Precipitation during γ-ε Phase Transformation in Biomedical Co-Cr-Mo Alloys Fabricated by Electron Beam Melting

Abstract

1. Introduction

2. Materials and Methods

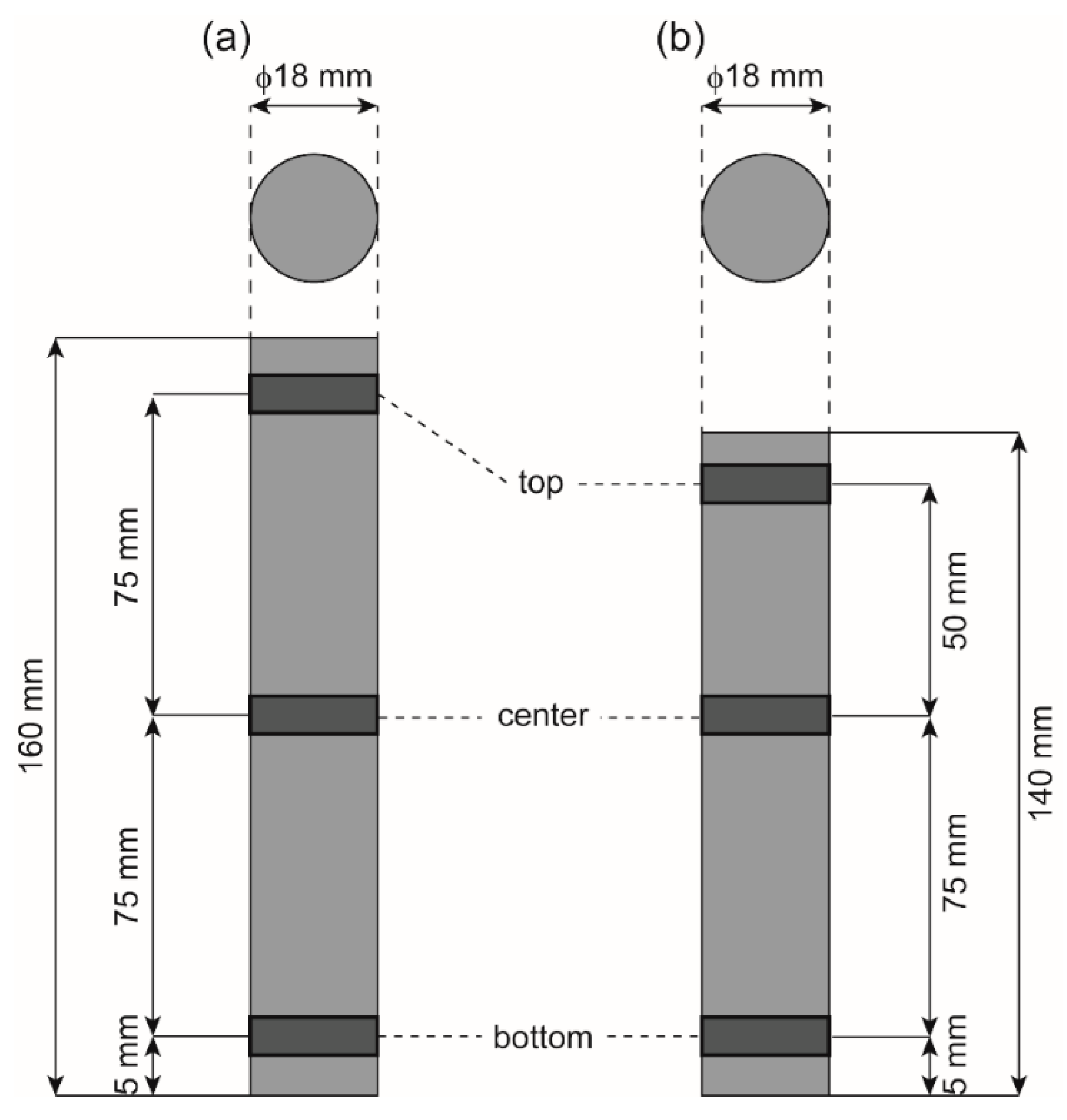

2.1. Specimens

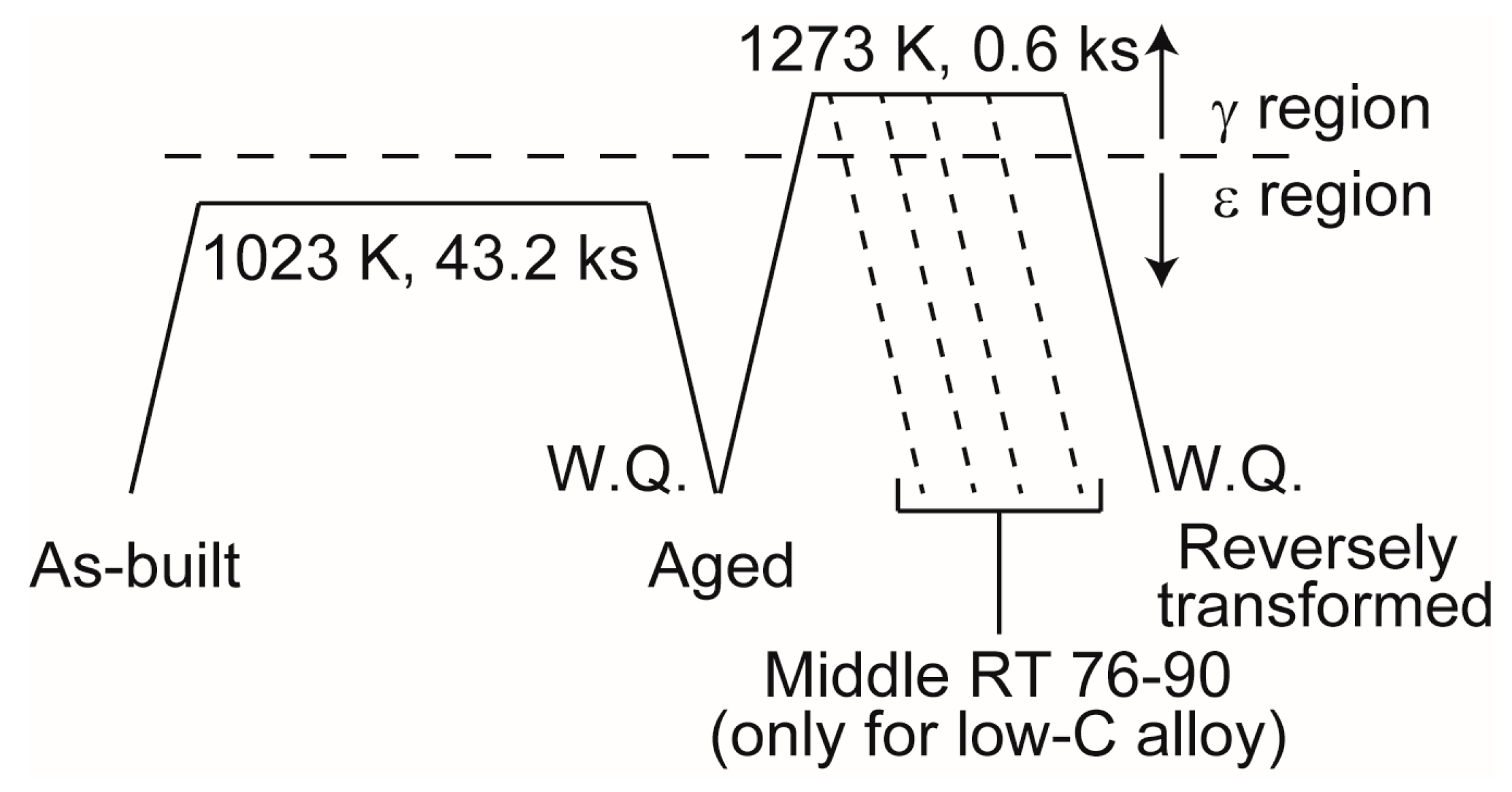

2.2. Heat Treatment

2.3. Microstructure Observation and Analysis

3. Results

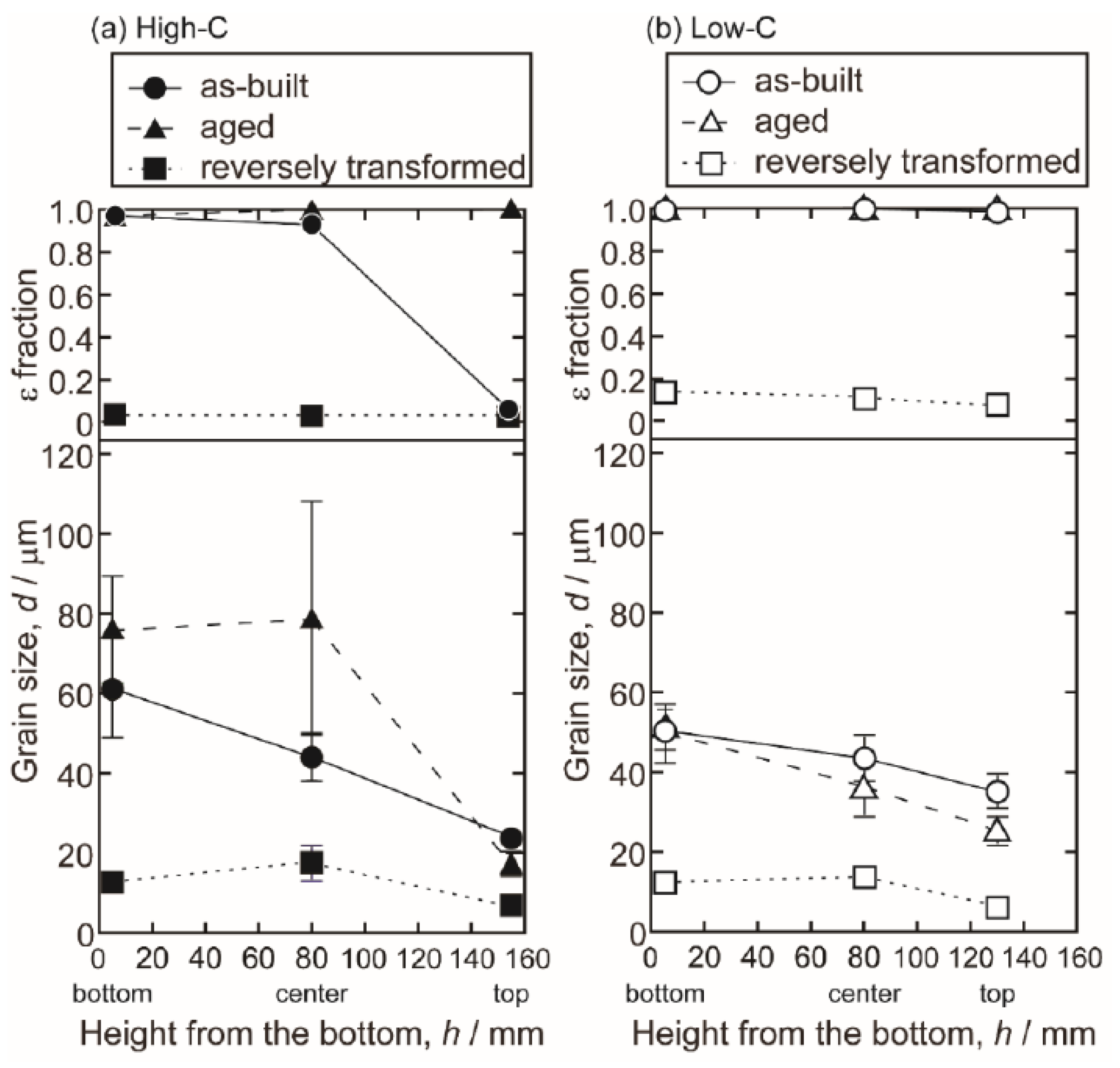

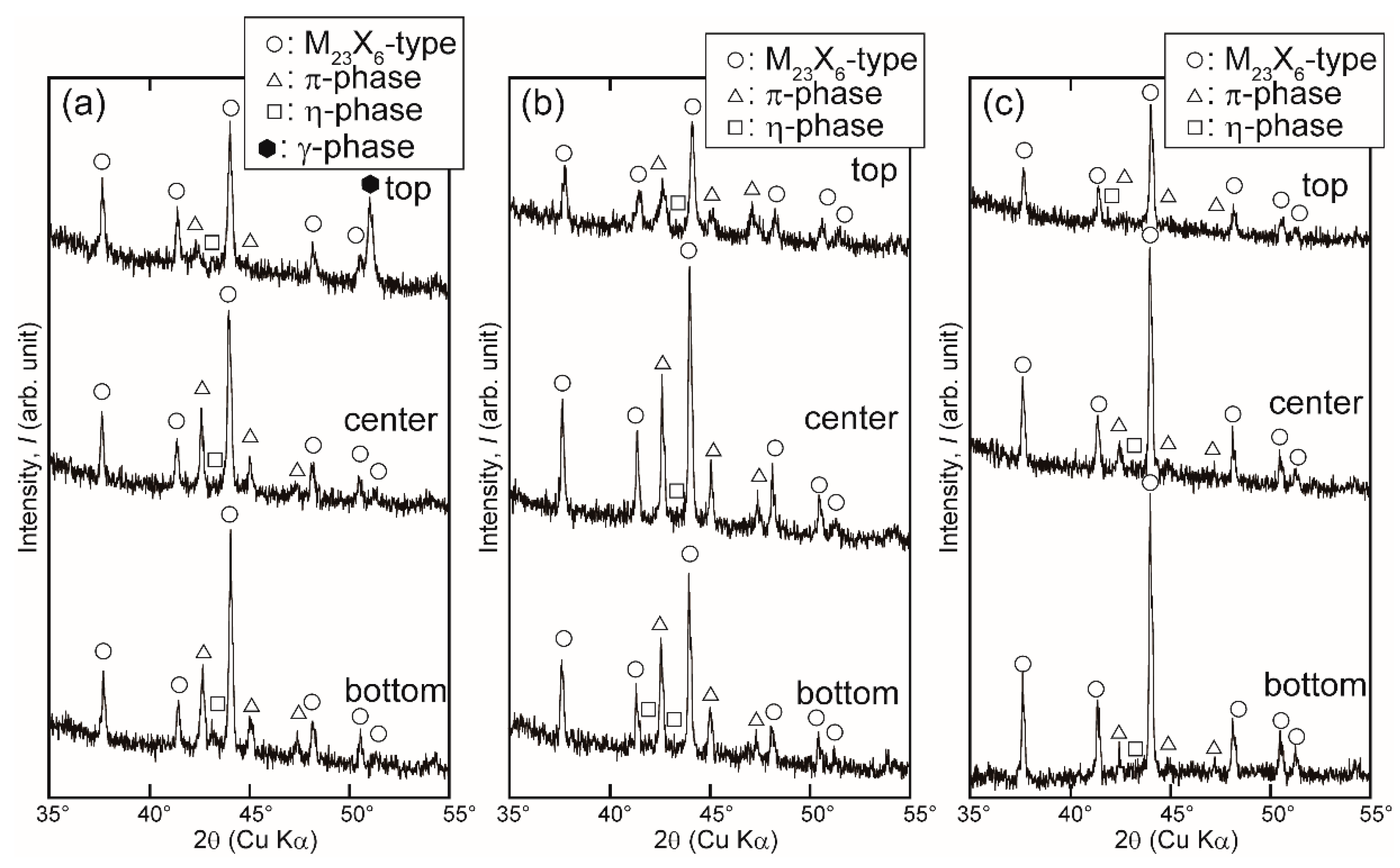

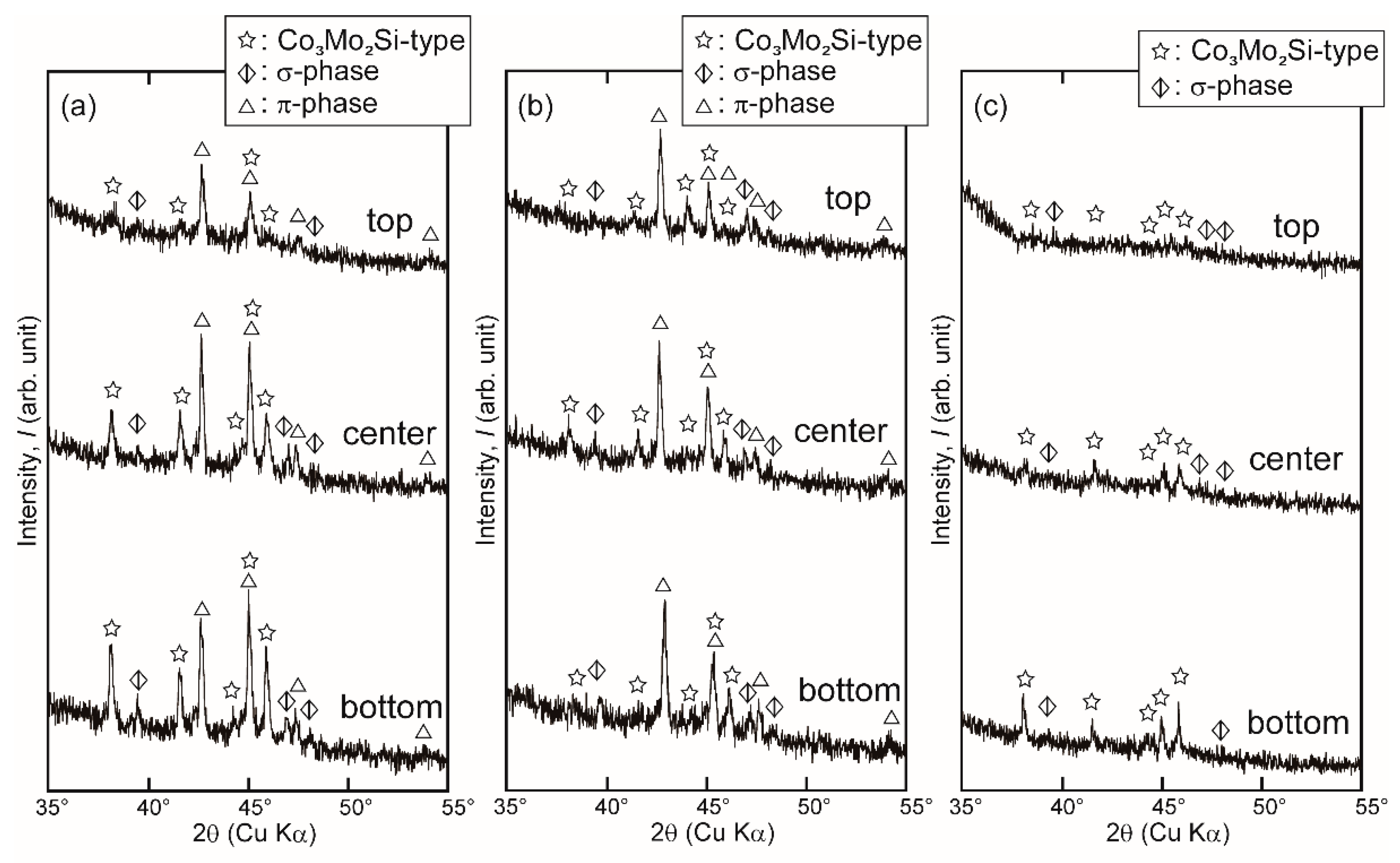

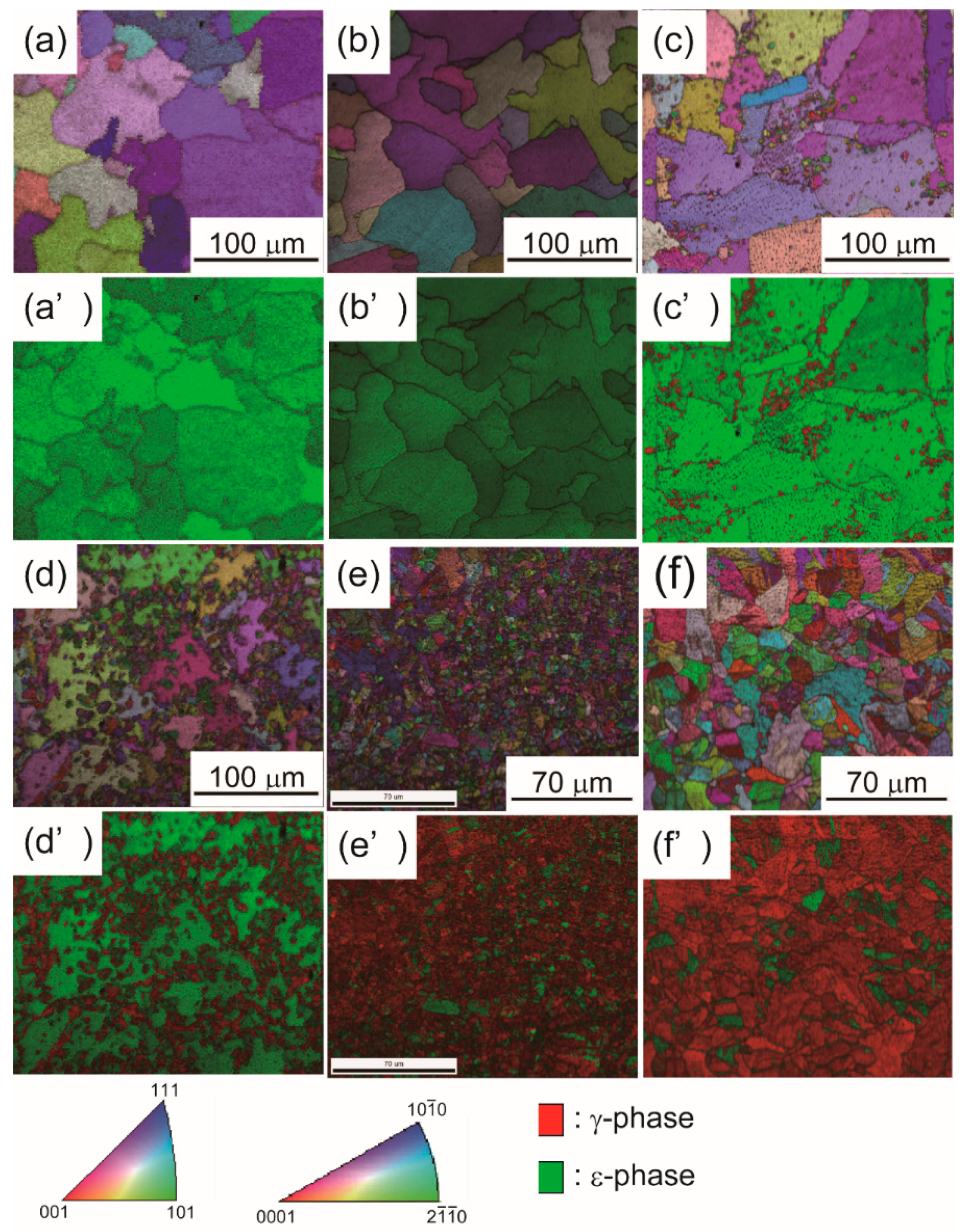

3.1. Phase Transformation Behavior during Aging and Reverse Transformation Treatment

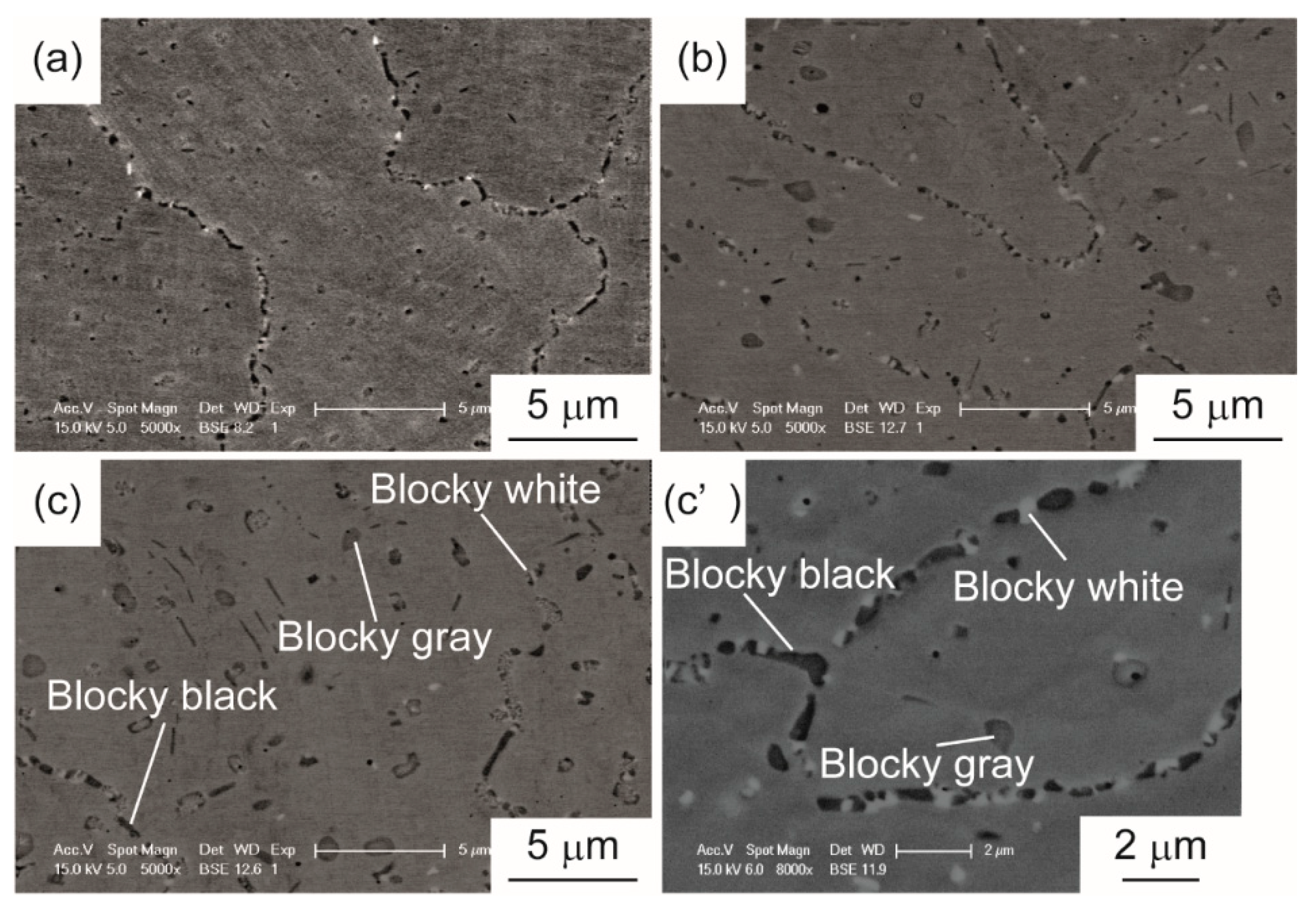

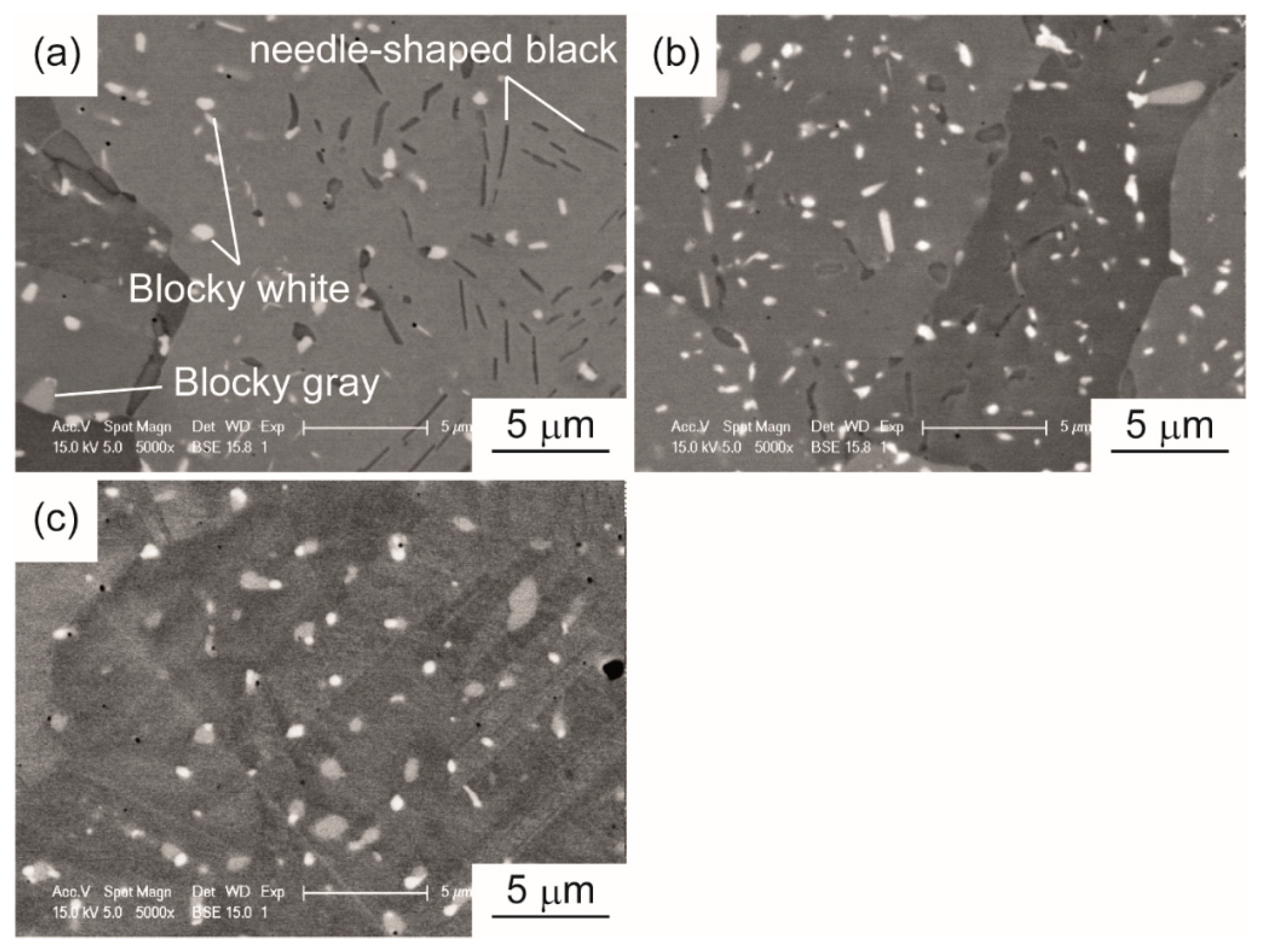

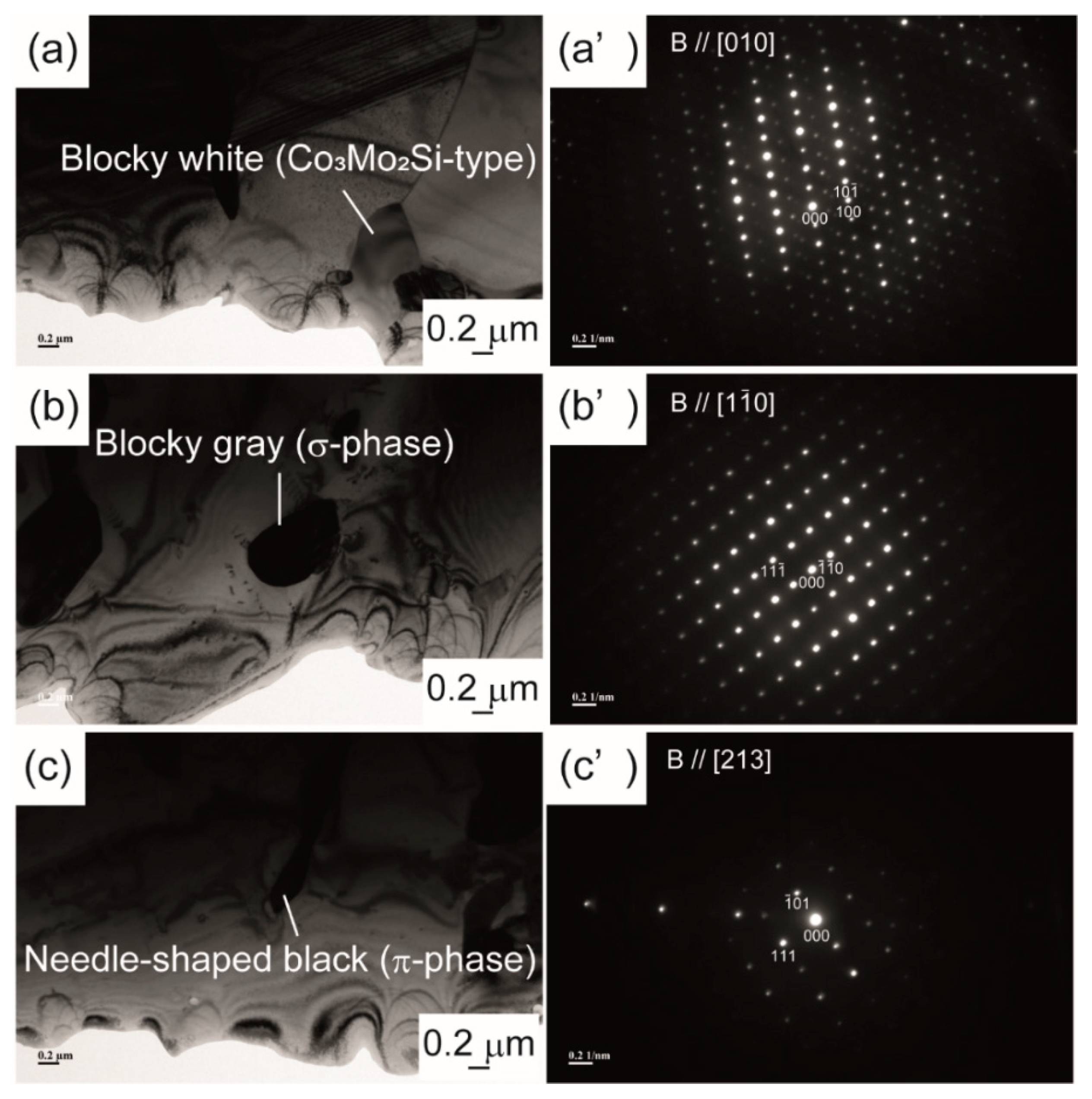

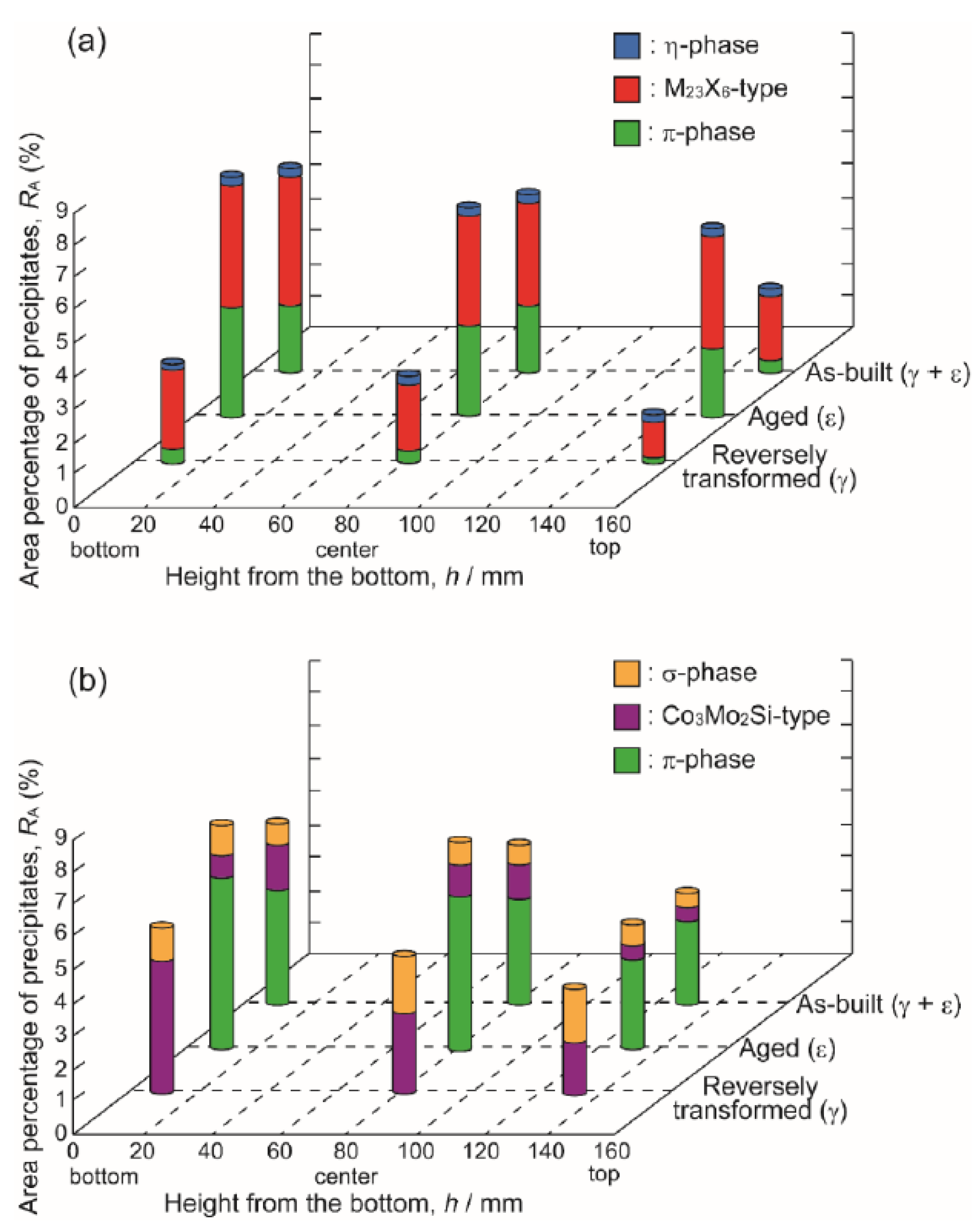

