Abstract

Molybdenum disulfide (MoS2) is a well-known solid lubricant for tribosystems running in vacuum or dry gases. Problems arise due to its sensitivity to humidity, which is a drawback for its application under ambient conditions. However, by using a physical vapor deposition (PVD) process, deposition parameters can be optimized not only to gain a coatings structure with favorable frictional properties but also to minimize the sensitivity to attack by water molecules. Therefore, an improved tribological behavior even under moist conditions can be achieved. MoS2 coatings are also candidates for being applied at cryogenic temperatures. They already have proven their suitability, e.g., for sliding support elements between superconducting magnets of the nuclear fusion-experiment Wendelstein 7-X. However, these coatings were exclusively produced for this particular application and the utilization for more common tribosystems may be precluded due to cost considerations. In view of a wider range of applications, pure and Cr containing PVD-MoS2 coatings with an optimized structure were tested under varying environments including hydrogen gas and cryogenic temperatures. Results of the most promising variant are presented in this paper.

1. Introduction—Lubricating Properties of MoS2

For vacuum and inert gaseous environment, molybdenum disulfide (MoS2) is a well suited and widely applied solid lubricant [1]. In vacuum, solid lubricants of this type show minimum friction coefficients as low as 0.03, and, under certain conditions, even lower. However, a major drawback for the application of MoS2 is its sensitivity to the presence of water vapor. In normal humid air, friction coefficients between 0.15 and 0.30, accompanied by high wear, are observed.

For low temperature environment some authors report a minimum temperature of 88 K for special liquid lubricants [2]. However, commercially available oils and greases are only applicable at temperatures above 173 K. Furthermore, the cryogenic liquids themselves are not able to build up hydrodynamic lubrication [3]. Therefore, for components such as bearings, liners, moving seals, and valves, dry sliding, dry rolling or non-contacting systems must be employed.

There are some special applications that require smooth sliding surfaces in vacuum environment at cryogenic temperatures. One example is the support structure of large superconducting magnets for nuclear fusion devices [4]. These magnets are cooled by liquid helium, which has a boiling temperature of 4.2 K. During cool down and ramping up of the magnetic field, the superconducting coils experience large forces due to thermal shrinkage of the materials and an increasing electrical current in the magnetic field. This results in a very slow tangential movement of several mm at the supports of the individual coils. Because frictional heat and mechanical shocks are able to initiate a normal conducting zone, a lubricant must be employed that guarantees low friction sliding without stick-slip at these supports. Tests have shown that only MoS2 coatings without any additions are able to meet such requirements [5].

Similar to graphite, MoS2 crystallizes in a lamellar structure. The Mo atoms form hexagonal planes with covalently bonded S atoms at both sides. The spacing between the Mo and Satoms is 0.154 nm, between the Satoms to the nearest MoS2 plane 0.308 nm. Between the planes only weak Van-der-Waals forces are acting, resulting in easy shearing tangential to the planes, which is responsible for the good lubricating properties. Molecular dynamic simulations show that during sliding a tribofilm is formed with basal orientation of the lattice planes [6]. These model calculations also show that, with perfectly aligned layers, a minimum friction coefficient of 0.006 is possible, due to the repulsive Coulomb forces between the sulfur atoms.

MoS2 is applied by burnishing, physical or chemical vapor deposition (PVD, CVD), or with binders as anti-friction (AF) coatings. It can also serve as friction reducing component in polymer composites [1].

Anti-friction (AF) coatings consist of one or more solid lubricants and, in most cases, an organic binder. Some variants, in particular those containing MoS2 or polytetrafluoroethylene (PTFE), are suitable for low temperature operation.

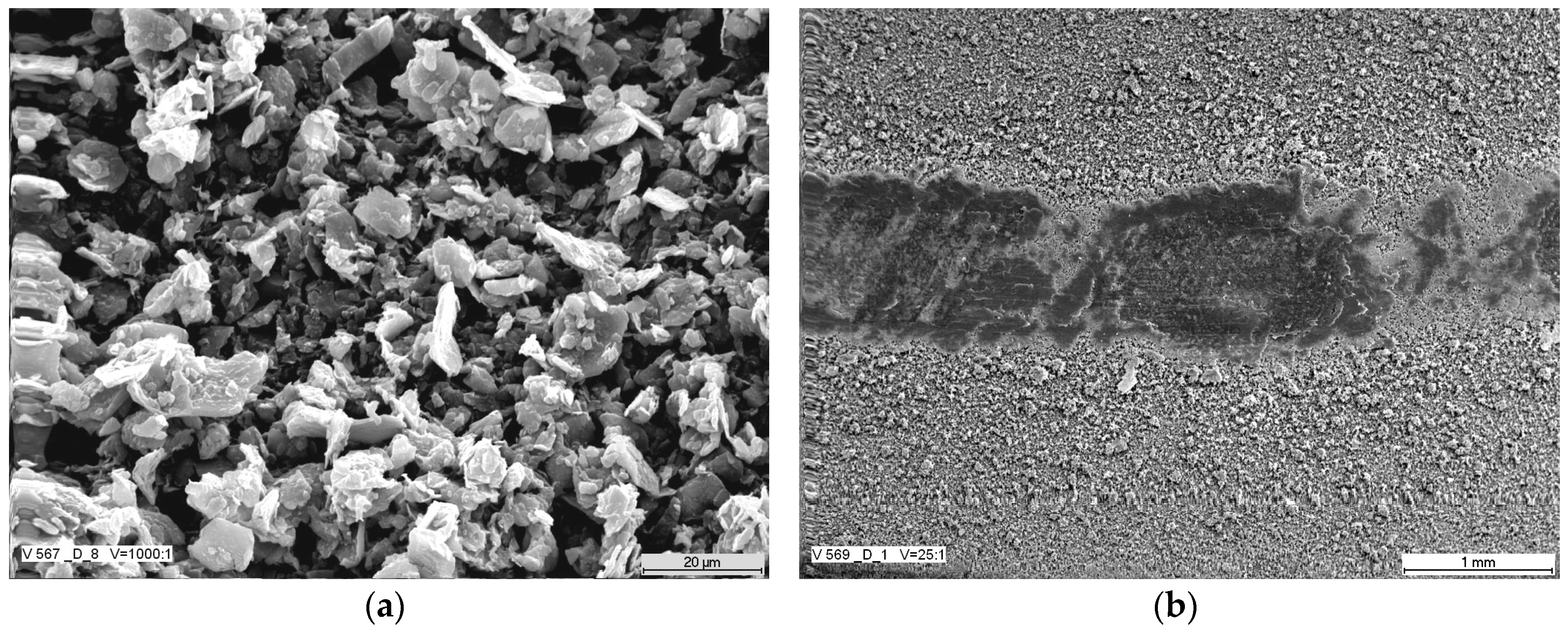

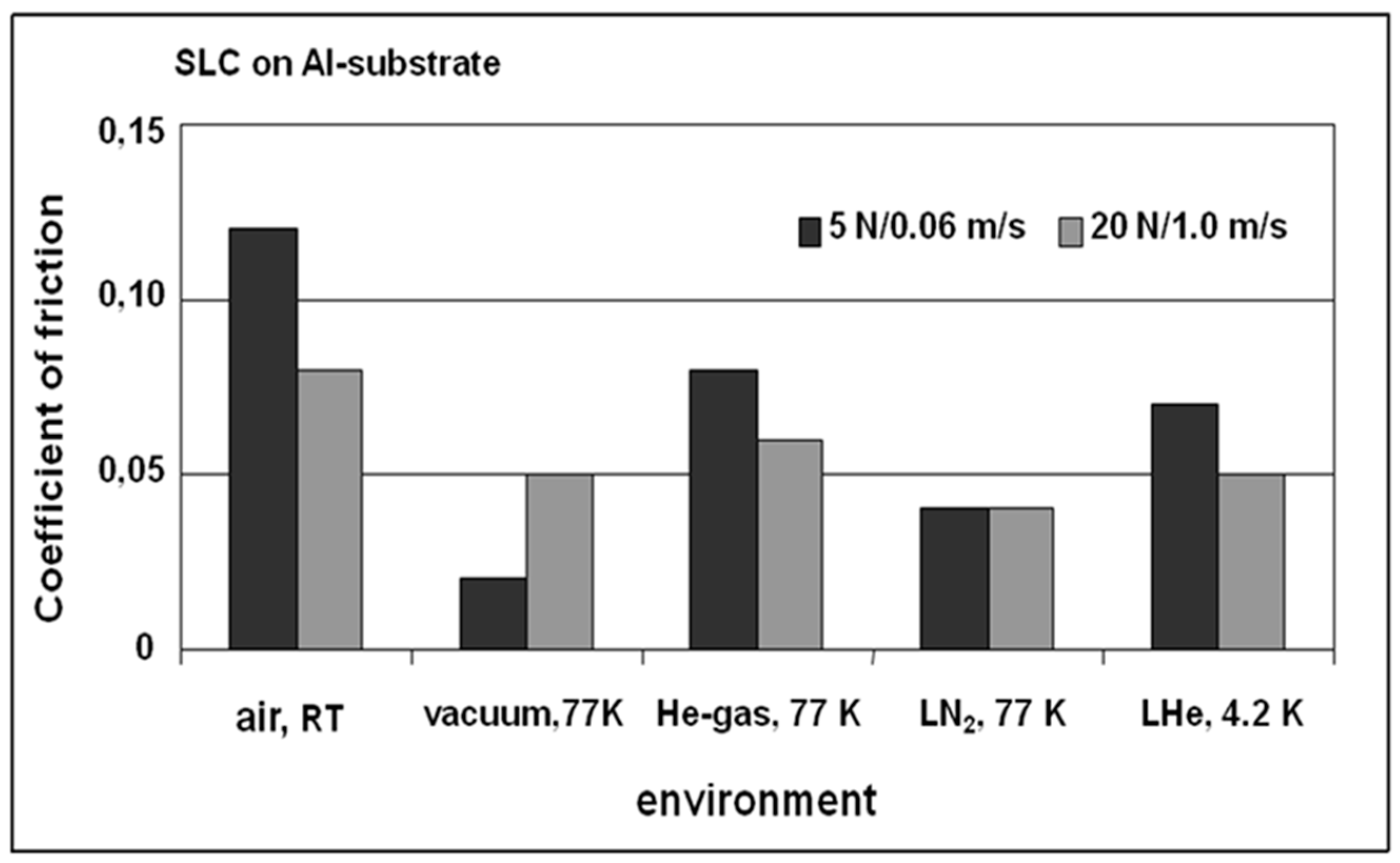

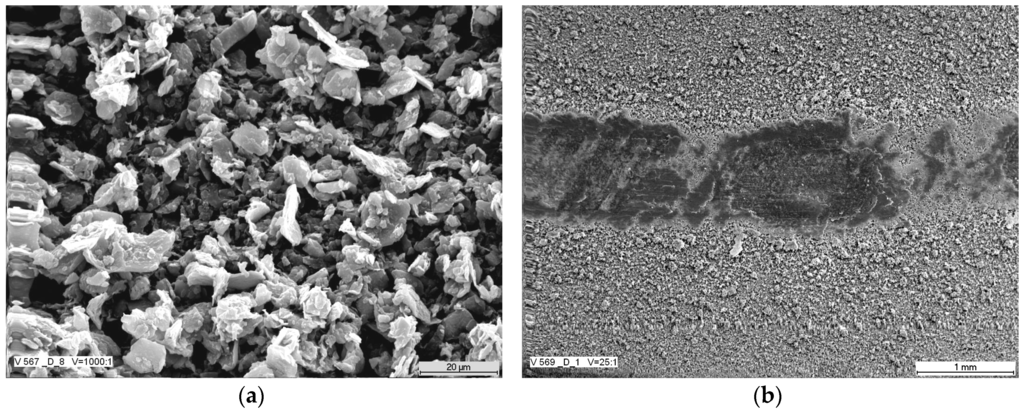

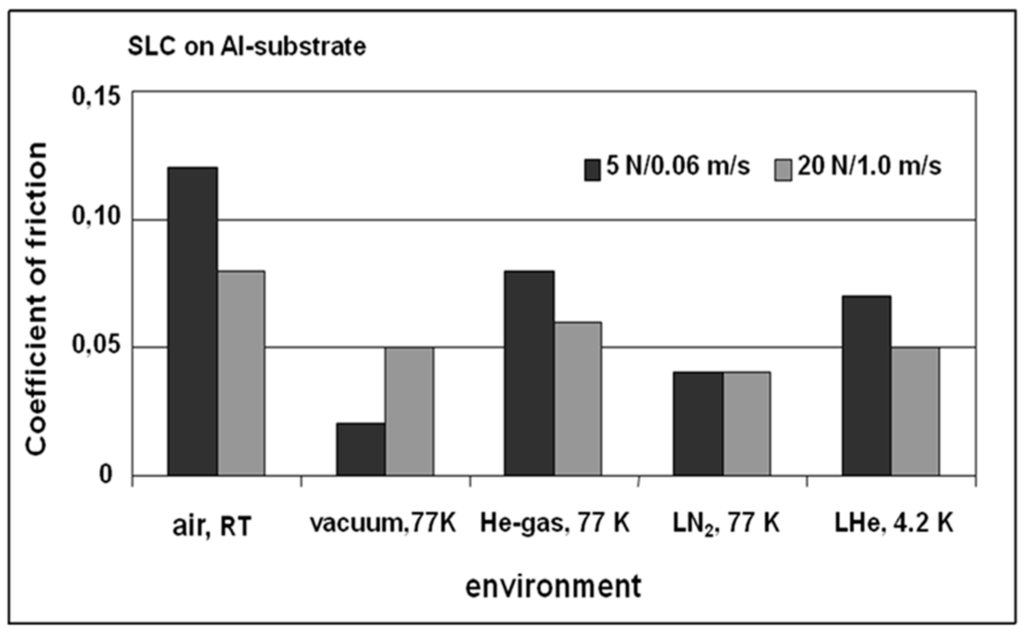

Many AF coatings need a certain running in for achieving the desired properties. One extreme case is shown in Figure 1. It is a sprayed MoS2 coating with polycarbamide binder, which was specially designed for space applications [7]. Figure 1a shows a scanning electron microscopy (SEM) image of the virgin coating, which consists of only loosely adhered particles. During loading and sliding the particles are compacted and get a preferred order, resulting in a very smooth film (Figure 1b). In Figure 2, the friction coefficients of this coating against 100Cr6 steel balls (AISI 52100) are shown for several cryogenic environments [8]. It can be seen that it provides effective lubrication in all of the investigated media. In cryogenic environment, friction is considerable lower than at room temperature. The lowest friction coefficient is 0.02 at 77 K in vacuum. In most cases, higher loads and velocities give lower friction, which is a common feature of MoS2 coatings.

