Study on Dynamic Mechanical Properties and Constitutive Model Construction of TC18 Titanium Alloy

Abstract

1. Introduction

2. Dynamic Mechanical Properties of TC18 Titanium Alloy

2.1. Preparation of Test Sample

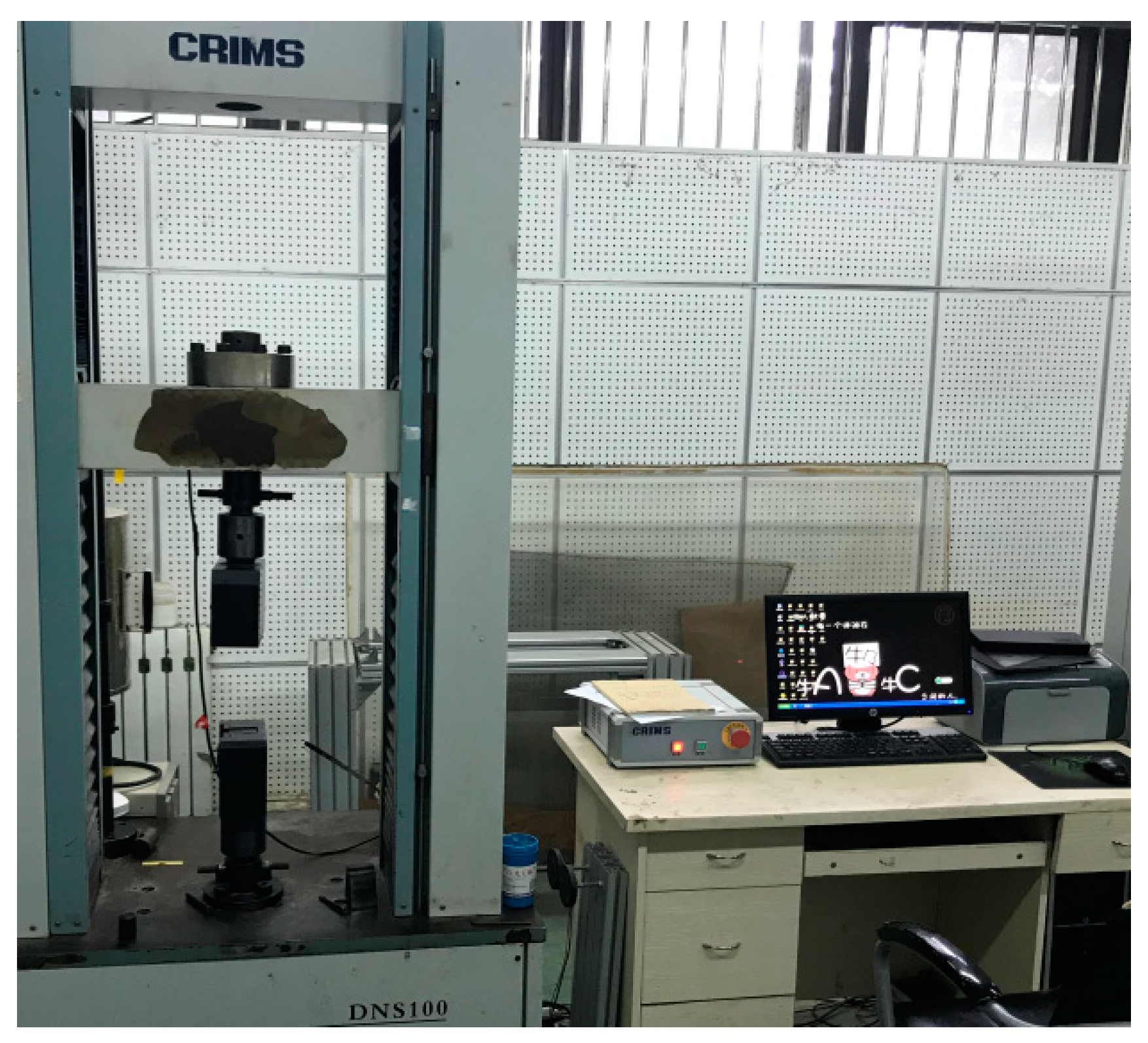

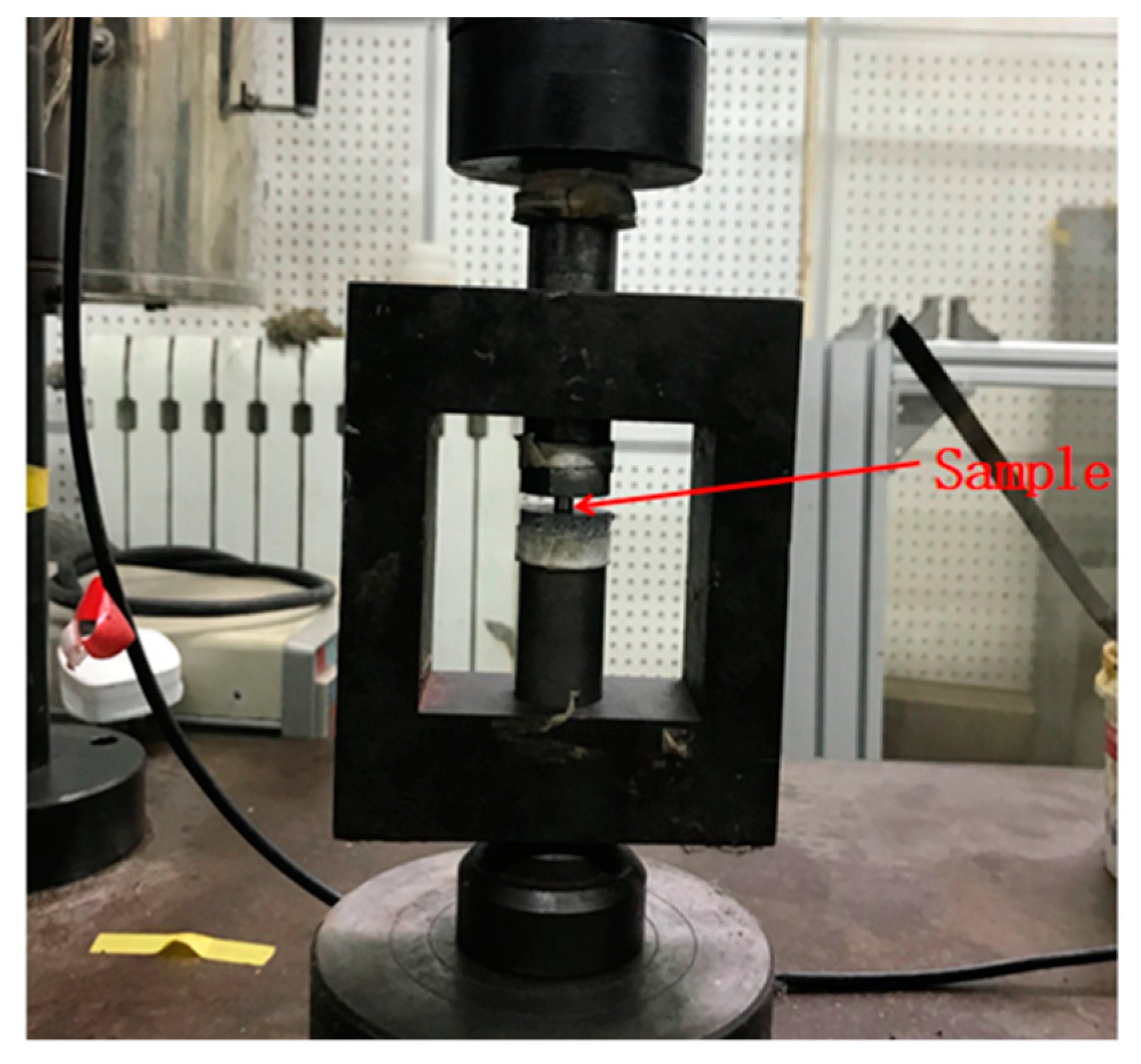

2.2. Quasi-Static Compression Test Device and Experimental Scheme

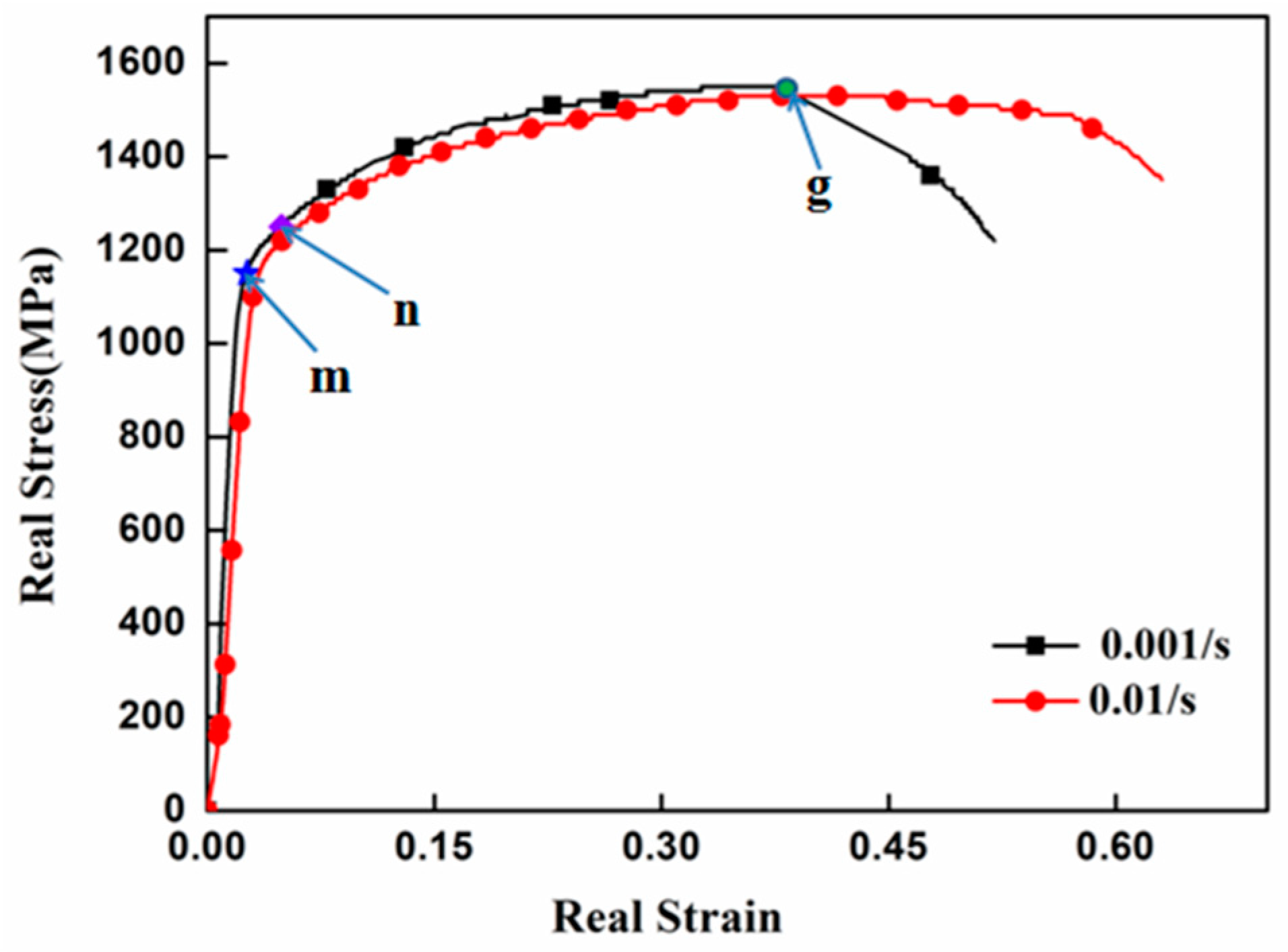

Experimental Results and Analysis under Quasi-Static Conditions

