A Review: Thin Protective Coating for Wear Protection in High-Temperature Application

Abstract

1. Introduction

- High temperature resistant

- Good strength

- Great thermal fatigue

- Chemically inert

- Low friction coefficient

- Low cost

2. State of the Art

2.1. Transition Metal

2.2. Post-Transition Metal

2.3. Lanthanides

2.4. Reactive Non-Metals

2.5. Hybrid

3. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Saini, V.K.; Khan, Z.A.; Siddiquee, A.N. Developments in conventional machining of aluminum matrix composite material: A review. Int. J. Adv. Manuf. Technol. 2014, 7, 73–81. [Google Scholar]

- Tyagi, A.; Walia, R.S.; Murtaza, Q.; Pandey, S.M.; Tyagi, P.K.; Bajaj, B. A critical review of diamond like carbon coating for wear resistance applications. Int. J. Refract. Met. Hard Mater. 2019, 78, 107–122. [Google Scholar] [CrossRef]

- Szeri, A.Z. (Ed.) Tribology: Friction, Lubrication, and Wear; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Prater, T.J. Predictive Process Modeling of Tool Wear in Friction Stir Welding of Metal Matrix Composites; Vanderbilt University: Nashville, TN, USA, 2012. [Google Scholar]

- Moore, M.A. The relationship between the abrasive wear resistance, hardness and microstructure of ferritic materials. Wear 1974, 28, 59–68. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Mitterer, C.; Hultman, L.; Clemens, H. Microstructural design of hard coatings. Prog. Mater. Sci. 2006, 51, 1032–1114. [Google Scholar] [CrossRef]

- Petrov, I.; Barna, P.B.; Hultman, L.; Greene, J.E. Microstructural evolution during film growth. J. Vac. Sci. Technol. 2003, 21, S117–S128. [Google Scholar] [CrossRef]

- Petrov, I.; Hultman, L.; Helmersson, U.; Sundgren, J.E.; Greene, J.E. Microstructure modification of TiN by ion bombardment during reactive sputter deposition. Thin Solid Film. 1989, 169, 299–314. [Google Scholar] [CrossRef]

- Mathiazhagan, A.; Joseph, R. Nanotechnology—A New prospective in organic coating—Review. Int. J. Chem. Eng. Appl. 2011, 2, 225. [Google Scholar] [CrossRef]

- Wilson, M.; Kannangara, K.; Smith, G.; Simmons, M.; Raguse, B. Nanotechnology: Basic Science and Emerging Technologies; Chapman and Hall/CRC: Boca Raton, FL, USA, 2002. [Google Scholar]

- Sidky, P.S.; Hocking, M.G. Review of inorganic coatings and coating processes for reducing wear and corrosion. Br. Corros. J. 1999, 34, 171–183. [Google Scholar] [CrossRef]

- Hedenqvist, P.; Olsson, M.; Wallén, P.; Kassman, Å.; Hogmark, S.; Jacobson, S. How TiN coatings improve the performance of high speed steel cutting tools. Surf. Coat. Technol. 1990, 41, 243–256. [Google Scholar] [CrossRef]

- Camp, A.D. Chipping and abrasion tests for paint coatings on chipping and abrasion tests for paint coatings on metal. Ind. Eng. Chem. 1928, 20, 851–852. [Google Scholar] [CrossRef]

- Hothersall, A.W. Factors affecting the smoothness and mechanical properties of electrodeposited copper. Trans. IMF 1930, 6, 95–122. [Google Scholar] [CrossRef]

- Monk, R.G.; Ellingham, H.J.T. Electrodeposition of tin alloys from alkaline stannate baths. Trans. Faraday Soc. 1935, 31, 1460–1468. [Google Scholar] [CrossRef]

- Du Rose, A.H. The protective value of lead and lead-tin deposits on steel. Trans. Faraday Soc. 1946, 89, 417–432. [Google Scholar]

- Rybakova, N. Production of Titanium Diboride Coatings by Electrolysis of High-Temperature Molten Salts. Ph.D. Thesis, University of Vienna, Vienna, Austria, 2011. [Google Scholar]

- Young, F.; Davis, B. Scuff-and Wear-Resistant Chemical Coatings; SAE Technical Paper 470250; SAE International: Warrendale, PA, USA, 1947. [Google Scholar]

- Killeffer, D.H. Chromium plating—A new aid to industry. Ind. Eng. Chem. 1927, 19, 773–776. [Google Scholar] [CrossRef]

- Dubpernell, G. Chromium plating. Electrochem. Soc. 1941, 80, 589–615. [Google Scholar] [CrossRef]

- Furman, V.V.; Apininskaya, L.M. Electrophoretic deposition of chromium carbide. Powder Metall. Met. Ceram. 1974, 13, 118–120. [Google Scholar]

- Heideman, R.J. Friction Stir Spot Welding of 6061 Aluminum-to-Copper. Ph.D. Thesis, The University of Wisconsin-Madison, Winsconsin, WI, USA, 2014. [Google Scholar]

- Corchia, M.; Delogu, P.; Nenci, F.; Belmondo, A.; Corcoruto, S.; Stabielli, W. Microstructural aspects of wear-resistant stellite and colmonoy coatings by laser processing. Wear 1987, 119, 137–152. [Google Scholar] [CrossRef]

- Chen, K.J.; Hung, F.Y.; Lui, T.S.; Shih, Y.R. Wear inducing phase transformation of plasma transfer arc coated tools during friction stir welding with Al alloy. J. Eng. 2019. [Google Scholar] [CrossRef]

- Fernandez, J.E.; Rodriguez, R.; Wang, Y.; Vijande, R.; Rincon, A. Sliding wear of a plasma sprayed Al2O3 coating. Wear 1995, 181, 417–425. [Google Scholar] [CrossRef]

- Li, C.J.; Sun, B. Microstructure and property of Al2O3 coating microplasma-sprayed using a novel hollow cathode torch. Mater. Lett. 2004, 58, 179–183. [Google Scholar] [CrossRef]

- Groner, M.D.; Fabreguette, F.H.; Elam, J.W.; George, S.M. Low-temperature Al2O3 atomic layer deposition. Chem. Mater. 2004, 16, 639–645. [Google Scholar] [CrossRef]

- Bahadori, E.; Javadpour, S.; Shariat, M.H.; Mahzoon, F. Preparation and properties of ceramic Al2O3 coating as TBCs on MCrAly layer applied on Inconel alloy by cathodic plasma electrolytic deposition. Surf. Coat. Technol. 2013, 228, 611–614. [Google Scholar] [CrossRef]