Figure 1.

AF coating with polycarbamide binder [7]: (a) virgin coating; and (b) after sliding in liquid helium (LHe).

Figure 2.

Coefficient of friction of a MoS2-AF coating with polycarbamide binder in air and cryogenic media [8].

By using a PVD process, deposition parameters can be optimized to gain coatings with a more textured structure orienting the (002) basal planes parallel to the substrate surface [9]. A similar concept has been used by Koch et al. [5] for coatings developed for support elements in the superconducting magnet system of the WENDELSTEIN W7-X fusion experiment. They are able to withstand extreme operational conditions such as temperatures as low as 5 K in combination with high vacuum. Other authors report friction coefficients between 0.015 and 0.06 in liquid nitrogen (LN2) and minimum wear on both sliding surfaces for Ti containing PVD-MoS2 coatings [10,11].

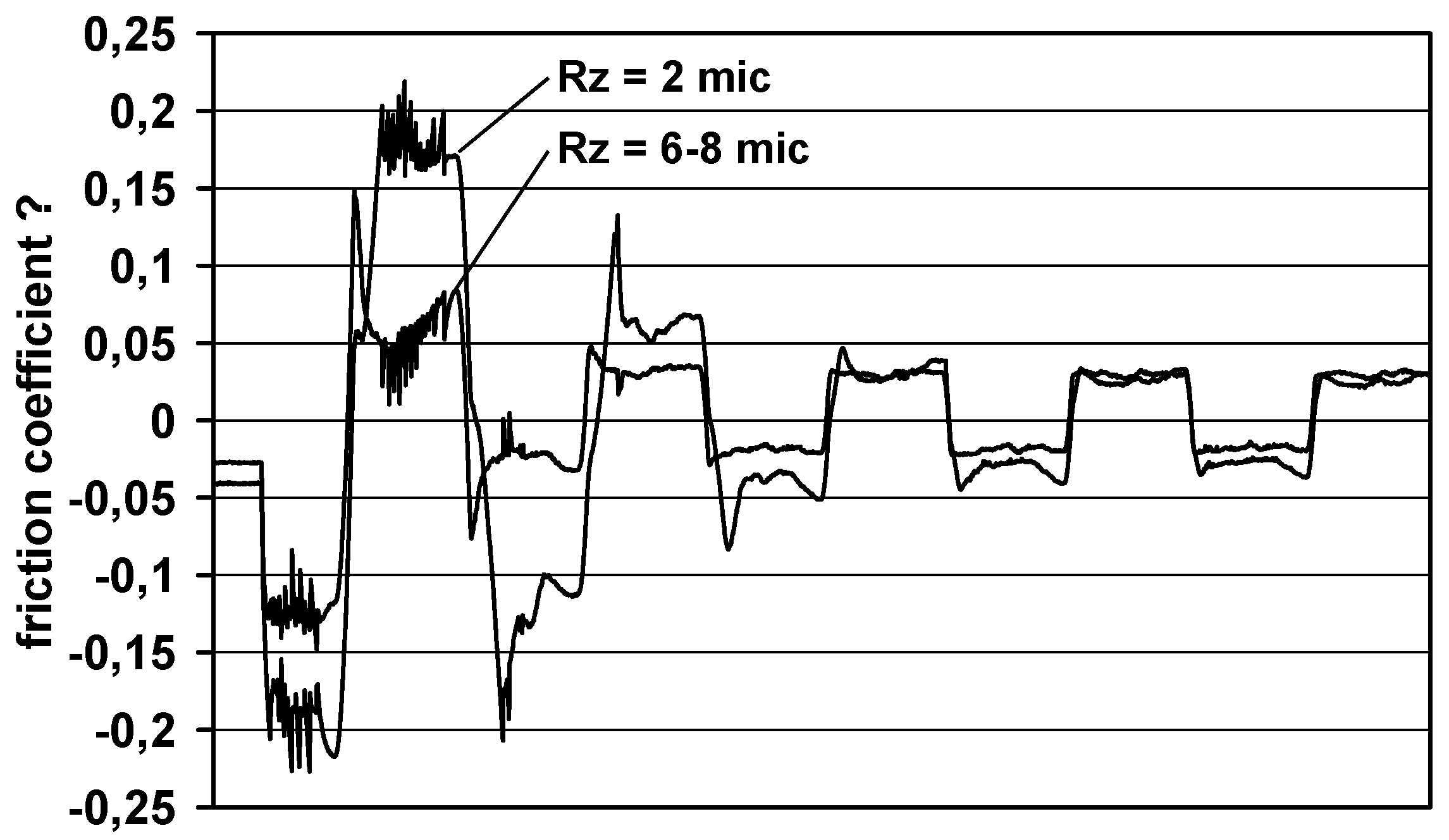

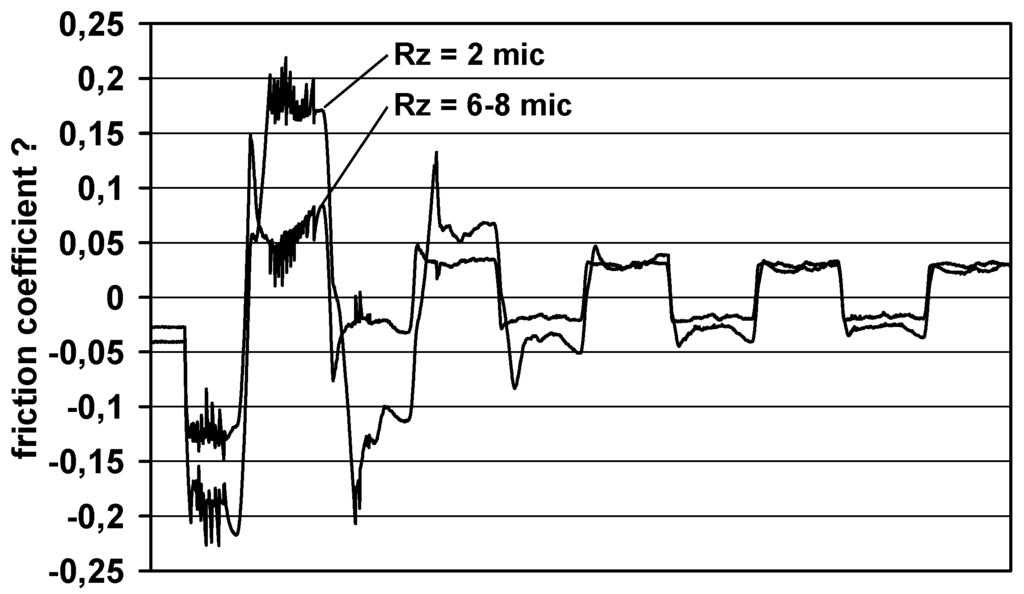

A general feature of MoS2 coatings is that the friction coefficient decreases with increasing load, which makes them suitable for high-loaded friction contacts. The friction curve of a PVD coating for such an application in cryogenics is shown in Figure 3. This is the type of coating which is used for the narrow support elements in the WENDELSTEIN 7-X magnet system. It was chosen because it provides low friction without stick-slip effects and needs nearly no running-in [12]. Only the first cycle deviates noticeably from the following. During the next few cycles a stable frictional behavior is established with friction coefficients in the range between 0.03 and 0.06. Only very small static friction peaks occur and no stick-slip effects are visible. Static and dynamic friction have almost the same values. No coating failure occurred within the test duration, which was several hundred cycles for this particular application. A further result of this test was that the roughness of the substrate has only negligible influence on the steady state friction coefficient. Other authors report an optimum substrate roughness of Ra = 0.1 to 0.15 µm [10]. The sample with a roughness of Rz = 2 µm is approximately within that range.

Figure 3.

First friction cycles of a sputtered MoS2 coating against Al-bronze in LHe environment; two samples with different substrate roughness; load: 250 N; average sliding velocity: 0.2 mm·s−1 (negative values indicate the reciprocating motion) [12].

Because the application of MoS2 coatings in normal humid air is still a problem a test program for further optimization by a variation of deposition parameters for pure MoS2 and doping by Cr atoms was conducted. The results of the best variants are shown in the following.

2. Materials and Methods

2.1. Test Rig for Tribological Measurements at Temperatures below 120 K

Tribological investigations at cryogenic temperatures require special devices (cryotribometers) in respect of cooling system, thermal insulation, and instrumentation. Figure 4 shows an example of an apparatus for pin-on-disc tests in liquid helium (LHe) [13]. The liquid coolant is filled directly into the sample chamber and the friction couple is immersed completely into the liquid cryogen (bath cryostat operation). Therefore, the environmental temperature is equal to the boiling temperature Tb of the coolant (LN2: Tb = 77.3 K; LH2: Tb = 20.4 K; LHe: Tb = 4.2 K). The advantage of this method is a very effective cooling of the sample. The frictional heat is not only removed by heat conduction and convection, but also by evaporation of the liquid. The cryostat shown in Figure 4 also allows cooling independently of the boiling temperature of the coolant. In this case, the coolant flows through a heat exchanger and the sample is surrounded by vacuum or contact gas. With additional heating, it is possible to adjust the temperature between 4.2 K (with LHe-cooling) and room temperature independently from the pressure in the sample chamber. The sample chamber can be evacuated to a residual pressure in the order of 10−5 mbar and therefore, the cryotribometer is also suitable for friction tests in high vacuum.

Figure 4.

Cryotribometer CT3, suitable for cryogenic, vacuum and H2 environment.

2.2. Materials and Sample Preparation

The disc-shaped specimens were coated by an unbalanced magnetron sputter process on a PVD coating plant H-O-T TT 300 at the Chair of Engineering Design, Friedrich-Alexander-Universität Erlangen-Nürnberg [14]. Samples were held in front of the target without additional rotation, thus enabling an adjustment of a well defined target/substrate distance. Coating thickness was kept constant at 1.8 µm ± 0.3 µm, adapting deposition time accordingly. To avoid unintended annealing effects during deposition, the substrate material consisted of secondary hardened high speed steel 1.3343 (S 6-5-2), which is tempering-resistant up to 450 °C; hardness remained at approximately 62 HRC.

Five different coatings were tested, three variants of pure MoS2 and two Cr containing types (MoS2:Cr). One coating denoted as “standard” (STD) was identified by a preceding extensive variation of deposition parameters, resulting in different mechanical and tribological properties. The methods and results of these tests are reported in detail in Reference [14].

Before the deposition, the substrates were polished and ultrasonically cleaned in acetone and isopropyl alcohol. Additionally, they were prepared by an argon-ion etching process at 2.3 Pa, applying a 600 V pulsed DC bias to the substrates for half an hour. Argon also served as working gas for sputtering.

The deposition parameters for the standard coating were a cathode voltage of 800 V, a deposition temperature of 150 °C, an argon pressure of 0.51 Pa and flow rate of 80 sccm, a distance of 90 mm between the sputter cathode and the sample and a resulting cathode current of 2.09 A. This type was further developed in order to produce coatings with higher intrinsic stress. The results of the two most promising variants are shown in the following. Both types, denoted as HS and LS, had higher intrinsic stresses than the standard coating (200 MPa), but to a different degree (HS: 370 MPa, LS: 300 MPa). For both variants the cathode voltage was 700 V and the temperature 50 °C. For the LS type, the cathode distance was reduced to 65 mm and the Ar flow rate increased to 115 sccm.

Additionally two coatings were doped with chromium at a high (120 A) and low (70 A) Cr cathode current, respectively, resulting in chromium contents of 10 and 5 at%. In the figures, these variants are referred to as CH and CL.

The tribological tests were carried out in ball-on-disc configuration. Hardened 100Cr6 steel balls (AISI 52100) with a diameter of 4 mm served as counter bodies. If not otherwise indicated in the figure captions, the applied load was 10 N (maximum Hertzian contact pressure: 1860.6 MPa) and the sliding velocity was 0.1 ms−1.

The tests were carried out in high vacuum, in vacuum with H2O vapor at a pressure of 1.4 × 103 Pa, in gaseous hydrogen at normal and low pressure (1 × 104 Pa) as well as in liquid hydrogen.

The wear coefficients were determined by stylus profilometry, measuring the wear track at four different positions (shifted by 90°). The coefficient of friction (COF) was averaged for a sliding distance of approximately 1000 m, excluding the running-in phase. In order to test the wear life, the tests were run until coating failure was detected (failure criterion: COF > 0.25).

