Performance of Volcano-Like Laser Textured Cutting Tools: An Experimental and Simulative Investigation

Abstract

1. Introduction

2. Experiment and Simulation Details

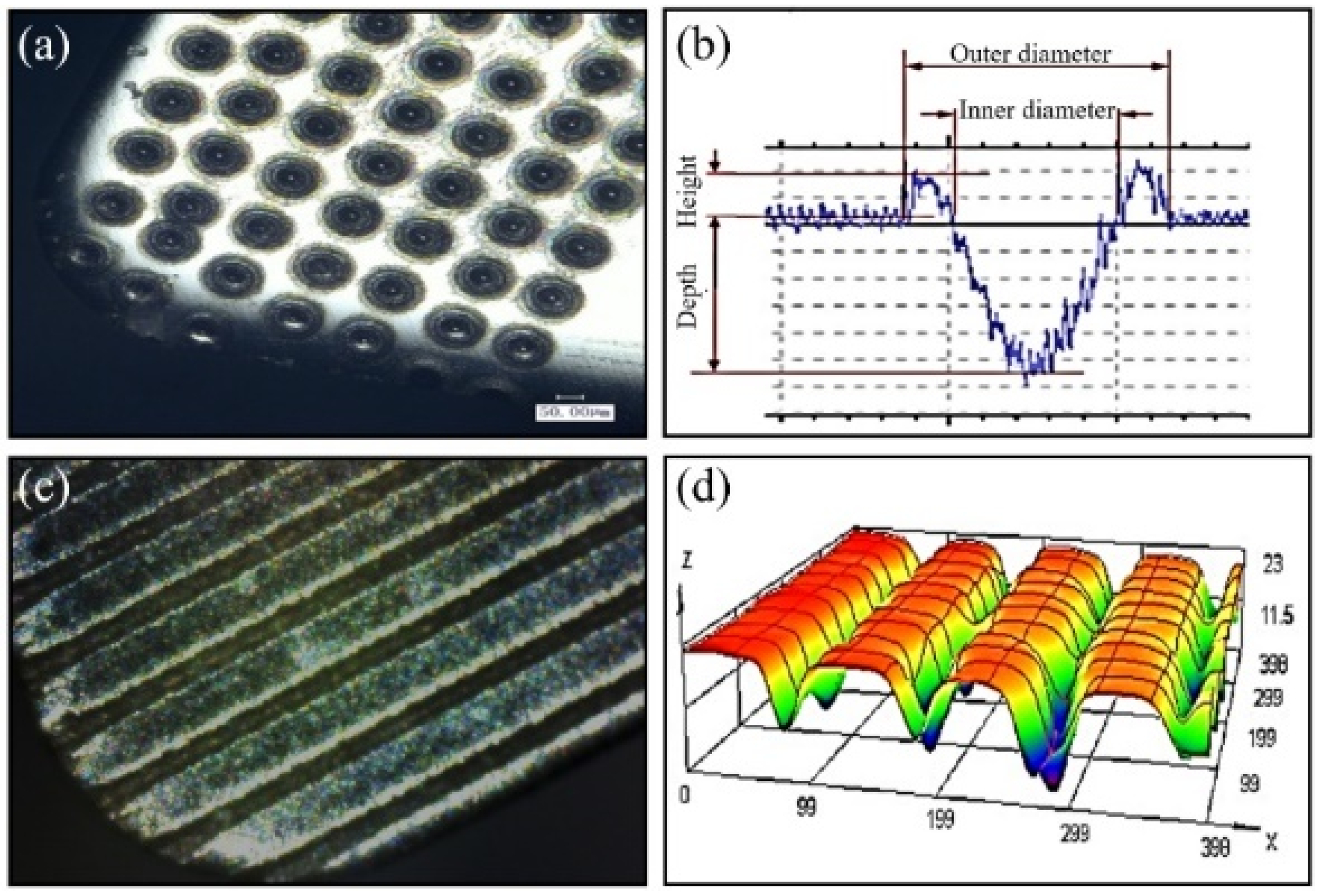

2.1. Texture Fabrication

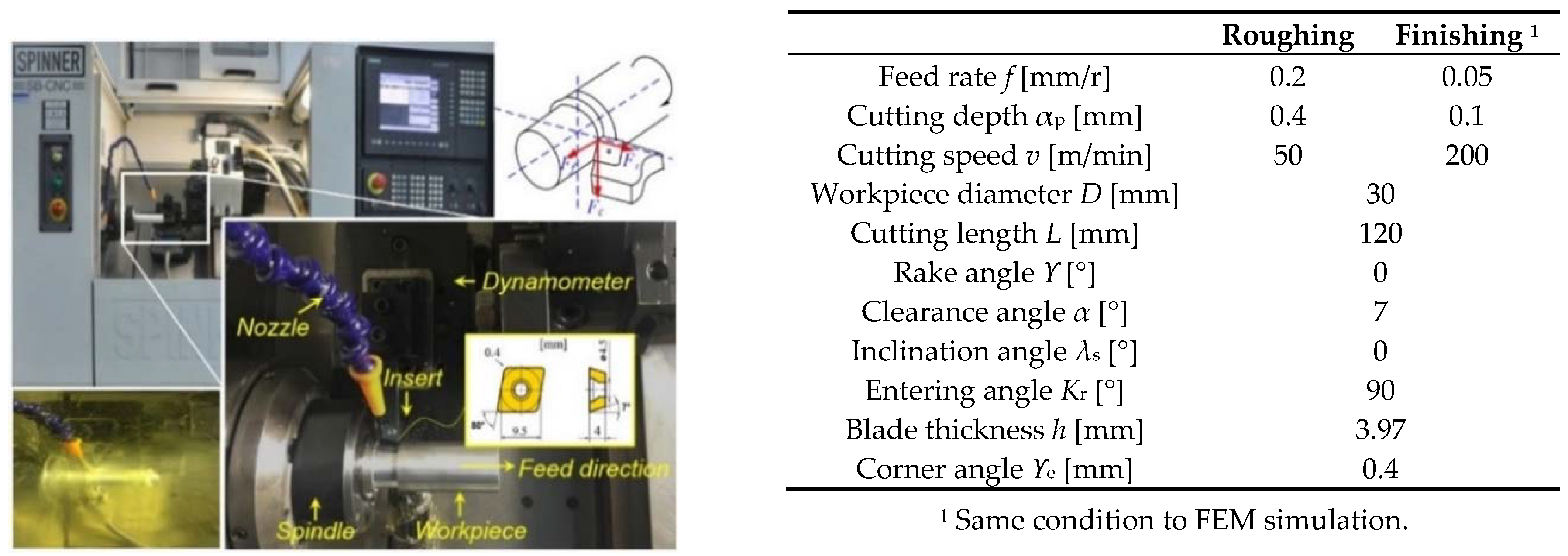

2.2. Cutting Experiment

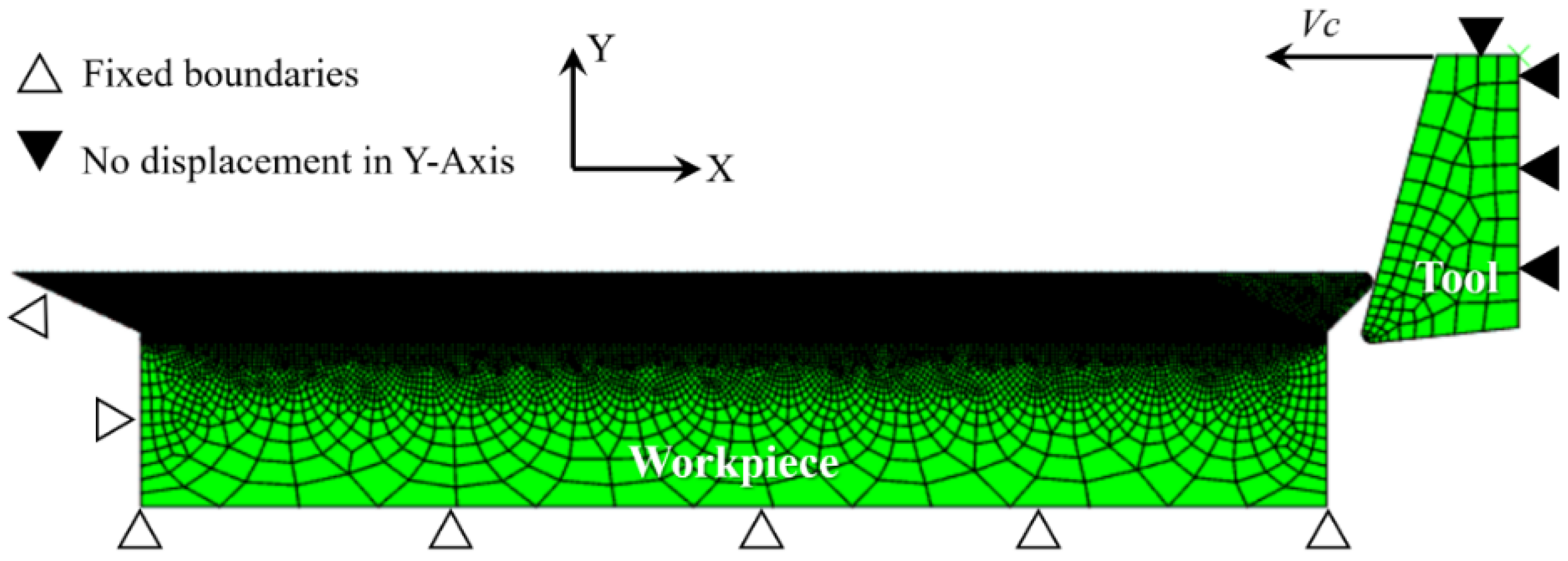

2.3. FEM Simulation

