Evaluation of the Effects of Drying Techniques on the Physical and Nutritional Characteristics of Cricket (Gryllus bimaculatus) Powder for Use as Animal Feedstuff

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Collection

2.2. Physical Characteristic Measurement

2.2.1. Bulk Density

2.2.2. Angle of Repose

2.2.3. Color Parameter

2.2.4. Particle Size and Distribution

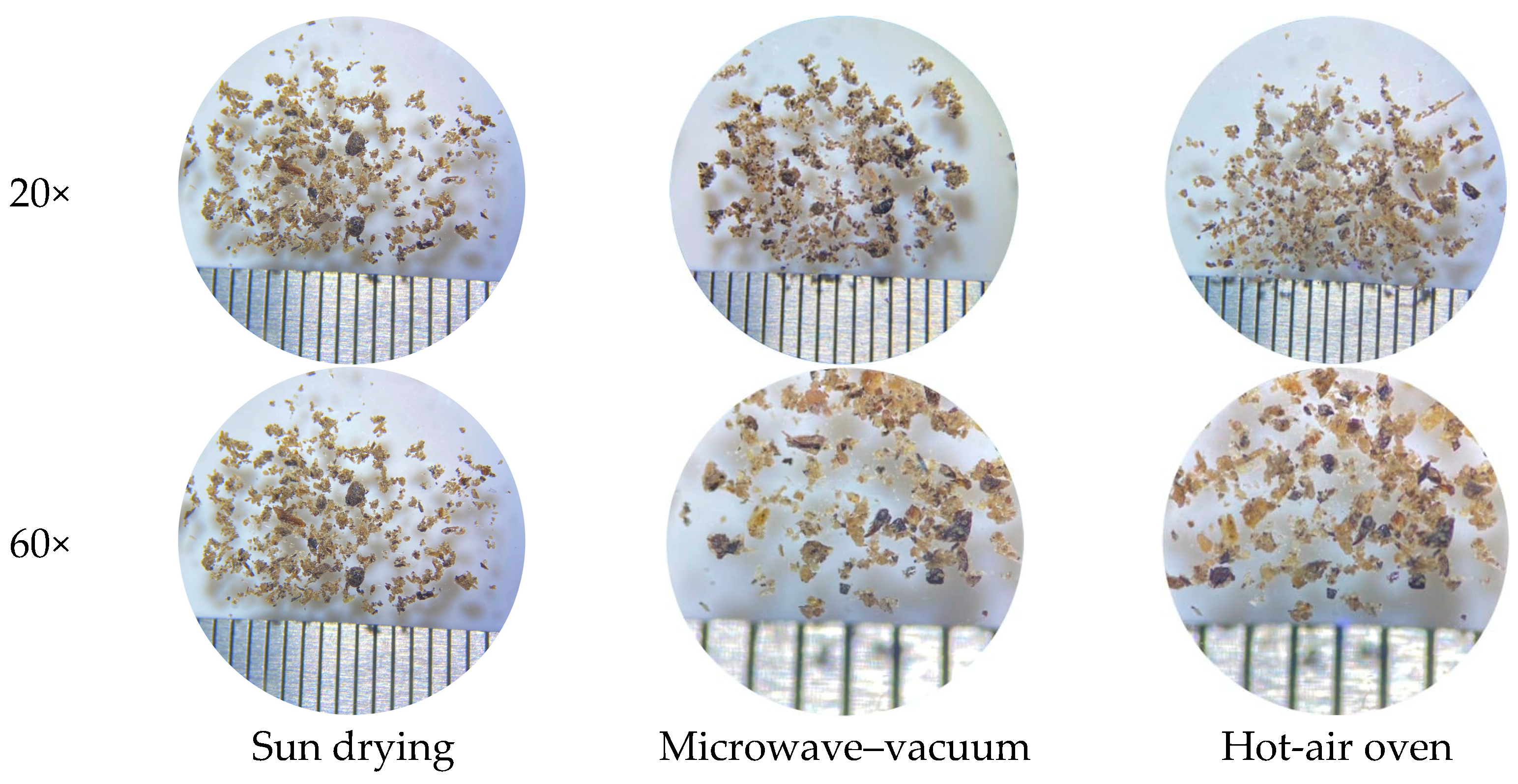

2.2.5. Microscopic Characterization

2.3. Chemical Composition

2.3.1. Chemical Compositions

2.3.2. Amino Acid Profiles

2.4. Manufacturing Costs

2.5. Statistical Analysis

3. Results

3.1. Physical Characteristics

3.1.1. Bulk Density, Angle of Repose, and Color

3.1.2. Particle Size and Distribution

3.1.3. Microscopic Characterization

3.2. Chemical Compositions

3.2.1. Chemical Compositions

3.2.2. Amino Acid Profiles

3.3. Manufacturing Costs

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Van Huis, A. Potential of insects as food and feed in assuring food security. Annu. Rev. Entomol. 2013, 58, 563–583. [Google Scholar] [CrossRef]

- Ruggeri, M.; Bianchi, E.; Vigani, B.; Sánchez-Espejo, R.; Spano, M.; Totaro Fila, C.; Mannina, L.; Viseras, C.; Rossi, S.; Sandri, G. Nutritional and functional properties of novel Italian spray-dried cricket powder. Antioxidants 2023, 12, 112. [Google Scholar] [CrossRef] [PubMed]

- Mekonnen, M.M.; Hoekstra, A.Y. A global assessment of the water footprint of farm animal products. Ecosystems 2012, 15, 401–415. [Google Scholar] [CrossRef]

- Dobermann, D.; Swift, J.A.; Field, L.M. Opportunities and hurdles of edible insects for food and feed. Nutr. Bull. 2017, 42, 293–308. [Google Scholar] [CrossRef]

