The Effect of Microstructural Imperfections on Corrosion Fatigue of Additively Manufactured ER70S-6 Alloy Produced by Wire Arc Deposition

Abstract

1. Introduction

2. Materials and Methods

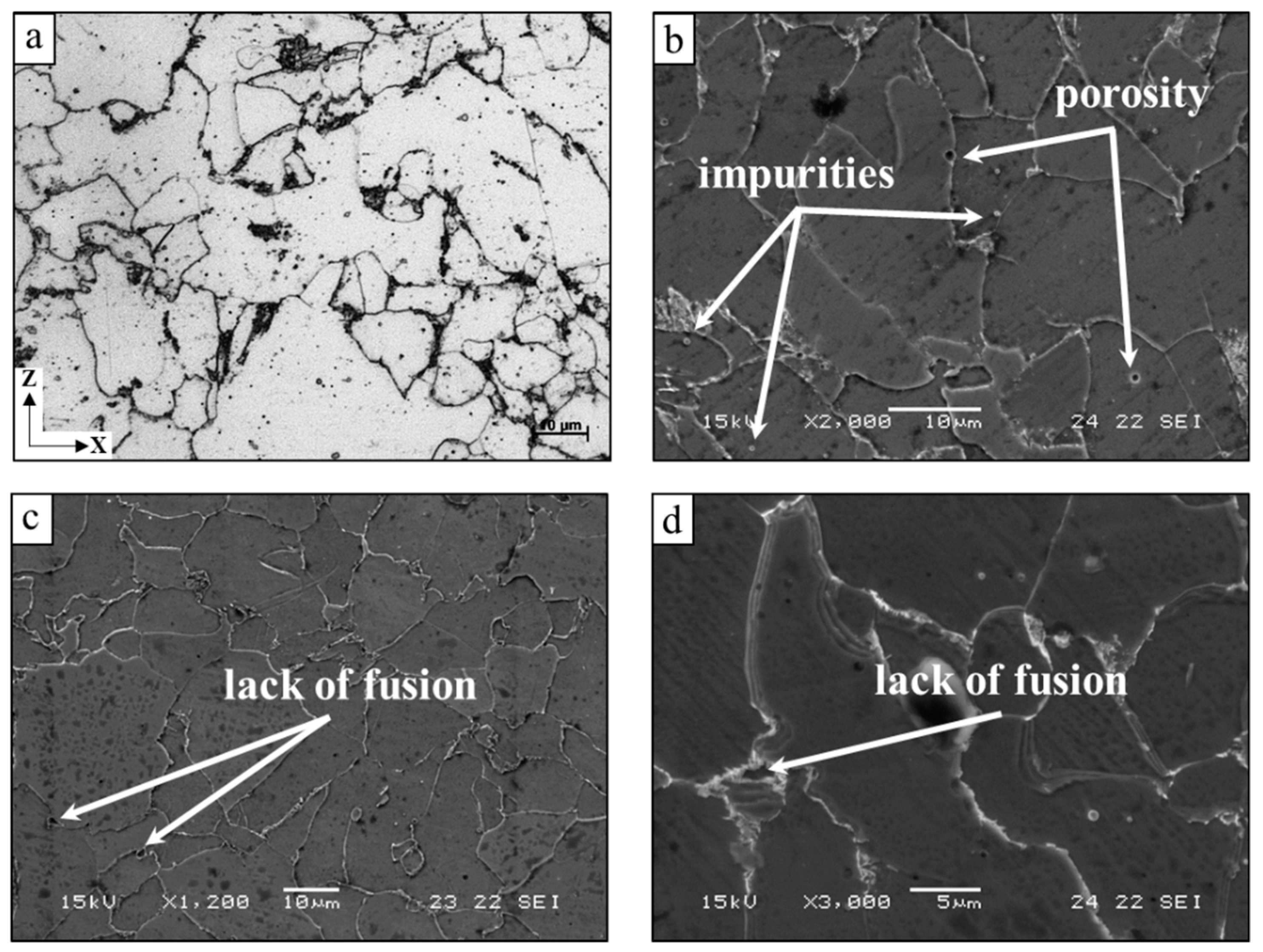

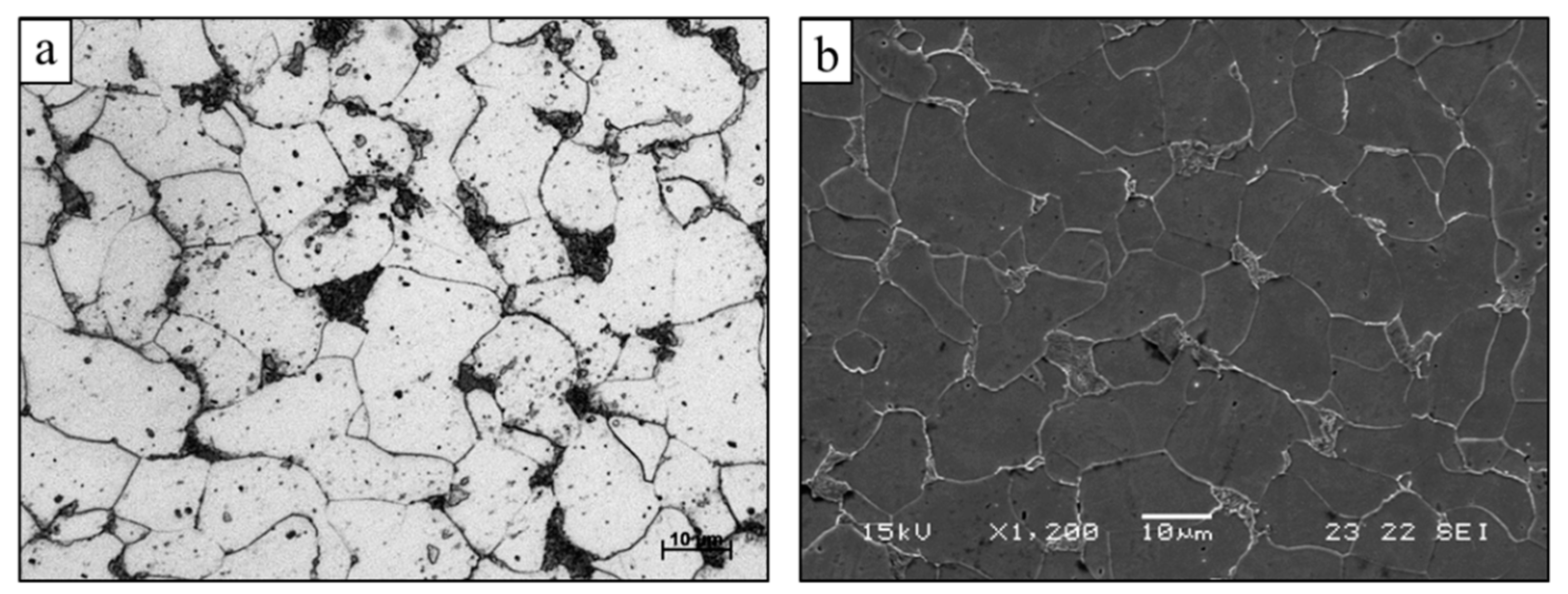

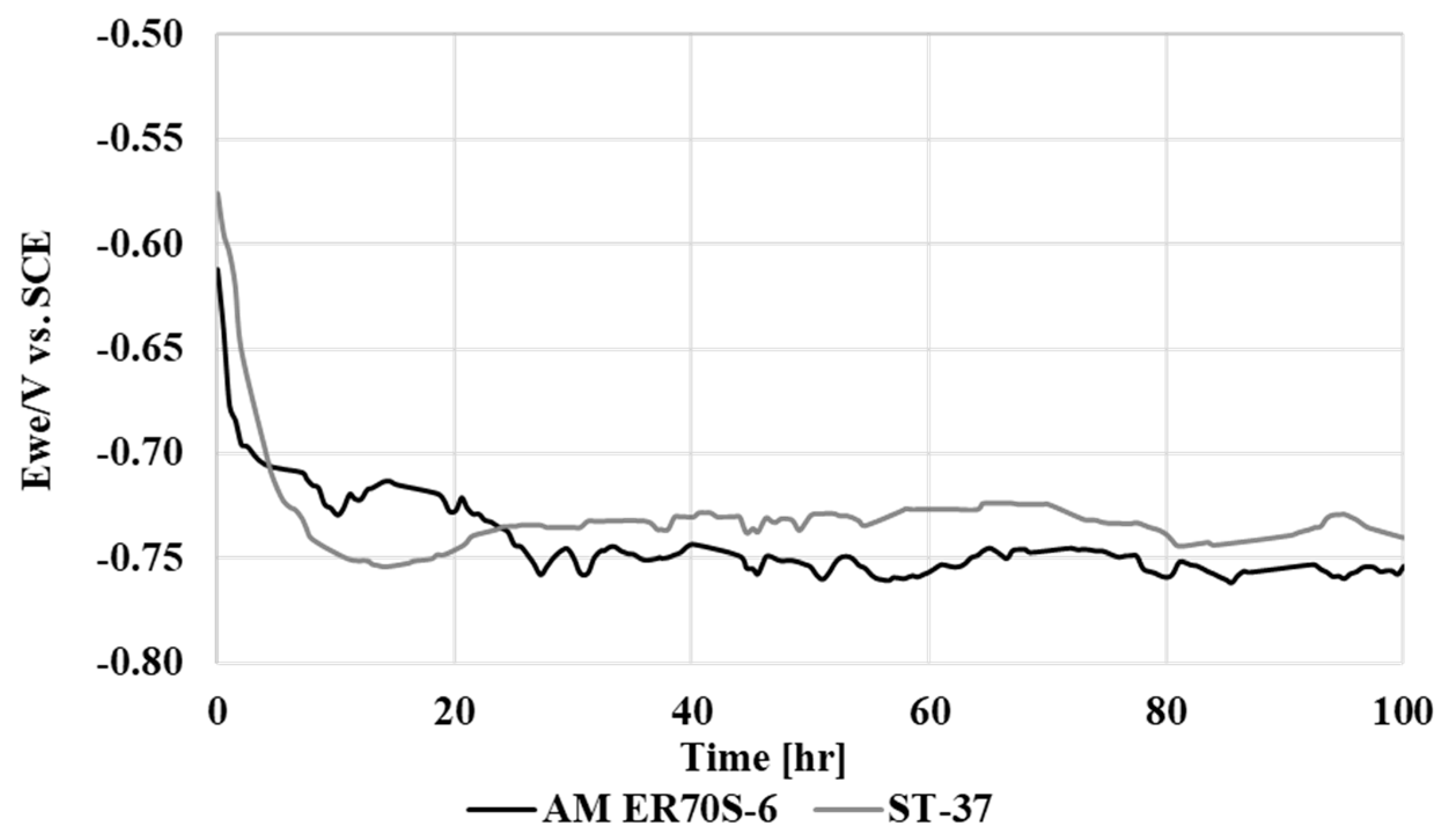

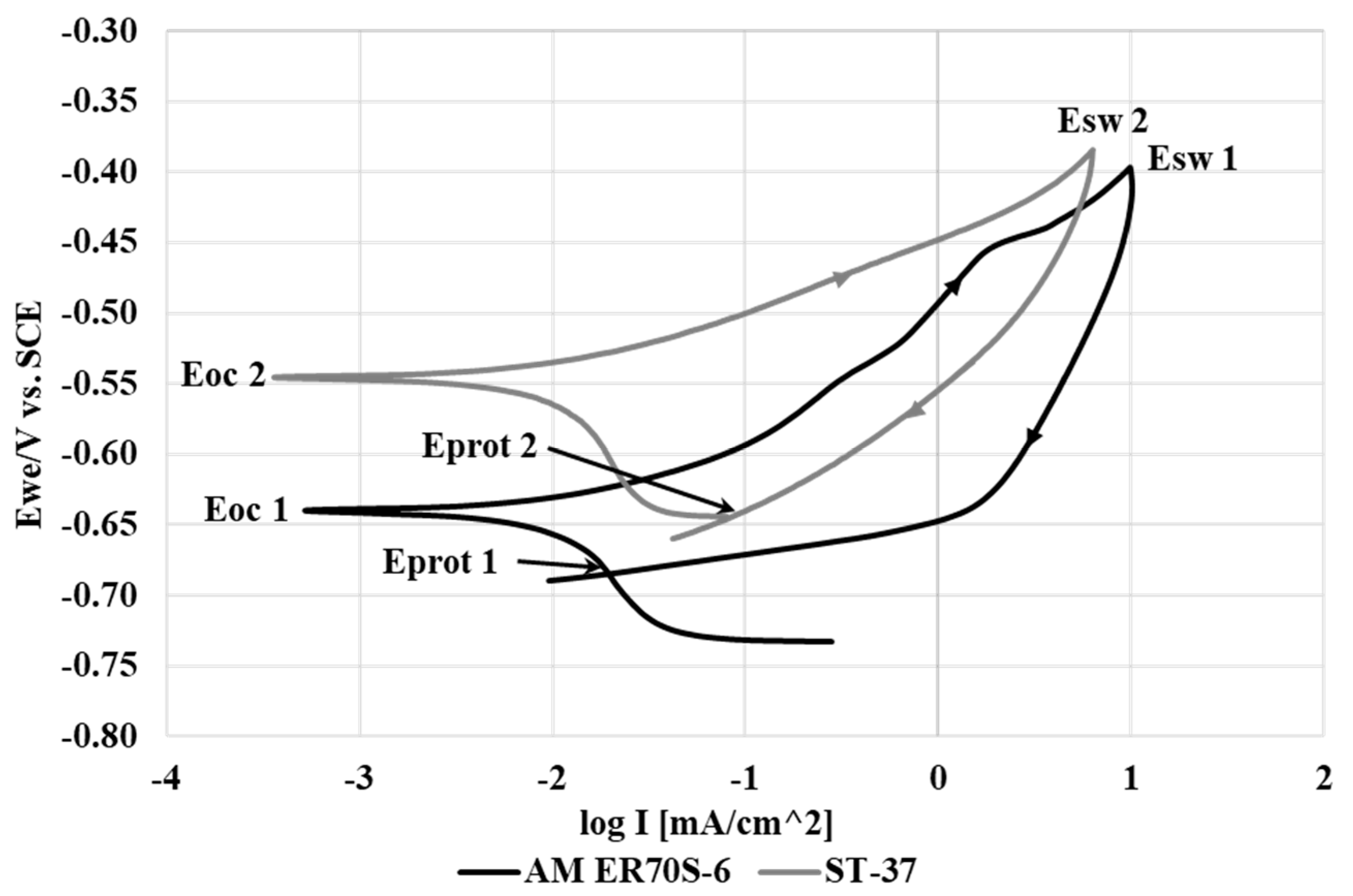

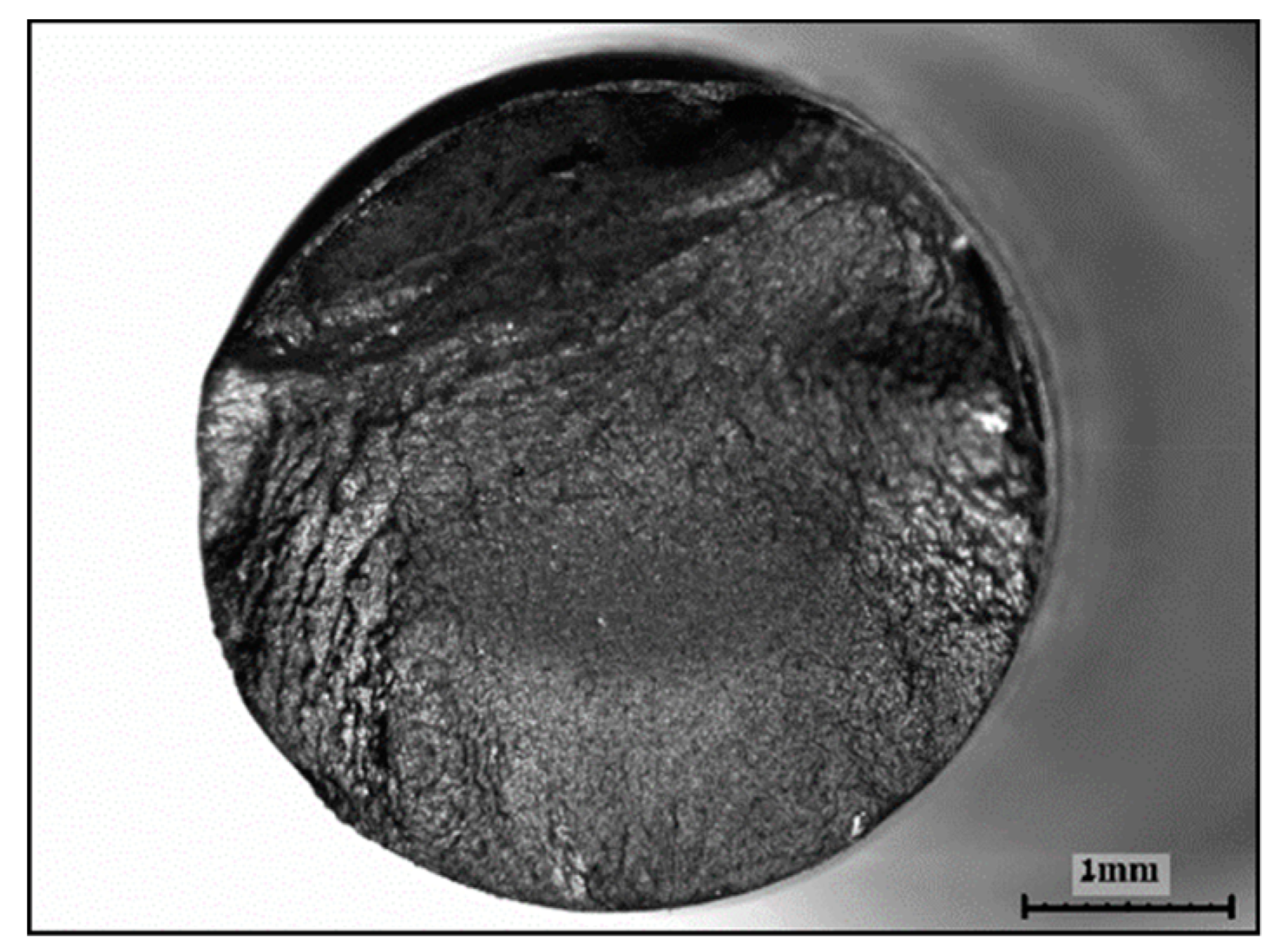

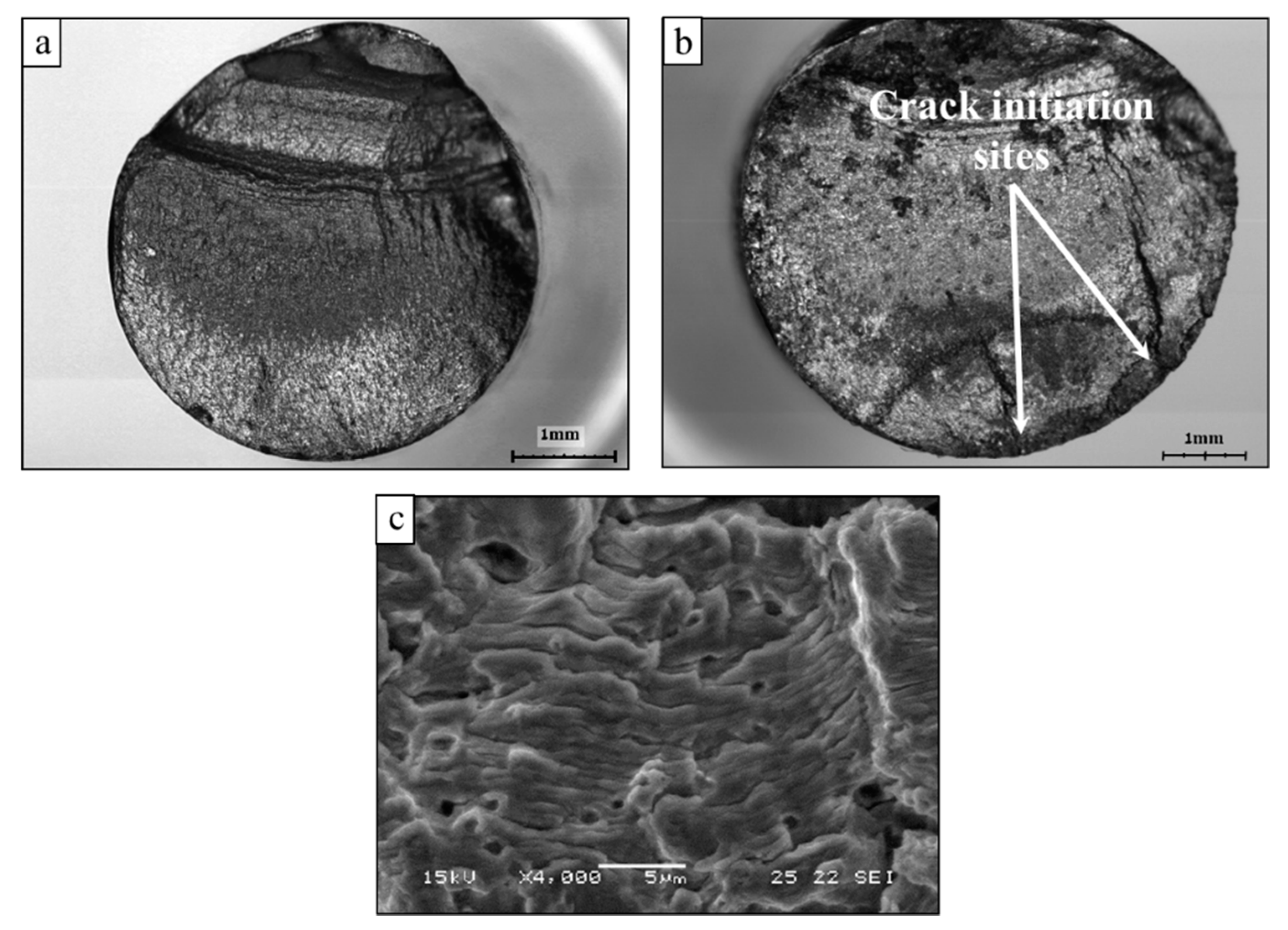

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rodrigues, T.A.; Duarte, V.; Avila, J.A.; Santos, T.G.; Miranda, R.M.; Oliveira, J.P. Wire and arc additive manufacturing of HSLA steel: Effect of thermal cycles on microstructure and mechanical properties. Addit. Manuf. 2019, 27, 440–450. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Duarte, V.; Miranda, R.M.; Santos, T.G.; Oliveira, J.P. Current status and perspectives on wire and arc additive manufacturing (WAAM). Materials 2019, 12, 1121. [Google Scholar] [CrossRef] [PubMed]

