Superlubricity in EHL Contacts with Water-Containing Gear Fluids †

Abstract

:1. Introduction

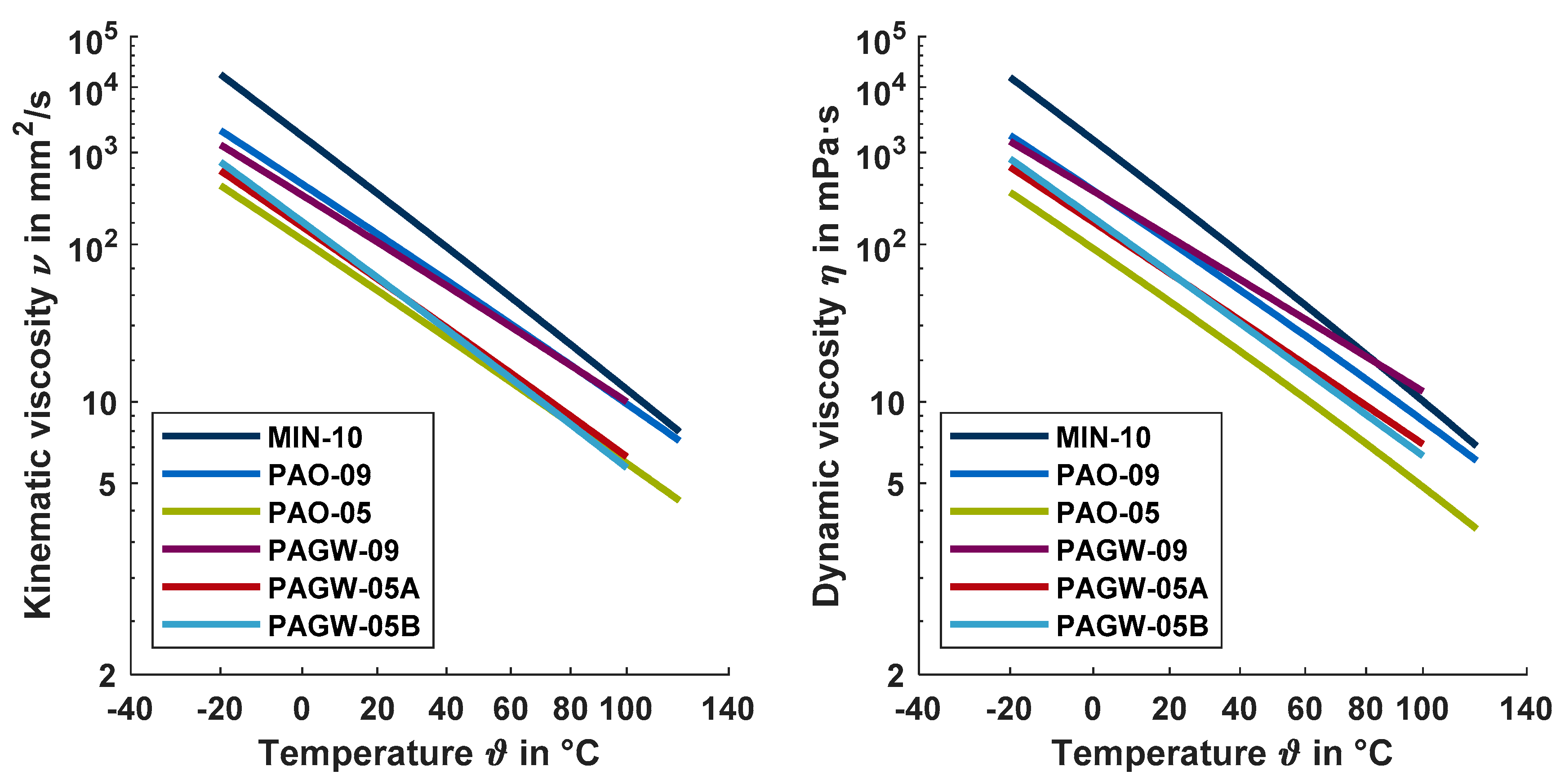

2. Lubricants