3. Results and Discussion

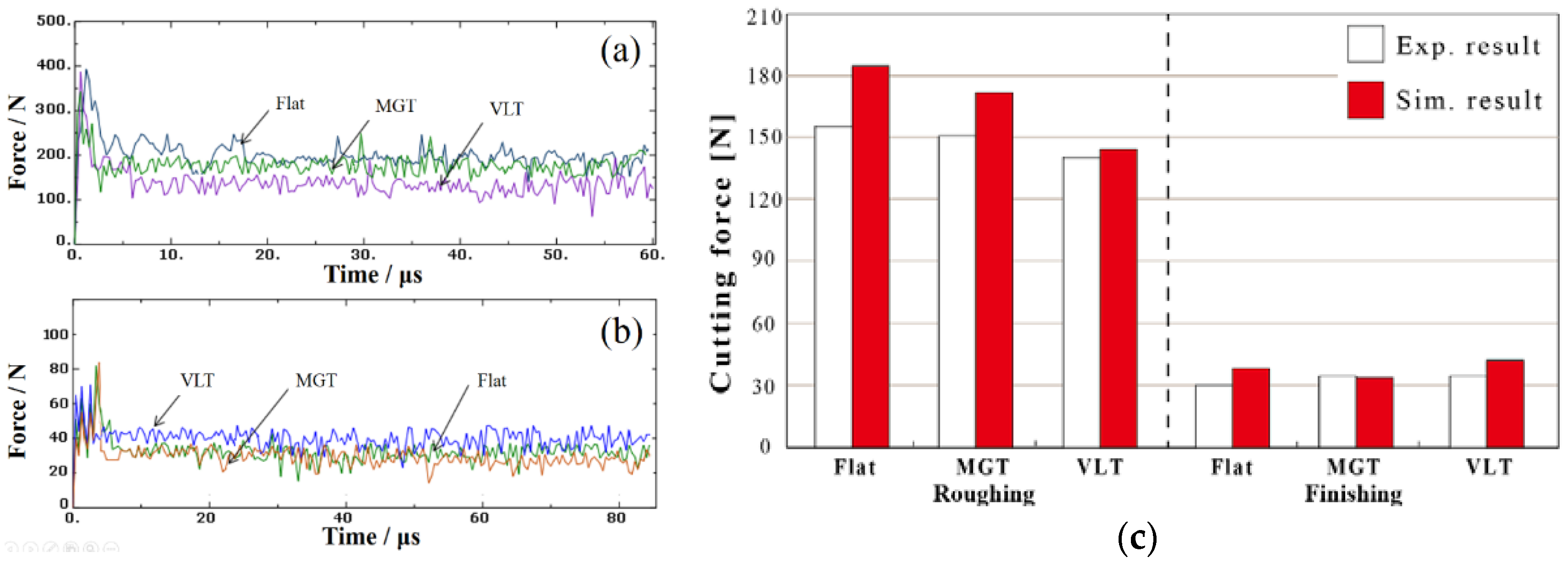

3.1. Numerical Model Validation

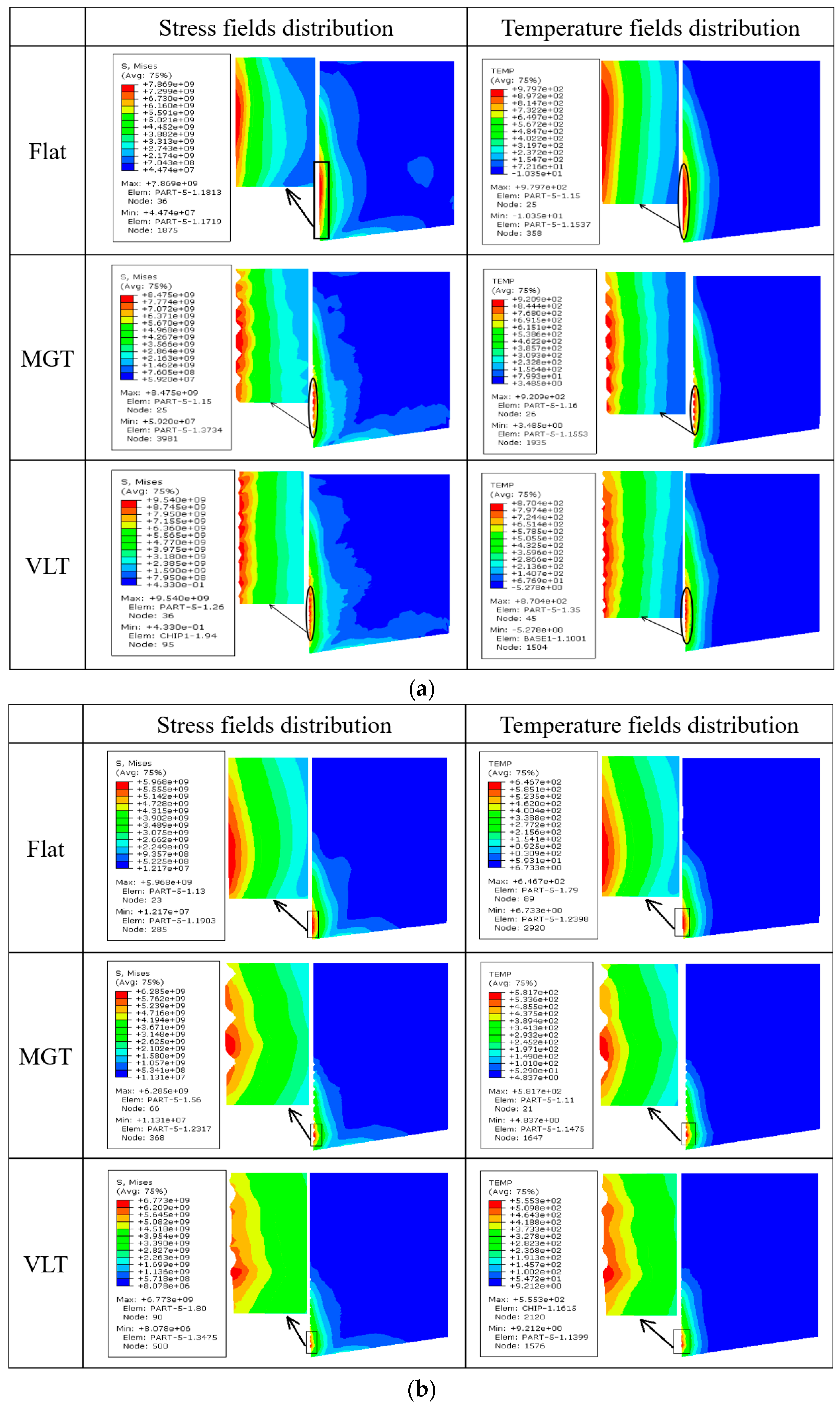

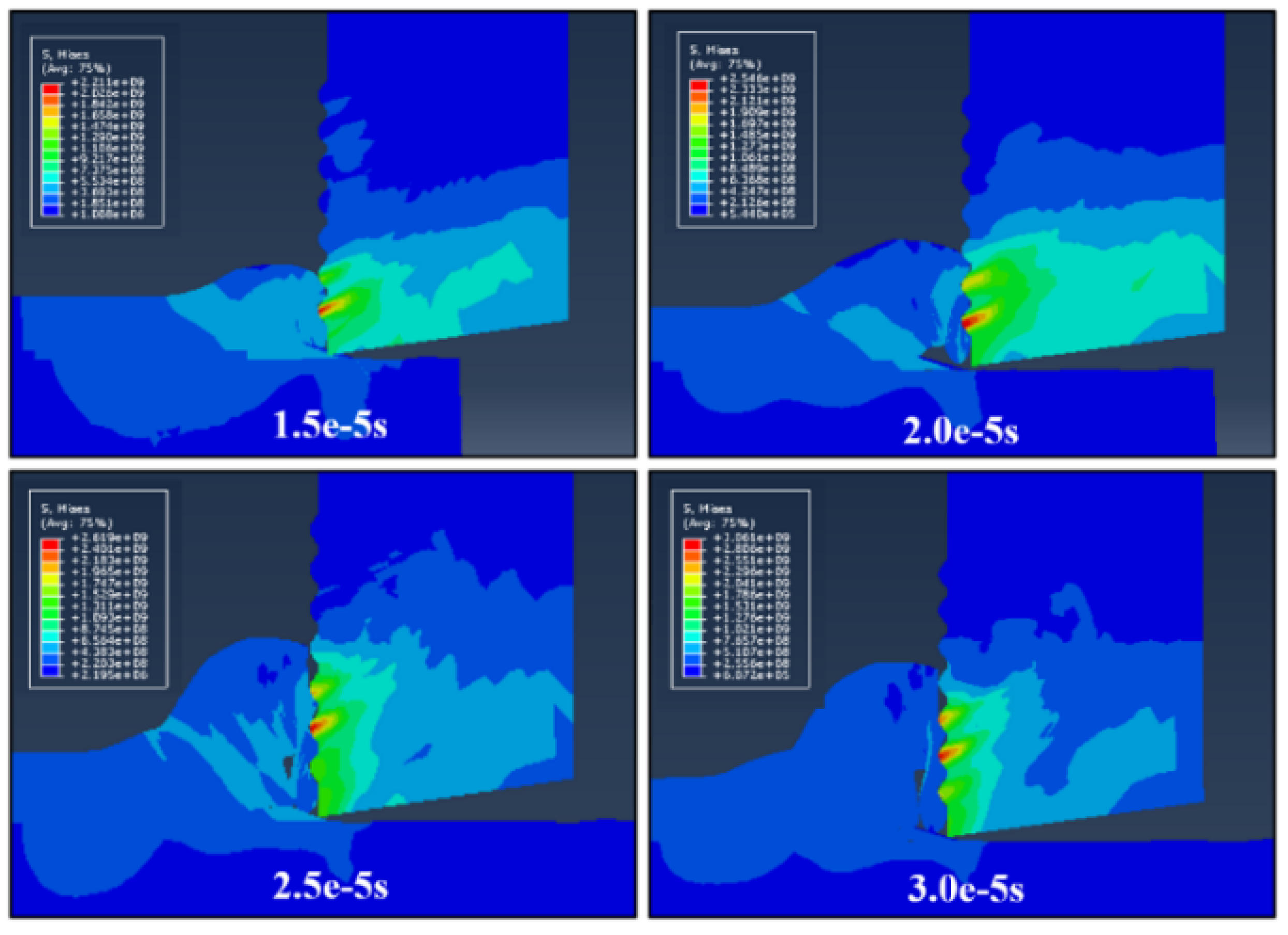