- Zakay, A.; Aghion, E. Effect of post-heat treatment on the corrosion behavior of AlSi10Mg alloy produced by additive manufacturing. JOM 2019, 71, 1150–1157. [Google Scholar] [CrossRef]

- Leon, A.; Shirizly, A.; Aghion, E.; Leon, A.; Shirizly, A.; Aghion, E. Corrosion behavior of AlSi10Mg alloy produced by additive manufacturing (AM) vs. its counterpart gravity cast alloy. Metals 2016, 6, 148. [Google Scholar] [CrossRef]

- Hosseini, V.A.; Högström, M.; Hurtig, K.; Bermejo, M.A.V.; Stridh, L.E.; Karlsson, L. Wire-arc additive manufacturing of a duplex stainless steel: Thermal cycle analysis and microstructure characterization. Weld. World 2019, 63, 975–987. [Google Scholar] [CrossRef]

- Donoghue, J.; Antonysamy, A.A.; Martina, F.; Colegrove, P.A.; Williams, S.W.; Prangnell, P.B. The effectiveness of combining rolling deformation with Wire–Arc Additive Manufacture on β-grain refinement and texture modification in Ti–6Al–4V. Mater. Charact. 2016, 114, 103–114. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Xu, J.; Norrish, J. A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Ge, J.; Ma, T.; Chen, Y.; Jin, T.; Fu, H.; Xiao, R.; Lei, Y.; Lin, J. Wire-arc additive manufacturing H13 part: 3D pore distribution, microstructural evolution, and mechanical performances. J. Alloys Compd. 2019, 783, 145–155. [Google Scholar] [CrossRef]

- Wang, L.; Xue, J.; Wang, Q. Correlation between arc mode, microstructure, and mechanical properties during wire arc additive manufacturing of 316L stainless steel. Mater. Sci. Eng. A 2019, 751, 183–190. [Google Scholar] [CrossRef]

- Bekker, A.C.M.; Jouke, C.V.; Giorgia, G. Challenges in assessing the sustainability of wire+ arc additive manufacturing for large structures. In Proceedings of the Solid Freeform Fabrication Symposium–An Additive Manufacturing Conference, Austin, TX, USA, 8–10 August 2016. [Google Scholar]

