Investigation on Fracture of a 6014-T4 Aluminum Alloy Sheet in the Flanging and Hemming Process Based on Numerical and Experimental Methods

Abstract

1. Introduction

2. Methods

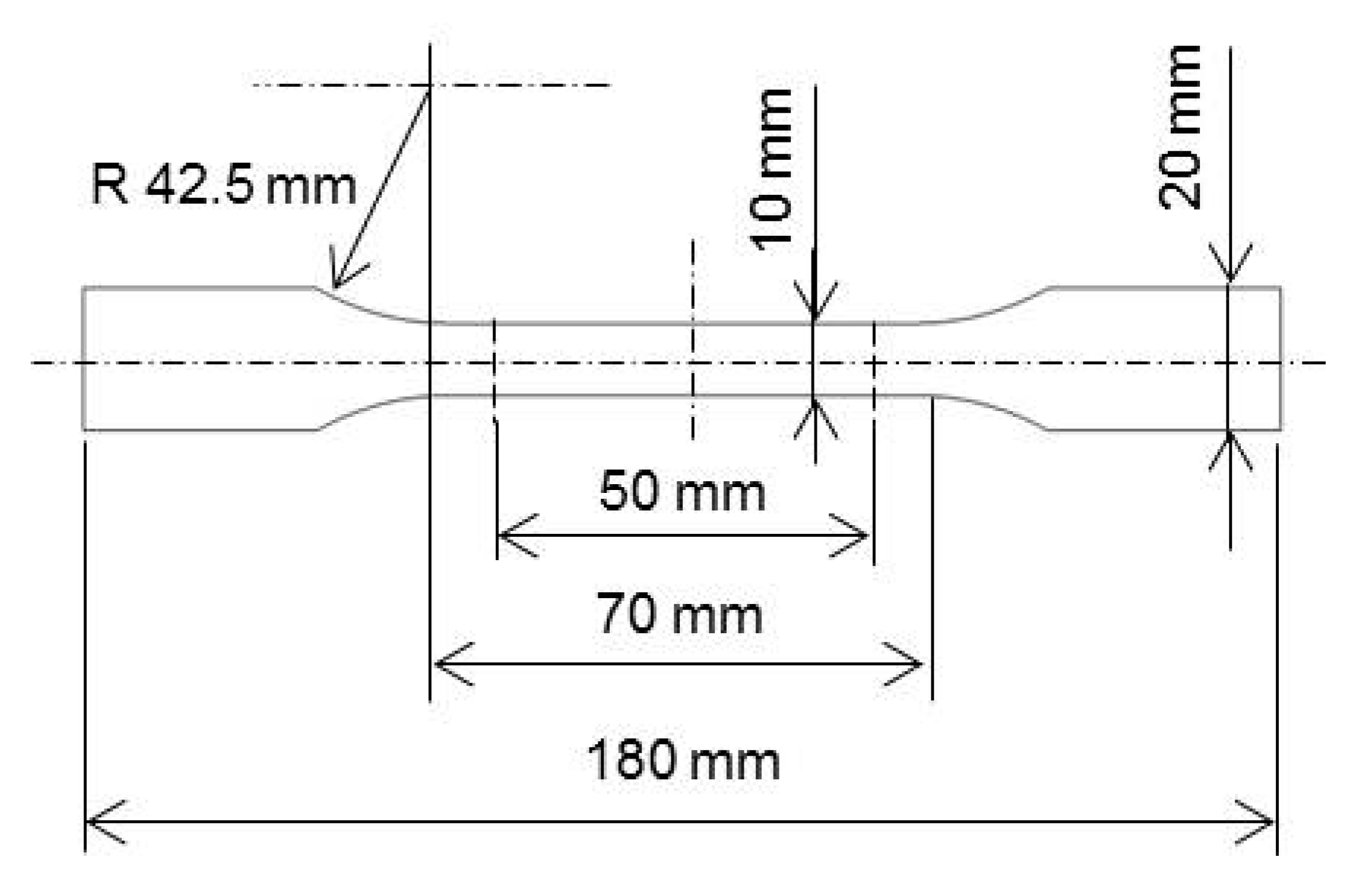

2.1. Mechanical Property Experiments

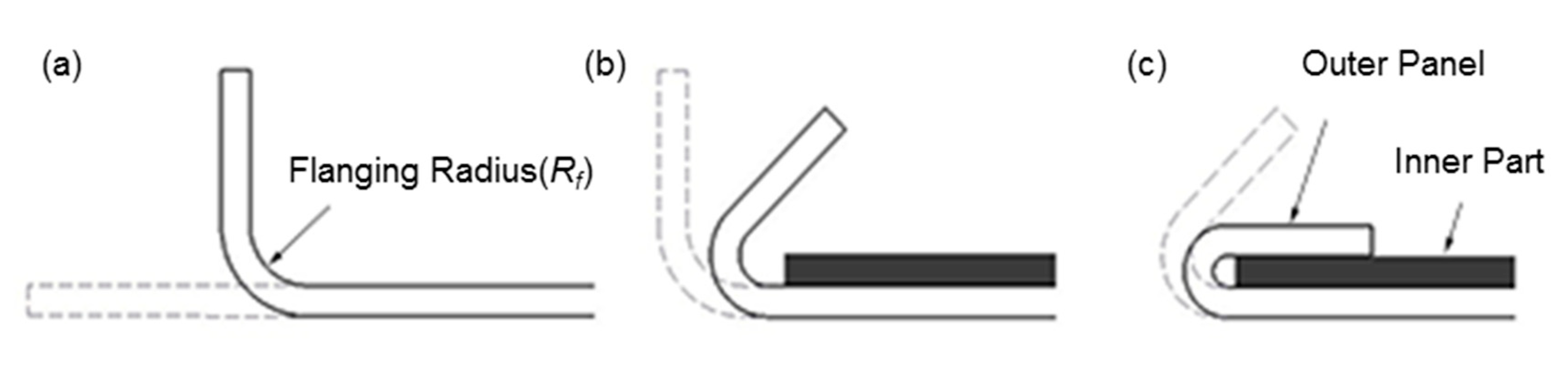

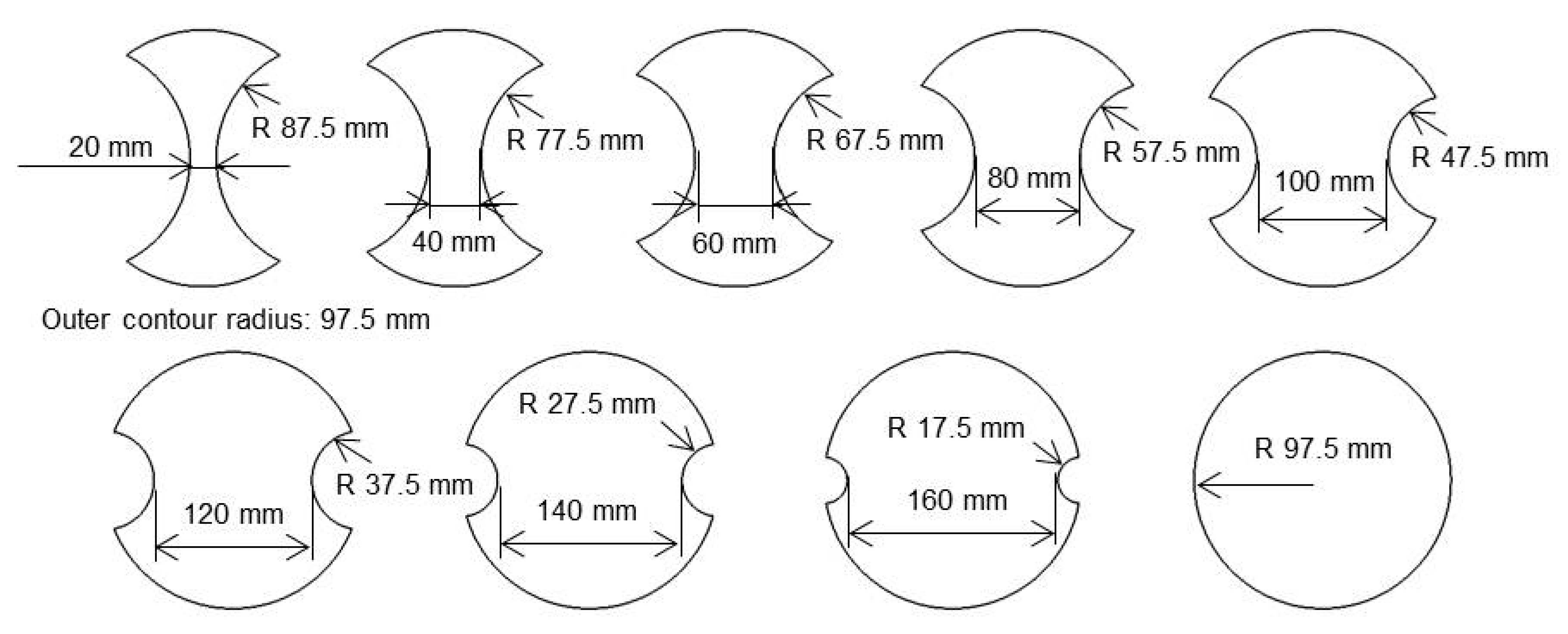

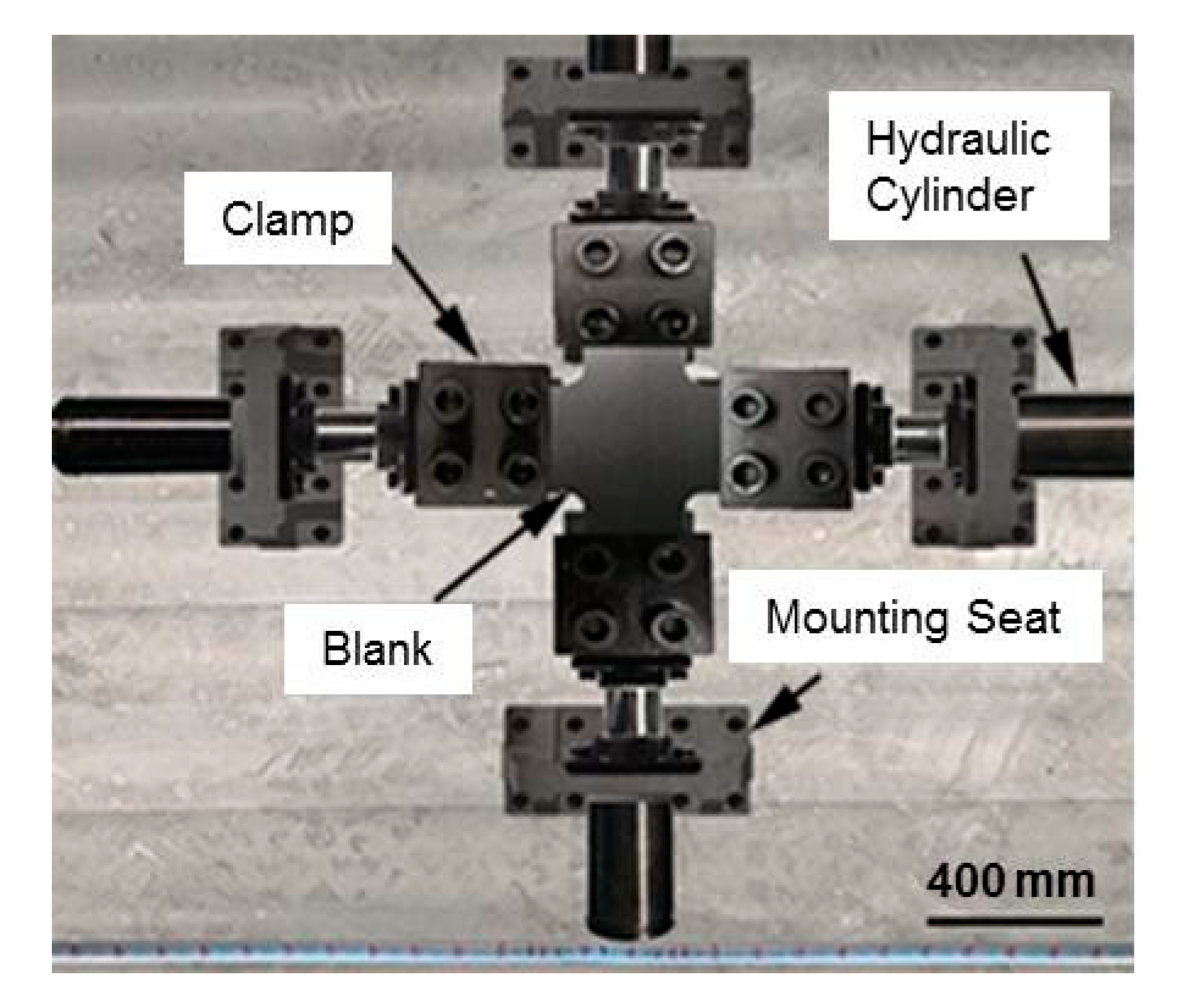

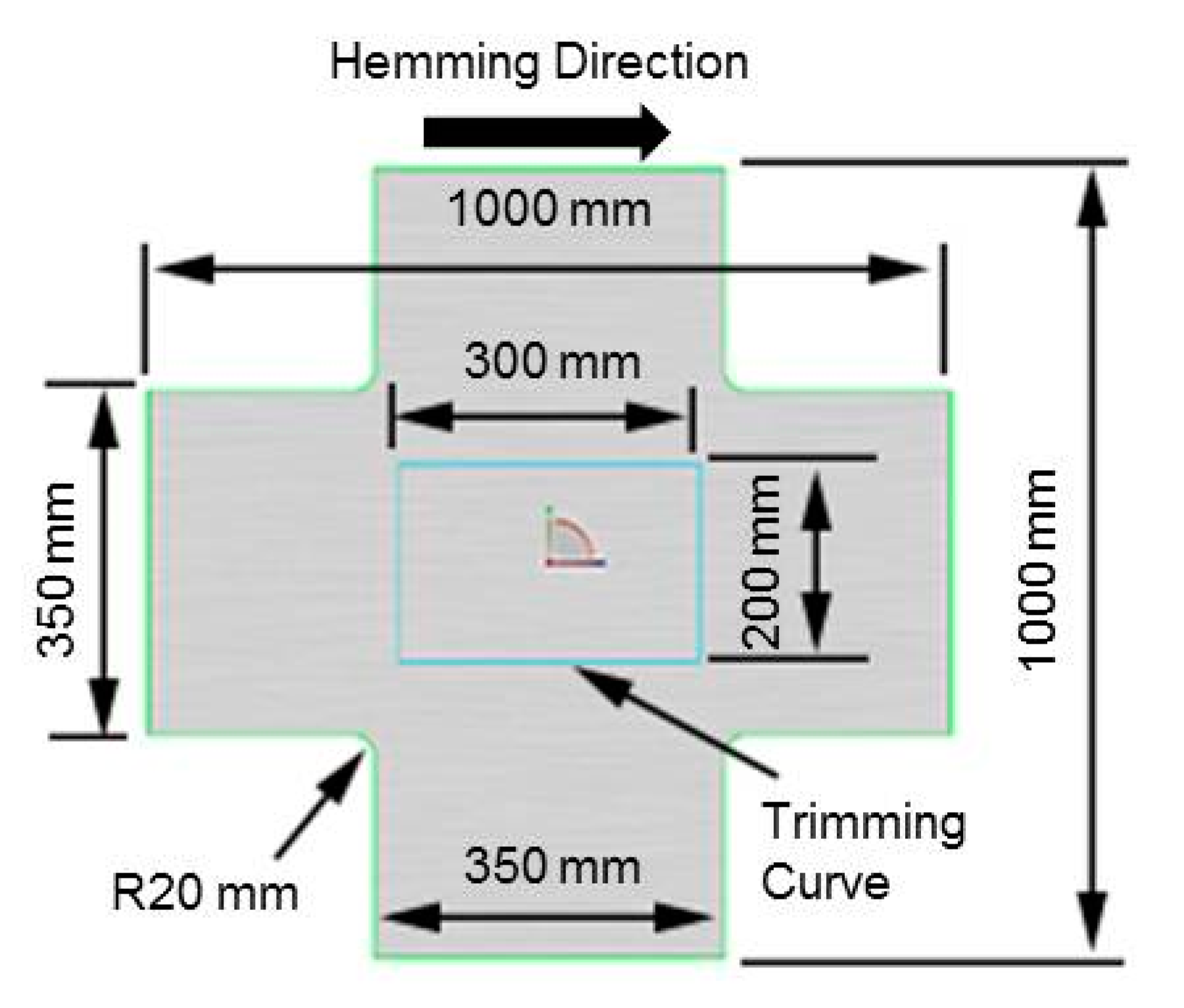

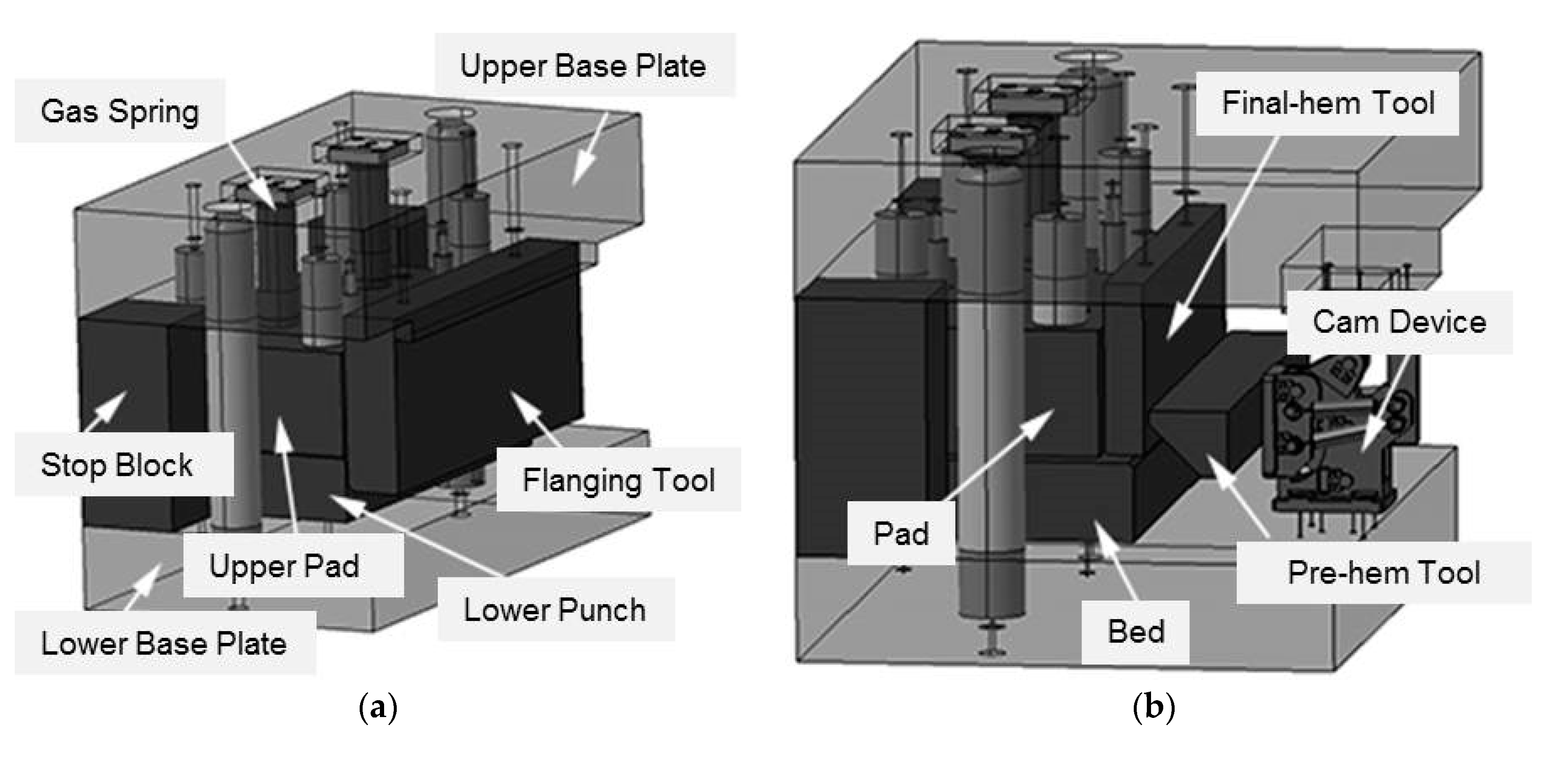

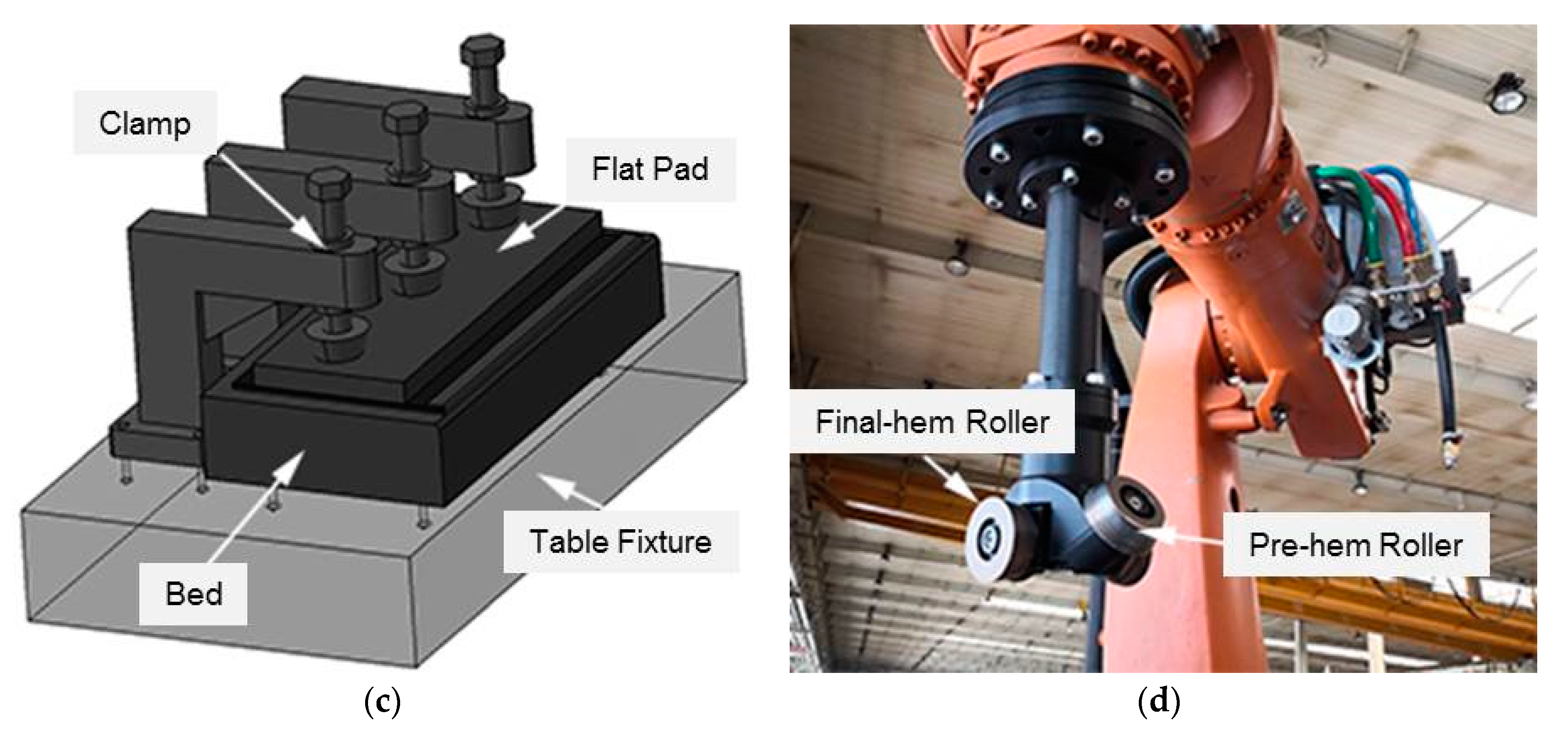

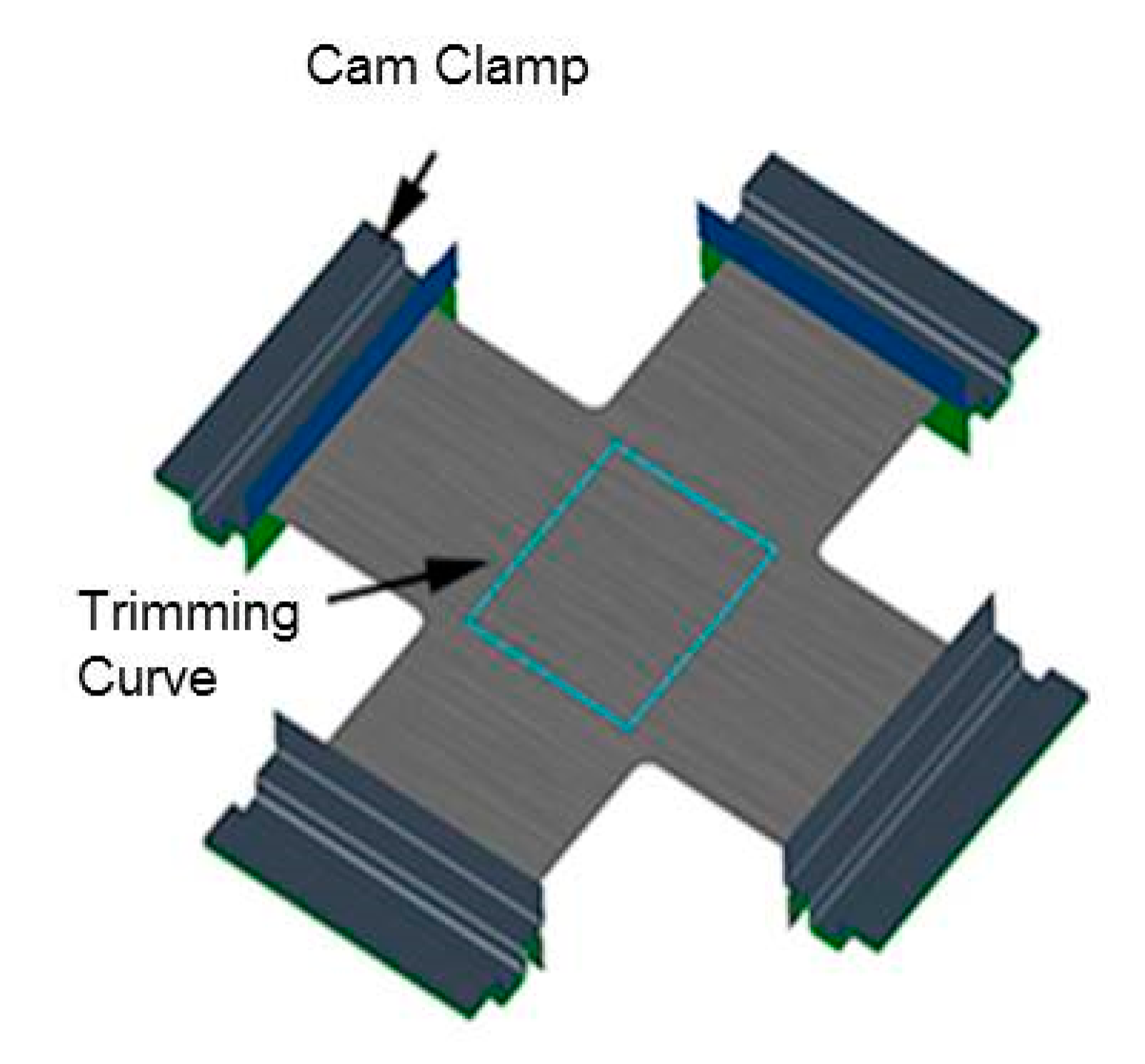

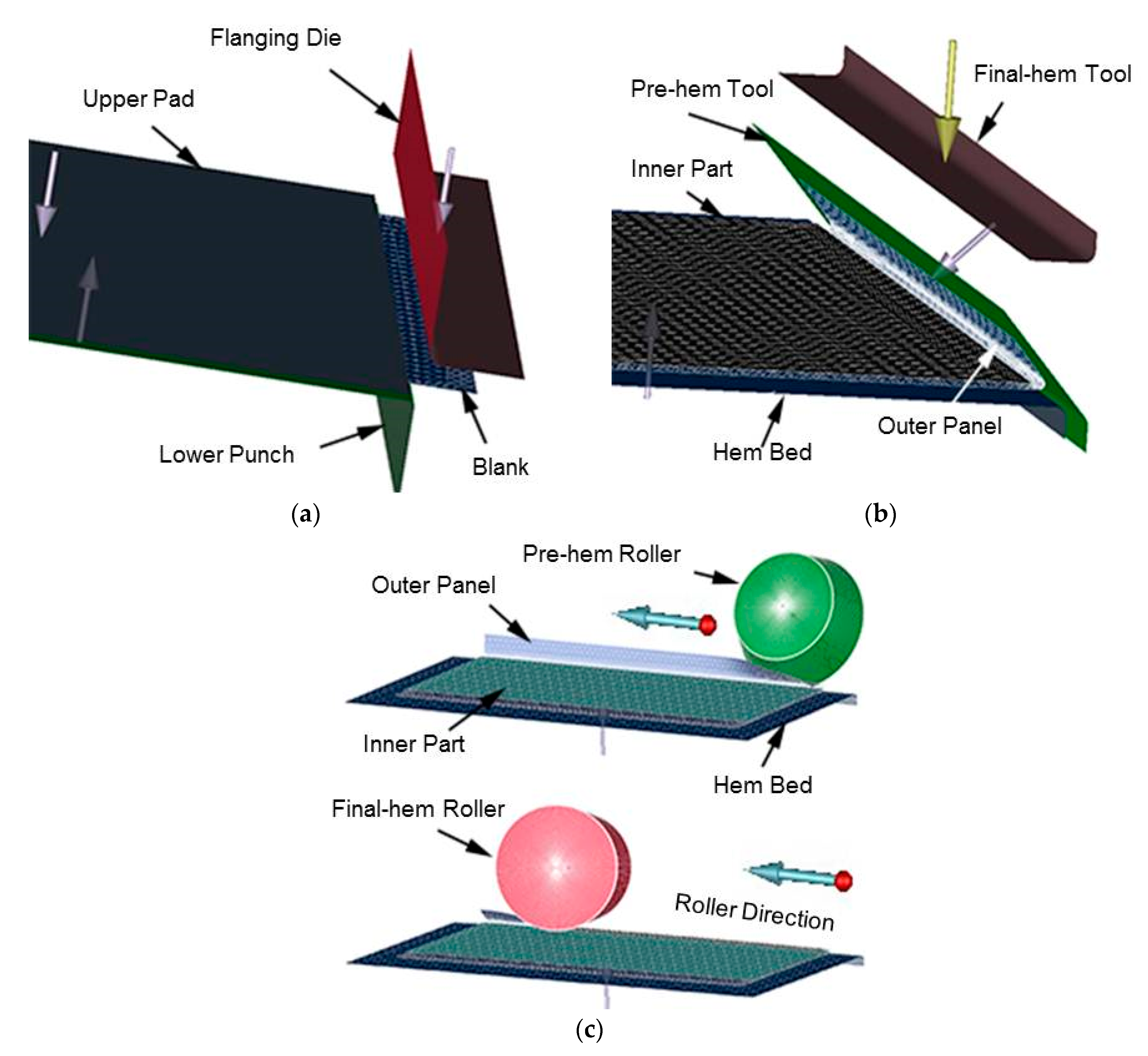

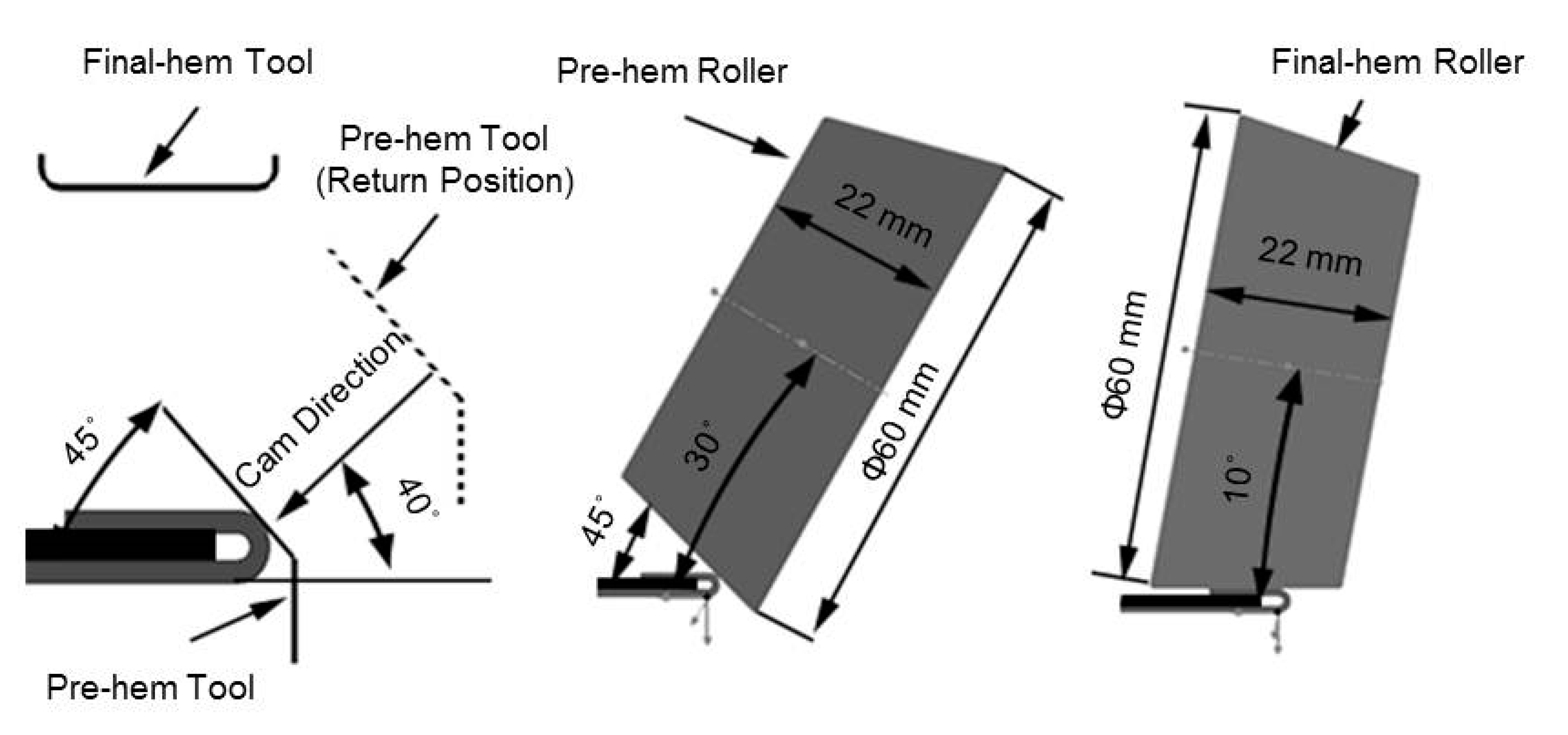

2.2. Forming Tests

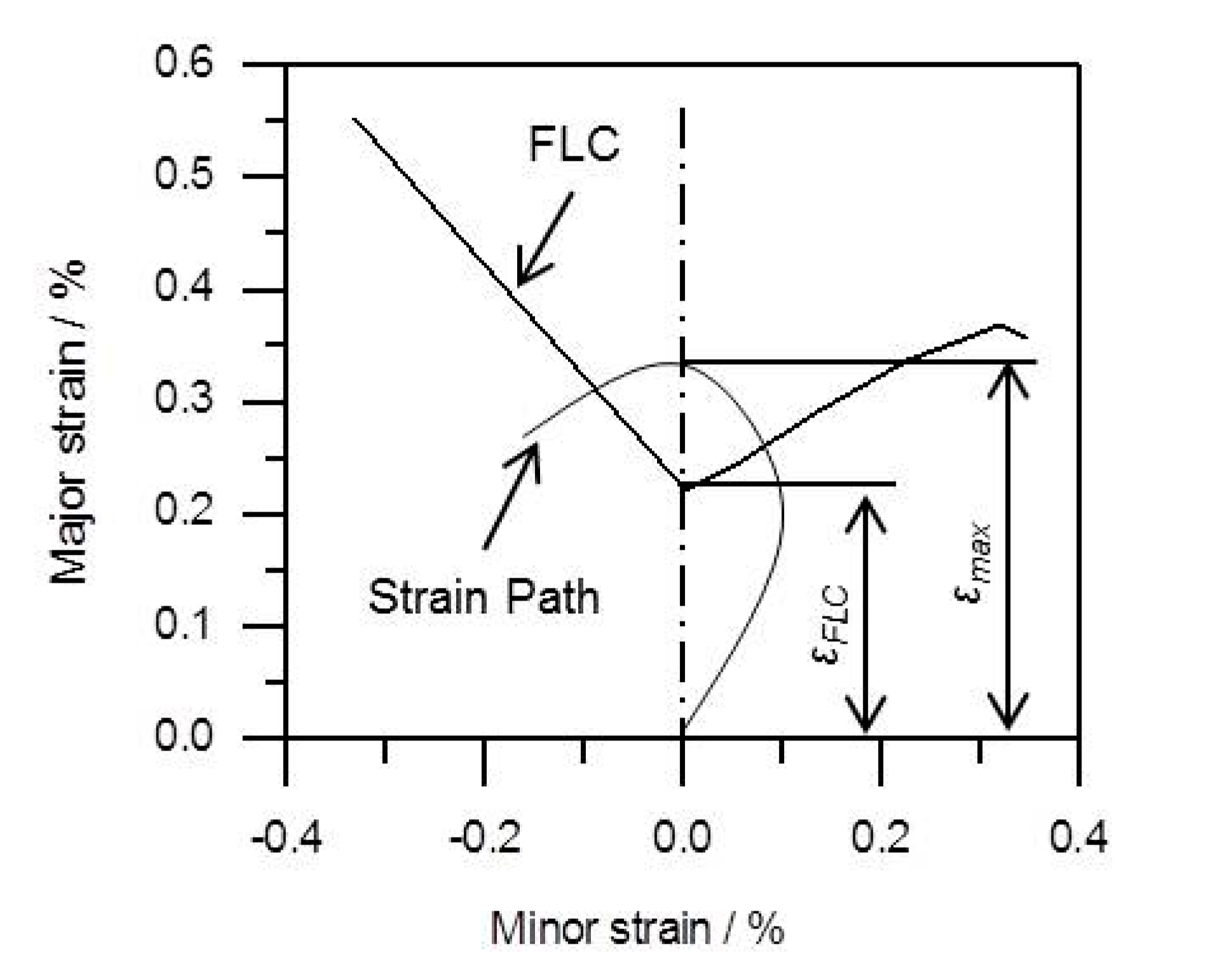

2.3. Numerical Simulation

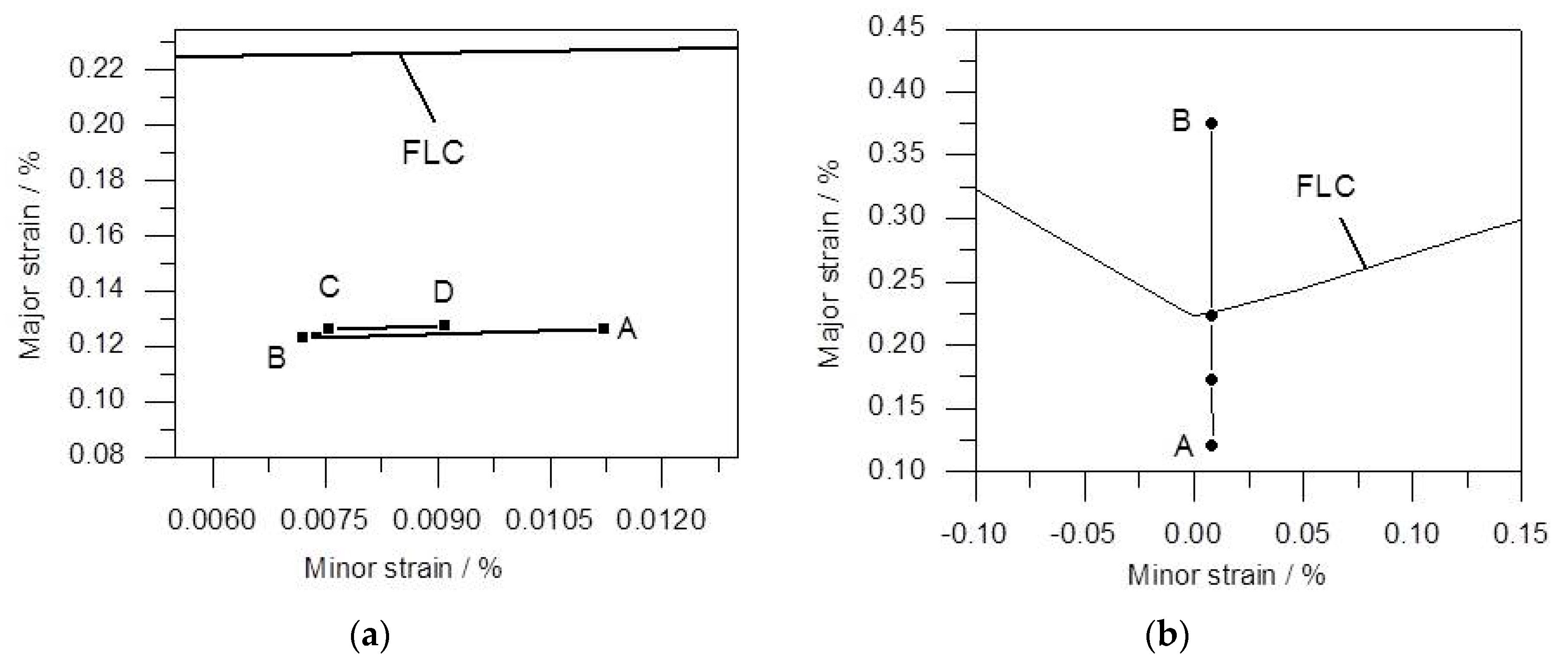