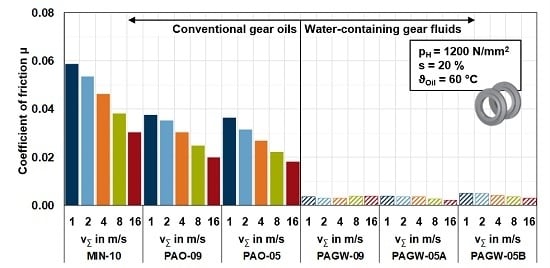

3. Experimental Setups

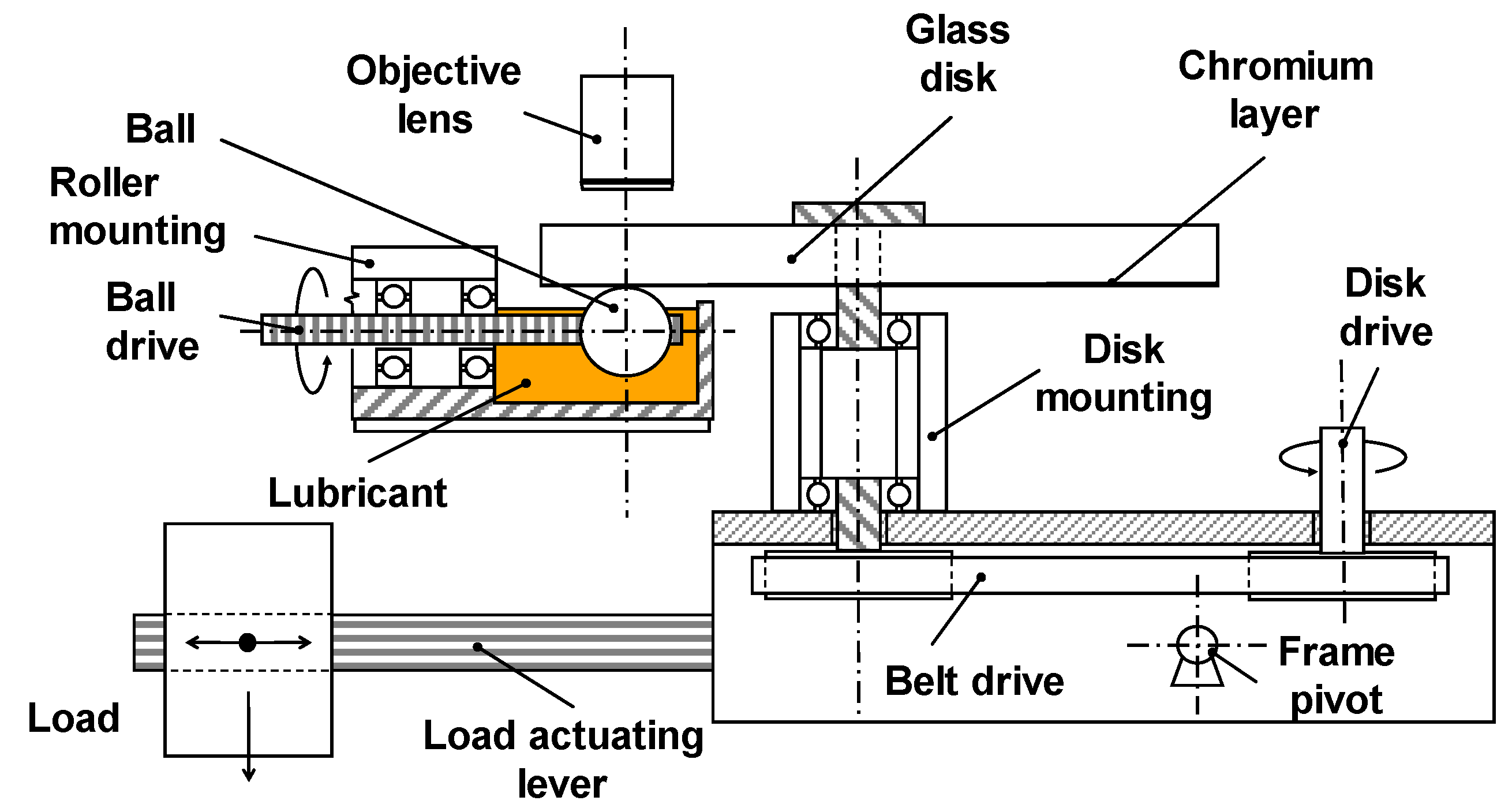

3.1. Optical EHL Tribometer

