Transformation-Induced Ductility of Reverse Austenite Evolved by Low-Temperature Tempering of Martensite

Abstract

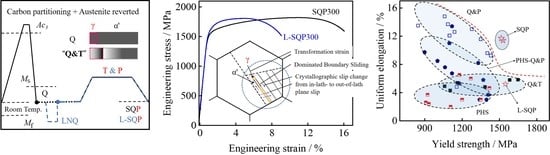

:1. Introduction

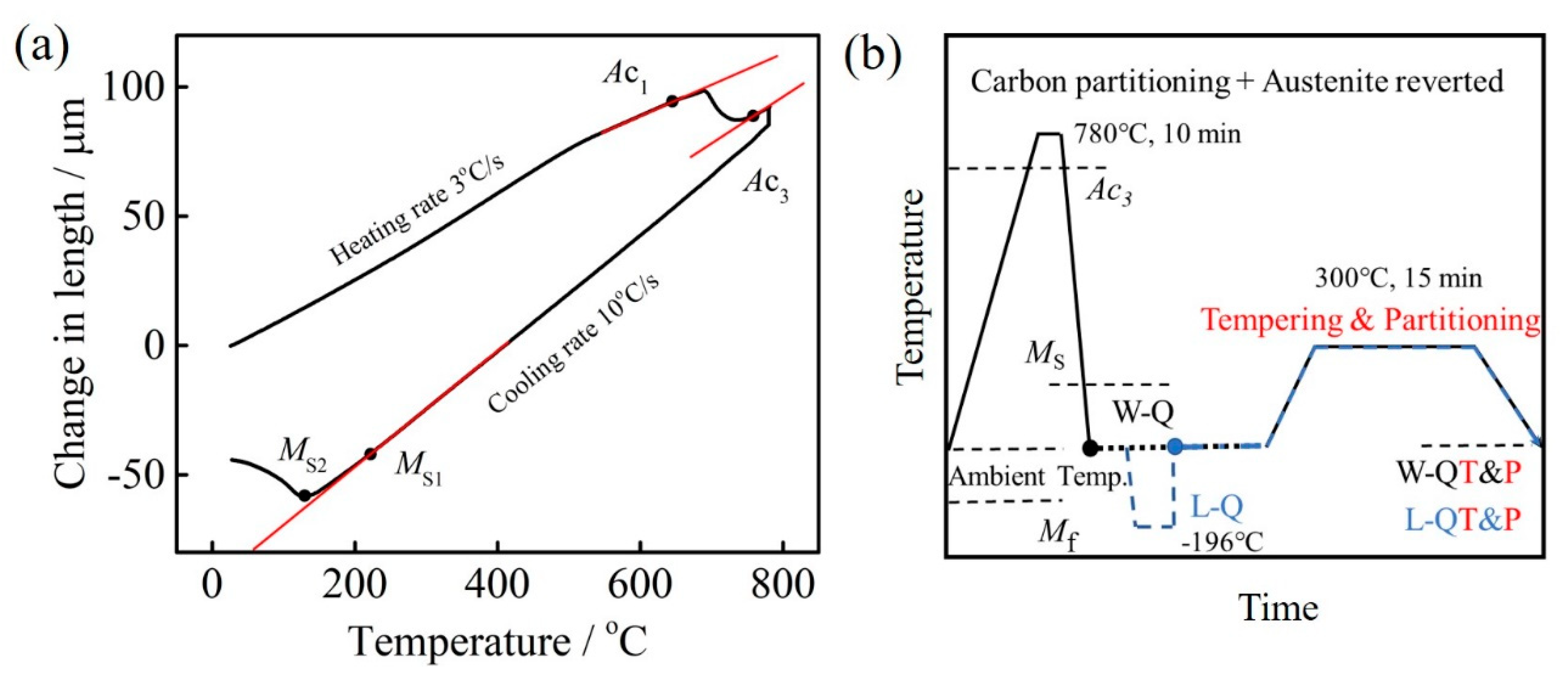

2. Materials and Methods

3. Results and Discussion

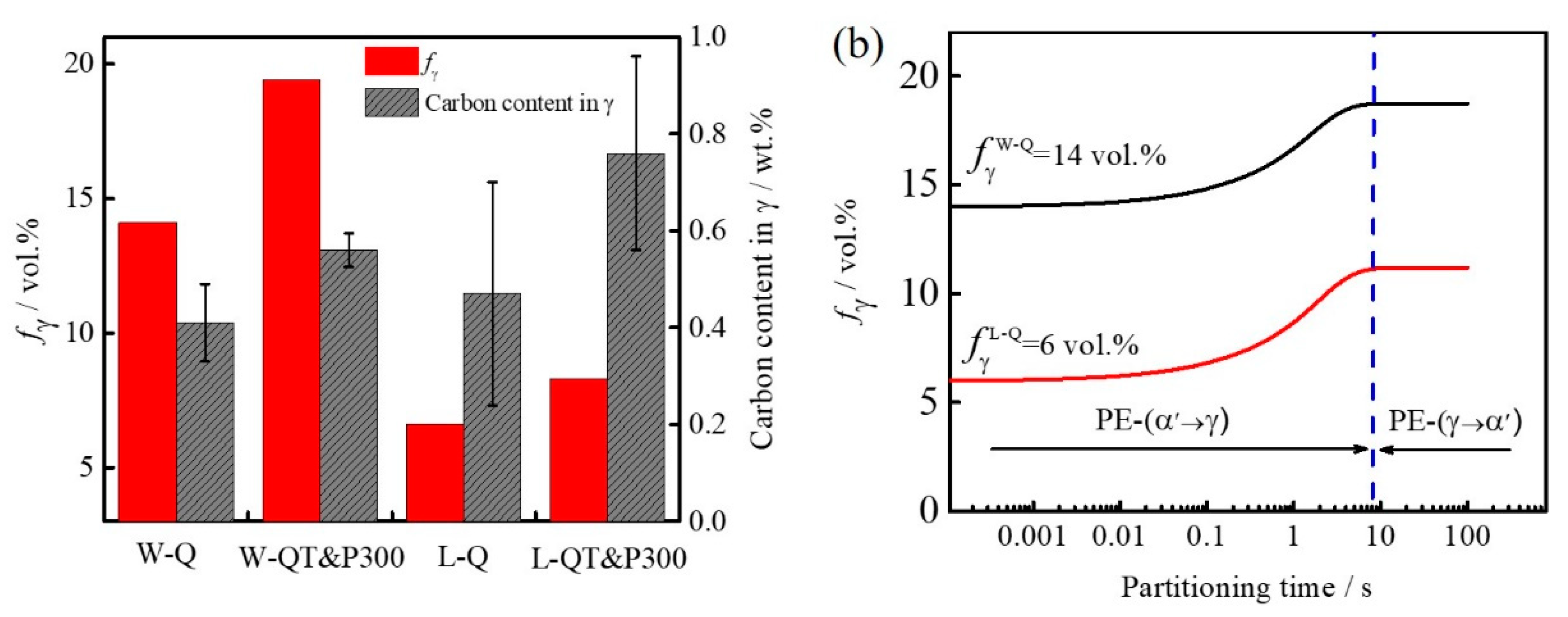

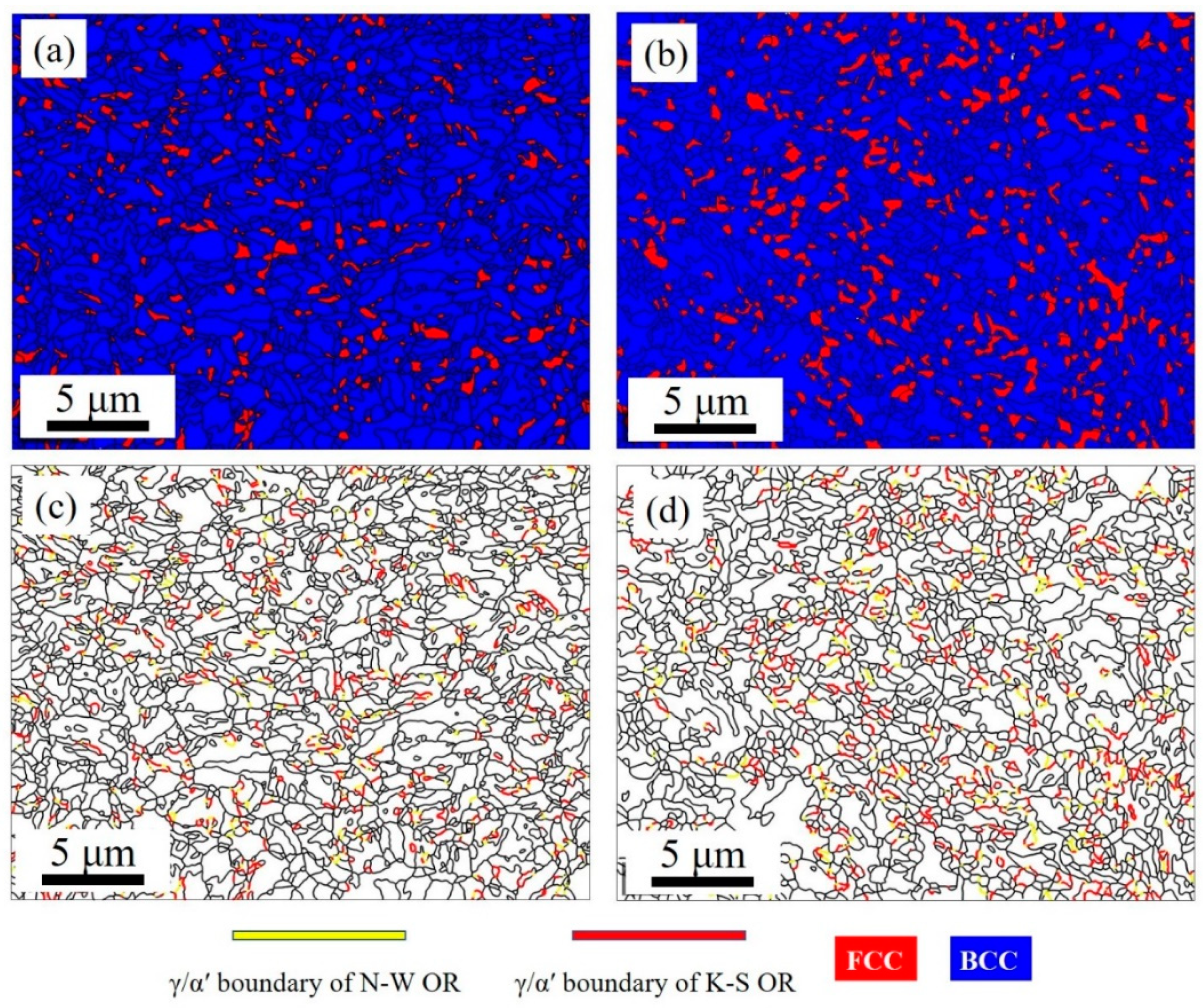

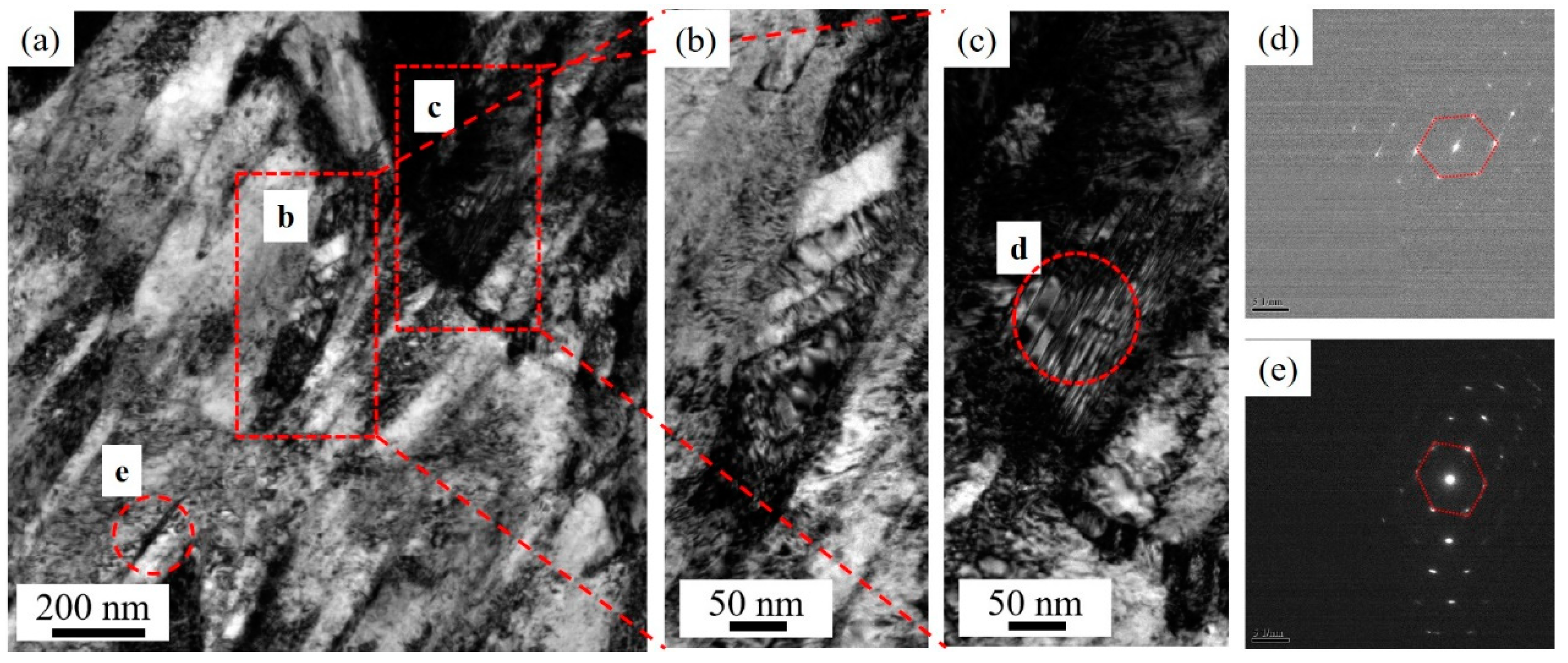