3. Results

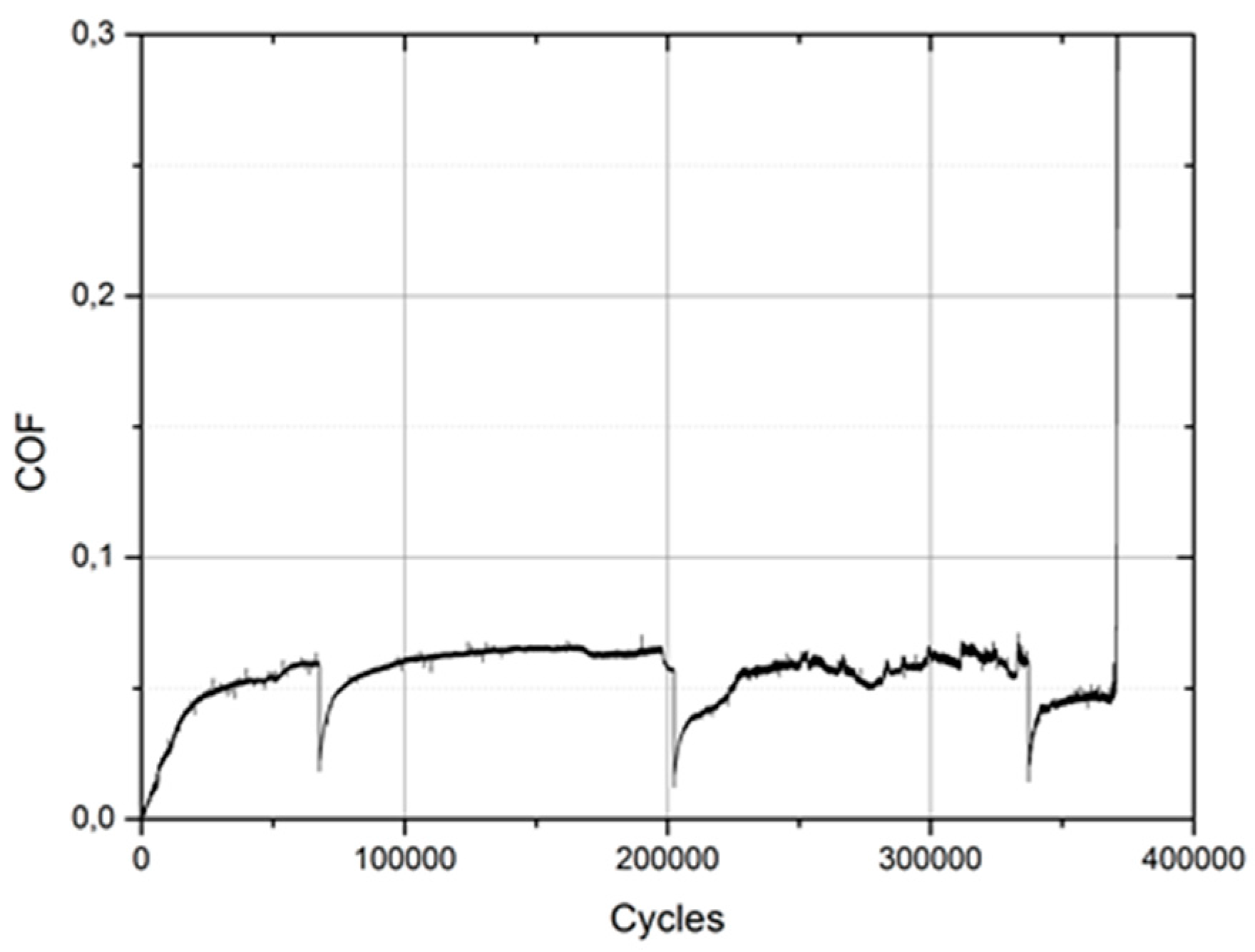

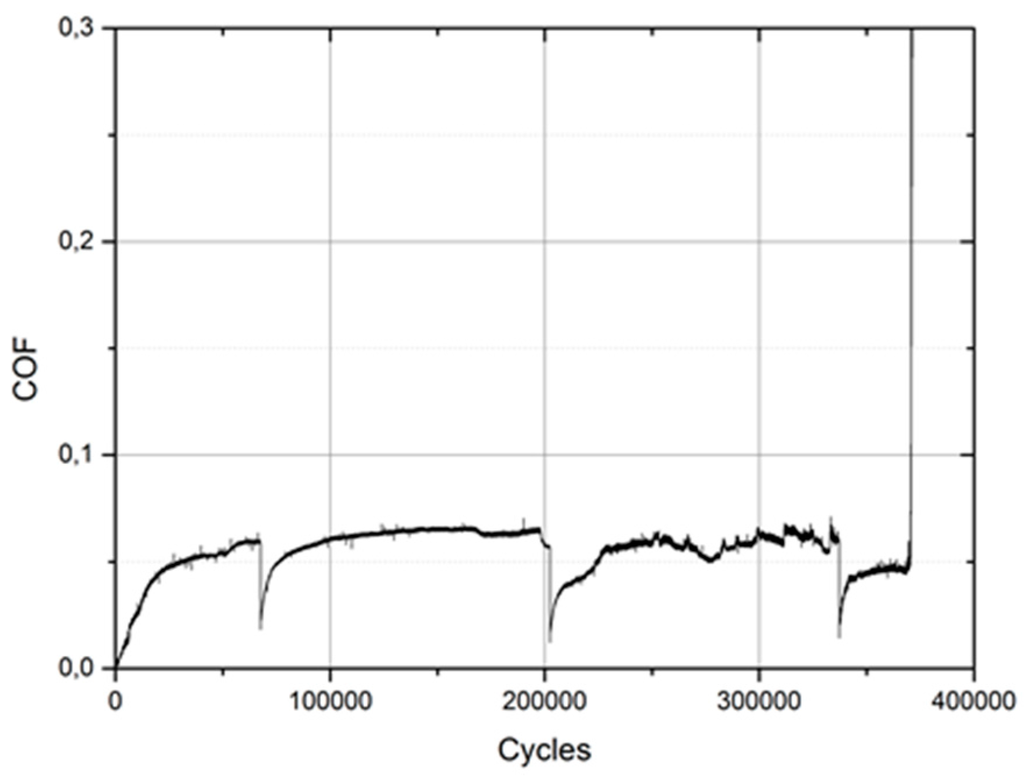

3.1. Vacuum Environment

Under vacuum conditions all variants showed friction coefficients below 0.1 and wear coefficients in the range of 1 to 3 × 10−7 mm3·N−1·m−1. As an example, Figure 5 shows a friction plot for a PVD-MoS2 coating in high vacuum. The coating is similar to the one used in the Wendelstein 7-X fusion experiment [5]. The peaks to negative direction are caused by test stops and restarts. It can be seen that the friction coefficient is around 0.06 and the wear life more than 350,000 cycles.

Figure 5.

Coefficient of friction of a PVD-MoS2 coating [5] under high vacuum conditions (residual pressure: 2 × 10−5 mbar); counterbody: 10-mm 100Cr6 ball, load: 40 N; sliding velocity: 0.5 ms−1.