3.1.1. Description and Measurement Technique

3.1.2. Operating Conditions

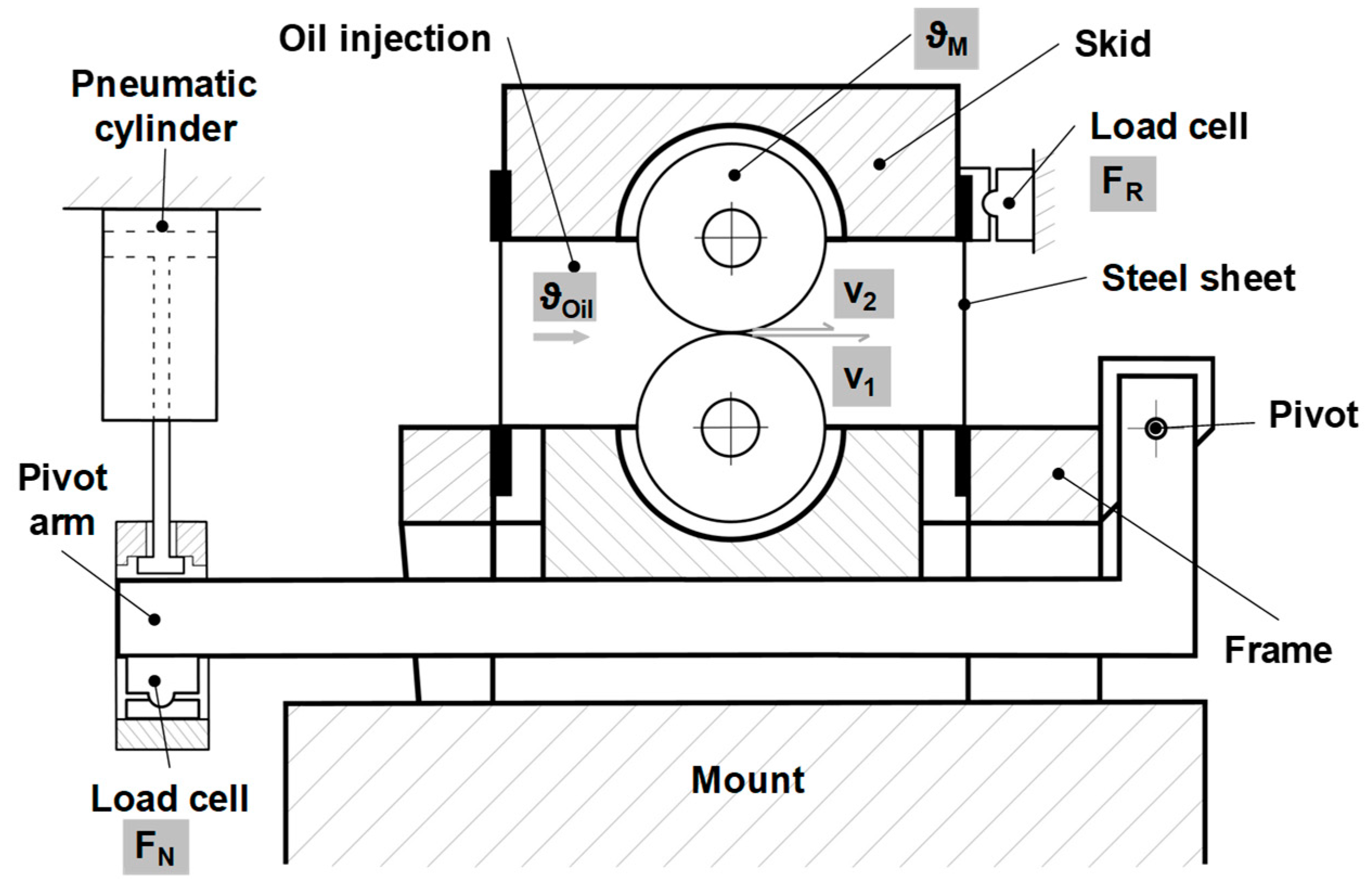

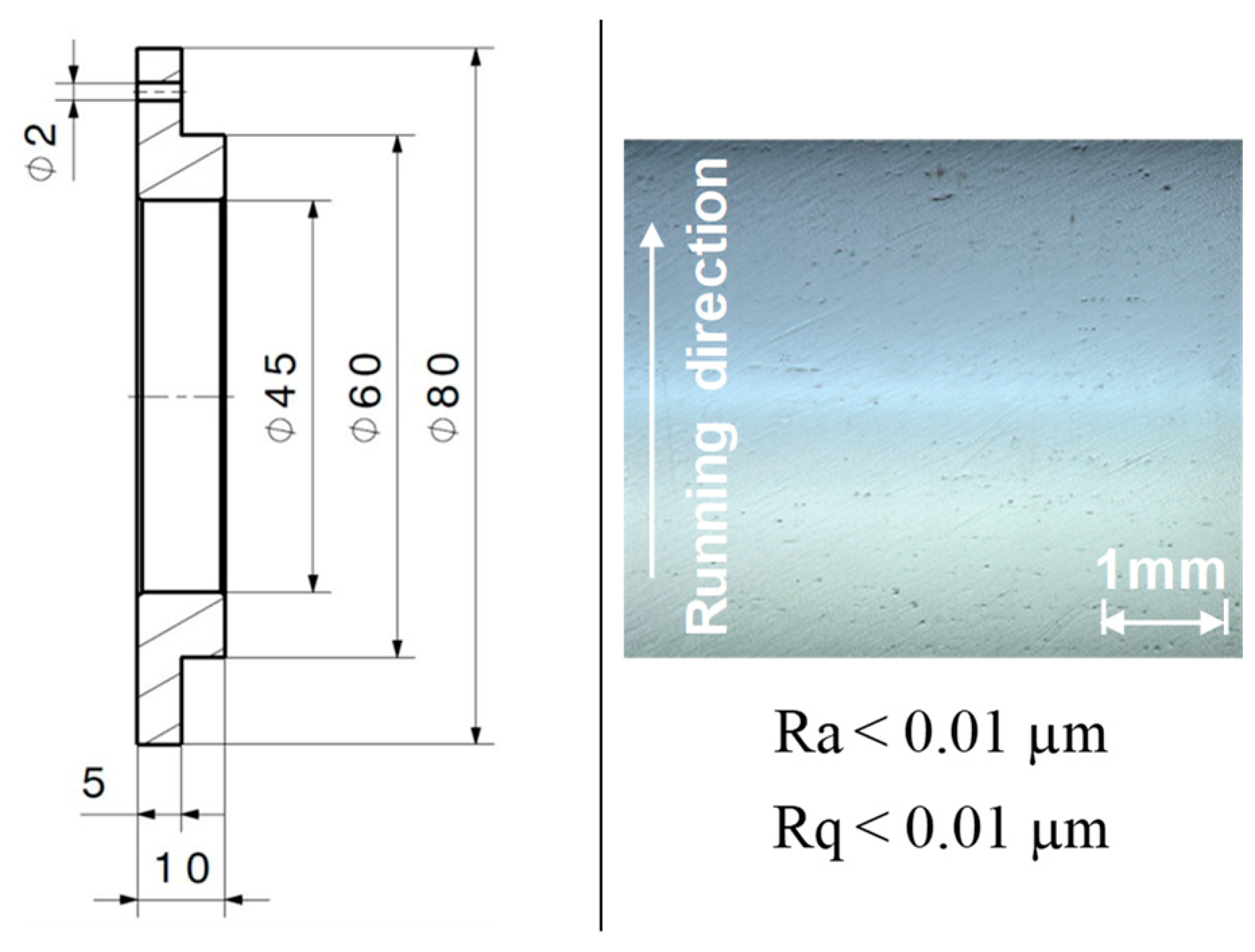

