Tensile Properties and Microstructural Evolution of an Al-Bearing Ferritic Stainless Steel at Elevated Temperatures

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

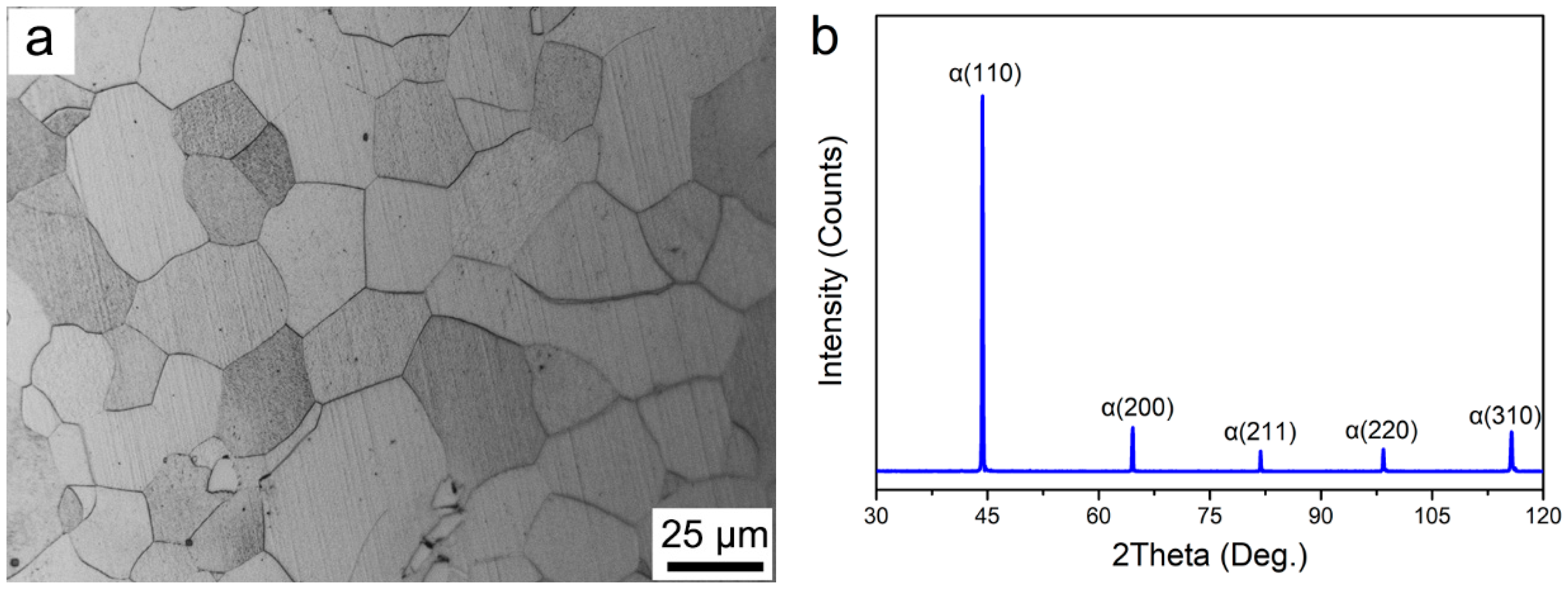

3.1. Initial Microstructure

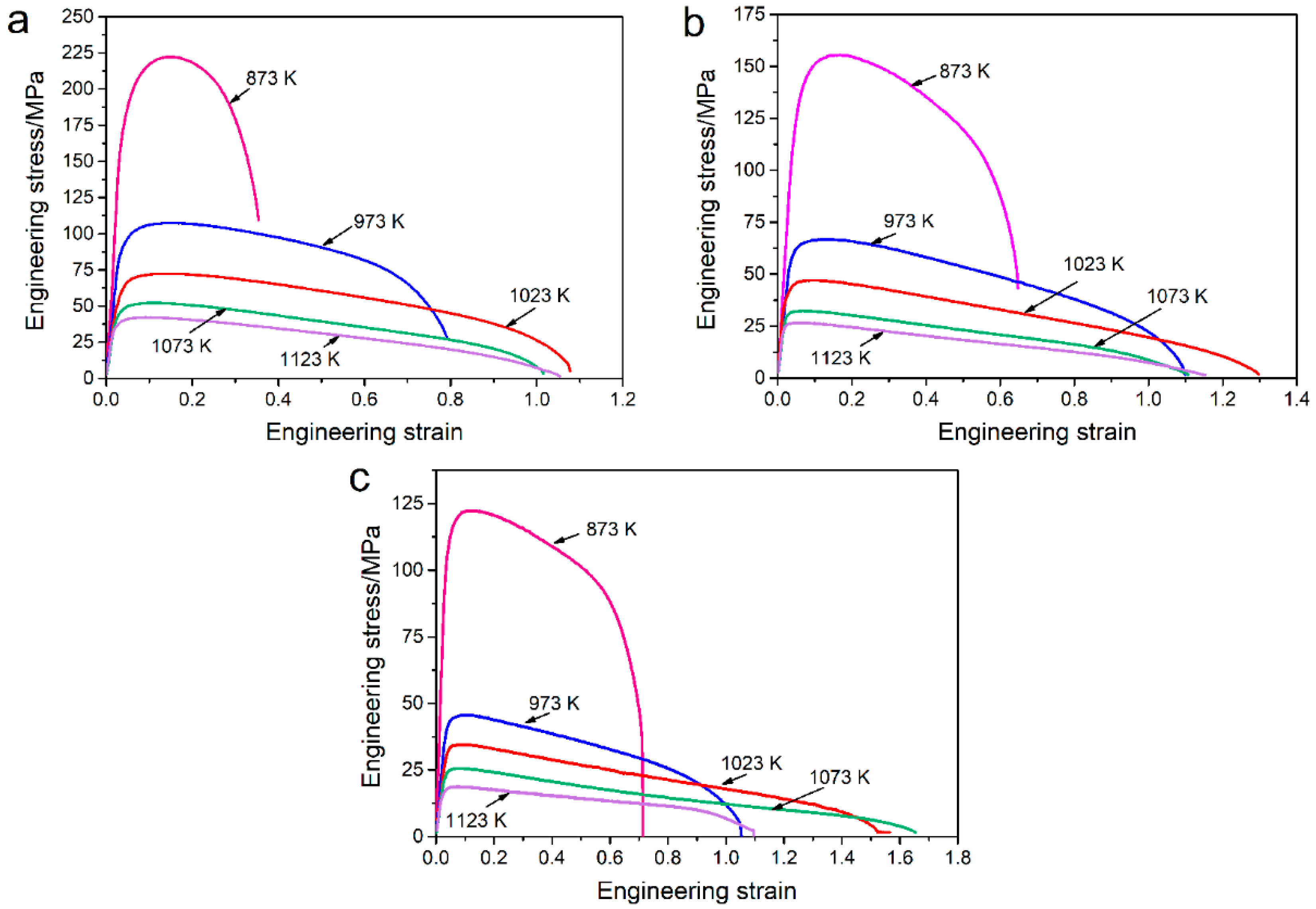

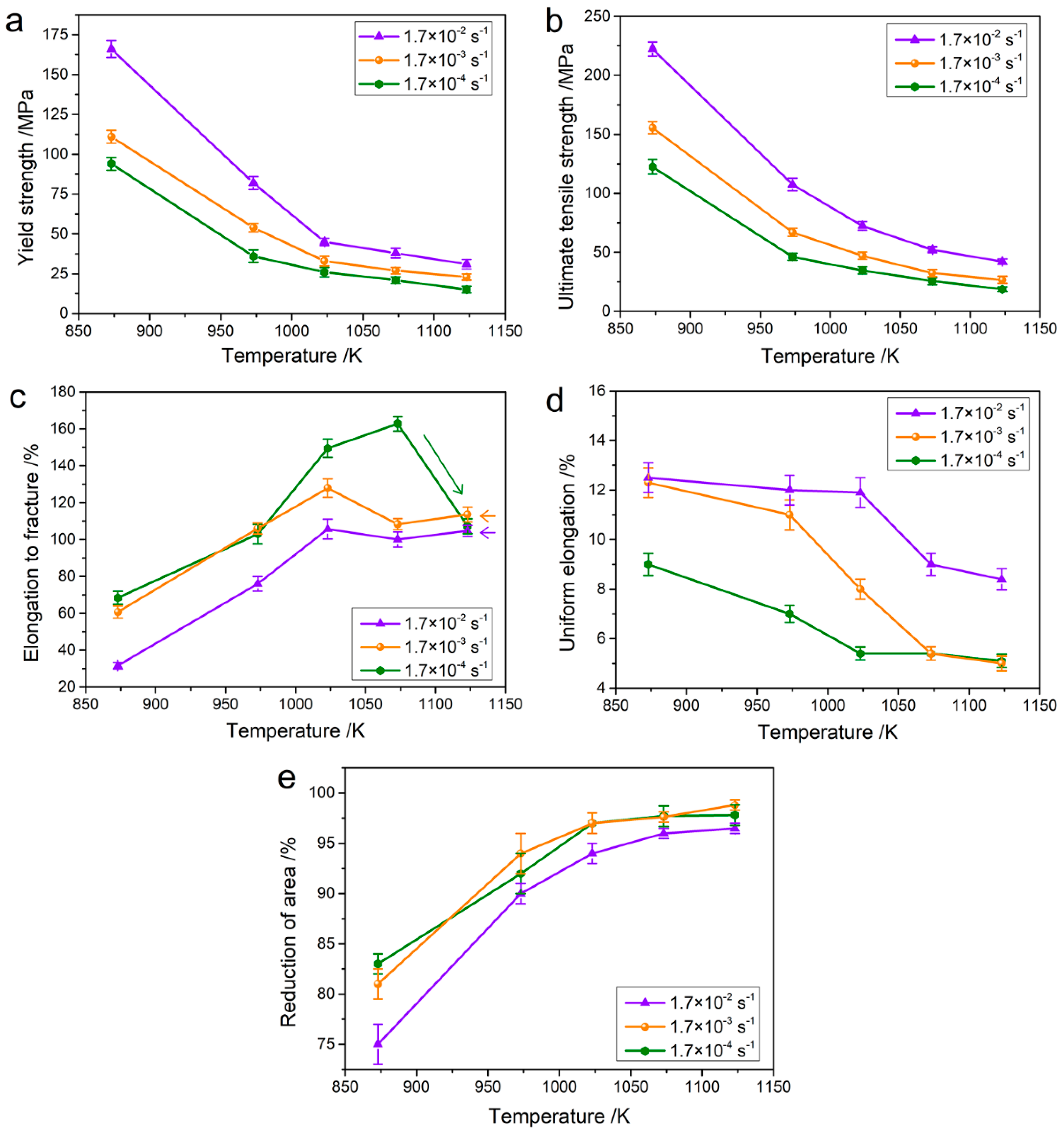

3.2. Tensile Properties

3.3. Microstructures Analyses

3.3.1. Microstructures Evolution Observed by OM

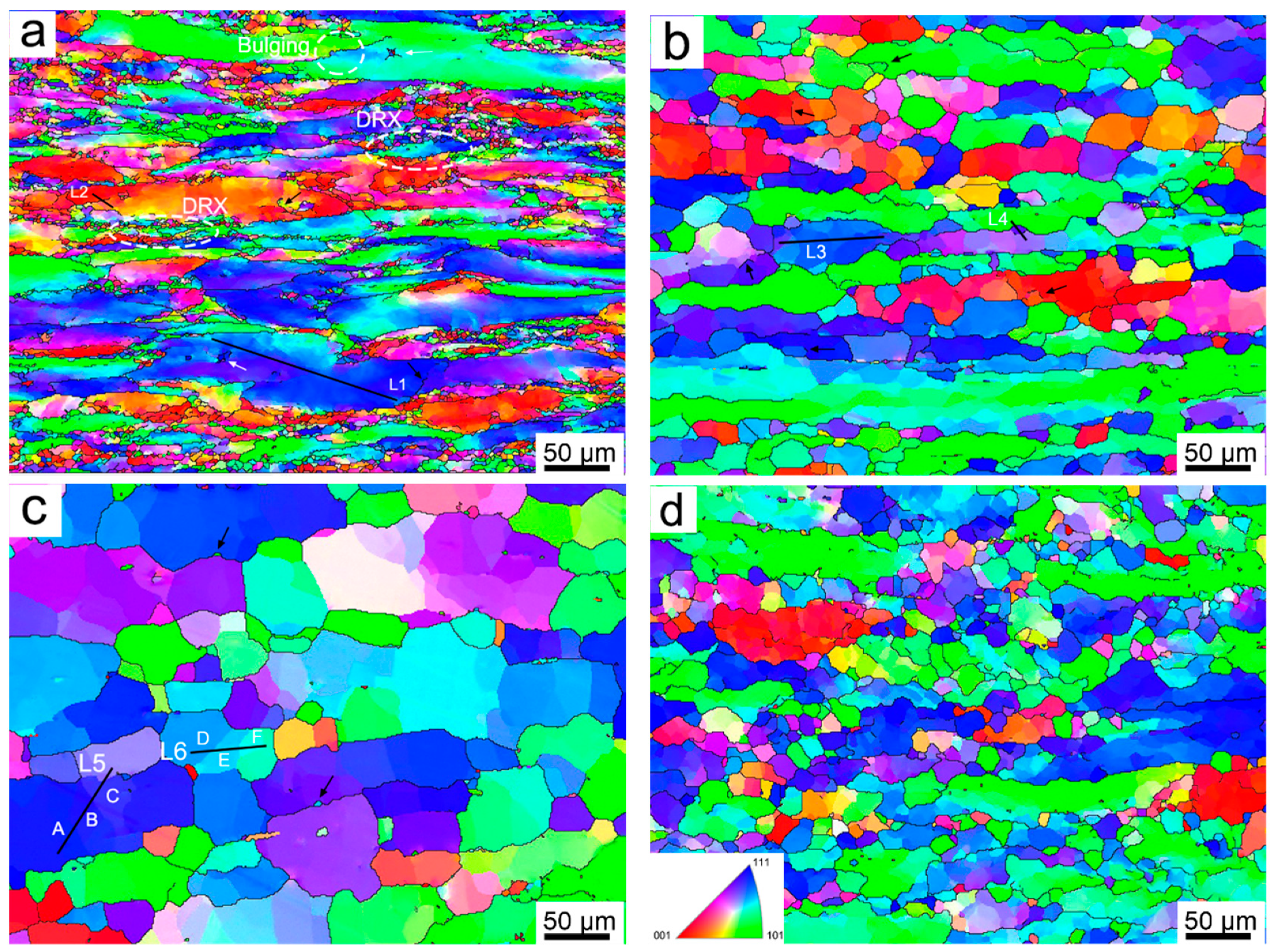

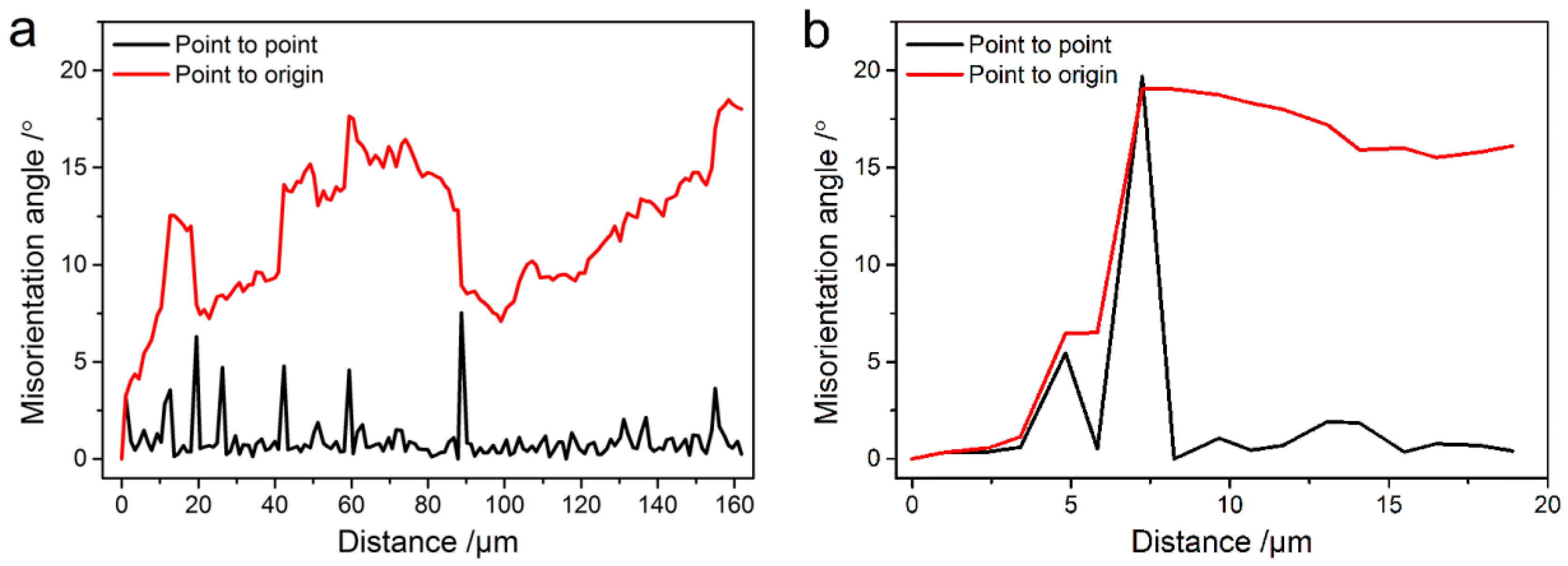

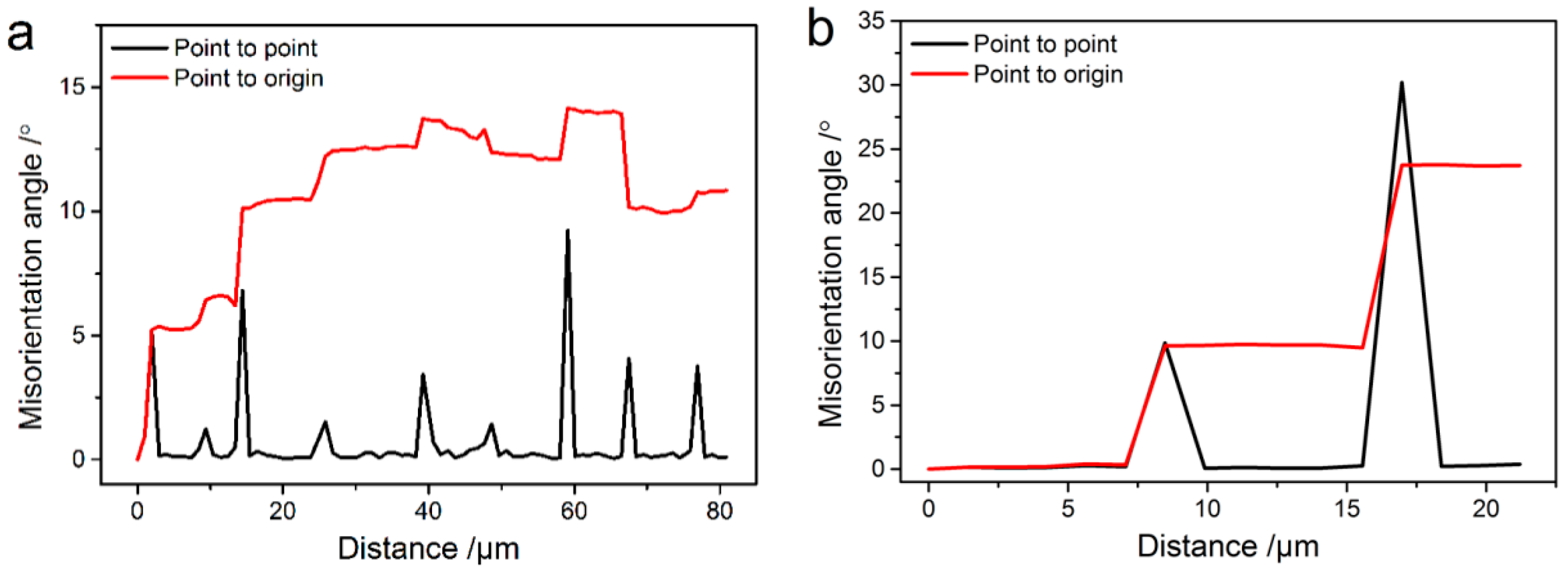

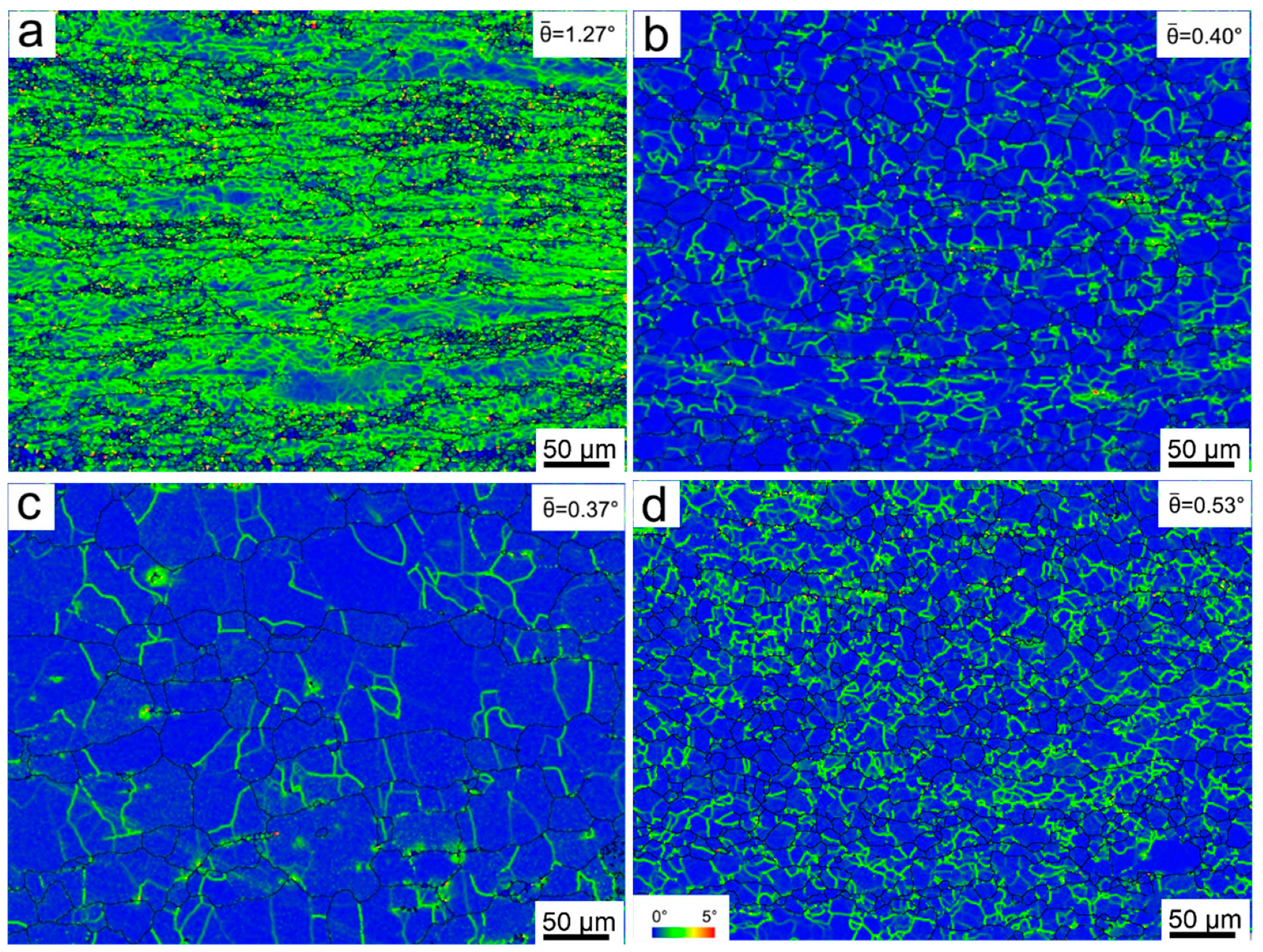

3.3.2. Microstructures Evolution Observed by EBSD

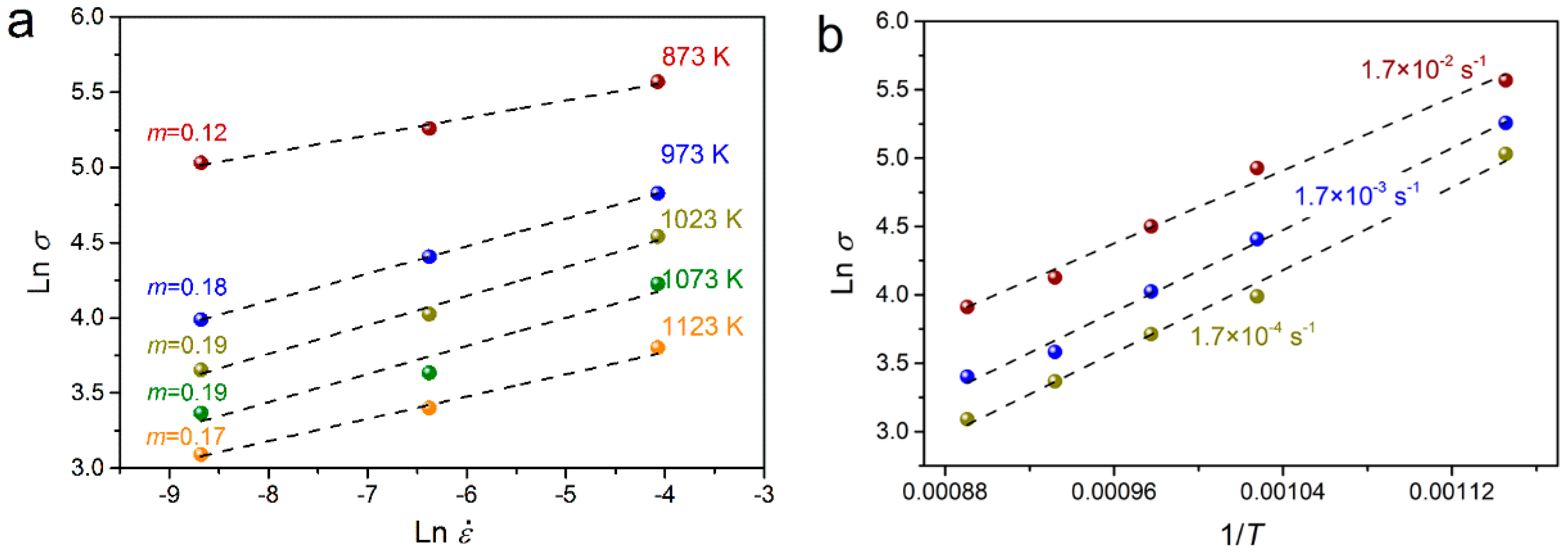

3.4. Kinetic Analysis

4. Conclusions

- (1)