3.1. Microstructure Evolution during the Quenching and Tempering Process

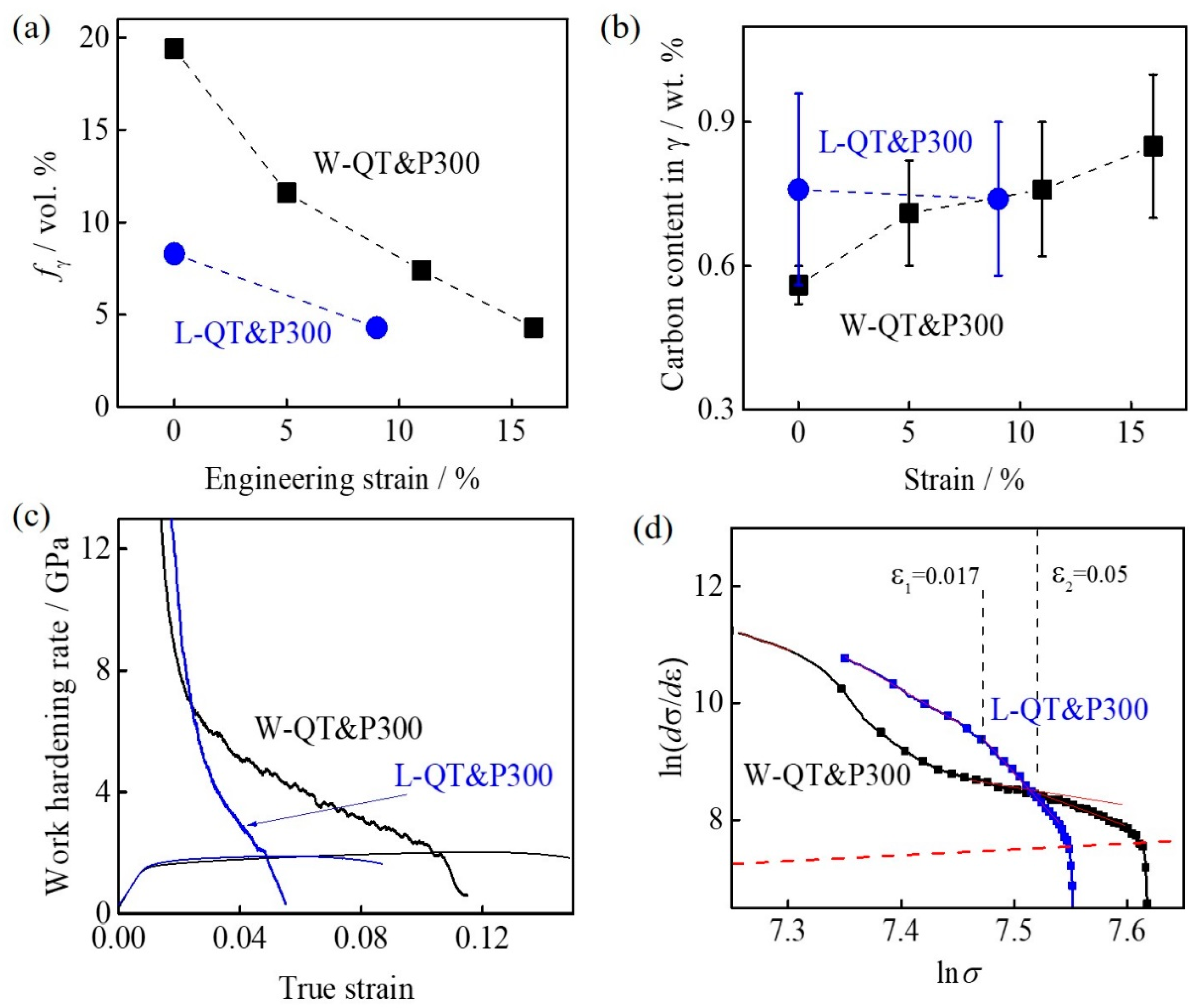

3.2. Mechanical Properties and Work Hardening Behavior

3.3. The Effect of Retained Austenite on Improving Ductility

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Matlock, D.K.; Speer, J.G. Third Generation of AHSS: Microstructure Design Concepts, Microstructure and Texture in Steels; Springer: Berlin/Heidelberg, Germany, 2009; pp. 185–205. [Google Scholar]

