, S. Shear response of the Σ9 ⟨110⟩ {221} symmetric tilt grain boundary in fcc metals studied by atomistic simulation methods. Phys. Rev. B 2010, 82, 214112. [Google Scholar] [CrossRef]

- Tschopp, M.A.; Coleman, S.P.; McDowell, D.L. Symmetric and asymmetric tilt grain boundary structure and energy in Cu and Al (and transferability to other fcc metals). Integr. Mater. Manuf. Innov. 2015, 4, 176–189. [Google Scholar] [CrossRef] [Green Version]

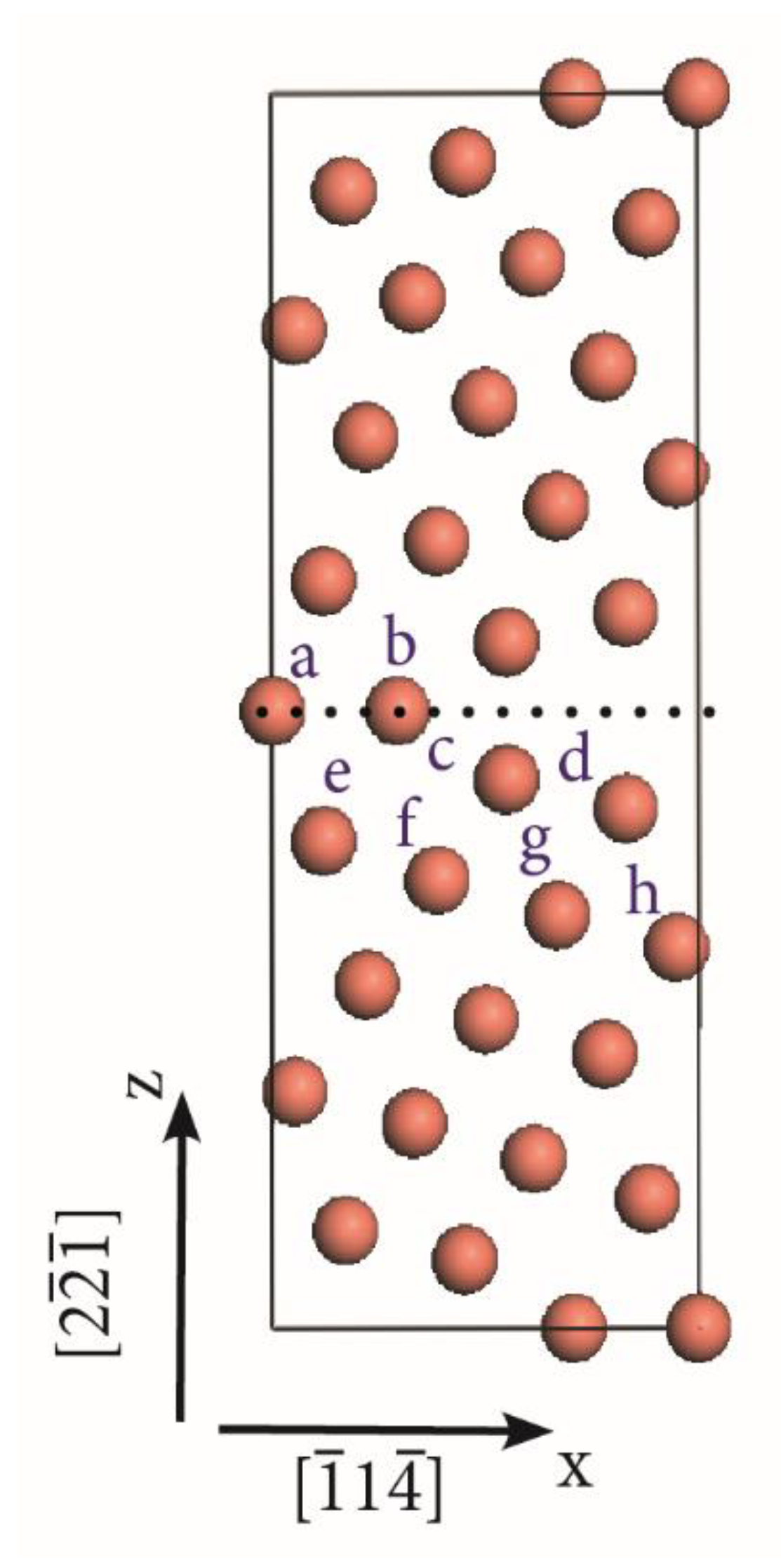

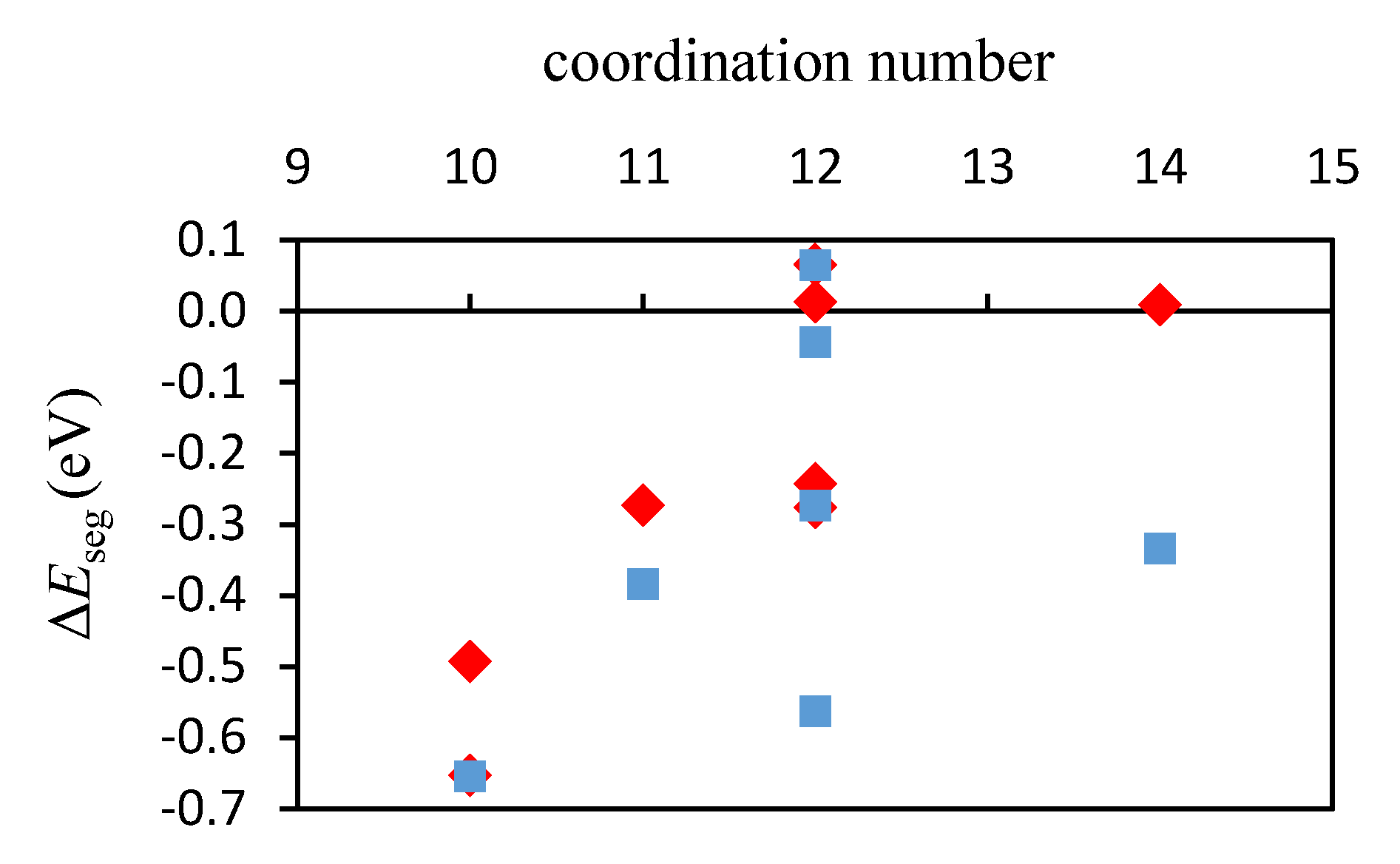

| Atomic Position | Impurity | z Coordinate (fractional) | z Coordinate (Å) | d (Å) | Coordination Number | Volume Expansion (%) | |

|---|---|---|---|---|---|---|---|

| P (ΔEseg) | S (ΔEseg) | ||||||

| a | −0.653 | −0.724 | 0.500 | 10.853 | 0.000 | 10 | 2.3 |

| b | 0.009 | −0.335 | 0.500 | 10.853 | 0.000 | 14 | 14.0 |

| c | −0.493 | −0.655 | 0.443 | 9.675 | 1.248 | 10 | 6.7 |

| d | −0.274 | −0.384 | 0.421 | 9.167 | 1.716 | 11 | 6.6 |

