1. Introduction

Energy is the prime mover for virtually all activities of existence, and it contributes to prosperity and lifts billions of people out of poverty. On the other hand, this leads to a relentless demand for natural resources. Today, energy is an integral catalyst inherent in every social, economic, and environmental aspect of human advancement. Energy serves as an invaluable part of economic prosperity. Energy services contribute to better living and environmental conditions and they aid with social development via public health and education. In addition, energy services are integral to meeting the most fundamental of human needs such food and shelter, as well as making possible the loftiest of human innovation and technology. While energy is a blessing in innumerable ways, there is always a potential downside to everything. Overuse of energy and resources can elevate carbon footprints and greenhouse gas emissions and poor execution of energy resources can be detrimental to extant ecosystems. The intricate interplay between energy use and human development is symbiotic, nuanced, and multifaceted. We will endeavor to unravel this complex relationship in this article.

There have been many attempts, some more successful than others, to bridge the gap between our demand for energy and the pernicious effects that can result from designing machinery and instruments which are still able to meet society’s needs while concurrently decreasing our reliance on fossil fuels for this energy. It is the mission of the designer to endeavor to span this gap between these two divergent polarities, which must find a way to coexist. A main component of achieving this objective is the reduction of wasteful systemic losses through wear and friction, which take a substantial toll on the performance of these machines. Identifying the components of a technology that have the most pronounced effect on the ecosystem is an alternate route to attempt to decrease or completely offset this impact. The development of appropriate lubricant technology is vital to protect machinery from frictional wear and subsequent energy loss. Lubricants are highly functionalized products meeting a multitude of requirements simultaneously. Today, they meet demanding technically oriented specifications. In the future, non-technical criteria, such as eco-toxicological properties and/or sustainability, will be loaded on top of already demanding requirements.

Composed of a wide variety of products, industrial lubricants can possess vastly different physical and chemical properties, depending on their tribological application [

1]. Liquid lubricants, such as petroleum oil, synthetic hydrocarbons, polyglycols, esters, silicones, and phosphate esters, are typically combined with various additives to enhance desirable chemical properties [

2]. Petroleum oil, especially, experiences prominent commercial success as a lubricant due to its availability in a wide viscosity range and good viscosity-pressure characteristics. On the other hand, solid lubricants, such as graphite and molybdenum disulfide, are commonly used under severe circumstances of elevated temperature, heavy load, ultra-low temperature, ultra-high vacuum, strong oxidation, and extreme radiation [

3]. In particular, graphene possesses high chemical inertness, extreme strength, and easy shear capability on its densely packed and atomically smooth surface, which allows for its tribological application to nano-scale or micro-scale systems [

4]. Biolubricant, the primary focus of our discussion, is a classification that applies to all lubricants that are easily biodegradable and non-toxic to the environment and humans. A biolubricant is not considered ecotoxic when the LD

50 (lethal dose), or dosage to kill 50% of a population, is above LD

50 > 2000 mg/kg or LC

50/IC

50 > 1000 mg/l in aquatic milieus [

5]. Biolubricant products either contain naturally occurring vegetable oils/animal fats or synthetic esters derived from chemical modifications and different catalytic processes. Common strategies to modify vegetable oils include transesterification reactions, epoxidation, hydrogenation, and estolides formation, with an emphasis on enhancing physicochemical properties while minimizing production costs [

5].

2. Estimated Energy and Economic Saving Potentials

It is necessary to deal with the frictional and wear losses, durability, reparability, and condition monitoring of the primary components of a mechanical system, but in order to do so it is fundamental to possess a firm grasp of the engineering and science buttressing their operation. Biodegradability is perceived by many as being synonymous to sustainability. This is insufficient. Second, these attributes figure in the Sustainable Development Goals (SDGs) of the United Nations [

6]. This is where the science of tribology comes into play. The potential environmental and economic benefits of tribological analysis are enormous [

7]. The study of tribology can help reduce total worldwide carbon emissions by decreasing friction [

8], extending the use of valuable resources, or reducing wear and thereby improving equipment life.