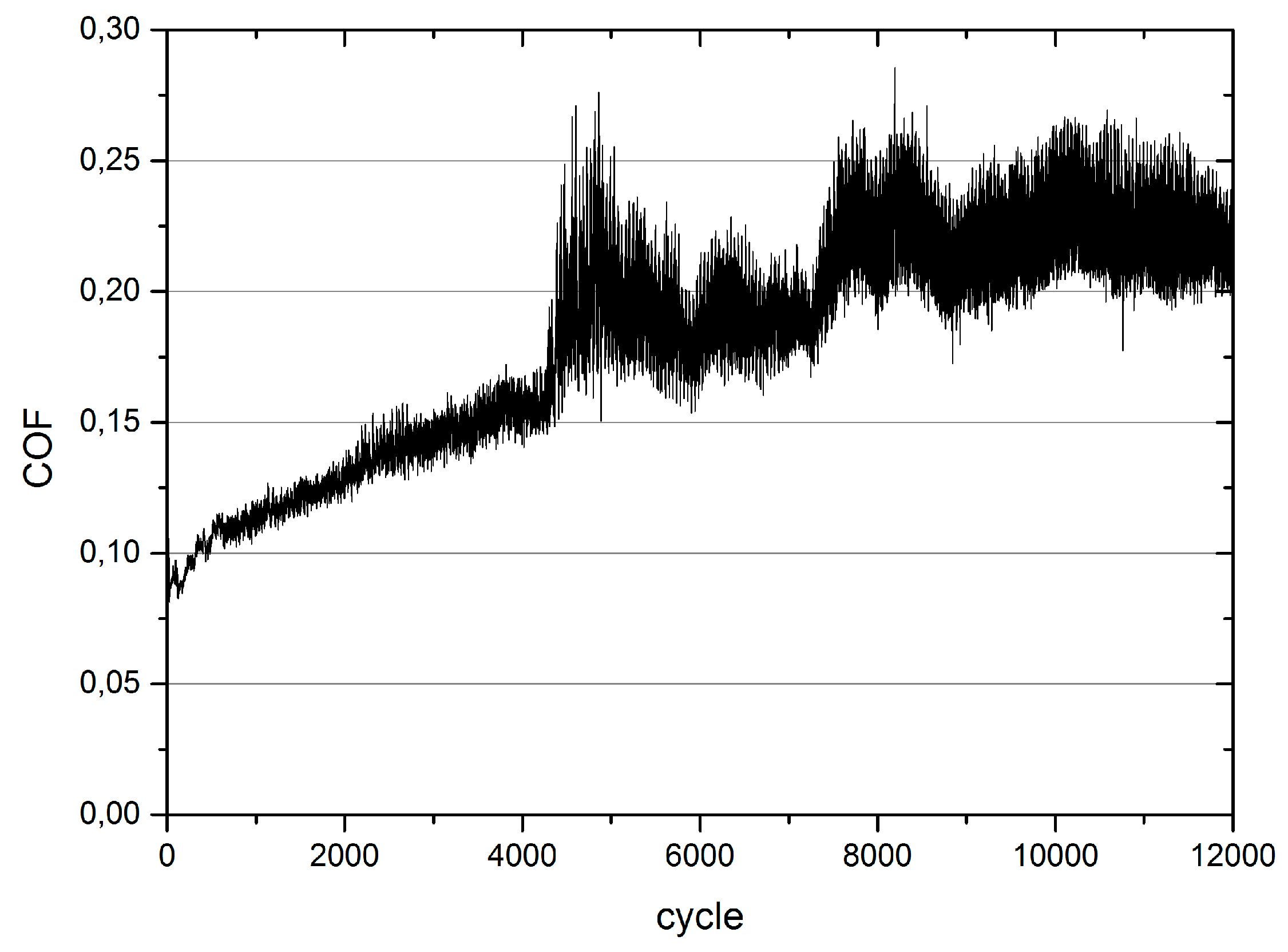

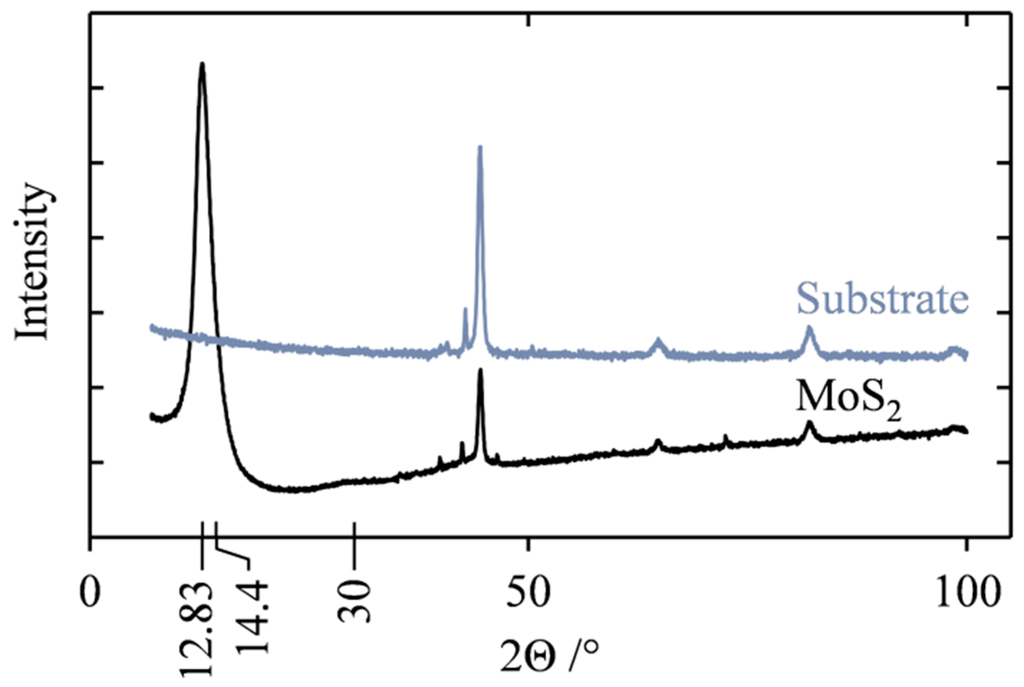

3.2. Air Environment with 50% Humidity

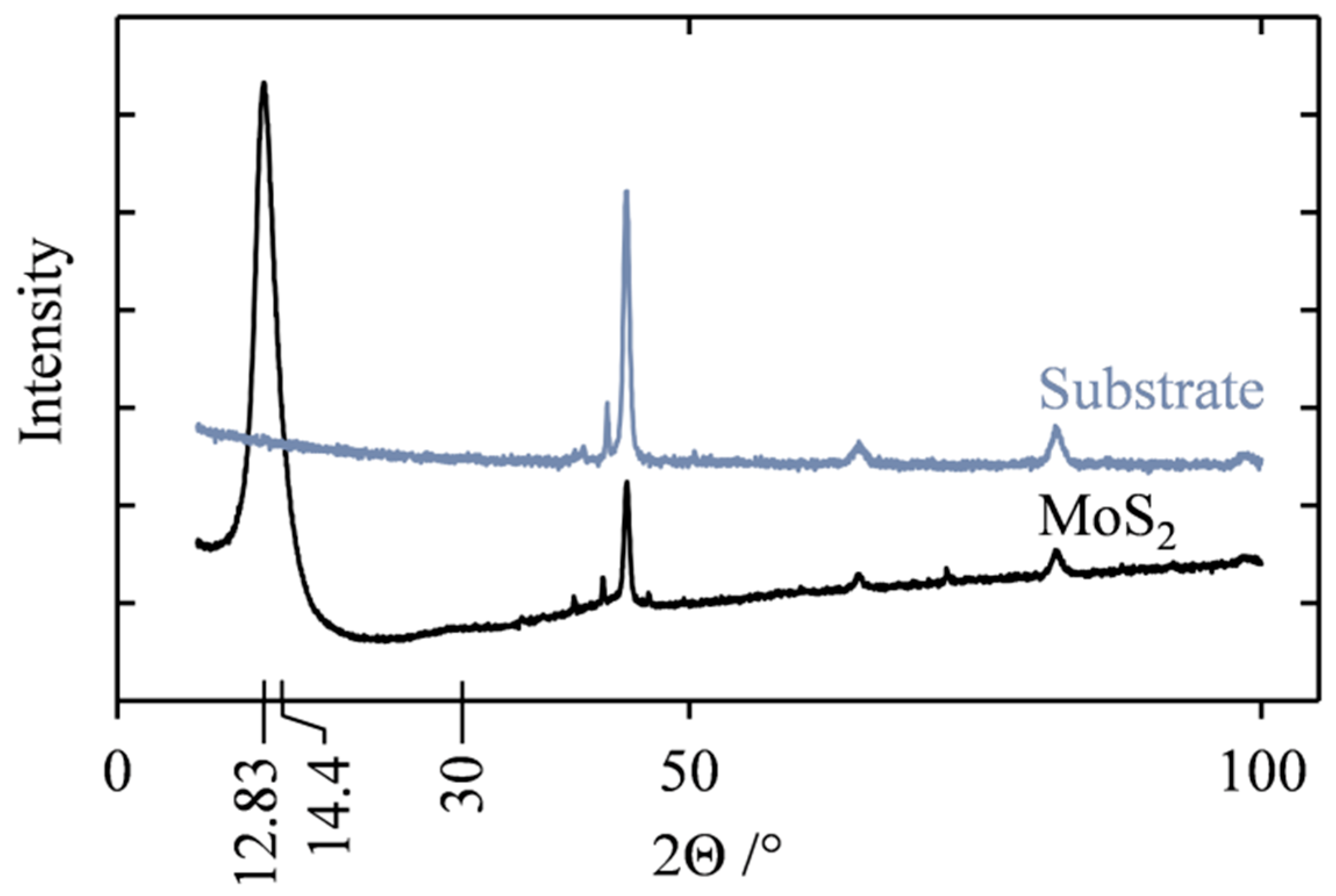

As expected, in normal air with a water vapor partial pressure of 1.4 × 103 Pa, corresponding to 50% relative humidity, the COF increased to values between 0.1 and 0.25 and the wear coefficient up to 10−5 mm3·N−1·m−1, which is more than one order of magnitude higher than under vacuum conditions. A typical example of the friction development is shown in Figure 6. However, best variants showed values in the order of 10−6 mm3·N−1·m−1, which is comparable to the wear of diamond-like carbon (DLC) coatings, developed for operation under high humidity [15]. As expected, coatings that were appropriate for ambient air conditions had a high degree of (002) basal plane orientation. This was detected by X-ray diffraction (XRD), which was carried out for the coating with the best performance in humid environment. The result is shown in Figure 7. Therefore, by means of a suitable adapted PVD-process MoS2 coatings without further dopants can be developed that are able to sufficiently withstand adverse conditions such as high humidity. The results of the corresponding test program and the effect of the deposition parameters are reported in detail in Reference [14].

Figure 6.

Example of the friction increase of a MoS2 coating in air with 50% relative humidity.

Figure 7.

X-ray diffraction (XRD) patterns: Dominating (002) orientation of the coating with highest durability under moist conditions. Pattern of the uncoated sample for comparison [14]. Reproduced with permission from “Surface and Coatings Technology”; published by Elsevier, 2013.

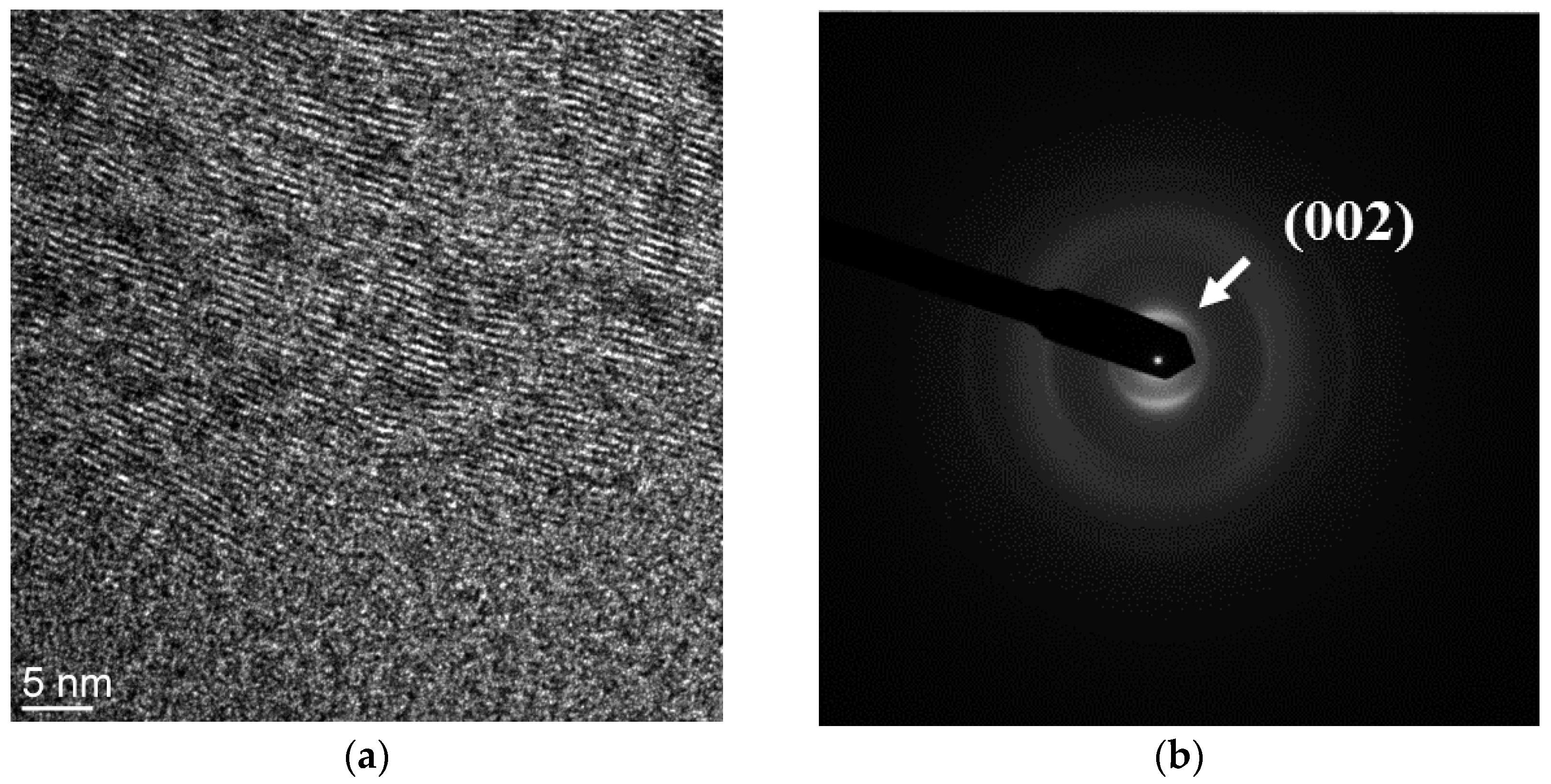

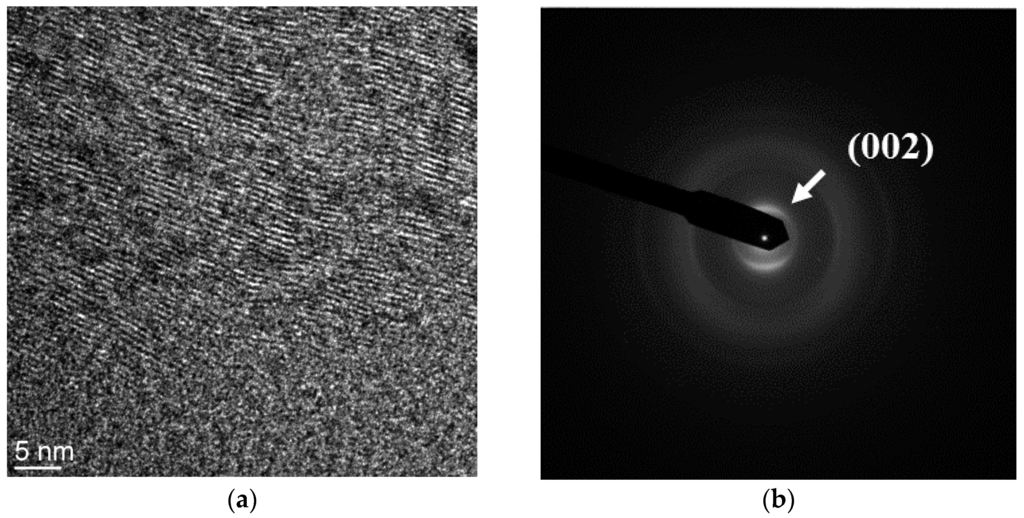

Figure 8a shows a high resolution transmission electron microscopy (HR-TEM) image of a coating with higher internal stress. It still has a highly ordered layered structure which is visible in the upper region. The selected area diffraction (SAED) image of Figure 8b clearly shows reflexes of the (002) planes.

Figure 8.

(a) High resolution transmission electron microscopy (HR-TEM) and (b) selected area diffraction (SAED) images of a MoS2 coating with higher internal stress.

3.3. Low Pressure Water Vapor Environment

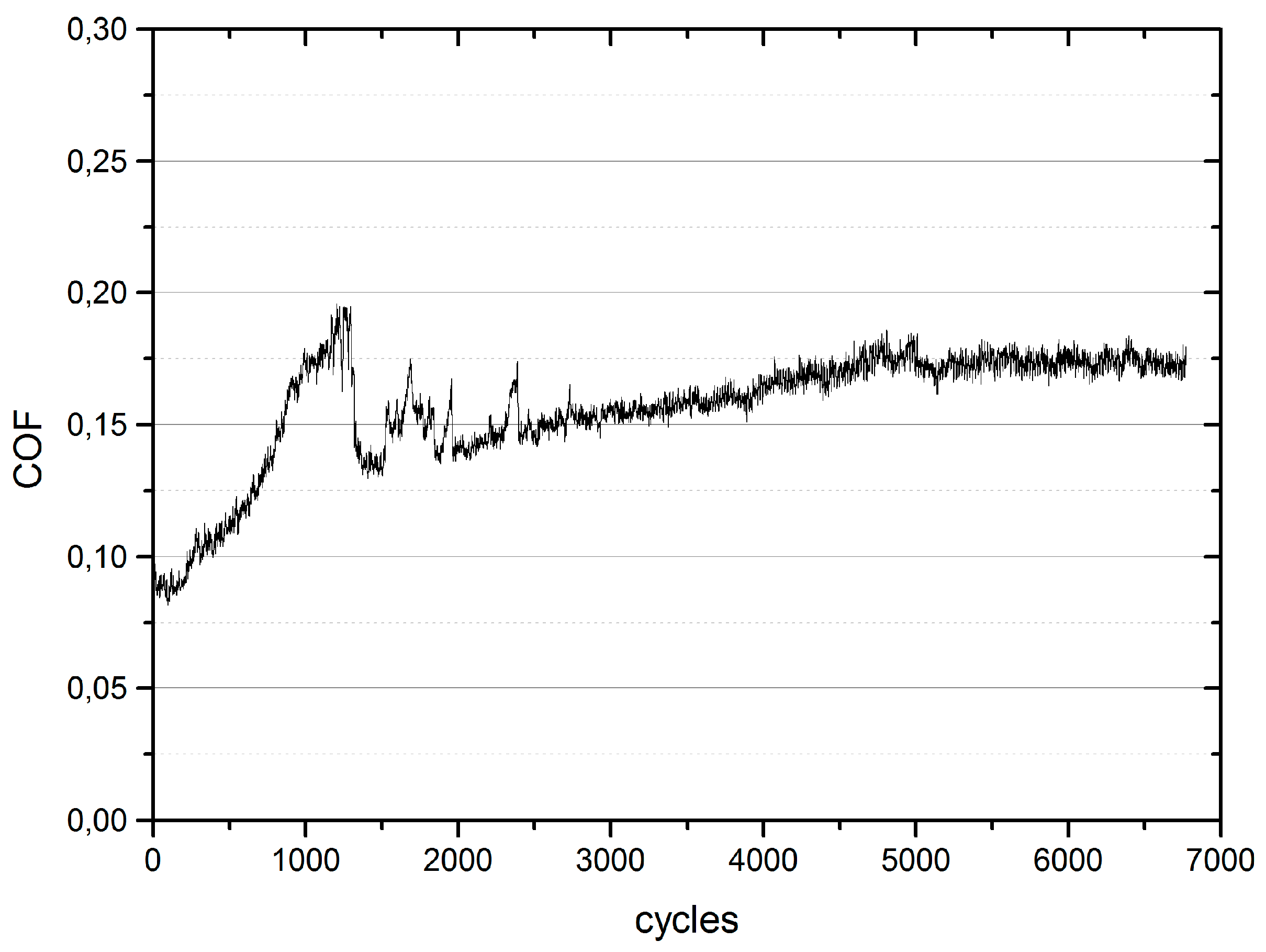

In order to test the influence of water vapor without the presence of oxygen, only H2O gas was filled into the vacuum chamber until a pressure corresponding to 100% rH was reached. In Figure 9, it can be seen that, for a MoS2:Cr variant with 5 at% Cr, the friction coefficient stabilized at about 0.17, which is considerably higher than in inert environment but still low for solid lubricants. This test clearly shows that oxidation to MoO3 is not the only acting wear mechanism.

