Influence of Laser Pulse Number on the Ablation of Cemented Tungsten Carbides (WC-CoNi) with Different Grain Size †

Abstract

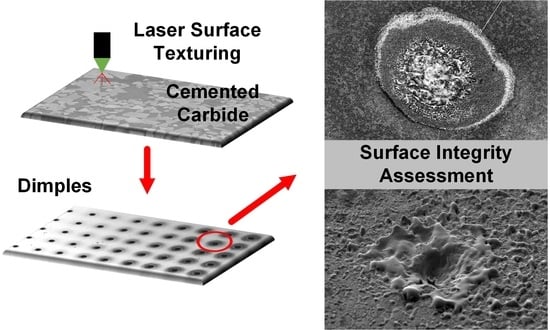

:1. Introduction

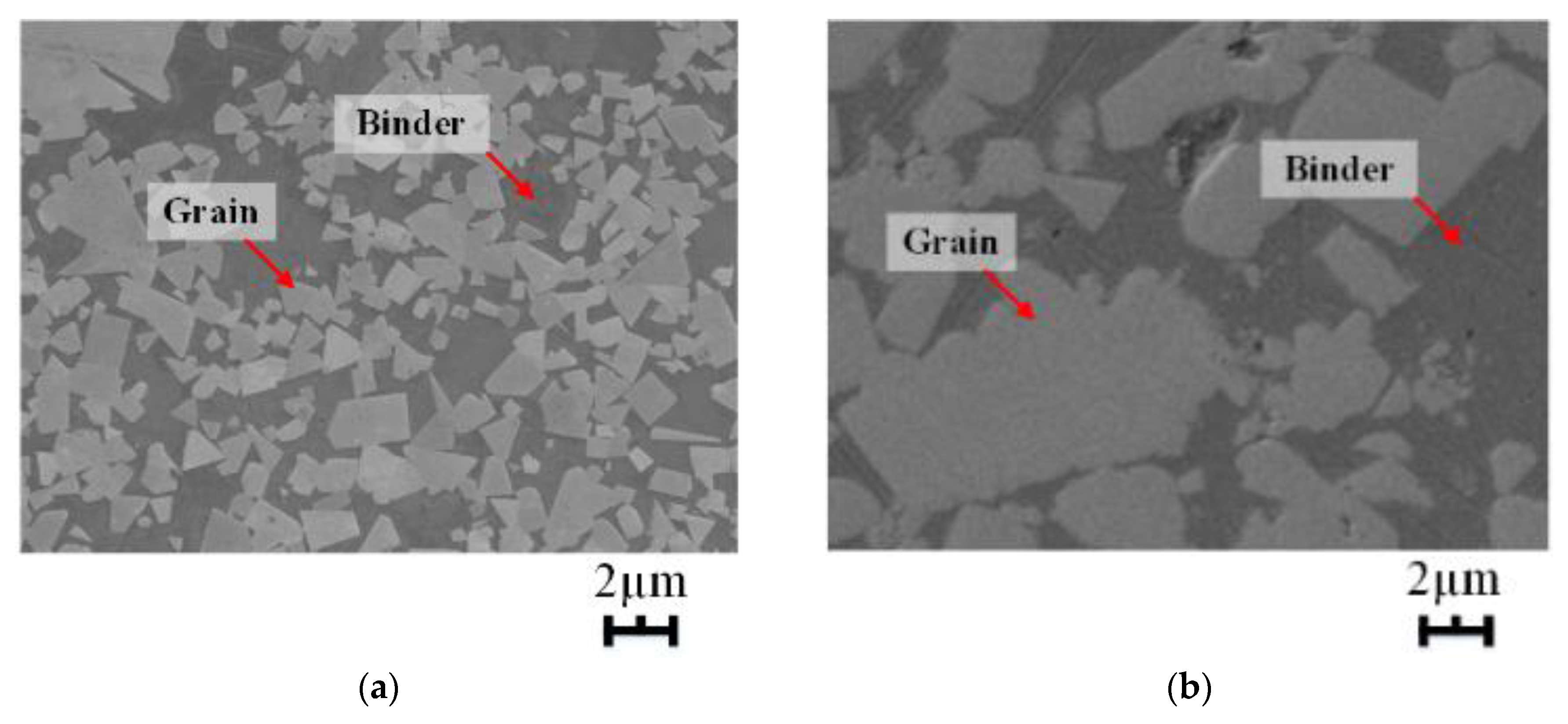

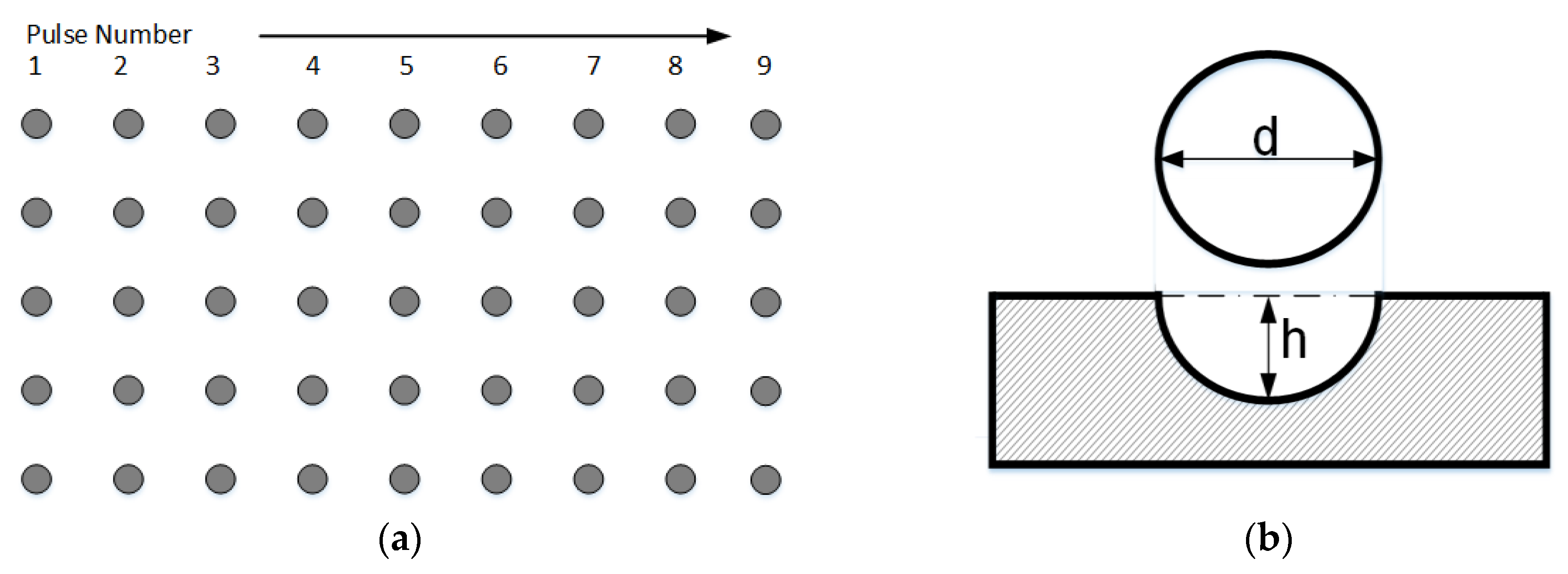