- Mottet, A.; de Haan, C.; Falcucci, A.; Tempio, G.; Opio, C.; Gerber, P. Livestock: On our plates or eating at our table? A new analysis of the feed/food debate. Glob. Food Secur. 2017, 14, 1–8. [Google Scholar] [CrossRef]

- Loypimai, P.; Moontree, T.; Pranil, T.; Moongngarm, A. A comparative study of nutritional components of Gryllus bimaculatus and Acheta domesticus cricket powder prepared using different drying methods. J. Food Meas. Charact. 2024, 18, 3974–3983. [Google Scholar] [CrossRef]

- Montowska, M.; Kowalczewski, P.Ł.; Rybicka, I.; Fornal, E. Nutritional value, protein and peptide composition of edible cricket powders. Food Chem. 2019, 289, 130–138. [Google Scholar] [CrossRef]

- Rumpold, B.A.; Schlüter, O.K. Nutritional composition and safety aspects of edible insects. Mol. Nutr. Food Res. 2013, 57, 802–823. [Google Scholar] [CrossRef]

- Fisher, H.J.; Empey, M.; MacIsaac, J.L.; Rathgeber, B.R.; Mason, B.; Colombo, S.M.; Collins, S.A. The effects of cricket meal (Gryllus sigillatus) on the meat quality, growth, and internal morphology of broiler chickens. Can. J. Anim. Sci. 2024, 104, 285–300. [Google Scholar] [CrossRef]

- Boontiam, W.; Hong, J.; Kitipongpysan, S.; Wattanachai, S. Full-fat field cricket (Gryllus bimaculatus) as a substitute for fish meal and soybean meal for weaning piglets: Effects on growth performance, intestinal health, and redox status. J. Anim. Sci. 2022, 100, skac080. [Google Scholar] [CrossRef] [PubMed]

- Phesatcha, B.; Phesatcha, K.; Viennaxay, B.; Matra, M.; Totakul, P.; Wanapat, M. Cricket meal (Gryllus bimaculatus) as a protein supplement on in vitro fermentation characteristics and methane mitigation. Insects 2022, 13, 129. [Google Scholar] [CrossRef]

