Investigation of the Restored Joint for Aluminum Alloy

Abstract

:1. Introduction

2. Mechanism

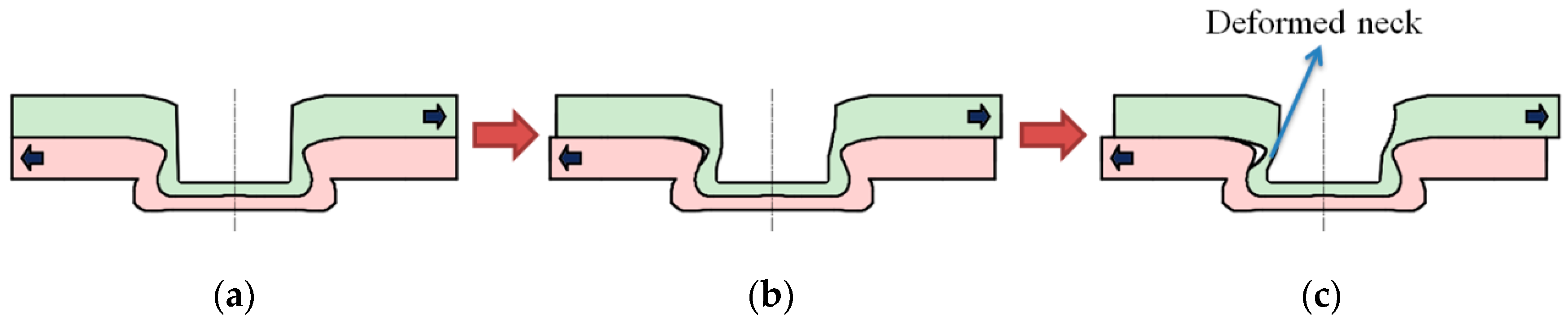

2.1. Mechanism of the Deforming Process

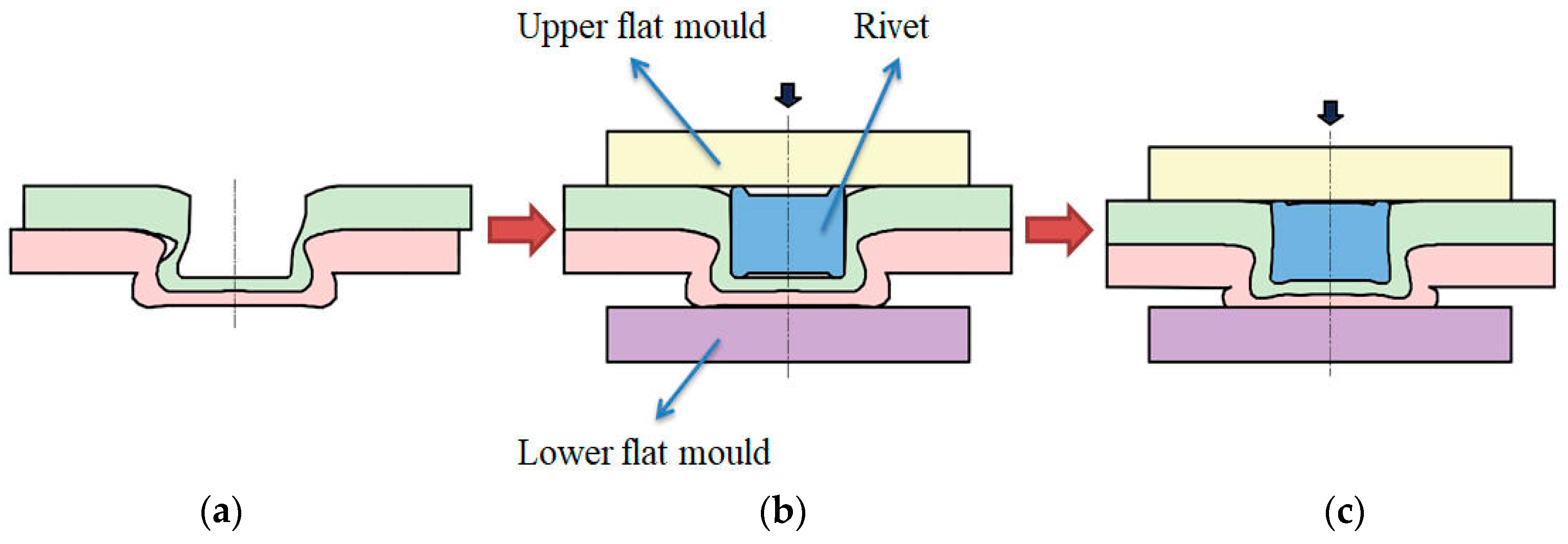

2.2. Mechanism of the Restoring Process

3. Procedure of Experiments

3.1. Materials

3.2. Mechanical Clinching Process

3.3. Deforming Process

3.4. Restoring Process

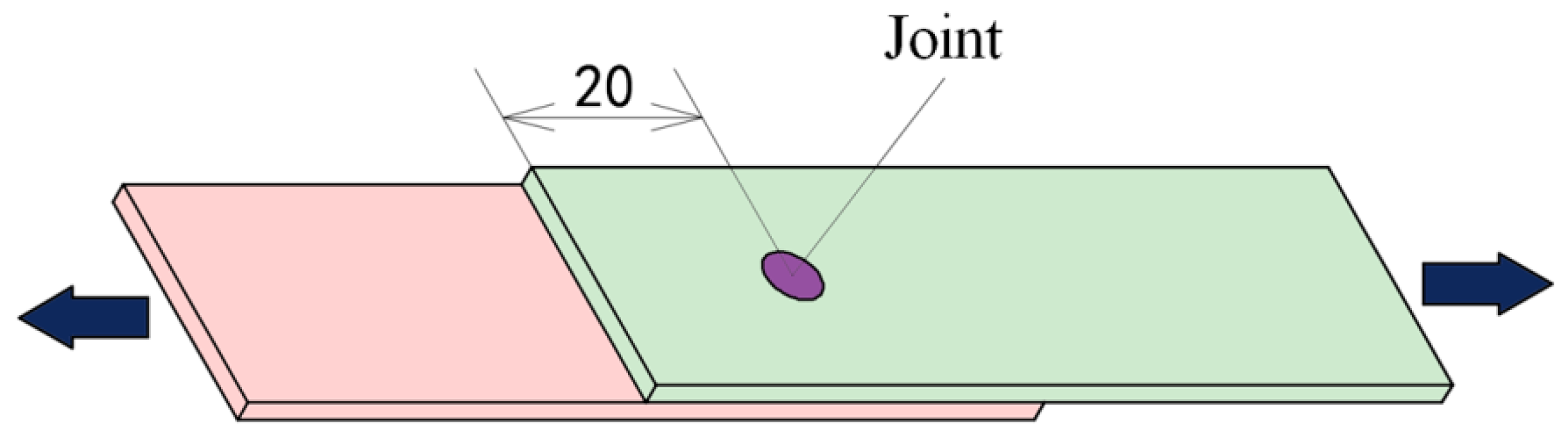

3.5. Static Shearing Test

4. Results and Discussion

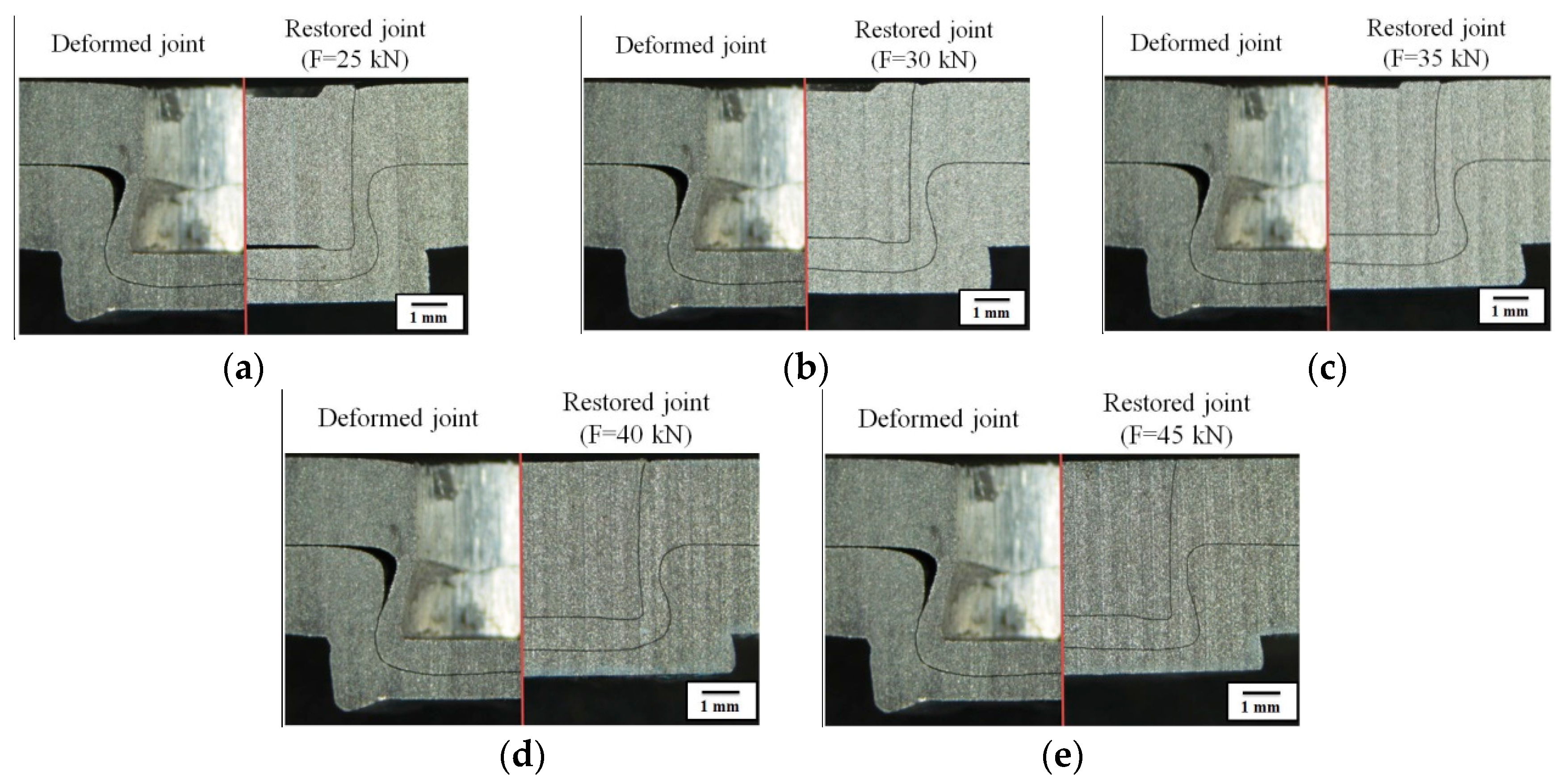

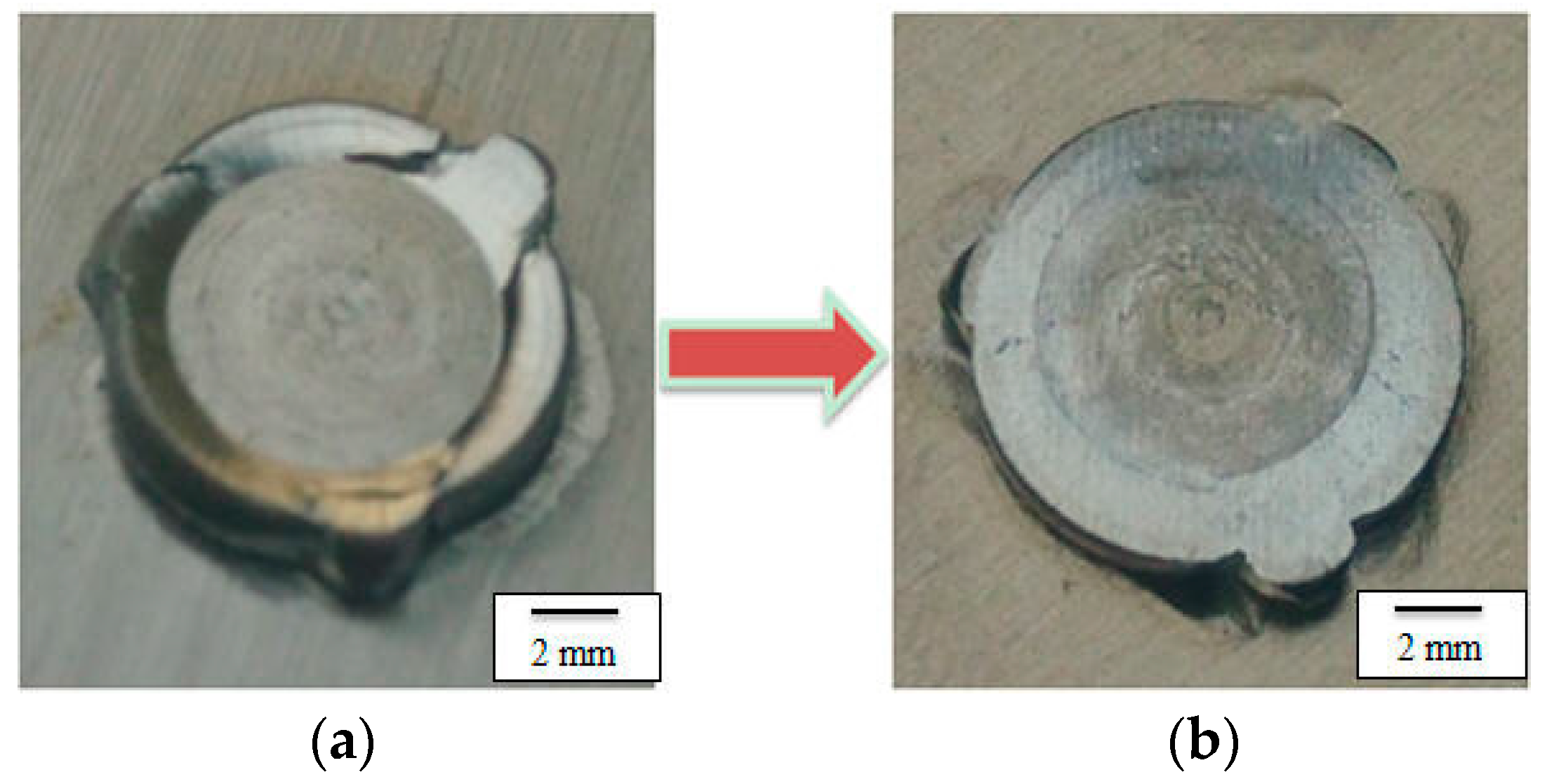

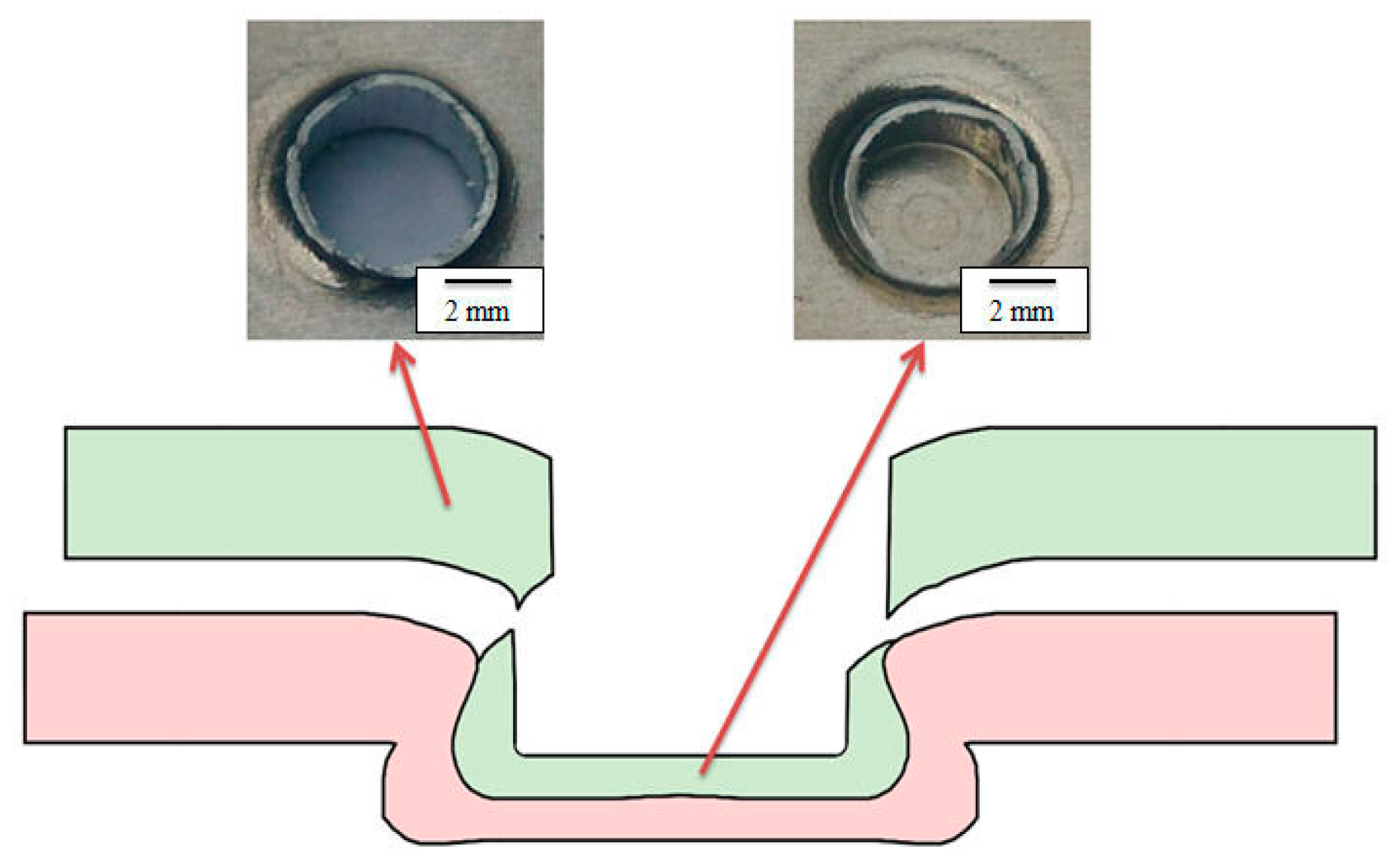

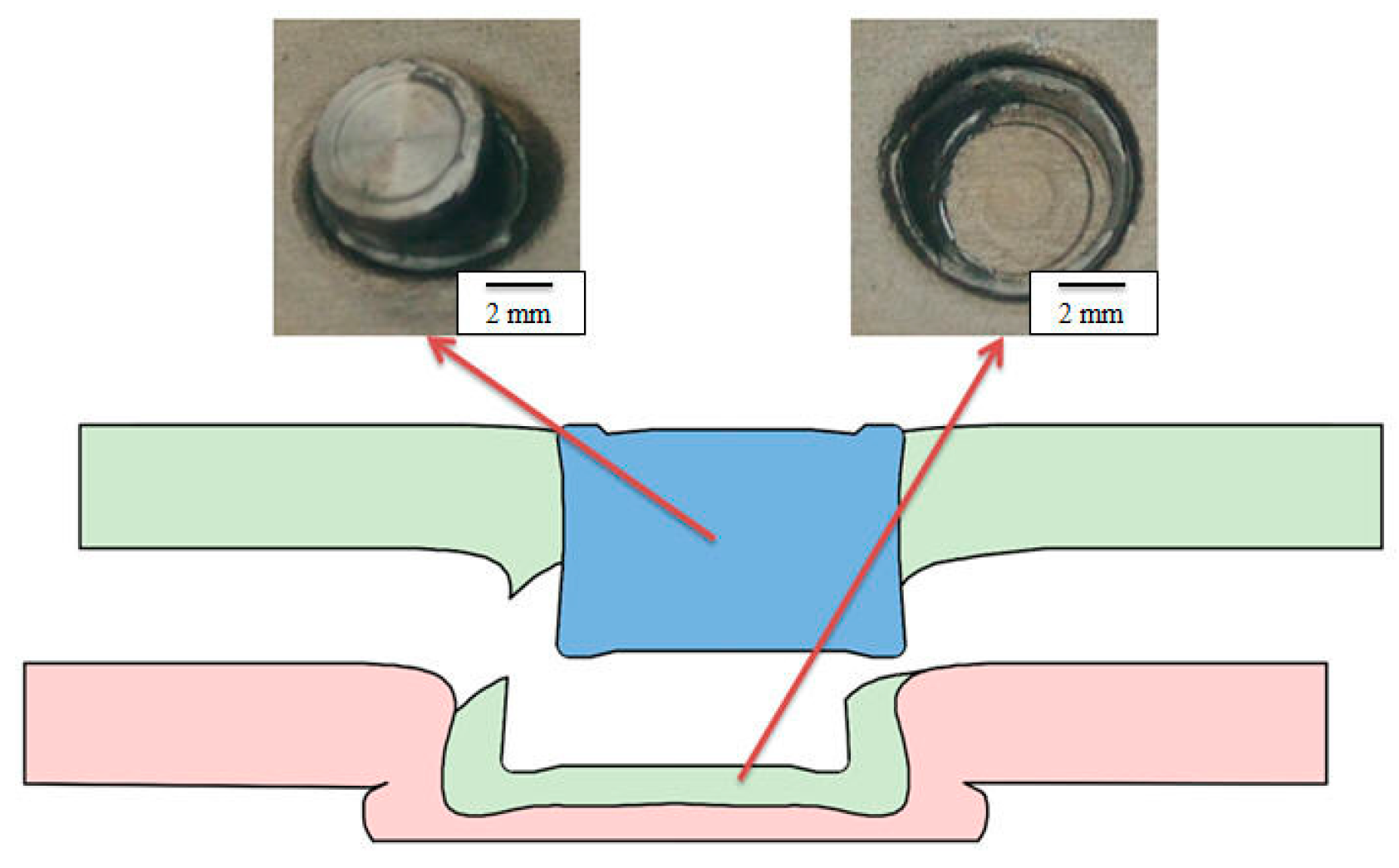

4.1. Material Flow

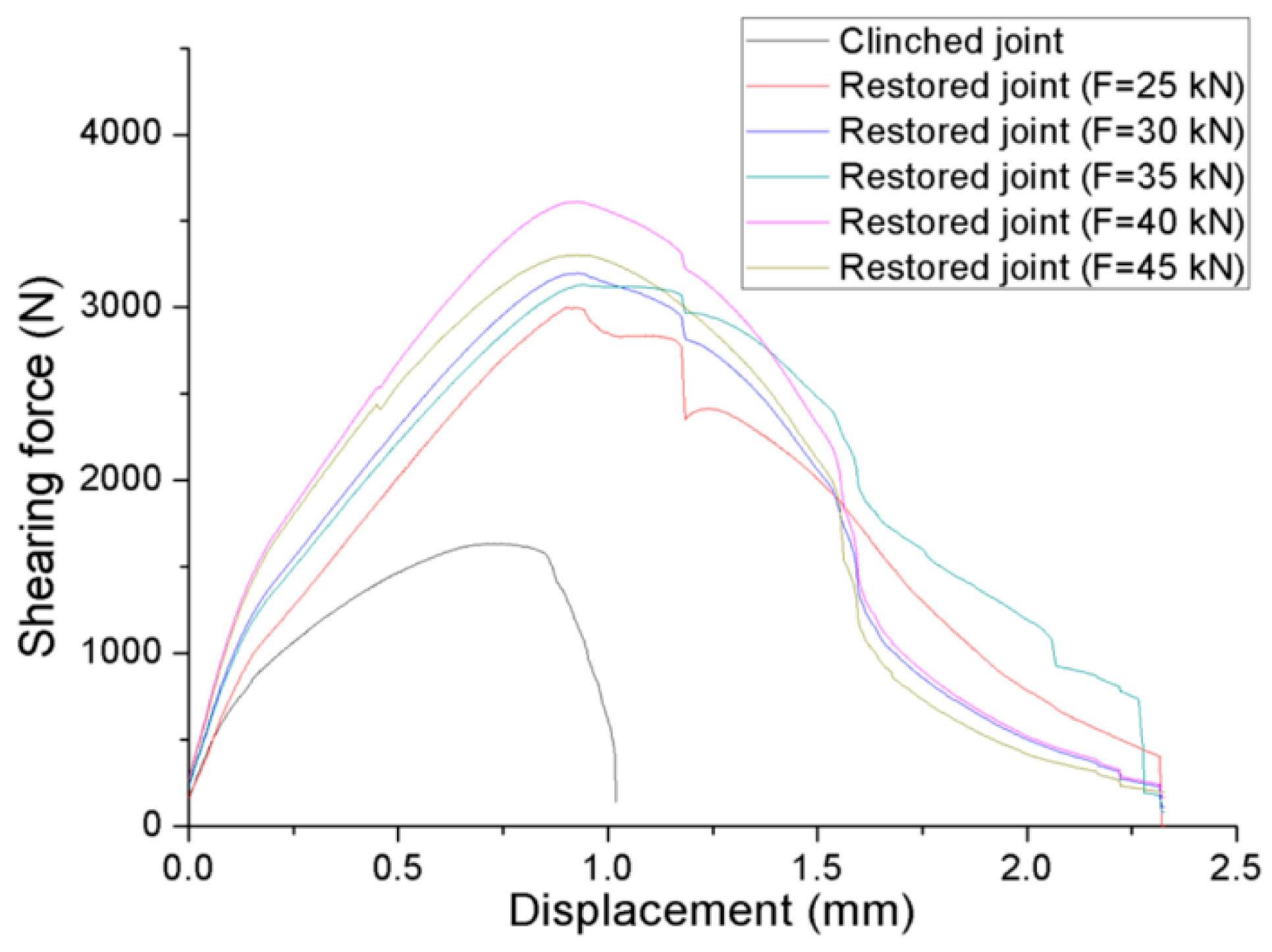

4.2. Mode of Failure

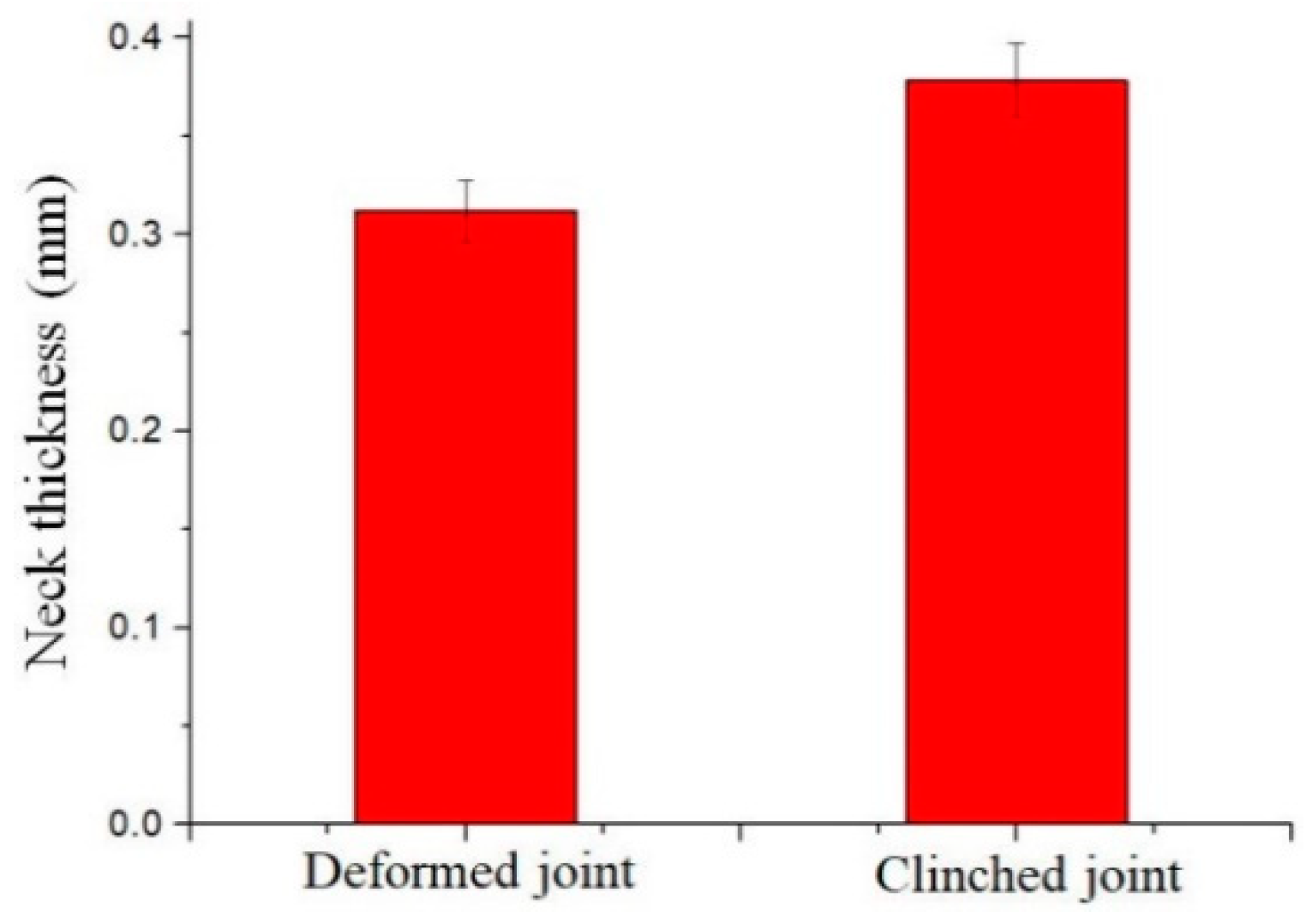

