The Influence of Heat Input on the Microstructure and Properties of Wire-Arc-Additive-Manufactured Al-Cu-Sn Alloy Deposits

Abstract

1. Introduction

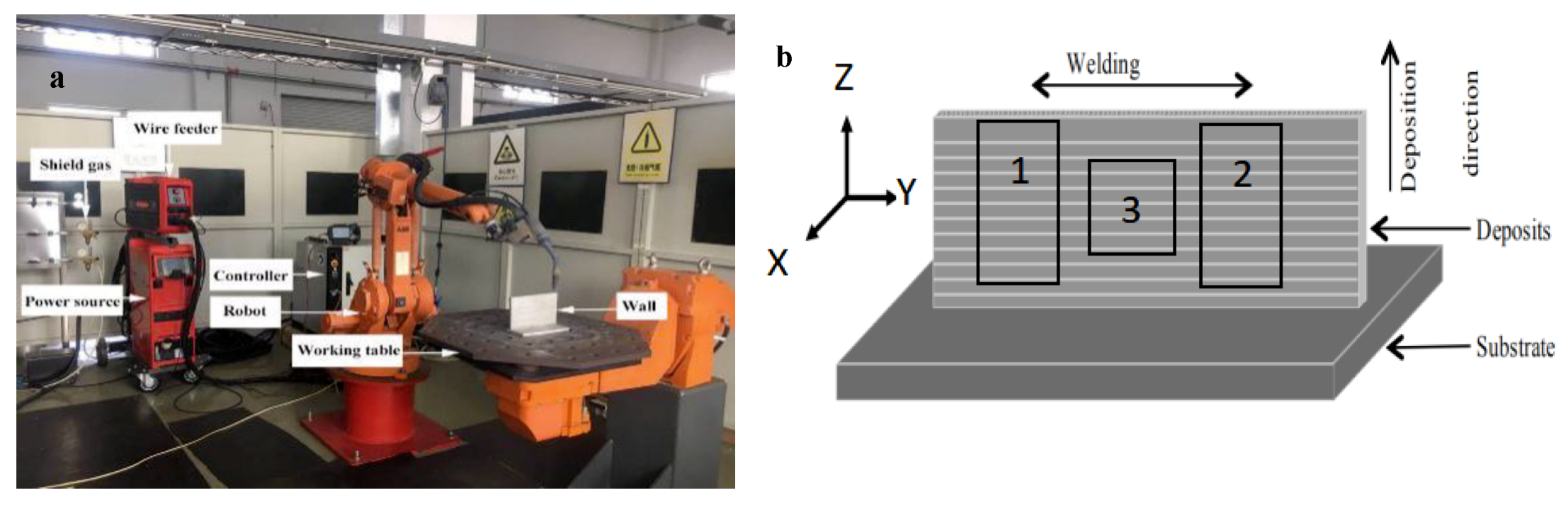

2. Materials and Methods

3. Results and Discussion

3.1. Appearance Size of Deposits

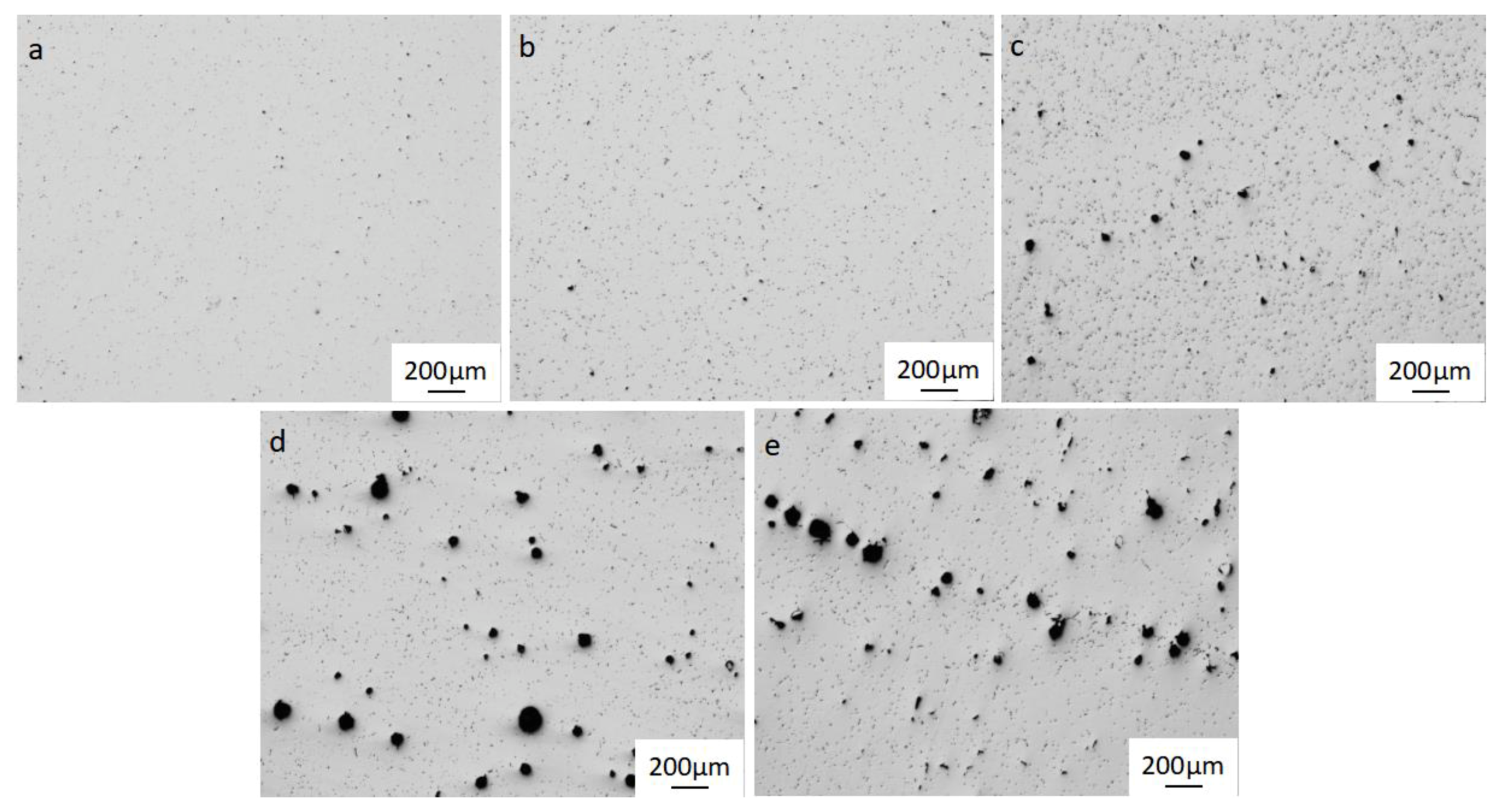

3.2. Pores of Deposits

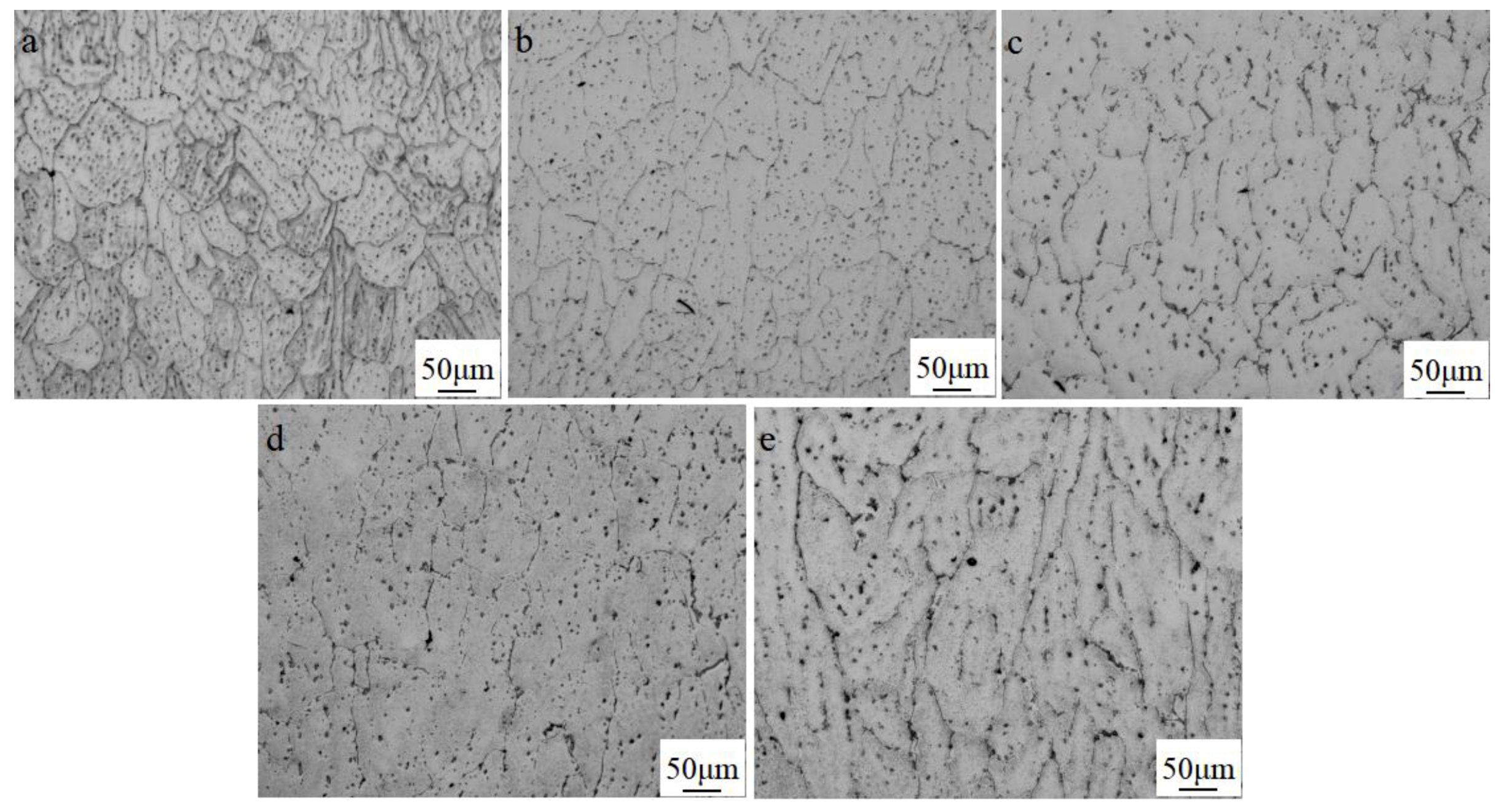

3.3. Microstructure of Deposits

3.3.1. Microstructure of Deposits in As-Deposit State

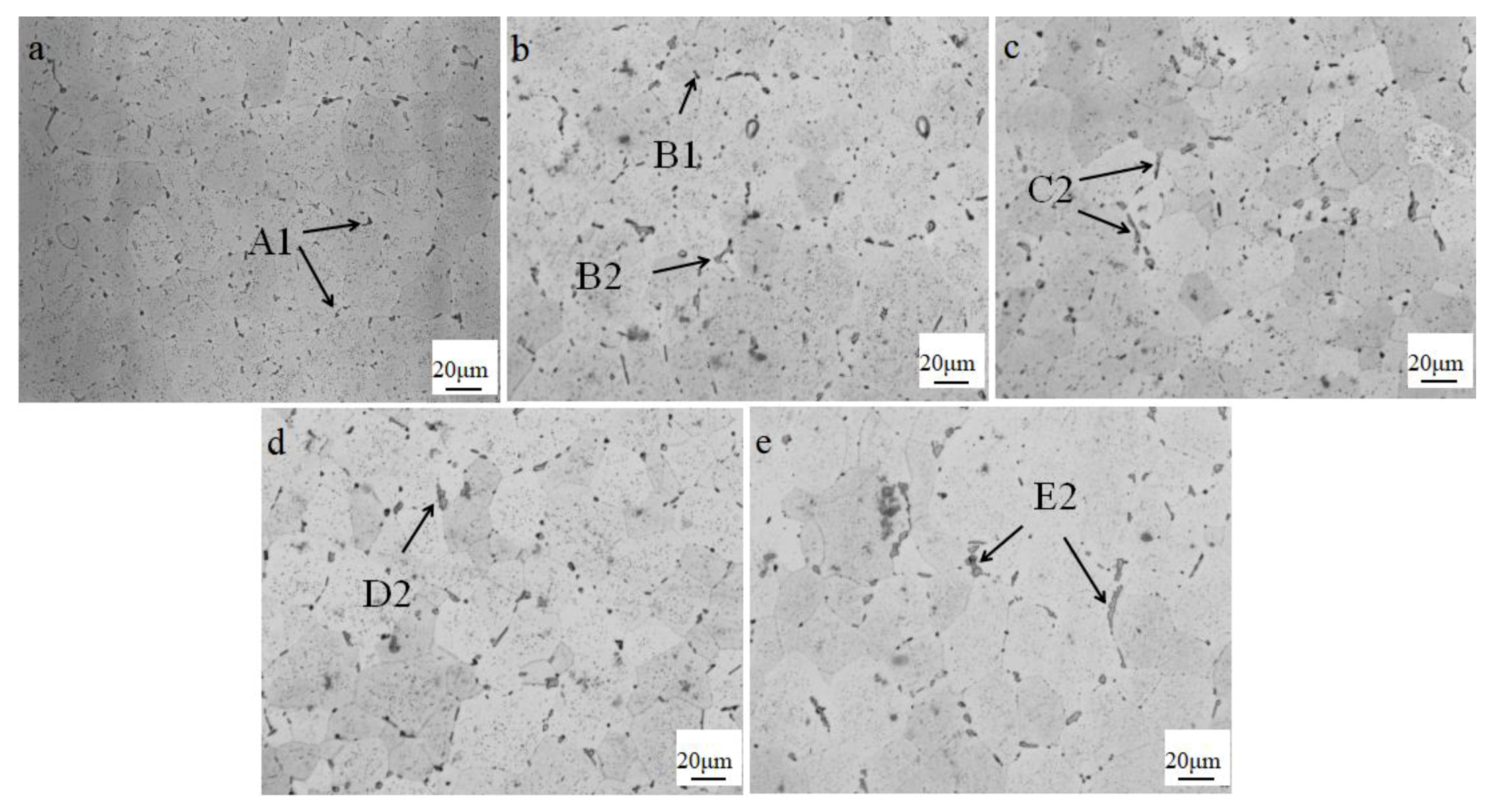

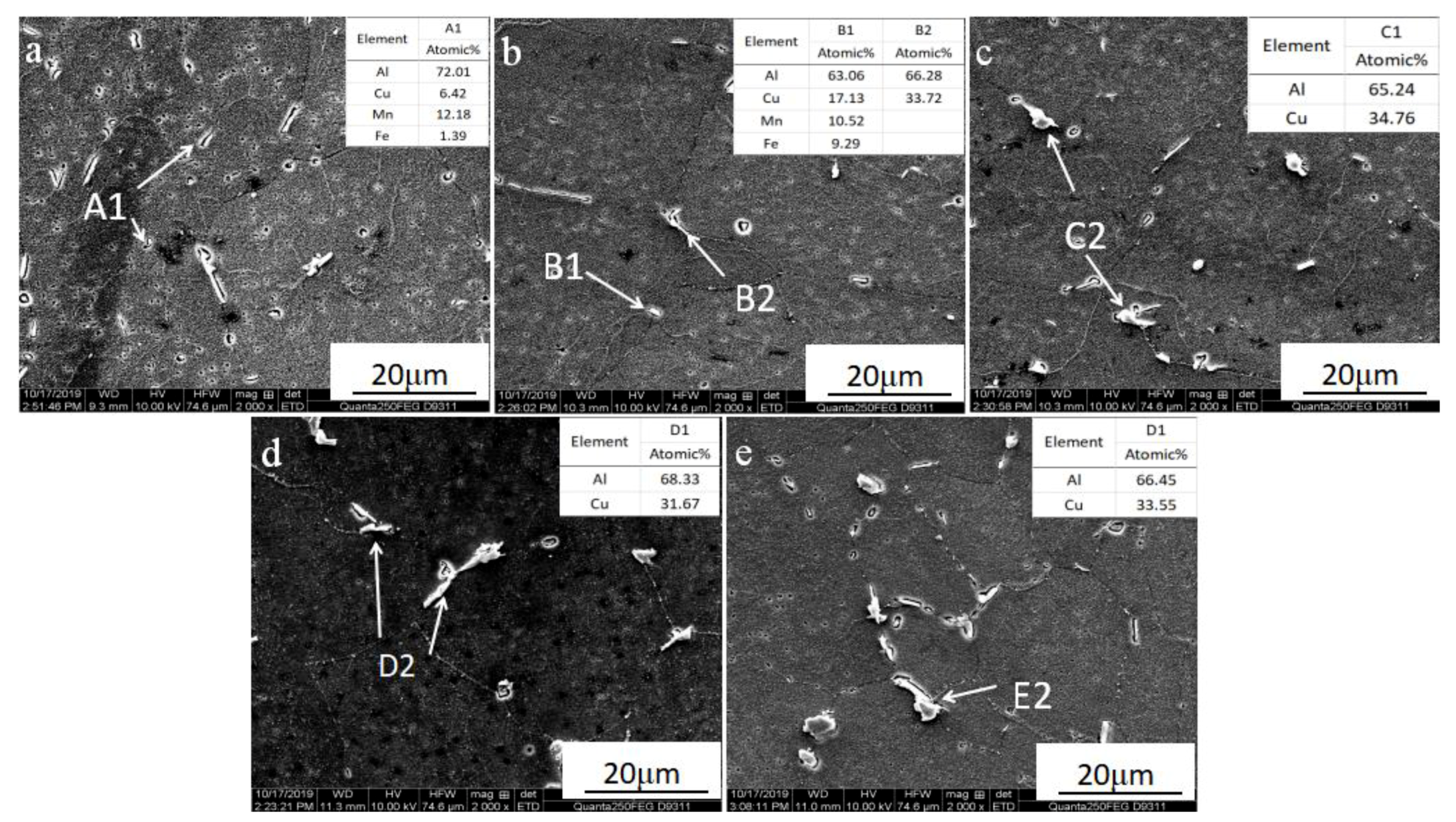