- Kröncke, N.; Grebenteuch, S.; Keil, C.; Demtröder, S.; Kroh, L.; Thünemann, A.F.; Benning, R.; Haase, H. Effect of different drying methods on nutrient quality of the yellow mealworm (Tenebrio molitor L.). Insects 2019, 10, 84. [Google Scholar] [CrossRef]

- Huang, C.; Zang, J.; Song, P.; Fan, P.; Chen, J.; Liu, D.; He, P.; Ma, X. Effects of particle size and drying methods of corn on growth performance, digestibility and haematological and immunological characteristics of weaned piglets. Arch. Anim. Nutr. 2015, 69, 30–45. [Google Scholar] [CrossRef]

- Pornsuwan, R.; Pootthachaya, P.; Bunchalee, P.; Hanboonsong, Y.; Cherdthong, A.; Tengjaroenkul, B.; Boonkum, W.; Wongtangtintharn, S. Evaluation of the physical characteristics and chemical properties of black soldier fly (Hermetia illucens) larvae as a potential protein source for poultry feed. Animals 2023, 13, 2244. [Google Scholar] [CrossRef] [PubMed]

- Tanpong, S.; Cherdthong, A.; Tengjaroenkul, B.; Tengjaroenkul, U.; Wongtangtintharn, S. Evaluation of physical and chemical properties of citric acid industrial waste. Trop. Anim. Health Prod. 2019, 105, 323–331. [Google Scholar] [CrossRef] [PubMed]

- Purschke, B.; Brüggen, H.; Scheibelberger, R.; Jäger, H. Effect of pre-treatment and drying method on physico-chemical properties and dry fractionation behaviour of mealworm larvae (Tenebrio molitor L.). Eur. Food Res. Technol. 2018, 244, 269–280. [Google Scholar] [CrossRef]

- Khatun, H.; Claes, J.; Smets, R.; De Winne, A.; Akhtaruzzaman, M.; Van Der Borght, M. Characterization of freeze-dried, oven-dried and blanched house crickets (Acheta domesticus) and Jamaican field crickets (Gryllus assimilis) by means of their physicochemical properties and volatile compounds. Eur. Food Res. Technol. 2021, 247, 1291–1305. [Google Scholar] [CrossRef]

- Oryza, S.M.; Wongtangtintharn, S.; Tengjaroenkul, B.; Cherdthong, A.; Tanpong, S.; Bunchalee, P.; Pootthachaya, P.; Reungsang, A.; Polyorach, S. Physico-chemical characteristics and amino acid content evaluation of citric acid by-product produced by microbial fermentation as a potential use in animal feed. Fermentation 2021, 7, 149. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 20th ed.; Association of Official Analytical Chemists: Rockville, MD, USA, 2016; Available online: http://www.eoma.aoac.org/app_f.pdf (accessed on 28 May 2025).

- Murugu, D.K.; Onyango, A.N.; Ndiritu, A.K.; Osuga, I.M.; Xavier, C.; Nakimbugwe, D.; Tanga, C.M. From farm to fork: Crickets as alternative source of protein, minerals, and vitamins. Front. Nutr. 2021, 8, 723321. [Google Scholar] [CrossRef]

- Alam, M.S.; Sarker, M.S.H.; Hasan, S.M.K.; Ahmed, M.; Wazed, M.A. Comparison on drying characteristic, efficiency, unit drying cost and quality of maize dried by a novel multi-crop mobile dryer, existing industrial dryer and sun drying method. J. Agric. Food Res. 2023, 14, 100804. [Google Scholar] [CrossRef]

- SAS Institute. Statistical Analysis Software (SAS) User’s Guide Version 9.4; SAS Institute, Inc.: Cary, NC, USA, 2016. [Google Scholar]

