Design and Performance Analysis of a New Variable Friction Pipeline Magnetic Flux Leakage Detection Robot

Abstract

1. Introduction

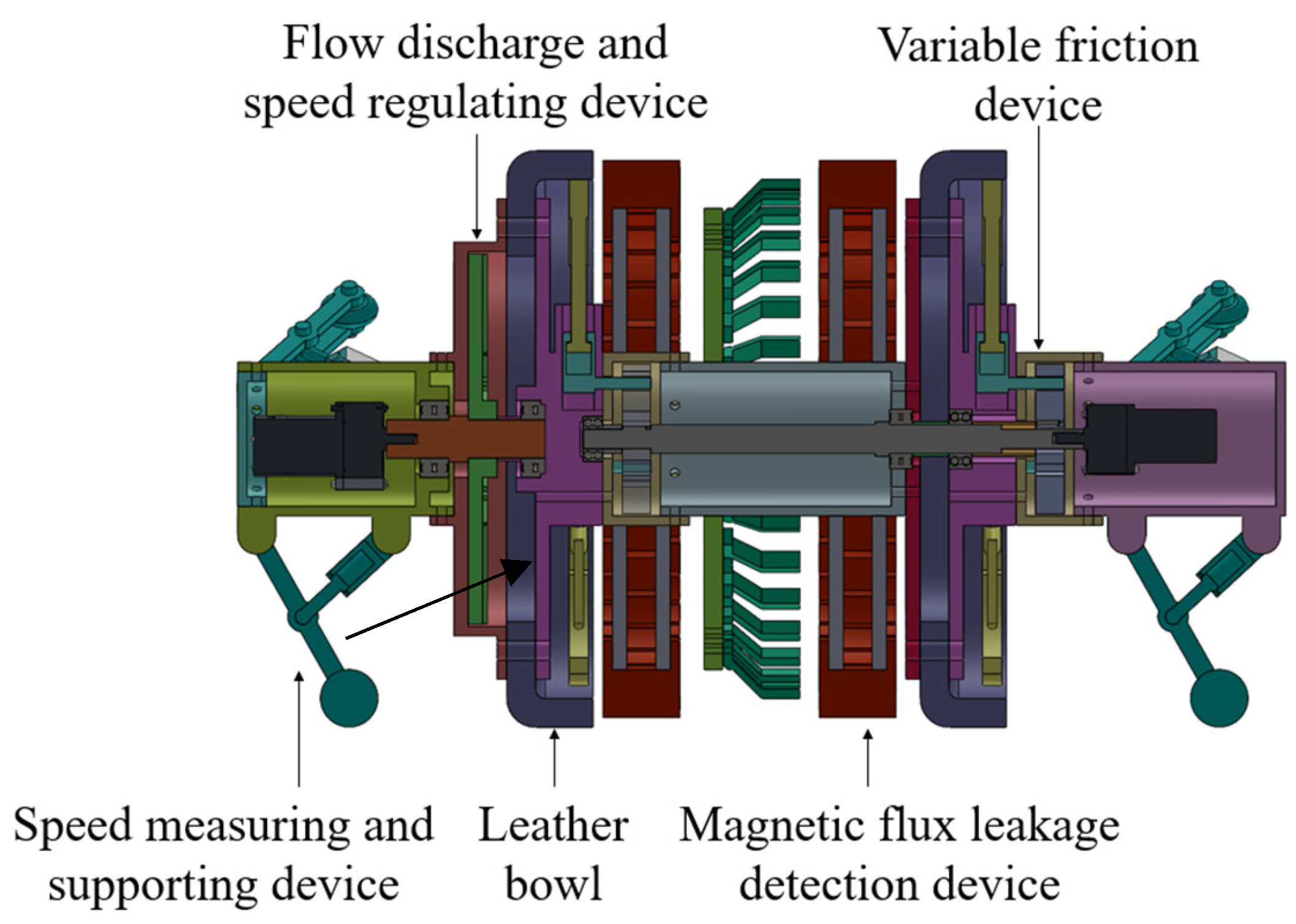

2. Overall Design of the In-Pipe MFL Inspection Robot

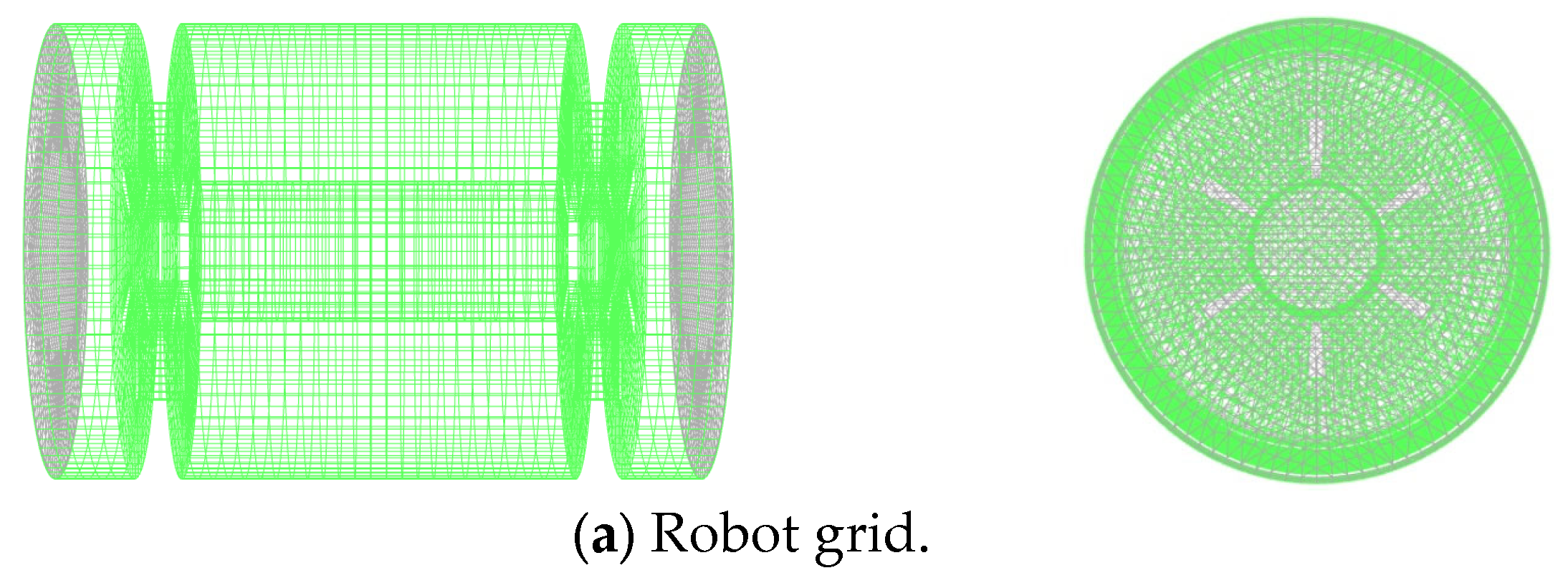

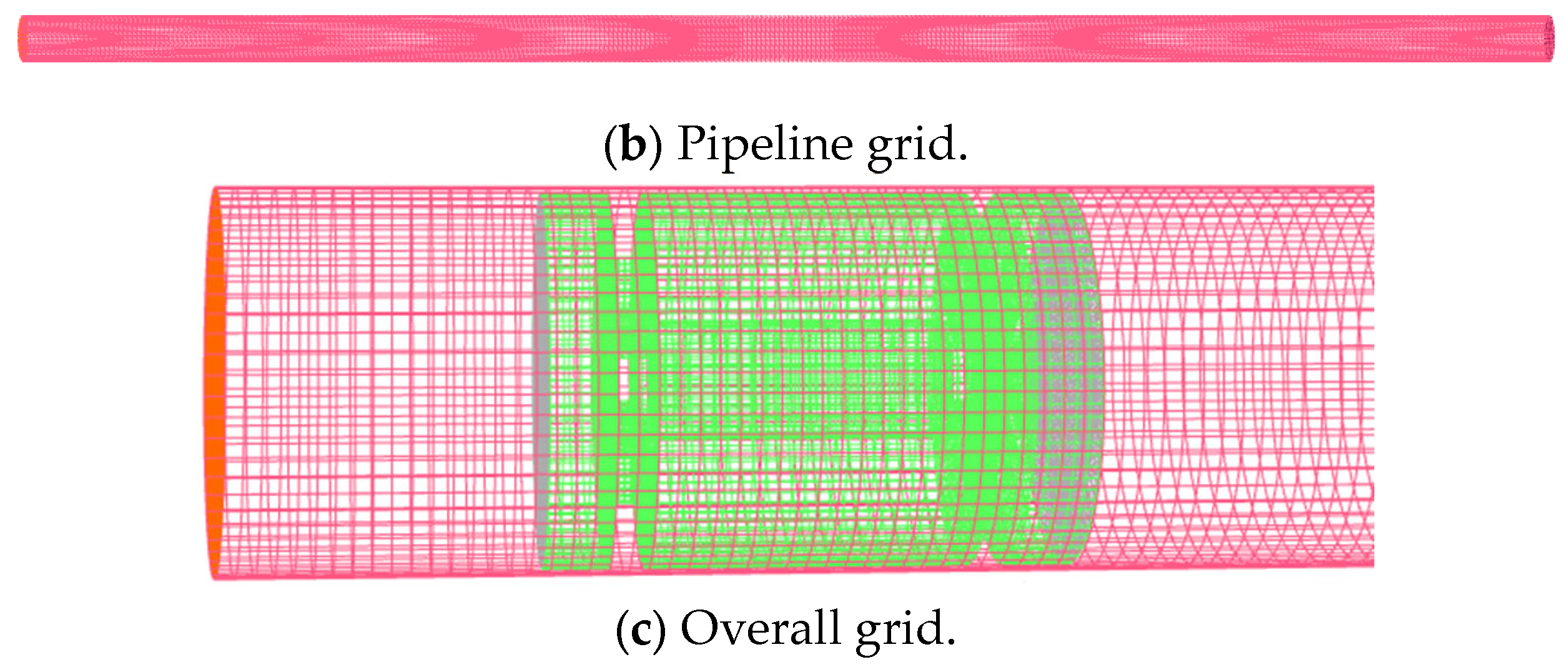

