Impact of Local Cathode Electrical Cut-Off on Bath–Metal Two-Phase Flow in an Aluminum Reduction Cell

Abstract

:1. Introduction

2. Model and Description

2.1. Physical Model and Material Properties

2.2. Mathematical Models

2.2.1. Multiphase Model

2.2.2. Turbulence Model

2.2.3. MHD Model

2.3. Boundary Conditions

3. Results and Analysis

3.1. Simulation for Reference State

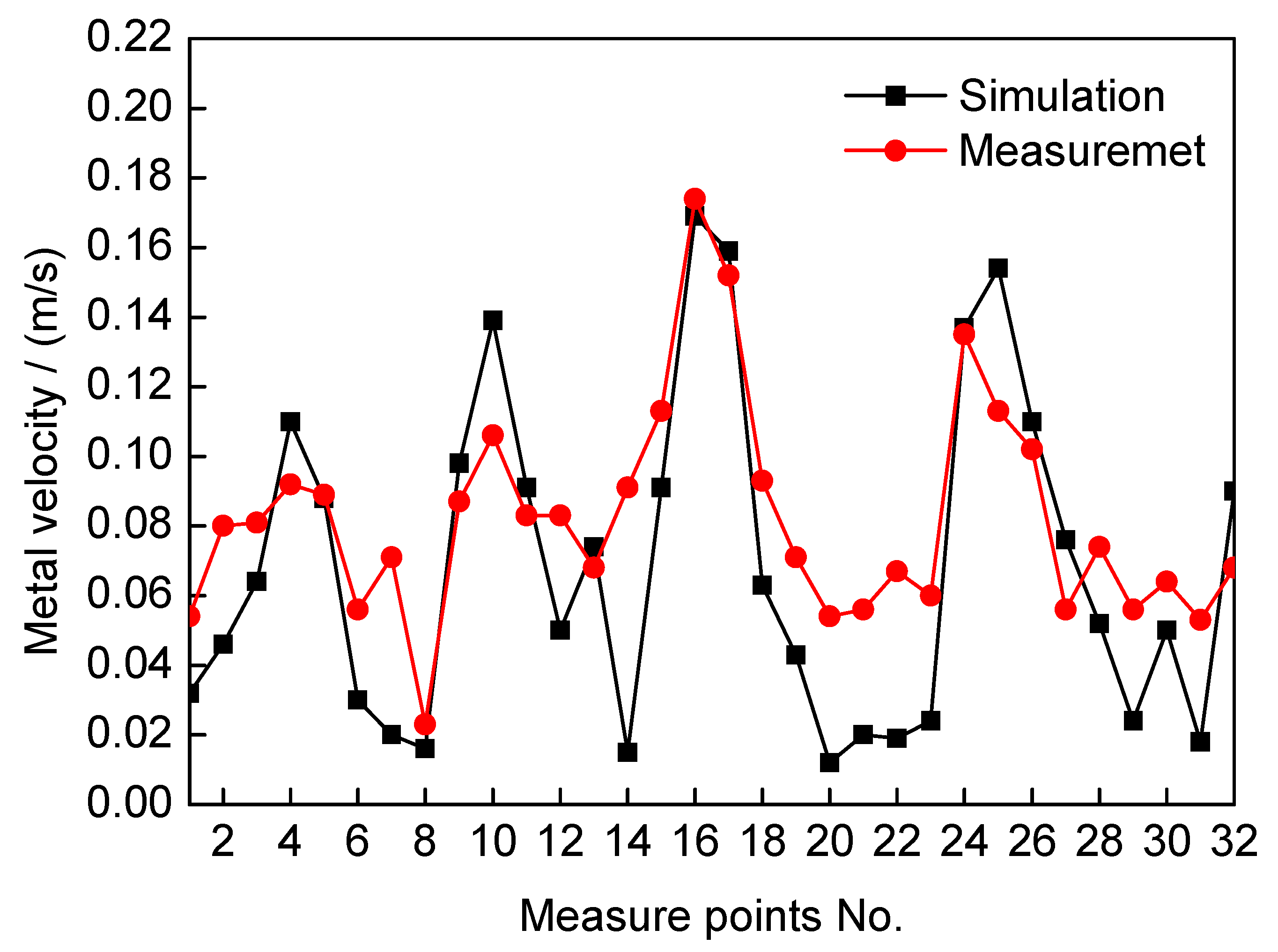

3.2. Model Validation

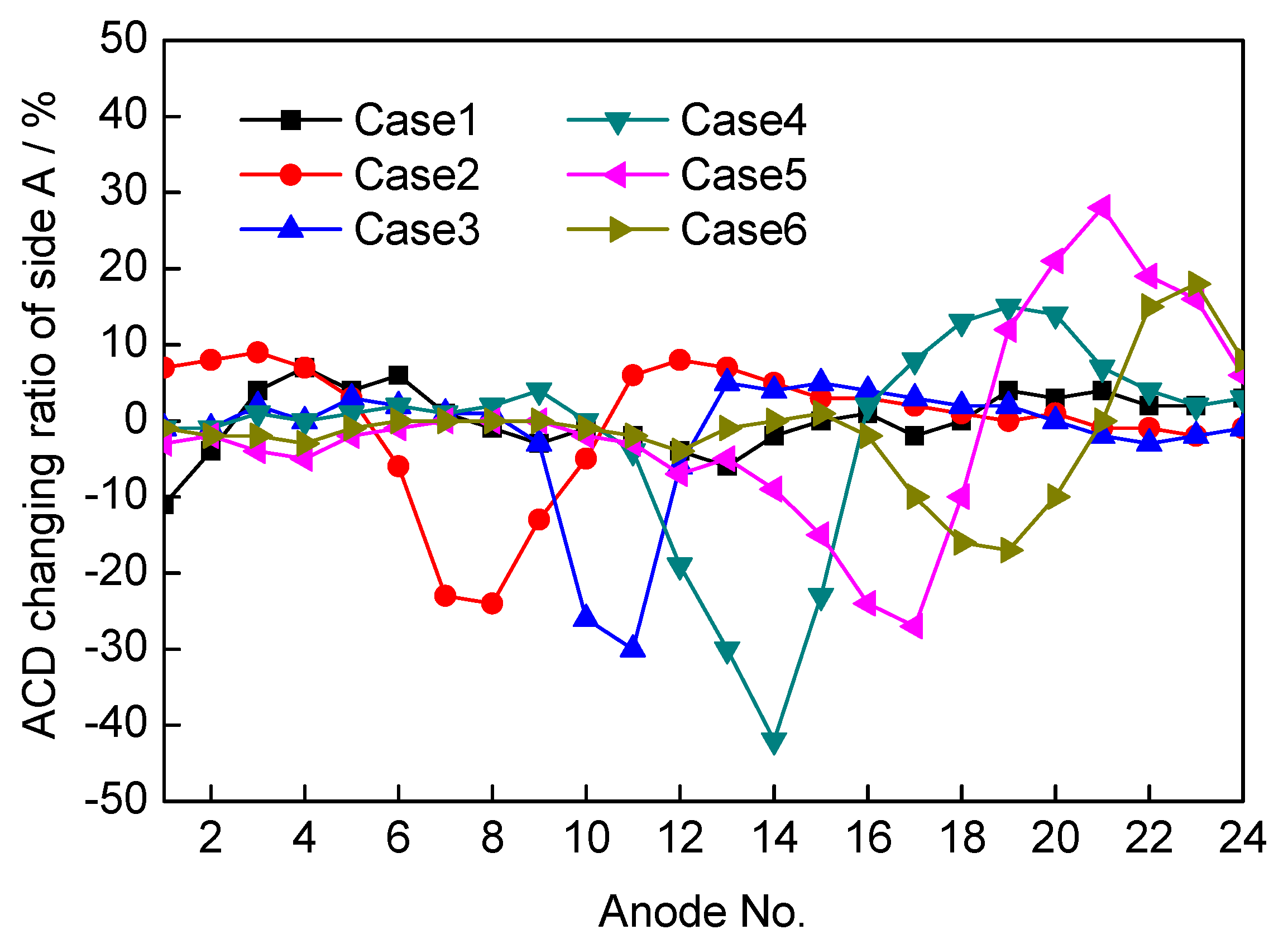

3.3. Simulation for Abnormal State

4. Conclusions

- (1)