- Bawa, M.; Songsermpong, S.; Kaewtapee, C.; Chanput, W. Effects of microwave and hot air oven drying on the nutritional, microbiological load, and color parameters of the house crickets (Acheta domesticus). J. Food Process. Preserv. 2020, 44, e14407. [Google Scholar] [CrossRef]

- Moss, A.F.; Chrystal, P.V.; Crowley, T.M.; Pesti, G.M. Raw material nutrient variability has substantial impact on the potential profitability of chicken meat production. J. Appl. Poult. Res. 2021, 30, 100129. [Google Scholar] [CrossRef]

- Al-Hashemi, H.M.B.; Al-Amoudi, O.S.B. A review on the angle of repose of granular materials. Powder Technol. 2018, 330, 397–417. [Google Scholar] [CrossRef]

- Bhadra, R.; Casada, M.E.; Thompson, S.A.; Boac, J.M.; Maghirang, R.G.; Montross, M.D.; Turner, A.; McNeill, S.G. Field-observed angles of repose for stored grain in the United States. Appl. Eng. Agric. 2017, 33, 131–137. [Google Scholar] [CrossRef]

- Gantner, M.; Sadowska, A.; Piotrowska, A.; Kulik, K.; Sionek, B.; Kostyra, E. Wheat bread enriched with house cricket powder (Acheta domesticus L.) as an alternative protein source. Molecules 2024, 29, 711. [Google Scholar] [CrossRef] [PubMed]

- Lenaerts, S.; Van Der Borght, M.; Callens, A.; Van Campenhout, L. Suitability of microwave drying for mealworms (Tenebrio molitor) as alternative to freeze drying: Impact on nutritional quality and colour. Food Chem. 2018, 254, 129–136. [Google Scholar] [CrossRef]

- Azzollini, D.; Derossi, A.; Severini, C. Understanding the drying kinetic and hygroscopic behaviour of larvae of yellow mealworm (Tenebrio molitor) and the effects on their quality. J. Insects Food Feed. 2016, 2, 233–244. [Google Scholar] [CrossRef]

- Lee, J.H.; Kim, T.K.; Park, S.Y.; Kang, M.C.; Yoon, J.; Lim, M.C.; Choi, Y.S. Effects of blanching methods on nutritional properties and physicochemical characteristics of hot-air dried edible insect larvae. Korean J. Food Sci. Anim. Resour. 2023, 43, 428–440. [Google Scholar] [CrossRef] [PubMed]

- Monteiro, R.L.; Link, J.V.; Tribuzi, G.; Carciofi, B.A.M.; Laurindo, J.B. Microwave vacuum drying and multi-flash drying of pumpkin slices. J. Food Eng. 2018, 232, 1–10. [Google Scholar] [CrossRef]

- Teleken, J.T.; Quadri, M.B.; Oliveira, A.P.N.; Laurindo, J.B.; Datta, A.K.; Carciofi, B.A.M. Mechanistic understanding of microwave-vacuum drying of non-deformable porous media. Dry. Technol. 2021, 39, 850–867. [Google Scholar] [CrossRef]

- Hernández-Álvarez, A.J.; Mondor, M.; Piña-Domínguez, I.A.; Sánchez-Velázquez, O.A.; Melgar Lalanne, G. Drying technologies for edible insects and their derived ingredients. Dry. Technol. 2021, 39, 1991–2009. [Google Scholar] [CrossRef]

- Bogusz, R.; Nowacka, M.; Bryś, J.; Rybak, K.; Szulc, K. Quality assessment of yellow mealworm (Tenebrio molitor L.) powders processed by pulsed electric field and convective drying. Sci. Rep. 2024, 14, 27792. [Google Scholar] [CrossRef]

- Opaliński, I.; Chutkowski, M.; Stasiak, M. Characterizing moist food-powder flowability using a Jenike shear-tester. J. Food Eng. 2012, 108, 51–58. [Google Scholar] [CrossRef]

- Jung, H.; Lee, Y.J.; Yoon, W.B. Effect of moisture content on the grinding process and powder properties in food: A review. Processes 2018, 6, 69. [Google Scholar] [CrossRef]