- Dezfuli, S.M.; Sabzi, M. Effect of yttria and benzotriazole doping on wear/corrosion responses of alumina-based nanostructured films. Ceram. Int. 2018, 44, 20245–20258. [Google Scholar] [CrossRef]

- Win, K.N. Structure and Electrochemical Behavior of Nitrogen Doped Diamond-Like Carbon Thin Films with or without Platinum and Ruthenium Doping. Ph.D. Thesis, Nanyang Technological University, Singapore, 2011. [Google Scholar]

- Basavakumar, K.G.; Mukunda, P.G.; Chakraborty, M. Influence of melt treatments and polished CVD diamond coated insert on cutting force and surface integrity in turning of Al-7Si and Al-7Si-2.5 Cu cast alloys. Bull. Mater. Sci. 2007, 30, 427–437. [Google Scholar] [CrossRef]

- Prater, T. An Investigation into the Friction Stir Welding of Al 6061 and Al 6061/Sic/17.5 P Using Diamond Coatings. Ph.D. Thesis, Vanderbilt University, Nashville, TN, USA, August 2008. [Google Scholar]

- Prater, T. Solid-state joining of metal matrix composites: A survey of challenges and potential solutions. Mater. Manuf. Process. 2011, 26, 636–648. [Google Scholar] [CrossRef]

- Rudd, A.L.; Breslin, C.B.; Mansfeld, F. The corrosion protection afforded by rare earth conversion coatings applied to magnesium. Corros. Sci. 2000, 42, 275–288. [Google Scholar] [CrossRef]

- Dabalà, M.; Brunelli, K.; Napolitani, E.; Magrini, M. Cerium-based chemical conversion coating on AZ63 magnesium alloy. Surf. Coat. Technol. 2003, 172, 227–232. [Google Scholar] [CrossRef]

- Su, H.Y.; Li, W.J.; Lin, C.S. Effect of acid pickling pretreatment on the properties of cerium conversion coating on AZ31 magnesium Alloy. J. Electrochem. Soc. 2012, 159, C219–C225. [Google Scholar] [CrossRef]

- Chen, B.; Li, Q.; Gao, H.; Fan, J.M.; Tan, X. Microstructural characteristics and corrosion property of non-chromate surface treatments on AZ91D magnesium alloy. Mater. Corros. 2009, 60, 521–526. [Google Scholar] [CrossRef]

- Song, D.; Jing, X.; Wang, J.; Lu, S.; Yang, P.; Wang, Y.; Zhang, M. Microwave-assisted synthesis of lanthanum conversion coating on Mg–Li alloy and its corrosion resistance. Corros. Sci. 2011, 53, 3651–3656. [Google Scholar] [CrossRef]

- Pezzato, L.; Brunelli, K.; Babbolin, R.; Dolcet, P.; Dabalà, M. Sealing of PEO coated AZ91 magnesium alloy using La-based solutions. Int. J. Corros. 2017, 1–13. [Google Scholar] [CrossRef]

- Cui, X.F.; Jin, G.; Yang, Y.Y.; Lin, L.L.; Wang, H.D.; Xu, B.S. Study of gadolinium based protective coating for magnesium alloys. Surf. Eng. 2012, 28, 719–724. [Google Scholar] [CrossRef]

- Cui, X.; Liu, Z.; Lin, L.; Jin, G.; Wang, H.; Xu, B. Investigation of carboxylic acid-neodymium conversion films on magnesium alloy. J. Mater. Eng. Perform. 2014, 24, 461–467. [Google Scholar] [CrossRef]

- Jin, G.; Yang, Y.; Cui, X.; Liu, E.; Wang, Z.; Li, Q. Chrome-free neodymium-based protective coatings for magnesium alloys. Mater. Lett. 2011, 65, 1145–1147. [Google Scholar] [CrossRef]

- Jamali, S.S.; Moulton, S.E.; Tallman, D.E.; Forsyth, M.; Weber, J.; Mirabedini, A.; Wallace, G.G. Corrosion protection afforded by praseodymium conversion film on Mg alloy AZNd in simulated biological fluid studied by scanning electrochemical microscopy. J. Electroanal. Chem. 2015, 739, 211–217. [Google Scholar] [CrossRef]

- Hou, L.; Cui, X.; Yang, Y.; Lin, L.; Xiao, Q.; Jin, G. Chrome-free samarium-based protective coatings for magnesium alloys. Phys. Procedia 2013, 50, 261–266. [Google Scholar] [CrossRef]

- Han, B.; Gu, D.; Yang, Y.; Fang, L.; Peng, G.; Yang, C. Preparation of yttrium-based rare earth conversion coating and its effect on corrosion resistance of AZ91D magnesium alloy. Int. J. Electrochem. Sci. 2017, 12, 374–385. [Google Scholar] [CrossRef]

- Ruth, R.P.; Marinace, J.C.; Dunlap, W.C., Jr. Vapor-deposited single-crystal germanium. J. Appl. Phys. 1960, 31, 995–1006. [Google Scholar] [CrossRef]

- Shesternenkov, V.I. Detonation coating. Powder Met. 1968, 7, 30–36. [Google Scholar] [CrossRef]

- Sahu, S. Performance Evaluation of Uncoated and Multi Layer Tin Coated Carbide Tool in Hard Turning. Ph.D. Thesis, National Institute of Technology, Rourkela, India, 5 June 2012. [Google Scholar]

- An, Q.; Huang, L.; Jiao, Y.; Bao, Y.; Zhong, B.; Geng, L. Intergrowth microstructure and superior wear resistance of (TiB + TiC)/Ti64 hybrid coatings by gas tungsten arc cladding. Mater. Des. 2019, 162, 34–44. [Google Scholar] [CrossRef]

- Soderberg, H.; Oden, M.; Larsson, T.; Hultman, L.; Molina-Aldareguia, J.M. Epitaxial stabiliza-tion of cubic-SiNx in TiN/SiNx multilayers. Appl. Phys. Lett. 2006, 88, 191902-1–191902-3. [Google Scholar] [CrossRef]

- Gassner, G.; Mayrhofer, P.H.; Kutschey, K.; Mitterer, C.; Kathrei, M. Magneli phase forma-tion of PVD Mo–N and W–N coatings. Surf. Coat. Technol. 2006, 201, 3335–3344. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Bratushka, S.N.; Boyko, V.I.; Shamanin, I.V.; Tsvintarnaya, Y.V. A review of mixing process in Ta/Fe and Mo/Fe systems treated by high current electron beams. NIM B 1998, 145, 373–390. [Google Scholar] [CrossRef]