3. Results and Discussion

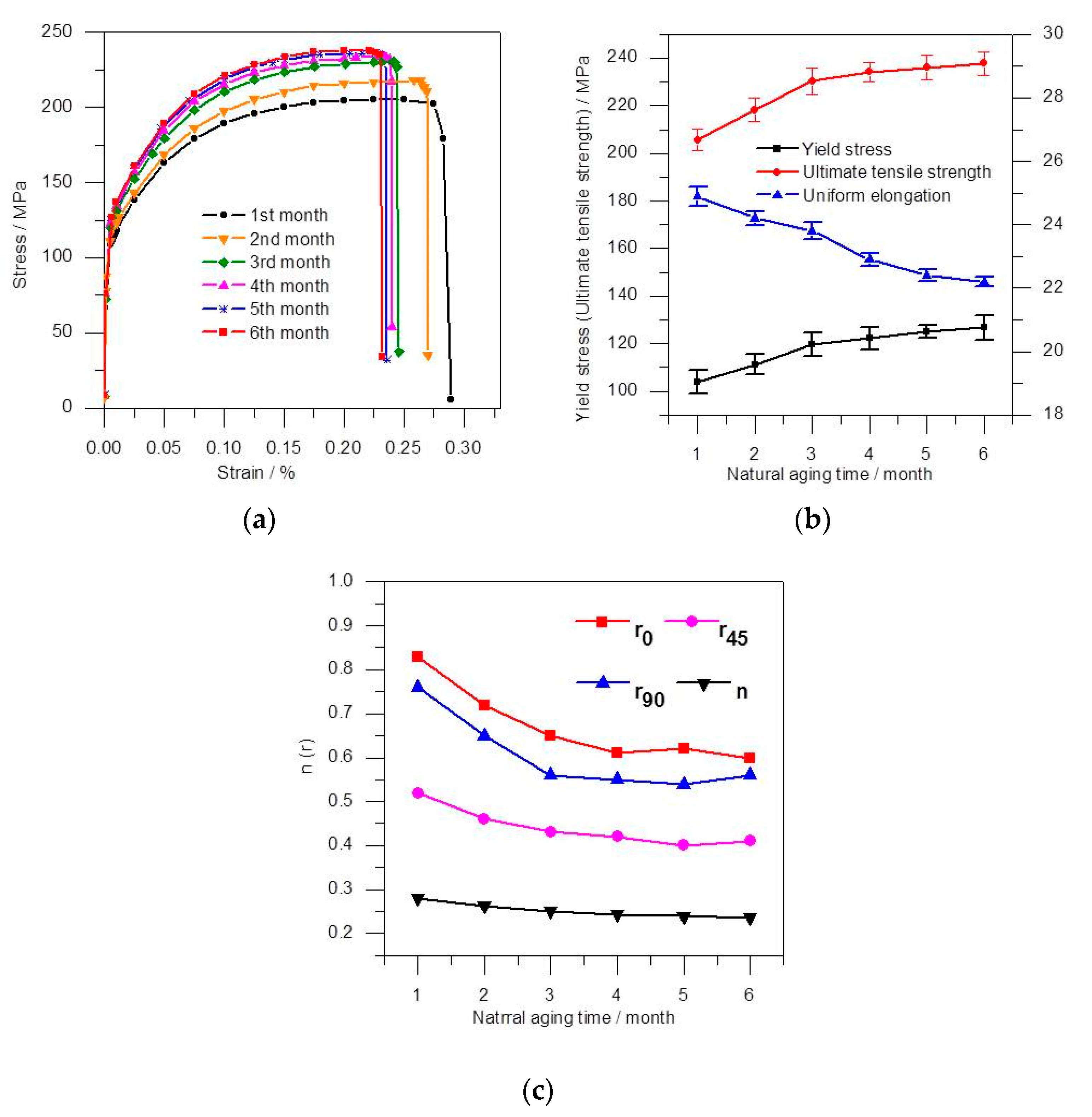

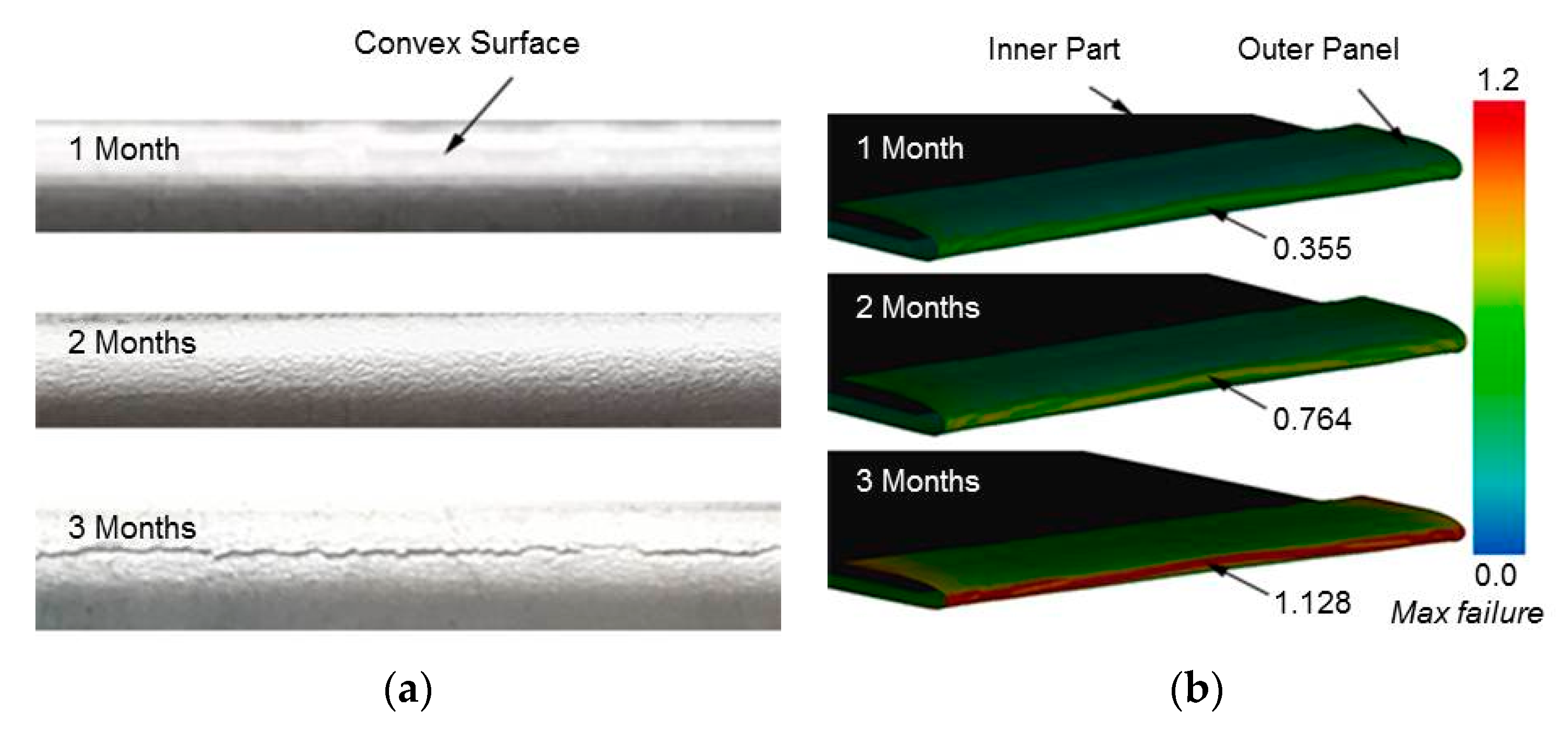

3.1. Natural Aging Characteristics

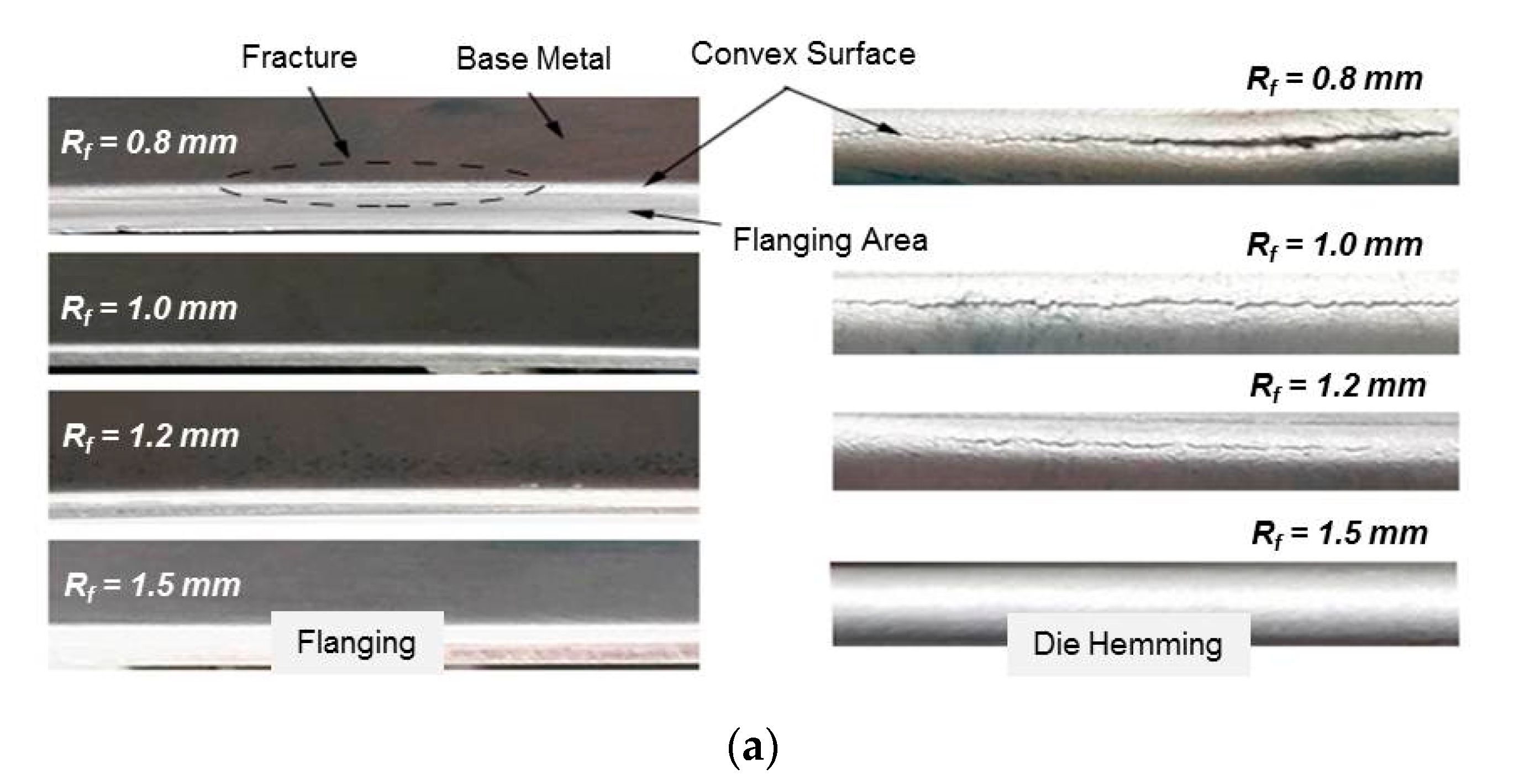

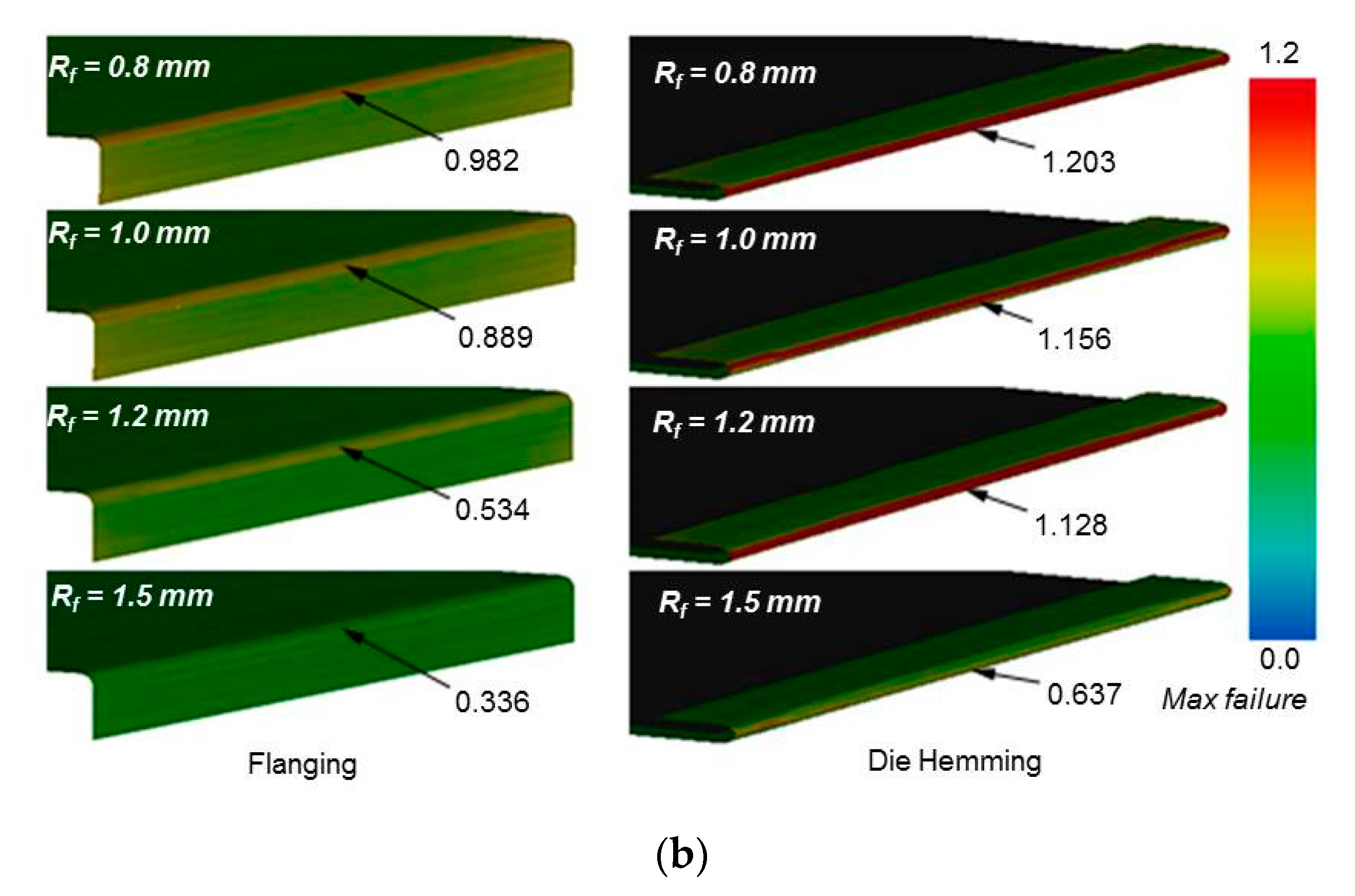

3.2. Flanging Radius

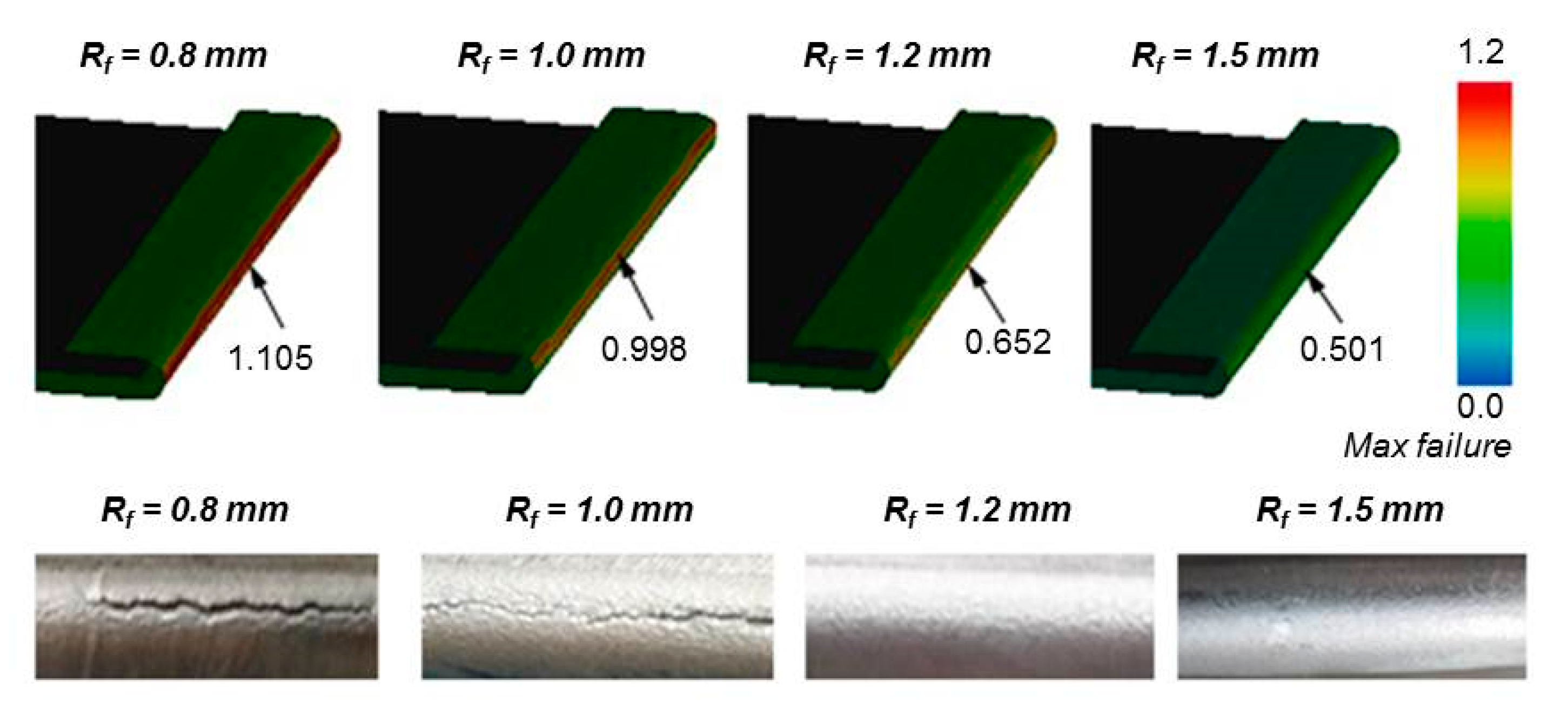

3.3. Hemming Process Comparison

4. Conclusions

5. Limitation

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Muderrisoglu, A.; Murata, M.; Ahmetoglu, M.A.; Kinzel, G.; Altan, T. Bending, flanging, and hemming of aluminum sheet—An experimental study. J. Mater. Process. Technol. 1996, 59, 10–17. [Google Scholar] [CrossRef]

- Tisza, M.; Czinege, I. Comparative study of the application of steels and aluminium in lightweight production of automotive parts. Int. J. Light. Mater. Manuf. 2018, 1, 229–238. [Google Scholar] [CrossRef]