- The maximum elongation to fracture can be obtained at 1023 K for the strain rates of 1.7 × 10−3 and 1.7 × 10−2 s−1. The temperature for the maximum elongation to fracture is delayed to 1073 K when decreasing the strain rate to 1.7 × 10−4 s−1. The decrease in necking deformation resistance caused by fast migration of boundaries and uneven grain distribution results in the low ductility at high temperature of 1123 K.

- (2)

- At low temperature, DRV dominates the softening process though a small number of DDRX occurs. As increasing the temperature, the flow softening by CDRX is reinforced due to the acceleration of rotation and coalescence of sub-grains. The main reason of ductility decrease at high temperature and low strain rate is the grain coarsening and the deformation discordance between small new DRX grains and coarse grains.

- (3)

- The stress exponent and the deformation activation energy are 5.9 and 355 kJ·mol−1 respectively. The dominant deformation mechanism is the dislocations motion controlled by climb.

Author Contributions

Funding

Conflicts of Interest

References

- Fu, J.; Li, F.; Sun, J.; Wu, Y. Texture, orientation, and mechanical properties of Ti-stabilized Fe-17Cr ferritic stainless steel. Mater. Sci. Eng. A 2018, 738, 335–343. [Google Scholar] [CrossRef]

- Han, J.; Li, H.; Zhu, Z.; Jiang, L.; Xu, H.; Ma, L. Effects of processing optimization on microstructure, texture, grain boundary and mechanical properties of Fe-17Cr ferritic stainless steel thick plates. Mater. Sci. Eng. A 2014, 616, 20–28. [Google Scholar] [CrossRef]

