Establish Using FEM Method of Constitutive Model for Chip Formation in the Cutting Process of Gray Cast Iron

Abstract

1. Introduction

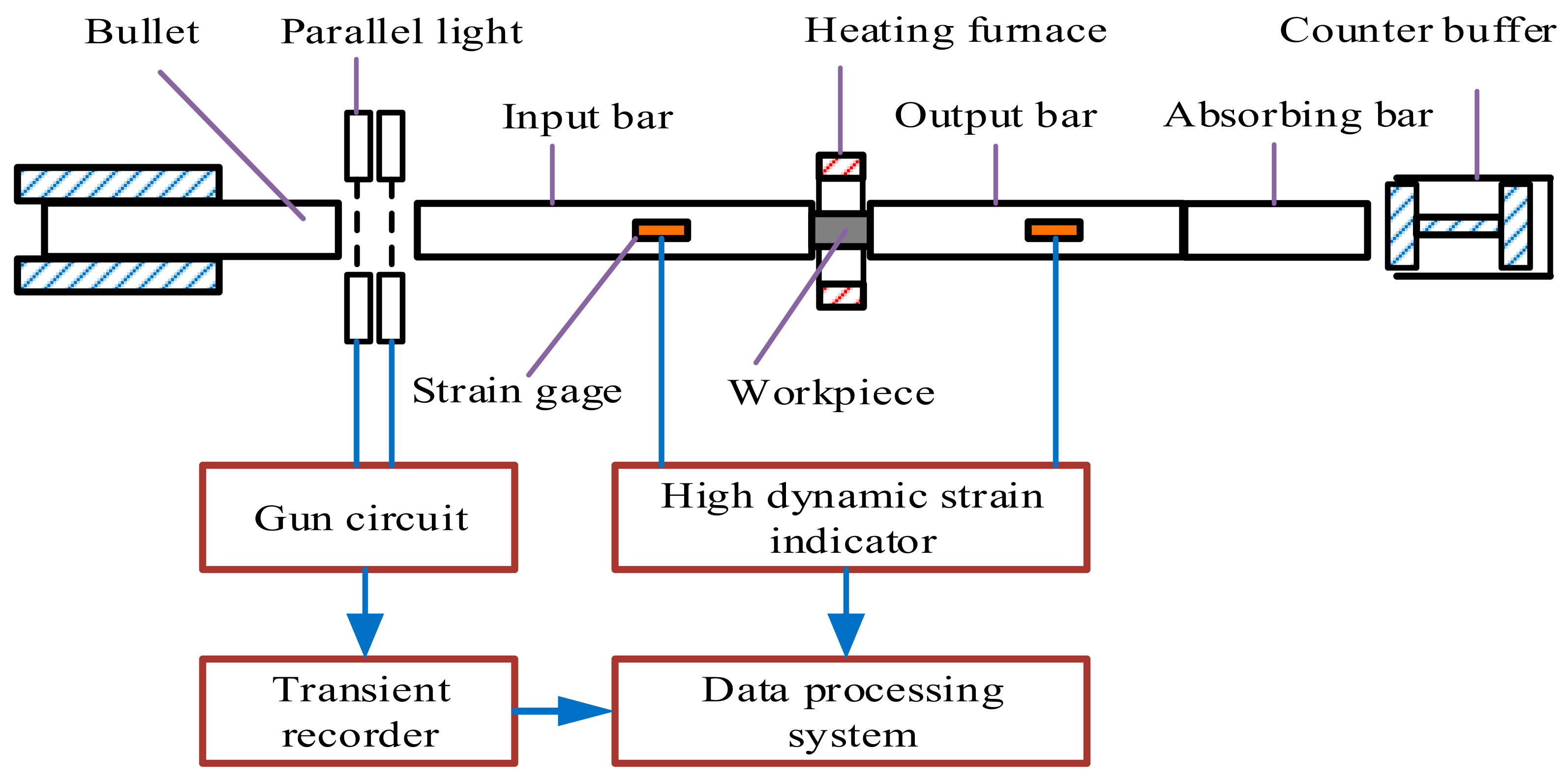

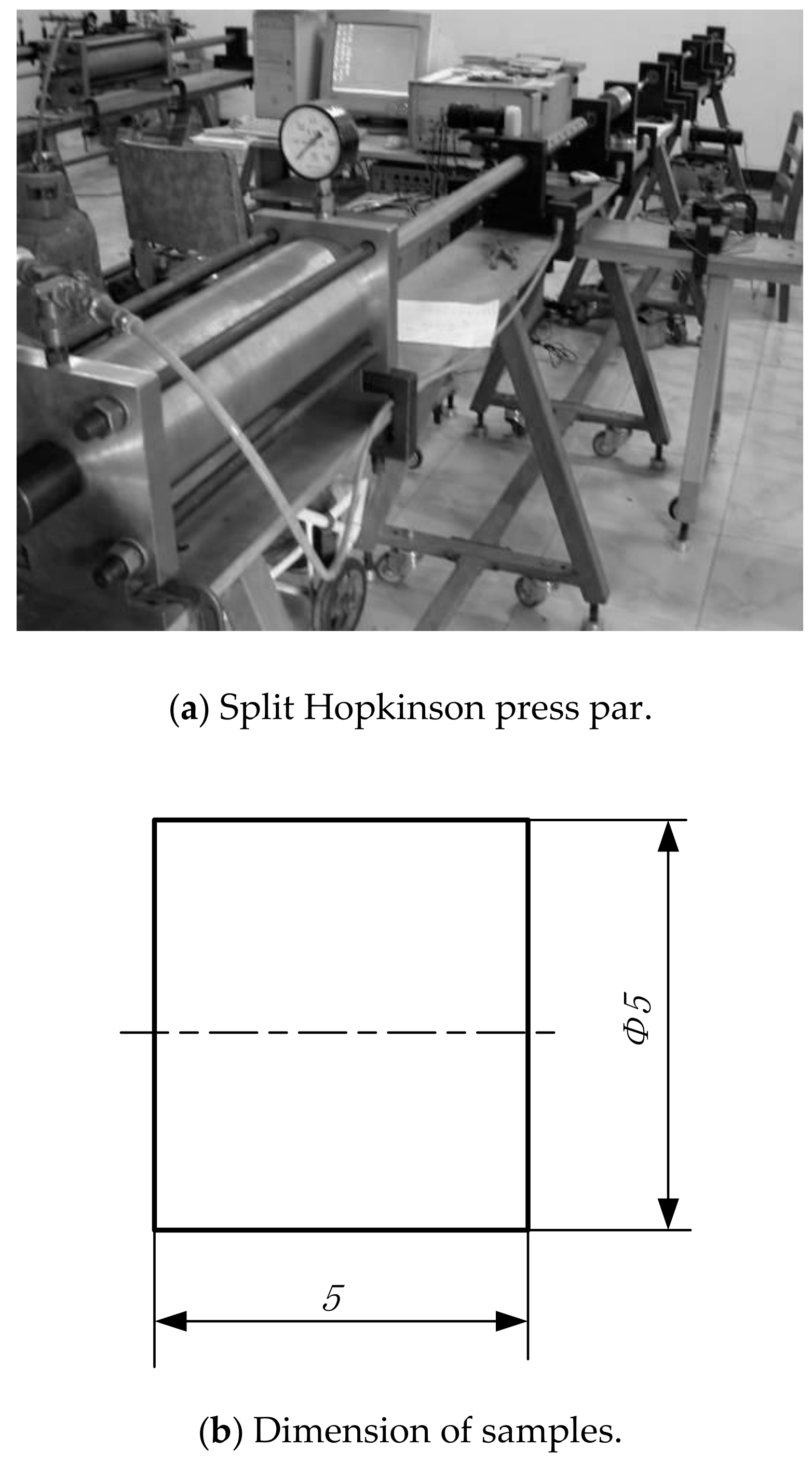

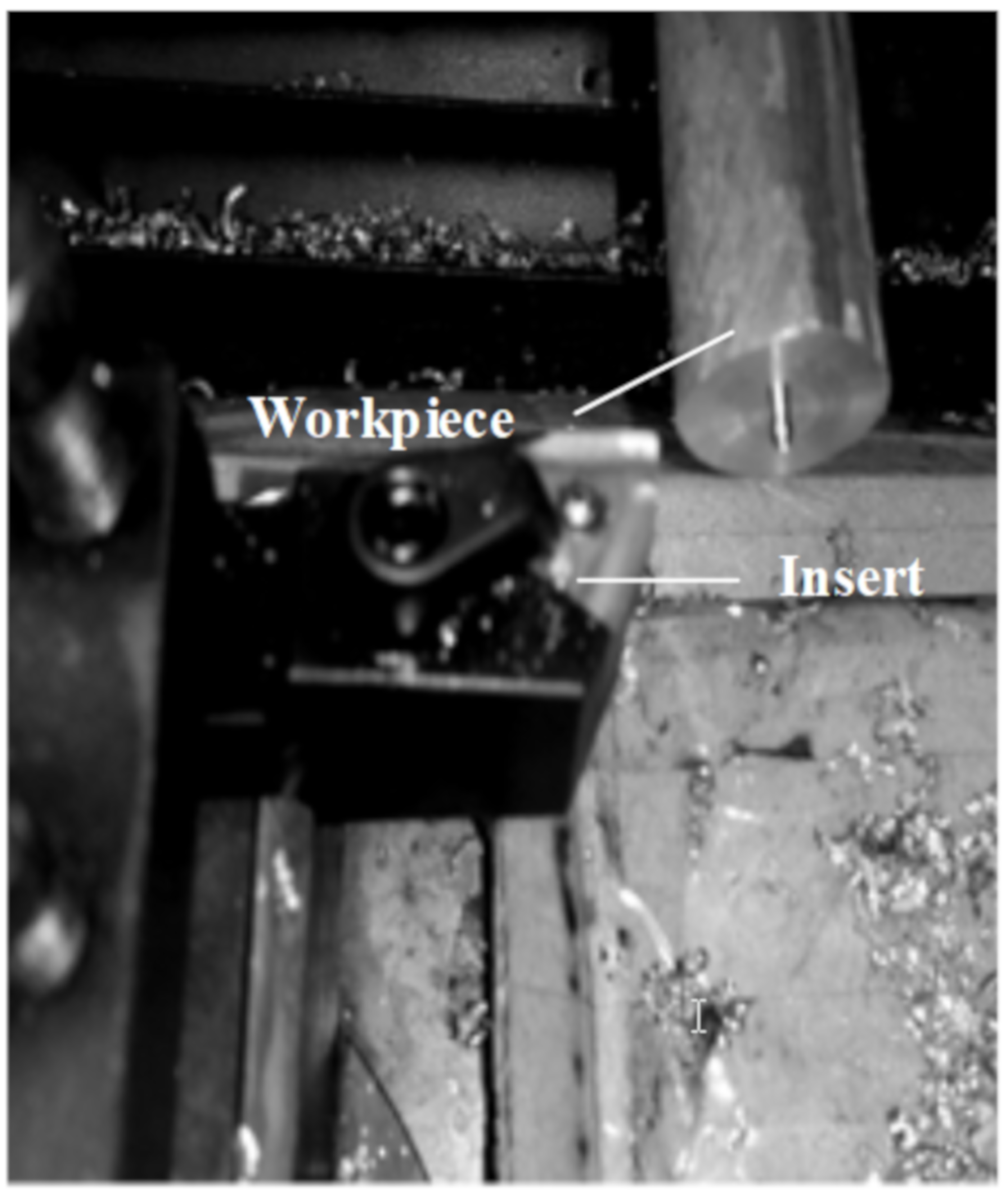

2. Experimental Setup

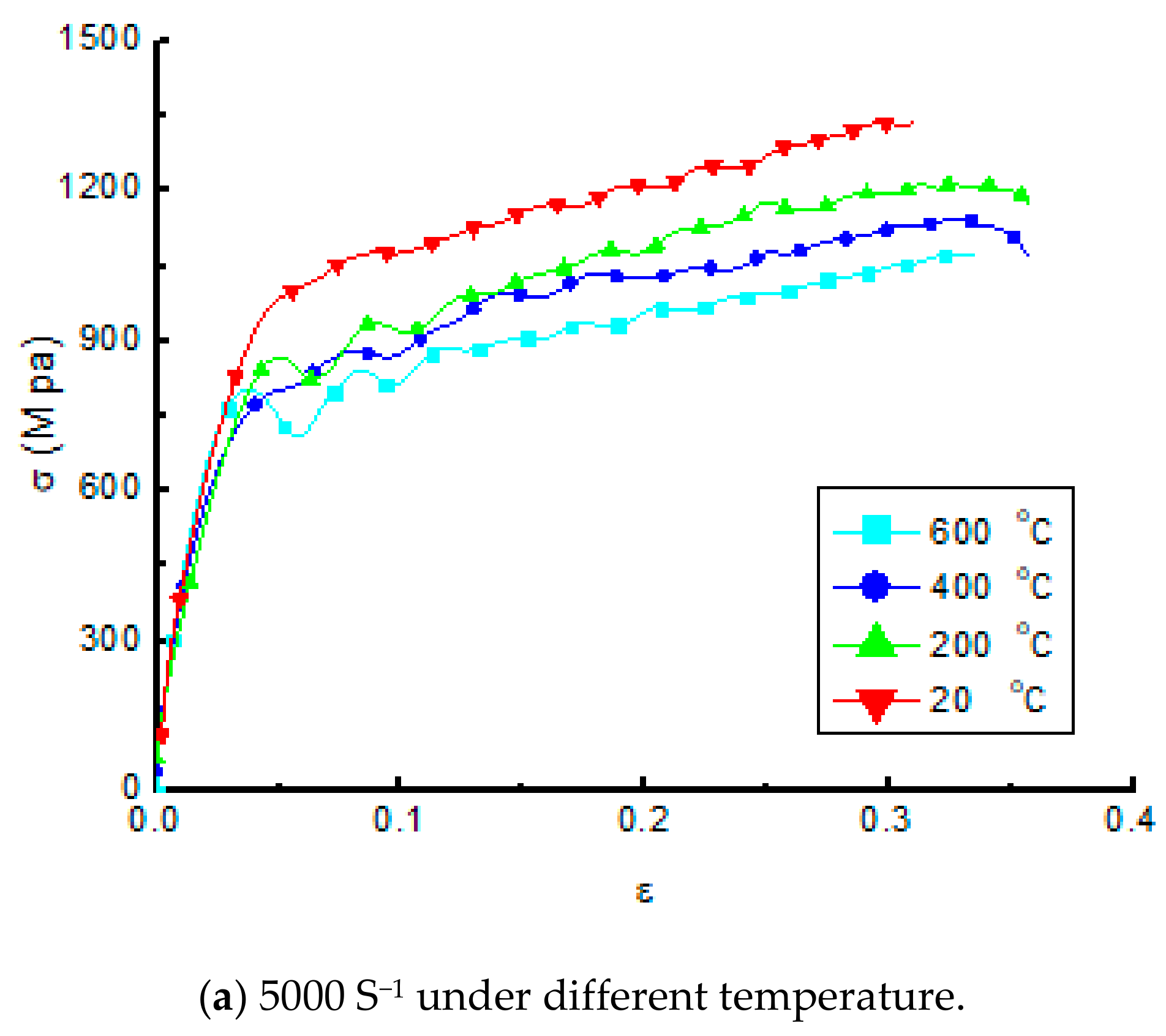

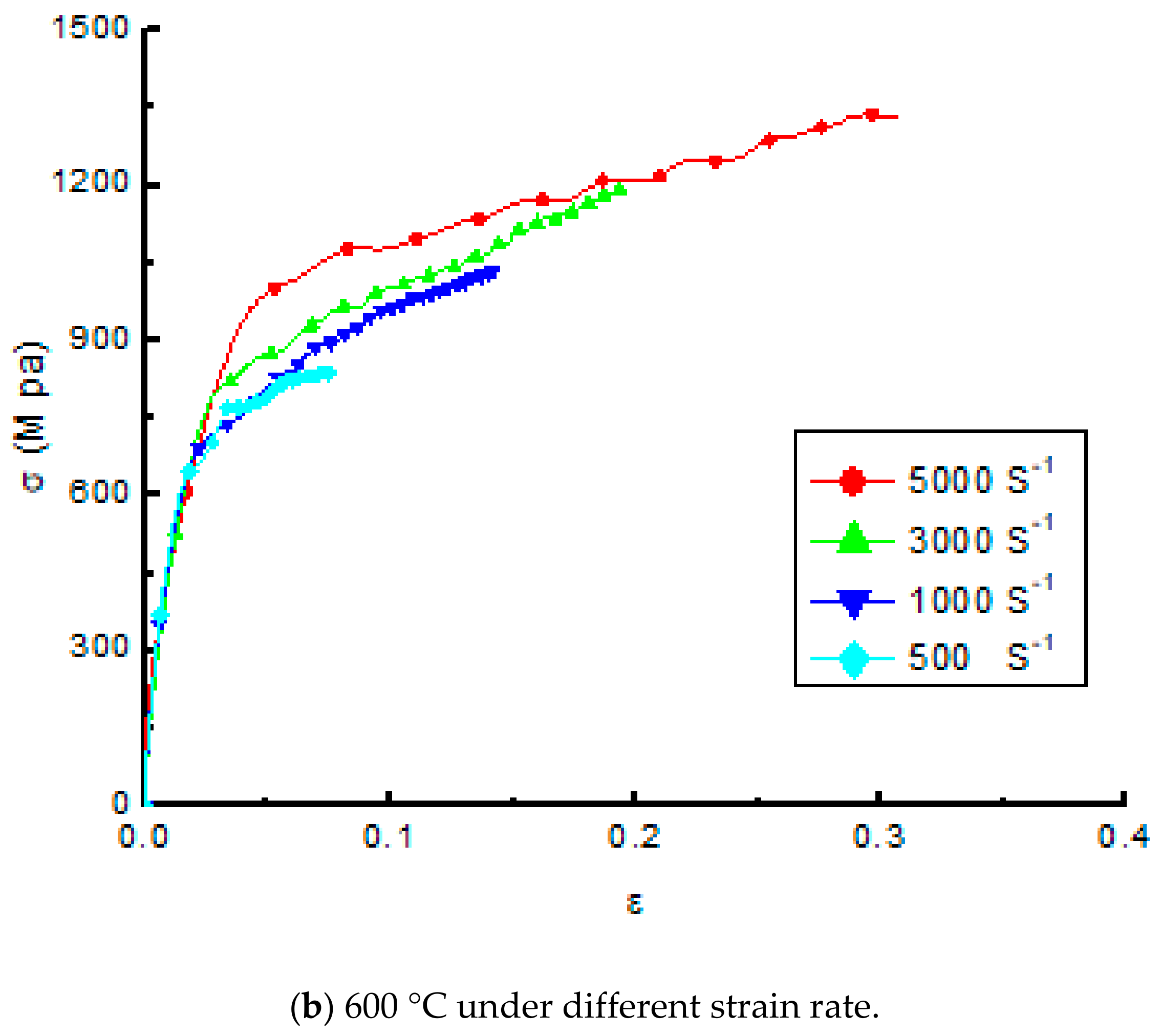

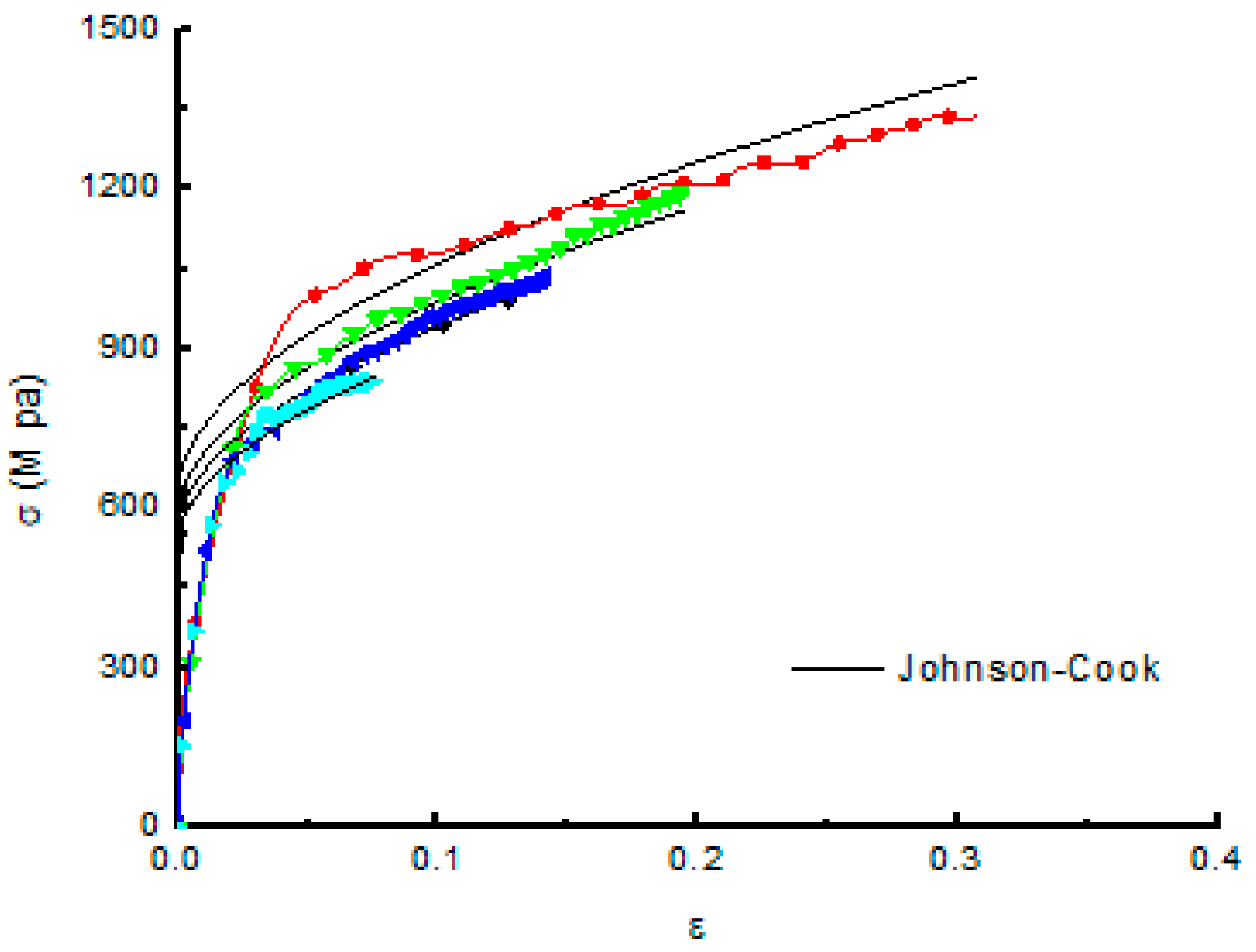

3. Establishment of Material Model