3.2. Stress and Temperature Field Distribution

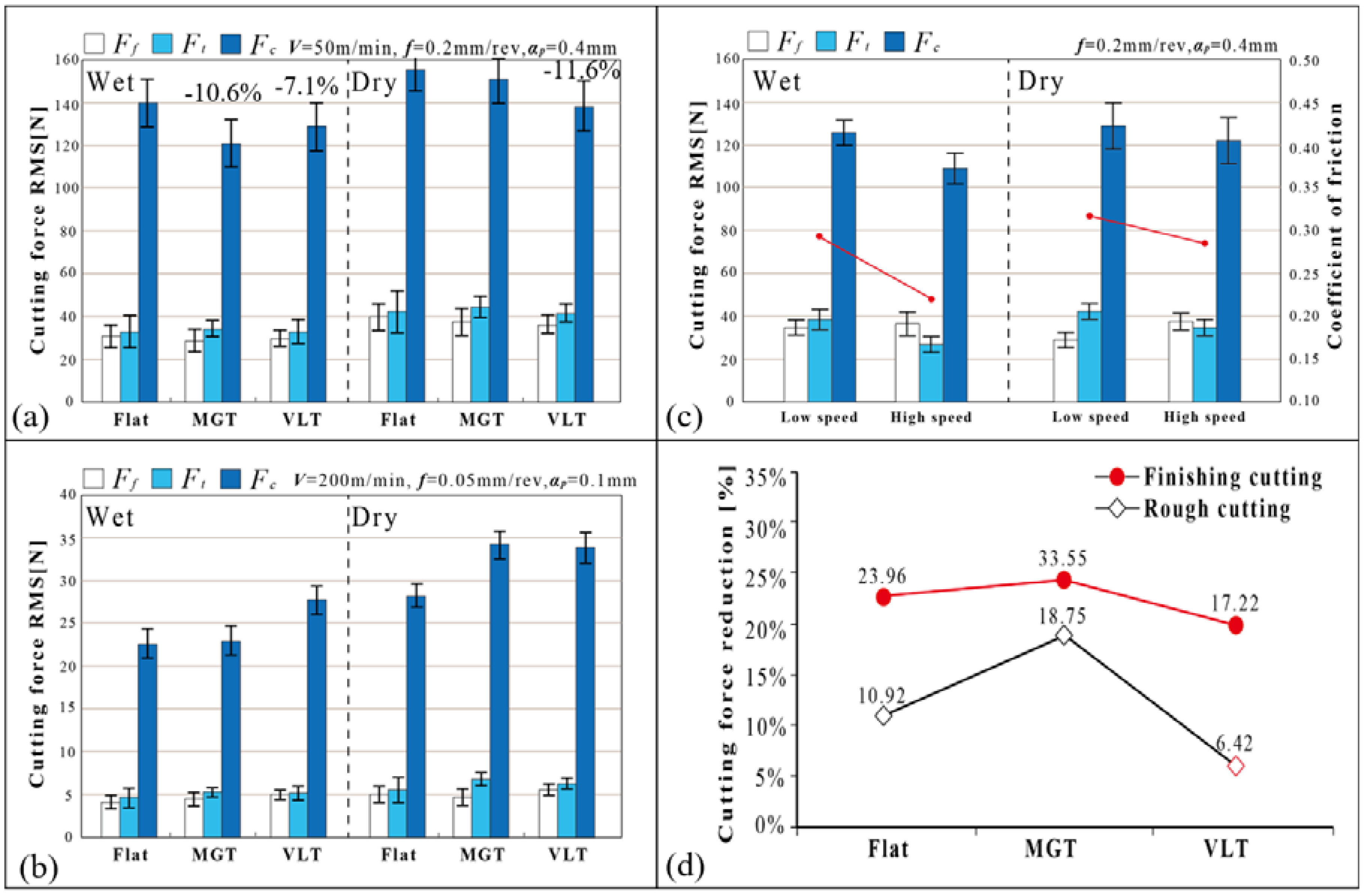

3.3. Cutting Forces

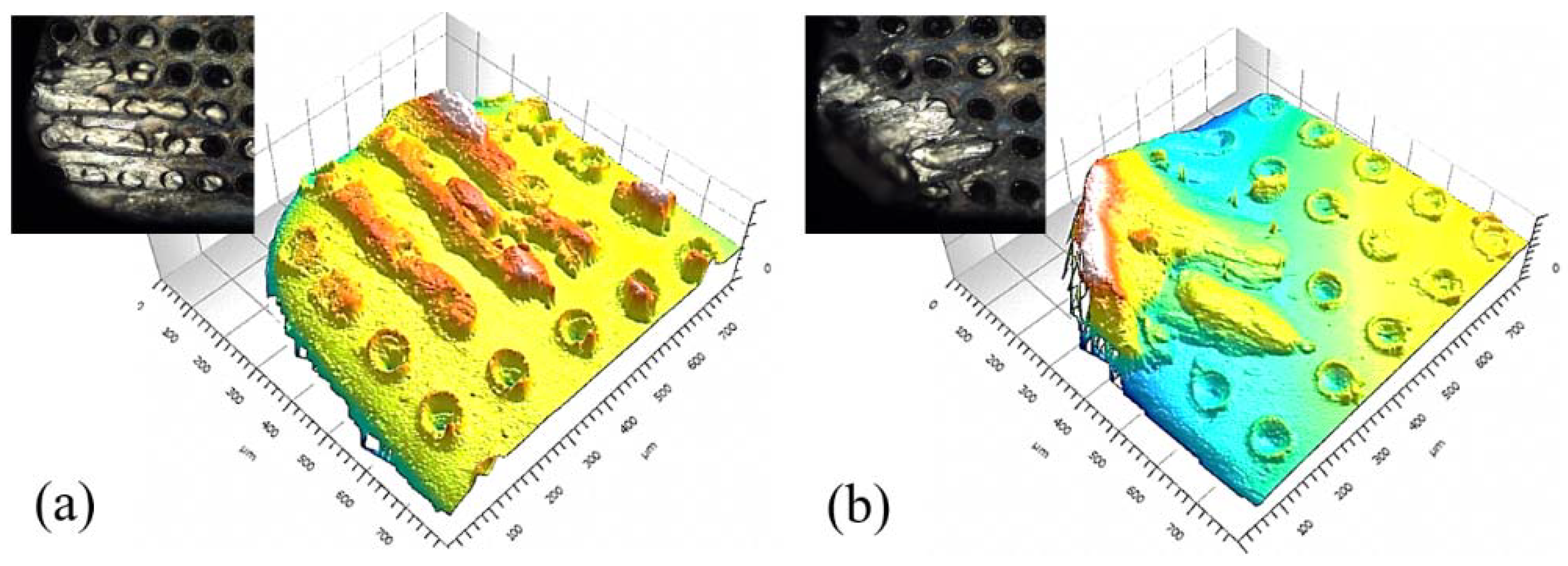

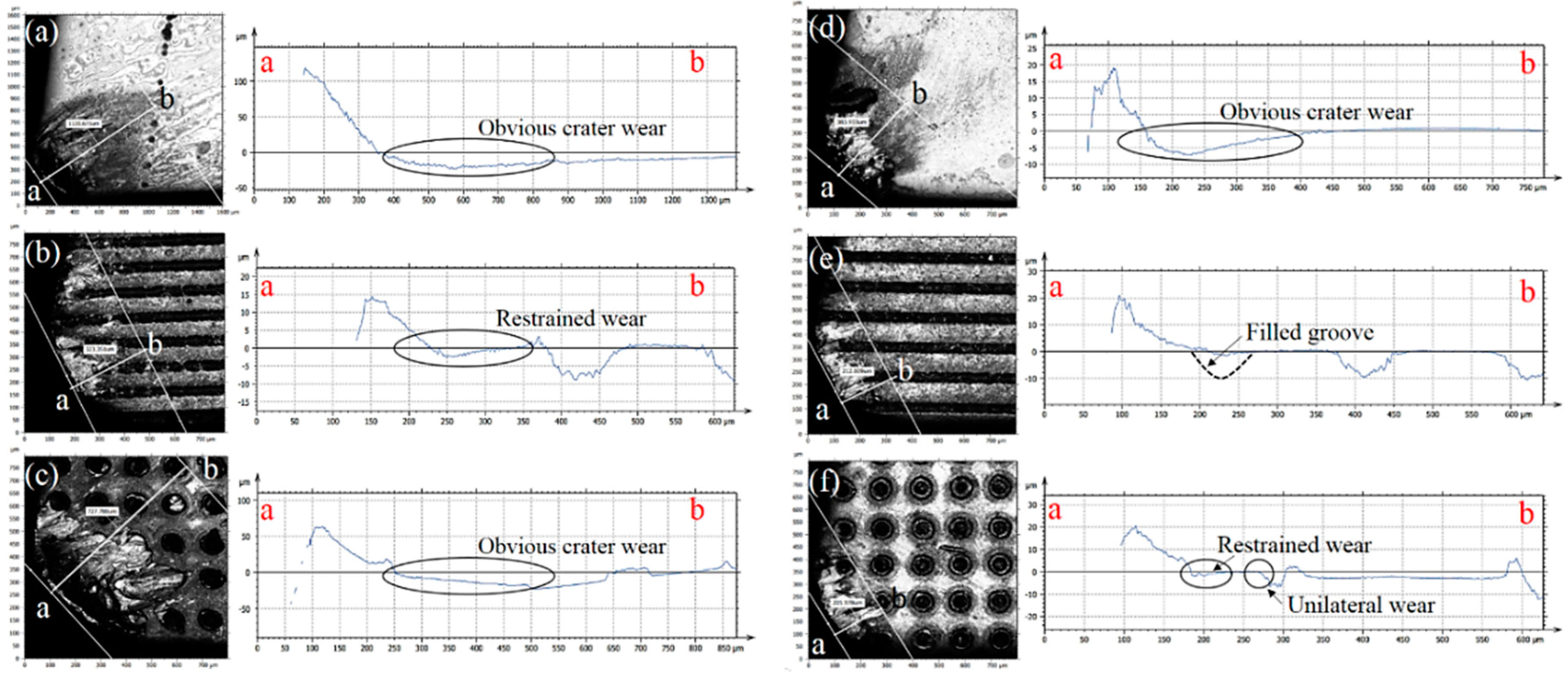