Table 1 summarizes the economic impact of past findings on the impact of savings through tribology by year. The large significance of tribology as an interdisciplinary science for national economics was pointed out by Sir Peter Jost in 1966 [

9] and highlighted on 31 October 1979 by President Jimmy Carter in the “Industrial Innovation“ initiative, which included tribology (friction, lubrication, and wear) within “generic technologies of economic significance”. The importance of tribology to energy efficiency has even made inroads into US politics. Specifically, resolutions #916 of 28 September 2016 and #306 of 02 May 2017 by the House of Representatives state “the importance of tribology for economic growth and competitiveness of the United States”. See also the excerpts of the citations below:

“Whereas approximately a third of the world’s primary energy consumption is attributed to friction, and about 70 percent of equipment failures is blamed on lubrication breakdown and wear loss;

Whereas reduction of friction is at the very core of improving fuel economy and reducing greenhouse gas emissions; …”.

In 1977, the American Society of Mechanical Engineers estimated savings by friction reduction of 10.9% of primary energy consumption [

10] or in monetary value,

$16.2 billion U.S. at that time. In 1976, the German Federal Ministry of Research and Development estimated economic savings of >2.0% of GDP [

11] by reducing friction and wear losses.

The total costs only for wear, maintenance, repair, and overhaul accounted in the Federal Republic of Germany (FRG) in 1982 for 102 billion € or 11.8% of GDP. These developments were followed by an in-depth overview of the results of a comprehensive two-year study conducted in 2006 by the Chinese Tribology Institution (CTI), which encompassed eight industrial branches and demonstrated conservatively estimated savings of

$41.4 billion per year [

12], or equivalent savings of 1.55% of the Chinese GDP.

It has to be noted that all of the aforementioned studies focused on monetary impacts. In future, the currency for sustainability will be CO2 or CO2 equivalents (CO2eq.) in order to compare and trade human activities.