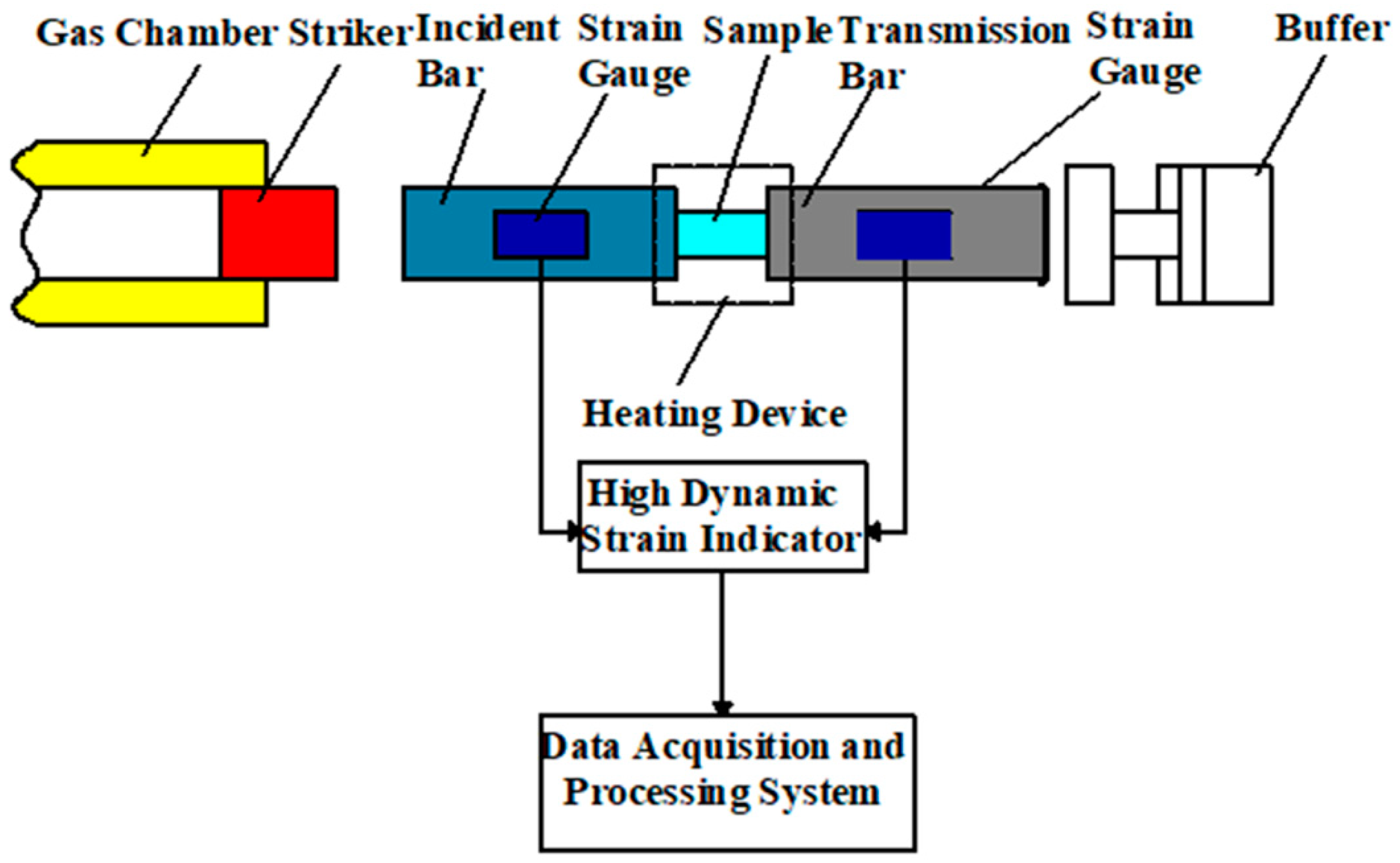

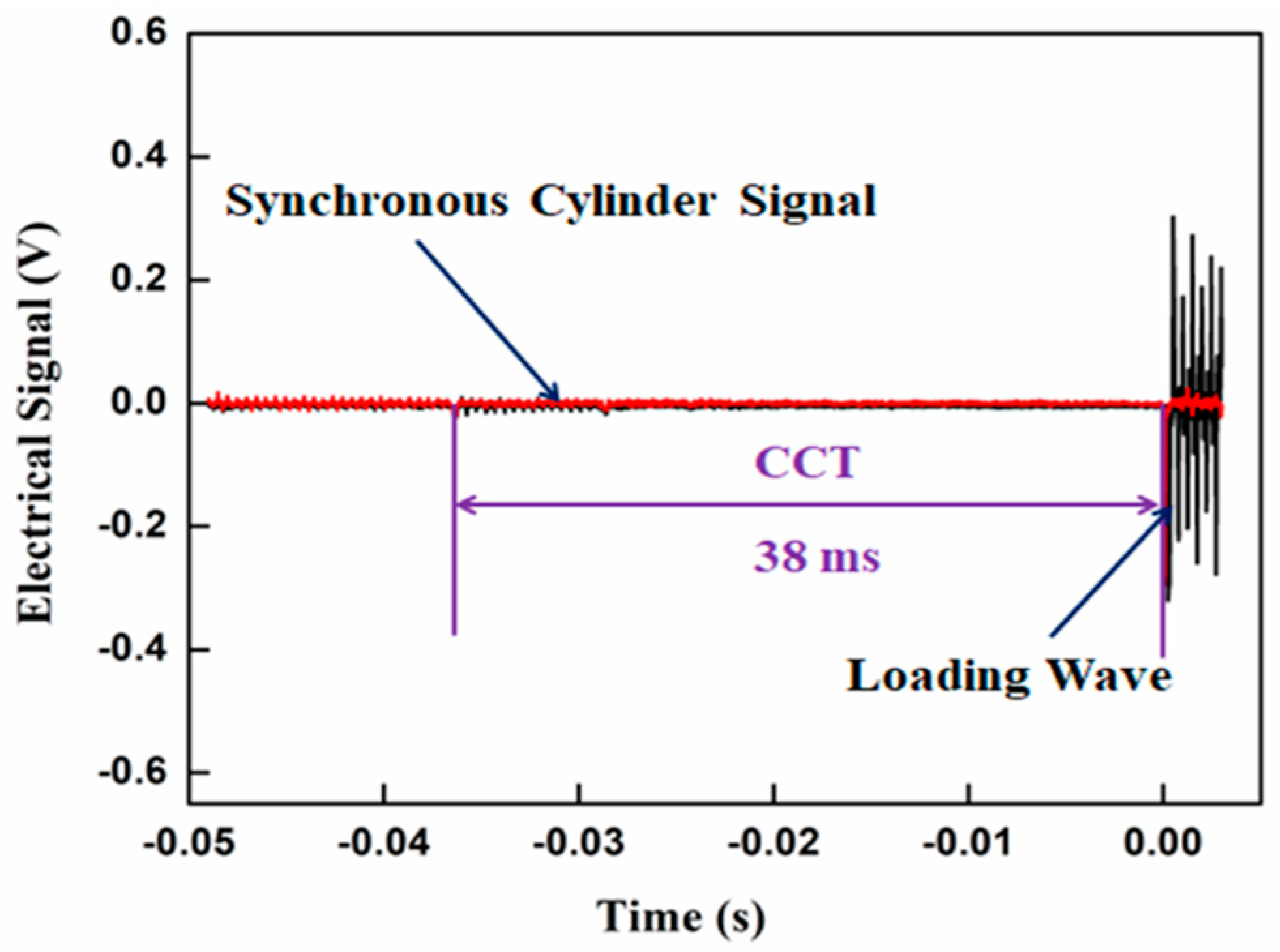

2.3. Hopkinson Pressure Bar Experiment Device, Principle, and Scheme

2.3.1. Split Hopkinson Pressure Bar Device

2.3.2. Experimental Principle of Split Hopkinson Compression Bar

2.3.3. Experimental Scheme of Split Hopkinson Compression Bar

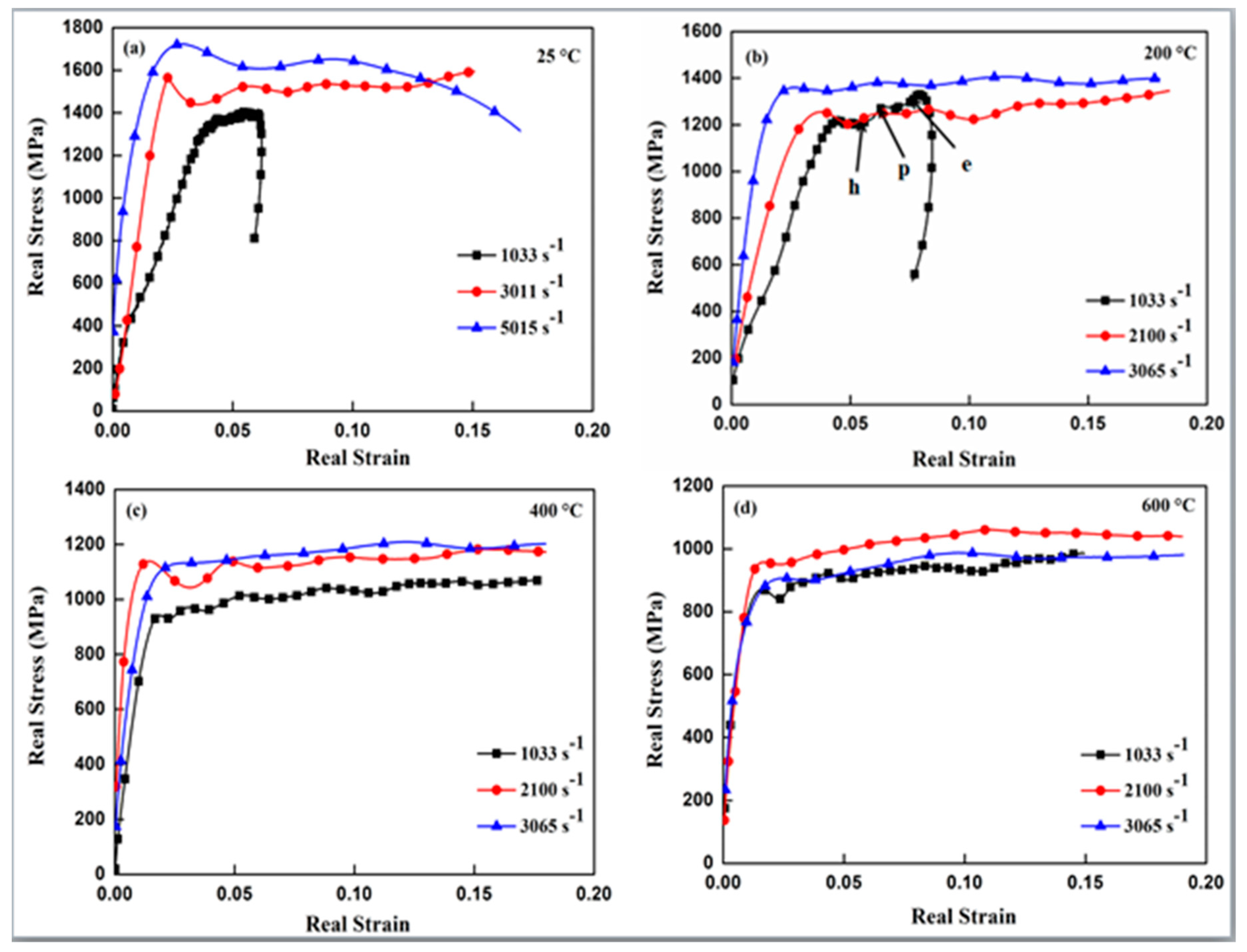

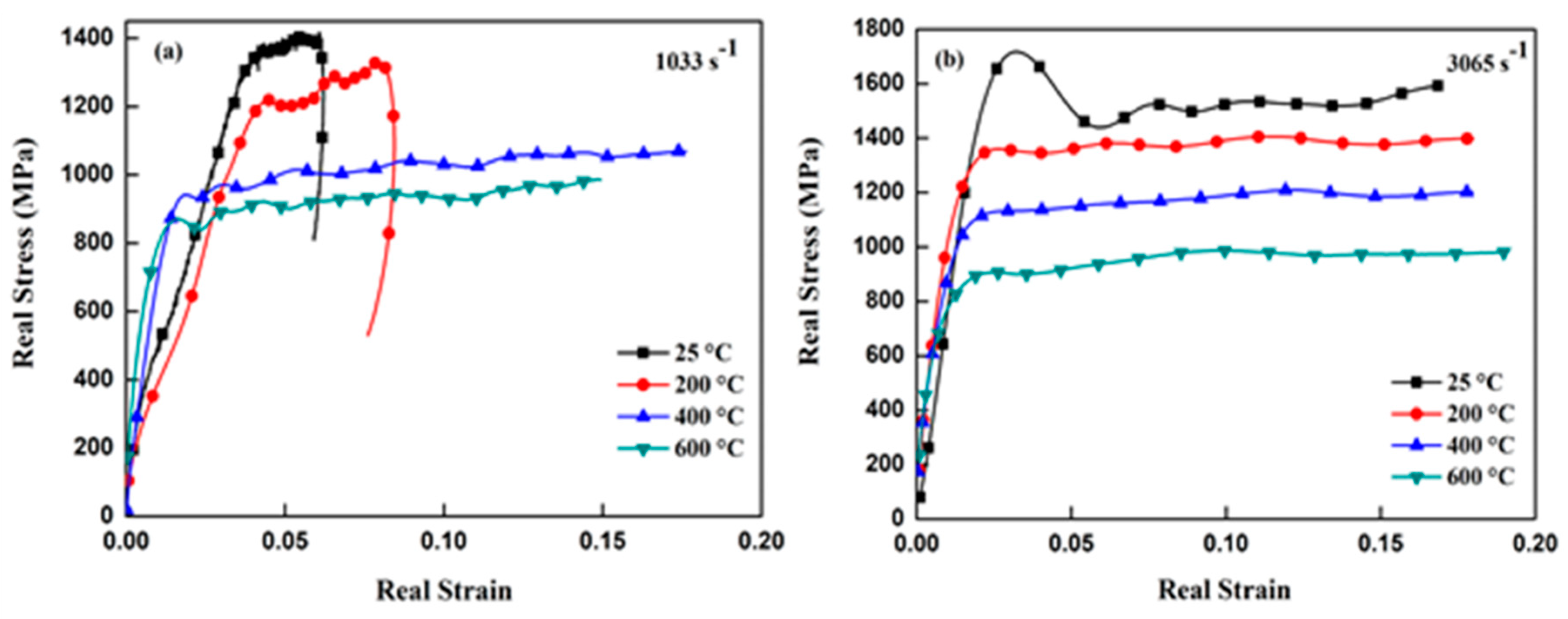

2.4. Dynamic Compression Test Results and Analysis of TC18 Titanium Alloy