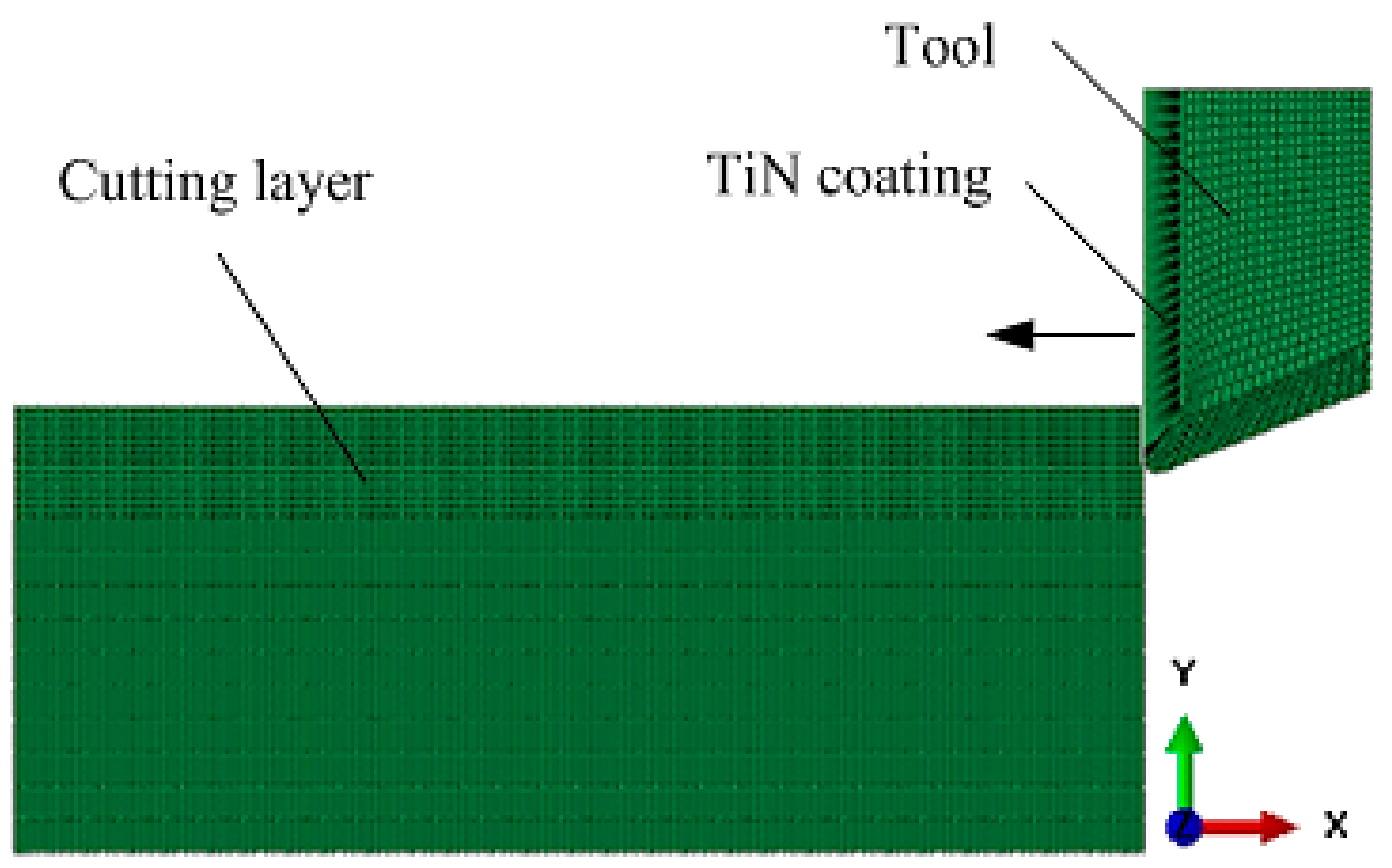

4. Finite Element Models

4.1. Cutting Model

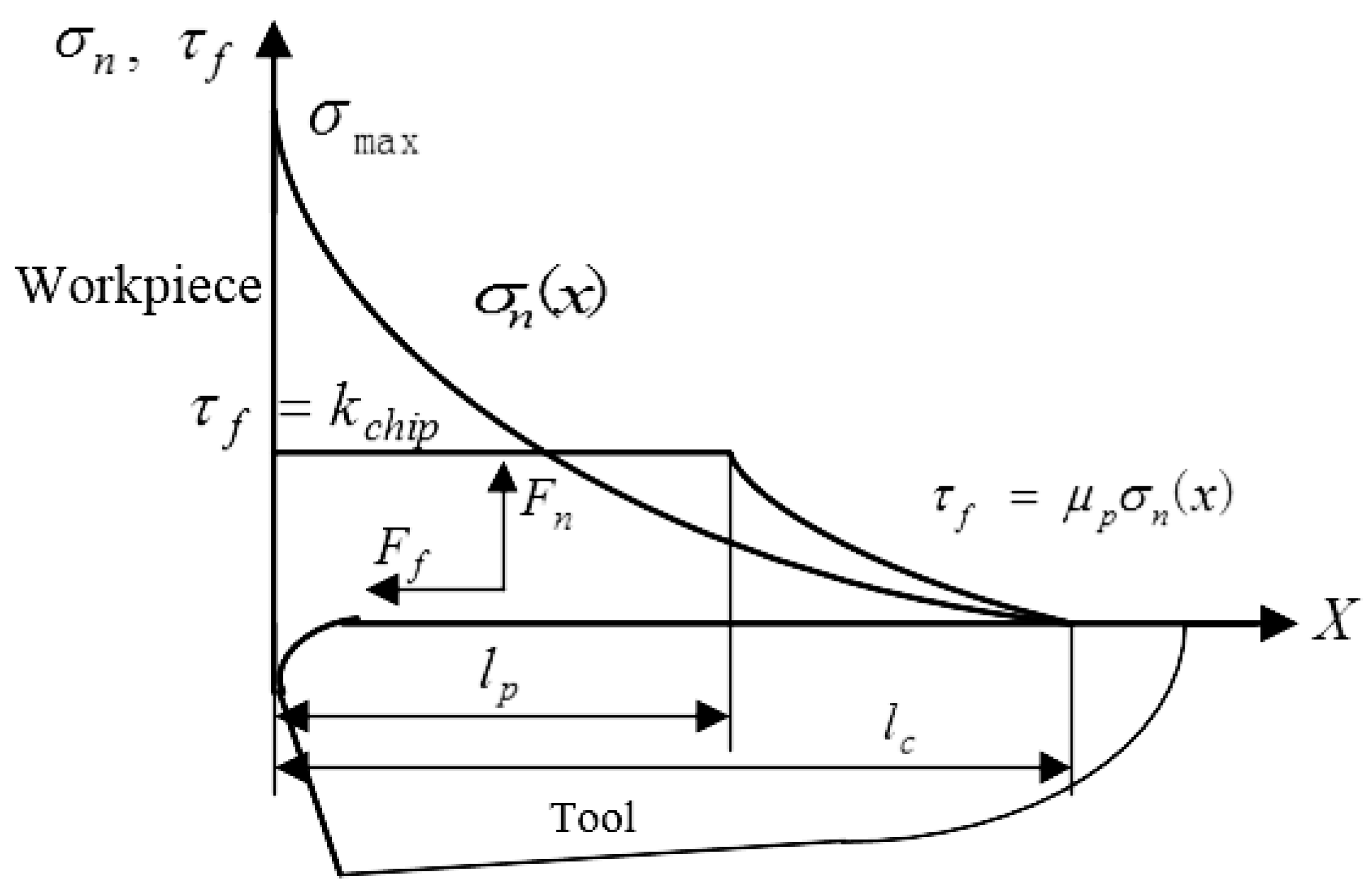

4.2. Friction Model

4.3. Damage Model

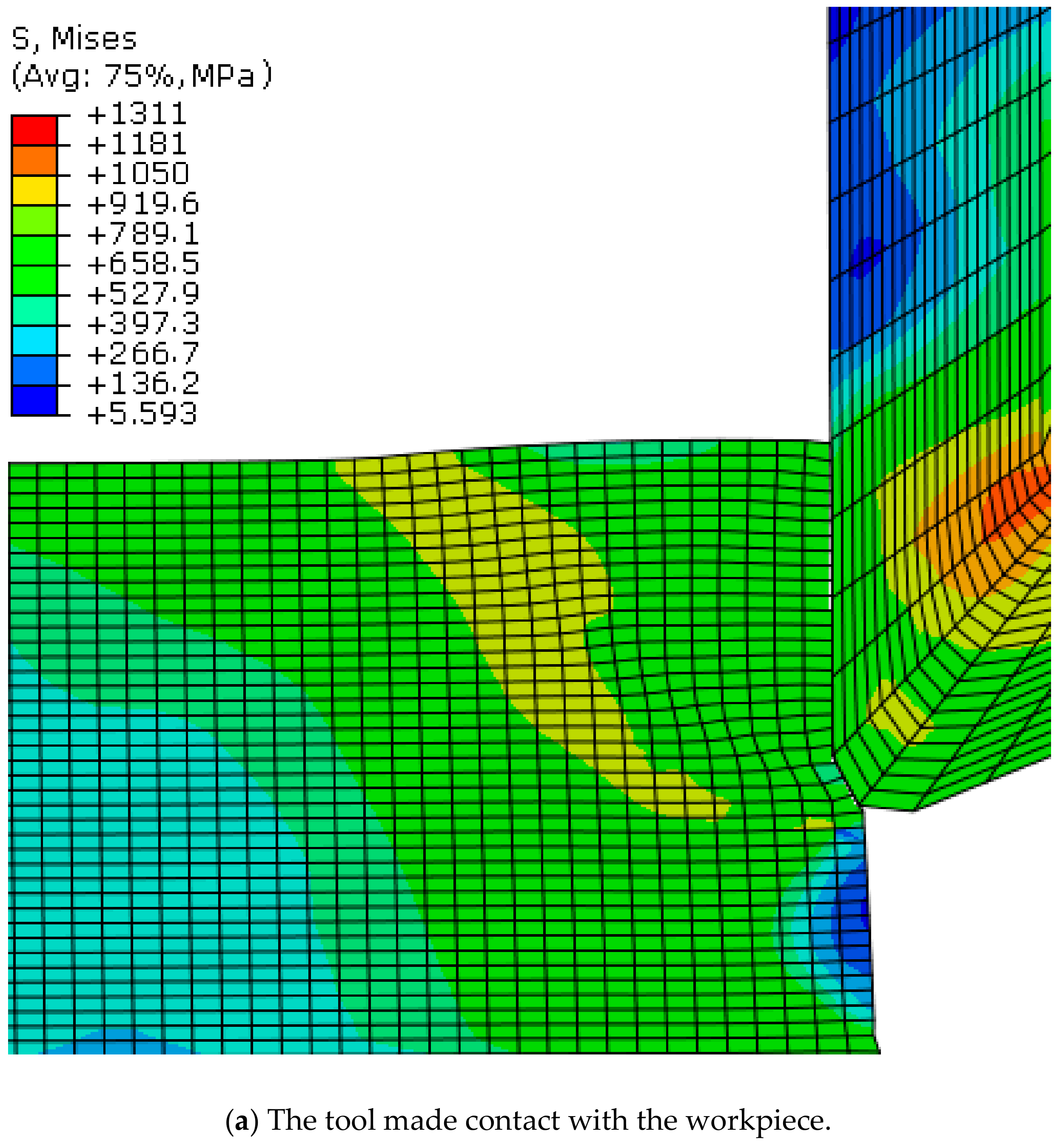

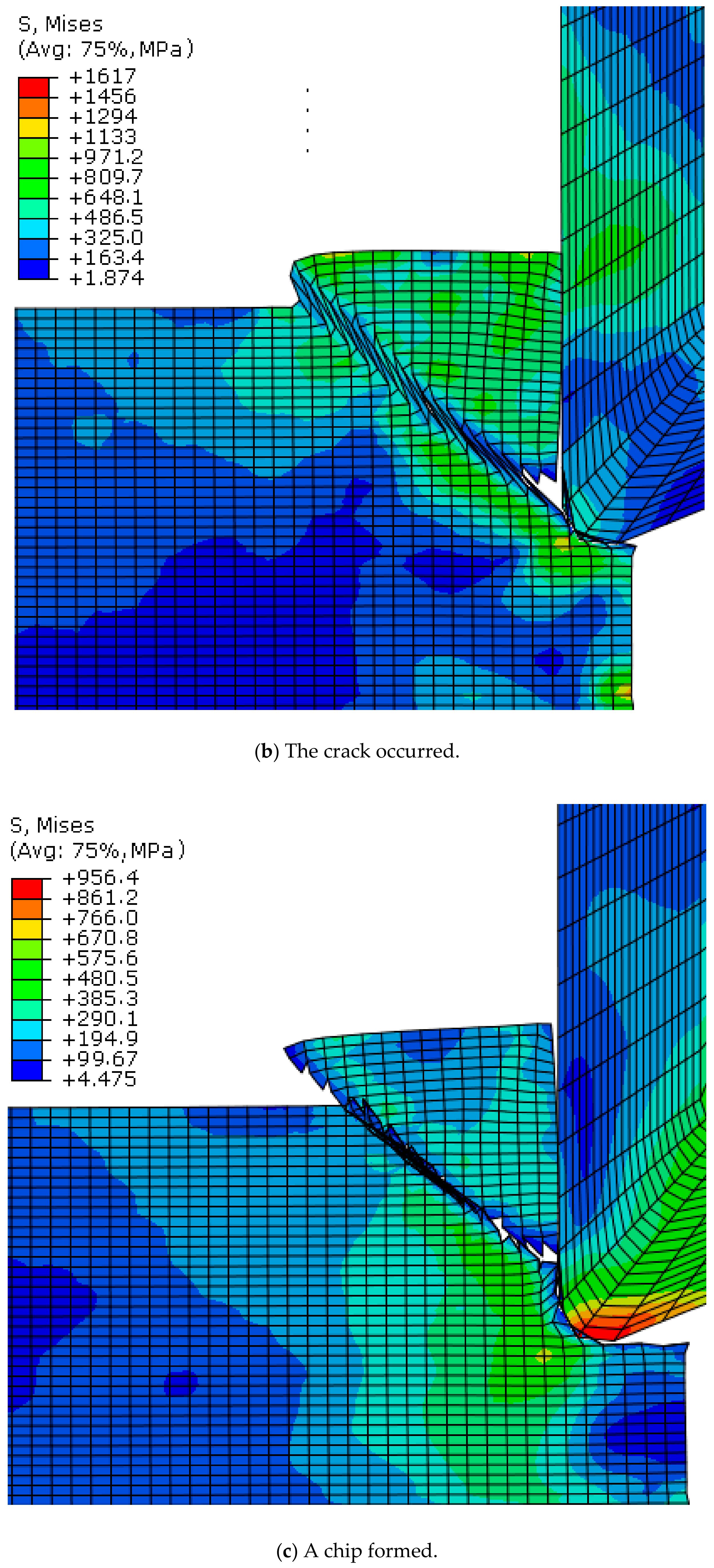

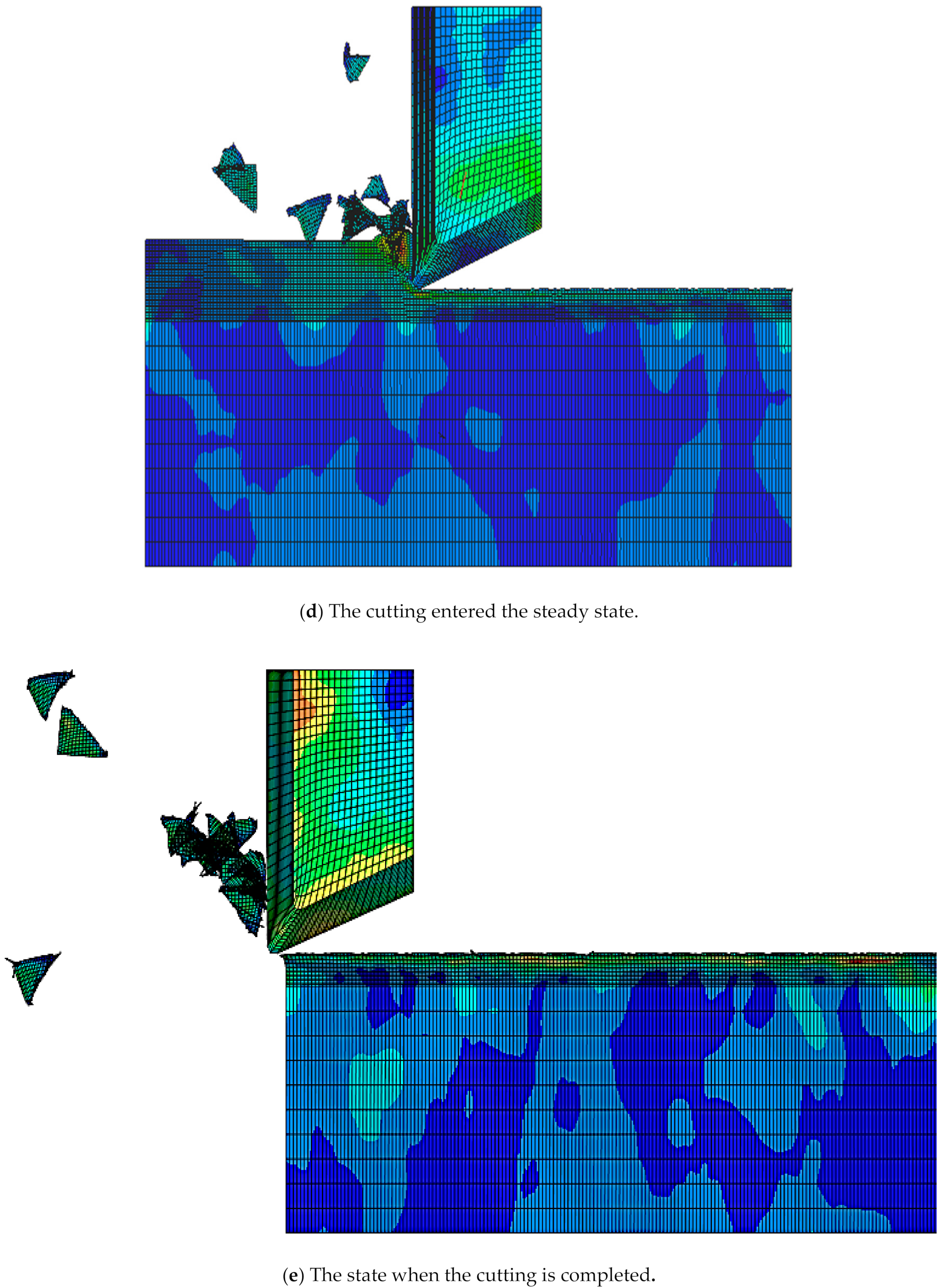

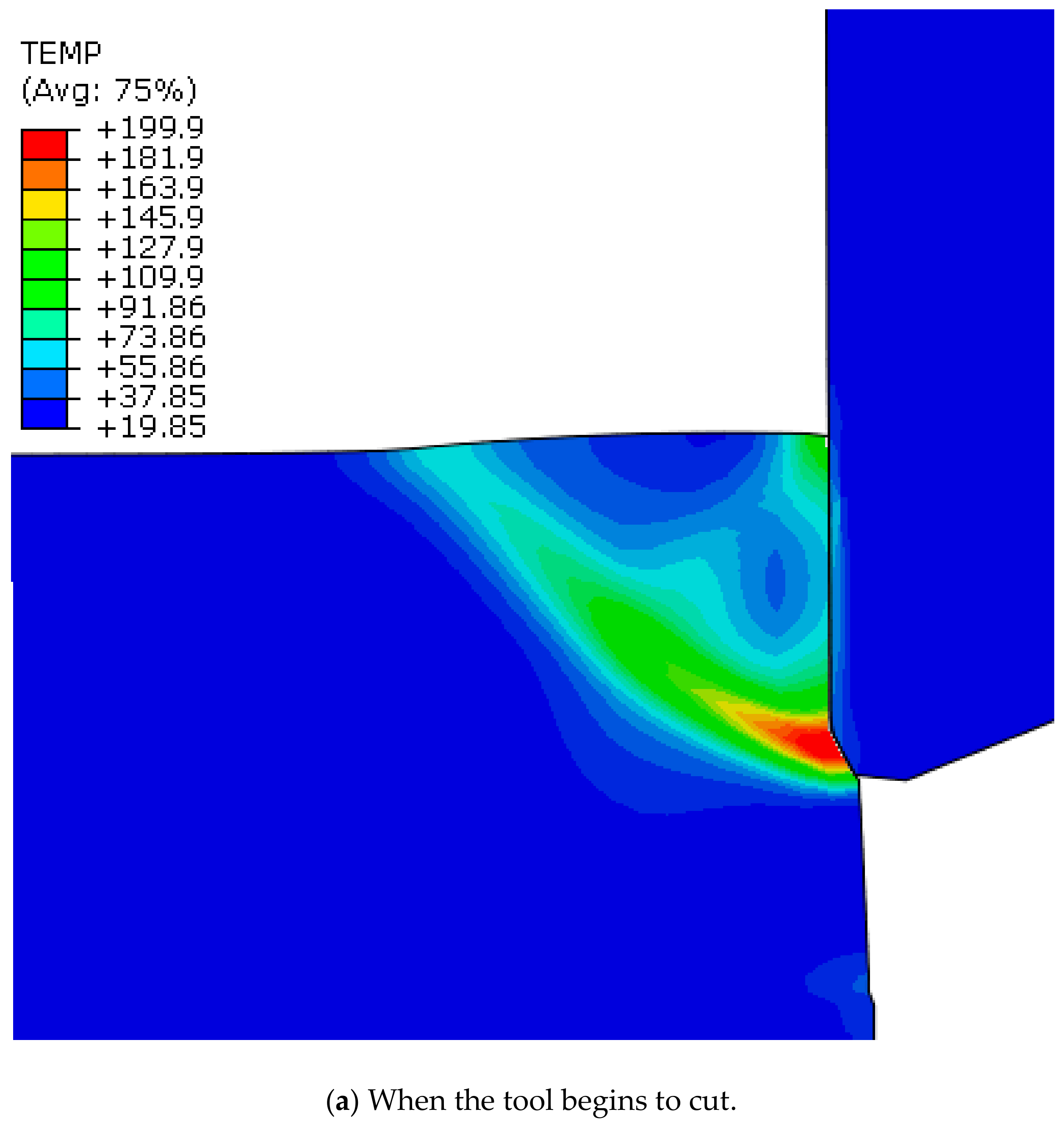

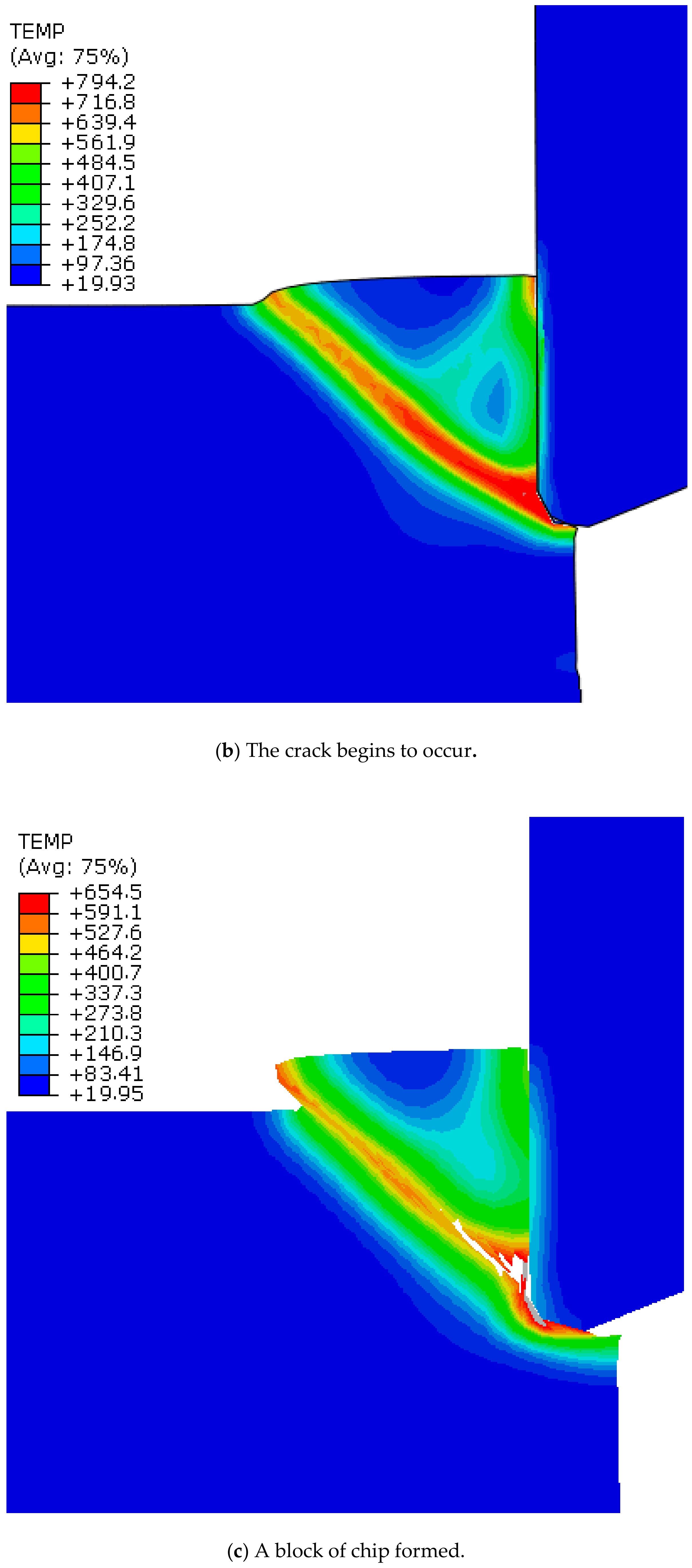

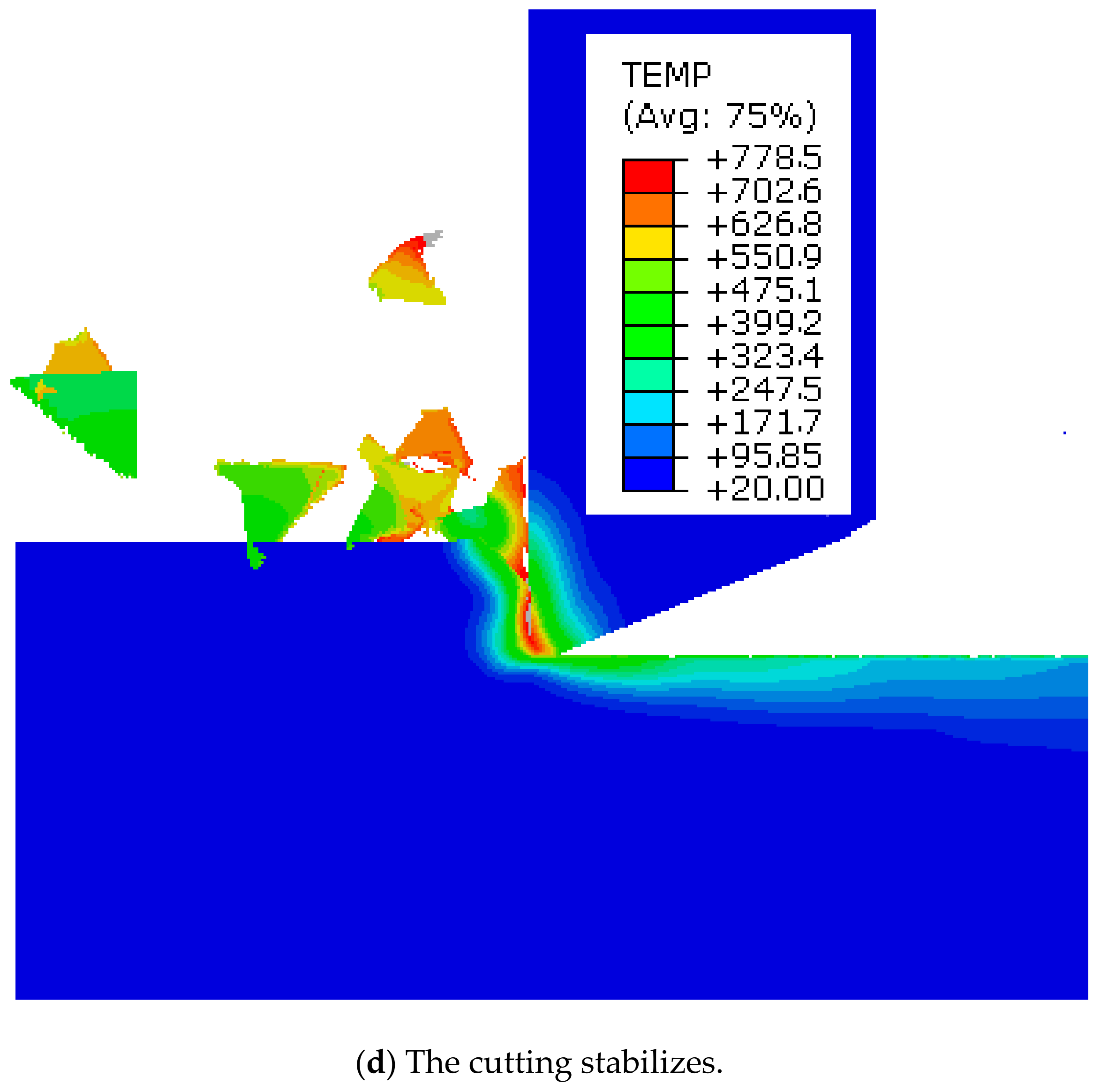

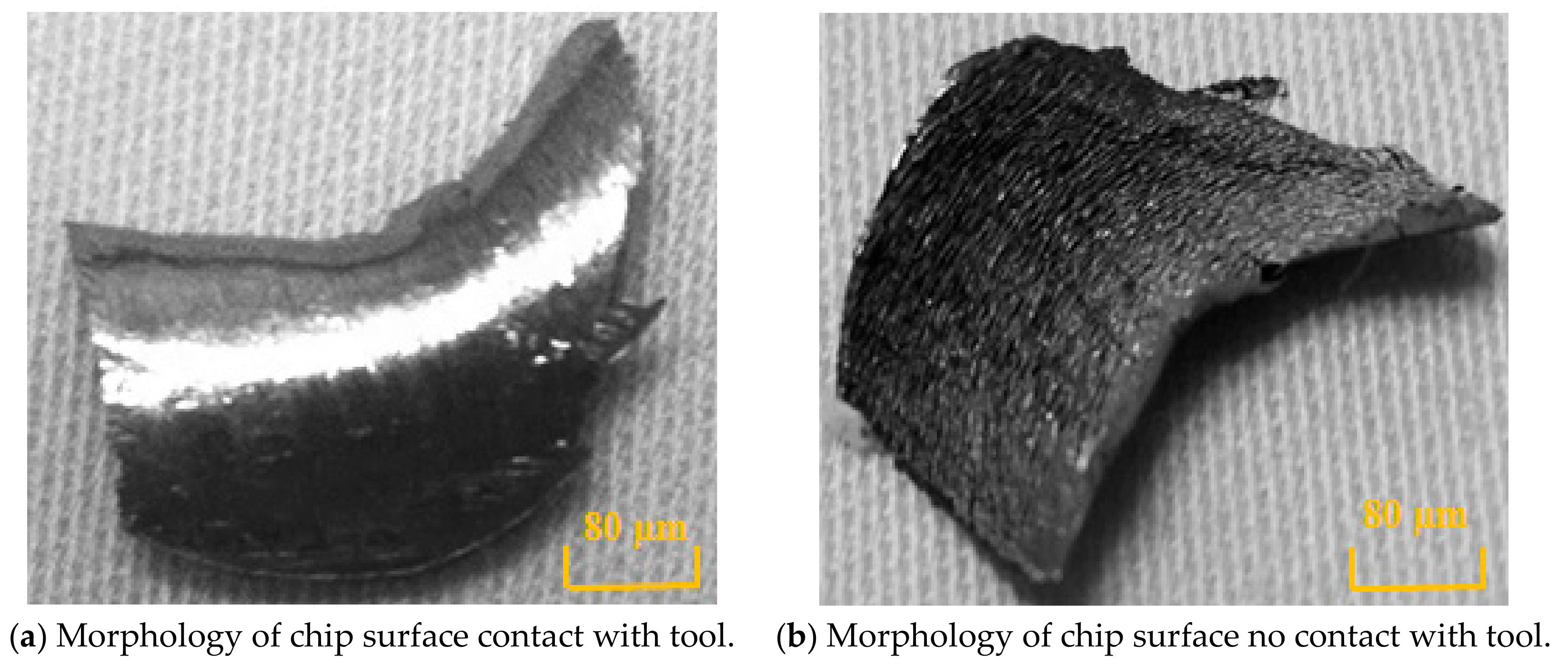