3. Projected Economic Incentive and Legislation

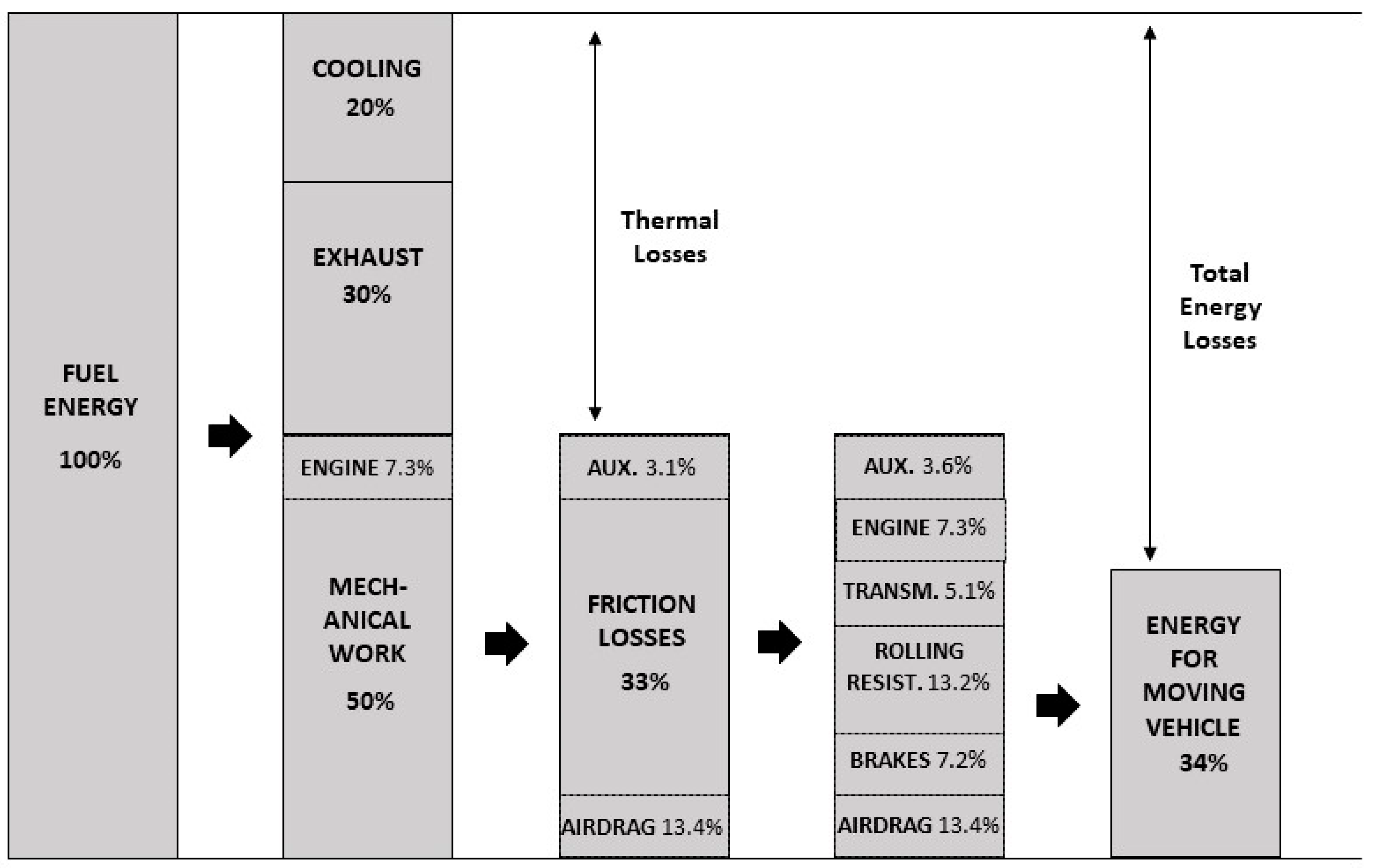

In heavy-duty vehicles, frictional losses in the engine, transmission, and other components comprise a major portion of the vehicles’ energy consumption profile (see

Figure 1). Only 34% of the total energy supplied by a fuel source is utilized to physically move the vehicle, while 66% of that energy is lost to the surroundings, either as thermal losses or through the aforementioned components [

13]. Consequently, the application of tribological knowledge in heavy-duty vehicle manufacturing can have profound fuel efficiency and economic benefits. According to Holmberg (2014), achieving a rolling friction coefficient of approximately 0.01 in heavy-duty vehicle tires within the decade will lead to a 13.8% fuel consumption reduction (2.7 million TJ/a). This equates to global savings of 104,500 million € per year [

8].

Current advancements in tribology focus on the discovery and development of new materials and lubricants to combat frictional and energy losses in transportation, manufacturing, power generation, and the residential sector [

14]. The implementation of modern tribological technology in these four sectors is projected to reduce frictional energy losses by 18% (21.5 EJ) in 8 years and 40% (46 EJ) in 15 years. Correspondingly, this would result in savings of up to 1.4% of GDP annually, and 8.7% of the global energy consumption for 15 years [

14].

The escalating demand for lubricants and increasingly stringent environmental regulations have shifted attention towards the development of biolubricants [

15]. Manufactured from biodegradable and renewable-based feedstocks, biolubricants are commonly utilized in environmentally sensitive areas. The inexhaustible nature of the renewable feedstocks used for biolubricant production has incentivized a gradual switch from petroleum-based lubricants. Currently, the US and Europe account for 85%–90% of biolubricant production and consumption, with the global market for biolubricants expected to grow at a compound annual growth rate of 5.4% from 2016 to 2024 [

15]. However, the cost of vegetable oil and synthetic ester-based lubricants is typically 2–3 times that of comparable conventional mineral oil-based lubricants [

16], although recent studies suggest that more price-competitive vegetable oil-based lubricant may only be 20% more costly than its petroleum counterpart [

17]. In addition, vegetable oil and synthetic ester-based lubricants are economically compatible with mineral oils due to much longer drains. Many countries, such as those in Europe, have further economic incentives for market introduction of biolubricants [

16]. Tax exemptions on environmentally acceptable lubricants (EALs), subsidies to consumers to cover the price difference between EALs and mineral lubricants, and preferential purchasing programs that require a percentage of product to be made from renewable resources, aid in alleviating the higher costs associated with biolubricants [

17].

4. Environmentally Considerate Lubricants

Around 1990 in Europe there appeared the first environmental acceptable lubricants “EAL” (preferably hydraulic and 2-stroke engine oils), which also met eco-toxicological properties. Environmentally friendly hydraulic fluids appeared around 1990 in Germany (VDMA Specifications 24,568 and 24,569), German Blue Angel RAL UZ 178 and in Sweden as Swedish standards SS155434 and SS155470. The rationale behind them is the relationship between water quality and lubricant consumption, when spilled or leaked. Today, the most important schemes for EALs are:

European ecolabel as per EC/2018/1702 (3rd revision)

Second issuance of the U.S. Vessel General Permit (VGP, 2013), now expected as the Vessel Incidental Discharge Act (VIDA) and

Biolubricants as per EN16807.