3.2. Twin-Disk Test Rig

3.2.1. Mechanical Setup

3.2.2. Operating Conditions

4. Results and Discussion

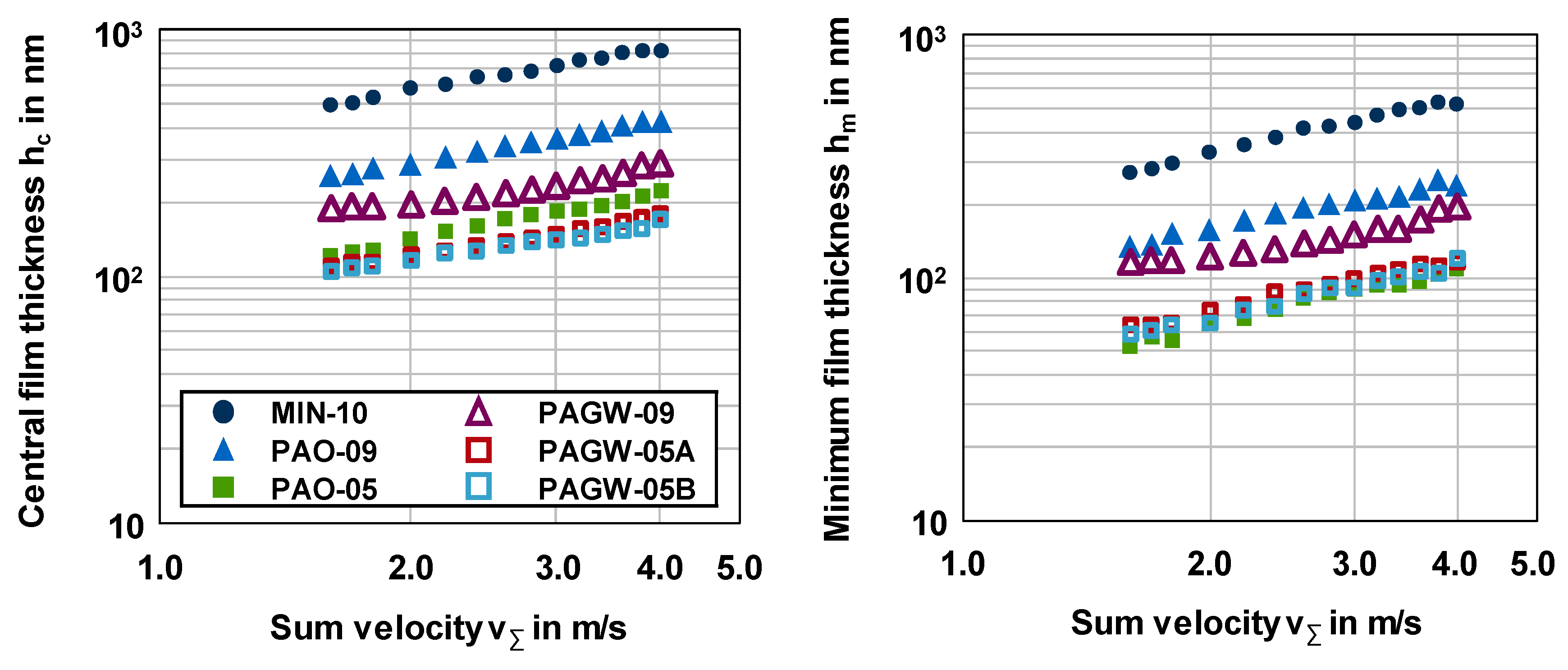