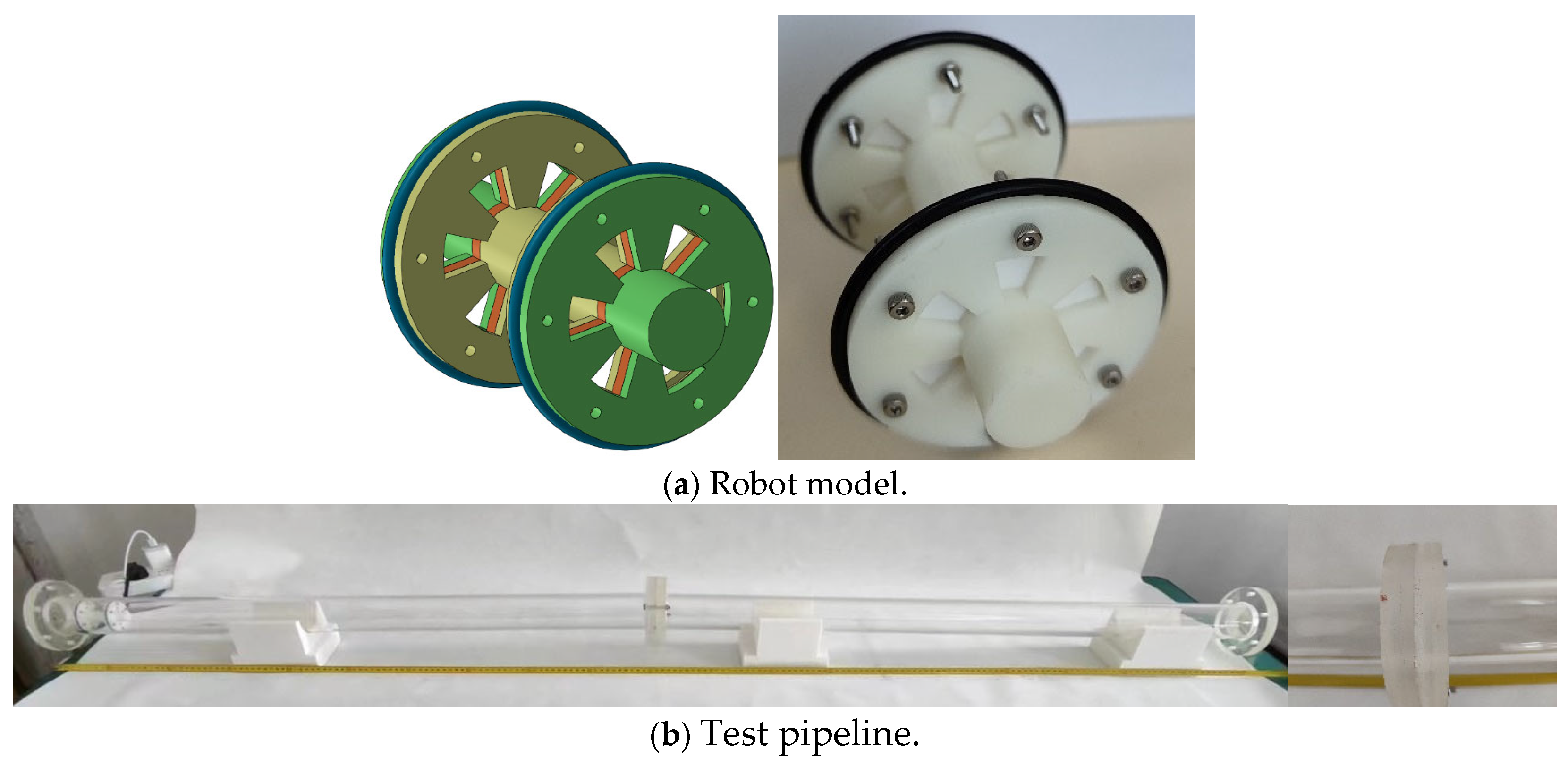

2.1. Basic Components of the Inspection Robot

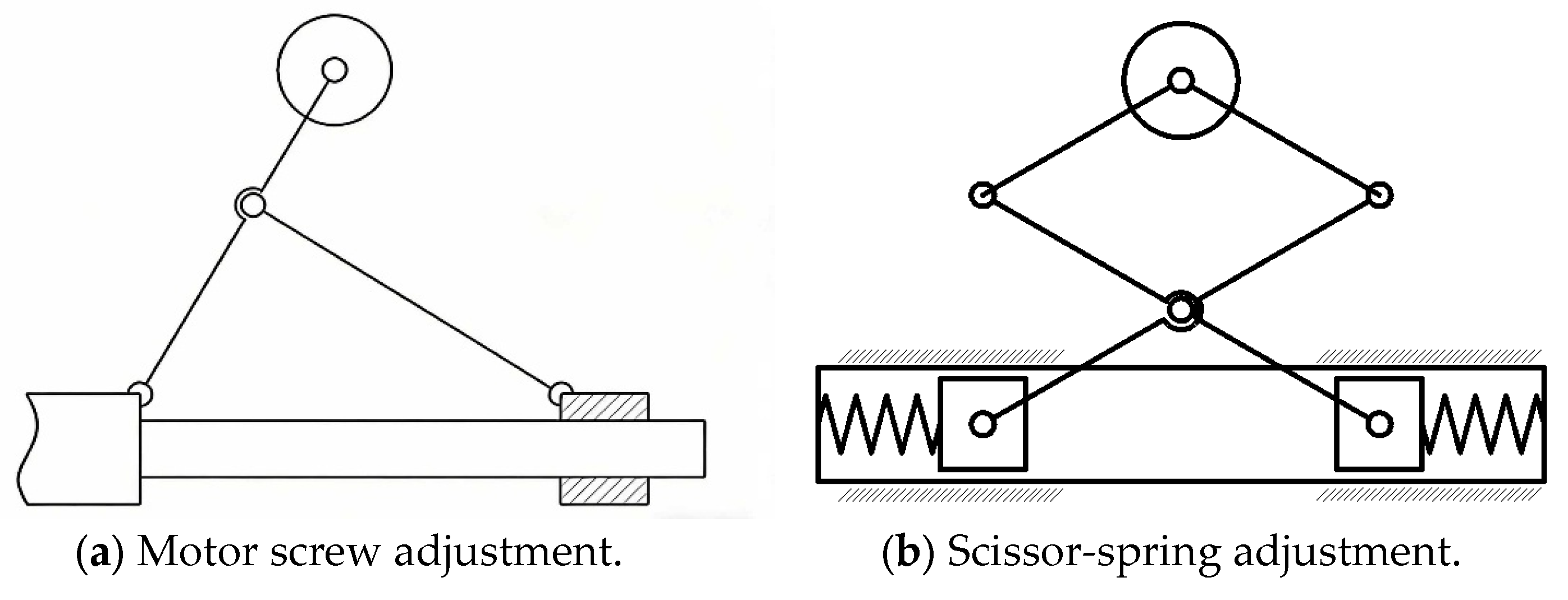

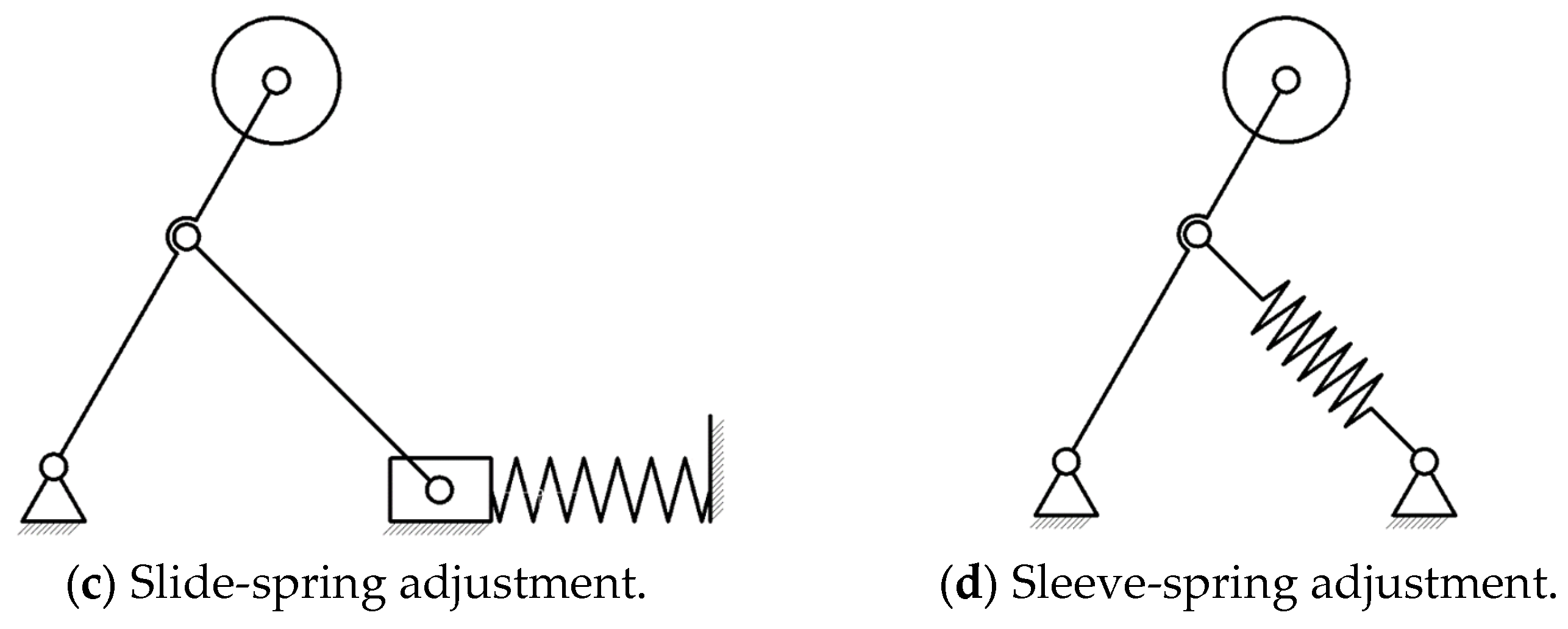

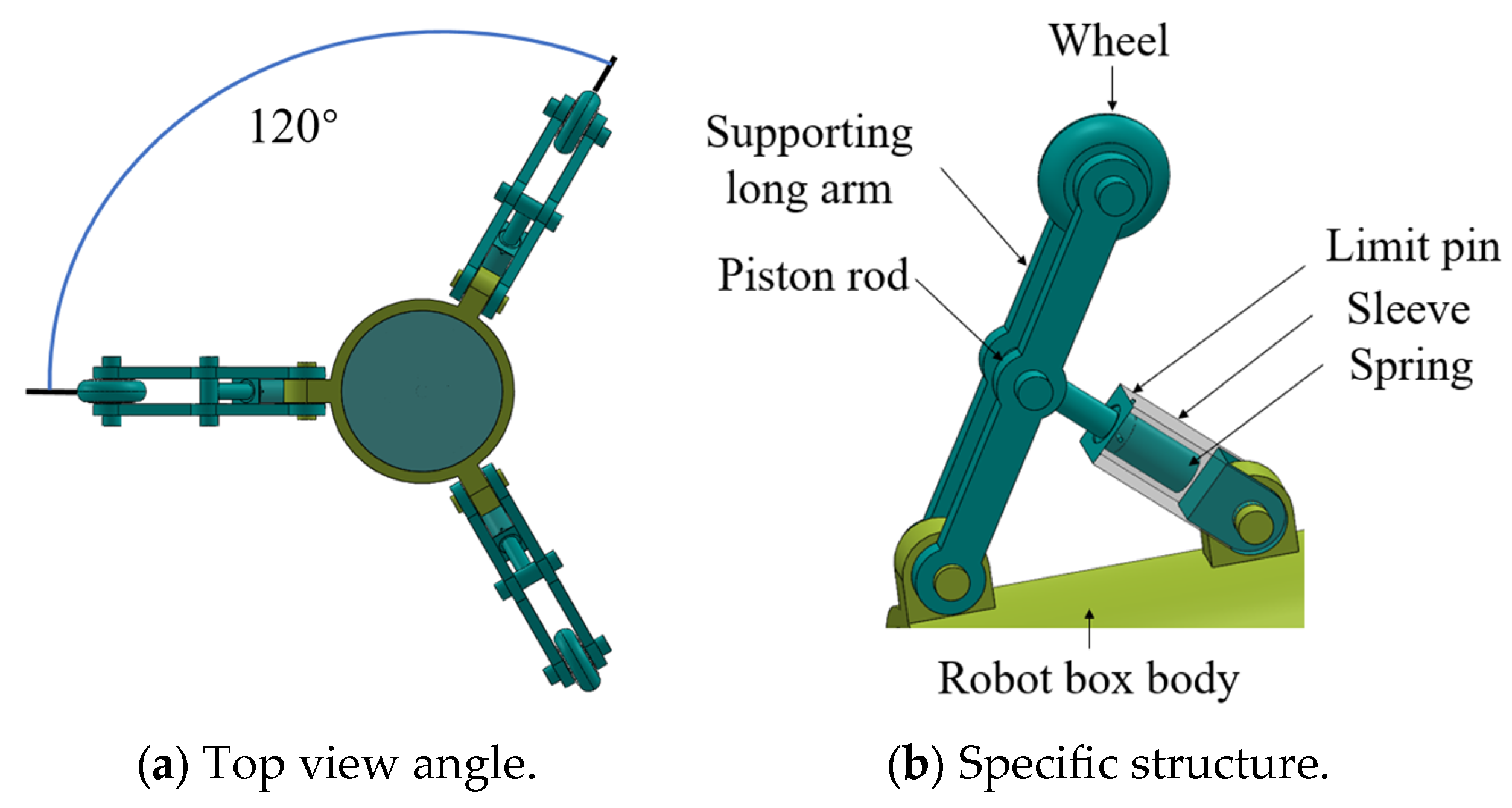

2.2. Design of the Speed Measurement Support Mechanism

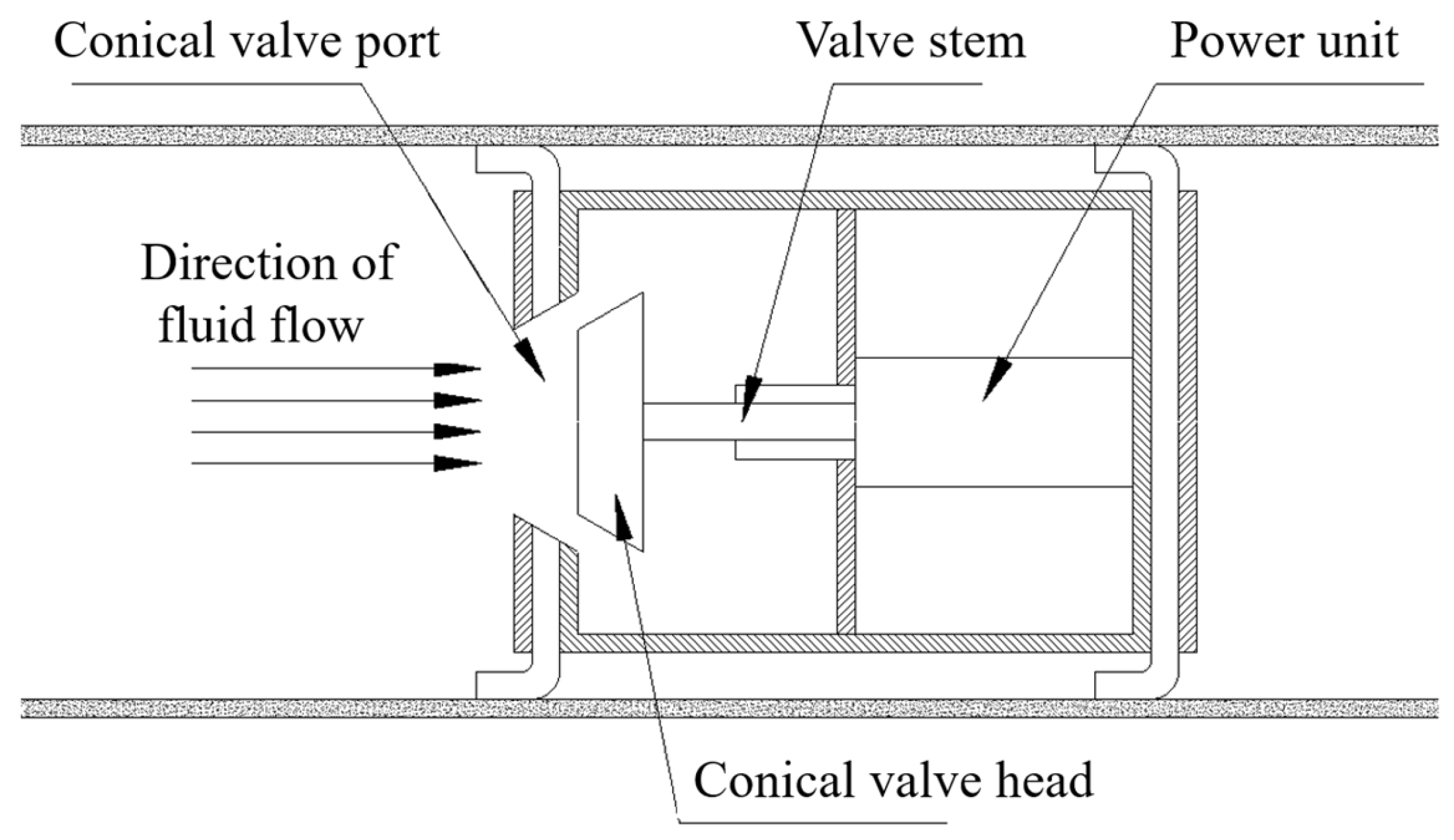

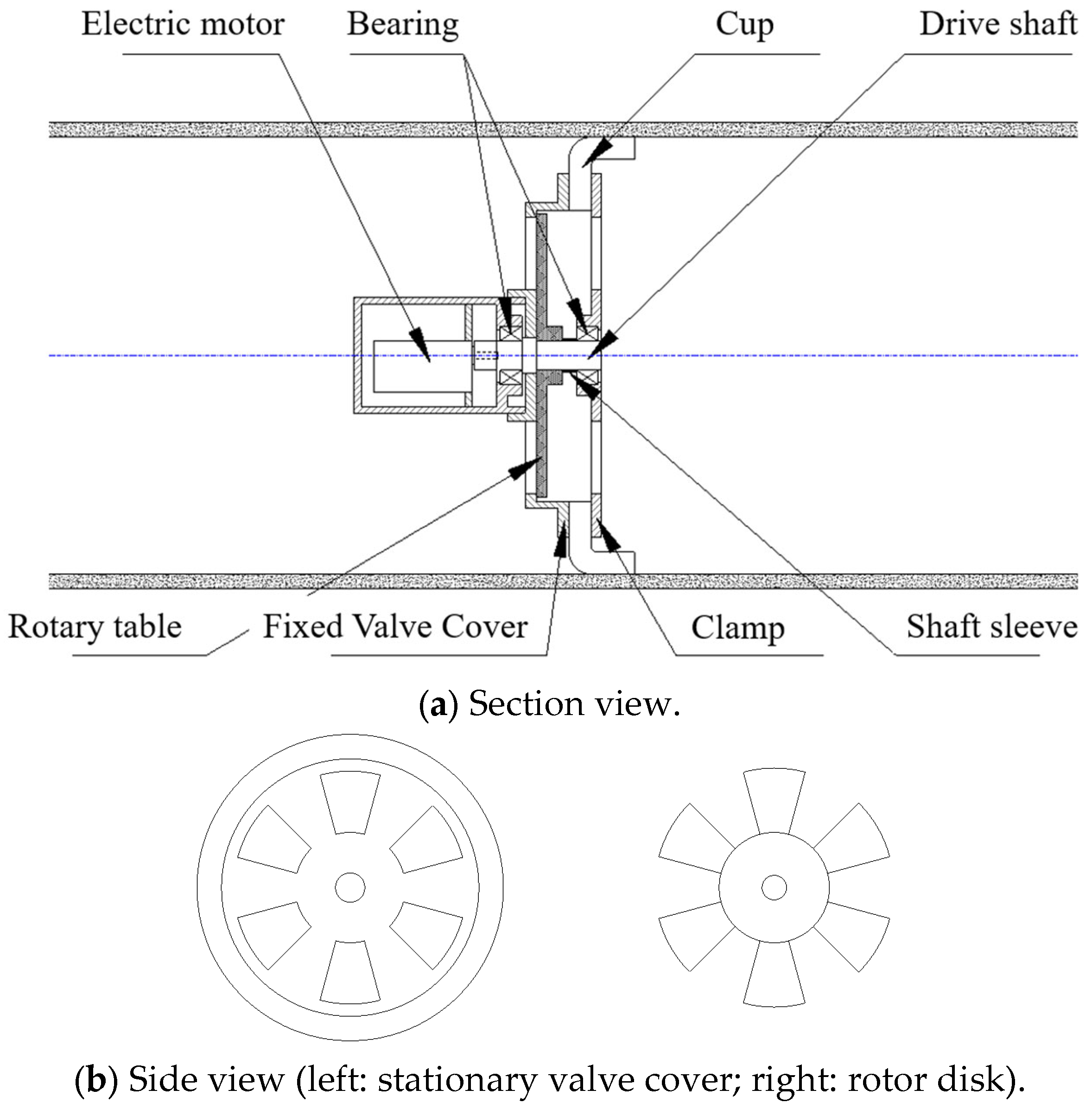