2. Materials and Experimental Aspects

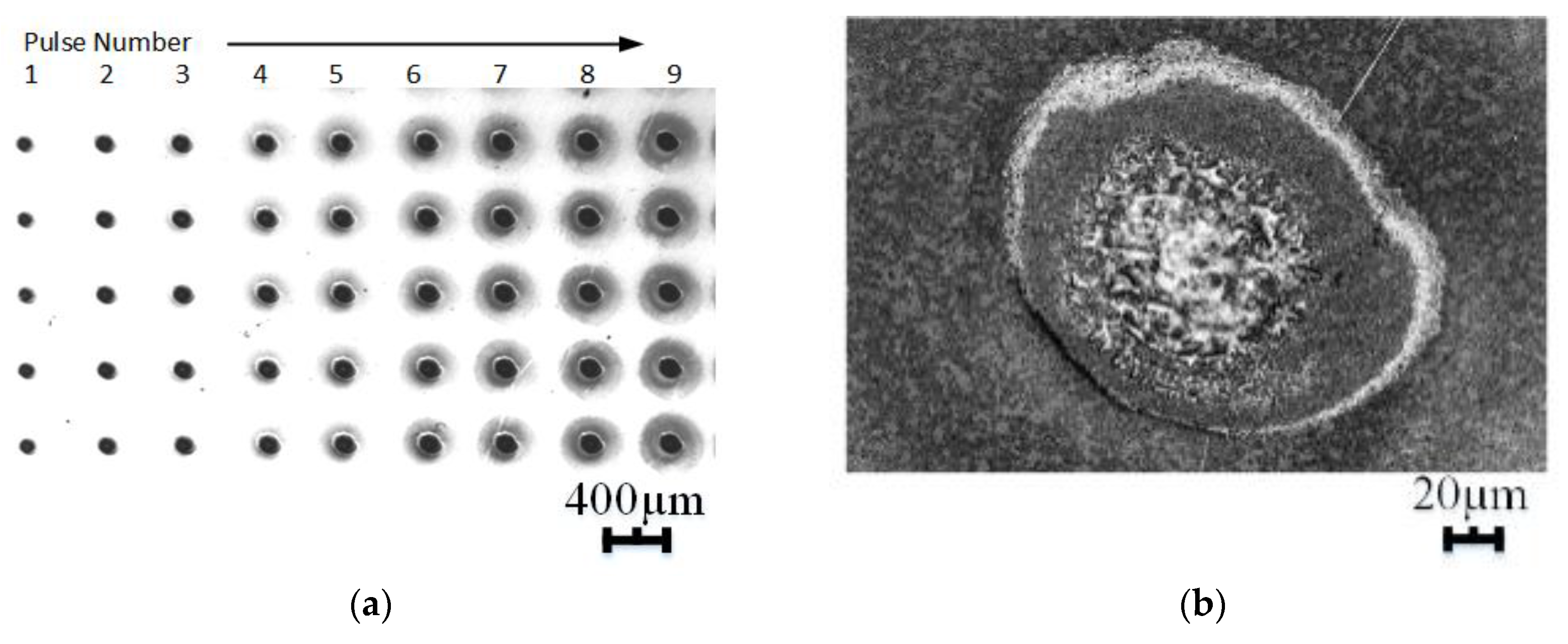

3. Results and Discussion

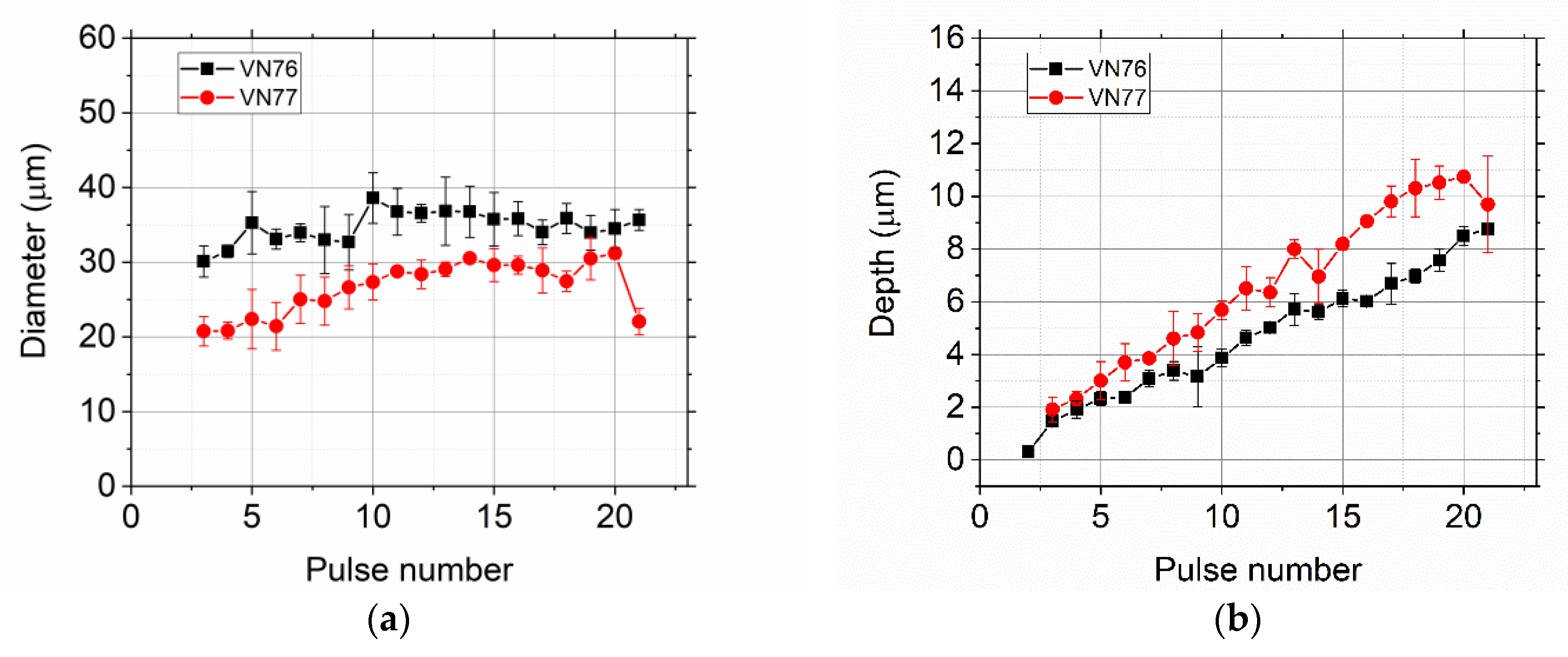

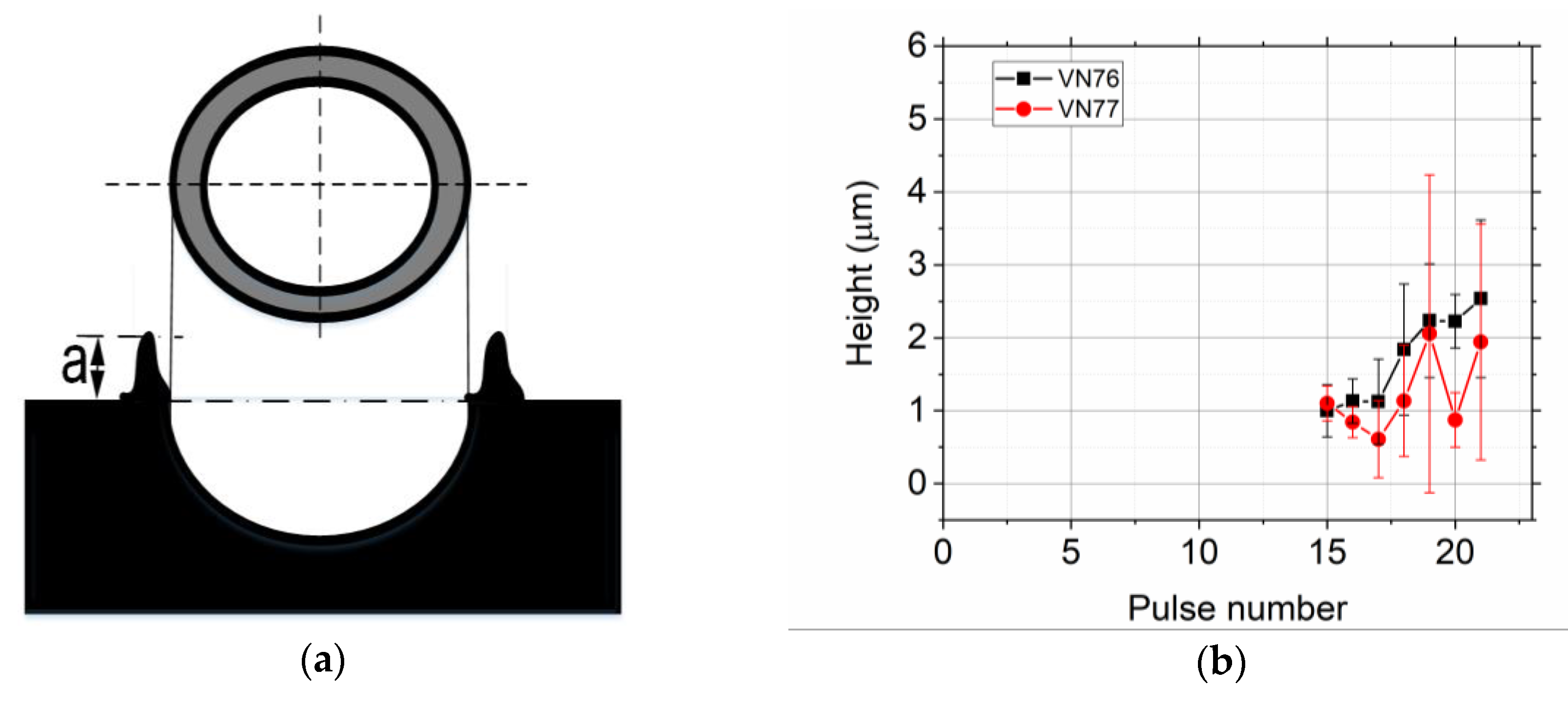

3.1. Measurement of Geometrical Properties

3.2. Assessment of Surface Integrity