3.2. Precipitation during Aging and Reverse Transformation Treatment

4. Discussion

4.1. Effect of Carbon Content on the Phase and Amount of Precipitates

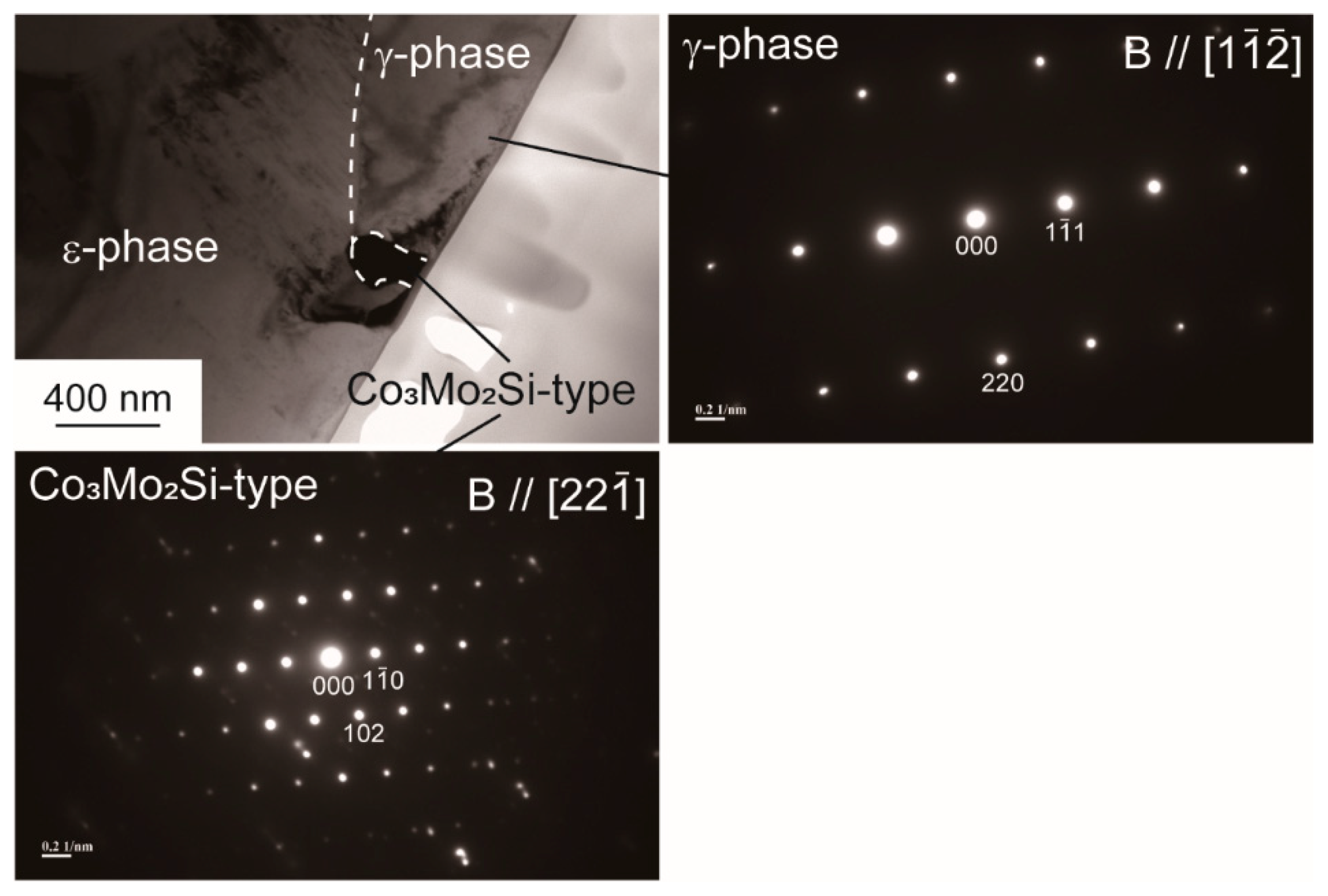

4.2. Co3Mo2Si-Type Precipitates

4.3. Effect of π-Phase and Co3Mo2Si-Type Precipitates on γ-ε Transformation during Heat Treatment

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Devine, T.M.; Wulff, J. Cast vs. wrought cobalt-chromium surgical implant alloys. J. Biomed. Mater. Res. 1975, 9, 151–167. [Google Scholar] [CrossRef] [PubMed]

- Niinomi, M. Recent metallic materials for biomedical applications. Metall. Mater. Trans. A 2002, 33, 477–486. [Google Scholar] [CrossRef]