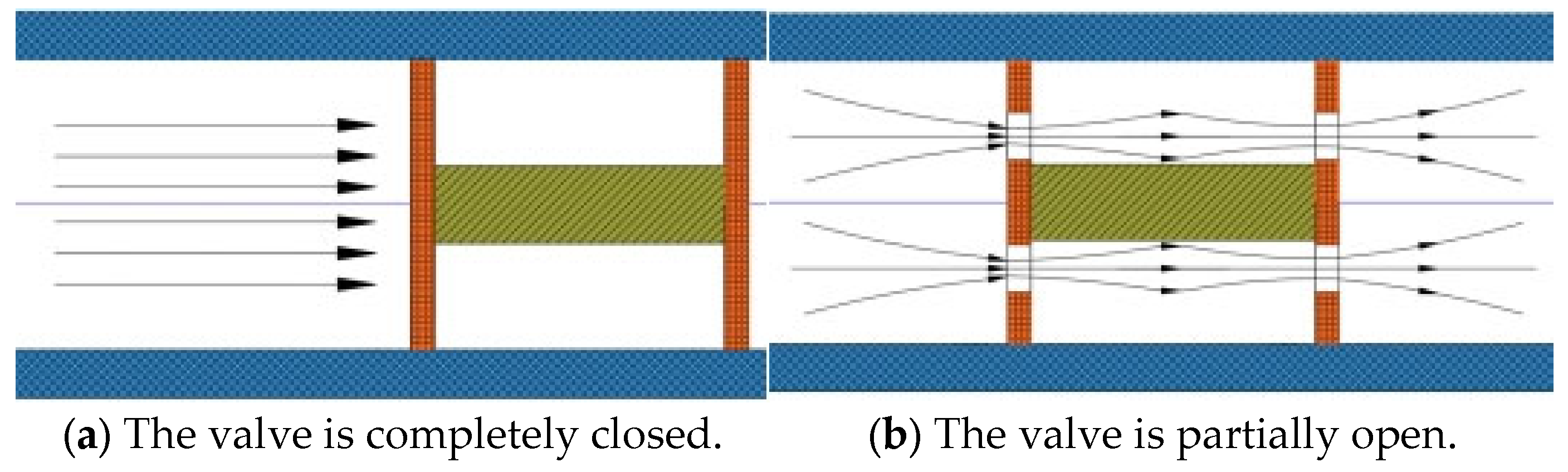

2.3. Design of the Flow-Discharge Speed Regulation Device

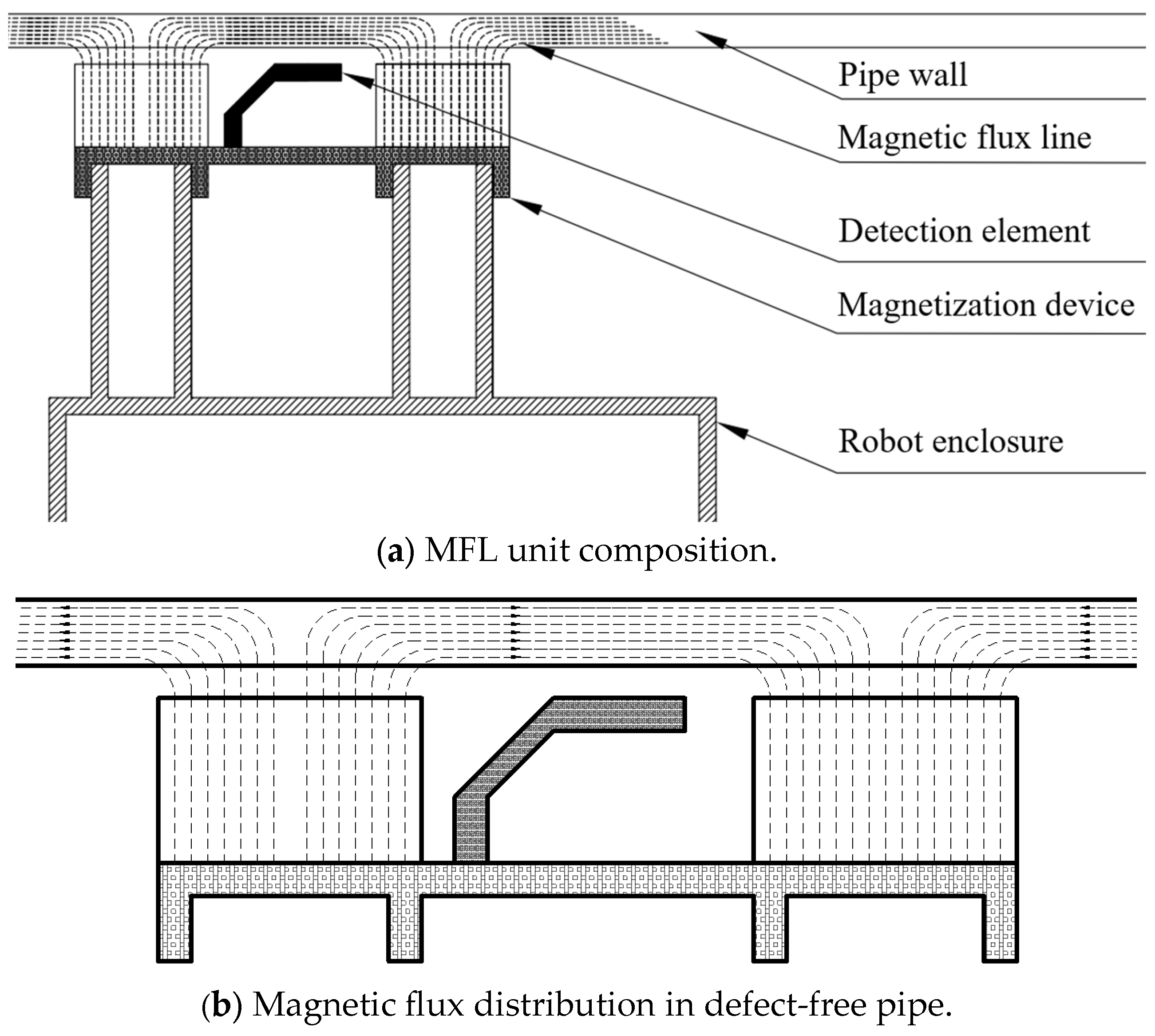

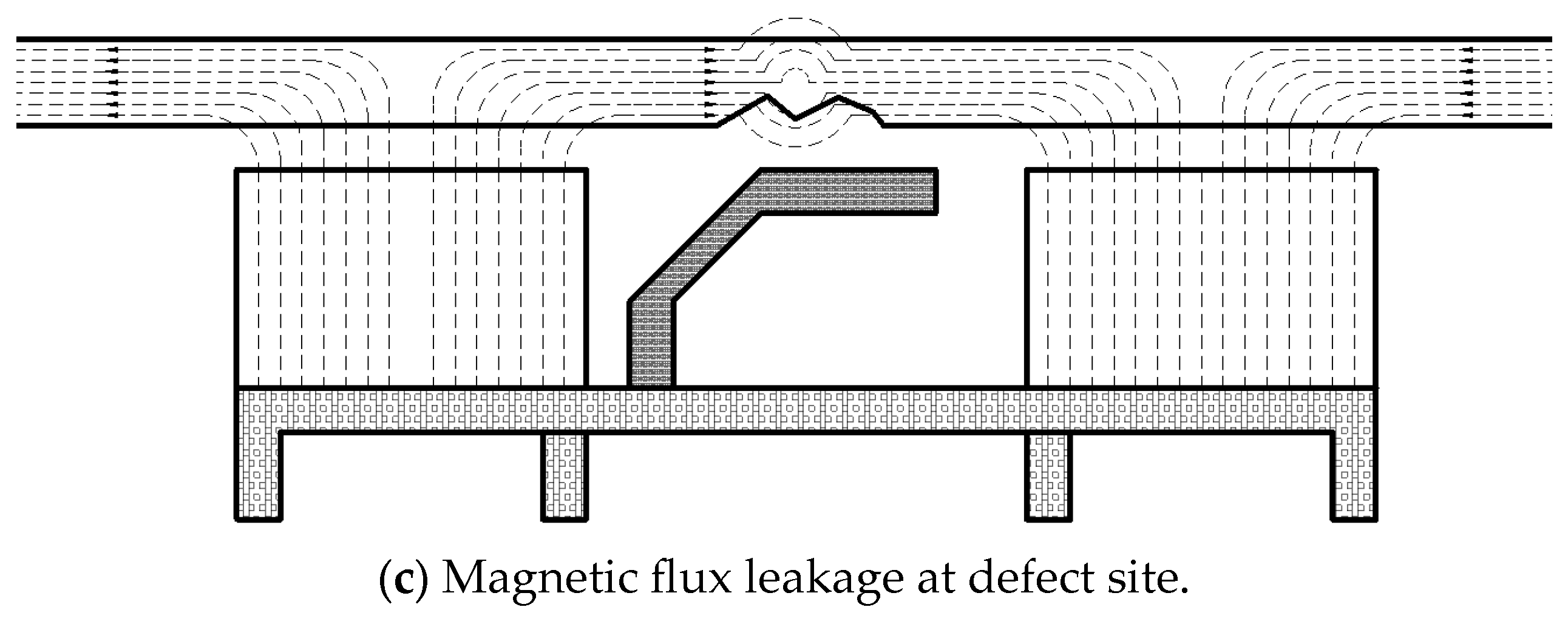

2.4. Design of the Magnetic Flux Leakage Detection Unit

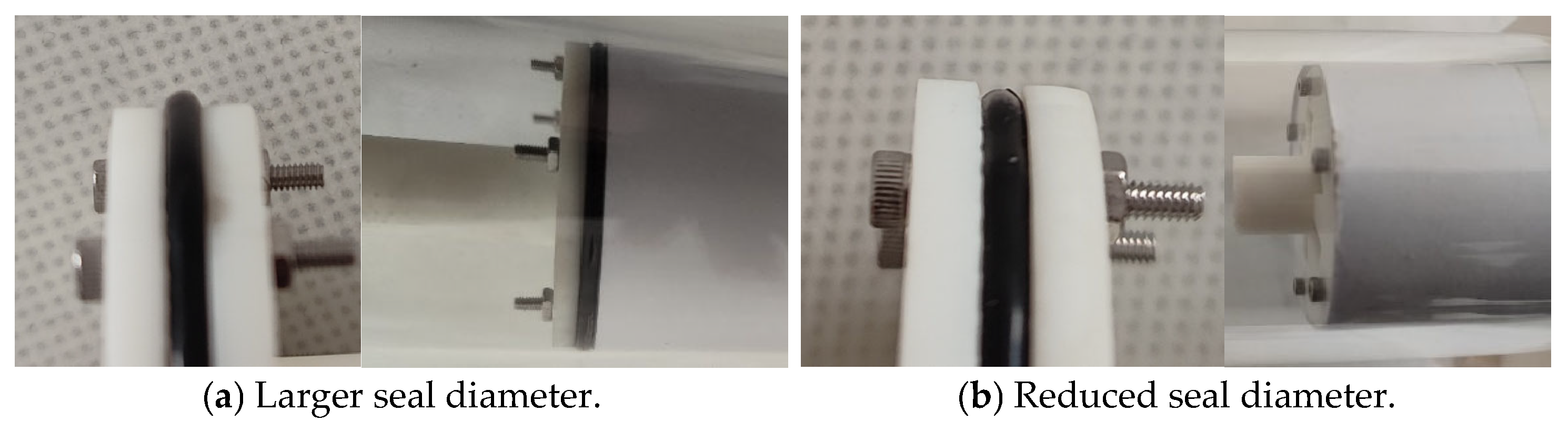

2.5. Design of the Variable Friction Device