- Tsui, T.Y.; Ross, C.A.; Pharr, G.M. Nanoindentation Hardness of Soft Films on Hard Substrates: Effects of the Substrate; Cambridge University Press: Cambridge, UK, 1997; p. 473, MRS Online Proceedings Library Archive. [Google Scholar]

- Chen, S.; Liu, L.; Wang, T. Investigation of the mechanical properties of thin films by nanoindentation, considering the effects of thickness and different coating–substrate combinations. Surf. Coat. Technol. 2005, 191, 25–32. [Google Scholar] [CrossRef]

- Mikhailov, P.A.; Ponomarenko, E.P.; Petergerya, D.M.; Domio, A.A.; Rybkin, V.F.; Khokhlov, V.P.; Kas’ Yanenko, V.G. Endurance and wear resistance of steels with vacuum-diffused coatings. Sov. Mater. Sci. A Transl. Fiz. Khimicheskaya Mekhanika Mater. Acad. Sci. Ukr. SSR 1969, 4, 94–97. [Google Scholar] [CrossRef]

- Guzmán Durán, P.A.; Navarro-Devia, J.H.; Aperador Chaparro, W. Machining with cutting tool coated with monolayer of HfN. Tecciencia 2016, 11, 1–6. [Google Scholar] [CrossRef][Green Version]

- Shiozawa, K.; Han, L. The effect of TiN film on low-cycle fatigue behavior of steel coated by PVD method. WIT Trans. Eng. Sci. 1970, 2. [Google Scholar] [CrossRef]

- Saini, R.; Roy, D.; Das, A.K.; Dixit, A.R.; Nayak, G.C. Tribological behaviour and characterisation of Ni-WS2 composite coating. Int. J. Surf. Sci. Eng. 2016, 10, 240–252. [Google Scholar] [CrossRef]

- Milošev, I.; Rodič, P. Cerium chloride and acetate salts as corrosion inhibitors for aluminum alloy AA7075-T6 in sodium chloride solution. Corrosion 2016, 72, 1021–1034. [Google Scholar]

- Aldykewicz, A.J.; Isaacs, H.S.; Davenport, A.J. The investigation of cerium as a cathodic inhibitor for aluminum-copper alloys. J. Electrochem. Soc. 1995, 142, 3342–3350. [Google Scholar] [CrossRef]

- Hinton, B.R. The inhibition of aluminum alloy corrosion by cerous cations. Met. Forum 1984, 7, 221. [Google Scholar]

- Hamdy, A.S.; Farahat, M. Chrome-free zirconia-based protective coatings for magnesium alloys. Surf. Coat. Technol. 2010, 204, 2834–2840. [Google Scholar] [CrossRef]

- Pan, F.; Yang, X.; Zhang, D. Chemical nature of phytic acid conversion coating on AZ61 magnesium alloy. Appl. Surf. Sci. 2009, 255, 8363–8371. [Google Scholar] [CrossRef]

- Mosiałek, M.; Mordarski, G.; Nowak, P.; Simka, W.; Nawrat, G.; Hanke, M.; Socha, R.P.; Michalska, J. Phosphate–permanganate conversion coatings on the AZ81 magnesium alloy: SEM, EIS and XPS studies. Surf. Coat. Technol. 2011, 206, 51–62. [Google Scholar] [CrossRef]

- Barranco, V.; Carmona, N.; Galván, J.C.; Grobelny, M.; Kwiatkowski, L.; Villegas, M.A. Electrochemical study of tailored sol–gel thin films as pre-treatment prior to organic coating for AZ91 magnesium alloy. Prog. Org. Coat. 2010, 68, 347–355. [Google Scholar] [CrossRef]

- Zucchi, F.; Frignani, A.; Grassi, V.; Trabanelli, G.; Monticelli, C. Stannate and permanganate conversion coatings on AZ31 magnesium alloy. Corros. Sci. 2007, 49, 4542–4552. [Google Scholar] [CrossRef]

- Zhou, W.; Shan, D.; Han, E.H.; Ke, W. Structure and formation mechanism of phosphate conversion coating on die-cast AZ91D magnesium alloy. Corros. Sci. 2008, 50, 329–337. [Google Scholar] [CrossRef]

- Takenaka, T.; Ono, T.; Narazaki, Y.; Naka, Y.; Kawakami, M. Improvement of corrosion resistance of magnesium metal by rare earth elements. Electrochim. Acta 2007, 53, 117–121. [Google Scholar] [CrossRef]

- Haley, T.J.; Raymond, K.; Komesu, N.; Upham, H.C. Toxicological and pharmacological effects of gadolinium and samarium chlorides. Br. J. Pharmacol. Chemother. 1961, 17, 526–532. [Google Scholar] [CrossRef]

- Tanaka, T.; Togashi, S.; Kamioka, H.; Amakawa, H.; Kagami, H.; Hamamoto, T.; Yuhara, M.; Orihashi, Y.; Yoneda, S.; Shimizu, H.; et al. JNdi-1: A neodymium isotopic reference in consistency with LaJolla neodymium. Chem. Geol. 2000, 168, 279–281. [Google Scholar] [CrossRef]

- Dai, Y.; Li, J.; Li, J.; Yu, L.; Dai, G.; Hu, A.; Yuan, L.; Wen, Z. Effects of rare earth compounds on growth and apoptosis of leukemic cell lines. In Vitro Cell. Dev. Biol. Anim. 2002, 38, 373–375. [Google Scholar] [CrossRef]

- Ji, Y.J.; Xiao, B.; Wang, Z.H.; Cui, M.Z.; Lu, Y.Y. The suppression effect of light rare earth elements on proliferation of two cancer cell lines. Biomed. Environ. Sci. 2000, 13, 287–292. [Google Scholar] [PubMed]

- Kostova, I.; Momekov, G.; Stancheva, P. New samarium (III), gadolinium (III), and dysprosium (III) complexes of coumarin-3-carboxylic acid as antiproliferative agents. Met. Based Drugs 2007. [Google Scholar] [CrossRef] [PubMed]

- Magda, D.; Miller, R.A. Motexafin gadolinium: A novel redox active drug for cancer therapy. Semin. Cancer Biol. 2006, 16, 466–476. [Google Scholar] [CrossRef] [PubMed]