4.1. Optical EHL Tribometer

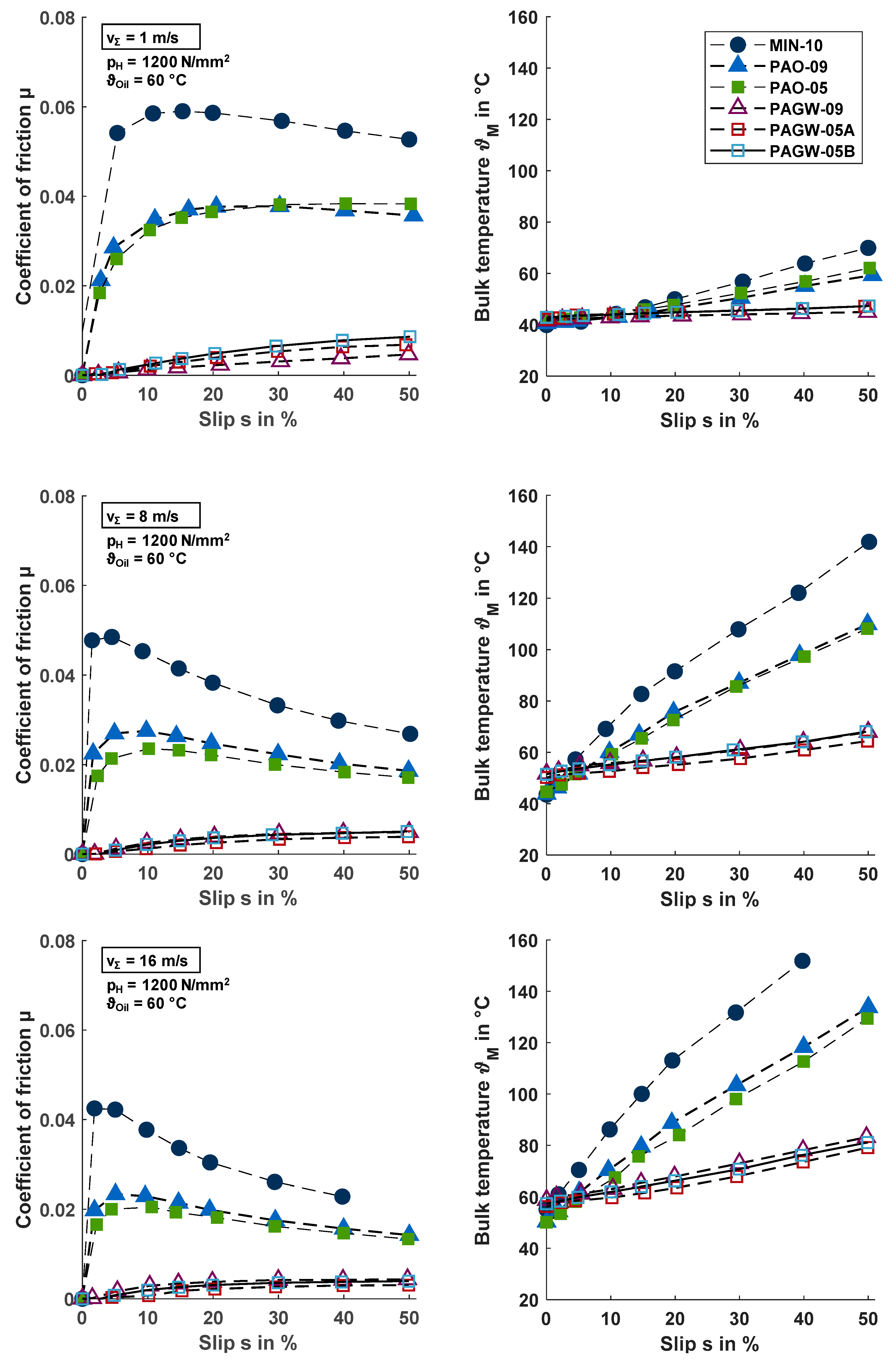

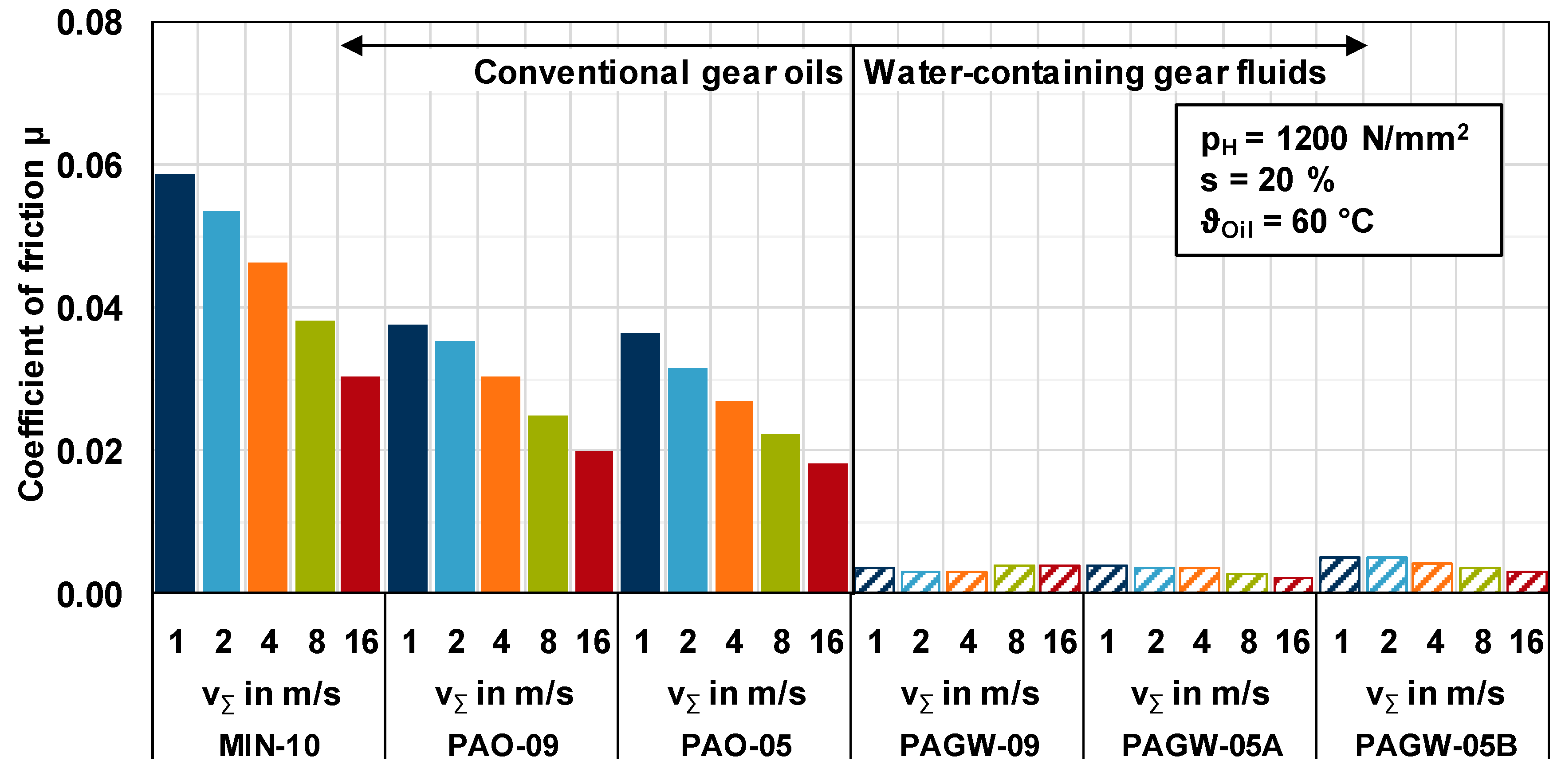

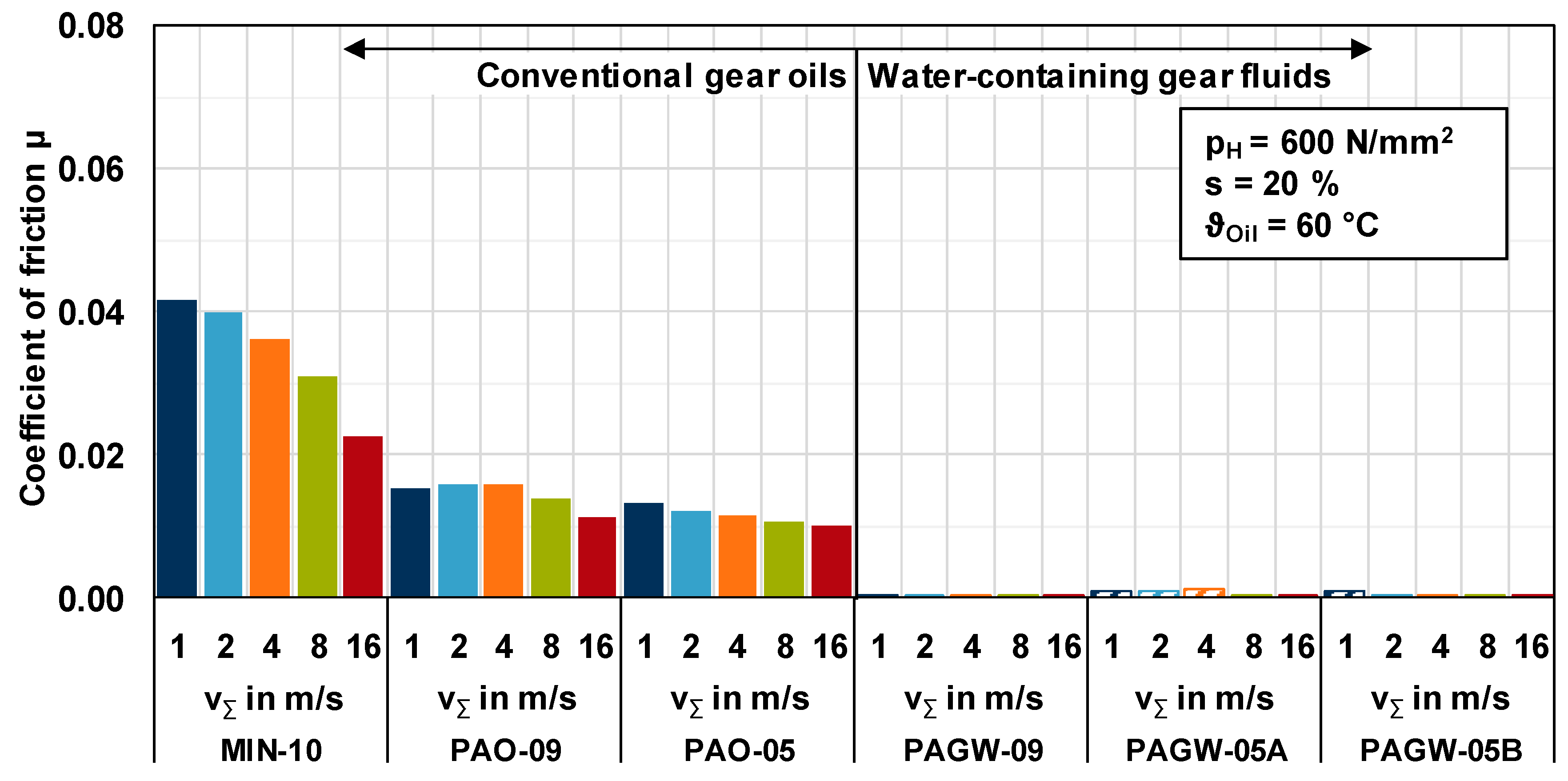