3.3.2. Microstructure of Deposits in T6 State

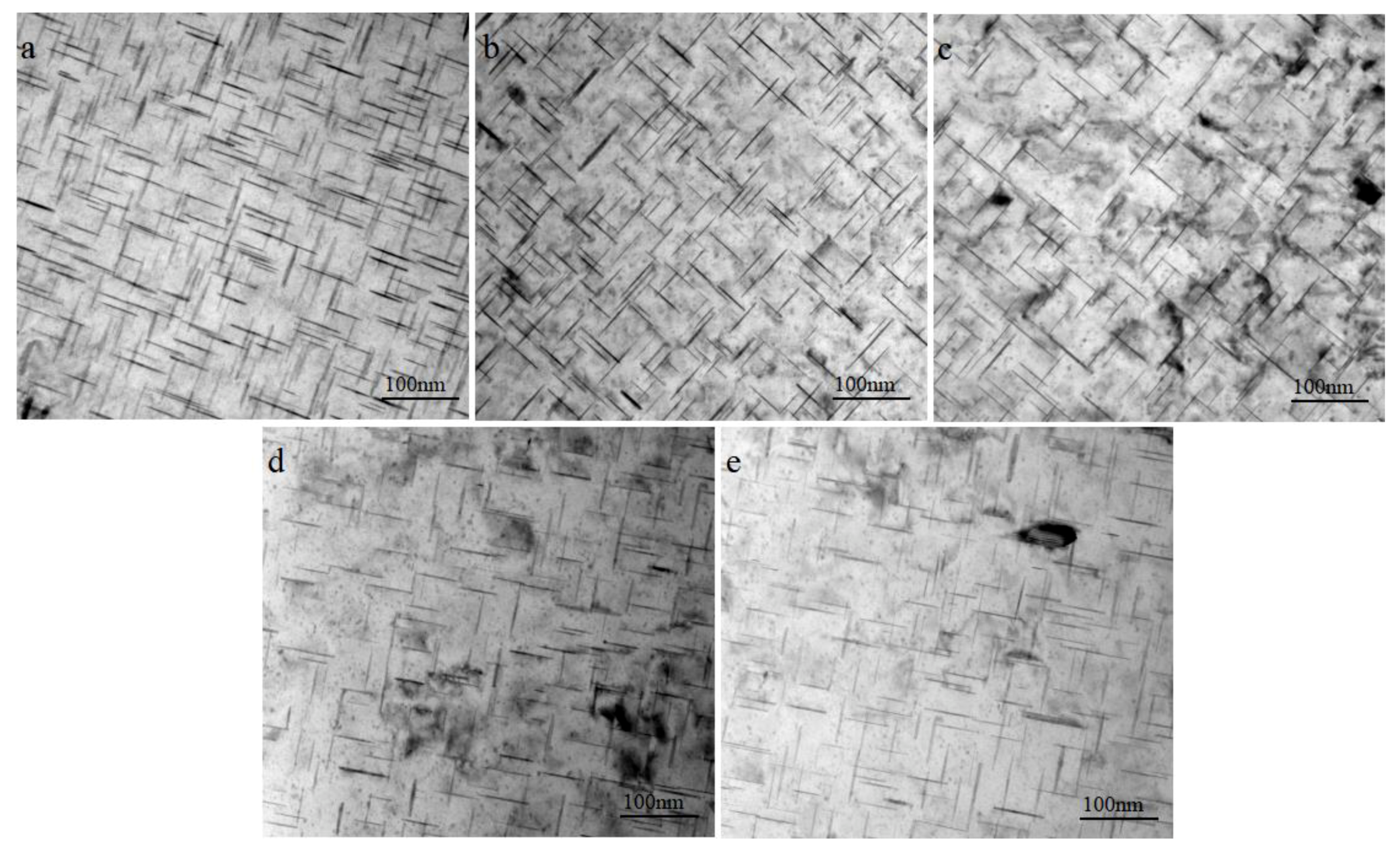

3.3.3. Strengthening Phase at Peak Aging

3.4. Mechanical Properties and Fracture Morphology of the Wall

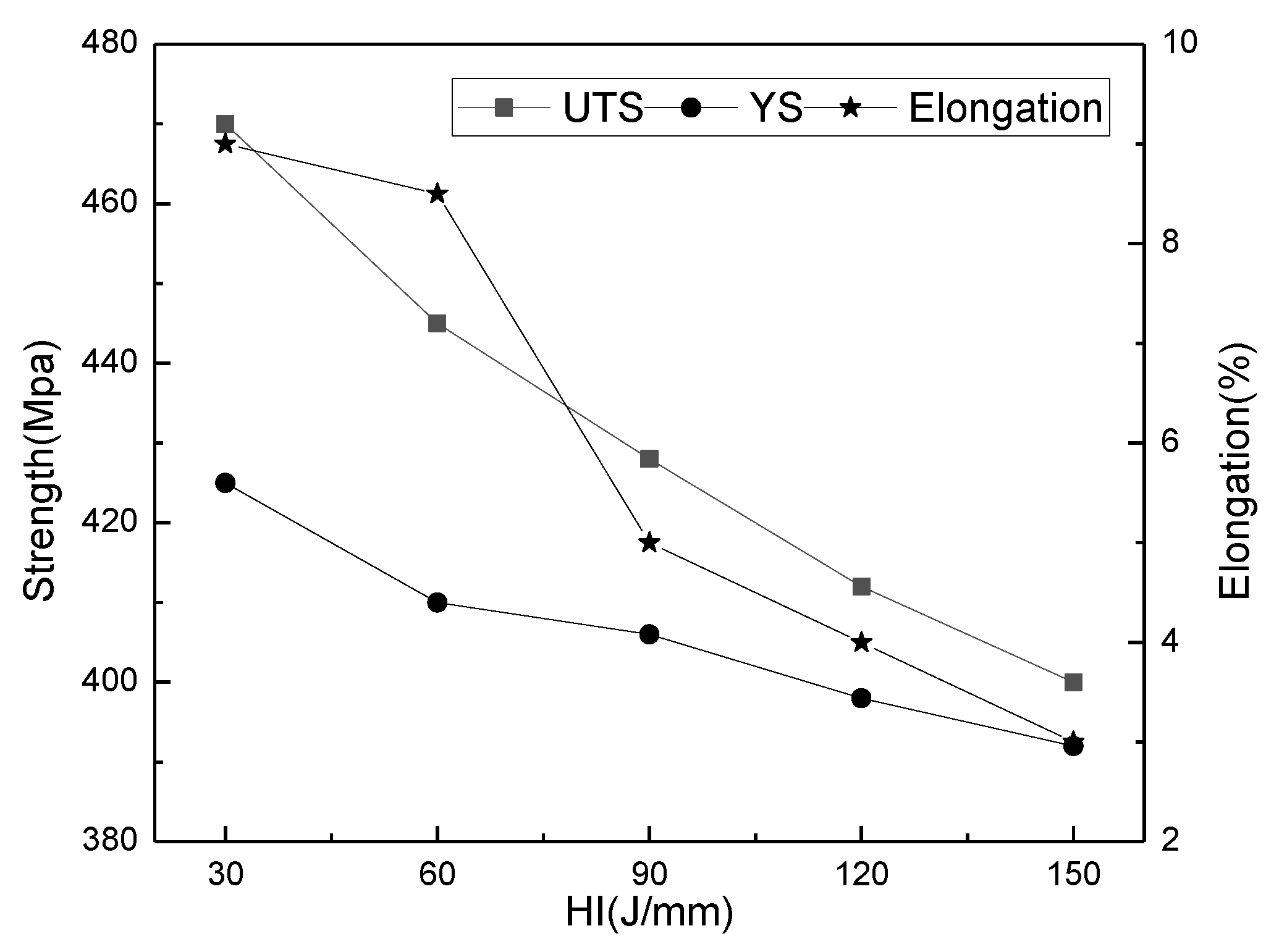

3.4.1. Mechanical Properties of the Wall

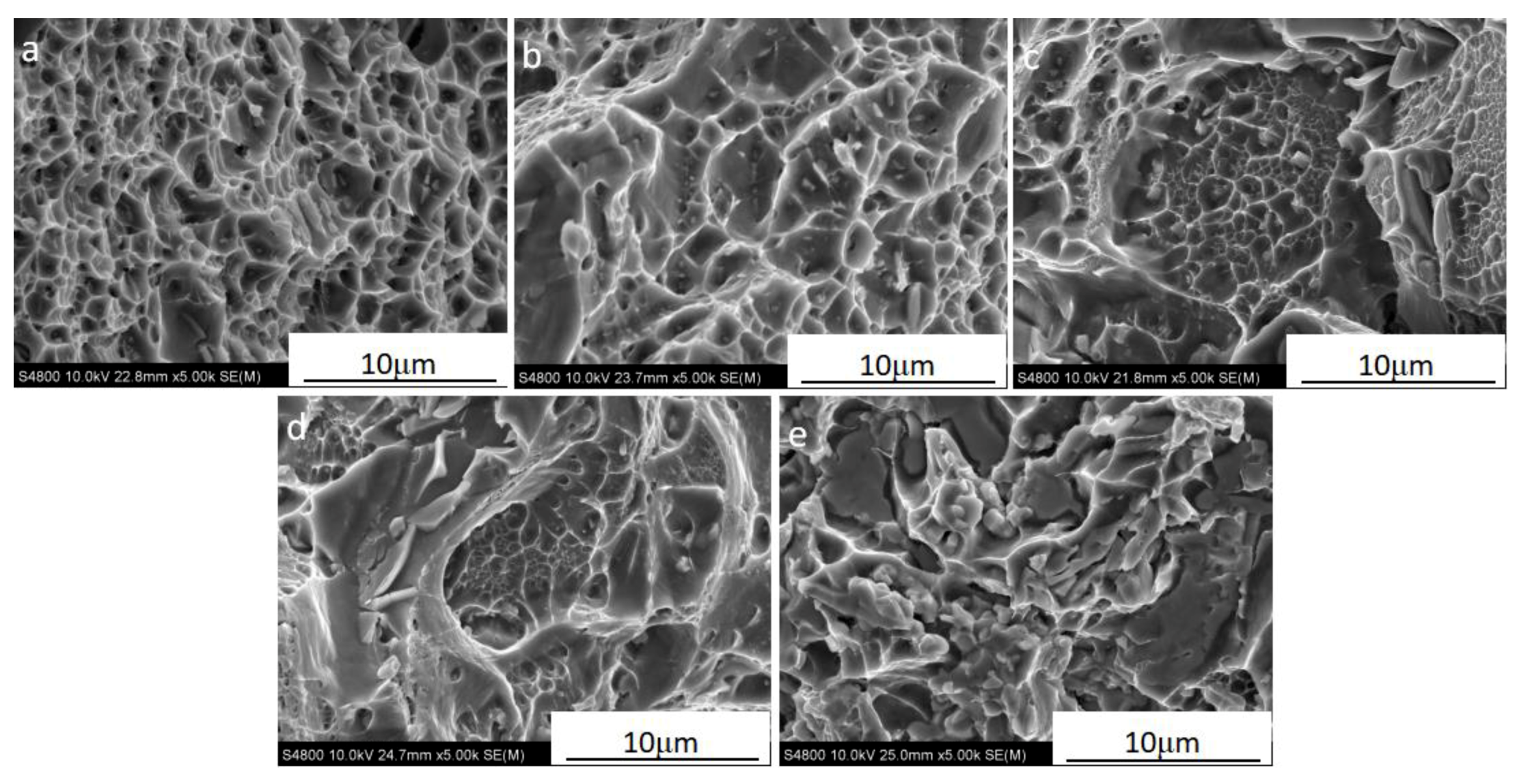

3.4.2. Fracture Morphology of Deposits

4. Conclusions

- (1)

- WAAM Al-Cu-Sn alloy deposits, as the heat input increased, the size and number of pores increased. The size of grains also increased. After solution treatment, the number of undissolved