- Cunningham, C.R.; Wikshåland, S.; Xu, F.; Kemakolam, N.; Shokrani, A.; Dhokia, V.; Newman, S.T. Cost modelling and sensitivity analysis of wire and arc additive manufacturing. Procedia Manuf. 2017, 11, 650–657. [Google Scholar] [CrossRef]

- Caballero, A.; Ding, J.; Ganguly, S.; Williams, S. Wire + Arc Additive Manufacture of 17-4 PH stainless steel: Effect of different processing conditions on microstructure, hardness, and tensile strength. J. Mater. Process. Technol. 2019, 268, 54–62. [Google Scholar] [CrossRef]

- Xu, X.; Ding, J.; Ganguly, S.; Diao, C.; Williams, S. Preliminary investigation of building strategies of maraging steel bulk material using wire + arc additive manufacture. J. Mater. Eng. Perform. 2019, 28, 594–600. [Google Scholar] [CrossRef]

- Leon, A.; Aghion, E. Effect of surface roughness on corrosion fatigue performance of AlSi10Mg alloy produced by selective laser melting (SLM). Mater. Charact. 2017, 131, 188–194. [Google Scholar] [CrossRef]

- Zhang, C.; Li, Y.; Gao, M.; Zeng, X. Wire arc additive manufacturing of Al-6Mg alloy using variable polarity cold metal transfer arc as power source. Mater. Sci. Eng. A 2018, 711, 415–423. [Google Scholar] [CrossRef]

- Lin, Z.; Goulas, C.; Ya, W.; Hermans, M.J.M. Microstructure and mechanical properties of medium carbon steel deposits obtained via wire and arc additive manufacturing using metal-cored wire. Metals 2019, 9, 673. [Google Scholar] [CrossRef]

- Gu, D. Laser Additive Manufacturing (AM): Classification, Processing Philosophy, and Metallurgical Mechanisms. In Laser Additive Manufacturing of High-Performance Materials; Springer: Heidelberg/Berlin, Germany, 2015; pp. 15–71. [Google Scholar]

- Lockett, H.; Ding, J.; Williams, S.; Martina, F. Design for wire + arc additive manufacture: Design rules and build orientation selection. J. Eng. Des. 2017, 28, 568–598. [Google Scholar] [CrossRef]