- Udomsil, N.; Imsoonthornruksa, S.; Gosalawit, C.; Ketudat-Cairns, M. Nutritional values and functional properties of House cricket (Acheta domesticus) and Field cricket (Gryllus bimaculatus). Food Sci. Technol. Res. 2019, 25, 597–605. [Google Scholar] [CrossRef]

- Kamau, E.; Mutungi, C.; Kinyuru, J.; Imathiu, S.; Tanga, C.; Affognon, H.; Ekesi, S.; Nakimbugwe, D.; Fiaboe, K.K.M. Moisture adsorption properties and shelf-life estimation of dried and pulverised edible house cricket Acheta domesticus (L.) and black soldier fly larvae Hermetia illucens (L.). Food Res. Int. 2018, 106, 420–427. [Google Scholar] [CrossRef] [PubMed]

- Son, J.; Park, S.H.; Jung, H.J.; You, S.J.; Kim, B.G. Effects of drying methods and blanching on nutrient utilization in black soldier fly larva meals based on in vitro assays for pigs. Animals 2023, 13, 858. [Google Scholar] [CrossRef]

- Selaledi, L.; Mabelebele, M. The influence of drying methods on the chemical composition and body color of yellow mealworm (Tenebrio molitor L.). Insects 2021, 12, 333. [Google Scholar] [CrossRef] [PubMed]

- Ritvanen, T.; Pastell, H.; Welling, A.; Raatikainen, M. The nitrogen-to-protein conversion factor of two cricket species-Acheta domesticus and Gryllus bimaculatus. Agric. Food Sci. 2020, 29, 1–5. [Google Scholar] [CrossRef]

- Mustafa, F.; Sajjad, A.; Sajjad, M.; Ali, M.; Bashir, H.S.; Abbas, M.G.; Binyameen, M.; Mozūratis, R. Comparative evaluation of Acheta domesticus and Hermetia illucens as alternative protein sources for the growth, health, and meat quality of the broiler. Front. Anim. Sci. 2025, 6, 1531761. [Google Scholar] [CrossRef]

- Wang, D.; Zhai, S.W.; Zhang, C.X.; Bai, Y.Y.; An, S.H.; Xu, Y.N. Evaluation on nutritional value of field crickets as a poultry feedstuff. Asian-Australas. J. Anim. Sci. 2005, 18, 667–670. [Google Scholar] [CrossRef]

- Makkar, H.P.; Tran, G.; Heuzé, V.; Ankers, P. State-of-the-art on use of insects as animal feed. Anim. Feed. Sci. Technol. 2014, 197, 1–33. [Google Scholar] [CrossRef]

| Parameters | Drying Methods | SEM | p-Value | ||

|---|---|---|---|---|---|

| Sun Drying | Microwave–Vacuum | Hot-Air Oven | |||

| Bulk density (g/L) | 462.35 | 453.89 | 443.30 | 12.29 | 0.06 |

| Angle of repose (o) | 43.40 | 45.10 | 44.70 | 0.87 | 0.12 |

| Color | |||||

| L* | 41.98 b | 44.07 a | 41.77 b | 0.59 | <0.01 |

| a* | 14.20 a | 10.38 b | 12.73 a | 0.96 | <0.01 |

| b* | 8.91 b | 9.66 a | 8.45 b | 0.42 | 0.01 |

| Browning index (BI) | 47.51 a | 41.36 b | 44.00 b | 1.74 | <0.01 |

| Sieve Mesh No. | Sieve Size (µm) | Sample (g) | Retain (%) | SEM | p-Value | Cumulative (%) | Passing (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sun Drying | Microwave–Vacuum | Hot-Air Oven | Sun Drying | Microwave–Vacuum | Hot-Air Oven | Sun Drying | Microwave–Vacuum | Hot-Air Oven | Sun Drying | Microwave–Vacuum | Hot-Air Oven | ||||