3.4. Wear and Adhesion on the Rake Face

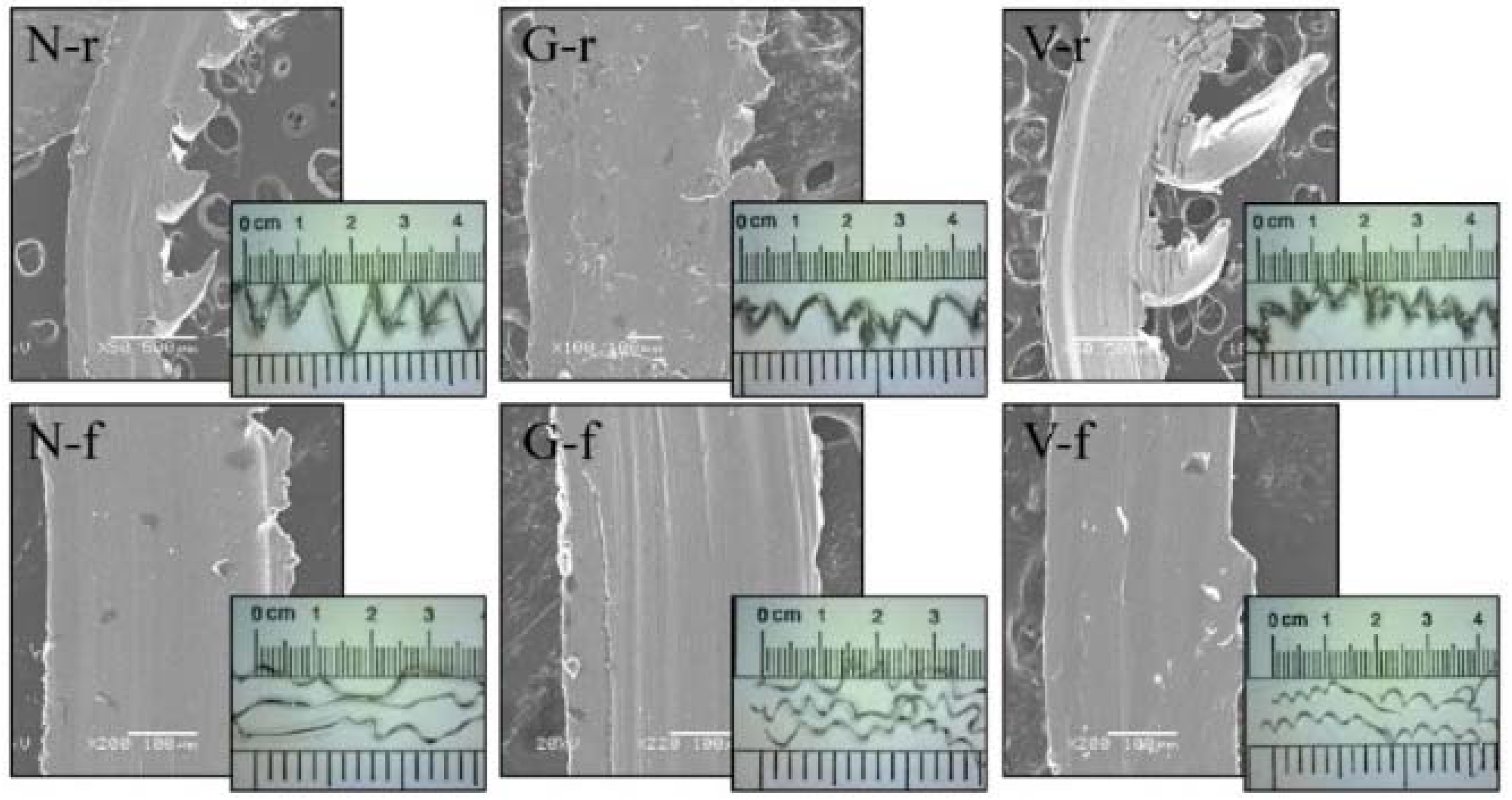

3.5. Chip Shape

4. Conclusions

- (1)

- VLT tools showed lower cutting forces in rough cutting; in wet cutting, on the contrary, the cutting forces of VLT tools increased greatly compared to MGT and flat tools. The poor compatibility of coolant and VLT could be the main reason.