θ phases increased. The number of θ phases decreased and phase spacing increased. When the heat input was greater than 90 J/mm, pore size in the bulk material was greater than 50 μm, grains were mainly columnar in the as-deposited state. After heat treatment, there were a large number of un-dissolved θ phases on the grain, and the distribution of θ’ phases was sparse;

- (2)

- In WAAM Al-Cu-Sn alloy deposits, as the heat input increased, the mechanical properties of the deposits decreased. When the heat input was greater than 90 J/mm, the fracture characterization of this sample showed brittle fracture characteristics.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, J.; Kulak, M. A new paradigm in the design of aluminum alloys for aerospace applications. Mater. Sci. Forum 2000, 331, 127–140. [Google Scholar] [CrossRef]

- Jongbeom, L.; Jeongmin, P.; Haguk, J. Effect of strain on mechanical and microstructural properties of Al/Cu claddings during caliber-rolling. Mater. Lett. 2018, 222, 122–125. [Google Scholar]

- Rooy, E.L. Metals Handbook; ASM International: Materials Park, OH, USA, 1988; Volume 15, pp. 743–770. [Google Scholar]

- Bikas, H.; Stavropoulos, P.; Chryssolouris, G. Additive manufacturing methods and modelling approaches: A critical review. Int. J. Adv. Manuf. Technol. 2015, 83, 389–405. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Foteinopoulos, P. Modelling of additive manufacturing processes: A review and classification. Manuf. Rev. 2018, 5, 2. [Google Scholar] [CrossRef]

- Cong, B.; Ding, J.; Williams, S.W. Effect of arc mode in cold metal transfer process on porosity of additively manufactured Al-6.3% Cu alloy. Int. J. Adv. Manuf. Technol. 2015, 76, 1593–1606. [Google Scholar] [CrossRef]