- Bruce, D.W.; Hietbrink, B.E.; DuBois, K.P. The acute mammalian toxicity of rare earth nitrates and oxides. Toxicol. Appl. Pharmacol. 1963, 5, 750–759. [Google Scholar] [CrossRef]

- Nakamura, Y.; Tsumura, Y.; Tonogai, Y.; Shibata, T.; Ito, Y. Differences in behavior among the chlorides of seven rare earth elements administered intravenously to rats. Toxicol. Sci. 1997, 37, 106–116. [Google Scholar] [CrossRef]

- Yang, W.; Zhang, P.; Liu, J.; Xue, Y. Effect of long-term intake of Y3+ in drinking water on gene expression in brains of rats. J. Rare Earths 2006, 24, 369–373. [Google Scholar] [CrossRef]

- Ramezanzadeh, B.; Vakili, H.; Amini, R. Improved performance of cerium conversion coatings on steel with zinc phosphate post-treatment. J. Ind. Eng. Chem. 2015, 30, 225–233. [Google Scholar] [CrossRef]

- Yi, A.; Du, J.; Wang, J.; Mu, S.; Zhang, G.; Li, W. Preparation and characterization of colored Ti/Zr conversion coating on AZ91D magnesium alloy. Surf. Coat. Technol. 2015, 276, 239–247. [Google Scholar] [CrossRef]

- Zhang, D.; Gou, Y.; Liu, Y.; Guo, X. A composite anodizing coating containing superfine Al2O3 particles on AZ31 magnesium alloy. Surf. Coat. Technol. 2013, 236, 52–57. [Google Scholar] [CrossRef]

- Zhu, L.; Li, Y.; Li, W. Influence of silica sol particle behavior on the magnesium anodizing process with different anions addition. Surf. Coat. Technol. 2008, 202, 5853–5857. [Google Scholar] [CrossRef]

- Christoglou, C.; Voudouris, N.; Angelopoulos, G.N.; Pant, M.; Dahl, W. Deposition of aluminium on magnesium by a CVD process. Surf. Coat. Technol. 2004, 184, 149–155. [Google Scholar] [CrossRef]

- Davies, J.L.; Glover, C.F.; Van De Langkruis, J.; Zoestbergen, E.; Williams, G. The effect of Mg concentration on the resistance of PVD Zn-Mg coatings to corrosion driven organic coating delamination. Corros. Sci. 2015, 100, 607–618. [Google Scholar] [CrossRef]

- Charitidis, C.; Laskarakis, A.; Kassavetis, S.; Gravalidis, C.; Logothetidis, S. Optical and nanomechanical study of anti-scratch layers on polycarbonate lenses. Superlattices Microstruct. 2004, 36, 171–179. [Google Scholar] [CrossRef]

- Roche, S.; Pavan, S.; Loubet, J.L.; Barbeau, P.; Magny, B. Influence of the substrate characteristics on the scratch and indentation properties of UV-cured clearcoats. Prog. Org. Coat. 2003, 47, 37–48. [Google Scholar] [CrossRef]

- Geng, K.; Yang, F.; Grulke, E.A. Nanoindentation of submicron polymeric coating systems. Mater. Sci. Eng. 2008, 479, 157–163. [Google Scholar] [CrossRef]

- Zhang, T.H.; Huan, Y. Nanoindentation and nanoscratch behaviors of DLC coatings on different steel substrates. Compos. Sci. Technol. 2005, 65, 1409–1413. [Google Scholar] [CrossRef]

- Drisko, G.L.; Sanchez, C. Hybridization in materials science–evolution, current state, and future aspirations. Eur. J. Inorg. Chem. 2012, 32, 5097–5105. [Google Scholar] [CrossRef]

- Tien, S.K.; Lin, C.H.; Tsai, Y.Z.; Duh, J.G. Oxidation behavior, microstructure evolution and thermal stability in nanostructured CrN/AlN multilayer hard coatings. J. Alloys Compd. 2010, 489, 237–241. [Google Scholar] [CrossRef]

- Alirezaei, S.; Monirvaghefi, S.M.; Saatchi, A.; Ürgen, M.; Motallebzadeh, A. High temperature friction and wear behaviour of Ni–P–Ag–Al2O3 hybrid nanocomposite coating. Trans. IMF 2013, 91, 207–213. [Google Scholar] [CrossRef]

- Skarvelis, P. Papadimitriou GD. Microstructural and tribological evaluation of potential self-lubricating coatings with MoS2\MnS additions produced by the plasma transferred arc technique. Tribol. Int. 2009, 42, 1765–1770. [Google Scholar] [CrossRef]

- Yang, M.S.; Liu, X.B.; Fan, J.W.; He, X.M.; Shi, S.H.; Fu, G.Y.; Wang, M.D.; Chen, S.F. Microstructure and wear behaviors of laser clad NiCr/Cr3C2–WS2 high temperature self-lubricating wear-resistant composite coating. Appl. Surf. Sci. 2012, 258, 3757–3762. [Google Scholar] [CrossRef]

- Lu, X.L.; Liu, X.B.; Yu, P.C.; Shai, Y.J.; Qiao, S.J.; Wang, M.D.; Wang, Y.G.; Chen, Y. Effects of heat treatment on microstructure and mechanical properties of Ni60/h-BN self-lubricating anti-wear composite coatings on 304 stainless steel by laser cladding. Appl. Surf. Sci. 2015, 355, 350–358. [Google Scholar] [CrossRef]

- Piasecki, A.; Kotkowiak, M.; Kulka, M. Self-lubricating surface layers produced using laser alloying of bearing steel. Wear 2017, 376, 993–1008. [Google Scholar] [CrossRef]

- Liu, X.B.; Zheng, C.; Liu, Y.F.; Fan, J.W.; Yang, M.S.; He, X.M.; Wang, M.D.; Yang, H.B.; Qi, L.H. A comparative study of laser cladding high temperature wear-resistant composite coating with the addition of self-lubricating WS2 and WS2/(Ni–P) encapsulation. J. Mater. Process Technol. 2013, 213, 51–58. [Google Scholar] [CrossRef]

- Fang, L.Y.; Yan, H.; Yao, Y.S.; Zhang, P.L.; Gao, Q.S.; Qin, Y. Reactive fabrication and effect of NbC on microstructure and tribological properties of CrS Co-based self-lubricating coatings by laser cladding. Materials 2018, 11, 44. [Google Scholar] [CrossRef] [PubMed]