- Wang, W.; Han, P.; Peng, P.; Zhang, T.; Liu, Q.; Yuan, S.-N.; Huang, L.-Y.; Yu, H.-L.; Qiao, K.; Wang, K.-S. Friction Stir Processing of Magnesium Alloys: A Review. Acta Met. Sin. Engl. Lett. 2019, 32, 1–15. [Google Scholar] [CrossRef]

- Wang, W.; Han, P.; Yuan, J.; Peng, P.; Liu, Q.; Qiang, F.; Qiao, K.; Wang, K.-S. Enhanced Mechanical Properties of Pure Zirconium via Friction Stir Processing. Acta Met. Sin. Engl. Lett. 2019, 32, 1–7. [Google Scholar] [CrossRef]

- Hu, W.Q.; Dong, Z.; Yu, L.M.; Ma, Z.Q.; Liu, Y.C. Synthesis of W-Y2O3 alloys by freeze-drying and subsequent low temperature sintering: Microstructure refinement and second phase particles regulation. J. Mater. Res. Technol. 2020, 36, 84–90. [Google Scholar] [CrossRef]

- Chiu, Y.-T.; Lin, C.-K.; Wu, J.-C. High-temperation tensile and creep properties of a ferritic stainless steel for interconnect in solid oxide fuel cell. J. Power Sources 2011, 196, 2005–2012. [Google Scholar] [CrossRef]

- Gurram, M.; Adepu, K.; Pinninti, R.R.; Gankidi, M.R. Effect of copper and aluminium addition on mechanical properties and corrosion behaviour of AISI 430 ferritic stainless steel gas tungsten arc welds. J. Mater. Res. Technol. 2013, 2, 238–249. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, Z.; Xu, Y.; Wang, G. The sticking behavior of an ultra purified ferritic stainless steel during hot strip rolling. J. Mater. Process. Technol. 2012, 212, 2183–2192. [Google Scholar] [CrossRef]

- Fujita, N.; Ohmura, K.; Kikuchi, M.; Suzuki, T.; Funaki, S.; Hiroshige, I. Effect of niobium on high-temperature properties for ferritic stainless steel. Scr. Mater. 1996, 35, 705–710. [Google Scholar] [CrossRef]

- Sim, G.M.; Ahn, J.C.; Hong, S.C.; Lee, K.J.; Lee, K.S. Effect of Nb precipitate coarsening on the high temperature strength in Nb containing ferritic stainless steels. Mater. Sci. Eng. A 2005, 396, 159–165. [Google Scholar] [CrossRef]

- Han, J.; Li, H.; Xu, H. Microalloying effects on microstructure and mechanical properties of 18Cr–2Mo ferritic stainless steel heavy plates. Mater. Des. 2014, 58, 518–526. [Google Scholar] [CrossRef]

- Chiu, Y.-T.; Lin, C.-K. Effects of Nb and W additions on high-temperature creep properties of ferritic stainless steels for solid oxide fuel cell interconnect. J. Power Sources 2012, 198, 149–157. [Google Scholar] [CrossRef]