- Sugimoto, K.I. Performance of Mechanical Properties of Ultrahigh-Strength Ferrous Steels Related to Strain-Induced Transformation. Metals 2020, 10, 875. [Google Scholar] [CrossRef]

- Shi, J.; Sun, X.; Wang, M.; Hui, W.; Dong, H.; Cao, W. Enhanced work-hardening behavior and mechanical properties in ultrafine-grained steels with large-fractioned metastable austenite. Sci. Mater. 2010, 63, 815–818. [Google Scholar] [CrossRef]

- Hu, B.; Luo, H.; Yang, F.; Dong, H. Recent progress in medium-Mn steels made with new designing strategies, a review. J. Mater. Sci. Technol. 2017, 33, 1457–1464. [Google Scholar] [CrossRef]

- Speer, J.; Matlock, D.K.; de Cooman, B.C.; Schroth, J.G. Carbon partitioning into austenite after martensite transformation. Acta Mater. 2003, 51, 2611–2622. [Google Scholar] [CrossRef]

- Seo, E.J.; Cho, L.; Estrin, Y.; de Cooman, B.C. Microstructure-mechanical properties relationships for quenching and partitioning (Q&P) processed steel. Acta Mater. 2016, 113, 124–139. [Google Scholar]

- Bouaziz, O.; Zurob, H.; Huang, M. Driving Force and Logic of Development of Advanced High Strength Steels for Automotive Applications. Steel Res. Int. 2013, 84, 937–947. [Google Scholar] [CrossRef]