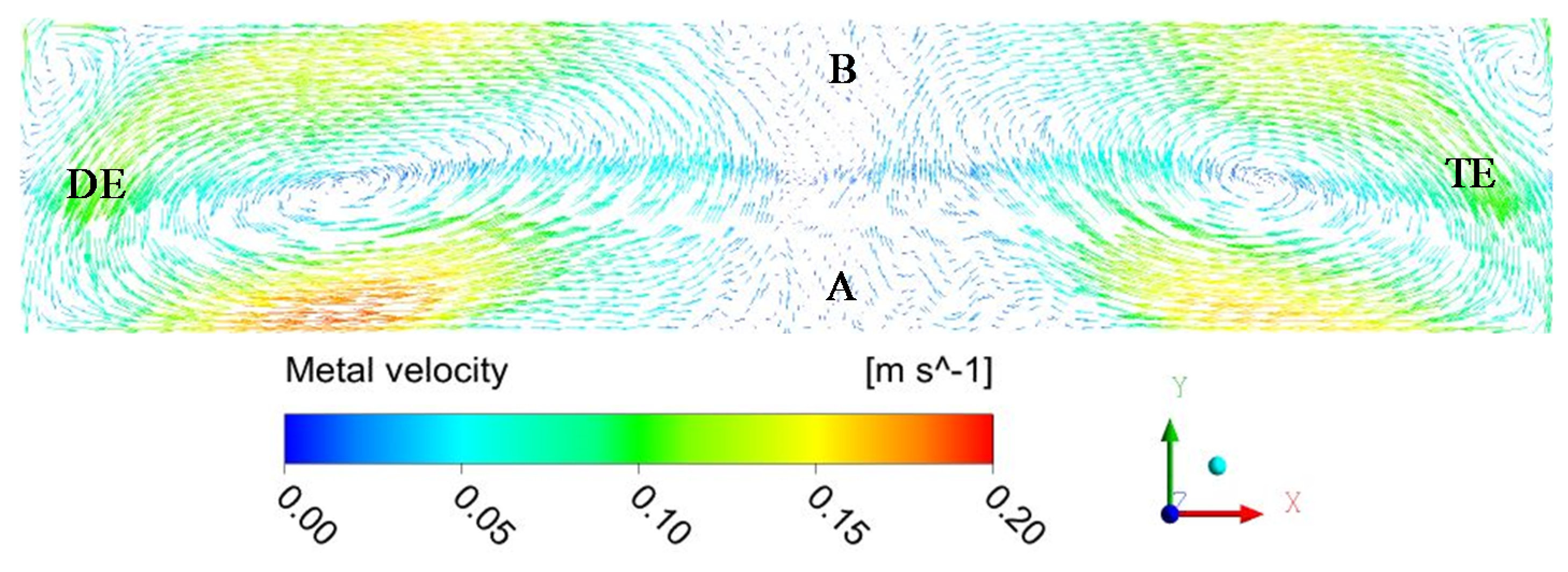

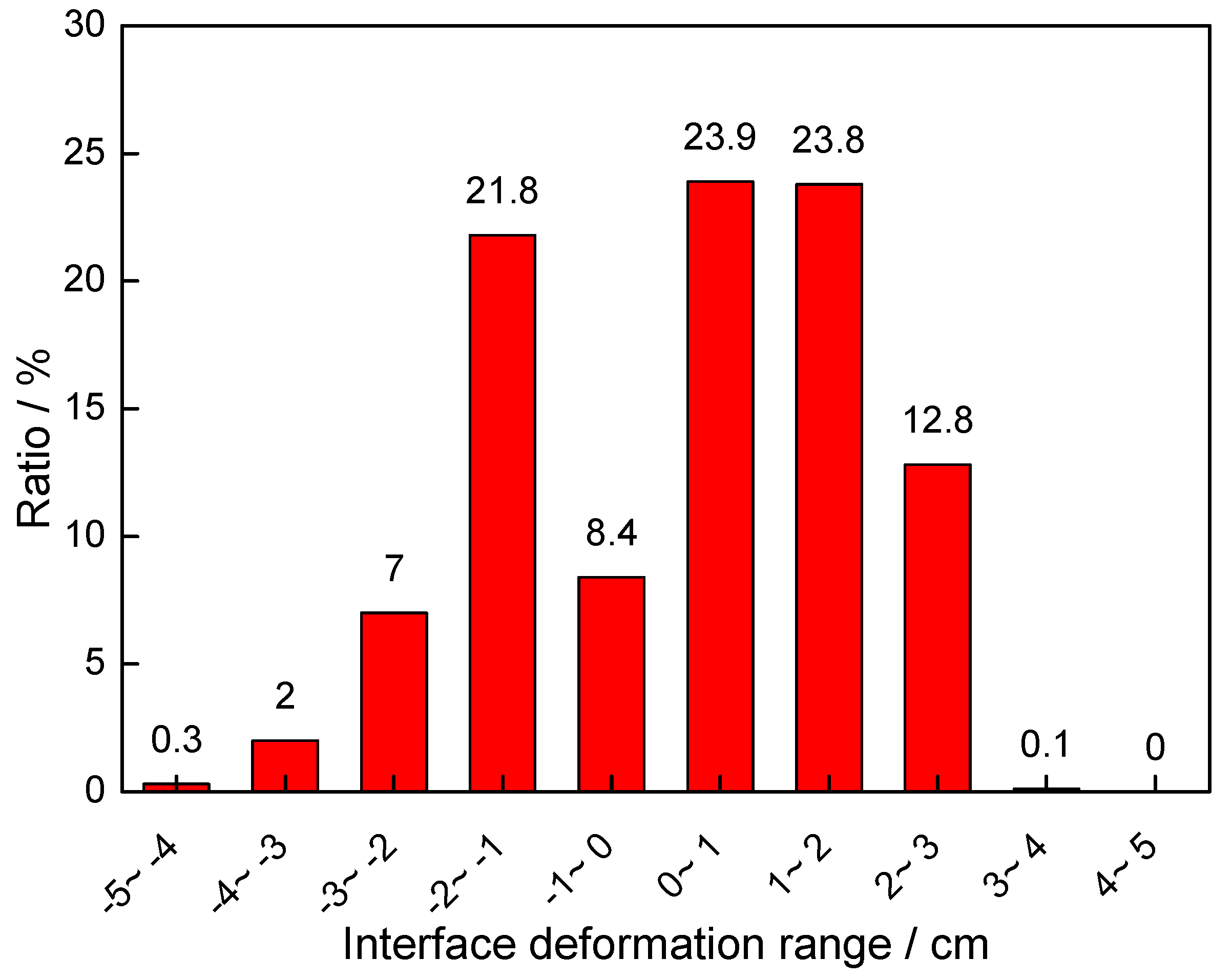

- There are two large vortices for metal velocity field in cell, with a clockwise vortex in the TE side, and a counter clockwise vortex in the DE side. Meanwhile, the metal velocity on side A is larger than on side B. There are interface depressions both on side A and two ends of the cell, but an interface hump on the center of side B. The metal velocity and interface deformation measurements show good agreement with the simulation results.

- (2)