They have in common the requirement of an accelerated, ultimate biodegradation (full mineralization) or short persistence in the environment when spilled, and high limits of toxicities for aquatic species including fish, daphnia and algae as well as alternatively a content of renewables (see

Table 2). The issue of environmental friendliness is solved today by legislations, test methods, and guidelines. Biolubricants are today available for all classes of lubricants and operate safely, e.g., are fit for purpose. Although EALs currently comprise only a small percentage of the total lubricant market, the use of biolubricants on vessels has been heavily encouraged in order to minimize damage to aquatic ecosystems from lubricants lost to the environment. In particular, the base oils derived from vegetable oils and synthetic esters have shown high biodegradation rates, low potentials for bioaccumulation, and have minimal toxicity to marine animals [

17].

The European Eco-label is becoming the most generally accepted label for EALs, consisting of seven criteria encompassing biodegradability, aquatic toxicity, bioaccumulation, and the presence of certain restricted substances. This labeling scheme was established to evaluate hydraulic fluids, greases, and two-stroke oils [

18]. O.E.C.D. tests 301 A-F, or equivalent, are utilized to determine the ultimate biodegradability of lubricants, e.g., full mineralization, which must total at least 90% for hydraulic oil formulations (75% for greases) [

19]. Additionally, lubricants must not have a high potential for bioaccumulation, requiring the fulfilment of one of the following conditions: a molar mass greater than 800 g/mol or a molecular diameter greater than 1.5 nm; a log K

ow less than 3 or greater than 7; or a measured bioconcentration factor (BCF) less than 100 L/kg [

17]. Aquatic toxicity evaluation requires all lubricant formulations and components to pass both OECD tests 201 (algae) and 202 (daphnia) for acute toxicity of >100 mg/L, and OECD 210 (fish) or 211 (daphnia) for chronic toxicity of >10 mg/L [

19].

5. Biodegradability and Other Benefits of Biolubricants

The development and application of biolubricants for industrial use has increased in popularity due to environmental concerns. Plant oil-based lubricants and derivatives are far superior to traditional mineral oils in terms of biodegradability. A study that evaluated the biodegradability of synthetic, bio-based lubricants using a bio-kinetic model without microorganisms produced favorable results comparatively to mineral oil [

21]. Two different biolubricants, BL1 and BL2, which were synthesized from 2-ethyl-1-hexanol and 1-octanol, underwent testing. The results were shown through an “effective composition for degradation” (ECB), half-lives and biodegradation time profile. The vegetable oil (castor oil) yielded the highest ECB value (0.78) with a half-life of 12 days, while mineral oil had a low ECB value (0.23) and a half-life of 225 days. The synthetic biolubricants, BL1 and BL2, produced ECB values (0.57, 0.64) and respective half-lives of 26 and 20 days, which were much closer to the results of vegetable oil [

21]. Moreover, a large disparity was observed when comparing the biodegradation as a function of time of the synthetic biolubricants with that of the mineral oil. In addition to being less of a toxicological hazard, plant oil-based lubricants have higher lubricity and higher viscosity indices, resulting in lower frictional losses and better fuel economy [

22]. Other advantages include:

- (a)

higher shear stability

- (b)

higher detergency, removing the necessity of detergent additives

- (c)

lower volatility, resulting in less exhaust emissions

- (d)

higher dispersancy

- (e)

higher flash point

However, the use of vegetable oils for lubrication-based applications is partially limited by the oils‘ higher melting points and low oxidative stability. Fortunately, these issues can be remedied through the usage of chemical modification and additives to alter problematic properties [

23].

The growing environmental concern surrounding the potential pollution and contamination of ecosystems due to the spillage or leakage of lubricants has necessitated the development of renewable and biodegradable lubricants. Classifications such as environmentally friendly, environmentally acceptable, biodegradable, and non-toxic are high priority qualities to consider in today’s lubricant market as a precautionary measure against environmental contamination. In general, 20%–40% of the consumed lubricants enters into the environment with altered physical properties and appearance. In Germany alone in the 1990s, the environment was exposed to about 150,000 tons p.a. of unaccounted losses and undisposed lubricants annually [

22], or ~15% of the consumed volume. Spills and leakages are, practically speaking, unavoidable, and the rationale behind rapid biodegradation is to have a persistence in nature at the lowest toxicological level possible. This means that spilled or leaked biolubes are also hazardous to waters, but to a lower extent. Subsequently, some European countries—Germany, Austria, and Switzerland—introduced the first policies and regulations that ban the usage of mineral oil-based lubricants in forest areas and around inland waterways. Furthermore, Germany has a program known as the “Market Introduction Program (MIP) Biolubricants and Biofuels”, which involves the German federal government reimbursing the cost of substituting mineral oil-based lubricants with renewable resource-based lubricants [

24].