- Yan, H.; Wang, A.H.; Zhang, X.L.; Huang, Z.W.; Wang, W.Y.; Xie, J.P. Nd: YAG laser cladding Ni base alloy/nano-h-BN self-lubricating composite coatings. Mater. Sci. Technol. 2010, 26, 461–468. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Eyidi, D.; Abadias, G.; Bondar, O.V.; Beresnev, V.M.; Sobol, O.V. Structure and properties of arc evaporated nanoscale TiN/MoN multilayered systems. Int. J. Refract. Met. Hard Mater. 2015, 48, 222–228. [Google Scholar] [CrossRef]

- Meng, Q.; Wen, M.; Liu, P.; Zhang, K.; Zheng, W. Correlation between interfacial electronic structure and mechanical properties of ZrN/SiNxfilms. Mater. Lett. 2013, 94, 61–64. [Google Scholar] [CrossRef]

- Abadias, G.; Guerin, P. In situ stress evolution during magnetron sputtering of transition metal nitride thin films. Appl. Phys. Lett. 2008, 93, 111908. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D. Investigation of element profiles, defects, phase composition andphysical and mechanical properties of superhard coatings Ti–Hf–Si–N. Mater. Sci. Appl. 2013, 4, 24–31. [Google Scholar]

- Wen, M.; Meng, Q.; Hu, C.; Au, T.; Su, Y.; Yu, W. Structure and mechanical properties of σ-NbN/SiNx and σ′-NbN/SiNx nano-multilayer films deposited by reactive magne-tron sputtering. Surf. Coat. Technol. 2009, 203, 1702–1708. [Google Scholar] [CrossRef]

- Lao, J.; Shao, N.; Mei, F.; Li, G.; Gu, M. Mutual promotion effect of crystal growth in TiN/SiC nanomultilayers. Appl. Phys. Lett. 2005, 86, 011902-1–011902-3. [Google Scholar] [CrossRef]

- Setoyama, M.; Nakayama, A.; Tanaka, M.; Kitagawa, N.; Nomura, T. Formation of cubic AlNin TiN/AlN superlattice. Surf. Coat. Technol. 1996, 86–87, 225–230. [Google Scholar] [CrossRef]

- Nordin, M.; Larsson, M.; Hogmark, S. Mechanical and tribological properties of multi-layered PVD TiN/CrN, TiN/MoN, TiN/NbN and TiN/TaN coatings on cemented carbide. Surf. Coat. Technol. 1998, 106, 234–241. [Google Scholar] [CrossRef]

- Musil, J. Hard nanocomposite coatings: Thermal stability, oxidation resistance and toughness. Surf. Coat. Technol. 2012, 207, 50–65. [Google Scholar] [CrossRef]

- Martev, I.N.; Dechev, D.A.; Ivanov, N.P.; Uzunov, T.D.; Kashchiev, E.P. Nanolaminated TiN/Mo2N hard multilayer coatings. J. Phys. Conf. Ser. 2010, 223, 012019. [Google Scholar] [CrossRef]

- Pogrebnjak, A.; Ivashchenko, V.; Bondar, O.; Beresnev, V.; Sobol, O.; Załęski, K.; Postolnyi, B. Multilayered vacuum-arc nanocomposite TiN/ZrN coatings before and after annealing: Structure, properties, first-principles calculations. Mater. Charact. 2017, 134, 55–63. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Beresnev, V.M.; Bondar, O.V.; Postolnyi, B.O.; Zaleski, K.; Coy, E.; Araujo, J.P. Superhard CrN/MoN coatings with multilayer architecture. Mater. Des. 2018, 153, 47–59. [Google Scholar] [CrossRef]

- Koshy, R.A.; Graham, M.E.; Marks, L.D. Synthesis and characterization of CrN/Mo2N multilayers and phases of Molybdenum nitride. Surf. Coat. Technol. 2007, 202, 1123–1128. [Google Scholar] [CrossRef]

- Koshy, R.A.; Graham, M.E.; Marks, L.D. Temperature activated self-lubrication in CrN/Mo2N nanolayer coatings. Surf. Coat. Technol. 2010, 204, 1359–1365. [Google Scholar] [CrossRef]

- Han, B.; Wang, Z.; Devi, N.; Kondamareddy, K.K.; Wang, Z.; Li, N.; Zuo, W.; Fu, D.; Liu, C. RBS depth profiling analysis of (Ti, Al) N/MoN and CrN/MoN multilayers. Nanoscale Res. Lett. 2017, 12, 161. [Google Scholar] [CrossRef] [PubMed]

- Navinšek, B.; Panjan, P.; Milošev, I. Industrial applications of CrN (PVD) coatings, deposited at high and low temperatures. Surf. Coat. Technol. 1997, 97, 182–191. [Google Scholar] [CrossRef]

- Gilewicz, A.; Warcholinski, B. Deposition and characterisation of Mo2N/CrN multilayer coatings prepared by cathodic arc evaporation. Surf. Coat. Technol. 2015, 279, 126–133. [Google Scholar] [CrossRef]

- Jauberteau, I.; Bessaudou, A.; Mayet, R.; Cornette, J.; Jauberteau, J.; Carles, P.; Merle-Méjean, T. Molybdenum nitride films: Crystal structures, synthesis, mechanical, electrical and some other properties. Coatings 2015, 5, 656–687. [Google Scholar] [CrossRef]

- Postolnyi, B.O.; Beresnev, V.M.; Abadias, G.; Bondar, O.V.; Rebouta, L.; Araujo, J.P.; Pogrebnjak, A.D. Multilayer design of CrN/MoN protective coatings for enhanced hardness and toughness. J. Alloy. Compd. 2017, 725, 1188–1198. [Google Scholar] [CrossRef]

- Larsson, M.; Bromark, M.; Hedenqvist, P.; Hogmark, S. Deposition and mechanical properties of multilayered PVD Ti-TiN. Surf. Coat. Technol. 1995, 202, 76–77. [Google Scholar] [CrossRef]

- Larsson, M.; Bromark, M.; Hedenqvist, P.; Hogmark, S. Deposition and microstructure of PVD TiN NbN multilayred coatings by combined reactive electron beam evaporation and DC sputtering. Surf. Coat. Technol. 1996, 351, 86–87. [Google Scholar]

- Wiklund, U.; Hedenqvist, P.; Hogmark, S.; Stridh, B.; Arbell, M. Multilayer coatings as corrosion protection of Zircaloy. Surf. Coat. Technol. 1996, 530, 86–87. [Google Scholar] [CrossRef]