Figure 9.

Friction of a MoS2:Cr coating (5 at% Cr) in low pressure water vapor at room temperature.

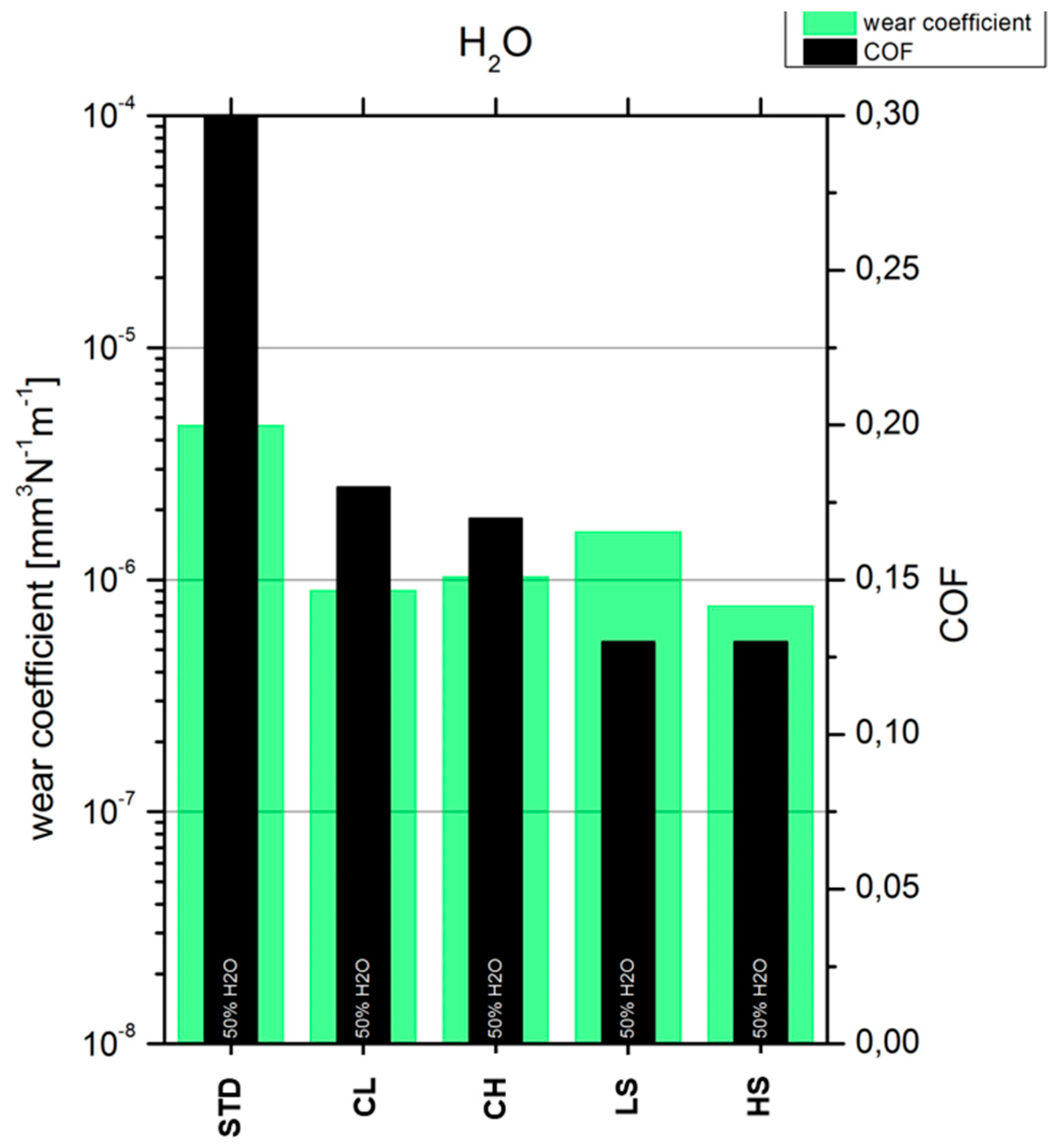

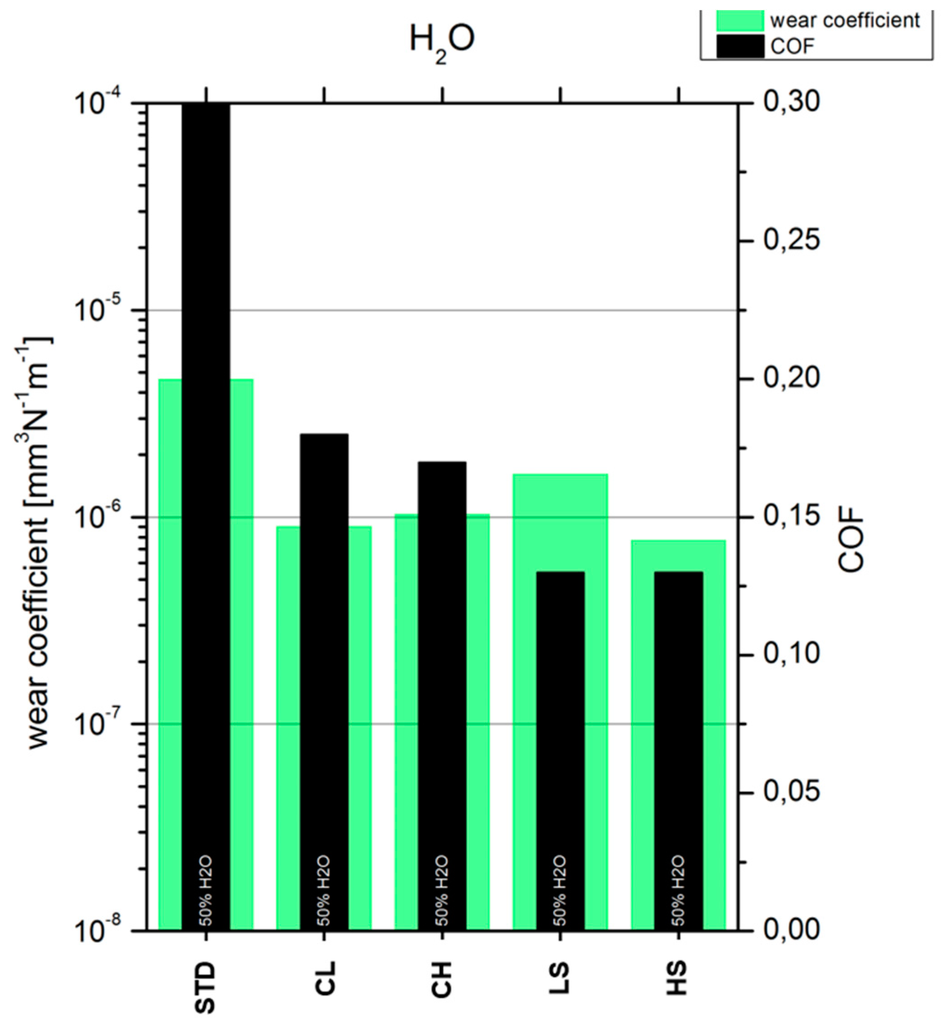

Figure 10 shows the friction and wear data for all five variants in water vapor. The friction coefficients of the pure LS and HS coatings are about 0.13 and 0.17, respectively, for the Cr containing variants. For all optimized coatings, the wear coefficients are in the order of 10−6 mm3·N−1·m−1. For the standard coating both, friction and wear are cosiderably higher. This proves the lower sensitivity to humidity of these variants.

Figure 10.

Friction and wear coefficients of optimized MoS2 coatings vs. 100Cr6 in low pressure H2O vapor; load: 10 N, sliding velocity: 0.1 ms−1.

3.4. Hydrogen Environment

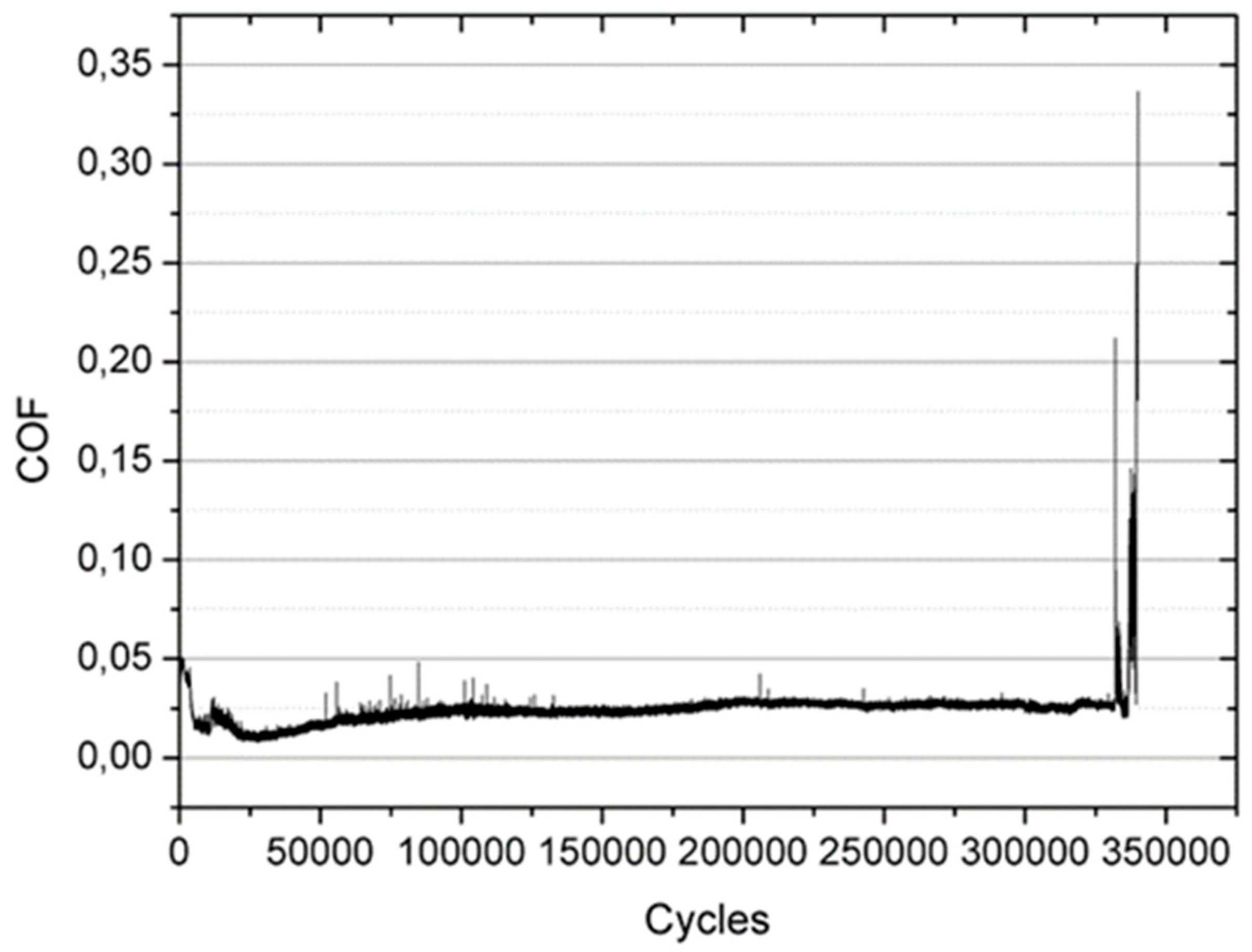

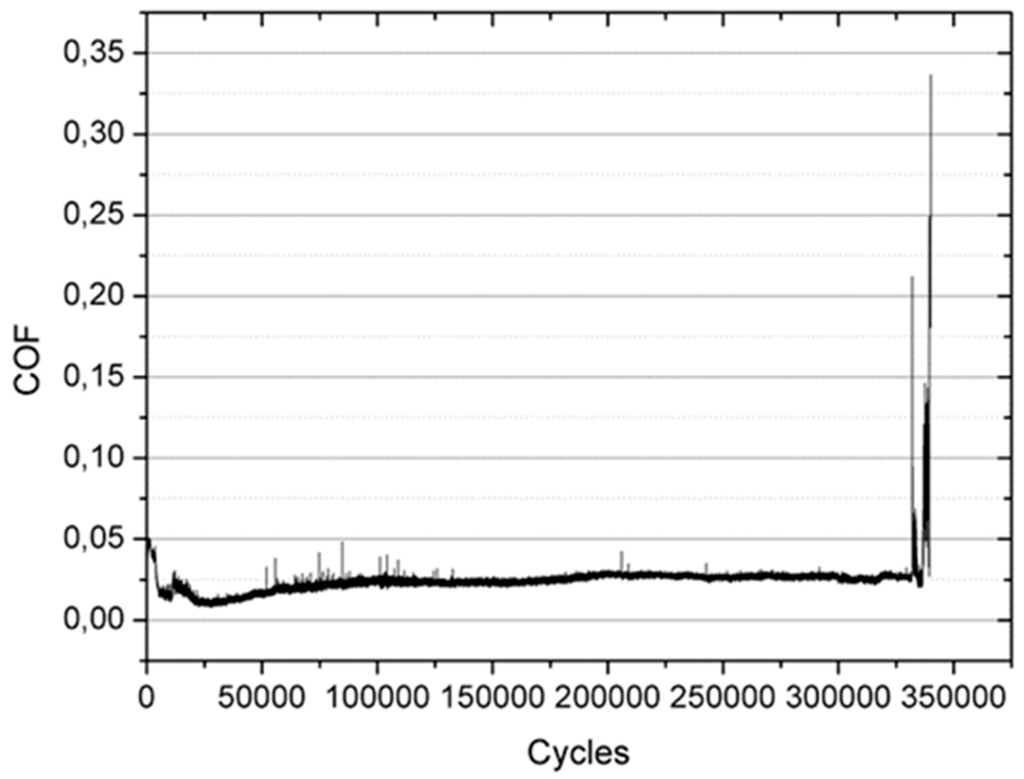

Tests in gaseous hydrogen were performed at 100 mbar and 1 bar environmental pressure. All variants showed a low COF, comparable to or even lower than the vacuum values. Figure 11 showes a friction plot for the reference coationg in H2 gas at 1 bar. Friction was very stable with a COF of 0.03 and the wear life with 340,000 cycles was satisfactory.