Stringent environmental regulations regarding the use conventional mineral oil-based lubricants have created a new class of lubricants with a market in Europe of 3%–3.5% [

25]. Nowadays, biolubricants, which are classified as environmentally friendly and non-toxic, are paving the way for greener and more sustainable tribology but their benefits are not limited to this. The continual implementation of relevant legislation that increases future lubrication demands and incentivizes the use of biodegradable lubricants will likely be the main driving factor for the success of biolubricants [

26]. On the other hand, fit-for-purpose of biolubes is the pre-requisite. Fully formulated engine oils meeting the performance specifications of the European Automobile Manufacturers’ Association (ACEA) and the American Petroleum Institute (API) were proposed from 1996–2001 [

27]. Castrol Greentec LS, ELF Victory HTX 822 or BP Vistra 7000, and FUCHS Titan GT1 were based on esters or were blends of esters with hydrocarbons. The FUCHS Titan GT1 contained >50% of renewable esters [

28]. These products did enter the market due to a lack of regulations and the much higher price level. Nowadays, the Castrol Edge BIO-SYNTHETIC contains 25% of renewables [

29].

The current biolubricant market is dominated by esters, but polyalkylene glycols (PAGs) and renewable hydrocarbons are on the rise. Esters and bio-olefins are miscible between each other, compatible with infrastructure and most additives, and interchangeable with existing hydrocarbon-based lubricants [

30]. The use of Kolbe electrolysis to convert vegetable oils into hydrocarbons allows for milder operating conditions and lower hydrogen consumption, comparatively, to the conventional hydrodeoxygenation process. However, the success of this prospect is largely dependent on finding a valuable use for glycerol (a by-product of the hydrolysis of vegetable oils, e.g., biodiesel production) and determining the most economical scale-up process [

30]. Bio-glycerine can be converted to propylene oxide, a building block in PAGs. Further research and development could facilitate the production of price-competitive, high-performance hydrocarbon-based biolubricants.

The beneficial physiochemical properties and technical advantages of bio-derived lubricants has directed some attention towards the use of biolubricants as alternatives in automotive applications [

31]. Beket et al. tested the use of a pongamia oil blend (45–60% oleic acid, 15–10% linoleic acid, iodine value 80–90) against a mineral oil blend as lubricants for a commercial CI engine [

32]. Results of the study showed that the low viscosity of the pongamia oil allowed the biolubricant to outperform the mineral oil in regard to reducing frictional losses, improving fuel efficiency, and completely eliminating the emissions of metal traces. The pongamia oil blend yielded the minimum brake-specific energy consumption and the highest brake thermal efficiency at medium- to high-load conditions. The high concentration of double bonds limits the oxidation stability. A study conducted by Jaina et al. evaluated the potential of biolubricants as an alternative to petroleum-based lubricants in industrial and maintenance applications [

33]. Biolubricants have a diverse range of physiochemical and performance benefits, such as low toxicity, high viscosity index, high lubricity, high load-carry capacities, superb anti-wear characteristics, low evaporation losses, and rapid biodegradability. The use of saturated biolubricants in industrial and maintenance applications reduces running costs at higher purchase prices, increases competitiveness, and facilitates the transition away from using petroleum-based products to more sustainable ones.

6. Sustainability as per U.N. SDGs

A wide audience uses the term sustainability, but everyone has a different perception and thus the meaning remains diffuse. Each company and everyone in the public has their own views, perceptions, and definitions of sustainability. All aspects of sustainability are illuminated by the seventeen Sustainable Development Goals (SDG) adopted by the general assembly of United Nations in October 2015 [

6]. SDGs #3.9 and #13, which are related to “environmental friendliness” and further aspects, such as resource efficiency, energy efficiency, renewable resources, waste reduction, and longevity, but also societal aspects, draw the frame for additional requirements related to sustainability and define it in a globally recognized form. The SDGs represent a safe foundation for decisions and developments. The definition of sustainability as per the U.N. is much wider than being limited only to biodegradability.