- Wei, L.; Zheng, J.; Chen, L.; Misra, R.D.K. High temperature oxidation behavior of ferritic stainless steel containing W and Ce. Corros. Sci. 2018, 142, 79–92. [Google Scholar] [CrossRef]

- DeMeyer, M.; Vanderschueren, D.; DeCoon, B.C. The influence of the substitutionof Si by Al on the properties of cold rolled C–Mn–Si TRIP steels. ISIJ Int. 1999, 39, 813–822. [Google Scholar]

- Hojo, T.; Sugimoto, K.-I.; Mukai, Y.; Ikeda, S. Effects of Aluminum on Delayed Fracture Properties of Ultra High Strength Low Alloy TRIP-aided Steels. ISIJ Int. 2008, 48, 824–829. [Google Scholar] [CrossRef]

- Qian, L.; Zhou, Q.; Zhang, F.; Meng, J.; Zhang, M.; Tian, Y. Microstructure and mechanical properties of a low carbon carbide-free bainitic steel co-alloyed with Al and Si. Mater. Des. 2012, 39, 264–268. [Google Scholar] [CrossRef]

- Chen, S.; Rana, R.; Haldar, A.; Ray, R.K. Current state of Fe-Mn-Al-C low density steels. Prog. Mater. Sci. 2017, 89, 345–391. [Google Scholar] [CrossRef]

- Wu, Z.; Tang, Y.; Chen, W.; Lu, L.; Li, E.; Li, Z.; Ding, H. Exploring the influence of Al content on the hot deformation behavior of Fe-Mn-Al-C steels through 3D processing map. Vacuum 2019, 159, 447–455. [Google Scholar] [CrossRef]

- Xu, S.; Zhou, Z.; Long, F.; Jia, H.; Guo, N.; Yao, Z.; Daymond, M.R. Combination of back stress strengthening and Orowan strengthening in bimodal structured Fe–9Cr–Al ODS steel with high Al addition. Mater. Sci. Eng. A 2019, 739, 45–52. [Google Scholar] [CrossRef]

- Ota, H.; Nakamura, T.; Maruyama, K. Effect of solute atoms on thermal fatigue properties in ferritic stainless steels. Mater. Sci. Eng. A 2013, 586, 133–141. [Google Scholar] [CrossRef]

- Zou, D.; Zhou, Y.; Zhang, X.; Zhang, W.; Han, Y. High temperature oxidation behavior of a high Al-containing ferritic heat-resistant stainless steel. Mater. Charact. 2018, 136, 435–443. [Google Scholar] [CrossRef]

- Sastry, S.D.; Rohatgi, P.K.; Abraham, K.P.; Prasad, Y.V.R.K. Influence of heat treatment on the strength and fracture behavior of Fe-12Cr-6Al ferritic stainless steel. J. Mater. Sci. 1982, 17, 3009–3016. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, L.; Xu, Y.; Li, J.; Xiao, X.; Jiang, L. Texture, microstructure and mechanical properties of aluminum modified ultra-pure 429 ferritic stainless steels. Mater. Des. 2016, 89, 626–635. [Google Scholar] [CrossRef]

- Gao, F.; Liu, Z.Y.; Misra, R.D.K.; Liu, H.T.; Yu, F.X. Constitutive modeling and dynamic softening mechanism during hotdeformation of an ultra-pure 17%Cr ferritic stainless steel stabilized with Nb. Met. Mater. Int. 2014, 20, 939–951. [Google Scholar] [CrossRef]

- Gao, F.; Song, B.; Xu, Y.; Xia, K. Substructural changes during hot deformation of an Fe-26Cr ferritic stainless steel. Met. Mater. Trans. A 2000, 31, 21–27. [Google Scholar] [CrossRef]

- Kim, S.-L.; Yoo, Y.-C. Continuous dynamic recrystallization of AISI 430 ferritic stainless steel. Met. Mater. Int. 2002, 8, 7–13. [Google Scholar] [CrossRef]

- Chauhan, A.; Litvinov, D.; Aktaa, J. High temperature tensile properties and fracture characteristics of bimodal 12Cr-ODS steel. J. Nucl. Mater. 2016, 468, 1–8. [Google Scholar] [CrossRef]

- Pan, L.; Zheng, L.; Han, W.; Zhou, L.; Hu, Z.; Zhang, H. High-temperature tensile properties of a NiTi–Al-based alloy prepared by directional solidification and homogenizing treatment. Mater. Des. 2012, 39, 192–199. [Google Scholar] [CrossRef]

- Liu, Y.; Ning, Y.; Nan, Y.; Liang, H.; Li, Y.; Zhao, Z.; Yao, Z.; Guo, H. Characterization of hot deformation behavior and processing map of FGH4096–GH4133B dual alloys. J. Alloy. Compd. 2015, 633, 505–515. [Google Scholar] [CrossRef]

- Jiang, Z.H.; Han, J.P.; Li, Y.; He, P. High temperature ductility and corrosion resistance property of novel tin-bearing economic 17Cr-xSn ferritic stainless steel. Ironmak Steelmak 2015, 42, 504–511. [Google Scholar] [CrossRef]

- Belyakov, A.; Sakai, T.; Kaibyshev, R. New grain formation during warm deformation of ferritic stainless steel. Met. Mater. Trans. A 1998, 29, 161–167. [Google Scholar] [CrossRef]