- (2)

- In finish cutting, VLT tools has similar tool-chip adhesion and contact length to MGT tools, while their failure modes were different, i.e., wear and blocking, respectively. The reduction proportion in contact length was nearly 50%. The depth of crater wear decreased from 7 to 2 μm, indicating an obvious promotion in wear-resistance.

- (3)

- The textured tools generated curlier chips compared to flat tools in finish cutting. VLT worked like a chip breaker, breaking the chip evenly. It also produced the smoothest chip compared to other tools.

- (4)

- VLT has better heat reduction effect on the rake face than MGT in roughing, and it is more likely to have an anti-adhesion effect in finish cutting. In addition, the distance between VLT and cutting edge should be carefully determined.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Arslan, A.; Masjuki, H.H.; Kalam, M.A.; Varman, M.; Mufti, R.A.; Mosarof, M.H.; Khuong, L.S.; Quazi, M.M. Surface texture manufacturing techniques and tribological effect of surface texturing on cutting tool performance: A review. Crit. Rev. Solid State Mater. Sci. 2016, 41, 447–481. [Google Scholar] [CrossRef]

- Sharma, V.; Pandey, P.M. Recent advances in turning with textured cutting tools: A review. J. Clean. Prod. 2016, 137, 701–715. [Google Scholar] [CrossRef]

- Etsion, I. State of the Art in Laser Surface Texturing. J. Tribol. 2005, 127, 761–762. [Google Scholar] [CrossRef]

- Jiang, X.J.; Whitehouse, D.J. Technological shifts in surface metrology. CIRP Ann. Manuf. Technol. 2012, 61, 815–836. [Google Scholar] [CrossRef]

- Enomoto, T.; Watanabe, T.; Aoki, Y.; Ohtake, N. Development of a Cutting Tool with Micro Structured Surface. Trans. Jpn. Soc. Mech. Eng. 2007, 73, 288–293. [Google Scholar] [CrossRef]

- Kawasegi, N.; Sugimori, H.; Morimoto, H.; Morita, N.; Hori, I. Development of cutting tools with microscale and nanoscale textures to improve frictional behavior. Precis. Eng. 2009, 33, 248–254. [Google Scholar] [CrossRef]

- Lei, S.; Devarajan, S.; Chang, Z. A study of micropool lubricated cutting tool in machining of mild steel. J. Mater. Process. Technol. 2009, 209, 1612–1620. [Google Scholar] [CrossRef]

- Fatima, A.; Mativenga, P.T. Assessment of tool rake surface structure geometry for enhanced contact phenomena. Int. J. Adv. Manuf. Technol. 2013, 69, 771–776. [Google Scholar] [CrossRef]

- Obikawa, T.; Kamio, A.; Takaoka, H.; Osada, A. Micro-texture at the coated tool face for high performance cutting. Int. J. Mach. Tools Manuf. 2011, 51, 966–972. [Google Scholar] [CrossRef]

- Sugihara, T.; Enomoto, T. Improving anti-adhesion in aluminum alloy cutting by micro stripe texture. Precis. Eng. 2012, 36, 229–237. [Google Scholar] [CrossRef]

- Chang, W.; Sun, J.; Luo, X.; Ritchie, J.M.; Mack, C. Investigation of microstructured milling tool for deferring tool wear. Wear 2011, 271, 2433–2437. [Google Scholar] [CrossRef]

- Sugihara, T.; Enomoto, T. Crater and flank wear resistance of cutting tools having micro textured surfaces. Precis. Eng. 2013, 37, 888–896. [Google Scholar] [CrossRef]

- Xie, J.; Luo, M.J.; Wu, K.K.; Yang, L.F.; Li, D.H. Experimental study on cutting temperature and cutting force in dry turning of titanium alloy using a non-coated micro-grooved tool. Int. J. Mach. Tools Manuf. 2013, 73, 25–36. [Google Scholar] [CrossRef]

- Sugihara, T.; Enomoto, T. Development of a cutting tool with a nano/micro textured surface-Improvement of anti-adhesive effect by considering the texture patterns. Precis. Eng. 2009, 33, 425–429. [Google Scholar] [CrossRef]

- Dong, M.K.; Lee, I.; Sun, K.K.; Bo, H.K.; Park, H.W. Influence of a micro patterned insert on characteristics of the tool-workpiece interface in a hard turning process. J. Mater. Process. Technol. 2015, 229, 160–171. [Google Scholar]

- Kang, Z.; Fu, Y.; Ji, J.; Tian, L. Numerical investigation of microtexture cutting tool on hydrodynamic lubrication. J. Tribol. 2017, 139, 054502. [Google Scholar] [CrossRef]

- Ivanović, L.; Vencl, A.; Stojanović, B.; Marković, B. Biomimetics design for tribological applications. In Proceedings of the 15th International Conference on Tribology, Kragujevac, Serbia, 17–19 May 2017. [Google Scholar]

- Bhushan, B.; Yong, C.J. Natural and biomimetic artificial surfaces for superhydrophobicity, self-cleaning, low adhesion, and drag reduction. Prog. Mater. Sci. 2011, 56, 1–108. [Google Scholar] [CrossRef]

- Parker, A.R.; Lawrence, C.R. Water capture by a desert beetle. Nature 2001, 414, 33–34. [Google Scholar] [CrossRef] [PubMed]