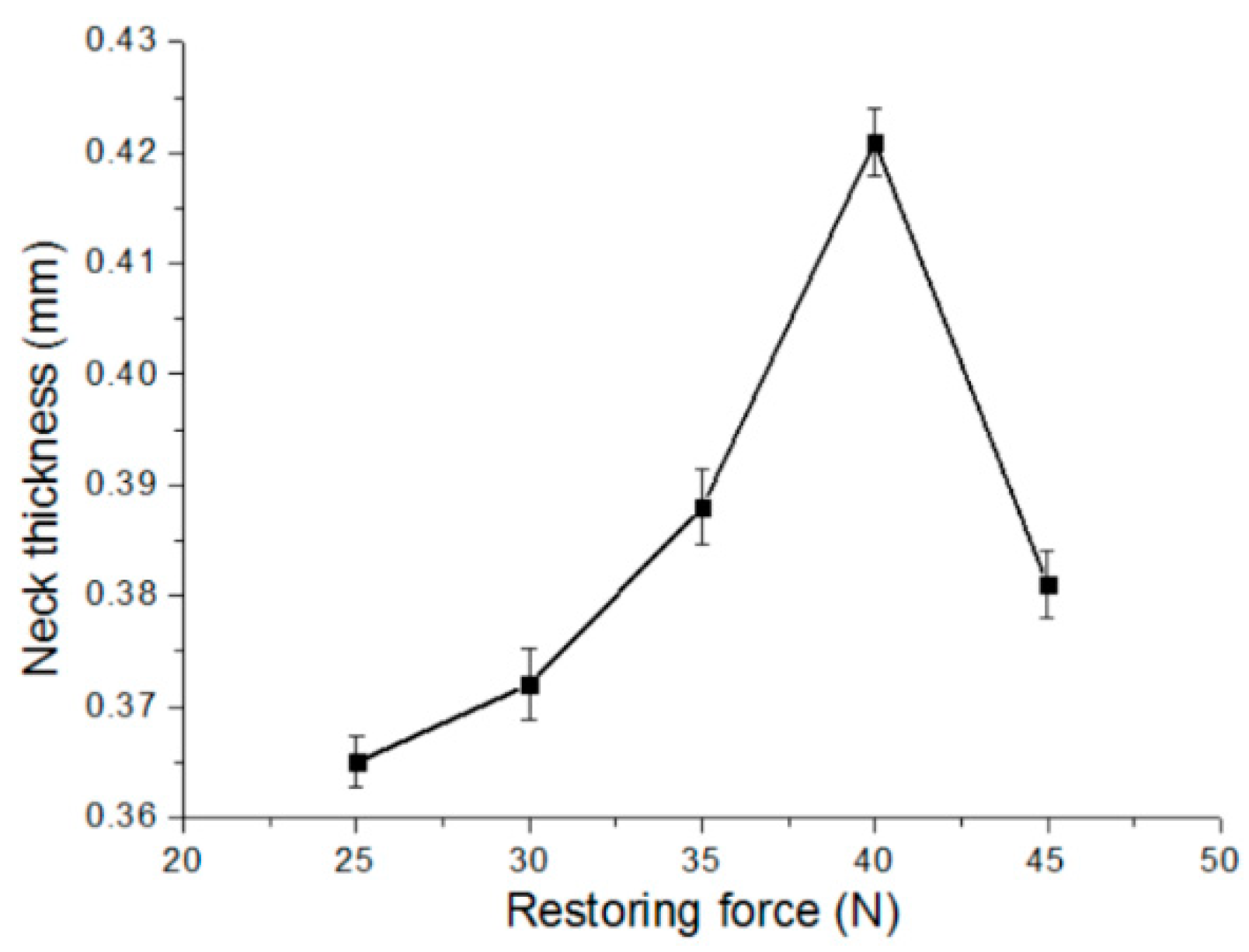

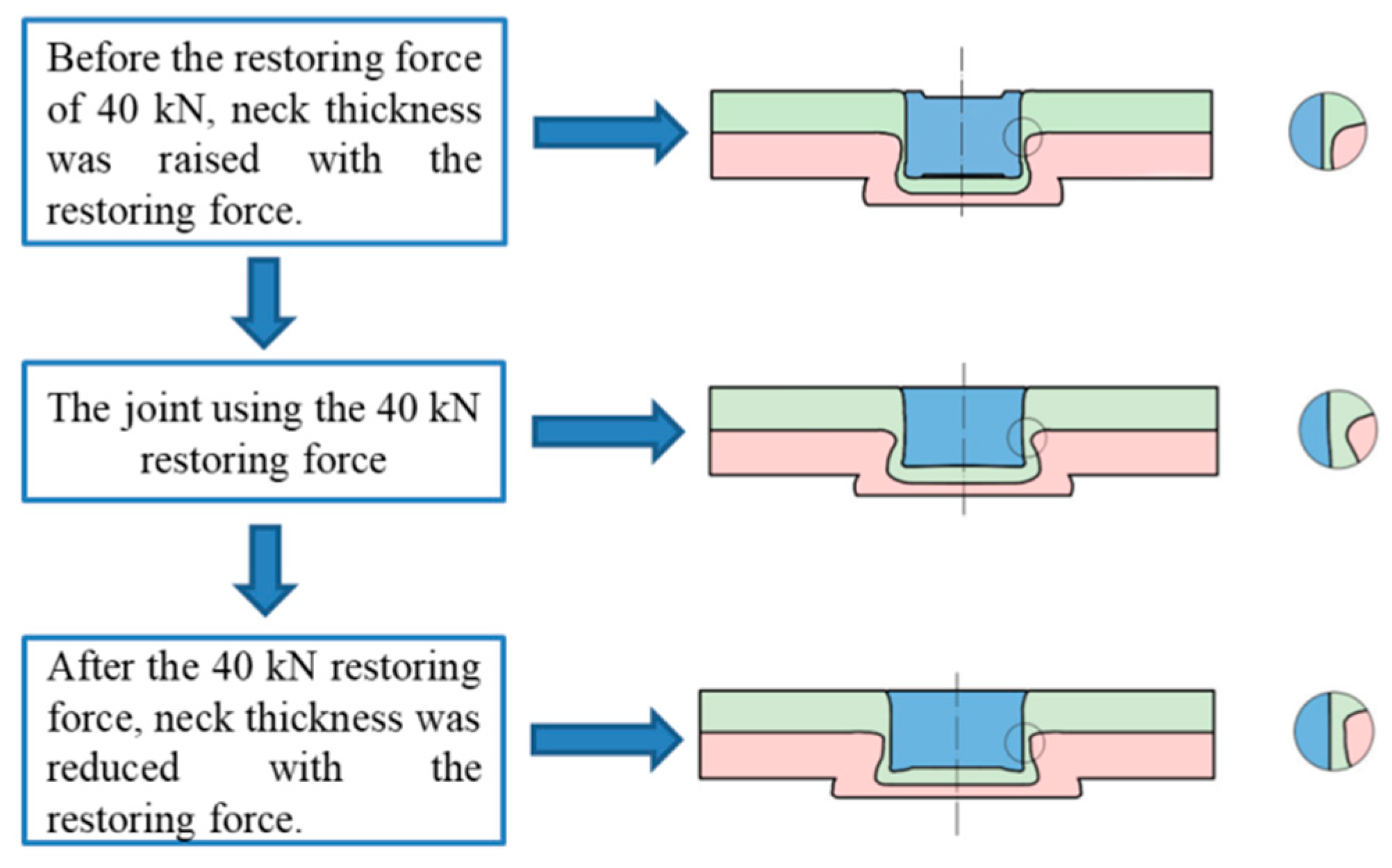

4.3. Thickness of Neck

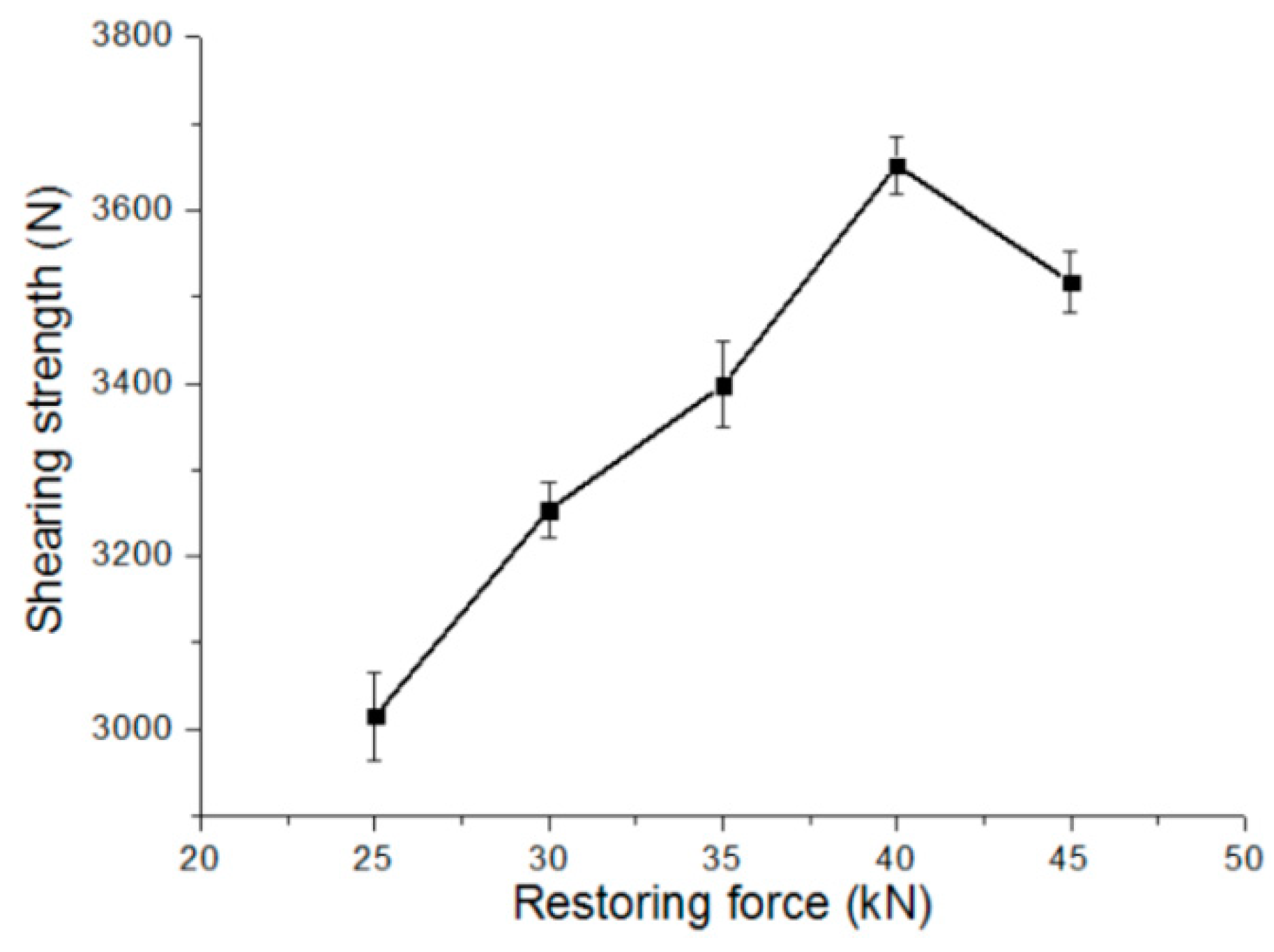

4.4. Shear Strength

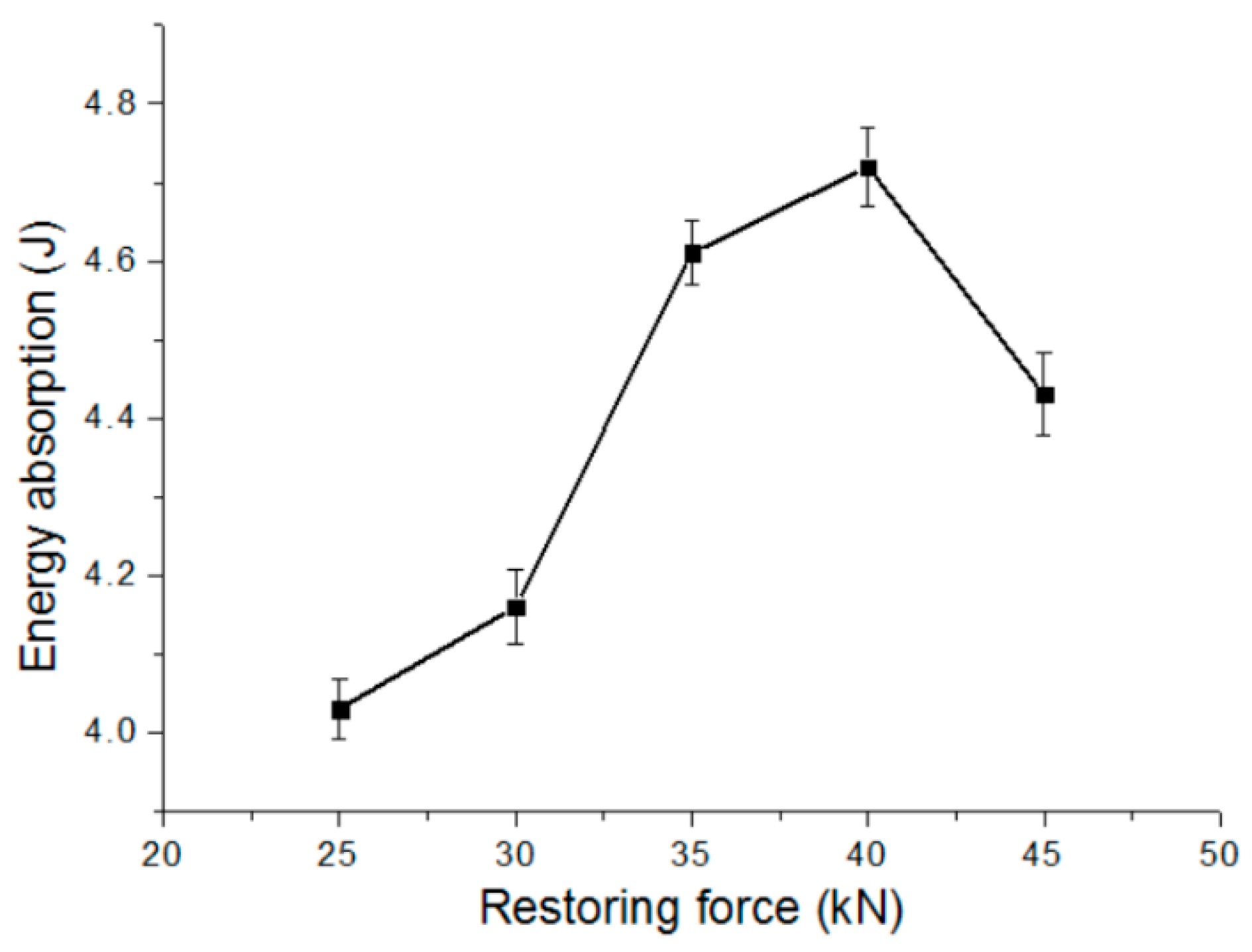

4.5. Absorption of Energy

5. Conclusions

- (1)

- In the restoring process, the customized rivet and the joint protrusion were deformed plastically. The protrusion material was compressed to flow upward and radially. The protrusion height was reduced and the protrusion diameter was increased in the restoring process.

- (2)

- The mode of neck fracture is the main failure mode of restored joint and clinched joint, which implies the thickness of joint neck performs an indispensable role in the joint shear strength. All the deformed joints have