- Zhang, K.; Liu, P.; Li, W.; Guo, Z.; Rong, Y. Ultrahigh strength-ductility steel treated by a novel quenching–partitioning–tempering process. Mater. Sci. Eng. A 2014, 619, 205–211. [Google Scholar] [CrossRef]

- Toji, Y.; Matsuda, H.; Herbig, M.; Choi, P.-P.; Raabe, D. Atomic-scale analysis of carbon partitioning between martensite and austenite by atom probe tomography and correlative transmission electron microscopy. Acta Mater. 2014, 65, 215–228. [Google Scholar] [CrossRef]

- Zhong, N.; Wang, X.; Rong, Y.; Wang, L. Interface migration between martensite and austenite during quenching and partitioning (Q&P) process. J. Mater. Sci. Technol. 2006, 22, 751–754. [Google Scholar]

- Santofimia, M.J.; Speer, J.G.; Clarke, A.J.; Zhao, L.; Sietsma, J. Influence of interface mobility on the evolution of austenite–martensite grain assemblies during annealing. Acta Mater. 2009, 57, 4548–4557. [Google Scholar] [CrossRef] [Green Version]

- Thomas, G.A.; Speer, J.G. Interface migration during partitioning of Q&P steel. Mater. Sci. Technol. 2014, 30, 998–1007. [Google Scholar]

- de Knijf, D.; Santofimia, M.J.; Shi, H.; Bliznuk, V.; Föjer, C.; Petrov, R.; Xu, W. In situ austenite–martensite interface mobility study during annealing. Acta Mater. 2015, 90, 161–168. [Google Scholar] [CrossRef]

- Wang, M.; Huang, M.X. Abnormal TRIP effect on the work hardening behavior of a quenching and partitioning steel at high strain rate. Acta Mater. 2020, 188, 551–559. [Google Scholar] [CrossRef]

- Liu, H.; Lu, X.; Jin, X.; Dong, H.; Shi, J. Enhanced mechanical properties of a hot stamped advanced high-strength steel treated by quenching and partitioning process. Sci. Mater. 2011, 64, 749–752. [Google Scholar] [CrossRef]

- Seo, E.J.; Cho, L.; de Cooman, B.C. Application of Quenching and Partitioning (Q&P) Processing to Press Hardening Steel. Metall. Mater. Trans. A 2014, 45, 4022–4037. [Google Scholar]

- Dai, Z.; Ding, R.; Yang, Z.; Zhang, C.; Chen, H. Elucidating the effect of Mn partitioning on interface migration and carbon partitioning during Quenching and Partitioning of the Fe-C-Mn-Si steels: Modeling and experiments. Acta Mater. 2018, 144, 666–678. [Google Scholar] [CrossRef]

- Arribas, M.; Gutiérrez, T.; Del Molino, E.; Arlazarov, A.; Diego-Calderón, D.; Martin, D.; De Caro, D.; Ayenampudi, S.; Santofimia, M.J. Austenite Reverse Transformation in a Q&P Route of Mn and Ni Added Steels. Metals 2020, 10, 862. [Google Scholar]

- Wang, M.M.; Hell, J.C.; Tasan, C.C. Martensite size effects on damage in quenching and partitioning steels. Sci. Mater. 2017, 138, 1–5. [Google Scholar] [CrossRef]

- Bhadeshia, H.; Honeycombe, R. Steels: Microstructure and Properties, 4th ed.; Butterworth-Heinemann: London, UK, 2017; pp. 148–151. [Google Scholar]

- Vandijk, N.; Butt, A.; Zhao, L.; Sietsma, J.; Offerman, S.; Wright, J.; Vanderzwaag, S. Thermal stability of retained austenite in TRIP steels studied by synchrotron X-ray diffraction during cooling. Acta Mater. 2005, 53, 5439–5447. [Google Scholar] [CrossRef]

- Bachmann, F.; Hielscher, R.; Schaeben, H. Texture Analysis with MTEX—Free and Open Source Software Toolbox. Solid State Phenom. 2010, 160, 62–68. [Google Scholar] [CrossRef] [Green Version]