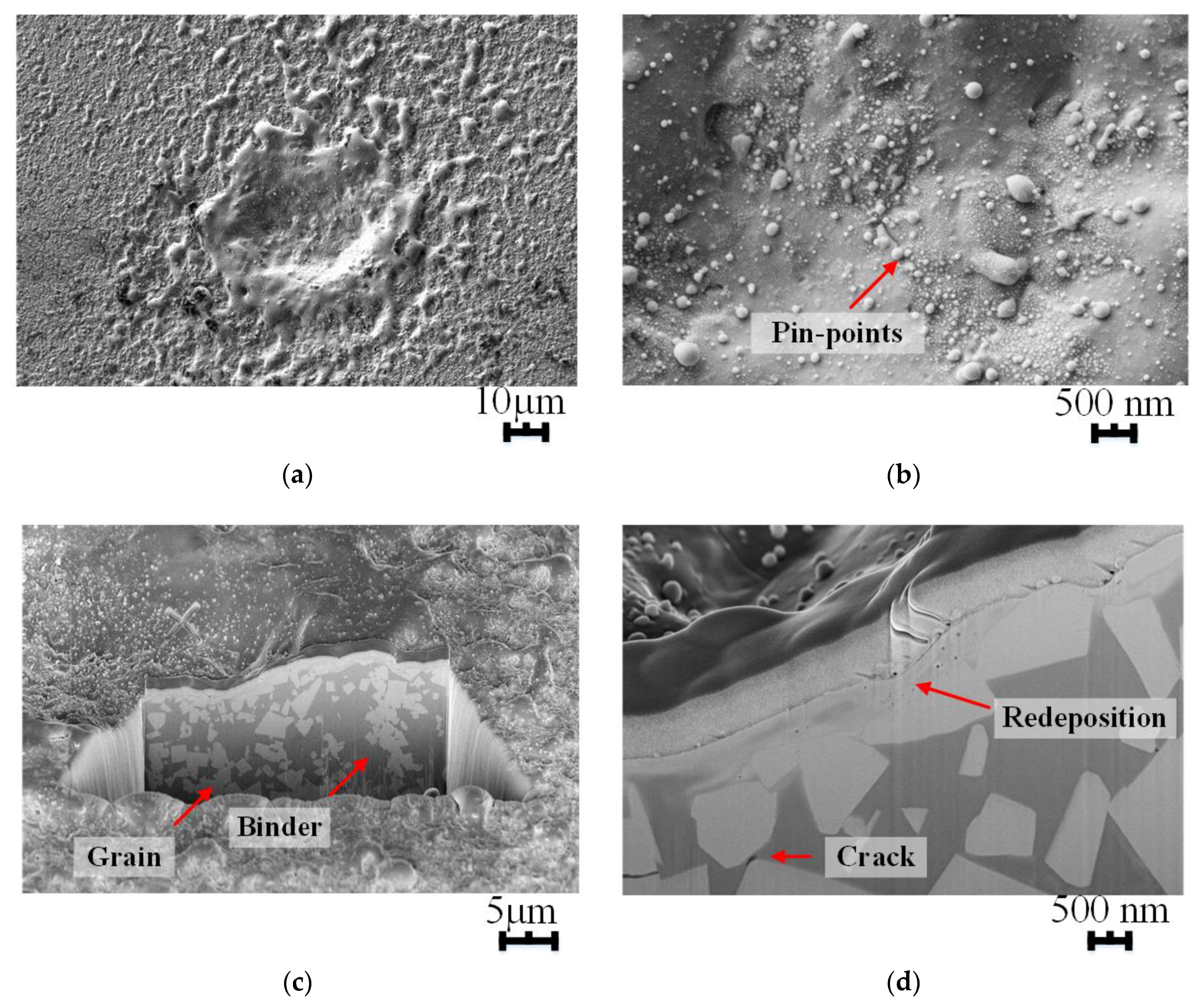

3.2.1. Dimples Produced on VN76 (Small Grains)

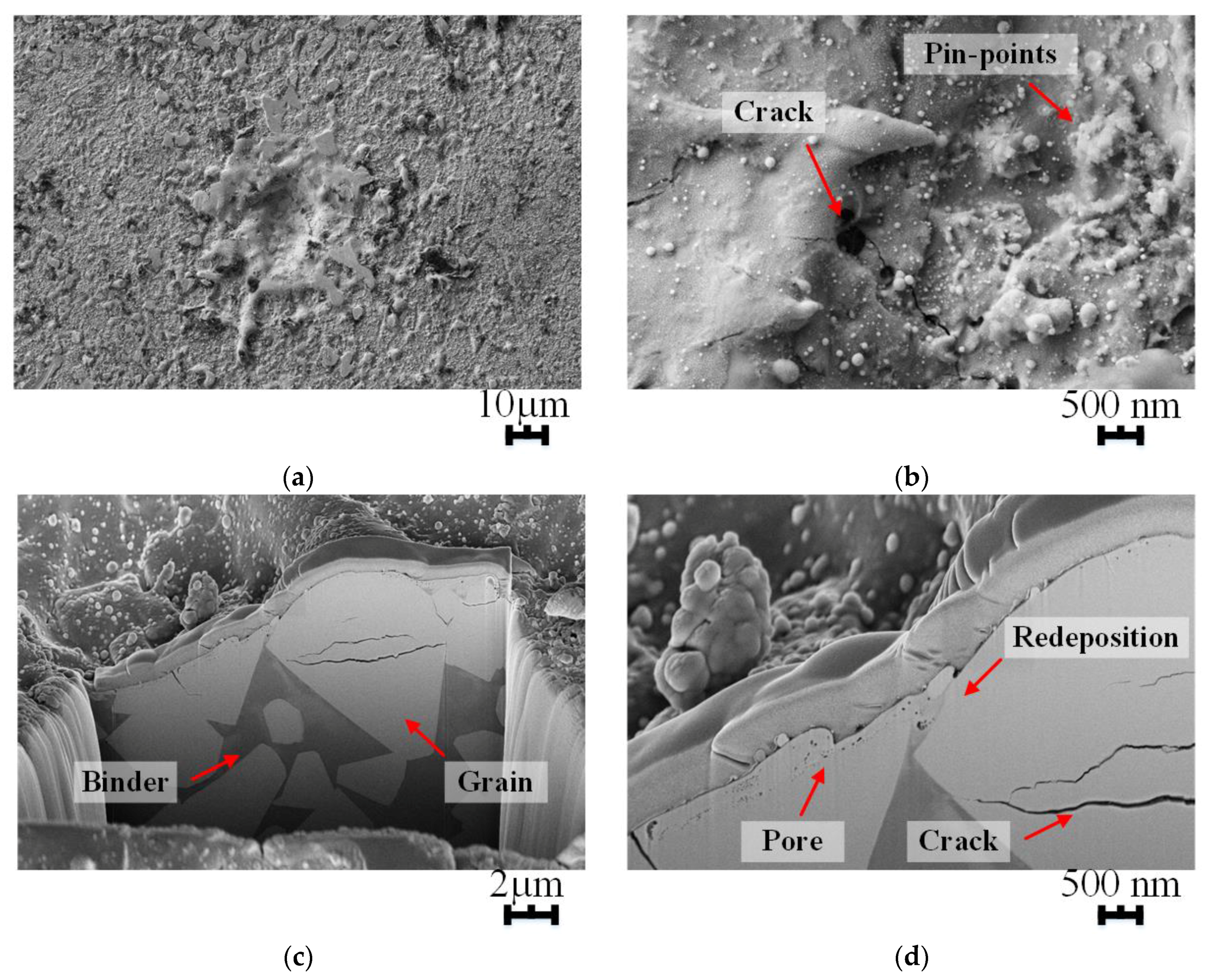

3.2.2. Dimples Produced on VN77 (Large Grains)

3.2.3. Chemical Composition of the Affected Zone

4. Conclusions and Perspectives

- The depth of the produced dimples increases approximately proportionally to the applied pulse number, but greater depth and a smaller laser-affected zone were achieved by VN77 (large grains) compared to VN76 (small grains). The depth increase rate of VN77 (large grains) is higher than that of VN76 (small grains). This could be a result of the different microstructures of these two grades; specifically, the grade with smaller grain size has a higher ablation threshold. The diameters of laser affected zones increase slightly along with the pulse number, and this is due to the deviation increase between the laser focus point and the point of laser-matter reaction when the ablation increases. Within this context, it is necessary to supply a position correction as a function of the pulse number for precision requirements.