- Mehtonen, S.; Palmiere, E.; Misra, R.; Karjalainen, L.; Porter, D. Dynamic restoration mechanisms in a Ti–Nb stabilized ferritic stainless steel during hot deformation. Mater. Sci. Eng. A 2014, 601, 7–19. [Google Scholar] [CrossRef]

- Ebied, S.; Hamada, A.; Borek, W.; Gepreel, M.; Chiba, A. High-temperature deformation behavior and microstructural characterization of high-Mn bearing titanium-based alloy. Mater. Charact. 2018, 139, 176–185. [Google Scholar] [CrossRef]

- Xie, B.; Zhang, B.; Ning, Y.; Fu, M. Mechanisms of DRX nucleation with grain boundary bulging and subgrain rotation during the hot working of nickel-based superalloys with columnar grains. J. Alloy. Compd. 2019, 786, 636–647. [Google Scholar] [CrossRef]

- Han, Y.; Liu, G.W.; Zou, D.N.; Liu, R.; Qiao, G.J. Deformation behavior and microstructural evolution of as-cast 904L austenitic stainless steel under hot compression. Mater. Sci. Eng. A 2013, 565, 342–350. [Google Scholar] [CrossRef]

- Xiao, W.; Wang, B.; Wu, Y.; Yang, X. Constitutive modeling of flow behavior and microstructure evolution of AA7075 in hot tensile deformation. Mater. Sci. Eng. A 2018, 712, 704–713. [Google Scholar] [CrossRef]

- Lin, Y.; Jiang, X.-Y.; Shuai, C.-J.; Zhao, C.-Y.; He, D.-G.; Chen, M.-S.; Chen, C. Effects of initial microstructures on hot tensile deformation behaviors and fracture characteristics of Ti-6Al-4V alloy. Mater. Sci. Eng. A 2018, 711, 293–302. [Google Scholar] [CrossRef]

- Liu, Z.; Li, P.; Xiong, L.; Liu, T.; He, L. High-temperature tensile deformation behavior and microstructure evolution of Ti55 titanium alloy. Mater. Sci. Eng. A 2017, 680, 259–269. [Google Scholar] [CrossRef]

- Mandal, S.; Bhaduri, A.K.; Sarma, V.S. A study on microstructural evolution and dynamic recrystallization during isothermal deformation of a Ti-modified austenitic stainless steel. Metall. Mater. Trans. A 2010, 42, 1062–1072. [Google Scholar] [CrossRef]

- Alsagabi, S.; Shrestha, T.; Charit, I. High temperature tensile deformation behavior of Grade 92 steel. J. Nucl. Mater. 2014, 453, 151–157. [Google Scholar] [CrossRef]

- Lin, Y.C.; Huang, J.; Li, H.-B.; Chen, D.-D. Phase transformation and constitutive models of a hot compressed TC18 titanium alloy in the α+β regime. Vacuum 2018, 157, 83–91. [Google Scholar] [CrossRef]

- Shrestha, T.; Basirat, M.; Charit, I.; Potirniche, G.P.; Rink, K.K.; Sahaym, U. Creep deformation mechanisms in modified 9Cr–1Mo steel. J. Nucl. Mater. 2012, 423, 110–119. [Google Scholar] [CrossRef]

- Shewmon, P. Diffusion in Solids, 2nd ed.; TMS: Warrendale, PA, USA, 1989. [Google Scholar]

- Gao, F.; Liu, Z.-Y.; Wang, G.-D. Hot deformation behavior of high-purified 17%Cr ferritic stainless steel. J. Northeast Univ. 2011, 32, 1406–1409. [Google Scholar]

- Mehtonen, S.; Karjalainen, L.; Porter, D. Hot deformation behavior and microstructure evolution of a stabilized high-Cr ferritic stainless steel. Mater. Sci. Eng. A 2013, 571, 1–12. [Google Scholar] [CrossRef]

- Gao, F.; Yu, F.-X.; Liu, H.-T.; Liu, Z.-Y.; Liu, F.-T. Hot Deformation Behavior and Flow Stress Prediction of Ultra Purified 17% Cr Ferritic Stainless Steel Stabilized with Nb and Ti. J. Iron Steel Res. Int. 2015, 22, 827–836. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, Y.; Sun, J.; Sun, Y.; Sun, J.; Ran, X. Tensile Properties and Microstructural Evolution of an Al-Bearing Ferritic Stainless Steel at Elevated Temperatures. Metals 2020, 10, 86. https://doi.org/10.3390/met10010086

Han Y, Sun J, Sun Y, Sun J, Ran X. Tensile Properties and Microstructural Evolution of an Al-Bearing Ferritic Stainless Steel at Elevated Temperatures. Metals. 2020; 10(1):86. https://doi.org/10.3390/met10010086

Chicago/Turabian StyleHan, Ying, Jiaqi Sun, Yu Sun, Jiapeng Sun, and Xu Ran. 2020. "Tensile Properties and Microstructural Evolution of an Al-Bearing Ferritic Stainless Steel at Elevated Temperatures" Metals 10, no. 1: 86. https://doi.org/10.3390/met10010086

APA StyleHan, Y., Sun, J., Sun, Y., Sun, J., & Ran, X. (2020). Tensile Properties and Microstructural Evolution of an Al-Bearing Ferritic Stainless Steel at Elevated Temperatures. Metals, 10(1), 86. https://doi.org/10.3390/met10010086