- Carleer, B. Effective Stamping Simulations along the Sheet Metal Process Chain. J. Physics: Conf. Ser. 2018, 1063, 012001. [Google Scholar] [CrossRef]

- Thuillier, S.; Le Maoût, N.; Manach, P.Y. Bending Limit Prediction of an Aluminum Thin Sheet. Int. J. Mater. Form. 2010, 3, 223–226. [Google Scholar] [CrossRef]

- Pradeau, A.; Thuillier, S.; Yoon, J.W. Prediction of failure in bending of an aluminium sheet alloy. Int. J. Mech. Sci. 2016, 119, 23–35. [Google Scholar] [CrossRef]

- Li, S.; Hu, X.; Zhao, Y.; Lin, Z.; Xu, N. Cyclic hardening behavior of roller hemming in the case of aluminum alloy sheets. Mater. Des. 2011, 32, 2308–2316. [Google Scholar] [CrossRef]

- Liewald, M.; Hönle, S.; Sindel, M. Surface roughening of an aluminum 6016 alloy during bending and hemming. Int. J. Mater. Form. 2016, 9, 203–213. [Google Scholar] [CrossRef]

- Muhammad, W.; Kang, J.; Brahme, A.P.; Ali, U.; Hirsch, J.; Brinkman, H.-J.; Engler, O.; Mishra, R.K.; Inal, K. Bendability enhancement of an age-hardenable aluminum alloy: Part I—Relationship between microstructure, plastic deformation and fracture. Mater. Sci. Eng. A 2019, 753, 179–191. [Google Scholar] [CrossRef]

- Engler, O.; Schäfer, C.; Myhr, O.R. Effect of natural ageing and pre-straining on strength and anisotropy in aluminium alloy AA 6016. Mater. Sci. Eng. A 2015, 639, 65–74. [Google Scholar] [CrossRef]

- Engler, O.; Marioara, C.; Aruga, Y.; Kozuka, M.; Myhr, O. Effect of natural ageing or pre-ageing on the evolution of precipitate