- Rathee, M.; Bhoria, M.; Boora, P. Oral rehabilitation with metal base complete denture for patient with oral lichen planus. IJRID 2014, 4, 117–122. [Google Scholar]

- Buford, A.; Goswami, T. Review of wear mechanisms in hip implants: Paper I—General. Mater. Des. 2004, 25, 385–393. [Google Scholar] [CrossRef]

- Vidal, C.V.; Muñoz, A.I. Electrochemical characterization of biomedical alloys for surgical implants in simulated body fluids. Corros. Sci. 2008, 50, 1954–1961. [Google Scholar] [CrossRef]

- Koizumi, Y.; Suzuki, S.; Yamanaka, K.; Lee, B.S.; Sato, K.; Li, Y.; Kurosu, S.; Matsumoto, H.; Chiba, A. Strain-induced martensitic transformation near twin boundaries in a biomedical Co-Cr-Mo alloy with negative stacking fault energy. Acta Mater. 2013, 61, 1648–1661. [Google Scholar] [CrossRef]

- Lee, S.H.; Nomura, N.; Chiba, A. Significant improvement in mechanical properties of biomedical Co-Cr-Mo alloys with combination of N addition and Cr-enrichment. Mater. Trans. 2008, 49, 260–264. [Google Scholar] [CrossRef]

- Lee, Y.; Yamashita, Y.; Tang, N.; Liu, B.; Kurosu, S.; Matsumoto, H.; Koizumi, Y.; Chiba, A. Influence of carbon and nitrogen addition on microstructure and hot deformation behavior of biomedical Co–Cr–Mo alloy. Mater. Chem. Phys. 2012, 135, 849–854. [Google Scholar]

- Murr, L.E. Metallurgy of additive manufacturing: Examples from electron beam melting. Addit. Manuf. 2015, 5, 40–53. [Google Scholar] [CrossRef]

- Takaichi, A.; Nakamoto, T.; Joko, N.; Nomura, N.; Tsutsumi, Y.; Migita, S.; Doi, H.; Kurosu, S.; Chiba, A.; Wakabayashi, N.; et al. Microstructures