Figure 11.

Friction of a MoS2 coating (STD) vs. 100Cr6 in H2 gas at room temperature.

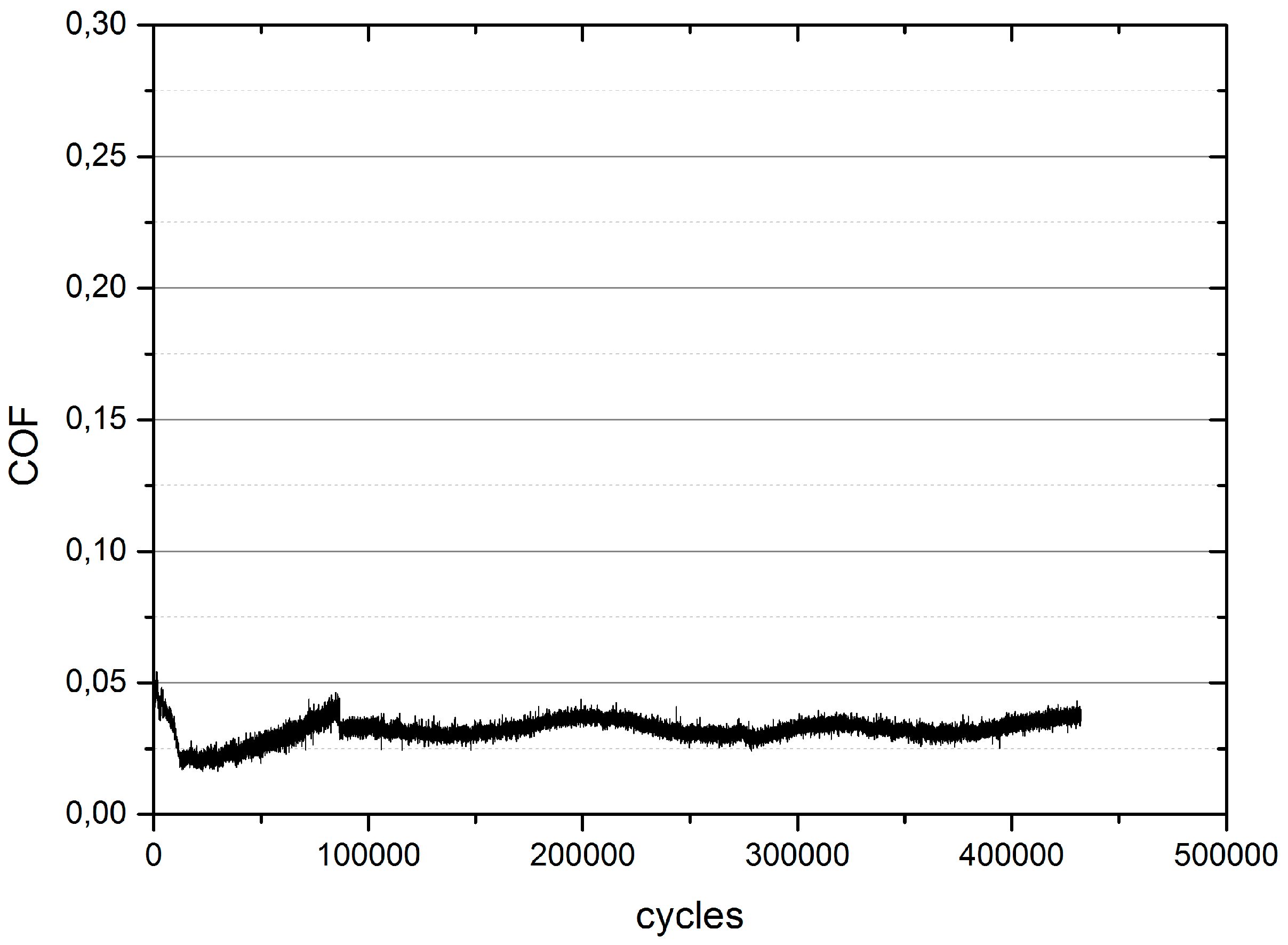

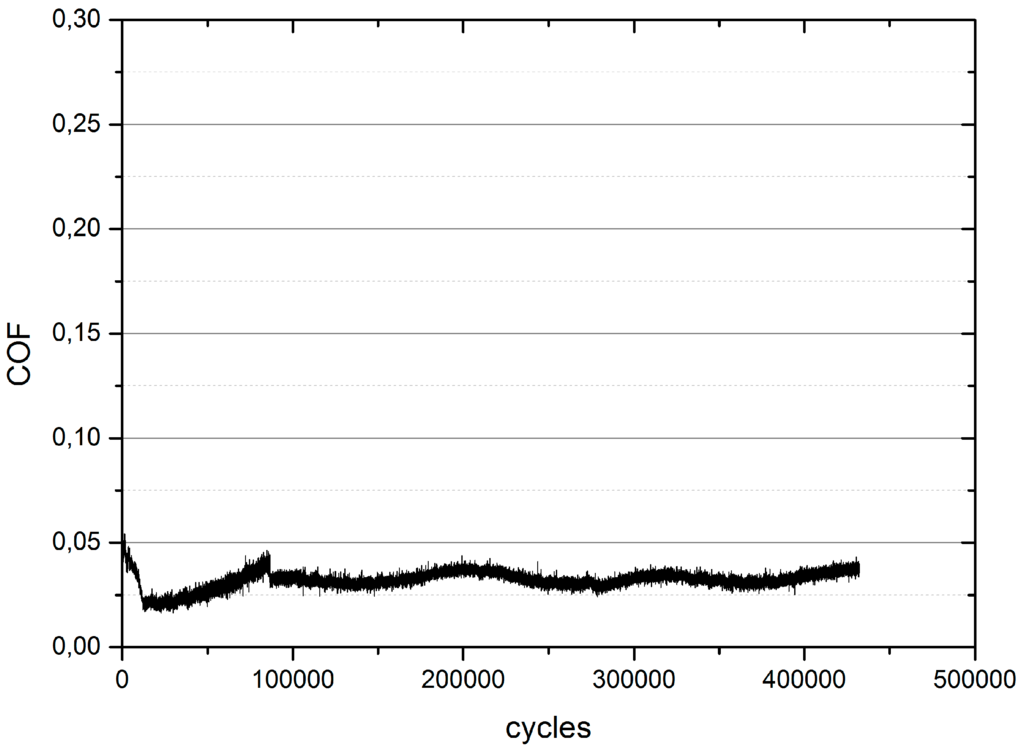

Results were similar for the Cr alloyed types (Figure 12), again showing friction and wear comparable to vacuum conditions. The wear life was longest in H2 gas at 1 bar. After about 100 h, or 430,000 cycles, the test was stopped without showing coating failure.

Figure 12.

Friction of MoS2:Cr (type CL) vs. 100Cr6 in H2 gas at room temperature.

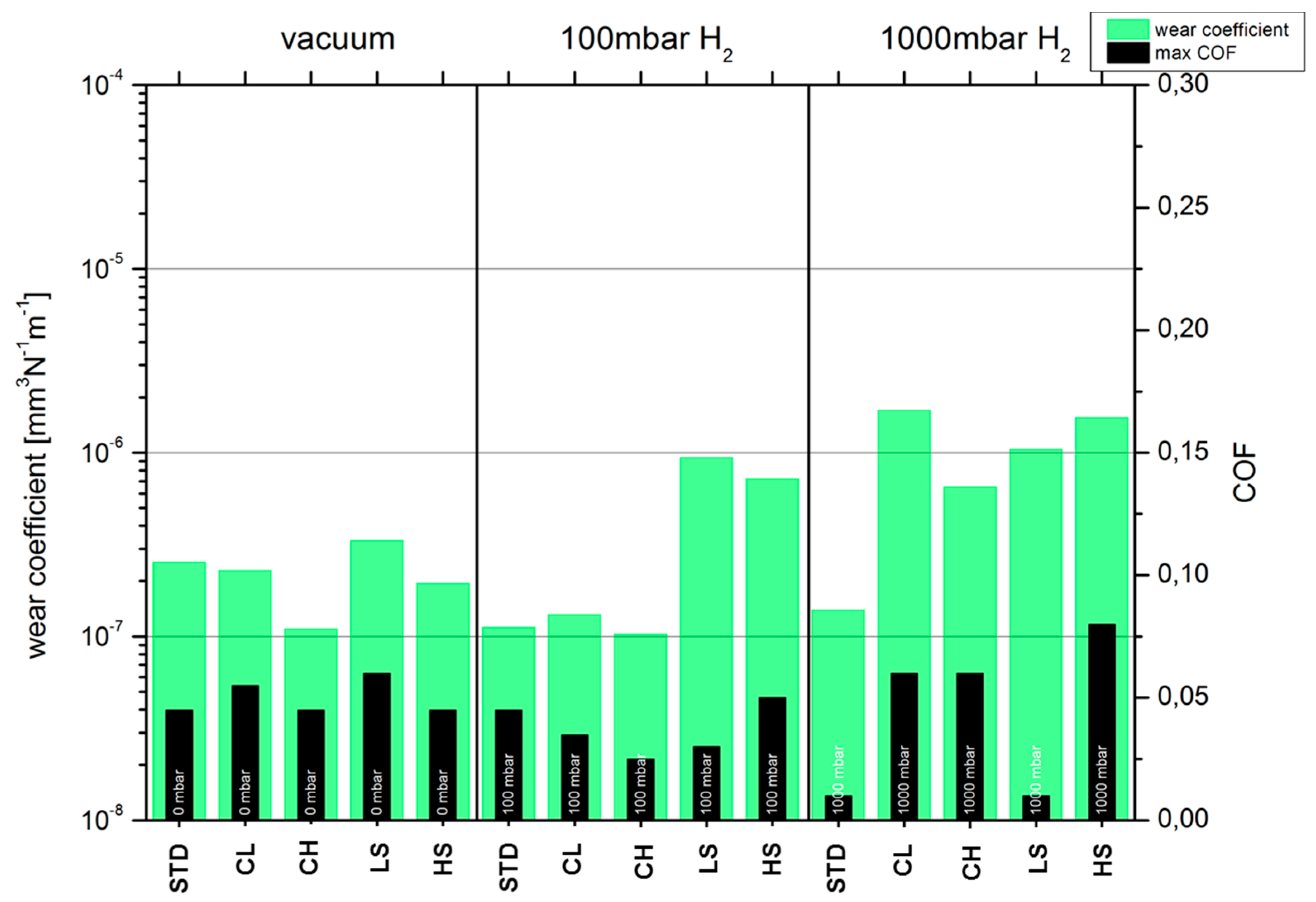

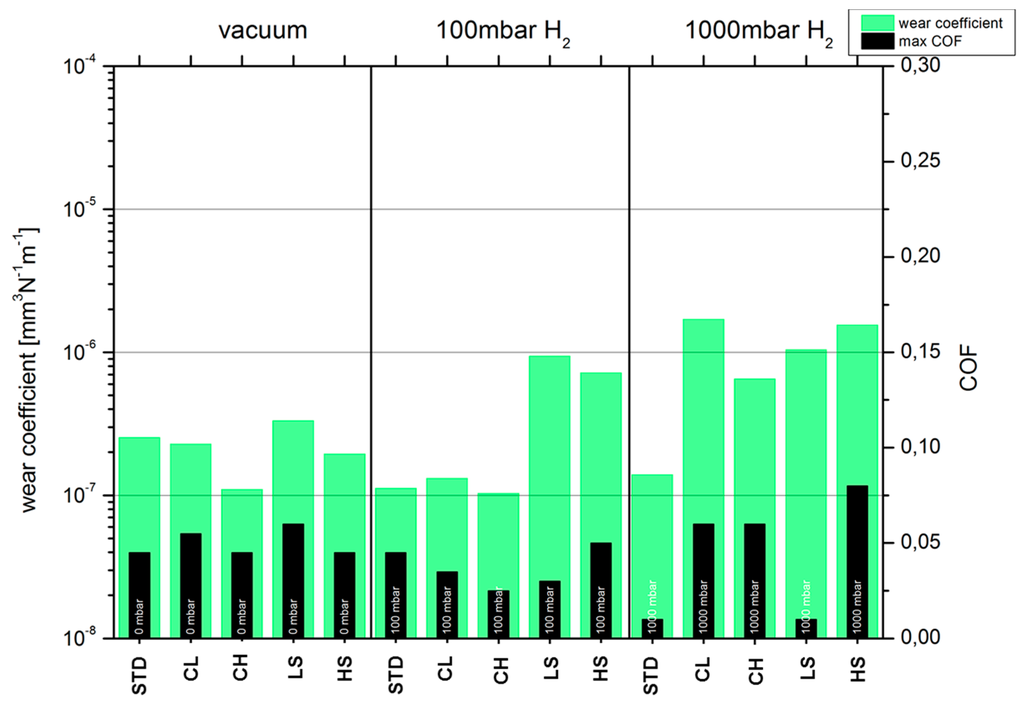

Figure 13 shows a comparison of the friction and wear behavior between high and low pressure hydrogen and vacuum environment for the four variants. Between vacuum and low pressure hydrogen, the differences are small. Only the pure coatings with optimized structure showed higher wear. In hydrogen gas at normal pressure all variants showed higher wear with the exception of the standard coating, which showed a similar wear rate and distinctively lower friction than in vacuum. In addition, the friction of the pure variant with lower intrinsic stress was as low as for the standard variant. However, these results are based on only two tests for each condition. Therefore, only the general tendency to low friction and wear in hydrogen environment is verified. The pressure dependence is less clear and needs to be proved by further tests.