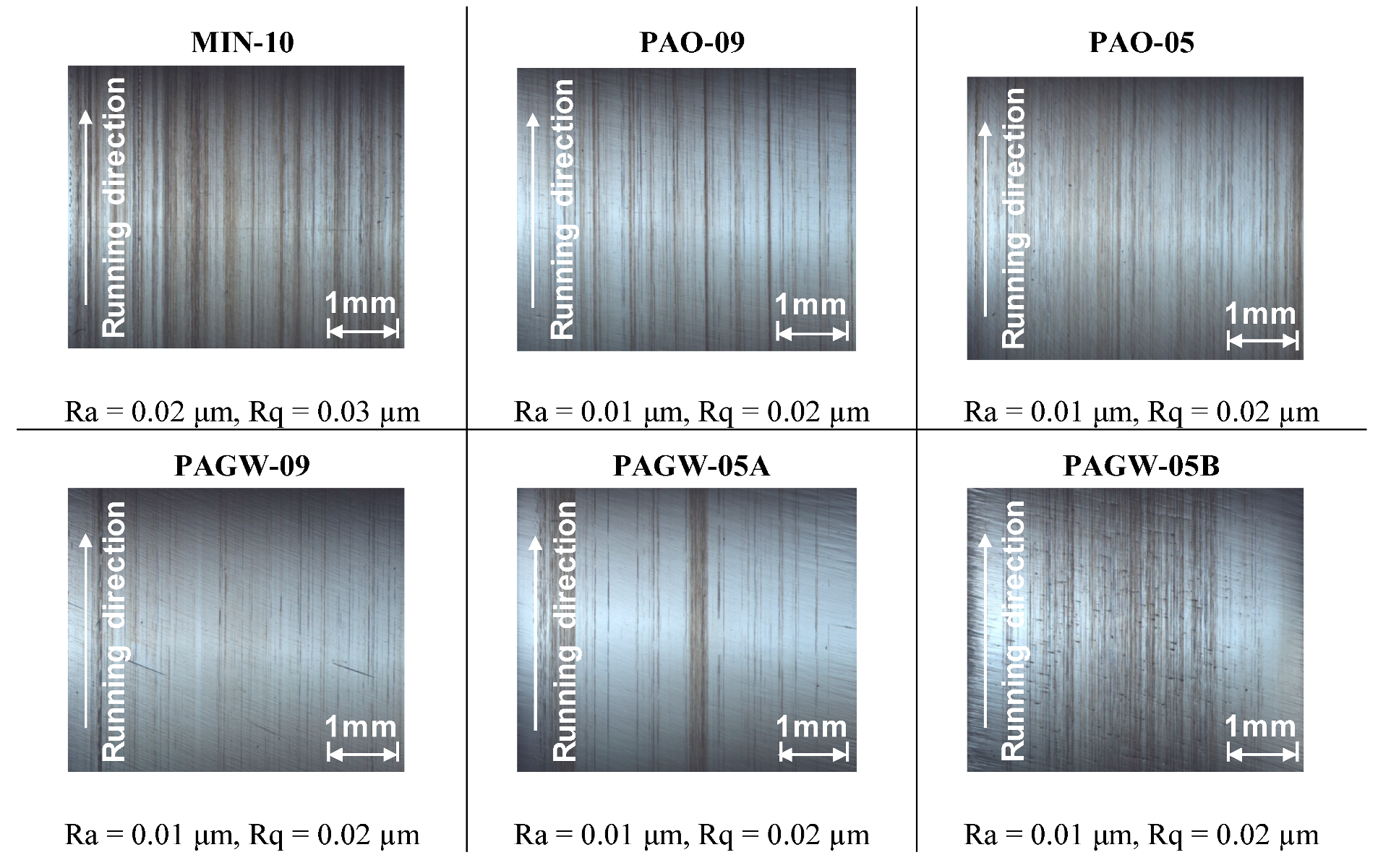

4.2. Twin-Disk Test Rig

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Reduced Young’s Modulus | N/mm2 | |