- The appearance of a crown-like structure is a side effect that becomes increasingly important with the increase of the pulse number. This is caused by repetitive melting and redeposition at the edge of the Gaussian laser beams, where the energy decreases when the laser-matter reaction point moves forward from the focus point. It is then advisable to use fewer laser pulses and correct the laser focus point in order to reduce the formation of crown-like structures.

- Regarding the cross-sectional analysis, a similar damage mechanism was found for both grades—grain cracks and binder melting—and no oxide was produced by the fs-laser. Damage occurred only at the very shallow subsurface for both grades, and side effects accumulated only slightly when the applied laser pulses increased. However, grains of VN77 (large grains) suffered from more pronounced damage compared to VN76 (small grains) under identical laser configuration. The microstructure of the cemented carbides could be the reason; therefore, it is suggested that cemented carbides with large grain sizes be ablated with less pulse energy.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wolfe, T.A.; Jewett, T.J.; Singh Gaur, R.P. Comprehensive Hard Materials. In Comprehensive Hard Materials; Elsevier: Oxford, UK, 2014; pp. 185–212. [Google Scholar]

- Cardarelli, F. Ceramics, Refractories, and Glasses. In Materials Handbook: A Concise Desktop Reference; Springer: London, UK, 2008; pp. 593–689. [Google Scholar]

- Exner, H.E. Physical and chemical nature of cemented carbides. Int. Met. Rev. 1979, 24, 149–173. [Google Scholar] [CrossRef]

- Gurland, J. New scientific approaches to development of tool materials. Int. Met. Rev. 1988, 33, 151–166. [Google Scholar] [CrossRef]

- Egashira, K.; Hosono, S.; Takemoto, S.; Masao, Y. Fabrication and cutting performance of cemented tungsten carbide micro-cutting tools. Precis. Eng. 2011, 35, 547–553. [Google Scholar] [CrossRef]

- Schmitt, C.; Bähre, D. An approach to the calculation of process forces during the precision honing of small bores. Procedia CIRP 2013, 7, 282–287. [Google Scholar] [CrossRef]

- Geiger, M.; Popp, U.; Engel, U. Excimer Laser Micro Texturing of Cold Forging Tool Surfaces—Influence on Tool Life. CIRP Ann. Manuf. Technol. 2002, 51, 231–234. [Google Scholar] [CrossRef]

- Etsion, I. State of the Art in Laser Surface Texturing. J. Tribol. 2005, 127, 248–253. [Google Scholar] [CrossRef]

- Jacobson, S.; Hogmark, S. Surface modifications in tribological contacts. Wear 2009, 266, 370–378. [Google Scholar] [CrossRef]

- Fang, S.; Herrmann, T.; Rosenkranz, A.; Gachot, C.; Marro, F.G.; Mücklich, F.; Llanes, L.; Bähre, D. Tribological Performance of Laser Patterned Cemented Tungsten Carbide Parts. Procedia CIRP 2016, 42, 439–443. [Google Scholar] [CrossRef]

- Fang, S.; Llanes, L.; Klein, S.; Gachot, C.; Rosenkranz, A.; Bähre, D.; Mücklich, F. Frictional Performance Assessment of Cemented Carbide Surfaces Textured by Laser. IOP Conf. Ser. Mater. Sci. Eng. 2017, 258, 012006. [Google Scholar] [CrossRef]

- Klein, S.; Fang, S.; Bähre, D. Analysis of Different Surface Structures of Hard Metal Guiding Stones in the Honing Process. Procedia Manuf. 2017, 10, 265–275. [Google Scholar] [CrossRef]

- Dumitru, G.; Lüscher, B.; Krack, M.; Bruneau, S.; Hermann, J.; Gerbig, Y. Laser processing of hardmetals: Physical basics and applications. Int. J. Refract. Met. Hard Mater. 2005, 23, 278–286. [Google Scholar] [CrossRef]

- Dumitru, G.; Romano, V.; Weber, H.P.; Sentis, M.; Marine, W. Femtosecond ablation of ultra-hard materials. Appl. Phys. A Mater. Sci. Process. 2002, 74, 729–739. [Google Scholar] [CrossRef]