Figure 13.

Friction and wear coefficients of optimized MoS2 coatings vs. 100Cr6 in vacuum and H2 environment; load: 10 N, sliding velocity: 0.1 ms−1; STD: reference coating; MoS2:Cr: CL: 5 at% Cr; CH: 10 at% Cr; pure coatings with higher internal stress: LS: 300 MPa; HS: 370 MPa.

3.5. Cryogenic Environment

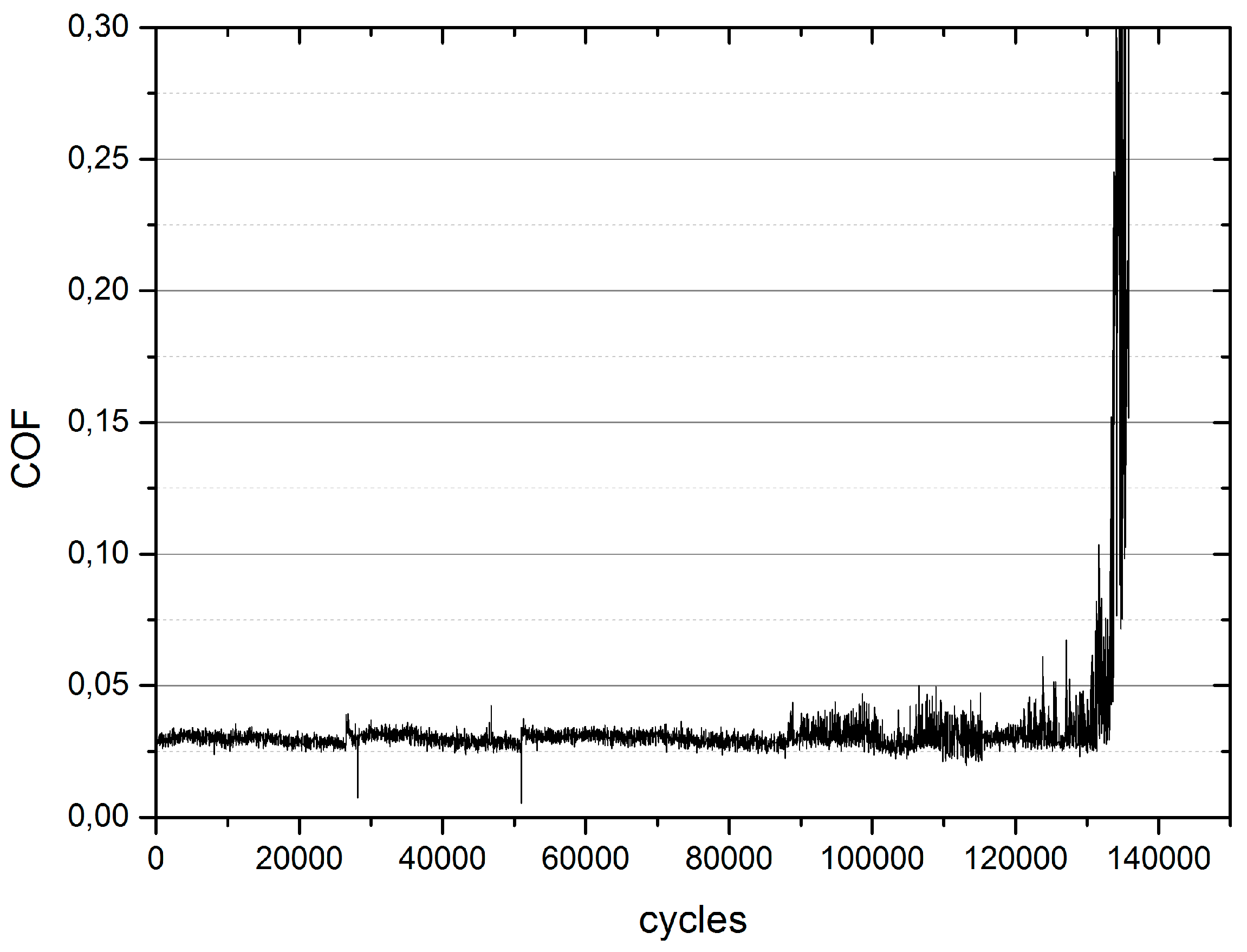

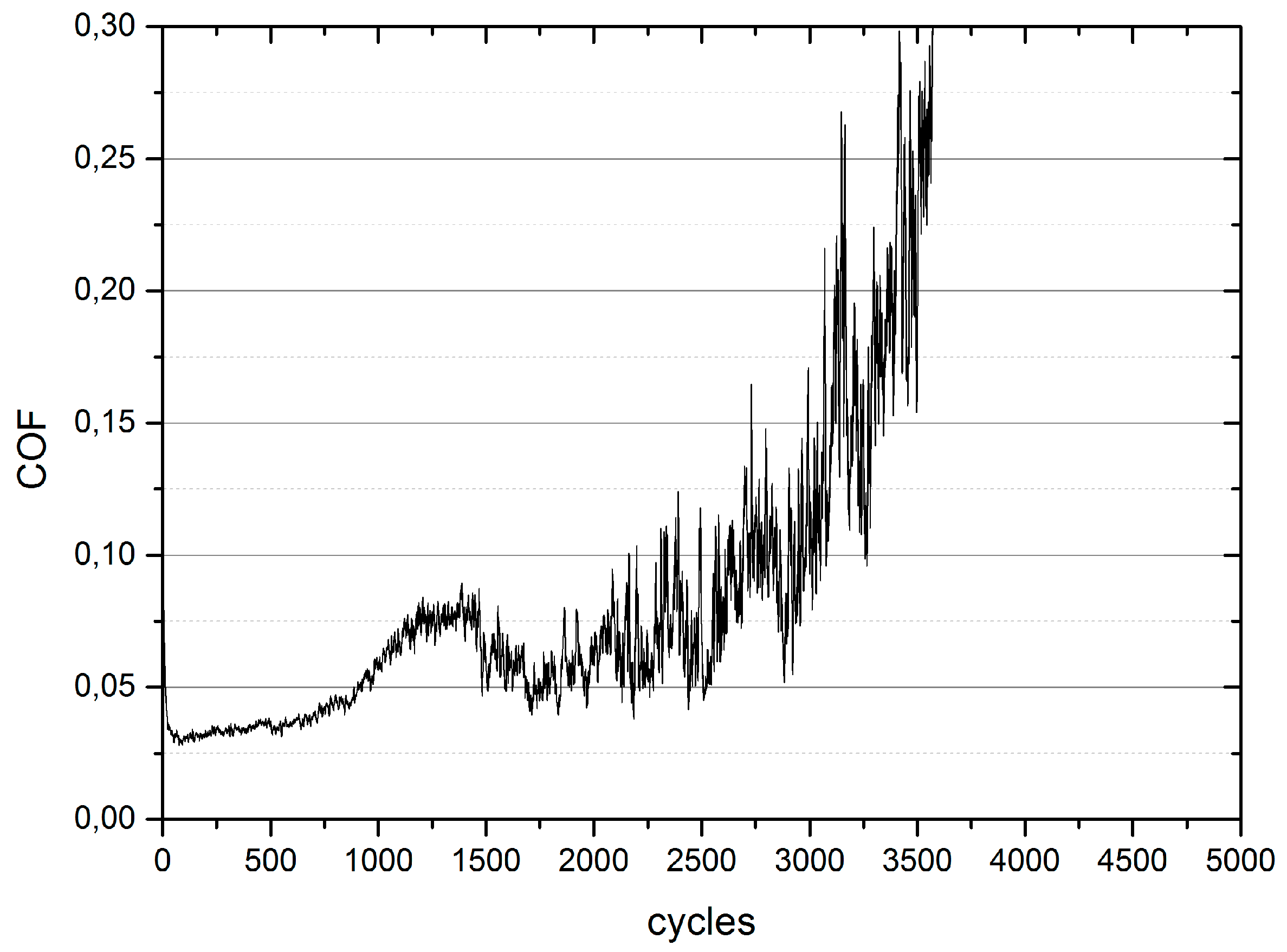

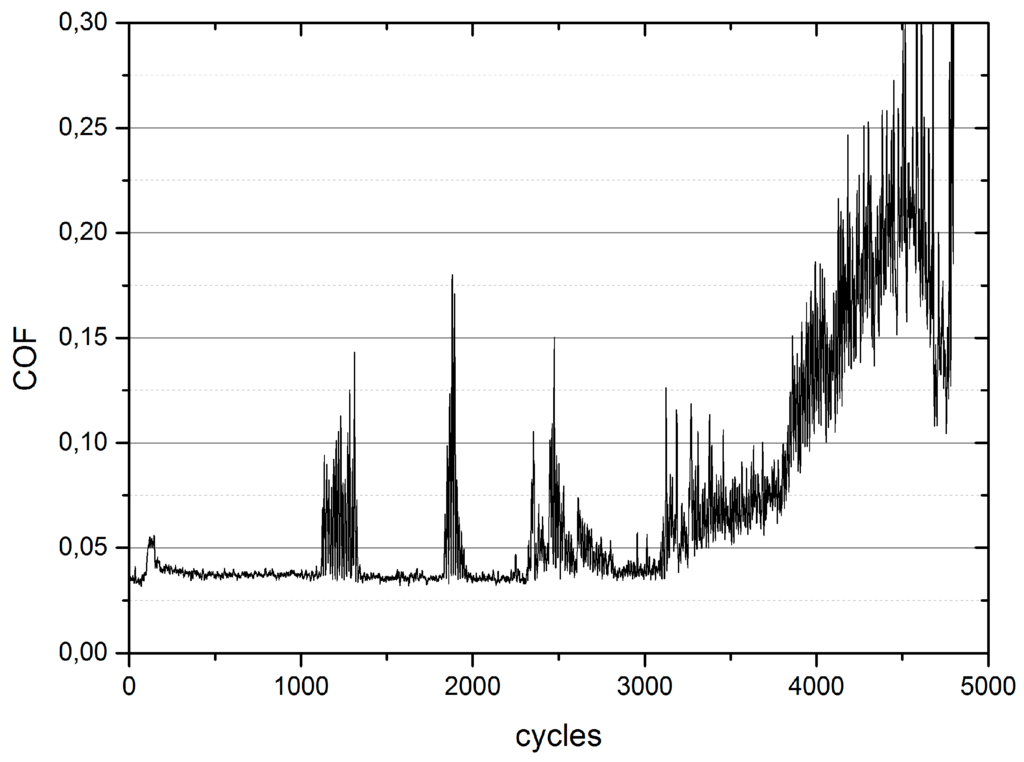

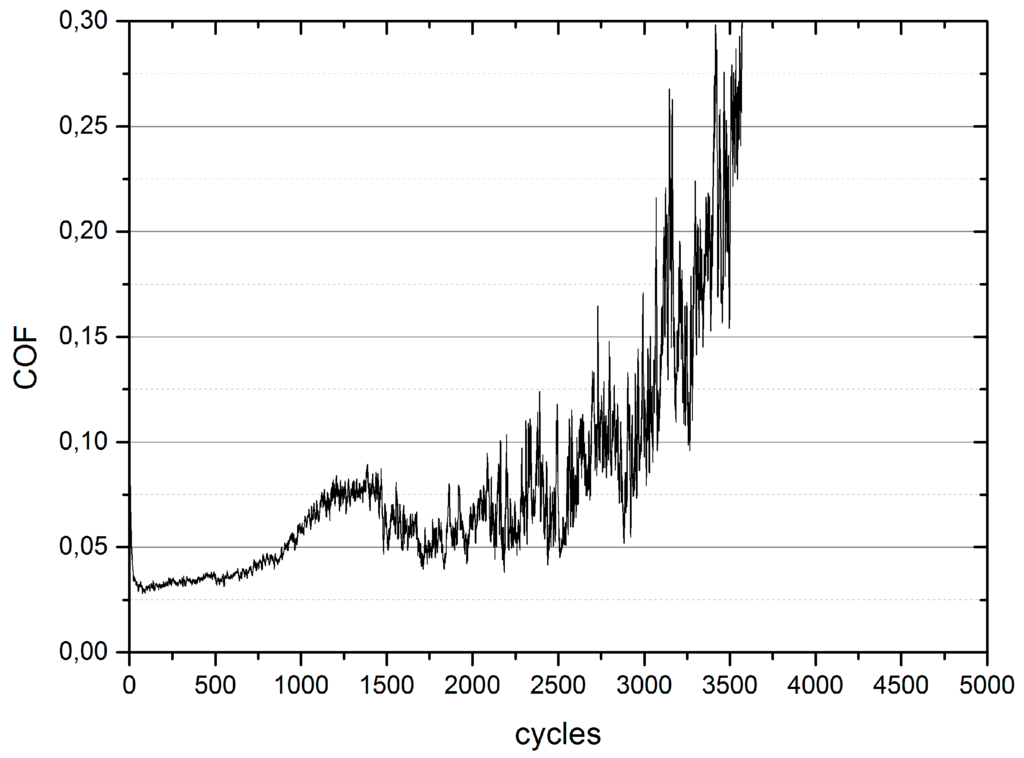

A relatively long endurance was measured for MoS2:Cr (5 at% Cr) at 77 K in liquid nitrogen (Figure 14). In contrast, in liquid helium, which is also an inert environment, the COF increased to 0.2 after only 3000 cycles (Figure 15). In addition, the large fluctuation indicated coating failure.