2.4.1. Strain Rate Sensitivity Analysis of TC18 Titanium Alloy

2.4.2. Temperature Sensitivity Analysis of TC18 Titanium Alloy

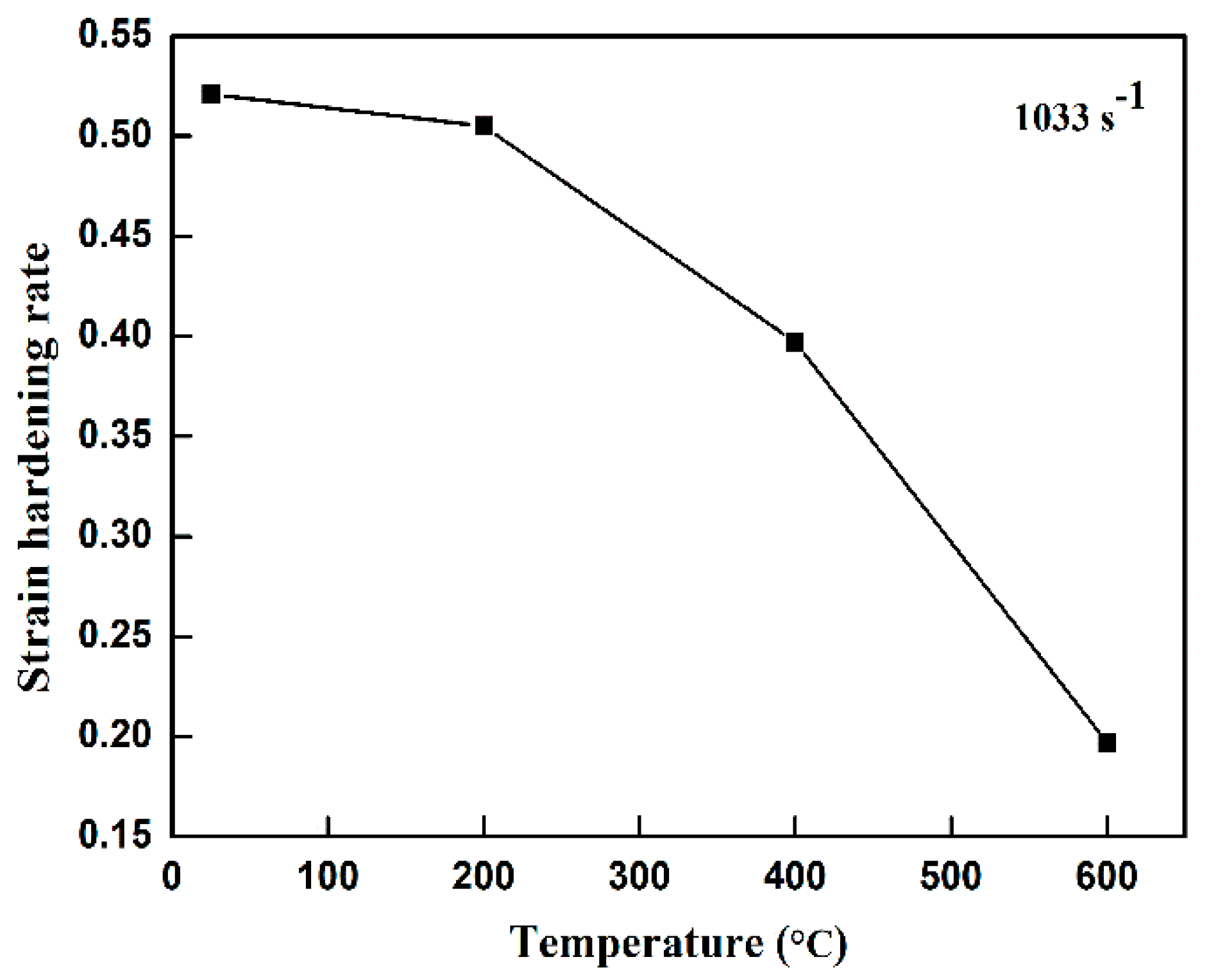

2.4.3. Analysis of Strain Hardening Rate of TC18 Titanium Alloy

2.5. JC Dynamic Constitutive Model for Dynamic Impact Test of TC18 Titanium Alloy

2.5.1. Determination of Parameters , , and in JC Constitutive Model

2.5.2. Determination of Parameters C and m in JC Constitutive Model