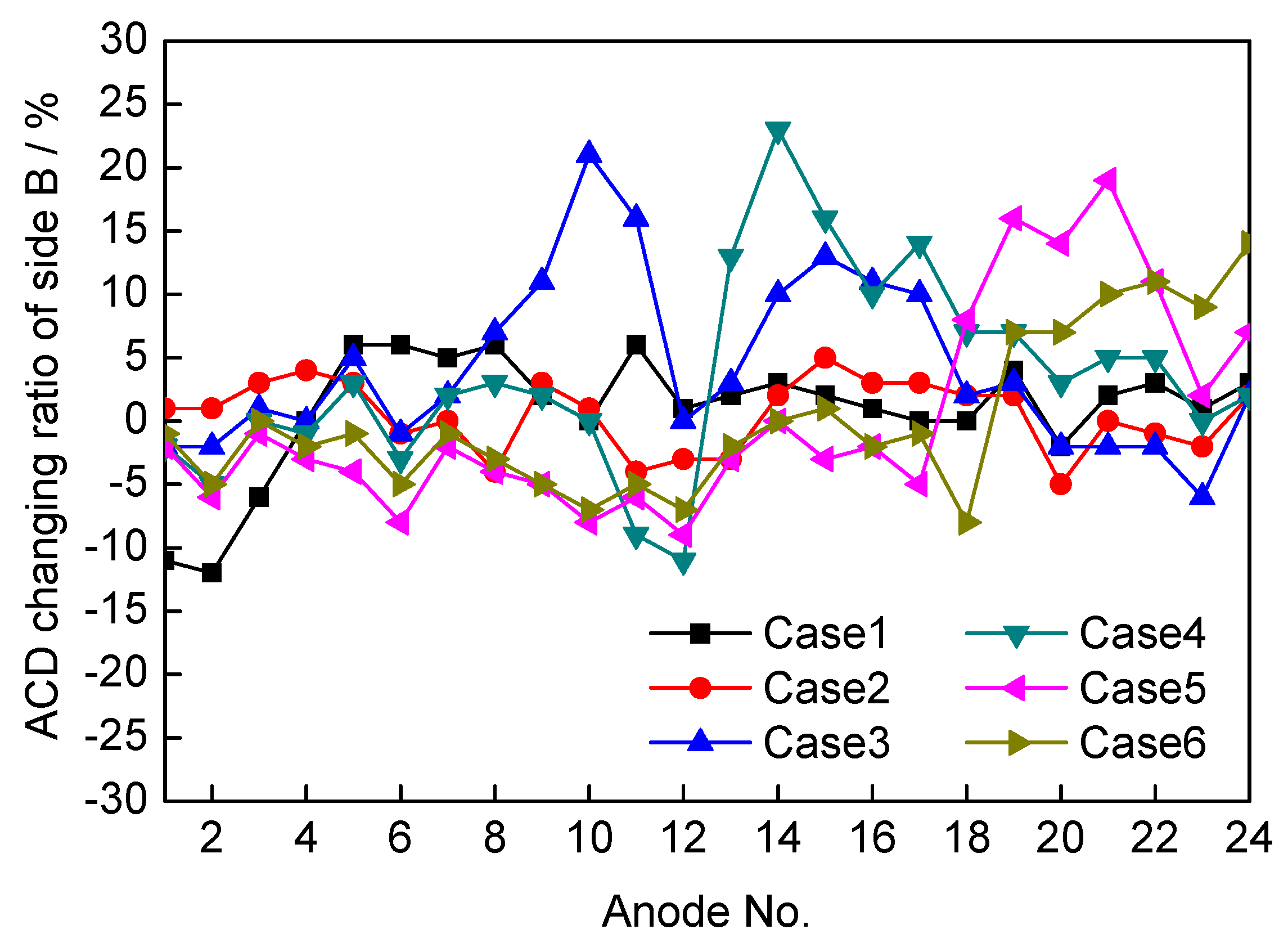

- The LCEC could not affect the overall tendency of the melt flow field; however, it could change the amplitude of the local metal velocity and interface deformation to a certain extent. It is helpful to suppress the interface hump on original low ACD zone if cutting off cathode electric on A2A3 and A10A11, with ACD average improvement of 3% and 7.5%, respectively. However, this could deteriorate the interface stability if cutting off the cathode electric on A18A19 and A22A23, with the ACD average decreasing 4% and 3%, respectively. Thus, it would be better to choose different treatments if the excessive current of local cathodes exists in different positions. Meanwhile, the cathode flexes in abnormal positions should be partially cut off step by step, and the number of cathode flex cut-offs should be determined by simulation.

- (3)

- The quantitative evaluation of MHD stability under abnormal states has certain guiding significance for the safety operation and management of 500 kA potlines. Compared with the uniform distribution of cathode current, the differential distribution of cathode current design may help to suppress the interface deformation and improve ACD distribution for cells.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| LCEC | Local cathode electrical cut-off |

| ACD | Anode cathode distance |

| MHD | Magnetohydrodynamics |

| VOF | Volume of fluid |

| TE | Tapping end |

| DE | Duct end |

| PTM | Pot tending machine |

| b | Bath |

| m | Metal |

References

- Urata, N.; Arita, Y.; Ikeuchi, H. Magnetic field and flow pattern of liquid aluminum in the reduction cells. In Proceedings of the TMS Light Metals, New York, NY, USA, 23–27 February 1975; pp. 233–250. [Google Scholar]

- Mori, K.; Shiota, K.; Urata, N.; Ikeuchi, H. The surface oscillation of liquid metal in aluminum reduction cells. In Proceedings of the TMS Light Metals, Las Vegas, NV, USA, 22–26 February 1976; pp. 77–95. [Google Scholar]