| Normal force | N | |

| Friction force | N | |

| G | Material parameter | - |

| hc | Central film thickness | nm |

| hm | Minimum film thickness | nm |

| Hertzian pressure | N/mm2 | |

| U | Velocity parameter | - |

| Ra | Arithmetic mean roughness | µm |

| Rq | Root-mean-squared mean roughness | µm |

| Reduced radius | mm | |

| Slip | % | |

| Time | s | |

| Sliding velocity | m/s | |

| Sum velocity | m/s | |

| W | Load parameter | - |

| Greek symbols | ||

| αp | Pressure–viscosity coefficient | 1/GPa |

| η | Dynamic viscosity | Pa |

| κ | Ellipticity parameter | - |

| λrel | Relative film thickness | - |

| Coefficient of friction | - | |

| Bulk temperature | °C | |

| Oil temperature | °C | |

| Kinematic viscosity | mm2/s | |

| Indices | ||

| 1 | Lower disk | |

| 2 | Upper disk |

References

- Mayer, J. Einfluss der Oberfläche und des Schmierstoffs auf das Reibungsverhalten im EHD-Kontakt (Influence of surface texture and lubricant on the frictional behaviour of EHL contacts). Ph.D. Thesis, Technical University of Munich, Munich, Germany, 2013. [Google Scholar]

- Bobach, L.; Bartel, D.; Beilicke, R.; Mayer, J.; Michaelis, K.; Stahl, K.; Bachmann, S.; Schnagl, J.; Ziegele, H. Reduction in EHL Friction by a DLC Coating. Tribol. Lett. 2015, 60, 17. [Google Scholar] [CrossRef]

- Bader, N.; Wang, D.; Poll, G. Traction and local temperatures measured in an elastohydrodynamic lubrication contact. Proc. Inst. Mech. Eng. 2017, 231, 1128–1139. [Google Scholar] [CrossRef]

- Evans, C.R.; Johnson, K.L. The rheological properties of elastohydrodynamic lubricants. Proc. Inst. Mech. Eng. Sci. 1986, 200, 303–312. [Google Scholar] [CrossRef]

- Björling, M.; Larsson, R.; Marklund, P. The Effect of DLC Coating Thickness on Elastohydrodynamic Friction. Tribol. Lett. 2014, 55, 353–362. [Google Scholar]

- Ndiaye, S.-N.; Martinie, L.; Philippon, D.; Devaux, N.; Vergne, P. A Quantitative Friction-Based Approach of the Limiting Shear Stress Pressure and Temperature Dependence. Tribol. Lett. 2017, 65, 149. [Google Scholar] [CrossRef]

- Bair, S.; Winer, W.O. Shear Strength Measurements of Lubricants at High Pressure. J. Lubr. Technol. 1979, 101, 251–257. [Google Scholar] [CrossRef]

- Martinie, L.; Vergne, P. Lubrication at Extreme Conditions: A Discussion About the Limiting Shear Stress Concept. Tribol. Lett. 2016, 63, 21. [Google Scholar] [CrossRef]

- Bair, S. The viscosity at the glass transition of a liquid lubricant. Friction 2019, 7, 86–91. [Google Scholar]

- Bair, S.; Yamaguchi, T.; Brouwer, L.; Schwarze, H.; Vergne, P.; Poll, G. Oscillatory and steady shear viscosity: The Cox-Merz rule, superposition, and application to EHL friction. Tribol. Int. 2014, 79, 126–131. [Google Scholar] [CrossRef]

- Sagraloff, N.; Dobler, A.; Tobie, T.; Stahl, K.; Ostojewski, J. Development of an oil free water-based lubricant for gear apllications. Lubricants 2019, 7, 33. [Google Scholar] [CrossRef]

- Martin, J.M.; De Barros-Bouchet, M.I. Water-Like Lubrication of Hard Contacts by Polyhydric Alcohols. Aqueous Lubr. Nat. Biometric Approaches 2014, 3, 219–235. [Google Scholar]

- Chen, Z.; Liu, Y.; Zhang, S.; Luo, J. Controllable Superlubricity of Glycerol Solution via Environment Humidity. Langmuir 2013, 29, 11924–11930. [Google Scholar] [CrossRef]

- Li, J.; Zhang, C.; Luo, J. Superlubricity Achieved with Mixtures of Polyhydroxy Alcohols and Acids. Langmuir 2013, 29, 5239–5245. [Google Scholar] [CrossRef]

- Li, J.; Zhang, C.; Ma, L.; Liu, Y.; Luo, J. Superlubricity Achieved with Mixtures of Acids and Glycerol. Langmuir 2013, 29, 271–275. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Y.; Li, J.; Luo, J. Investigation of Superlubricity Achieved by Polyalkylene Glycol Aqueous Solutions. Adv. Mater. Interfaces 2016, 3, 1600531. [Google Scholar] [CrossRef]

- Yilmaz, M.; Mirza, M.; Lohner, T.; Stahl, K. Superlubricity in EHL Contacts with Water-Containing Gear Fluids. In Proceedings of the 7th European Conference on Tribology, Vienna, Austria, 12–14 June 2019. [Google Scholar]

- Laukotka, E.M. FVA-Heft Nr. 660—Referenzöle Datensammlung; Forschungsvereinigung Antriebstechnik e.V.: Frankfurt/Main, Germany, 2007. [Google Scholar]

- Slope, M. DIN 51563. Prüfung von Mineralölen und verwandten Stoffen—Bestimmung des Viskosität-Temperatur-Verhaltens—Richtungskonstante (Testing of Mineral Oils and Related Materials—Determination of Viscosity Temperature Relation); DIN—German Institute for Standardization: Berlin, Germany, 1976. [Google Scholar]

- Omasta, M.; Ebner, M.; Sperka, P.; Lohner, T.; Krupka, I.; Hartl, M.; Höhn, B.-R.; Stahl, K. Film formation in EHL contacts with oil-impregnated sintered materials. Ind. Lubr. Tribo. 2018, 70, 612–619. [Google Scholar] [CrossRef]

- Ebner, M.; Omasta, M.; Lohner, T.; Sperka, P.; Krupka, I.; Hartl, M.; Michaelis, K.; Höhn, B.-R.; Stahl, K. Local Effects in EHL Contacts with Oil-Impregnated Sintered Materials. Lubricants 2019, 7, 1. [Google Scholar] [CrossRef]