3. Mechanical Performance Analysis of the In-Pipe MFL Inspection Robot

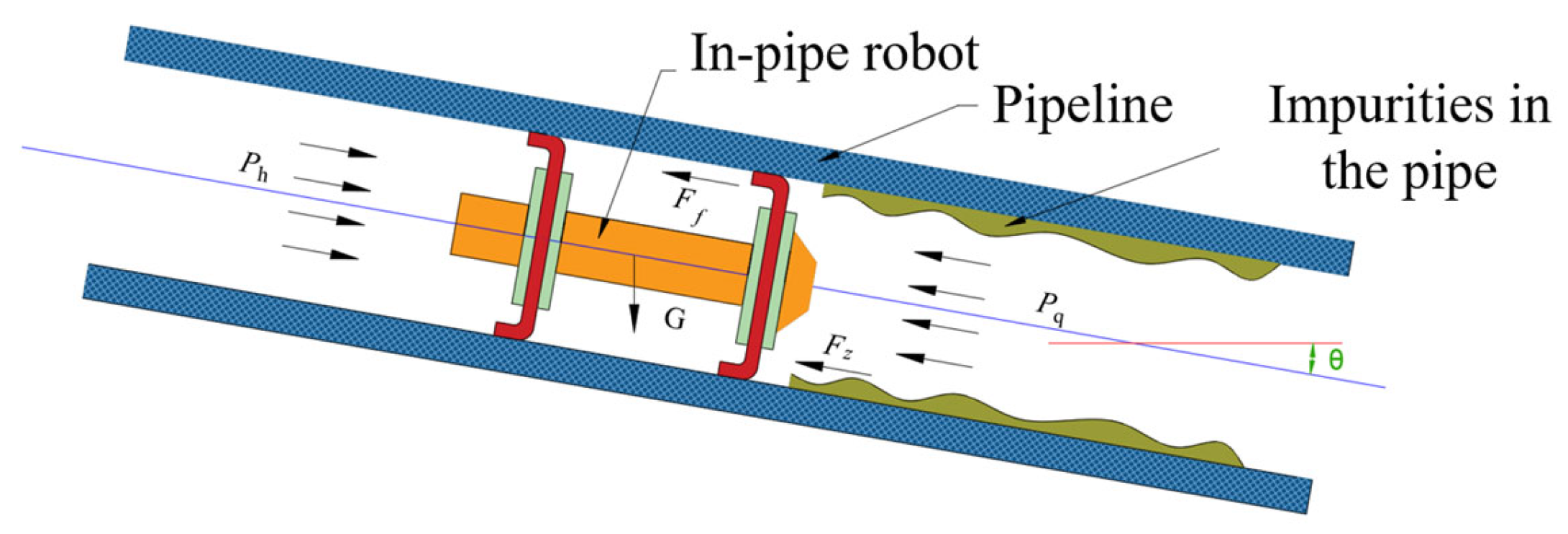

3.1. Kinematic Force Analysis of the Robot in Pipeline

3.2. The Driving Force of Robots

3.3. Resistance Calculation for the Robot

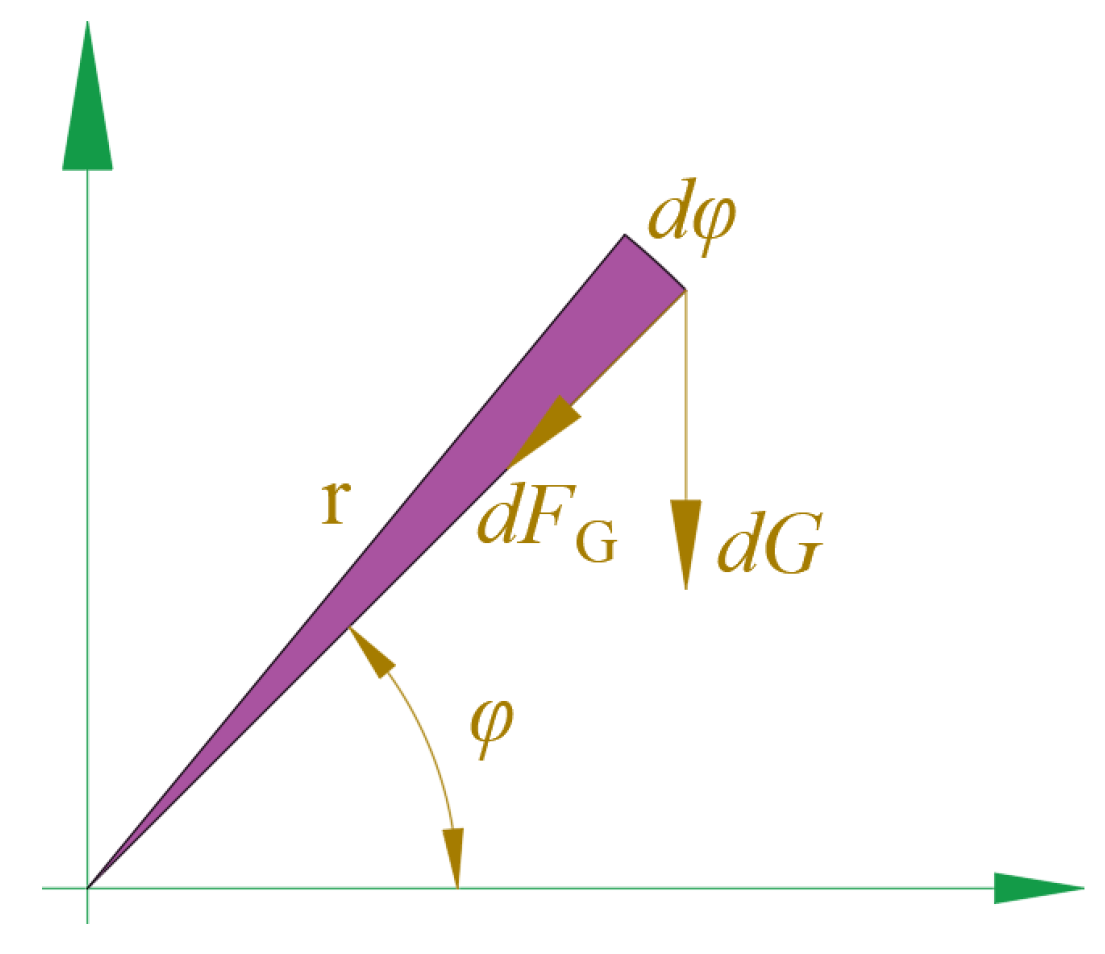

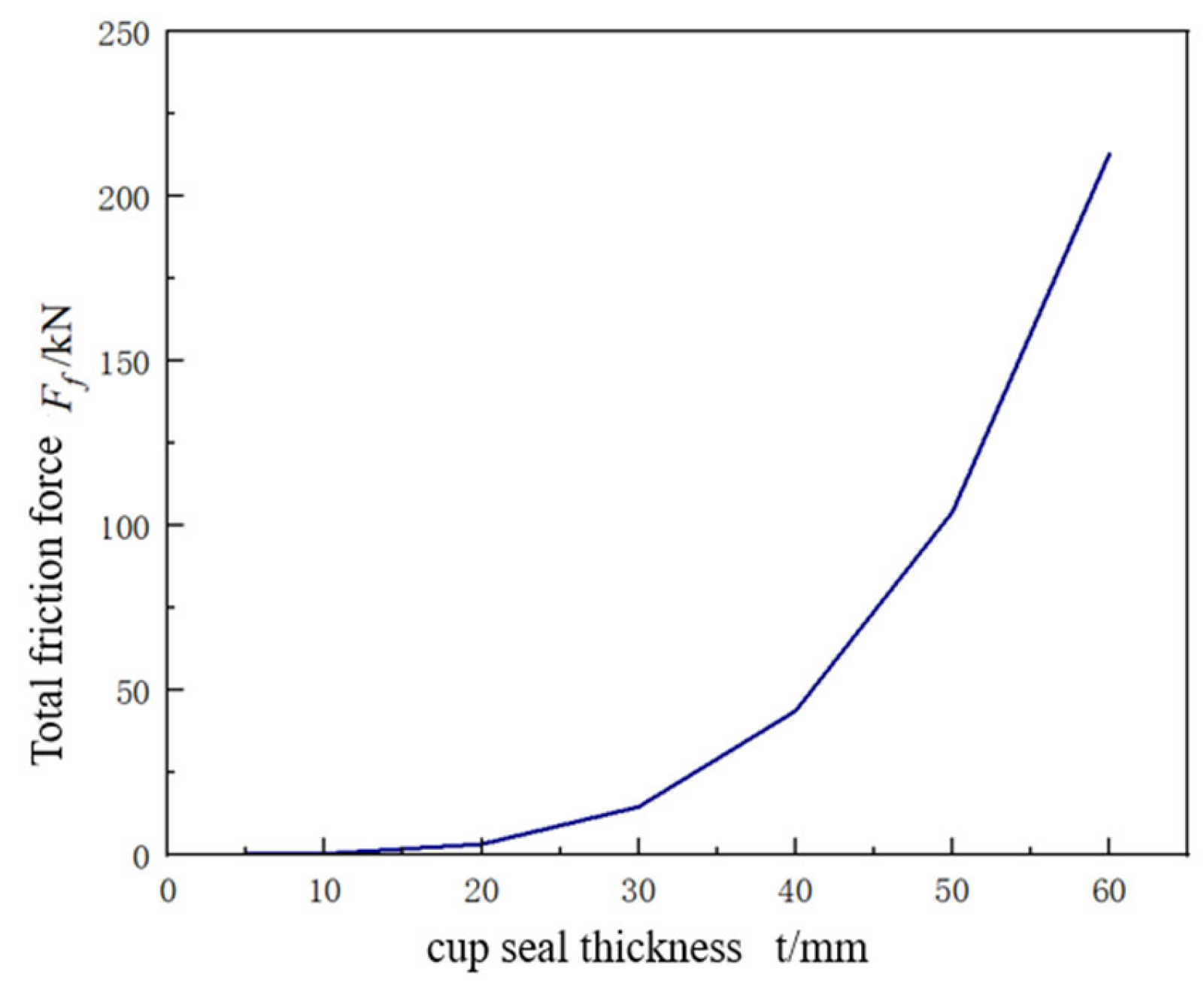