structure and strength during age hardening of Al–Mg–Si alloy AA 6016. Mater. Sci. Eng. A 2019, 759, 520–529. [Google Scholar] [CrossRef]

- Wang, G.; Gu, Z.; Xu, H.; Yu, G. Numerical analysis and experimental investigation of surface defects in die hemming process. Int. J. Mater. Form. 2019, 1–12. [Google Scholar] [CrossRef]

- Aruga, Y.; Kim, S.N.; Kozuka, M.; Kobayashi, E.; Sato, T. Effects of cluster characteristics on two-step aging behavior in Al-Mg-Si alloys with different Mg/Si ratios and natural aging periods. Mater. Sci. Eng. A Struct. 2019, 718, 371–376. [Google Scholar] [CrossRef]

- Zhu, S.; Li, Z.; Yan, L.; Li, X.; Huang, S.; Yan, H.; Zhang, Y.; Xiong, B. Natural aging behavior in pre-aged Al–Mg–Si–Cu alloys with and without Zn addition. J. Alloy. Compd. 2019, 773, 496–502. [Google Scholar] [CrossRef]

- Martinsen, F.; Ehlers, F.; Torsæter, M.; Holmestad, R. Reversal of the negative natural aging effect in Al–Mg–Si alloys. Acta Mater. 2012, 60, 6091–6101. [Google Scholar] [CrossRef]

- Hu, X.; Lin, Z.; Li, S.; Zhao, Y. Fracture limit prediction for roller hemming of aluminum alloy sheet. Mater. Des. 2010, 31, 1410–1416. [Google Scholar] [CrossRef]

- Gorji, M.; Berisha, B.; Hora, P.; Barlat, F. Modeling of localization and fracture phenomena in strain and stress space for sheet metal forming. Int. J. Mater. Form. 2016, 9, 573–584. [Google Scholar] [CrossRef]

- Gorji, M.; Berisha, B.; Manopulo, N.; Hora, P. Effect of through thickness strain distribution on shear fracture hazard and its mitigation by using multilayer aluminum sheets. J. Mater. Process. Technol. 2016, 232, 19–33. [Google Scholar] [CrossRef]