- Gu, J.L. Study on Microstructure and Mechanical Properties of Additively Manufactured Al-Cu-(Mg) Alloys with the CMT Process. Ph.D. Thesis, Northeastern University, Shenyang, China, 2016. [Google Scholar]

- Wang, S.; Gu, H.; Wang, W.; Li, C.; Ren, L.; Wang, Z.; Zhai, Y.; Ma, P. Microstructure and mechanical properties of aluminum alloy (ZL205A) wall produced by wire arc additive manufacturing method. Rare Metal Mater. Eng. 2019, 48, 2910–2916. [Google Scholar]

- Qi, Z.; Cong, B.; Qi, B.; Zhao, G.; Ding, J. Properties of wire+ arc additively manufactured 2024 aluminum alloy with different solution treatment temperature. Mater. Lett. 2018, 230, 275–278. [Google Scholar] [CrossRef]

- Ganaha, T.; Pearce, B.P.; Kerr, H.W. Grain structures in aluminum alloy GTA welds. Metall. Trans. A 1980, 11, 1351–1359. [Google Scholar] [CrossRef]

- Katayama, S. Solidification phenomena of weld metals (1st report). Characteristic solidification morphologies, microstructures and solidification theory. Weld. Int. 2000, 14, 25–37. [Google Scholar] [CrossRef]