lower thickness of neck than the restored joints. The restoring process not only can restore the deformed neck, but also can enlarge the thickness of neck.

- (3)

- All of the clinched joints have lower absorption of energy and shear strength than the restored joints. The restored joint using the 40 kN restoring force has the highest shear strength and absorption of energy in this research.

Author Contributions

Funding

Conflicts of Interest

References

- Eshtayeh, M.M.; Hrairi, M. Recent and future development of the application of finite element analysis in clinching process. Int. J. Adv. Manuf. Technol. 2016, 84, 2589–2608. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, S.D.; Cui, M.C.; Han, X.L.; Fan, S.Q. Numerical and experimental investigations of the reshaped joints with and without a rivet. Int. J. Adv. Manuf. Technol. 2017, 88, 2039–2051. [Google Scholar] [CrossRef]

- Calabrese, L.; Galtieri, G.; Borsellino, C.; Di Bella, G.; Proverbio, E. Durability of hybrid clinch-bonded steel aluminum joints in salt spray environment. Int. J. Adv. Manuf. Technol. 2016, 87, 3137–3147. [Google Scholar] [CrossRef]

- Eshtayeh, M.; Hrairi, M.; Mohiuddin, A.K.M. Multi objective optimization of clinching joints quality using Grey-based Taguchi method. Int. J. Adv. Manuf. Technol. 2016, 87, 233–249. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, S.D.; Cui, M.C.; Han, X.L.; Fan, S.Q. Mechanical properties of the two-steps clinched joint with a clinch-rivet. J. Mater. Process. Technol. 2016, 237, 361–370. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, S.D.; Han, X.L.; Cui, M.C.; Zhao, X.Z.; Ishida, T. Experimental investigation of the mechanical reshaping process for joining aluminum alloy sheets with different thicknesses. J. Manuf. Process. 2017, 26, 105–112. [Google Scholar] [CrossRef]

- Mucha, J.; Witkowski, W. The clinching joints strength analysis in the aspects of changes in the forming technology and load conditions. Thin-Walled Struct. 2014, 82, 55–66. [Google Scholar] [CrossRef]

- Chen, C.; Li, Y.X.; Zhai, Z.Y.; Zhao, S.D.; Zhang, P.; Huang, M.H.; Li, Y.B. Comparative investigation of three different reforming processes for clinched joint to increase joining strength. J. Manuf. Process. 2019, 45, 83–91. [Google Scholar] [CrossRef]

- Mucha, J.; Witkowski, W. The experimental analysis of the double joint type change effect on the joint destruction process in uniaxial shearing test. Thin-Walled Struct. 2013, 66, 39–49. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, S.D.; Han, X.L.; Cui, M.C.; Fan, S.Q. Investigation of mechanical behavior of the reshaped joints realized with different reshaping forces. Thin-Walled Struct. 2016, 107, 266–273. [Google Scholar] [CrossRef]

- Eshtayeh, M.; Hrairi, M.; Mohiuddin, A.K.M. Clinching process for joining dissimilar materials: State of the art. Int. J. Adv. Manuf. Technol. 2016, 82, 179–195. [Google Scholar] [CrossRef]

- Chen, C.; Fan, S.Q.; Han, X.L.; Zhao, S.D.; Cui, M.C.; Ishida, T. Experimental study on the height-reduced joints to increase the cross-tensile strength. Int. J. Adv. Manuf. Technol. 2017, 91, 2655–2662. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, S.D.; Cui, M.C.; Han, X.L.; Zhao, X.Z.; Ishida, T. Effects of geometrical parameters on the strength and energy absorption of the height-reduced joint. Int. J. Adv. Manuf. Technol. 2017, 90, 3533–3541. [Google Scholar] [CrossRef]

- Wen, T.; Huang, Q.; Liu, Q.; Ou, W.X.; Zhang, S. Joining different metallic sheets without protrusion by flat hole clinching process. Int. J. Adv. Manuf. Technol. 2014, 85, 217–225. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, S.D.; Cui, M.C.; Han, X.L.; Fan, S.Q.; Ishida, T. An experimental study on the compressing process for joining Al6061 sheets. Thin-Walled Struct. 2016, 108, 56–63. [Google Scholar] [CrossRef]