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| 0.59 | 0.22 | 0.12 | 0.08 | 0.65 | 0.01 | 0.01 | 0.03 | Bal. |

| E (GPa) | ν | σ0 (MPa) | Rm (MPa) | n | r0 | r45 | r90 |

|---|---|---|---|---|---|---|---|

| 70 | 0.3 | 116 | 225.4 | 0.253 | 0.65 | 0.43 | 0.56 |

| Process | Flanging Radius | |||

|---|---|---|---|---|

| 0.8 mm | 1.0 mm | 1.2 mm | 1.5 mm | |

| Flanging | Y | Y | N | N |

| Die hemming | Y | Y | Y | N |

| Roller hemming | Y | Y | N | N |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, Z.; Wang, G.; Yu, G. Investigation on Fracture of a 6014-T4 Aluminum Alloy Sheet in the Flanging and Hemming Process Based on Numerical and Experimental Methods. Metals 2020, 10, 81. https://doi.org/10.3390/met10010081

Gu Z, Wang G, Yu G. Investigation on Fracture of a 6014-T4 Aluminum Alloy Sheet in the Flanging and Hemming Process Based on Numerical and Experimental Methods. Metals. 2020; 10(1):81. https://doi.org/10.3390/met10010081

Chicago/Turabian StyleGu, Zhengwei, Gang Wang, and Ge Yu. 2020. "Investigation on Fracture of a 6014-T4 Aluminum Alloy Sheet in the Flanging and Hemming Process Based on Numerical and Experimental Methods" Metals 10, no. 1: 81. https://doi.org/10.3390/met10010081

APA StyleGu, Z., Wang, G., & Yu, G. (2020). Investigation on Fracture of a 6014-T4 Aluminum Alloy Sheet in the Flanging and Hemming Process Based on Numerical and Experimental Methods. Metals, 10(1), 81. https://doi.org/10.3390/met10010081