Energy efficiency fits with low-friction lubricants and results in CO

2 reductions [

7,

8] as per SDGs #7 and #13. Waste reduction anticipates long-life oils, condition monitoring, re-refining as a “second life” of lubes, but interacts also with resource efficiency through extended drains, which reduce the volume of used oils and wastes. The usage of biomass (renewable resource) for biodegradable lubricants has been recommended by the European Lead Markets Initiative (LMI) for environmentally sensitive areas [

7] and is stated in SDG target #12.2. Biolubricants fulfill the expectations of SDGs #3, #6, and #12. Fully formulated biolubricants are beginning to be readily available and in use, primarily for hydraulic, automotive, and metalworking applications [

34]. Coconut oil, abundantly available in Southern India, has been used as a two-stroke engine lubricant in autorickshaws and scooters, with increased fuel efficiency, acceleration, smoother operation, and reduced smoke [

34]. However, the high pour point of coconut oil limits its application to regions with high ambient temperatures.

The development and demand for biolubricants is anticipated to grow in the future due to an increasingly environmentally conscious market. Although edible vegetable oils are available as feedstock sources for bio-lubricant production, they are likely non-sustainable sources for long-term production. Edible vegetable oil feedstocks give rise to sustainability concerns regarding their involvement with the human food cycle and the prospect of deforestation and eutrophication for plantation purposes [

35]. However, the use of non-edible vegetable oil feedstocks can be a sustainable solution because most non-edible plants can be grown on non-arable lands, thus fertile agricultural land can be maintained for cultivating edible plant crops. They generate additional income to farmers. Non-edible vegetable feedstock has the same environmentally friendly, non-toxic, and lubricity qualities as edible plant-based lubricants, maintaining its edge over conventional petroleum based mineral oils [

35]. In

Table 3, the biodegradability of different lubricant base stocks is displayed, as per ASTM D5864. These values are a summary of the results of an interlaboratory study that tested ten different lubricant base stock samples to evaluate the test method’s reproducibility, as reported in Research Report RR # D02-1584 [

36]. Fully formualated engine oils based on polyalkylene glycols (PAG) meet the criteria of easy/rapid biodegradation of >60% [

37].

The concept of sustainability for lubricants involves factors beyond just functionality and eco-friendliness, as considerations must be made in regard to future applications and problems. Even those advocating lubricants manufactured from renewable resources, like biolubricants, must consider the option of using non-edible plant feedstocks in anticipation of controversies such as the food-versus-fuel debate. The other option for renewable resources represent biomasses, such as lignocellulose, straw, used frying oils, sugar, etc. Notably, studies have been conducted on the tribological characteristics and compatibility of non-edible jatropha oil-based biolubricants for automotive applications. Jatropha Lesquerella are hydroxy-fatty acid (HFA) and is a source of non-edible biomass. One such study involved the testing of six different samples, containing a mixture of 10%, 20%, 30%, 40%, 50%, and 60% jatropha oil and SAE40 lubricant. The results showed that the addition of 10% jatropha oil in the base lubricant, JBL10, yielded the best overall performance in terms of wear rate, coefficient of friction, viscosity, and rise in temperature [

38]. Third-generation and fourth-generation technology involve the use of microalgae and genetically synthesized microorganisms to produce high yields of bio-based products [

39]. The appeal of fourth-generation biomass is built upon the process of carbon capture and storage during crop cultivation. Produced carbon dioxide is stored in exhausted oil/gas fields, mineral storage (as carbonates), and saline aquifers, which qualifies fourth-generation biomass production as carbon negative [

40]. Although research and development regarding fourth-generation biomass is predominantly centered on biofuel production, use of these renewable feedstocks is applicable to manufacturing biolubricants as well.

7. Conclusions

The economic importance, environmental properties, and sustainability of lubricants are integral points of discussion when envisioning the future of tribology. Evidence demonstrates a decisive conclusion that the reduction of energy lost from friction significantly improves fuel economy, reduces greenhouse gas emissions, and generates economic savings. The potential environmental repercussions resulting from lubricant leaks and spills necessitate the development of eco-friendly and non-toxic options. Biolubricants aptly meet the environmental criteria due to their biodegradable and renewable nature, along with possessing superior lubricity and other chemical properties over traditional petroleum-based lubricants. Typically, saturated esters and synthetic base oils (polyalkylene glycols, bio-olefins) dominate the market for biolubricants. The term of sustainability extends the list of requirements beyond biodegradation and toxicity, which can be fulfilled by lubricants.

Lubricants must meet societal demands and will evolve from a purely technical fulfillment of functions, to which eco-toxicological properties and/or sustainability criteria will be added. This will promote new developments perceived by some as disruptive, but basically the formulations must change and open the door for alternative base oils and additive concepts.