- Cong, B.; Ouyang, R.; Qi, B.; Ding, J. Influence of cold metal transfer process and its heat input on weld bead geometry and porosity of aluminum-copper alloy welds. Rare Metal Mater. Eng. 2016, 45, 0606–0611. [Google Scholar] [CrossRef]

- Ferrie, E.; Buffiere, J.; Ludwig, W. 3D characterisation of the nucleation of a short fatigue crack at a pore in a cast Al alloy using high resolution synchrotron microtomography. Int. J. Fatigue 2005, 27, 1215–1220. [Google Scholar] [CrossRef]

- Hua, G.; Ahmadi, H.; Nouri, M.; Li, D. Positive effect of yttrium on the reduction of pores in cast Al alloy. Mater. Chem. Phys. 2015, 149, 140–144. [Google Scholar] [CrossRef]

- Fujii, H.; Nogi, K. Formation and disappearance of pores in aluminum alloy molten pool under microgravity. Sci. Technol. Adv. Mater. 2004, 5, 219–223. [Google Scholar] [CrossRef]

- Guang, R.J.; Liu, Y.; Li, Y.X. A model for calculating hydrogen solubility in molten aluminum alloys. Acta Metall. Sin. 2008, 2, 129–133. [Google Scholar]

- Zhang, W. Metal Fusion Welding Principle and Technology; Machinery Industry Press: Beijing, China, 1983; pp. 160–169. [Google Scholar]

- Grong, O. Metallurgical Modelling of Welding; Institute of Materials: London, UK, 1997. [Google Scholar]

- Hall, M.G.; Haworth, C.W. Dissolution of θ phase in Al-5% Cu. Acta Metall. 1970, 18, 331–337. [Google Scholar] [CrossRef]

- Banerjee, S.; Robi, P.S.; Srinivasan, A.; Lakavath, P.K. Effect of trace additions of Sn on microstructure and mechanical properties of Al–Cu–Mg alloys. Mater. Des. 2010, 31, 4007–4015. [Google Scholar] [CrossRef]

- Badin, C.; Marino, F.; Verne, E. Calorimetric study on precipitation path in 2024 alloy and its SiC composite. Mater. Sci. Eng. A 1995, 191, 185–191. [Google Scholar] [CrossRef]

- Anyalebechi, P.N. Hydrogen-induced gas porosity formation in Al-4.5wt% Cu-1.4 wt% Mg alloy. Mater. Sci. 2013, 48, 5342–5353. [Google Scholar] [CrossRef]

| Element | Fe | Si | Mg | Cu | Mn | Ti | Sn | Zr | B | V |

|---|---|---|---|---|---|---|---|---|---|---|

| Content (wt.%) | 0.100 | 0.040 | 0.025 | 5.102 | 0.421 | 0.272 | 0.103 | 0.177 | 0.034 | 0.125 |

| Heat Input (J·mm−1) | I/A | U/V | νWFS/m·min−1 | νTS/m·min−1 |

|---|---|---|---|---|

| 150 | 125 | 17.7 | 6.1 | 11.8 |

| 120 | 106 | 17 | 5.3 | 12 |

| 90 | 80 | 16.5 | 4.0 | 11.7 |

| 60 | 63 | 14.6 | 3.7 | 12.3 |

| 30 | 55 | 14.6 | 2.9 | 21.4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Gu, H.; Wang, W.; Li, C.; Ren, L.; Wang, Z.; Zhai, Y.; Ma, P. The Influence of Heat Input on the Microstructure and Properties of Wire-Arc-Additive-Manufactured Al-Cu-Sn Alloy Deposits. Metals 2020, 10, 79. https://doi.org/10.3390/met10010079

Wang S, Gu H, Wang W, Li C, Ren L, Wang Z, Zhai Y, Ma P. The Influence of Heat Input on the Microstructure and Properties of Wire-Arc-Additive-Manufactured Al-Cu-Sn Alloy Deposits. Metals. 2020; 10(1):79. https://doi.org/10.3390/met10010079

Chicago/Turabian StyleWang, Shuai, Huimin Gu, Wei Wang, Chengde Li, Lingling Ren, Zhenbiao Wang, Yuchun Zhai, and Peihua Ma. 2020. "The Influence of Heat Input on the Microstructure and Properties of Wire-Arc-Additive-Manufactured Al-Cu-Sn Alloy Deposits" Metals 10, no. 1: 79. https://doi.org/10.3390/met10010079

APA StyleWang, S., Gu, H., Wang, W., Li, C., Ren, L., Wang, Z., Zhai, Y., & Ma, P. (2020). The Influence of Heat Input on the Microstructure and Properties of Wire-Arc-Additive-Manufactured Al-Cu-Sn Alloy Deposits. Metals, 10(1), 79. https://doi.org/10.3390/met10010079