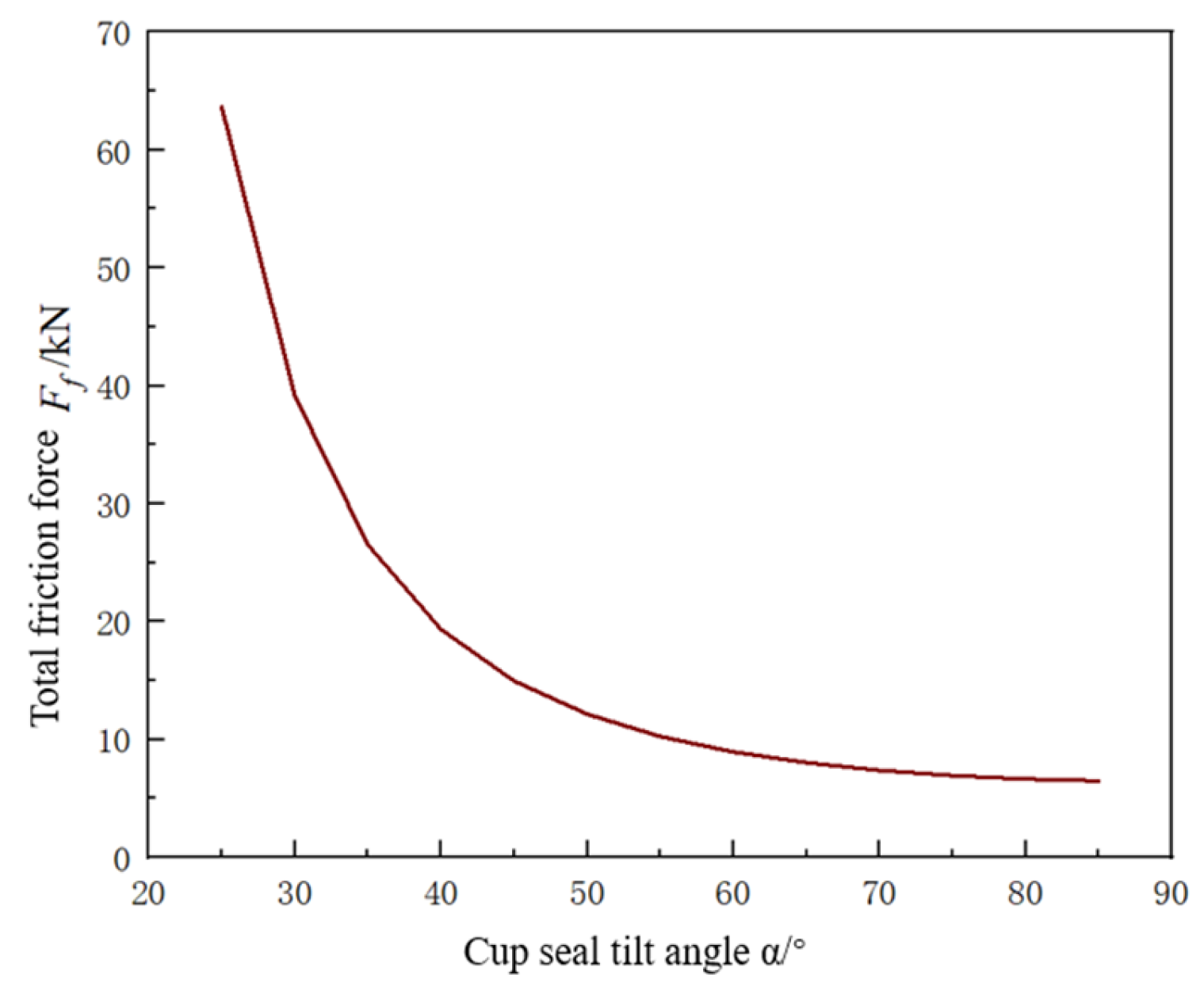

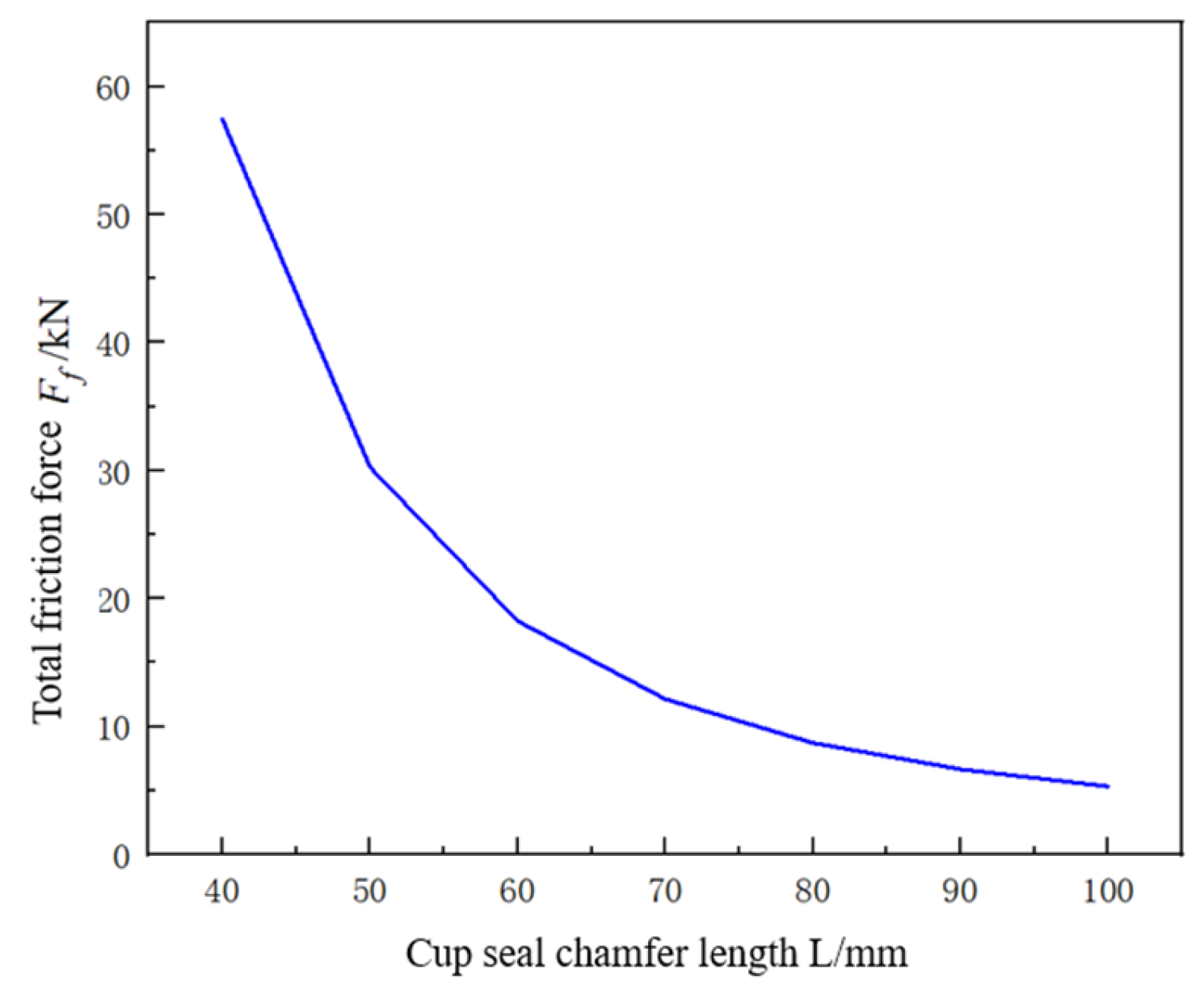

3.4. Parameter Calculation of the Sealing Cup

- (1)

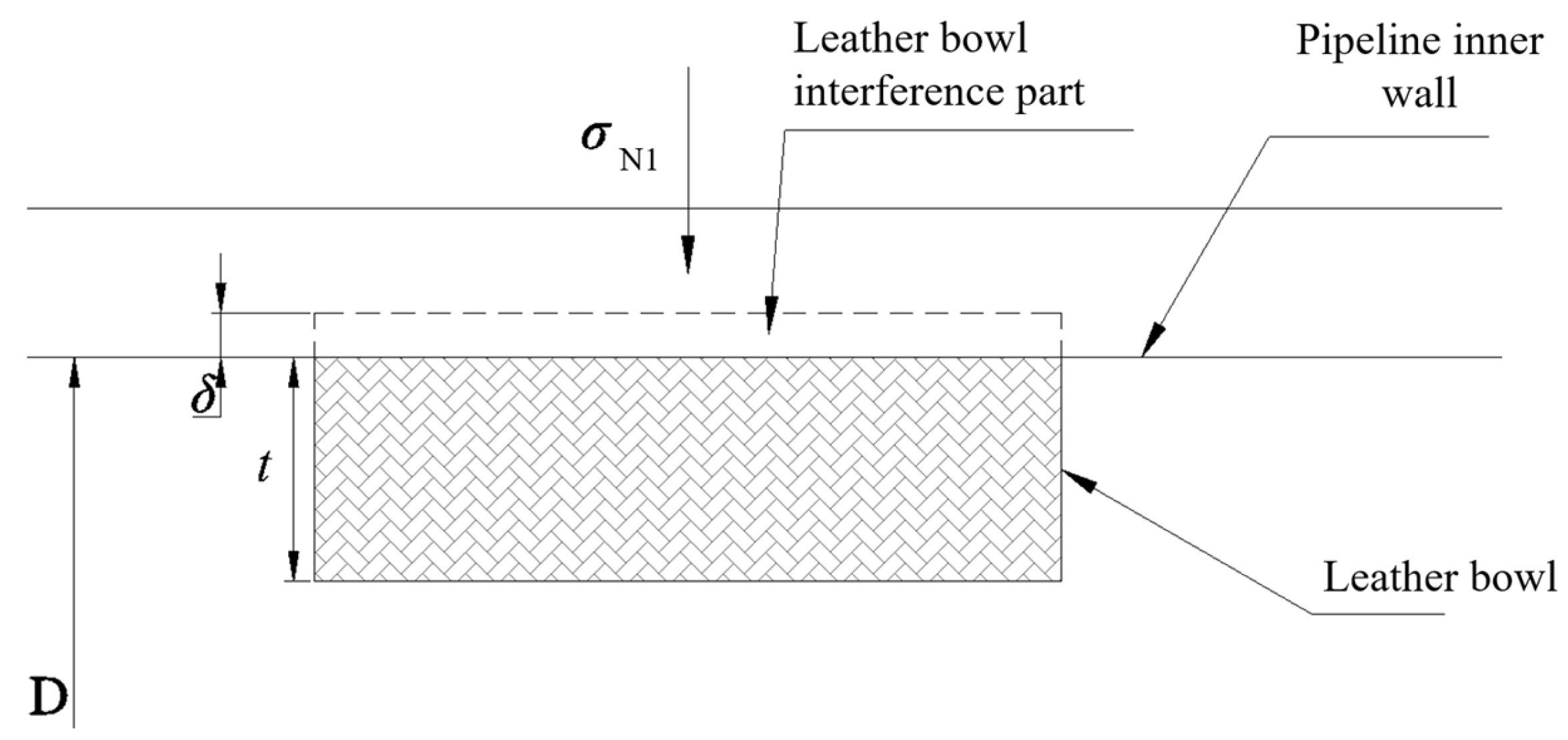

- Cylindrical Interference Mechanics Model: The lip region of the sealing cup experiences contact pressure FN1, inducing compressive stress σN1. As shown in Figure 12, to determine FN1, the force model is converted by equating lip pressure to an externally applied compressive stress σN1 causing a reduction in the outer diameter of the cup.

- (2)

- Cantilever Beam Mechanics Model: Under pressure FN2, the sealing cup experiences compressive stress σN2. The force diagram is shown in Figure 13.