| e | −0.276 | −0.562 | 0.392 | 8.636 | 2.360 | 12 | 5.5 |

| f | −0.243 | −0.274 | 0.363 | 7.956 | 2.972 | 12 | 0.5 |

| g | 0.065 | 0.000 | 0.340 | 7.343 | 3.488 | 12 | −0.9 |

| h | 0.013 | 0.000 | 0.315 | 6.808 | 4.015 | 12 | 0.8 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lousada, C.M.; Korzhavyi, P.A. Segregation of P and S Impurities to A Σ9 Grain Boundary in Cu. Metals 2020, 10, 1362. https://doi.org/10.3390/met10101362

Lousada CM, Korzhavyi PA. Segregation of P and S Impurities to A Σ9 Grain Boundary in Cu. Metals. 2020; 10(10):1362. https://doi.org/10.3390/met10101362

Chicago/Turabian StyleLousada, Cláudio M., and Pavel A. Korzhavyi. 2020. "Segregation of P and S Impurities to A Σ9 Grain Boundary in Cu" Metals 10, no. 10: 1362. https://doi.org/10.3390/met10101362

APA StyleLousada, C. M., & Korzhavyi, P. A. (2020). Segregation of P and S Impurities to A Σ9 Grain Boundary in Cu. Metals, 10(10), 1362. https://doi.org/10.3390/met10101362