2.5.3. Verification of JC Constitutive Model of TC18 Titanium Alloy

3. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Boyer, R.R. An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. A 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Jia, B.H.; Song, W.D.; Tang, H.P.; Wang, Z.H.; Mao, X.N.; Ning, J.G. Hot deformation behavior and constitutive model of TC18 alloy during compression. Rare Met. 2014, 33, 383–389. [Google Scholar] [CrossRef]

- Ning, Y.Q.; Xie, B.C.; Liang, H.Q.; Li, H.; Yang, X.M.; Guo, H.Z. Dynamic softening behavior of TC18 titanium alloy during hot deformation. Mater. Des. 2015, 71, 68–77. [Google Scholar] [CrossRef]

- Nyakana, S.L.; Fanning, J.C.; Boyer, R.R. Quick reference guide for β titanium alloys in the 00s. Mater. Eng. Perform. 2005, 14, 799–811. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Li, A.B.; Wang, G.S.; Cui, X.P. Effects of hot compression and heat treatment on the microstructure and tensile property of Ti-6.5Al-3.5Mo-1.5Zr-0.3Si alloy. Mater. Sci. Eng. A 2008, 489, 330–336. [Google Scholar] [CrossRef]

- Imayev, V.; Imayev, R.; Khismatullin, T.; Güther, V.; Beck, W.; Fecht, H.J. Superplastic behavior of Ti-43Al-7(Nb, Mo)-0.2B alloy in the cast + heat-treated condition. Scr. Mater. 2007, 57, 193–196. [Google Scholar] [CrossRef]

- Ko, Y.G.; Lee, C.S.; Shin, D.H. Deformation characteristics of sub microcrystalline Ti-6Al-4V. Scr. Mater. 2008, 58, 1094–1097. [Google Scholar] [CrossRef]