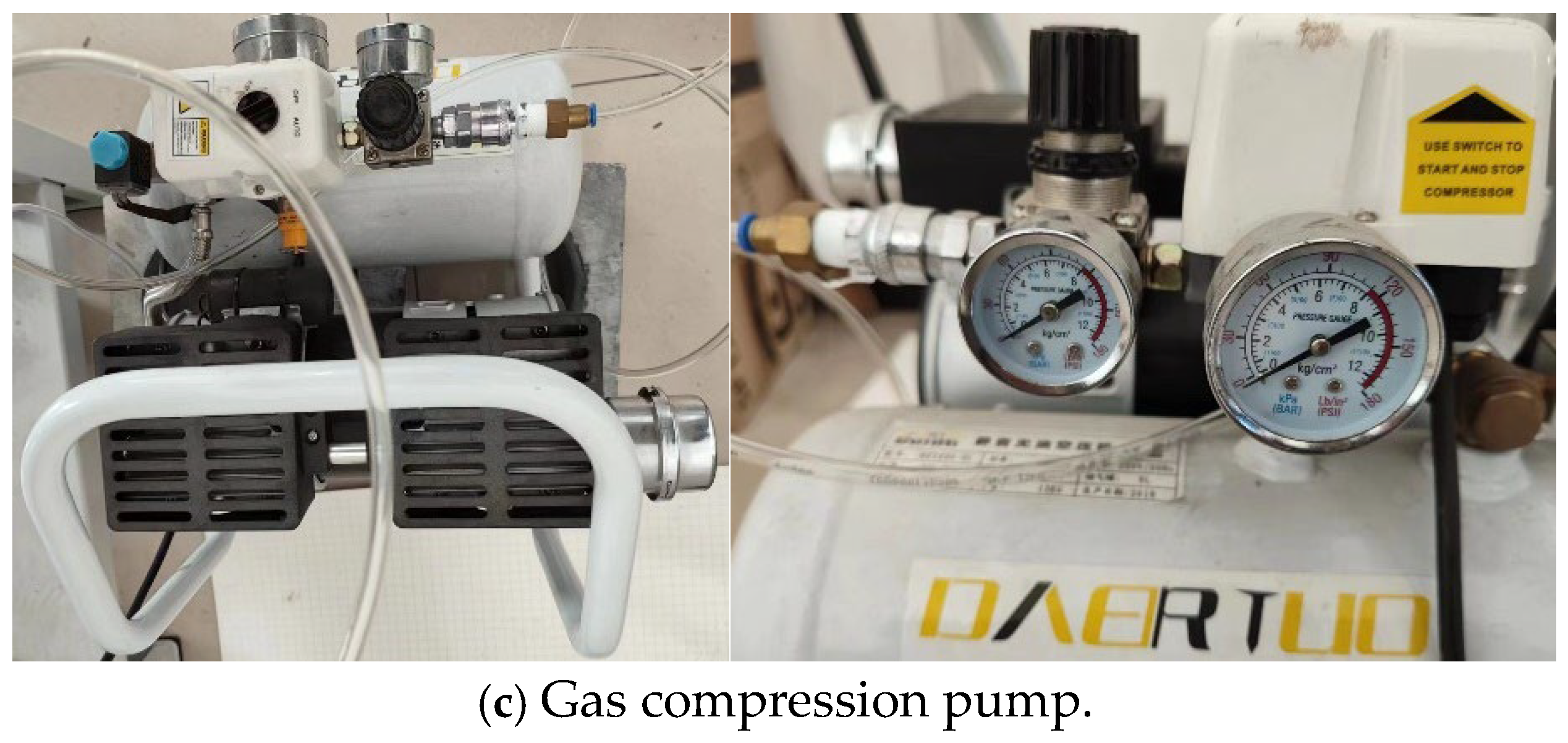

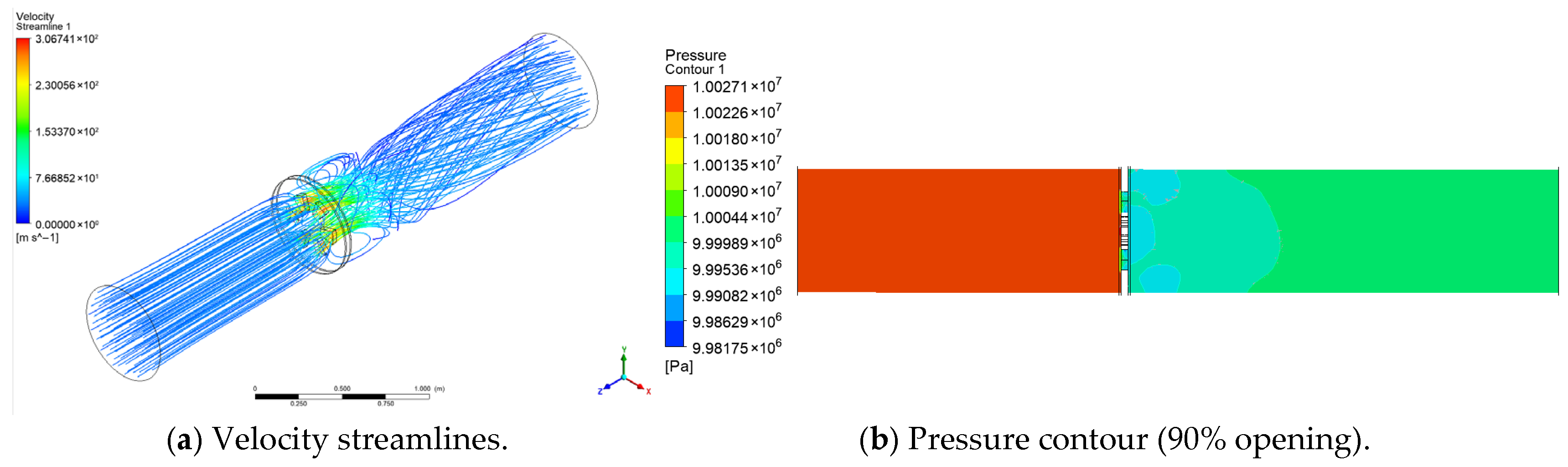

4. Simulation and Experimental Analysis of the In-Pipe MFL Inspection Robot

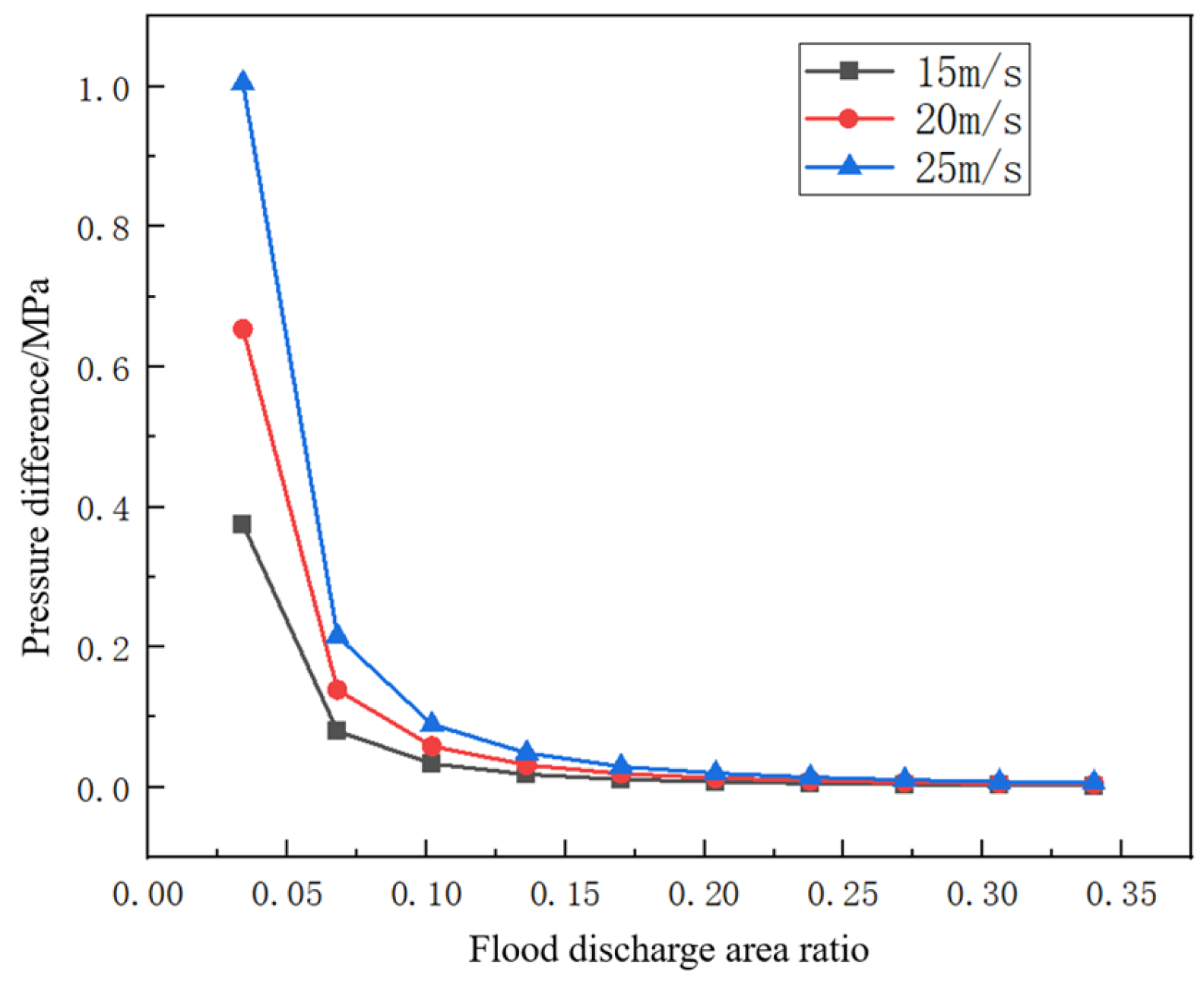

4.1. Determination of Discharge Area for the Flow-Discharge Speed Regulation Device