- Hartl, M.; Krupka, I.; Liska, M. Differential colorimetry: tool for evaluation of chromatic interference patterns. Opt. Eng. 1997, 39, 2384–2391. [Google Scholar] [CrossRef]

- Molimard, J.; Querry, M.; Vergne, P.; Krupka, I.; Hartl, M.; Poliscuk, R.; Liska, M. Differential Colorimetry: A tool for the analysis of fluid film lubrication. Mec. Ind. 2002, 3, 571–581. [Google Scholar]

- Stößel, K. Reibungszahlen unter elasto-hydrodynamischen Bedingungen (Coefficients of friction under elastohydrodynamic conditions). Ph.D. Thesis, Technical University of Munich, Munich, Germany, 1971. [Google Scholar]

- Lohner, T.; Merz, R.; Mayer, J.; Michaelis, K.; Kopnarski, M.; Stahl, K. On the Effect of Plastic Deformation (PD) Additives in Lubricants. Tribol. Schmierungstech. 2015, 62, 13–24. [Google Scholar]

- Ebner, M.; Lohner, T.; Michaelis, K.; Stemplinger, J.-P.; Höhn, B.-R.; Stahl, K. Self-Lubricated Elastohydrodynamic (EHL) Contacts with Oil-Impregnated Sintered Materials. In Proceedings of the TAE Esslingen 20th International Colloquium, Tribology—Industrial and Automotive Lubrication, Stuttgart, Germany, 12–14 January 2016. [Google Scholar]

- Yilmaz, M.; Kratzer, D.; Lohner, T.; Michaelis, K.; Stahl, K. A study on highly-loaded contacts under dry lubrication for gear applications. Tribol. Int. 2018, 128, 410–420. [Google Scholar] [CrossRef]

- Hamrock, B.J.; Dowson, D. Isothermal Elastohydrodynamic Lubrication of Point Contacts. J. Lubr. Technol. 1977, 99, 264–276. [Google Scholar] [CrossRef]

- Hirano, M.; Shinjo, K. Atomistic locking and friction. Phys. Rev. B 1990, 41, 11837–11851. [Google Scholar] [CrossRef]

- Dowsonn, D.; Higginson, G.R. Elastohydrodynamic Lubrication—The Fundamental of Roller and Gear Lubrication; Perganom Press: Oxford, UK, 1966. [Google Scholar]

| Lubricant Property | Conventional Gear Oils | Water-Containing Gear Fluids | ||||

|---|---|---|---|---|---|---|

| MIN-10 | PAO-09 | PAO-05 | PAGW-09 | PAGW-05A | PAGW-05B | |

| ν (40 °C) in mm2/s | 94.1 | 50.2 | 20.4 | 45.7 | 23.6 | 22.9 |

| ν (100 °C) in mm2/s | 10.6 | 9.0 | 5.0 | 9.2 | 5.3 | 4.8 |

| Viscosity index VI | 95 | 165 | 185 | 189 | 167 | 135 |

| ρ (15 °C) in kg/m3 | 884.5 | 850.0 | 840.0 | 1115.0 | 1109.0 | 1097.0 |

| Parameter | Value |

|---|---|

| Hertzian pressure, pH in N/mm2 | 530 |

| Sum velocity, vΣ in m/s | 1.6–4.0 |

| Slip ratio, s in % | 0 |

| Oil temperature, ϑOil in °C | 40 |

| Parameter | Value |

|---|---|

| Hertzian pressure, pH in N/mm2 | 600; 1200 |

| Sum velocity, vΣ in m/s | 1; 2; 4; 8; 16 |

| Slip ratio, s in % | 0–50 |

| Oil temperature, ϑOil in °C | 60 |

| Pressure-Viscosity Coefficient | Conventional Gear Oils | Water-Containing Gear Fluids | ||||

|---|---|---|---|---|---|---|

| MIN-10 | PAO-09 | PAO-05 | PAGW-09 | PAGW-05A | PAGW-05B | |

| αp (40 °C) in 1/GPa | 25.76 | 16.71 | 14.02 | 6.26 | 5.92 | 5.61 |

| Relative Film Thickness | vΣ = 1 m/s | vΣ = 8 m/s | vΣ = 16 m/s | |||

|---|---|---|---|---|---|---|

| s = 0% | s = 50% | s = 0% | s = 50% | s = 0% | s = 50% | |

| MIN-10 | 24.0 | 9.7 | 102.9 | 14.3 | 167.1 | - |

| PAO-09 | 11.6 | 7.2 | 49.9 | 13.9 | 81.1 | 17.9 |

| PAO-05 | 5.6 | 3.9 | 24.1 | 8.8 | 39.2 | 12.8 |

| PAGW-09 | 7.3 | 7.0 | 31.4 | 17.4 | 51.0 | 13.6 |

| PAGW-05A | 4.5 | 3.9 | 19.3 | 12.0 | 31.4 | 15.4 |

| PAGW-05B | 4.2 | 3.6 | 18.2 | 10.3 | 29.5 | 13.7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yilmaz, M.; Mirza, M.; Lohner, T.; Stahl, K. Superlubricity in EHL Contacts with Water-Containing Gear Fluids. Lubricants 2019, 7, 46. https://doi.org/10.3390/lubricants7050046

Yilmaz M, Mirza M, Lohner T, Stahl K. Superlubricity in EHL Contacts with Water-Containing Gear Fluids. Lubricants. 2019; 7(5):46. https://doi.org/10.3390/lubricants7050046

Chicago/Turabian StyleYilmaz, Mustafa, Michael Mirza, Thomas Lohner, and Karsten Stahl. 2019. "Superlubricity in EHL Contacts with Water-Containing Gear Fluids" Lubricants 7, no. 5: 46. https://doi.org/10.3390/lubricants7050046

APA StyleYilmaz, M., Mirza, M., Lohner, T., & Stahl, K. (2019). Superlubricity in EHL Contacts with Water-Containing Gear Fluids. Lubricants, 7(5), 46. https://doi.org/10.3390/lubricants7050046