- Zhou, Z.B.; Fei, Y.; Lai, M.J.; Kou, H.C.; Chang, H.; Shang, G.Q.; Zhu, Z.S.; Li, J.S.; Zhou, L. Microstructure and mechanical properties of new metastable β type titanium alloy. Trans. Nonferrous Met. Soc. China 2010, 20, 2253–2258. [Google Scholar] [CrossRef]

- Zhou, Z.B.; Li, J.S.; Kou, H.C.; Zhou, Z.S. Aging response of TB-13 titanium alloy. Mater. Sci. Forum 2010, 654–656, 859–862. [Google Scholar] [CrossRef]

- Umbrello, D. Finite element simulation of conventional and high speed machining of Ti6Al4V alloy. Mater. Process. Technol. 2007, 196, 79–87. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, Z.; Wang, G.; Chen, L.; Liu, X.; Yang, R. Microstructural evolution during aging of Ti-5Al-5Mo-5V-1Cr-1Fe alloy. Cent. South. Univ. 2009, 16, 354–359. [Google Scholar] [CrossRef]

- Balaykin, A.V.; Nosova, E.A.; Galkina, N.V. Study of the Ti-5Al-5Mo-5V-1Cr-1Fe titanium alloy grain structure uniformity after bending and annealing. IOP Conf. Ser. Mater. Sci. Eng. 2017, 177, 012106. [Google Scholar] [CrossRef]

- Ran, C.; Chen, P.; Li, L.; Zhang, W.; Liu, Y.; Zhang, X. High-strain-rate plastic deformation and fracture behaviour of Ti-5Al-5Mo-5V-1Cr-1Fe titanium alloy at room temperature. Mech. Mater. 2018, 116, 3–10. [Google Scholar] [CrossRef]

- Luo, J.; Liu, S.F.; Li, M.Q. Quantitative analysis of microstructure and deformation mechanisms during isothermal compression of Ti–5Al–5Mo–5V–1Cr–1Fe alloy. Mater. Charact. 2015, 108, 115–123. [Google Scholar] [CrossRef]

- Shi, C.; Wu, G.; Sha, A.; Jiang, H. Effect of microstructures on fatigue property of TC18 titanium alloy with equal strength. Procedia Eng. 2012, 27, 1209–1215. [Google Scholar] [CrossRef][Green Version]

- Luo, J.; Wang, L.F.; Liu, S.F.; Li, M.Q. The correlation between the flow behavior and the microstructure evolution during hot working of TC18 alloy. Mater. Sci. Eng. A 2016, 654, 213–220. [Google Scholar] [CrossRef]

- Nie, X.; Liu, H.; Zhou, X.; Yi, D.; Huang, B.; Hu, Z.; Xu, Y.; Yang, Q.; Wang, D.; Gao, Q. Creep of Ti–5Al–5Mo–5V–1Fe–1Cr alloy with equiaxed and lamellar microstructures. Mater. Sci. Eng. A 2016, 651, 37–44. [Google Scholar] [CrossRef]

- Zherebtsov, S.V.; Murzinova, M.A.; Klimova, M.V.; Salishchev, G.A.; Popov, A.A.; Semiatin, S.L. Microstructure evolution during warm working of Ti-5Al-5Mo-5V-1Cr-1Fe at 600 °C and 800 °C. Mater. Sci. Eng. A 2013, 563, 168–176. [Google Scholar] [CrossRef]

- Wang, K.; Bao, R.; Jiang, B.; Wu, Y.; Liu, D.; Yan, C. Effect of primary, α phase on the fatigue crack path of laser melting deposited Ti–5Al–5Mo–5V–1Cr–1Fe near, β titanium alloy. Inter. J. Fatigue 2018, 116, 535–542. [Google Scholar] [CrossRef]

- Masahito, M.; Makoto, H.; Toshio, H. Numerical analysis of welding residual stress and its verification using neutron diffraction measurement. Trans. ASME J. Eng. Mater. Tech. 2000, 122, 98–103. [Google Scholar] [CrossRef]

- Kampfe, B. Investigation of residual stresses in microsystems using X-ray diffraction. Mater. Sci. Eng. A 2000, 288, 119–125. [Google Scholar] [CrossRef]

- Xiao, J.; Wang, J.; Guo, W.G.; He, Y.; Li, P. The influence of heat treatment and strain rate on the third type strain ageing phenomenon. Mater. High. Temp. 2019, 36, 104–110. [Google Scholar] [CrossRef]

- Chen, X.; Soveja, A.; Chaussumier, M.; Zhang, P.; Wei, D.; Ding, F. Effect of MEVVA ion implantation on fatigue properties of TC18 titanium alloy. Surf. Coat. Tech. 2018, 344, 572–578. [Google Scholar] [CrossRef]

- Wood, P.K.C.; Schley, C.A.; Mcgregor, I.; Dutton, T. Characterizing performance of automotive materials at high strain rate for improved crash design. J. Phys. IV Proc. 2006, 134, 1167–1174. [Google Scholar] [CrossRef]

- Wang, J.; Guo, W.G.; Li, P.; Zhou, P.; Wang, Z. Dynamic tensile properties of a single crystal Nickel-base superalloy at high temperatures measured with an improved SHTB technique. Mater. Sci. Eng. A 2016, 670, 1–8. [Google Scholar] [CrossRef]

- Peirs, J.; Verleysen, P.; Degrieck, J.; Coghe, F. The use of hat-shaped specimens to study the high strain rate shears behaviour of Ti-6Al-4V. Inter. J. Impact Eng. 2010, 37, 703–714. [Google Scholar] [CrossRef]