- Pinger, T.; Rückriem, E.-M. Investigation on the corrosion and mechanical behavior of thin film batch galvanized thick plate components in clinch joints. Int. J. Adv. Manuf. Technol. 2016, 86, 29–36. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, S.D.; Cui, M.C.; Han, X.L.; Fan, S.Q.; Zhao, X.Z. Comparative investigation of auxiliary processes for increasing the strength of clinched joints. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2018, 232, 165–172. [Google Scholar] [CrossRef]

- Neugebauer, R.; Todtermuschke, M.; Mauermann, F.; Riedel, F. Overview on the state of development and the application potential of dieless mechanical joining processes. Arch. Civ. Mech. Eng. 2008, 4, 51–60. [Google Scholar] [CrossRef]

- Mucha, J.; Kašcák, L.; Spišák, E. Joining the car-body sheets using clinching process with various thickness and mechanical property arrangements. Arch. Civ. Mech. Eng. 2011, 11, 135–148. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, S.D.; Han, X.L.; Cui, M.C.; Fan, S.Q. Investigation of the height-reducing method for clinched joint with AL5052 and AL6061. Int. J. Adv. Manuf. Technol. 2017, 89, 2269–2276. [Google Scholar] [CrossRef]

- Oudjene, M.; Ben-Ayed, L.; Delamézière, A.; Batoz, J.-L. Shape optimization of clinching tools using the response surface methodology with Moving Least-Square approximation. J. Mater. Process. Technol. 2009, 209, 289–296. [Google Scholar] [CrossRef]

- Lee, C.J.; Kim, J.Y.; Lee, S.K.; Ko, D.C.; Kim, B.M. Design of mechanical clinching tools for joining of aluminium alloy sheets. Mater. Des. 2010, 31, 1854–1861. [Google Scholar] [CrossRef]

- Lambiase, F.; Di Ilio, A. An experimental study on clinched joints realized with different dies. Thin-Walled Struct. 2014, 85, 71–80. [Google Scholar] [CrossRef]

- Mucha, J. The analysis of lock forming mechanism in the clinching joint. Mater. Des. 2011, 32, 4943–4954. [Google Scholar] [CrossRef]

- Lambiase, F. Influence of process parameters in mechanical clinching with extensible dies. Int. J. Adv. Manuf. Technol. 2013, 66, 2123–2131. [Google Scholar] [CrossRef]

- Oudjene, M.; Ben-Ayed, L. On the parametrical study of clinch joining of metallic sheets using the Taguchi method. Eng. Struct. 2008, 30, 1782–1788. [Google Scholar] [CrossRef]

- He, X.C.; Liu, F.L.; Xing, B.Y.; Yang, H.Y.; Wang, Y.Q.; Deng, C.J.; Gu, F.S.; Ball, A. Numerical and experimental investigations of extensible die clinching. Int. J. Adv. Manuf. Technol. 2014, 74, 1229–1236. [Google Scholar] [CrossRef]

- Lambiase, F.; Durante, M.; Di Ilio, A. Fast joining of aluminum sheets with Glass Fiber Reinforced Polymer (GFRP) by mechanical clinching. J. Mater. Process. Technol. 2016, 236, 241–251. [Google Scholar] [CrossRef]

- Lambiase, F.; Ko, D.-C. Feasibility of mechanical clinching for joining aluminum AA6082-T6 and Carbon Fiber Reinforced Polymer sheets. Mater. Des. 2016, 107, 341–352. [Google Scholar] [CrossRef]

- Lambiase, F.; Di Ilio, A. Mechanical clinching of metal–polymer joints. J. Mater. Process. Technol. 2015, 215, 12–19. [Google Scholar] [CrossRef]

- Lambiase, F. Joinability of different thermoplastic polymers with aluminium AA6082 sheets by mechanical clinching. Int. J. Adv. Manuf. Technol. 2015, 80, 1995–2006. [Google Scholar] [CrossRef]

- Lambiase, F. Mechanical behaviour of polymer–metal hybrid joints produced by clinching using different tools. Mater. Des. 2015, 87, 606–618. [Google Scholar] [CrossRef]

- Jiang, T.; Liu, Z.X.; Wang, P.C. Effect of aluminum pre-straining on strength of clinched galvanized SAE1004 steel-to-AA6111-T4 aluminum. J. Mater. Process. Technol. 2015, 215, 193–204. [Google Scholar] [CrossRef]

- Jiang, T.; Liu, Z.X.; Wang, P.C. Quality inspection of clinched joints of steel and aluminum. Int. J. Adv. Manuf. Technol. 2015, 76, 1393–1402. [Google Scholar] [CrossRef]

- Abe, Y.; Mori, K.; Kato, T. Joining of high strength steel and aluminium alloy sheets by mechanical clinching with dies for control of metal flow. J. Mater. Process. Technol. 2012, 212, 884–889. [Google Scholar] [CrossRef]

- Lee, C.J.; Lee, J.M.; Ryu, H.Y.; Lee, H.Y.; Lee, K.H.; Kim, B.M.; Ko, D.C. Design of hole-clinching process for joining of dissimilar materials—Al6061-T4 alloy with DP780 steel, hot-pressed 22MnB5 steel, and carbon fiber reinforced plastic. J. Mater. Process. Technol. 2014, 214, 2169–2178. [Google Scholar] [CrossRef]

- Xing, B.Y.; He, X.C.; Wang, Y.Q.; Yang, H.Y.; Deng, C.J. Study of mechanical properties for copper alloy H62 sheets joined by self-piercing riveting and clinching. J. Mater. Process. Technol. 2015, 216, 28–36. [Google Scholar] [CrossRef]

- He, X.C.; Zhang, Y.; Xing, B.Y.; Gu, F.S.; Ball, A. Mechanical properties of extensible die clinched joints in titanium sheet materials. Mater. Des. 2015, 71, 26–35. [Google Scholar] [CrossRef]

- Zhao, S.D.; Xu, F.; Guo, J.H.; Han, X.L. Experimental and numerical research for the failure behavior of the clinched joint using modified Rousselier model. J. Mater. Process. Technol. 2014, 214, 2134–2145. [Google Scholar] [CrossRef]

- Xu, F.; Zhao, S.D.; Han, X.L. Use of a modified Gurson model for the failure behaviour of the clinched joint on Al6061 sheet. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 335–348. [Google Scholar] [CrossRef]

- Lambiase, F.; Di Ilio, A. Damage analysis in mechanical clinching: Experimental and numerical study. J. Mater. Process. Technol. 2016, 230, 109–120. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Zhang, H.; Peng, H.; Ran, X.; Pan, Q. Investigation of the Restored Joint for Aluminum Alloy. Metals 2020, 10, 97. https://doi.org/10.3390/met10010097

Chen C, Zhang H, Peng H, Ran X, Pan Q. Investigation of the Restored Joint for Aluminum Alloy. Metals. 2020; 10(1):97. https://doi.org/10.3390/met10010097

Chicago/Turabian StyleChen, Chao, Huiyang Zhang, Hao Peng, Xiangkun Ran, and Qing Pan. 2020. "Investigation of the Restored Joint for Aluminum Alloy" Metals 10, no. 1: 97. https://doi.org/10.3390/met10010097

APA StyleChen, C., Zhang, H., Peng, H., Ran, X., & Pan, Q. (2020). Investigation of the Restored Joint for Aluminum Alloy. Metals, 10(1), 97. https://doi.org/10.3390/met10010097