- Panjan, P.; Navinsek, B.; Milosev, I. Oxidation of TiN, ZrN, TiZrN, CrN, TiCrN and TiN/CrN multilayer hard coatings reactively sputtered at low temperature. Thin Solid Film. 1996, 298, 281–282. [Google Scholar] [CrossRef]

| Type | Reference | Materials | Substrate | Deposition Method and Parameters | Application | Remarks | |

|---|---|---|---|---|---|---|---|

| (a) | [13] | TiN | JIS S35C | Method | Hollow cathode discharge | Machine and structure | 0.35%~0.4% increase |

| Preparation | Electropolished | ||||||

| Gas/electrolyte | Nitrogen | ||||||

| [17] | TiB2 | Mo, WC, Steel | Method | Electrochemical deposition | High temperature | Oxidized above 700 °C Additive layer: FLiNaK el; electrolyte | |

| Preparation | Etching | ||||||

| Arc current | 0.3 A | ||||||

| Pressure | Atmospheric | ||||||

| Time | 15–20 min | ||||||

| Gas/ electrolyte | Inert | ||||||

| [18] | Chemical coating | Cast iron | Method | Electrodeposited | Automotive | Beneficial for rapid break-in | |

| Preparation | Treating bath | ||||||

| [1] | Ni-WS2 composite | EN31 steel surface | Method | Direct current electro-deposition | High temperature | Optimum bath properties resulted in minimum cracks | |

| Preparation | Etching | ||||||

| Bias | 4.0–12.0 V | ||||||

| Time | 60 min | ||||||

| [19] | Chromium | - | Method | Electrodepositing | Wear prone | Electrodepositing smoothness lengthen lifetime | |

| Temperature | 40 °C | ||||||

| Gas/electrolyte | Acid bath | ||||||

| [20] | Chromium | Nickel | Method | Electrodepositing | Corrosion prone | Considerable interpretation of result | |

| Preparation | Wet cleaning/dry cleaning | ||||||

| Temperature | 25~65 °C | ||||||

| Time | 6~2110 min. | ||||||

| Gas/electrolyte | Chromic acid/catalyst acid radical bath | ||||||

| [21] | Chromium carbide | - | Method | Electrophoretic deposition | Wear resistance alloy | Rate of mitigation decreased | |

| Temperature | Room temperature | ||||||

| Arc current | Distilled propyl alcohol | ||||||

| Time | 48 h | ||||||

| Gas/electrolyte | Aluminum nitrite solution | ||||||

| [22] | CrN/TiCN | Densimet 17.7 | Method | PVD | Friction stir spot welding | Neither both prevent tool buildup | |

| [23] | Stellite 6 and Colmonoy 5 powders | AISI 304 stainless steel | Method | Laser processing method | Nuclear field | Gradual transition of the microstructure with no abrupt change of properties | |

| DC Power | 15 kW | ||||||

| Gas/electrolyte | Inert gas | ||||||

| [24] | Stellite 1 powder | SKD61-ST1 | Method | Plasma transfer arc | Friction stir welding | Thinner phase transfer layer thus increased wear resistance | |

| Arc current/Bias | 90 A/36 V | ||||||

| Gas/electrolyte | Plasma gas | ||||||

| Type | Reference | Materials | Substrate | Deposition Method and Parameters | Application | Remarks | |

|---|---|---|---|---|---|---|---|

| (b) | [25] | Al2O3 | AISI 1020 | - | Ambient plasma spraying | Machining | Plastic deformation, adhesive wear, and brittle fracture failure type |

| [26] | Al2O3 | Mild steel | Method | Microplasma spray | Wear prone | Comparable abrasive wear resistance | |

| Preparation | Sandblasting | ||||||

| Pressure | 0.3–0.5 M | ||||||

| Gas/electrolyte | Ar | ||||||

| [27] | Al2O3 | n-Si | Method | Atomic layer deposition | Thermally fragile | Increase hydrogen concentration with decrease temperature | |