- Xu, W.-C.; Shan, D.-B.; Yang, G.-P.; Lv, Y. Flow behavior and microstructure evolution during hot compression of TA15 titanium alloy. Trans. Nonferrous Met. Soc. China 2006, 16, 2066–2071. [Google Scholar]

- Field, J.E.; Walley, S.M.; Proud, W.G.; Goldrein, H.T.; Siviour, C.R. Review of experimental techniques for high rate deformation and shock studies. Int. J. Impact Eng. 2004, 30, 725–775. [Google Scholar] [CrossRef]

- Sun, S.D.; Zong, Y.Y.; Shan, D.B.; Guo, B. Hot deformation behavior and microstructure evolution of TC4 titanium alloy. Trans. Nonferrous Met. Soc. China 2010, 20, 2181–2184. [Google Scholar] [CrossRef]

- Martinez, F.; Murr, L.E.; Ramirez, A.; Lopez, M.I.; Gaytan, S.M. Dynamic deformation and adiabatic shear microstructures associated with ballistic plug formation and fracture in Ti–6Al–4V targets. Mater. Sci. Eng. A (Struct. Mater. Prop. Microstruct. Process.) 2007, 454–455, 581–589. [Google Scholar] [CrossRef]

- Wang, L. Influences of Stress Wave propagation upon studying dynamic response of materials at high strain rates. J. Beijing Inst. Tech. 2004, 13, 225–235. [Google Scholar] [CrossRef]

- Zhan, H.; Kent, D.; Wang, G.; Dargusch, M.S. The dynamic response of a β titanium alloy to high strain rates and elevated temperatures. Mater. Sci. Eng. A 2014, 607, 417–426. [Google Scholar] [CrossRef]

- Dey, S.; Borvik, T.; Hopperstad, O.S.; Langseth, M. On the influence of constitutive relation in projectile impact of steel plates. Inter. J. Impact Eng. 2007, 34, 464–486. [Google Scholar] [CrossRef]

- Slycken, J.V.; Verleysen, P.; Degrieck, J.; Samek, L.; de Cooman, B.C. High-strain-rate behavior of low-alloy multiphase aluminum- and silicon-based transformation-induced plasticity steels. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2006, 37, 1527–1539. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, G.; Yu, J. Hot deformation behavior and constitutive modeling of homogenized 6026 aluminum alloy. Mater. Des. 2015, 74, 25–35. [Google Scholar] [CrossRef]

- Chen, J.L.; Li, J.F.; Sun, J.; Wang, Z.Q. The influence of material constitutive constants on numerical simulation of orthogonal cutting of titanium alloy Ti6Al4V. Key Eng. Mater. 2008, 375–376, 182–186. [Google Scholar] [CrossRef]

- Coghe, F.; Rabet, L.; Kestens, L. Deformation mechanisms of a commercial titanium alloy Ti6Al4V as a function of strain rate and initial texture. Le J. Phys. IV 2006, 134, 845–850. [Google Scholar] [CrossRef]

- Samantaray, D.; Mandal, S.; Bhaduri, A.K. A comparative study on Johnson Cook modified Zerilli–Armstrong and Arrhenius-type constitutive models to predict elevated temperature flow behaviour in modified 9Cr–1Mo steel. Comput. Mater. Sci. 2009, 47, 568–576. [Google Scholar] [CrossRef]

- Di, C.C.; Cui, K.B.; Qin, J.Q.; Wu, D.L. Parameters identification of Johnson-Cook constitutive equation for aluminum brass. Adv. Mater. Res. 2014, 887–888, 1032–1035. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Guo, W.; Guo, J. A modified model of residual strength prediction for metal plates with through-thickness cracks. J. Theor. Appl. Mech. 2019, 57, 537–547. [Google Scholar] [CrossRef]

| Al | Mo | V | Cr | Fe | O | N | Ti |

|---|---|---|---|---|---|---|---|

| 4.67 | 4.78 | 5.08 | 1.06 | 0.936 | 0.14 | 0.012 | Bal |

| Tensile Strength σb/MPa | Yield Strength σ0.2/MPa | Reduction of Area ψ/% | Elongation δ/% |

|---|---|---|---|

| 1120 | 1060 | 17% | 8.5% |

| Temperature | 25 °C | 200 °C | 400 °C | 600 °C |

|---|---|---|---|---|

| Strain rate | 1033 s−1 | 1033 s−1 | 1033 s−1 | 1033 s−1 |

| 3011 s−1 | 2100 s−1 | 2100 s−1 | 2100 s−1 | |

| 5015 s−1 | 3065 s−1 | 3065 s−1 | 3065 s−1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Mu, A.; Wang, Y.; Zhang, H. Study on Dynamic Mechanical Properties and Constitutive Model Construction of TC18 Titanium Alloy. Metals 2020, 10, 44. https://doi.org/10.3390/met10010044

Zhang C, Mu A, Wang Y, Zhang H. Study on Dynamic Mechanical Properties and Constitutive Model Construction of TC18 Titanium Alloy. Metals. 2020; 10(1):44. https://doi.org/10.3390/met10010044

Chicago/Turabian StyleZhang, Changming, Anle Mu, Yun Wang, and Hui Zhang. 2020. "Study on Dynamic Mechanical Properties and Constitutive Model Construction of TC18 Titanium Alloy" Metals 10, no. 1: 44. https://doi.org/10.3390/met10010044

APA StyleZhang, C., Mu, A., Wang, Y., & Zhang, H. (2020). Study on Dynamic Mechanical Properties and Constitutive Model Construction of TC18 Titanium Alloy. Metals, 10(1), 44. https://doi.org/10.3390/met10010044