- Arita, Y.; Ikeuchi, H. Numerical calculation of bath and metal convection patterns and their interface profile in reduction cells. In Proceedings of the TMS Light Metals, Chicago, IL, USA, 22–26 February 1981; pp. 357–371. [Google Scholar]

- Moreau, R.; Evans, J.W. Analysis of the hydrodynamics of aluminum reduction cells. J. Electrochem. Soc. 1984, 131, 2251–2259. [Google Scholar] [CrossRef]

- Moreau, R.; Evans, J.W. The Moreau-Evans hydrodynamic model applied to actual Hall-Héroult cells. Metall. Trans. B 1988, 19, 737–744. [Google Scholar] [CrossRef]

- Zikanov, O.; Thess, A.; Davidson, P.A.; Ziegler, D.P. A new approach to numerical simulation of melt flow and interface instability in hall-heroult cells. Metall. Mater. Trans. B 2000, 31, 1541–1550. [Google Scholar] [CrossRef]

- Tarapore, E.D. Magnetic fields in aluminum reduction cells and their influence on metal pad circulation. In Proceedings of the TMS Light Metals, New York, NY, USA, 18–22 February 1979; pp. 541–550. [Google Scholar]

- Potocnik, V.; Laroche, F. Comparison of measured and calculated metal pad velocities for different prebake cell designs. In Proceedings of the TMS Light Metals, New Orleans, LA, USA, 11–15 February 2001; pp. 419–425. [Google Scholar]

- Severo, D.S.; Gusberti, V.; Schneider, A.F.; Pinto, E.V.; Potocnik, V. Comparison of various methods for modeling the metal-bath interface. In Proceedings of the TMS Light Metals, New Orleans, LA, USA, 9–13 March 2008; pp. 413–418. [Google Scholar]

- Bojarevics, V.; Sira, S. MHD stability for irregular and disturbed aluminum reduction cells. In Proceedings of the TMS Light Metals, San Diego, CA, USA, 16–20 February 2014; pp. 685–690. [Google Scholar]

- Dupuis, M.; Bojarevics, V. Influence of the cathode surface geometry on the metal pad current density. In Proceedings of the TMS Light Metals, San Diego, CA, USA, 16–20 February 2014; pp. 479–484. [Google Scholar]

- Severo, D.S.; Schneider, A.F.; Pinto, E.C.V.; Gusberti, V.; Potocnik, V. Modeling magneto-hydrodynamics of aluminum electrolysis cells with ANSYS and CFX. In Proceedings of the TMS Light Metals, San Francisco, CA, USA, 13–17 February 2005; pp. 475–480. [Google Scholar]

- Zhou, P.; Mei, C.; Zhou, N.; Jiang, C.; Cai, Q. Comparison of three turbulent model predictions of metal flow in aluminum reduction cells and industrial measurements (in Chinese). Acta Metall. Sin. 2004, 1, 77–82. [Google Scholar]

- Liu, W.; Zhou, D.; Liu, Y.; Liu, M.; Yang, X. Simulation and measurements on the flow field of 600kA aluminum reduction pot. In Proceedings of the TMS Light Metals, Orlando, FL, USA, 15–19 March 2015; pp. 479–482. [Google Scholar]

- He, Z.; Xia, T.; Xiong, W.; Shen, Q.; Li, B. Mathematical models for the novel cathode convexes in a reduction cell. J. Metall. 2013, 2013. [Google Scholar] [CrossRef]

- Wang, Q.; Li, B.; He, Z.; Feng, N. Simulation of magnetohydrodynamic multiphase flow phenomena and interface fluctuation in aluminum electrolytic cell with innovative cathode. Metall. Mater. Trans. B 2014, 45, 272–294. [Google Scholar] [CrossRef]

- Hua, J.S.; Rudshaug, M.; Droste, C.; Jorgensen, R.; Giskeodegard, N. Numerical simulation of multiphase magnetohydrodynamic flow and deformation of electrolyte-metal interface in aluminum electrolysis cells. Metall. Mater. Trans. B 2018, 49, 1246–1266. [Google Scholar] [CrossRef]

- Song, Y.; Peng, J.; Di, Y.; Wang, Y.; Feng, N. The impact of cathode material and shape on current density in an aluminum electrolysis cell. JOM 2016, 68, 593–599. [Google Scholar] [CrossRef]