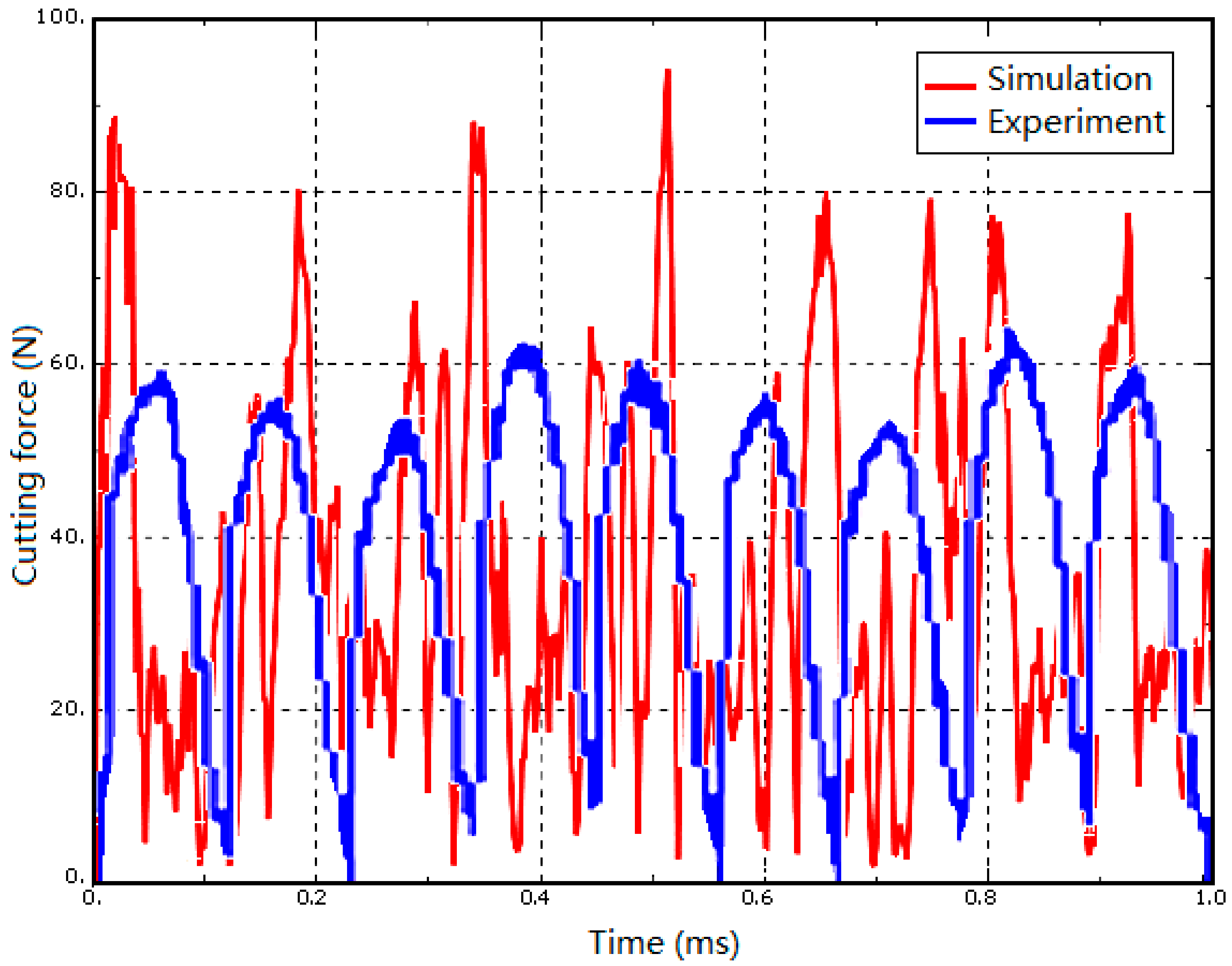

5. Results of Cutting Simulation

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Fallböhmer, P.; Rodríguez, C.A.; Özel, T.; Altan, T. High-speed machining of cast iron and alloy steels for die and mold manufacturing. J. Mater. Process. Technol. 2000, 98, 104–115. [Google Scholar] [CrossRef]

- Kato, H.; Shintani, K.; Sumiya, H. Cutting performance of a binder-less sintered cubic