and mechanical properties of Co-29Cr-6Mo alloy fabricated by selective laser melting process for dental application. J. Mech. Behav. Biomed. Mater. 2013, 21, 67–76. [Google Scholar] [CrossRef] [PubMed]

- Sing, S.L.; Huang, S.; Yeong, W.Y. Effect of solution heat treatment on microstructure and mechanical properties of laser powder bed fusion produced cobalt-28chromium-6molybdenum. Mater. Sci. Eng. A 2020, 769, 138511. [Google Scholar] [CrossRef]

- Wei, D.; Koizumi, Y.; Takashima, T.; Nagasako, M.; Chiba, A. Fatigue improvement of electron beam melting-fabricated biomedical Co–Cr–Mo alloy by accessible heat treatment. Mater. Res. Lett. 2018, 6, 93–99. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Medina, F.; Martinez, E.; Martinez, J.L.; Hernandez, D.H.; Machado, B.I.; Ramirez, D.A.; Wicker, R.B. Characterization of Ti-6Al-4V open cellular foams fabricated by additive manufacturing using electron beam melting. Mater. Sci. Eng. A 2010, 527, 1861–1868. [Google Scholar] [CrossRef]

- Ramirez, D.A.; Murr, L.E.; Li, S.J.; Tian, Y.X.; Martinez, E.; Martinez, J.L.; Machado, B.I.; Gaytan, S.M.; Medina, F.; Wicker, R.B. Open-cellular copper structures fabricated by additive manufacturing using electron beam melting. Mater. Sci. Eng. A 2011, 528, 5379–5386. [Google Scholar] [CrossRef]

- Sun, S.H.; Koizumi, Y.; Kurosu, S.; Li, Y.P.; Chiba, A. Phase and grain size inhomogeneity and their influence on creep behavior of Co–Cr–Mo alloy additive manufactured by electron beam melting. Acta Mater. 2015, 86, 305–318. [Google Scholar] [CrossRef]

- López, H.F.; Saldivar-Garcia, A.J. Martensitic transformation in a cast Co-Cr-Mo-C alloy. Metall. Mater. Trans. A 2008, 39, 8–18. [Google Scholar] [CrossRef]

- Wei, D.; Koizumi, Y.; Chiba, A.; Ueki, K.; Ueda, K.; Narushima, T.; Tsutsumi, T.; Hanawa, T. Heterogeneous microstructures and corrosion resistance of biomedical Co-Cr-Mo alloy fabricated by electron beam melting (EBM). Addit. Manuf. 2018, 24, 103–114. [Google Scholar] [CrossRef]

- Sun, S.H.; Koizumi, Y.; Kurosu, S.; Li, Y.P.; Matsumoto, H.; Chiba, A. Build direction dependence of microstructure and high-temperature tensile property of Co–Cr–Mo alloy fabricated by electron beam melting. Acta Mater. 2014, 64, 154–168. [Google Scholar] [CrossRef]