- Ridgway, S.H.; Carder, D.A. Features of dolphin skin with potential hydrodynamic importance. IEEE Eng. Med. Biol. 1993, 12, 83–88. [Google Scholar] [CrossRef]

- Xing, Y.; Deng, J.; Zhao, J.; Zhang, G.; Zhang, K. Cutting performance and wear mechanism of nanoscale and microscale textured Al2O3/TiC ceramic tools in dry cutting of hardened steel. Int. J. Refract. Met. Hard Mater. 2014, 43, 46–58. [Google Scholar] [CrossRef]

- Koshy, P.; Tovey, J. Performance of electrical discharge textured cutting tools. CIRP Ann. Manuf. Technol. 2011, 60, 153–156. [Google Scholar] [CrossRef]

- Xie, J.; Luo, M.J.; He, J.L.; Liu, X.R.; Tan, T.W. Micro-grinding of micro-groove array on tool rake surface for dry cutting of titanium alloy. Int. J. Precis. Eng. Manuf. 2012, 13, 1845–1852. [Google Scholar] [CrossRef]

- Du, D.; He, Y.F.; Sui, B.; Xiong, L.J.; Zhang, H. Laser texturing of rollers by pulsed Nd: YAG laser. J. Mater. Process. Technol. 2005, 161, 456–461. [Google Scholar] [CrossRef]

- Ma, J.F.; Duong, N.H.; Lei, S. Numerical investigation of the performance of microbump textured cutting tool in dry machining of AISI 1045 steel. J. Manuf. Process. 2014, 19, 194–204. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, X.; Li, H.; Wang, B. Adhesive behavior of micro/nano-textured surfaces. Appl. Surf. Sci. 2015, 329, 174–183. [Google Scholar] [CrossRef]

- Kang, Z.Y.; Fu, Y.H.; Ji, J.H.; Wang, H. Characterisation of group behavior surface texturing with multi-layers fitting method. Nondestruct. Test. Eval. 2016, 31, 235–246. [Google Scholar] [CrossRef]

- Xing, Y.; Deng, J.; Feng, X.; Yu, S. Effect of laser surface texturing on Si3N4/Tic ceramic sliding against steel under dry friction. Mater. Des. 2013, 52, 234–245. [Google Scholar] [CrossRef]

- Arulkirubakaran, D.; Senthilkumar, V.; Kumawat, V. Effect of micro-textured tools on machining of Ti-6Al-4V alloy: An experimental and numerical approach. Int. J. Refract. Met. Hard Mater. 2016, 54, 165–177. [Google Scholar] [CrossRef]

- Zhang, Y.C.; Mabrouki, T.; Nelias, D.; Gong, Y.D. Chip formation in orthogonal cutting considering interface limiting shear stress and damage evolution based on fracture energy approach. Finite Elem. Anal. Des. 2011, 47, 850–863. [Google Scholar] [CrossRef]

- Johnson, G.C.; Bammann, D.J. Discussion of stress rates in finite deformation problems. Int. J. Solids Struct. 1984, 20, 725–737. [Google Scholar] [CrossRef]

- Kümmel, J.; Braun, D.; Gibmeier, J.; Schneider, J.; Greiner, C.; Schulze, V. Study on micro texturing of uncoated cemented carbide cutting tools for wear improvement and built-up edge stabilization. J. Mater. Process. Technol. 2015, 215, 62–70. [Google Scholar] [CrossRef]

- Rao, P.N. Manufacturing Technology: Metal Cutting and Machine Tools, 3rd ed.; McGraw-Hill Education: New York, NY, USA, 2013; Volume 2. [Google Scholar]

| Types | Width wg [μm] | Depth hg [μm] | Spacing sg [μm] | Area Density ρg [%] 1 |

|---|---|---|---|---|

| Flat | - | - | - | - |

| MGT | 50 | 10 | 120 | 30 |

| VLT | Diameter dv [μm] | Height hv [μm] | Spacing sv [μm] | Area density ρv [%] 2 |

| 90 | 3 | 180 | 20 |

| A [Mpa] | B [Mpa] | m | C | n | Tm [°C] | T0 [°C] |

|---|---|---|---|---|---|---|

| 324 | 114 | 1.34 | 0.002 | 0.42 | 610 | 20 |

| Physical Parameters | A6061 | YG6 |

|---|---|---|

| Density, ρ [kg/m3] | 2700 | 15,290 |

| Elastic modulus, E [GPa] | 70 | 600 |

| Poisson’s ratio, ν | 0.33 | 0.23 |

| Specific heat, Cp [J/kg/°C] | 896 | 178 |

| Thermal conductivity, λ [W/m/°C] | 173 | 24 |

| Thermal expansion coefficient, α [μm/m/°C] | 23.5 | 5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, Z.; Fu, Y.; Fu, X.; Jun, M.B.-G. Performance of Volcano-Like Laser Textured Cutting Tools: An Experimental and Simulative Investigation. Lubricants 2018, 6, 98. https://doi.org/10.3390/lubricants6040098

Kang Z, Fu Y, Fu X, Jun MB-G. Performance of Volcano-Like Laser Textured Cutting Tools: An Experimental and Simulative Investigation. Lubricants. 2018; 6(4):98. https://doi.org/10.3390/lubricants6040098

Chicago/Turabian StyleKang, Zhengyang, Yonghong Fu, Xingyu Fu, and Martin Byung-Guk Jun. 2018. "Performance of Volcano-Like Laser Textured Cutting Tools: An Experimental and Simulative Investigation" Lubricants 6, no. 4: 98. https://doi.org/10.3390/lubricants6040098

APA StyleKang, Z., Fu, Y., Fu, X., & Jun, M. B.-G. (2018). Performance of Volcano-Like Laser Textured Cutting Tools: An Experimental and Simulative Investigation. Lubricants, 6(4), 98. https://doi.org/10.3390/lubricants6040098