- Derekar, K.S. A review of wire arc additive manufacturing and advances in wire arc additive manufacturing of aluminium. Mater. Sci. Technol. 2018, 34, 895–916. [Google Scholar] [CrossRef]

- Ghaffari, M.; Nemani, A.V.; Rafieazad, M.; Nasiri, A. Effect of solidification defects and HAZ softening on the anisotropic mechanical properties of a wire arc additive-manufactured low-carbon low-alloy steel part. JOM 2019, 71, 4215–4224. [Google Scholar] [CrossRef]

- Gordon, J.; Hochhalter, J.; Haden, C.; Harlow, D.G. Enhancement in fatigue performance of metastable austenitic stainless steel through directed energy deposition additive manufacturing. Mater. Des. 2019, 168. [Google Scholar] [CrossRef]

- Fadaei, A.; Mokhtari, H. Finite element modeling and experimental study of residual stresses in repair butt weld of ST-37 plates. Iran. J. Sci. Technol. Trans. Mech. Eng. 2015, 39, 291–307. [Google Scholar]

- Ron, T.; Levy, G.K.; Dolev, O.; Leon, A.; Shirizly, A.; Aghion, E. Environmental behavior of low carbon steel produced by a wire arc additive manufacturing Process. Metals 2019, 9, 888. [Google Scholar] [CrossRef]

- Shirizly, A.; Dolev, O. From wire to seamless flow-formed tube: Leveraging the combination of wire arc additive manufacturing and metal forming. JOM 2019, 71, 709–717. [Google Scholar] [CrossRef]

- Kaya, A.A.; Uzan, P.; Eliezer, D.; Aghion, E. Electron microscopical investigation of as cast AZ91D alloy. Mater. Sci. Technol. 2000, 16, 1001–1006. [Google Scholar] [CrossRef]

- Elkaiam, L.; Hakimi, O.; Goldman, J.; Aghion, E. The effect of Nd on mechanical properties and corrosion performance of biodegradable Mg-5%Zn alloy. Metals 2018, 8, 438. [Google Scholar] [CrossRef]

- Itzhak, D.; Aghion, E. Corrosion behaviour of hot-pressed austenitic stainless steel in H2SO4 solutions at room temperature. Corros. Sci. 1983, 23, 1085–1094. [Google Scholar] [CrossRef]

- Itzhak, D.; Aghion, E. An anodic behaviour study of an analogical sintered system of austenitic stainless steel in H2SO4 solution. Corros. Sci. 1984, 24, 145–149. [Google Scholar] [CrossRef]

- Kafri, A.; Ovadia, S.; Goldman, J.; Drelich, J.; Aghion, E. The suitability of Zn–1.3%Fe alloy as a biodegradable implant material. Metals 2018, 8, 153. [Google Scholar] [CrossRef]

- Gerengi, H.; Uygur, I.; Solomon, M.; Yildiz, M.; Goksu, H. Evaluation of the inhibitive effect of Diospyros kaki (Persimmon) leaves extract on St37 steel corrosion in acid medium. Sustain. Chem. Pharm. 2016, 4, 57–66. [Google Scholar] [CrossRef]

- Tayanç, M.; Aytaç, A.; Bayram, A. The effect of carbon content on fatigue strength of dual-phase steels. Mater. Des. 2007, 28, 1827–1835. [Google Scholar] [CrossRef]

- Campbell, E.; Flake, C. Elements of Metallurgy and Engineering Alloys; Chapter 14, Fatigue; ASM International: Cleveland, OH, USA, 2008. [Google Scholar]

- Sonsino, C.M. Course of SN-curves especially in the high-cycle fatigue regime with regard to component design and safety. Int. J. Fatigue 2007, 29, 2246–2258. [Google Scholar] [CrossRef]

- Naito, T.; Ueda, H.; Kikuchi, M. Fatigue behavior of carburized steel with internal oxides and nonmartensitic microstructure near the surfsace. Metall. Trans. A 1984, 15, 1431–1436. [Google Scholar] [CrossRef]

- Mutoh, Y.; Tanaka, K. Fretting fatigue in several steels and a cast iron. Wear 1988, 125, 175–191. [Google Scholar] [CrossRef]