- Li, T.; Lou, Q.; Dong, J.; Wei, Y.; Liu, J. Modified surface morphology in surface ablation of cobalt-cemented tungsten carbide with pulsed UV laser radiation. Appl. Surf. Sci. 2001, 172, 331–344. [Google Scholar] [CrossRef]

- Yao, Y.L.; Chen, H.; Zhang, W. Time scale effects in laser material removal: A review. Int. J. Adv. Manuf. Technol. 2005, 26, 598–608. [Google Scholar] [CrossRef]

- Li, T.; Lou, Q.; Dong, J.; Wei, Y.; Liu, J. Phase transformation during surface ablation of cobalt-cemented tungsten carbide with pulsed UV laser. Appl. Phys. A 2001, 73, 391–397. [Google Scholar] [CrossRef]

- Fang, S.; Llanes, L.; Bähre, D. Wear Characterization of Cemented Carbides (WC-CoNi) Processed by Laser Surface Texturing under Abrasive Machining Conditions. Lubricants 2017, 5, 20. [Google Scholar] [CrossRef]

- Haustrup, N.; O’Connor, G.M. The influence of thin film grain size on the size of nanoparticles generated during UV femtosecond laser ablation of thin gold films. Appl. Surf. Sci. 2013, 278, 86–91. [Google Scholar] [CrossRef]

- Costa, H.L.; Hutchings, I.M. Hydrodynamic lubrication of textured steel surfaces under reciprocating sliding conditions. Tribol. Int. 2007, 40, 1227–1238. [Google Scholar] [CrossRef]

- Nakano, M.; Korenaga, A.; Korenaga, A.; Miyake, K.; Murakami, T.; Ando, Y.; Usami, H.; Sasaki, S. Applying micro-texture to cast iron surfaces to reduce the friction coefficient under lubricated conditions. Tribol. Lett. 2007, 28, 131–137. [Google Scholar] [CrossRef]

- Leitz, K.H.; Redlingshöfer, B.; Reg, Y.; Otto, A.; Schmidt, M. Metal ablation with short and ultrashort laser pulses. Phys. Procedia 2011, 12, 230–238. [Google Scholar] [CrossRef]

- Xu, X. Phase explosion and its time lag in nanosecond laser ablation. Appl. Surf. Sci. 2002, 197–198, 61–66. [Google Scholar] [CrossRef]

| Material | Grain Size (µm) | Co (wt %) | Ni (wt %) | Density (g/cm³) | Hardness (HV30) |

|---|---|---|---|---|---|

| VN76 | <2.5 | 14 | 14 | 12.77 | 710 |

| VN77 | >5 | 14 | 14 | 12.82 | 610 |

| Laser Type | Laser Source | Pulse Duration (fs) | Wave Length (nm) | PRF (Hz) | Average Power (W) |

|---|---|---|---|---|---|

| fs-laser | Ti:Sapphire | 150 | 800 | 1000 | 2.6 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, S.; Hsu, C.-J.; Klein, S.; Llanes, L.; Bähre, D.; Mücklich, F. Influence of Laser Pulse Number on the Ablation of Cemented Tungsten Carbides (WC-CoNi) with Different Grain Size. Lubricants 2018, 6, 11. https://doi.org/10.3390/lubricants6010011

Fang S, Hsu C-J, Klein S, Llanes L, Bähre D, Mücklich F. Influence of Laser Pulse Number on the Ablation of Cemented Tungsten Carbides (WC-CoNi) with Different Grain Size. Lubricants. 2018; 6(1):11. https://doi.org/10.3390/lubricants6010011

Chicago/Turabian StyleFang, Shiqi, Chia-Jui Hsu, Sven Klein, Luis Llanes, Dirk Bähre, and Frank Mücklich. 2018. "Influence of Laser Pulse Number on the Ablation of Cemented Tungsten Carbides (WC-CoNi) with Different Grain Size" Lubricants 6, no. 1: 11. https://doi.org/10.3390/lubricants6010011

APA StyleFang, S., Hsu, C.-J., Klein, S., Llanes, L., Bähre, D., & Mücklich, F. (2018). Influence of Laser Pulse Number on the Ablation of Cemented Tungsten Carbides (WC-CoNi) with Different Grain Size. Lubricants, 6(1), 11. https://doi.org/10.3390/lubricants6010011