- Wei, D.; Anniyaer, A.; Koizumi, Y.; Aoyagi, K.; Nagasako, M.; Kato, H.; Chiba, A. On microstructural homogenization and mechanical properties optimization of biomedical Co-Cr-Mo alloy additively manufactured by using electron beam melting. Addit. Manuf. 2019, 28, 215–227. [Google Scholar] [CrossRef]

- Kurosu, S.; Matsumoto, H.; Chiba, A. Grain refinement of biomedical Co–27Cr–5Mo–0.16 N alloy by reverse transformation. Mater. Lett. 2010, 64, 49–52. [Google Scholar] [CrossRef]

- Mori, M.; Yamanaka, K.; Chiba, A. Phase decomposition in biomedical Co–29Cr–6Mo–0.2 N alloy during isothermal heat treatment at 1073 K. J. Alloys Compd. 2014, 590, 411–416. [Google Scholar] [CrossRef]

- Kurosu, S.; Matsumoto, H.; Chiba, A. Isothermal phase transformation in biomedical Co-29Cr-6Mo alloy without addition of carbon or nitrogen. Metall. Mater. Trans. A 2010, 41, 2613–2625. [Google Scholar] [CrossRef]

- Mineta, S.; Namba, S.; Yoneda, T.; Ueda, K.; Narushima, T. Precipitates in as-cast and heat-treated ASTM F75 Co-Cr-Mo alloys containing Si and/or Mn. Metall. Mater. Trans. A 2011, 42, 1941–1949. [Google Scholar]

- Mineta, S.; Namba, S.; Yoneda, T.; Ueda, K.; Narushima, T. Precipitates in biomedical Co-28Cr-6Mo-(0–0.41) C alloys heat-treated at 1473 K to 1623 K (1200 °C to 1350 °C). Metall. Mater. Trans. A 2012, 43, 3351–3358. [Google Scholar] [CrossRef]

- Mineta, S.; Namba, S.; Yoneda, T.; Ueda, K.; Narushima, T. Carbide formation and dissolution in biomedical Co-Cr-Mo alloys with different carbon contents during solution treatment. Metall. Mater. Trans. A 2010, 41, 2129–2138. [Google Scholar] [CrossRef]

- Narushima, T.; Mineta, S.; Kurihara, Y.; Ueda, K. Precipitates in biomedical Co-Cr alloys. JOM 2013, 65, 489–504. [Google Scholar] [CrossRef]

- Narushima, T.; Mineta, S.; Namba, S.; Yoneda, T.; Ueda, K. Precipitates in biomedical Co-Cr-Mo-C-Si-Mn alloys. Adv. Mater. Res. 2011, 277, 51–58. [Google Scholar] [CrossRef]

- Ueki, K.; Kurihara, Y.; Mineta, S.; Ueda, K.; Namba, S.; Yoneda, T.; Narushima, T. Changes in microstructure of biomedical Co-Cr-Mo alloys during aging at 973 to 1373 K. Mater. Trans. 2016, 57, 2048–2053. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.M. Elevated temperature wear behaviors of a Co–Mo–Si ternary metal silicide alloy. Scrip. Materialia 2005, 52, 1235–1240. [Google Scholar] [CrossRef]

- Bardos, D.I.; Gupta, K.P.; Beck, P.A. Ternary laves phases with transition elements and silicon. Trans. Metall. Soc. AIME 1961, 221, 1087–1088. [Google Scholar]

- Liu, R.; Yao, M.X.; Patnaik, P.C.; Wu, X. Effects of heat treatment on mechanical and tribological properties of cobalt-base tribaloy alloys. J. Mater. Eng. Perform. 2005, 14, 634–640. [Google Scholar] [CrossRef]

- Liu, R.; Xi, S.Q.; Kapoor, S.; Wu, X.J. Effects of chemical composition on solidification, microstructure and hardness of Co-Cr-W-Ni and Co-Cr-Mo-Ni alloy systems. Int. J. Res. Rev. Appl. Sci. 2010, 5, 110–122. [Google Scholar]

- Santecchia, E.; Gatto, A.; Bassoli, E.; Denti, L.; Rutkowski, B.; Mengucci, P. Precipitates formation and evolution in a Co-based alloy produced by pwder bed fusion. J. Alloy. Compd. 2019, 797, 652–658. [Google Scholar] [CrossRef]

- Achmad, T.L.; Fu, W.; Chen, H.; Zhang, C.; Yang, Z.G. First-principles calculations of generalized-stacking-fault-energy of Co-based alloys. Comp. Mater. Sci. 2016, 121, 86–96. [Google Scholar] [CrossRef]

| Alloy | Co | Cr | Mo | Ni | Fe | Si | Mn | C | N | O | S |

|---|---|---|---|---|---|---|---|---|---|---|---|

| high-C (mass%) | Bal. | 28.1 | 6.12 | 0.13 | 0.23 | 0.35 | 0.42 | 0.184 | 0.114 | 0.0058 | 0.0024 |

| low-C (mass%) | Bal. | 27.5 | 6.01 | 0.01 | 0.02 | 0.6 | 0.41 | 0.018 | 0.101 | 0.0076 | 0.0006 |

| Alloy | Co | Cr | Mo | Si | ||||

|---|---|---|---|---|---|---|---|---|

| mass% | at% | mass% | at% | mass% | at% | mass% | at% | |

| as-built | 40.37 | 46.03 | 13.95 | 18.02 | 43.36 | 30.37 | 2.33 | 5.58 |

| reversely transformed | 35.84 | 42.14 | 11.88 | 15.83 | 49.82 | 35.98 | 2.45 | 6.05 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ueki, K.; Kasamatsu, M.; Ueda, K.; Koizumi, Y.; Wei, D.; Chiba, A.; Narushima, T. Precipitation during γ-ε Phase Transformation in Biomedical Co-Cr-Mo Alloys Fabricated by Electron Beam Melting. Metals 2020, 10, 71. https://doi.org/10.3390/met10010071

Ueki K, Kasamatsu M, Ueda K, Koizumi Y, Wei D, Chiba A, Narushima T. Precipitation during γ-ε Phase Transformation in Biomedical Co-Cr-Mo Alloys Fabricated by Electron Beam Melting. Metals. 2020; 10(1):71. https://doi.org/10.3390/met10010071

Chicago/Turabian StyleUeki, Kosuke, Motoka Kasamatsu, Kyosuke Ueda, Yuichiro Koizumi, Daixiu Wei, Akihiko Chiba, and Takayuki Narushima. 2020. "Precipitation during γ-ε Phase Transformation in Biomedical Co-Cr-Mo Alloys Fabricated by Electron Beam Melting" Metals 10, no. 1: 71. https://doi.org/10.3390/met10010071

APA StyleUeki, K., Kasamatsu, M., Ueda, K., Koizumi, Y., Wei, D., Chiba, A., & Narushima, T. (2020). Precipitation during γ-ε Phase Transformation in Biomedical Co-Cr-Mo Alloys Fabricated by Electron Beam Melting. Metals, 10(1), 71. https://doi.org/10.3390/met10010071