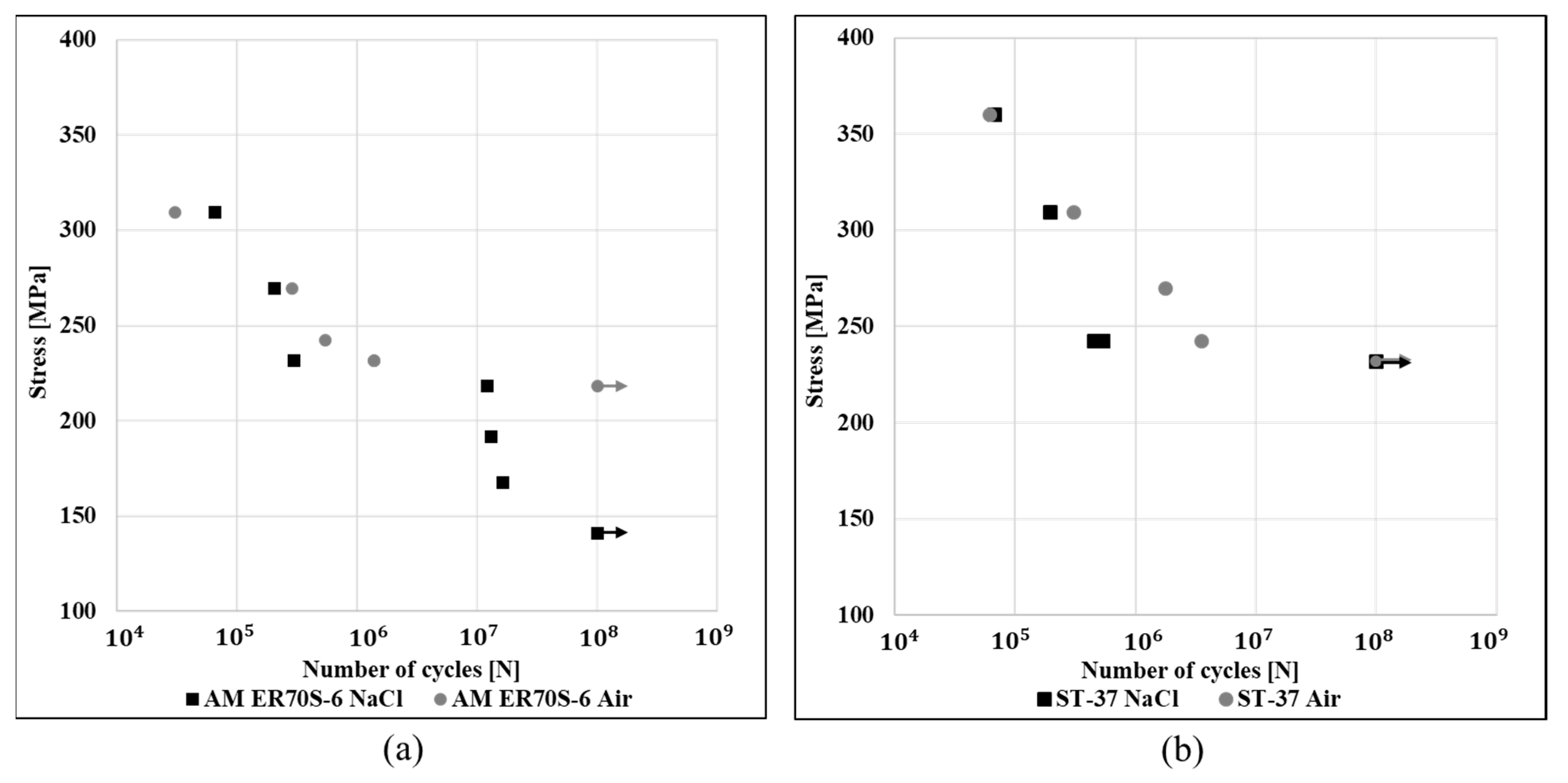

| AM ER70S-6 | ST-37 | |

|---|---|---|

| Ecorr (V) | −0.65 ± 0.002 | −0.56 ± 0.03 |

| Icorr (μA) | 6.12 ± 0.6 | 6.6 ± 0.7 |

| Corrosion rate (mmpy) | 0.13 ± 0.01 | 0.08 ± 0.01 |

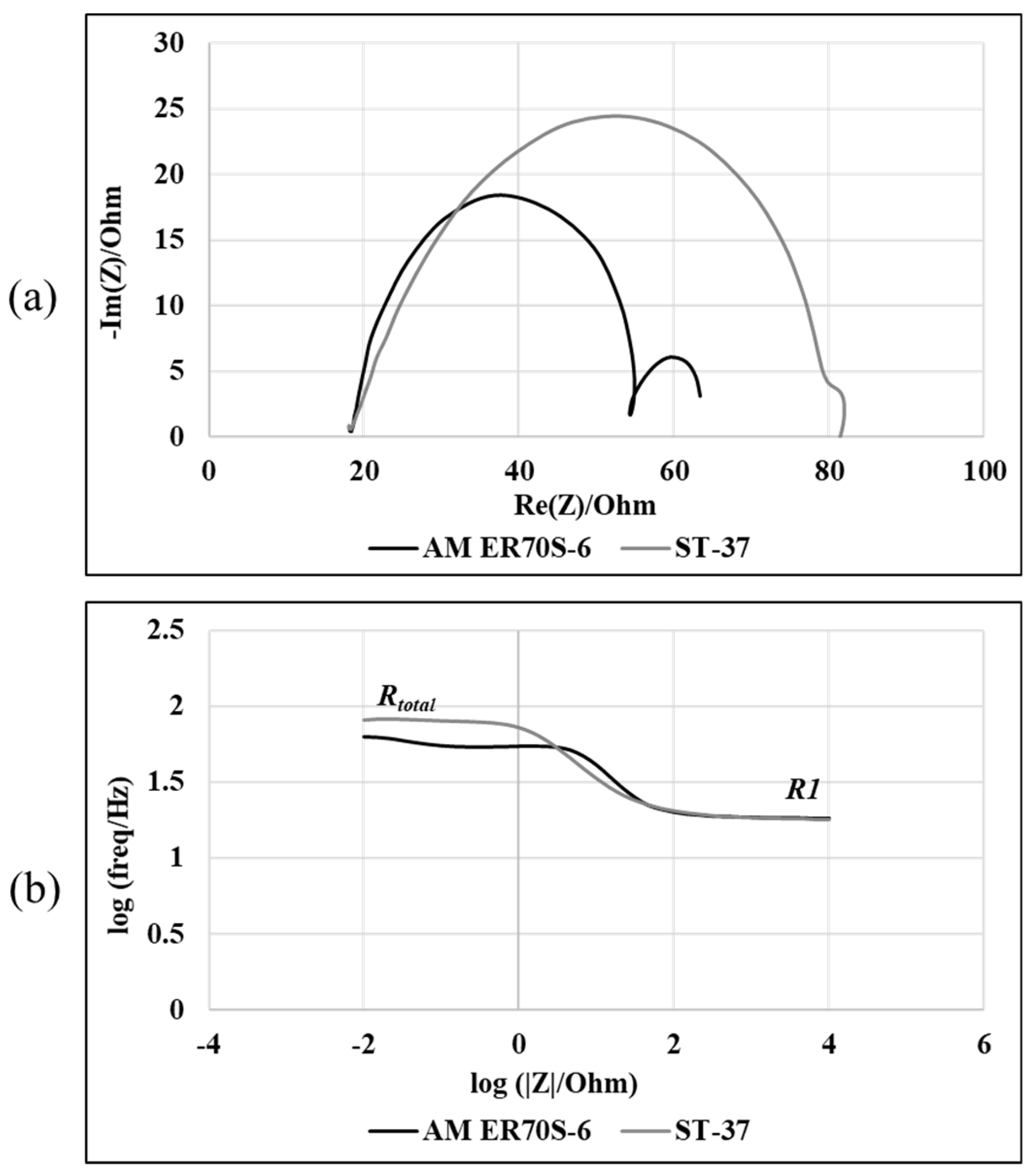

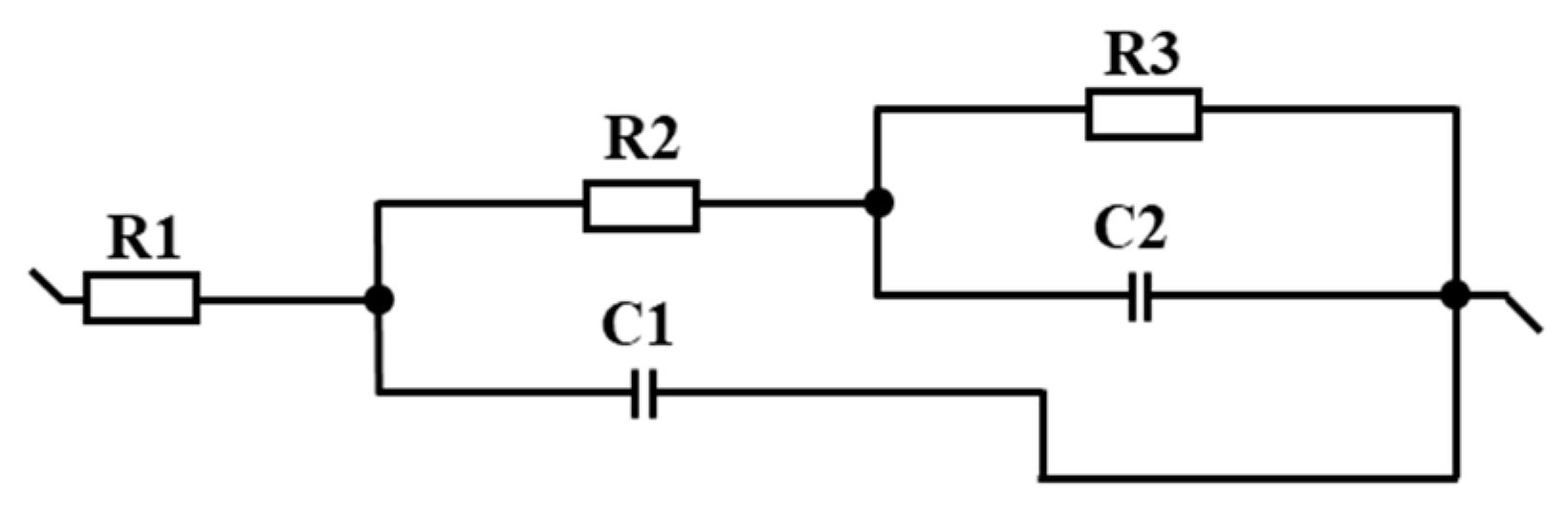

| R1 [Ohm] | C1 [F] | R2 [Ohm] | C2 [F] | R3 [Ohm] | |

|---|---|---|---|---|---|

| AM ER70S-6 | 18.32 | 2.55∙10−4 | 6.31 | 2.44∙10−4 | 31.98 |

| ST-37 | 18.65 | 4.13∙10−4 | 18.86 | 1.14∙10−3 | 42.15 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ron, T.; Levy, G.K.; Dolev, O.; Leon, A.; Shirizly, A.; Aghion, E. The Effect of Microstructural Imperfections on Corrosion Fatigue of Additively Manufactured ER70S-6 Alloy Produced by Wire Arc Deposition. Metals 2020, 10, 98. https://doi.org/10.3390/met10010098

Ron T, Levy GK, Dolev O, Leon A, Shirizly A, Aghion E. The Effect of Microstructural Imperfections on Corrosion Fatigue of Additively Manufactured ER70S-6 Alloy Produced by Wire Arc Deposition. Metals. 2020; 10(1):98. https://doi.org/10.3390/met10010098

Chicago/Turabian StyleRon, Tomer, Galit Katarivas Levy, Ohad Dolev, Avi Leon, Amnon Shirizly, and Eli Aghion. 2020. "The Effect of Microstructural Imperfections on Corrosion Fatigue of Additively Manufactured ER70S-6 Alloy Produced by Wire Arc Deposition" Metals 10, no. 1: 98. https://doi.org/10.3390/met10010098

APA StyleRon, T., Levy, G. K., Dolev, O., Leon, A., Shirizly, A., & Aghion, E. (2020). The Effect of Microstructural Imperfections on Corrosion Fatigue of Additively Manufactured ER70S-6 Alloy Produced by Wire Arc Deposition. Metals, 10(1), 98. https://doi.org/10.3390/met10010098