| 20 | 850 | 37.46 | 42.02 | 35.94 | 37.41 ab | 41.94 a | 35.90 b | 2.45 | 0.04 | 37.41 | 41.94 | 35.90 | 62.59 | 58.06 | 64.10 |

| 40 | 425 | 55.64 | 52.62 | 57.08 | 55.56 | 52.53 | 57.01 | 1.89 | 0.06 | 92.97 | 94.47 | 92.91 | 7.03 | 5.53 | 7.09 |

| 60 | 250 | 6.00 | 4.68 | 6.04 | 5.99 a | 4.67 b | 6.03 a | 0.51 | 0.02 | 98.96 | 99.14 | 98.94 | 1.04 | 0.86 | 1.06 |

| 80 | 180 | 1.04 | 0.86 | 1.06 | 1.04 | 0.86 | 1.06 | 0.26 | 0.64 | 100.00 | 100.00 | 100.00 | 0.00 | 0.00 | 0.00 |

| 100 | 150 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | - | - | 100.00 | 100.00 | 100.00 | 0.00 | 0.00 | 0.00 |

| Pan | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | - | - | 100.00 | 100.00 | 100.00 | 0.00 | 0.00 | 0.00 | |

| Total | 100.14 | 100.18 | 100.12 | 100.00 | 100.00 | 100.00 | |||||||||

| Parameters | Drying Methods | SEM | p-Value | ||

|---|---|---|---|---|---|

| Sun Drying | Microwave–Vacuum | Hot-Air Oven | |||

| Moisture (%) | 3.73 a | 2.37 b | 1.99 c | 0.05 | <0.01 |

| Ash (%) | 5.24 | 4.61 | 4.81 | 0.44 | 0.39 |

| Crude protein (%) | 55.82 | 54.99 | 54.47 | 0.08 | 0.11 |

| Ether extract (%) | 25.60 | 26.80 | 26.87 | 0.07 | 0.08 |

| Crude fiber (%) | 9.24 | 9.32 | 9.21 | 0.16 | 0.51 |

| Nitrogen-free extract (%) | 4.10 | 4.28 | 4.74 | 0.16 | 0.29 |

| Calcium (%) | 0.11 | 0.19 | 0.10 | 0.04 | 0.23 |

| Phosphorus (%) | 0.01 | 0.01 | 0.01 | 0.00 | 0.16 |

| Gross energy (kcal/kg) | 5897.44 b | 5966.72 ab | 6126.43 a | 123.90 | 0.04 |

| Parameters | Drying Methods | SEM | p-Value | ||

|---|---|---|---|---|---|

| Sun Drying | Microwave–Vacuum | Hot-Air Oven | |||

| Essential amino acids (g/100g) | |||||

| Lysine | 3.28 | 3.49 | 3.52 | 0.44 | 0.77 |

| Valine | 2.21 | 2.60 | 2.61 | 0.51 | 0.57 |

| Leucine | 2.20 | 2.24 | 2.24 | 0.23 | 0.97 |

| Methionine | 0.67 | 0.93 | 0.88 | 0.40 | 0.70 |

| Isoleucine | 1.09 | 1.21 | 1.22 | 0.21 | 0.71 |

| Histidine | 0.04 | 0.08 | 0.06 | 0.03 | 0.42 |

| Threonine | 1.03 | 1.14 | 1.12 | 0.13 | 0.58 |

| Phenylalanine | 1.32 | 1.72 | 1.68 | 0.60 | 0.69 |

| Tryptophan | 0.35 | 0.40 | 0.41 | 0.20 | 0.93 |

| Total essential amino acids | 12.19 | 13.81 | 13.74 | 1.91 | 0.73 |

| Non-essential amino acids (g/100g) | |||||

| Glutamic | 5.35 | 5.55 | 5.57 | 0.48 | 0.87 |

| Glutamine | 1.53 | 1.82 | 1.82 | 0.75 | 0.90 |

| Aspartic | 4.30 | 4.34 | 4.31 | 0.32 | 0.99 |

| Alanine | 2.65 | 2.85 | 2.84 | 0.79 | 0.94 |

| Glycine | 1.49 | 1.58 | 1.58 | 0.58 | 0.98 |

| Proline | 2.85 | 2.75 | 2.86 | 0.82 | 0.98 |

| Serine | 1.34 | 1.28 | 1.36 | 0.33 | 0.95 |