Figure 14.

Friction of MoS2:Cr (5 at% Cr) vs. 100Cr6 in LN2, load: 10 N, sliding velocity: 0.1 ms−1.

Figure 15.

Friction of MoS2:Cr (5 at% Cr) vs. 100Cr6 in LHe, load: 10 N, sliding velocity: 0.1 ms−1.

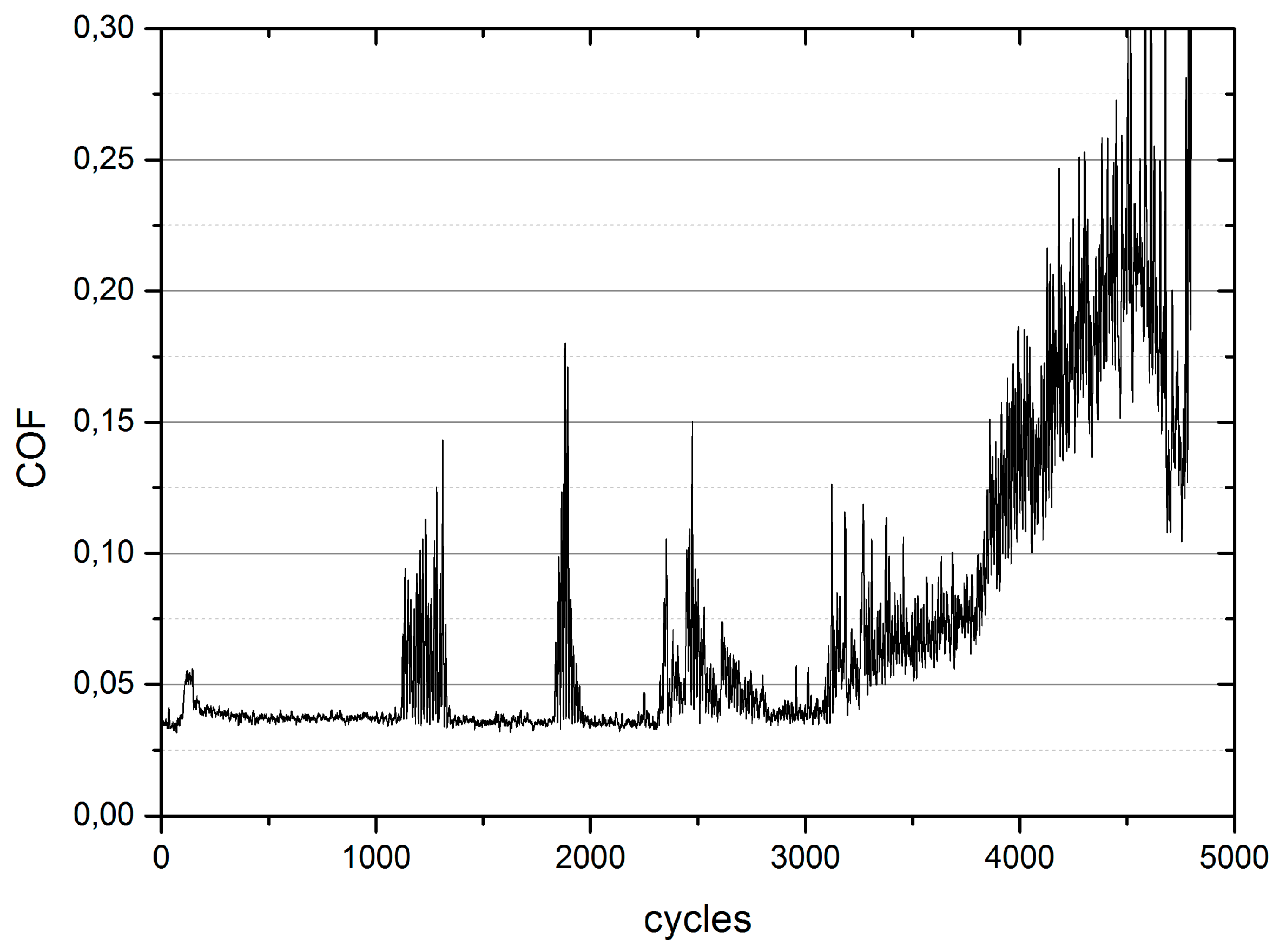

Additional experiments were conducted in liquid hydrogen (LH2) at 20 K. In this environment, for most samples, the COF was initially as low as approximately 0.05, while the Cr-containing types yielded 0.06. However, as can be seen in the friction curve of Figure 16, wear life was short. The COF began to rise steeply beyond 0.1 after only 1000 and 3000 cycles for all variants. A maximum in durability was achieved at 4000 cycles before the test was aborted at COF > 0.25. Again, the variants with optimized structure showed no improvement in comparison to the standard coating.

Figure 16.

Friction of MoS2:Cr (5 at% Cr) vs. 100Cr6 in liquid hydrogen (LH2), load: 10 N, sliding velocity: 0.1 ms−1.

4. Discussion

The results for the optimized variants show that already pure MoS2 coatings with increased internal stress have a higher durability in humid environment. Doping with Cr does not result in lower friction and the wear is not influenced significantly. The reason for the lower sensitivity to humidity of the coatings with optimized structure may be the lower number of MoS2 crystallite edges at the surface, which are postulated to be favorite areas for water adsorption [1]. Water molecules at the crystallite edges may be responsible for blocking crystallite alignment and shearing of the MoS2-planes. This mechanism is active only at the surface and crystallite edges and may be an explanation for the fact that Cr-atoms in the bulk materials do not have a positive influence. Because, even for the best variants, numerous active sites are present at the surface, a low friction coefficient similar to the vacuum value cannot be achieved.

In contrast to H2O, low pressure H2 environment at room temperature enhances the friction properties of MoS2. For all variants, friction is considerably lower than in humid environment. Depending on the coating type, wear is unchanged or up to one order of magnitude lower. In normal pressure hydrogen, all new variants show a slightly higher friction and a wear rate similar to humid environment. However, the wear life is also long in hydrogen gas at 1 bar. Because, for such coatings, most of the film thickness is removed during running in, wear rate is not directly related to the wear life. Contrary to humid environment, in hydrogen, a remaining thin layer seems to be stable for a long time.

The differences in the tribological behavior of all tested variants between the different environments show that oxidation is not the only mechanism responsible for increasing friction and wear of MoS2. H2O molecules seem to impede the alignment and shearing of the MoS2 layers resulting in higher friction. In contrast, H2 may act as termination of reactive edges of the MoS2 planes, which is a mechanism similar to hydrogen in carbon coatings [15]. As a second effect, H2 may trap residual oxygen in the environment.

There is no straight forward explanation for the very short wear life of all tested coatings in LHe and LH2; in particular, because at 77 K in liquid nitrogen, more than 100,000 friction cycles with a COF not higher than 0.03 are still possible. However, in earlier tests with other MoS2 variants, deviations in the tribological behavior between 77 and 4.2 K were also detected [16]. One reason for early failure in LHe and LH2 may be thermal expansion mismatch between the coating and the substrate. The stress caused by this effect increases with decreasing temperature. For a verification of this effect, tests with coatings with different internal stresses are planned.

5. Conclusions

Under humid environmental conditions, MoS2 usually exhibits high friction and short wear life. Improvements can be achieved by optimizing the deposition process in order to an orientation of the (002) basal plane parallel to the substrate surface or by doping with metal atoms, e.g., Cr.

Gaseous H environment at room temperature enhances the tribological properties of MoS2 coatings. Friction and wear are low and comparable to the vacuum values under different hydrogen gas pressures at room temperature.

Early coating failure is observed in liquid hydrogen with a boiling temperature of 20 K. However, in liquid nitrogen at 77 K, friction is low and wear life is satisfactory. In liquid hydrogen as well as in liquid helium (4.2 K), friction is only low at the very beginning of sliding. After a few friction cycles, all variants showed early failure. Thus, in this extreme temperature range, thermal mismatch seems to dominate the tribological behavior and should be accounted for in future.

The initially low COF could motivate more elaborate testing in the future on this topic as well as on wear reduction. Operating components such as pumps and valves reliably in (liquid) hydrogen could become more important as hydrogen gains momentum as medium for energy storage and conversion.

Acknowledgments

This work is funded by the German Research Foundation (DFG) as a part of the project Tribological Optimization of Molybdenum Disulfide PVD-Coatings for Varying Environmental Conditions (GR 1002/8-1, ME 1029/17-1, SZ 258/1-1). The coatings were provided Bernd Vierneusel, researcher at the Chair of Engineering Design, Friedrich-Alexander-Universität Erlangen-Nürnberg. The HR-TEM and SAED images were contributed by Werner Österle of BAM, Division 5.1, Materialography, Fractography and Ageing of Engineering Materials.

Author Contributions

Thomas Schneider designed and carried out the experiments in vacuum, inert, and hydrogen environment. Thomas Gradt wrote the paper.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| COF | Coefficient of friction |

| LN2 | Liquid nitrogen |

| LH2 | Liquid hydrogen |

| LHe | Liquid helium |

| PVD | Physical vapor deposition |

| CVD | Chemical vapor deposition |

| HR-TEM | High resolution transmission electron microscope |

| SAED | Selected area electron diffraction |

| RT | Room temperature |

| STD | reference or standard coating |

| HS | coating variant with an internal stress of 370 MPa |

| LS | coating variant with an internal stress of 300 MPa |

| CH | MoS2:Cr coating with 10 at% Cr |

| CL | MoS2:Cr coating with 5 at% Cr |

References

- Landsdown, A.R. Tribology Series 35: Molybdenium Disulphide Lubrication; Dowson, D., Ed.; Elsevier: Amsterdam, The Netherlands, 1999. [Google Scholar]

- Kragelsky, I.V.; Alisin, V.V. Chapter 14 “Friction at low temperatures”. In Tribology Handbook, Friction Wear Lubrication; Pergamon Press: Oxford, UK, 1981; pp. 75–92. [Google Scholar]

- Bozet, J.-L. Modelling of friction and wear for designing cryogenic valves. Tribol. Int. 2001, 34, 207–215. [Google Scholar] [CrossRef]

- Gasparotto, M.; Elio, F.; Heinemann, B.; Jaksic, N.; Mendelevitch, B.; Simon-Weidner, J.; Streibl, B. The WENDELSTEIN 7-X mechanical structure support elements: Design and tests. Fusion Eng. Des. 2005, 74, 161–165. [Google Scholar] [CrossRef]

- Koch, F.; Nocentini, R.; Heinemann, B.; Linding, S.; Junghans, P.; Bolt, H. MoS2 coatings for the narrow support elements of the W-7X nonplanar coils. Fusion Eng. Des. 2007, 82, 1614–1620. [Google Scholar] [CrossRef]

- Morita, Y.; Onodera, T.; Suzuki, A.; Sahnoun, R.; Koyama, M.; Tsuboi, H.; Hatakeyama, N.; Endou, A.; Takaba, H.; Kubo, M.; et al. Development of a new molecular dynamics method for tribochemical reaction and its application to formation dynamics of MoS2 tribofilm. Appl. Surf. Sci. 2008, 254, 7618–7621. [Google Scholar] [CrossRef]

- Yukhno, T.P.; Vvedenskij, Y.V.; Sentyurikhina, L.N. Low temperature investigations on frictional behaviour and wear resistance of solid lubricant coatings. Tribol. Intern. 2001, 34, 293–298. [Google Scholar] [CrossRef]

- Gradt, T.; Hübner, W.; Ostrovskaya, Y. Tribologisches Verhalten von Gleitlacken für kryogene Anwendungen. Tribol. Schmier. 2004, 51, 37–40. [Google Scholar]

- Zhang, X.; Prakash, B.; Lauwerens, W.; Zhu, X.; He, J.; Celis, J.-P. Low friction MoSx coatings resistant to wear in ambient air of low and high humidity. Tribol. Lett. 2003, 14, 131–135. [Google Scholar] [CrossRef]

- Roberts, E.W. Thin solid lubricant films in space. Tribol. Int. 1990, 23, 95–104. [Google Scholar] [CrossRef]

- Subramonian, B.; Kato, K.; Adachi, K.; Basu, B. Experimental evaluation of friction and wear properties of solid lubricant coatings on SUS440C steel in liquid nitrogen. Tribol. Lett. 2005, 20, 263–272. [Google Scholar] [CrossRef]

- Gradt, T.; Aßmus, K. Tribological behaviour of solid lubricants at low Temperatures. In Proceedings of the 21st International Cryogenic Engineering Conference (ICEC 21), Prague, Czech Republic, 17–21 July 2006; pp. 173–176.

- Gradt, T.; Börner, H.; Schneider, T. Low temperature tribometers and the behaviour of ADLC-Coatings in cryogenic environment. Tribol. Int. 2001, 34, 225–230. [Google Scholar] [CrossRef]

- Vierneusel, B.; Tremmel, S.; Wartzack, S. Humidity resistant MoS2 coatings deposited by unbalanced magnetron sputtering. Surf. Coat. Technol. 2013, 235, 97–107. [Google Scholar] [CrossRef]

- Ronkainen, H.; Holmberg, K. Tribology of Diamond-Like Carbon Films; Donnet, C., Erdemir, A., Eds.; Springer: New York, NY, USA, 2008; pp. 155–200. [Google Scholar]

- Gradt, T.; Schneider, T.; Lingertat, J.; Junghanns, P.; Aßmus, K.; Schauer, F. Cryogenic vacuum tests of scaled down narrow support elements for the W7-X coil system. Fusion Eng. Des. 2009, 84, 840–884. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).