boron nitride tool in the high-speed milling of gray cast iron. J. Mater. Process. Technol. 2002, 127, 217–221. [Google Scholar] [CrossRef]

- Yang, Y.; Li, J.F. Study on mechanism of chip formation during high-speed milling of alloy cast iron. Int. J. Adv. Manuf. Technol. 2010, 46, 43–50. [Google Scholar] [CrossRef]

- Oliveira, A.J.D.; Boing, D.; Schroeter, R.B. Effect of PCBN tool grade and cutting type on hard turning of high-chromium white cast iron. Int. J. Adv. Manuf. Technol. 2016, 82, 797–807. [Google Scholar] [CrossRef]

- De Sales, A.M., Jr.; Sales, W.F.; Santos, S.C.; Machado, A.R. Performance of single Si3N4, and mixed Si3N4+PCBN wiper cutting tools applied to high speed face milling of cast iron. Int. J. Mach. Tools Manuf. 2005, 45, 335–344. [Google Scholar]

- Martinez, I.; Tanaka, R.; Yamane, Y.; Sekiya, K.; Yamada, K.; Ishihara, T.; Furuya, S. Wear characteristics of coated carbide tools in the face milling of ductile cast iron. Key Eng. Mater. 2017, 749, 178–184. [Google Scholar] [CrossRef]

- Chen, L.; Stahl, J.E.; Zhao, W.; Zhou, J. Assessment on abrasiveness of high chromium cast iron material on the wear performance of PCBN cutting tools in dry machining. J. Mater. Process. Technol. 2017, 255, 110–120. [Google Scholar] [CrossRef]

- Luan, X.; Zhang, S.; Cai, G. Optimal Cutting Parameters to Reduce Power Consumption in Face Milling of a Cast Iron Alloy for Environmental Sustainability. In Proceedings of the International Conference on Sustainable Design and Manufacturing, Heraklion, Greece, 4–6 April 2016; Volume 52, pp. 135–148. [Google Scholar]

- Xie, J.Q.; Bayoumi, A.E.; Zbib, H.M. FEA modeling and simulation of shear localized chip formation in metal cutting. Int. J. Mach. Tools Manuf. 1998, 38, 1067–1087. [Google Scholar] [CrossRef]