- Song, Y.; Peng, J.; Di, Y.; Wang, Y.; Feng, N. Performance of the cathodes with trapezoidal protrusions in aluminum electrolysis cells. JOM 2017, 69, 2844–2850. [Google Scholar] [CrossRef]

- Song, Y.; Peng, J.; Di, Y.; Wang, Y.; Feng, N. Metal flow performance in aluminum electrolytic cells with different side-wall types. Can. Metall. Q. 2018, 57, 253–261. [Google Scholar] [CrossRef]

- Dupuis, M. Modeling gravity waves in an aluminum reduction cell with OpernFOAM. In Proceedings of the TMS Light Metals, Nashville, TN, USA, 14–18 February 2016; pp. 909–914. [Google Scholar]

- Liu, W.; Zhou, D.; Zhao, Z.B. Progress in application of energy-saving measures in aluminum reduction cells. JOM 2019, 71, 2420–2429. [Google Scholar] [CrossRef]

- Bazhin, V.U.; Smol’nikov, A.D.; Petrov, P.A. Concept of energy efficiency aluminum production «ELECTROLYSIS 600+». Int. Res. J. 2016, 47, 37–40. [Google Scholar] [CrossRef]

- Rene, G.; Andre, C.; Olivier, M.; Bertrand, A.; Andre, M.; Francois, C. Preparation and start-up of ARVIDA smelter, AP60 technological center. In Proceedings of the TMS Light Metals, San Diego, CA, USA, 16–20 February 2014; pp. 797–801. [Google Scholar]

- Feng, Y.; Schwarz, M.P.; Yang, W.; Cooksey, M. Two-phase CFD model of the bubble-driven flow in the molten electrolyte layer of a hall-heroult aluminum cell. Metall. Mater. Trans. B 2015, 46, 1959–1981. [Google Scholar] [CrossRef]

- Bradley, B.F.; Dewing, E.W.; Rogers, J.N. Metal pad velocity measurements by the iron rod method. In Proceedings of the TMS Light Metals, New York, NY, USA, 24–28 February 1985; pp. 541–552. [Google Scholar]

| Phase | Density | Viscosity | Conductivity |

|---|---|---|---|

| kg·m−3 | Pa·s | S·m−1 | |

| Metal | 2.30 × 103 | 1.18 × 10−3 | 4.17 × 106 |

| Bath | 2.13 × 103 | 2.51 × 10−3 | 0.23 × 103 |

| Case No. | Location | Metal Velocity (m/s) | Interface Deformation (m) | ||

|---|---|---|---|---|---|

| Max | Ave | Min | Max | ||

| Case1 | A2A3 | 0.195 | 0.071 | −0.048 | 0.033 |

| Case2 | A6A7 | 0.191 | 0.067 | −0.047 | 0.031 |

| Case3 | A10A11 | 0.196 | 0.073 | −0.045 | 0.030 |

| Case4 | A14A15 | 0.198 | 0.069 | −0.046 | 0.032 |

| Case5 | A18A19 | 0.186 | 0.069 | −0.053 | 0.033 |

| Case6 | A22A23 | 0.175 | 0.068 | −0.054 | 0.032 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, F.; Zhang, Q.; Liu, W.; Yang, Y.; Wang, Z. Impact of Local Cathode Electrical Cut-Off on Bath–Metal Two-Phase Flow in an Aluminum Reduction Cell. Metals 2020, 10, 110. https://doi.org/10.3390/met10010110

Wang F, Zhang Q, Liu W, Yang Y, Wang Z. Impact of Local Cathode Electrical Cut-Off on Bath–Metal Two-Phase Flow in an Aluminum Reduction Cell. Metals. 2020; 10(1):110. https://doi.org/10.3390/met10010110

Chicago/Turabian StyleWang, Fuqiang, Qinsong Zhang, Wei Liu, Youjian Yang, and Zhaowen Wang. 2020. "Impact of Local Cathode Electrical Cut-Off on Bath–Metal Two-Phase Flow in an Aluminum Reduction Cell" Metals 10, no. 1: 110. https://doi.org/10.3390/met10010110

APA StyleWang, F., Zhang, Q., Liu, W., Yang, Y., & Wang, Z. (2020). Impact of Local Cathode Electrical Cut-Off on Bath–Metal Two-Phase Flow in an Aluminum Reduction Cell. Metals, 10(1), 110. https://doi.org/10.3390/met10010110