| Arginine | 2.70 | 2.68 | 2.72 | 0.32 | 0.99 |

| Tyrosine | 2.22 | 2.24 | 2.24 | 0.58 | 0.78 |

| Cysteine | 0.41 | 0.41 | 0.43 | 0.77 | 0.67 |

| Total non-essential amino acids | 24.84 | 25.50 | 25.73 | 3.69 | 0.98 |

| Parameters | Drying Methods | ||

|---|---|---|---|

| Sun Drying | Microwave–Vacuum | Hot-Air Oven | |

| Batch size (kg) | 3.00 | 3.00 | 3.00 |

| Drying time (h) | 48.00 | 0.25 | 48.00 |

| Total dried output (kg/batch) | 1.15 | 1.12 | 1.09 |

| Loss rate (%) | 61.67 | 62.67 | 63.67 |

| Electricity cost (USD/kWh) | 0.12 | 0.12 | 0.12 |

| Power rating (kWh) | 0.00 | 0.27 | 0.17 |

| Electricity cost (USD) | 0.00 | 0.16 | 33.45 |

| Labor cost (USD) | 9.17 | 4.59 | 9.17 |

| Equipment maintenance cost (USD/batch) | 0.31 | 4.59 | 1.52 |

| Total cost (USD/batch) | 9.48 | 9.34 | 44.17 |

| Cost per dried weight (USD/kg) | 8.24 | 8.34 | 40.53 |

| Total cost per 300 kg of fresh cricket (USD) | 14.22 | 933.58 | 66.26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Puangsap, W.; Pootthachaya, P.; Oryza, M.; Cherdthong, A.; Chankitisakul, V.; Tengjaroensakul, B.; Phaengphairee, P.; Wongtangtintharn, S. Evaluation of the Effects of Drying Techniques on the Physical and Nutritional Characteristics of Cricket (Gryllus bimaculatus) Powder for Use as Animal Feedstuff. Insects 2025, 16, 814. https://doi.org/10.3390/insects16080814

Puangsap W, Pootthachaya P, Oryza M, Cherdthong A, Chankitisakul V, Tengjaroensakul B, Phaengphairee P, Wongtangtintharn S. Evaluation of the Effects of Drying Techniques on the Physical and Nutritional Characteristics of Cricket (Gryllus bimaculatus) Powder for Use as Animal Feedstuff. Insects. 2025; 16(8):814. https://doi.org/10.3390/insects16080814

Chicago/Turabian StylePuangsap, Warin, Padsakorn Pootthachaya, Mutyarsih Oryza, Anusorn Cherdthong, Vibuntita Chankitisakul, Bundit Tengjaroensakul, Pheeraphong Phaengphairee, and Sawitree Wongtangtintharn. 2025. "Evaluation of the Effects of Drying Techniques on the Physical and Nutritional Characteristics of Cricket (Gryllus bimaculatus) Powder for Use as Animal Feedstuff" Insects 16, no. 8: 814. https://doi.org/10.3390/insects16080814

APA StylePuangsap, W., Pootthachaya, P., Oryza, M., Cherdthong, A., Chankitisakul, V., Tengjaroensakul, B., Phaengphairee, P., & Wongtangtintharn, S. (2025). Evaluation of the Effects of Drying Techniques on the Physical and Nutritional Characteristics of Cricket (Gryllus bimaculatus) Powder for Use as Animal Feedstuff. Insects, 16(8), 814. https://doi.org/10.3390/insects16080814