| Preparation | Etching | ||||||

| Bias | 5 V | ||||||

| Pressure | 0.13 Pa | ||||||

| Time | 3.3 min | ||||||

| Gas/electrolyte | N2 | ||||||

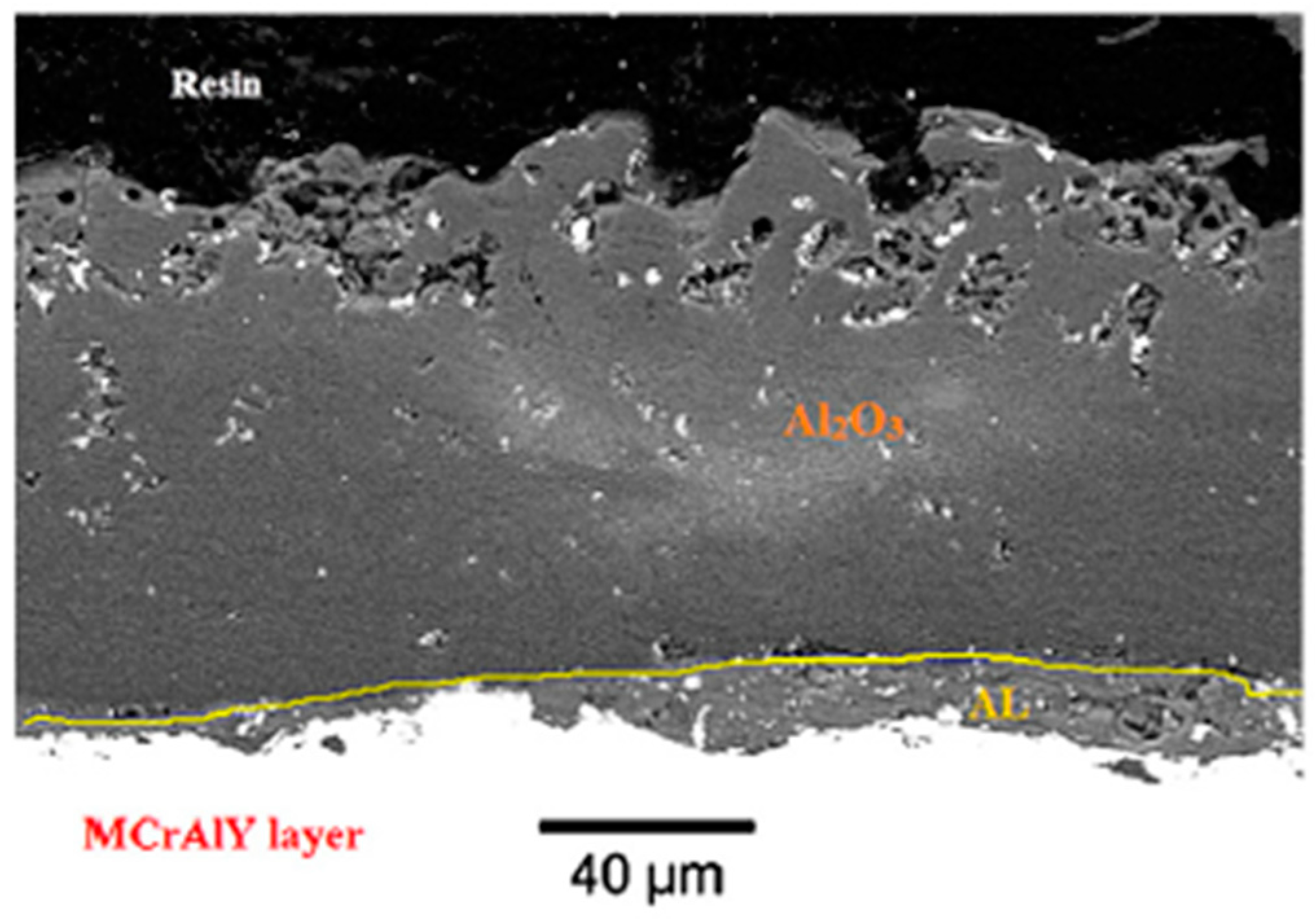

| [28] | Al2O3 | IN738 | Method | Chatodic plasma electrolytic deposition | High temperature | Agreeable the usage of MCrAly as bond coat Additive layer: MCrAly | |

| Preparation | High velocity oxy feul | ||||||

| Arc current | 1 A | ||||||

| Time | 12 min | ||||||

| Gas/electrolyte | AlCl3/H2/CO2 | ||||||

| [29] | Alumina-yttria-benzotriazole | St52 steel | Method | Sol-gel | Abrasion prone | Shift from adhesive wear to sheet wear | |

| Preparation | Isopropanol | ||||||

| Time | 24 h | ||||||

| (c) | [30] | N-DLC/ | p-Si | Method | Filtered cathodic vacuum arc/ | Electroanalysis | Stable linear relationship between tangential force and normal load Additive layer: Gold |

| Preparation | 2 cm × 2 cm | ||||||

| Bias | 1500 V | ||||||

| Pressure | 2.8 × 10−6 Pa | ||||||

| Gas/electrolyte | N2 | ||||||

| PtRuN-DLC | p-Si | Method | DC magnetron sputtering deposition | ||||

| Preparation | 2 cm × 2 cm | ||||||

| Bias | 30 V/650 W | ||||||

| Pressure | 0.399 Pa | ||||||

| Time | 120 min | ||||||

| Gas/electrolyte | N2 | ||||||

| [31] | Diamond | - | Method | CVD | Lathe Insert | Low surface roughness, remarkable dry performance | |

| [32] | Diamond | Mo | Method | Microwave plasma enhanced | Friction stir welding | Reduction in axial force, which has the potential to enhance robotic FSW applications | |

| DC Power | 5000 W | ||||||

| Pressure | 15.998 Pa | ||||||

| [33] | Diamond | WC-Co | Method | CVD | - | Reduction of wear expand the potential of FSW on MMC | |

| Type | Reference | Materials | Substrate | Deposition Method and Parameters | Application | Remarks | |

|---|---|---|---|---|---|---|---|

| (d) | [34] | Ce, La, Pr | Mg, WE43 | Method | Conversion coating bath | Light weight engineering | Three-fold increase in the polarization resistance |

| Preparation | Polished | ||||||

| Temperature | Room temperature | ||||||

| Treatment | Ce(NO3)3/La(NO3)3/Pr(NO3)3 | ||||||

| Time | 5 min | ||||||

| Post treatment | CeCl3 + 50 mg/LH2O2 | ||||||

| [35] | Ce | AZ63 | Method | Conversion coating bath | Engineering Application | An increase of both hydrogen peroxide concentration and immersion time produces a worsening of the alloy to corrosion. | |

| Preparation | Polished | ||||||

| Temperature | Room | ||||||

| Treatment | CeCl3 + H2O2 | ||||||

| Time | 30–180 s | ||||||

| [36] | Ce | AZ31 | Method | Conversion coating bath | Aerospace, automobile | Corrosion resistance greatly improved | |

| Preparation | Polished | ||||||

| Temperature | 35 °C | ||||||

| Treatment | Ce (NO3)3 + KMnO4 | ||||||

| Time | 20 min | ||||||

| [37] | La | Mg-Li | Method | Conversion coating bath | Aerospace, automobile, military | Increasing the impedance value | |

| Preparation | Polished | ||||||

| Temperature | 40 °C | ||||||

| Treatment | La (NO3)3 | ||||||

| Time | 10 min | ||||||

| [38] | La | Mg-Li | Method | Microwave synthesis | Aerospace, automobile, military | Increasing the impedance value | |

| Preparation | Smelting method | ||||||

| Temperature | 40 °C | ||||||

| Treatment | La (NO3)3 | ||||||

| Time | 10 min | ||||||

| [39] | La | AZ91 | Method | Conversion coating bath | Engineering application | Decreasing of the corrosion current density up to two order | |

| Preparation | Polished | ||||||

| Temperature | 30–50 °C | ||||||

| Treatment | Gd (NO3)3 | ||||||

| Time | 10–30 min | ||||||

| [40] | Gd | AZ91 | Method | Conversion coating bath | Atomic, microwave | Corrosion induced current decreased | |

| Preparation | Polished | ||||||

| Temperature | 50 °C | ||||||

| Treatment | Gd (NO3)3 + H2O2 | ||||||

| Time | 20 min | ||||||

| [41] | Nd | AZ31 | Method | Conversion coating bath | Atomic, microwave | Great corrosion resistance | |

| Preparation | Polished | ||||||

| Temperature | 40 °C | ||||||

| Treatment | Nd (NO3)3 + H2O2 | ||||||

| Time | 7 min | ||||||

| Post-treatment | Alumina sol | ||||||

| [42] | Nd | AZ91 | Method | Conversion coating bath | High toxicity compound replacement | Improved corrosion resistance | |