- Dai, Z.; Wang, X.; He, J.; Yang, Z.; Zhang, C.; Chen, H. Effect of Interfacial Mn Partitioning on Carbon Partitioning and Interface Migration During the Quenching and Partitioning Process. Metall. Mater. Trans. A 2017, 48, 3168–3174. [Google Scholar] [CrossRef]

- Krauss, G. Tempering of Lath Martensite in Low and Medium Carbon Steels: Assessment and Challenges. Steel Res. Int. 2017, 88, 1700038. [Google Scholar] [CrossRef]

- Taylor, T.; Clough, A. Critical review of automotive hot-stamped sheet steel from an industrial perspective. Mater. Sci. Technol. 2018, 34, 809–861. [Google Scholar] [CrossRef]

- Liang, J.; Zhao, Z.; Sun, B.; Lu, H.; Liang, J.; He, Q.; Chen, W.; Tang, D. A novel ultra-strong hot stamping steel treated by quenching and partitioning process. Mater. Sci. Technol. 2018, 34, 2241–2249. [Google Scholar] [CrossRef]

- Seo, E.J.; Cho, L.; de Cooman, B.C. Application of Quenching and Partitioning Processing to Medium Mn Steel. Metall. Mater. Trans. A 2014, 46, 27–31. [Google Scholar] [CrossRef] [Green Version]

- Cai, M.; Huang, H.; Zuo, X.; Ding, H.; Stanford, N. Enhanced strength-ductility of medium Mn steel by quenching, partitioning and tempering. Mater. Sci. Technol. 2020, 36, 584–597. [Google Scholar] [CrossRef]

- Ramos, L.F.; Matlock, D.K.; Krauss, G. On the deformation behavior of dual-phase steels. Metall. Mater. Trans. A 1979, 10, 259–261. [Google Scholar] [CrossRef]

- Bhadeshia, H.K. TRIP-assisted steels? ISIJ Int. 2002, 42, 1059–1060. [Google Scholar] [CrossRef] [Green Version]

- Morsdorf, L.; Jeannin, O.; Barbier, D.; Mitsuhara, M.; Raabe, D.; Tasan, C.C. Multiple mechanisms of lath martensite plasticity. Acta Mater. 2016, 121, 202–214. [Google Scholar] [CrossRef]

- Du, C.; Hoefnagels, J.P.M.; Vaes, R.; Geers, M.G.D. Plasticity of lath martensite by sliding of substructure boundaries. Sci. Mater. 2016, 120, 37–40. [Google Scholar] [CrossRef]

- Ohmura, T.; Minor, A.M.; Stach, E.A.; Morris, J.W. Dislocation–grain boundary interactions in martensitic steel observed through in situ nanoindentation in a transmission electron microscope. J. Mater. Res. 2004, 19, 3626–3632. [Google Scholar] [CrossRef]

- Nambu, S.; Michiuchi, M.; Ishimoto, Y.; Asakura, K.; Inoue, J.; Koseki, T. Transition in deformation behavior of martensitic steel during large deformation under uniaxial tensile loading. Sci. Mater. 2009, 60, 221–224. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, P.; Chen, P.; Misra, D.K.; Wu, D.; Yi, H. Transformation-Induced Ductility of Reverse Austenite Evolved by Low-Temperature Tempering of Martensite. Metals 2020, 10, 1343. https://doi.org/10.3390/met10101343

Du P, Chen P, Misra DK, Wu D, Yi H. Transformation-Induced Ductility of Reverse Austenite Evolved by Low-Temperature Tempering of Martensite. Metals. 2020; 10(10):1343. https://doi.org/10.3390/met10101343

Chicago/Turabian StyleDu, Pengju, Peng Chen, Devesh K. Misra, Di Wu, and Hongliang Yi. 2020. "Transformation-Induced Ductility of Reverse Austenite Evolved by Low-Temperature Tempering of Martensite" Metals 10, no. 10: 1343. https://doi.org/10.3390/met10101343

APA StyleDu, P., Chen, P., Misra, D. K., Wu, D., & Yi, H. (2020). Transformation-Induced Ductility of Reverse Austenite Evolved by Low-Temperature Tempering of Martensite. Metals, 10(10), 1343. https://doi.org/10.3390/met10101343