- Shih, A.J. Finite element analysis of the rake angle effects in orthogonal metal cutting. Int. J. Mech. Sci. 1995, 38, 1–17. [Google Scholar] [CrossRef]

- Wu, H.B.; Zhang, S.J. Effects of cutting conditions on the milling process of titanium alloy Ti6Al4V. Int. J. Adv. Manuf. Technol. 2015, 77, 2235–2240. [Google Scholar] [CrossRef]

- Matsumura, T.; Usui, E. Simulation of cutting process in peripheral milling by predictive cutting force model based on minimum cutting energy. Int. J. Mach. Tools Manuf. 2010, 50, 467–473. [Google Scholar] [CrossRef]

- Maurel-Pantel, A.; Fontaine, M.; Thibaud, S.; Gelin, J.C. 3D FEM simulations of shoulder milling operations on a 304L stainless steel. Simul. Model. Pract. Theory 2012, 22, 13–27. [Google Scholar] [CrossRef]

- Ji, C.; Li, Y.; Qin, X.; Zhao, Q.; Sun, D. 3D FEM simulation of helical milling hole process for titanium alloy Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2015, 81, 1733–1742. [Google Scholar] [CrossRef]

- Mir, A.; Luo, X.; Siddiq, A. Smooth particle hydrodynamics study of surface defect machining for diamond turning of silicon. Int. J. Adv. Manuf. Technol. 2017, 88, 2461–2476. [Google Scholar] [CrossRef]

- Wu, H.B.; Guo, L. Machinability of titanium alloy TC21 under orthogonal turning process. Mater. Manuf. Process. 2014, 29, 1441–1445. [Google Scholar] [CrossRef]

- Kilic, Z.M.; Altintas, Y. Generalized modelling of cutting tool geometries for unified process simulation. Int. J. Mach. Tools Manuf. 2016, 104, 14–25. [Google Scholar] [CrossRef]

- Jafarian, F.; Ciaran, M.I.; Umbrello, D.; Arrazola, P.L.; Filice, L. Finite element simulation of machining Inconel 718 alloy including microstructure changes. Int. J. Mech. Sci. 2014, 88, 110–121. [Google Scholar] [CrossRef]

- Komvopoulos, K.; Erpenbeck, S.A. Finite element modeling of orthogonal metal cutting. J. Eng. Ind. 1991, 113, 253. [Google Scholar] [CrossRef]

- Ceretti, E.; Lucchi, M.; Altan, T. FEM simulation of orthogonal cutting: Serrated chip formation. J. Mater. Process. Technol. 1999, 95, 17–26. [Google Scholar] [CrossRef]

- Özel, T.; Altan, T. Process simulation using finite element method—prediction of cutting forces, tool stresses and temperatures in high-speed flat end milling. Int. J. Mach. Tools Manuf. 2000, 40, 713–738. [Google Scholar] [CrossRef]

- Xiong, R.; Wu, H. Study on cutting mechanism of Ti6Al4V in ultra-precision machining. Int. J. Adv. Manuf. Technol. 2016, 86, 1–7. [Google Scholar]

- Paturi, U.M.R.; Narala, S.K.R.; Pundir, R.S. Constitutive flow stress formulation, model validation and FE cutting simulation for AA7075-T6 aluminum alloy. Mater. Sci. Eng. A 2014, 605, 176–185. [Google Scholar] [CrossRef]

- Boldyrev, I.S.; Shchurov, I.A.; Nikonov, A.V. Numerical simulation of the aluminum 6061-T6 cutting and the effect of the constitutive material model and failure criteria on cutting forces’ prediction. Procedia Eng. 2016, 150, 866–870. [Google Scholar] [CrossRef]

- Umbrello, D. Finite element simulation of conventional and high speed machining of Ti6Al4V alloy. J. Mater. Process. Technol. 2007, 196, 79–87. [Google Scholar] [CrossRef]

- Pantalé, O.; Bacaria, J.-L.; Dalverny, O.; Rakotomalala, R.; Caperaa, S. 2D and 3D numerical models of metal cutting with damage effects. Comput. Methods Appl. Mech. Eng. 2004, 193, 4383–4399. [Google Scholar] [CrossRef]

- Johnson, R.; Cook, W.K. A constitutive model and data for metals subjected to large strains high strain rates and high temperatures. In Proceedings of the 7th International Symposium on Balistics, The Hague, The Netherlands, 19–21 April 1983; pp. 541–547. [Google Scholar]

- Daoud, M.; Chatelain, J.F.; Bouzid, A. Effect of rake angle on Johnson-Cook material constants and their impact on cutting process parameters of Al2024-T3 alloy machining simulation. Int. J. Adv. Manuf. Technol. 2015, 81, 1987–1997. [Google Scholar] [CrossRef]

- Shrot, A.; Bäker, M. Is it possible to identify Johnson-Cook law parameters from machining simulations? Int. J. Mater. Form. 2010, 3, 443–446. [Google Scholar] [CrossRef]

- Wu, H.B.; To, S. Serrated chip formation and their adiabatic analysis by using the constitutive model of titanium alloy in high speed cutting. J. Alloy. Compd. 2015, 629, 368–373. [Google Scholar] [CrossRef]

- Wang, X.; Huang, C.; Zou, B.; Liu, H.; Zhu, H.; Wang, J. Dynamic behavior and a modified Johnson—Cook constitutive model of Inconel 718 at high strain rate and elevated temperature. Mater. Sci. Eng. A 2013, 580, 385–390. [Google Scholar] [CrossRef]

- Seo, S.; Min, O.; Yang, H. Constitutive equation for Ti–6Al–4V at high temperatures measured using the SHPB technique. Int. J. Impact Eng. 2005, 31, 735–754. [Google Scholar] [CrossRef]

- Zhong, W.Z.; Mbarek, I.A.; Rusinek, A.; Bernier, R.; Jankowiak, T. Development of an experimental set-up for dynamic force measurements during impact and perforation, coupling to numerical simulations. Int. J. Impact Eng. 2016, 91, 102–115. [Google Scholar] [CrossRef]

- Jaspers, S.P.F.C.; Dautzenberg, J.H. Material behaviour in conditions similar to metal cutting: flow stress in the primary shear zone. J. Mater. Process. Technol. 2002, 122, 322–330. [Google Scholar] [CrossRef]

- Dabboussi, W.; Nemes, J.A. Modeling of ductile fracture using the dynamic punch test. Int. J. Mech. Sci. 2005, 47, 1282–1299. [Google Scholar] [CrossRef]

- Zhou, T.; Wu, J.; Che, J.; Wang, Y.; Wang, X. Dynamic shear characteristics of titanium alloy Ti-6Al-4V at large strain rates by the split hopkinson pressure bar test. Int. J. Impact Eng. 2017, 109, 167–177. [Google Scholar] [CrossRef]

- Church, P.; Cornish, R.; Cullis, I.; Gould, P.; Lewtas, I. Using the split Hopkinson pressure bar to validate material models. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20130294. [Google Scholar] [CrossRef] [PubMed]

- Fowles, R.; Williams, R.F. Plane stress wave propagation in solids. J. Appl. Phys. 1970, 41, 360–363. [Google Scholar] [CrossRef]

- Zorev, N.N. Inter-relationship between shear processes occurring along tool face and shear plane in metal cutting. Int. Res. Prod. Eng. 1963, 5, 42–49. [Google Scholar]

- Johnson, G.R.; Cook, W.H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Fe |

|---|---|---|---|---|---|

| 3.5 | 2.1 | 0.8 | 0.01 | 0.095 | Others |

| Properties | Value |

|---|---|

| Hardness (HRC) | 43 |

| Density (Kg/m3) | 7135 |

| Elastic modulus (GPa) | 126 |

| Heat conductivity (W/mk) | 39.2 |

| Specific heat (J/kg·K) | 480 |

| Parameters | Values |

|---|---|

| Depth of cut (mm) | 0.4 |

| Spindle speed (r/min) | 3000 |

| Feeding speed (mm/min) | 120 |

| Cutting speed (m/min) | 188 |

| Cutting environment | Dry cutting |

| A (Mpa) | B (Mpa) | n | C | m |

|---|---|---|---|---|

| 419 | 405 | 0.2 | 0.032 | 1.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tu, L.; Shi, W. Establish Using FEM Method of Constitutive Model for Chip Formation in the Cutting Process of Gray Cast Iron. Metals 2020, 10, 33. https://doi.org/10.3390/met10010033

Tu L, Shi W. Establish Using FEM Method of Constitutive Model for Chip Formation in the Cutting Process of Gray Cast Iron. Metals. 2020; 10(1):33. https://doi.org/10.3390/met10010033

Chicago/Turabian StyleTu, Lihui, and Weimin Shi. 2020. "Establish Using FEM Method of Constitutive Model for Chip Formation in the Cutting Process of Gray Cast Iron" Metals 10, no. 1: 33. https://doi.org/10.3390/met10010033

APA StyleTu, L., & Shi, W. (2020). Establish Using FEM Method of Constitutive Model for Chip Formation in the Cutting Process of Gray Cast Iron. Metals, 10(1), 33. https://doi.org/10.3390/met10010033