| Preparation | Polished | ||||||

| Temperature | 50 °C | ||||||

| Treatment | Nd (NO3)3 + H2O2 | ||||||

| Time | 20 min | ||||||

| [43] | Pr | AZNd | Method | Conversion coating bath | Biomedical application | Less concentration will be deposited in a short time | |

| Preparation | Ultrasonic cleaned | ||||||

| Treatment | Pr (NO3)3 | ||||||

| Time | 30 s | ||||||

| Method | Conversion coating bath | ||||||

| [44] | Sm | AZ91 | Method | Conversion coating bath | High toxicity compound replacement | Improved corrosion resistance of the relevant coated substrate | |

| Preparation | Polished | ||||||

| Treatment | Sm (NO3)3 | ||||||

| Time | 20–50 min | ||||||

| Method | Conversion coating bath | ||||||

| [45] | Y | AZ91D | Method | Conversion coating bath | Aerospace, automobile | Corrosion current density had been decreased two orders of magnitude | |

| Preparation | Polished | ||||||

| Temperature | 30 °C | ||||||

| Treatment | Y(NO3)3 (Y-Yttrium) | ||||||

| Post-treatment | Silica sol + air dried | ||||||

| Type | Reference | Materials | Substrate | Deposition Method and Parameters | Application | Remarks | |

|---|---|---|---|---|---|---|---|

| (e) | [48] | (TiB + TiC)/Ti64 | Network structured TMC | Method | Gas tungsten arc cladding | Aircraft, Automobile | Brittle debonding, oxidation and slight micro-ploughing observed |

| Preparation | Polished | ||||||

| Arc Current/Bias | 120 A/11.3 V | ||||||

| Gas/electrolyte | Argon | ||||||

| [49] | Ni–P–Ag–Al2O3 | Medium carbon steel | Method | Electroless bath | Friction and wear prone | Self-lubricating Ni–P–Ag–Al2O3 coating | |

| Preparation | Polished | ||||||

| Temperature | 90 °C | ||||||

| Treatment | Nickel sulphate + NaH2PO2 | ||||||

| Time | 2 h | ||||||

| Post-treatment | Heat treatment | ||||||

| [50] | TiN/ MoN | A 570 Grade 36, AISI M2 | Method | Vacuum arc evaporation | Modern science refractory metal | Increase critical loading of destruction Additive layer: Rutherford backscattering method | |

| Preparation | Glow discharge | ||||||

| Arc Current/Bias | 95–100 A/−40 V | ||||||

| Pressure | 0.5 Pa | ||||||

| Time | 20–80 min | ||||||

| [51] | TiN/ZrN | A 570 Grade 36 | Method | Vacuum arc evaporation | Aggressive environment | Long lifetime in harsh environment | |

| Preparation | Polished | ||||||

| Arc Current/Bias/Temperature | 100 A/−200 V/250–350 °C | ||||||

| Pressure | 0.4 Pa | ||||||

| Time | 1 h | ||||||

| Post-treatment | Annealed | ||||||

| [52] | TiN/ CrN, TiN/MoN, TiN/NbN, TiN/TaN | Cemented carbide | Method | PVD | Cutting tool | Superior tribological properties in general | |

| Preparation | Nitrogen degrease and dried | ||||||

| Temperature /Bias | 449.85 °C/−10–200 V | ||||||

| Pressure | 0.2~0.25 Pa | ||||||

| Time | 35~60 min | ||||||

| Post-treatment | Helium cooled | ||||||

| [53] | CrN/AlN multilayer coating | Silicon (100) | Method | RF magnetron sputtering | High temperature | Superior oxidation resistance | |

| DC Power | 150 W for Cr, 100 W for Al | ||||||

| Pressure | 8.0 × 10−4 Pa | ||||||

| [54] | Multilayer TiCN + TiC + TiCN + Al2O3 + TiN | AISI 4340 steel | - | - | Machining | Tools capability with reasonable tool life | |

| Parameter | Growth Temperature/°C | |||||

|---|---|---|---|---|---|---|

| 177 | 125 | 102 | 80 | 58 | 33 | |

| TMA exposure time/s | 1 | 1 | 1 | 1 | 1 | 1 |

| Purge time/s | 5 | 5 | 5 | 5 | 10 | 20 |

| Water exposure time/s | 1 | 2 | 2 | 2 | 2 | 2 |

| Purge time/s | 5 | 10 | 20 | 20 | 30 | 180 |

| Mass gain/cycle (bg/cm2) | 38 | 39 | 36 | 34 | 30 | 28 |

| Location | Cr | Al | O | N | Phase |

|---|---|---|---|---|---|

| 1 | 9.9 | 18.9 | 71.2 | - | Crystalline Al-rich oxide |

| 2 | - | - | - | - | Nano-voids |

| 3 | 17.6 | 16.3 | 66.2 | - | Mixed (AlxCr1−x)sO3 |

| 4 | 34.3 | 21.8 | - | 43.9 | CrN/AlN film |

| 5 | 5.8 | 27.4 | 66.8 | - | Amorphous Al-rich oxide |

| 6 | 25.0 | 14.3 | 60.7 | - | Crystalline Cr-rich oxide |

| 7 | 14.5 | 23.3 | 62.3 | - | Mixed (AlxCr1−x)sO3 |

| 8 | 8.7 | 25.4 | 65.9 | - | Amorphous Al-rich oxide |

| 9 | 14.9 | 22.5 | 62.6 | - | Amorphous Al-rich oxide |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Awang, M.; Khalili, A.A.; Pedapati, S.R. A Review: Thin Protective Coating for Wear Protection in High-Temperature Application. Metals 2020, 10, 42. https://doi.org/10.3390/met10010042

Awang M, Khalili AA, Pedapati SR. A Review: Thin Protective Coating for Wear Protection in High-Temperature Application. Metals. 2020; 10(1):42. https://doi.org/10.3390/met10010042

Chicago/Turabian StyleAwang, Mokhtar, Amirul Amin Khalili, and Srinivasa Rao Pedapati. 2020. "A Review: Thin Protective Coating for Wear Protection in High-Temperature Application" Metals 10, no. 1: 42. https://doi.org/10.3390/met10010042

APA StyleAwang, M., Khalili, A. A., & Pedapati, S. R. (2020). A Review: Thin Protective Coating for Wear Protection in High-Temperature Application. Metals, 10(1), 42. https://doi.org/10.3390/met10010042