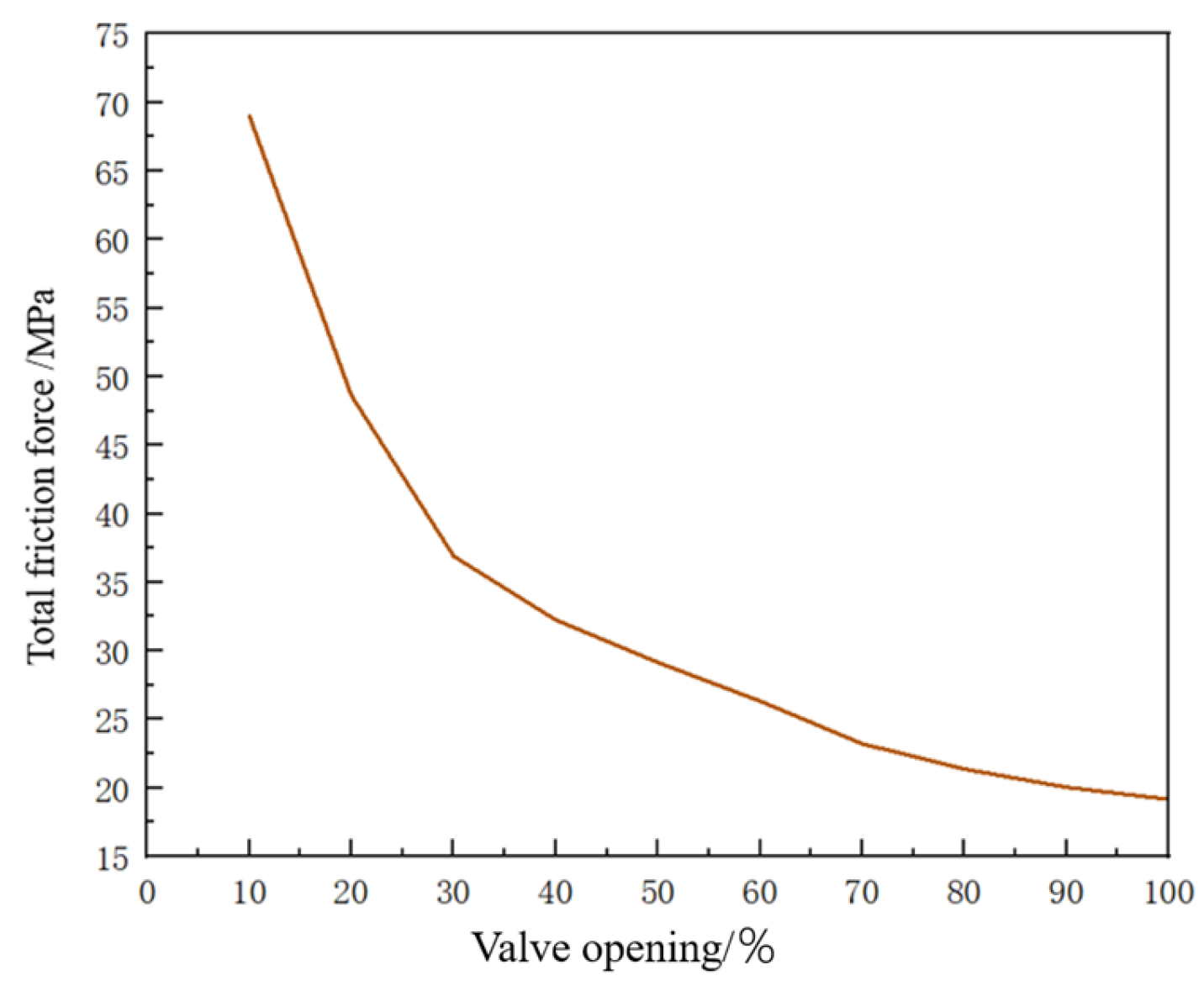

4.2. Valve Opening Degree vs. Valve Torque

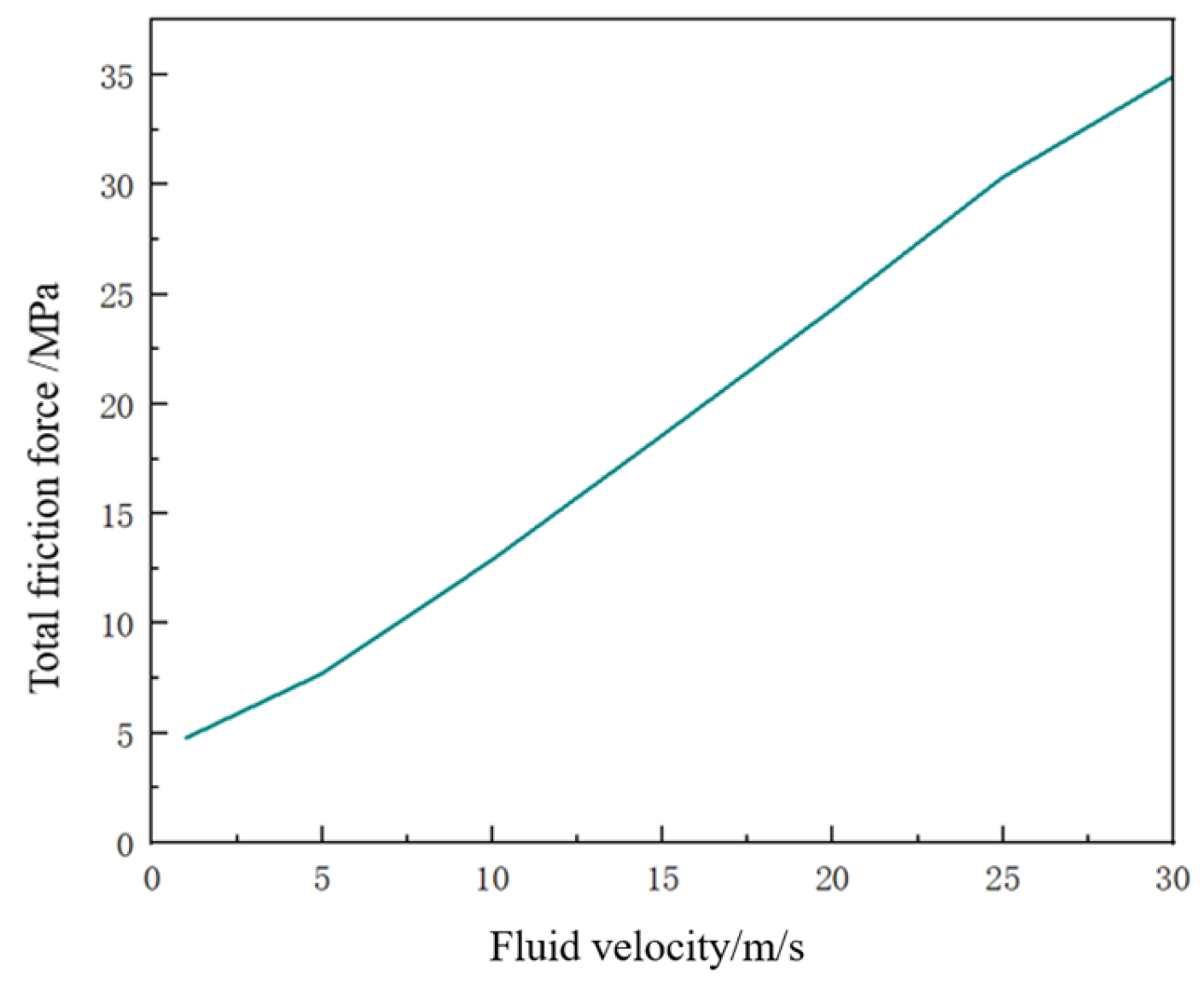

4.3. Fluid Velocity vs. Valve Torque

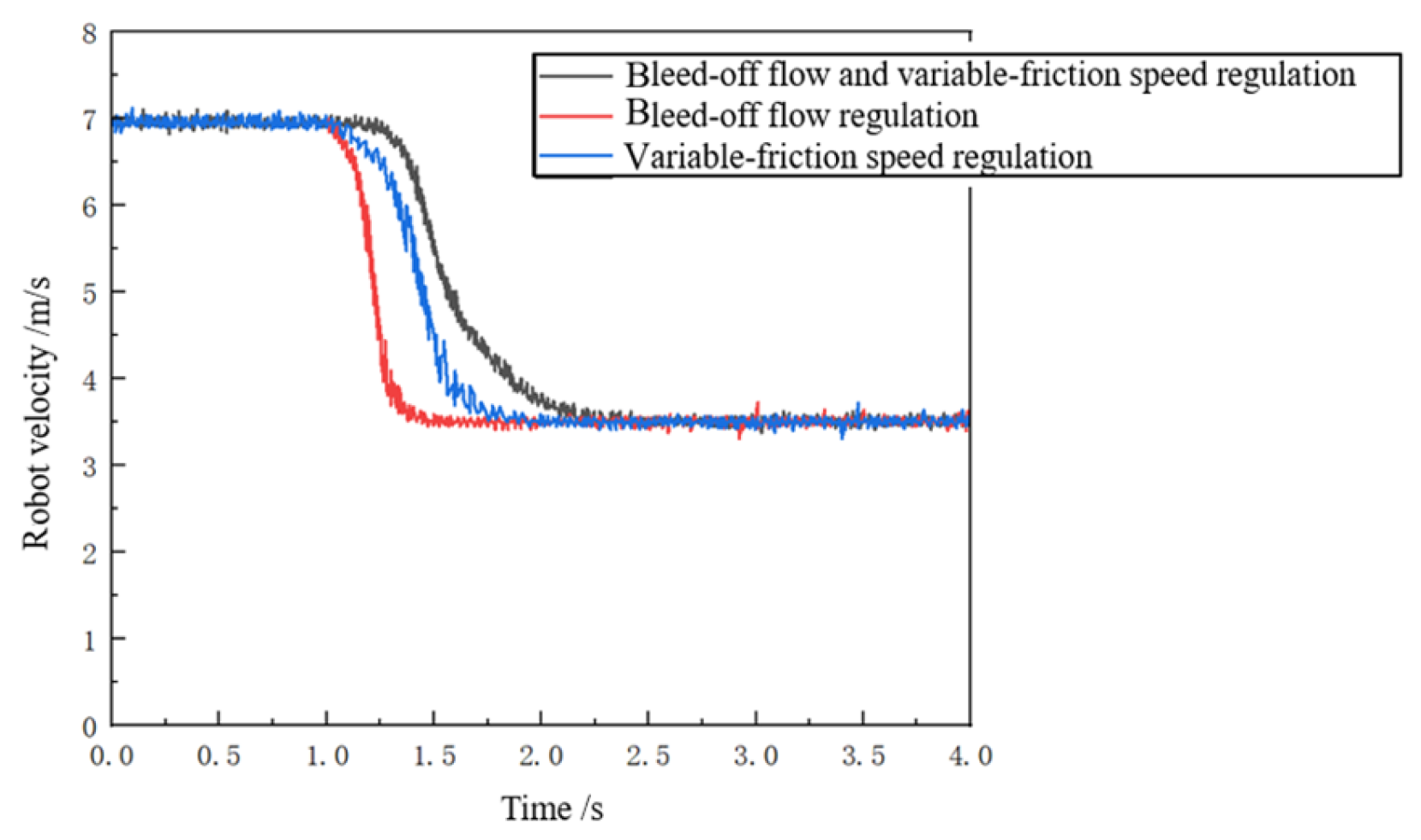

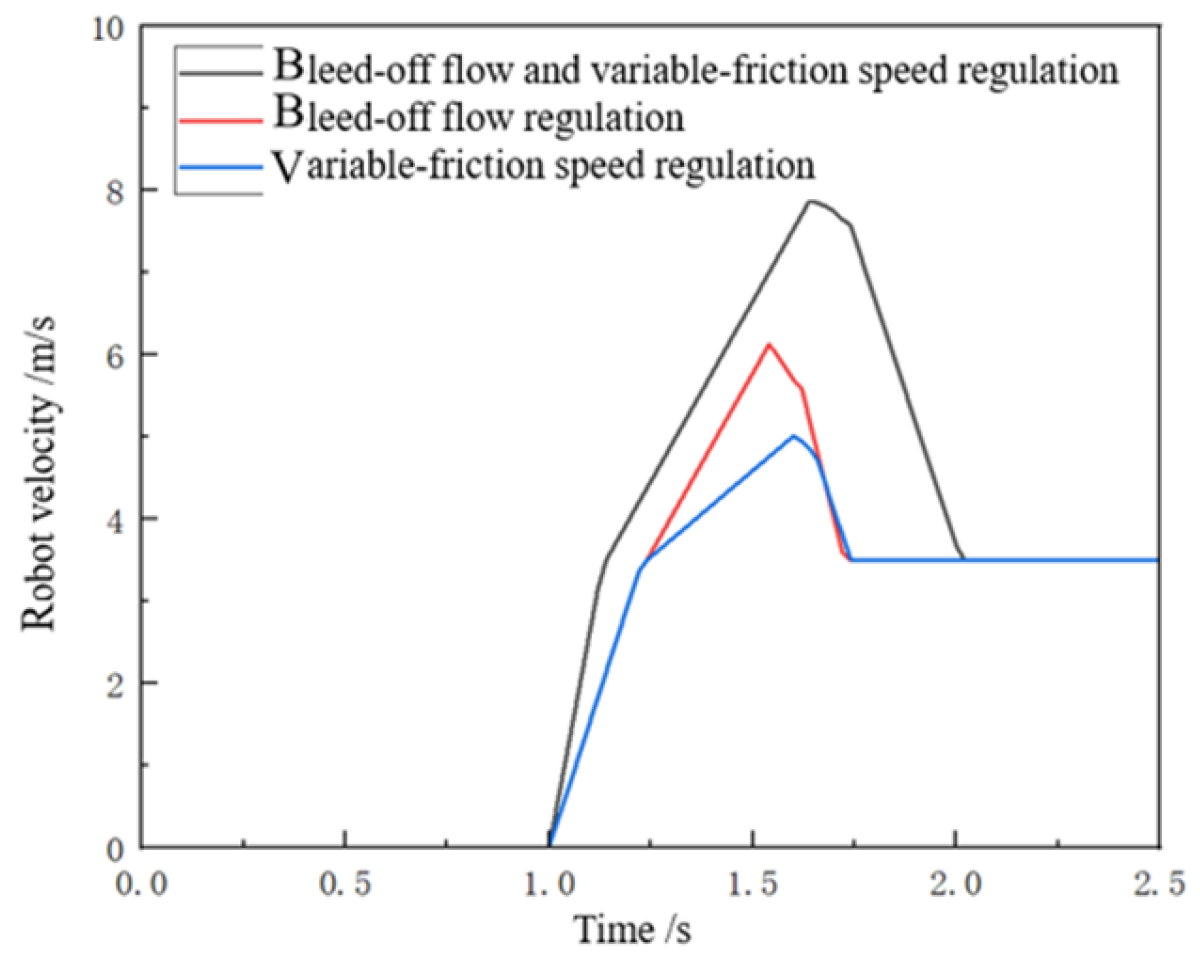

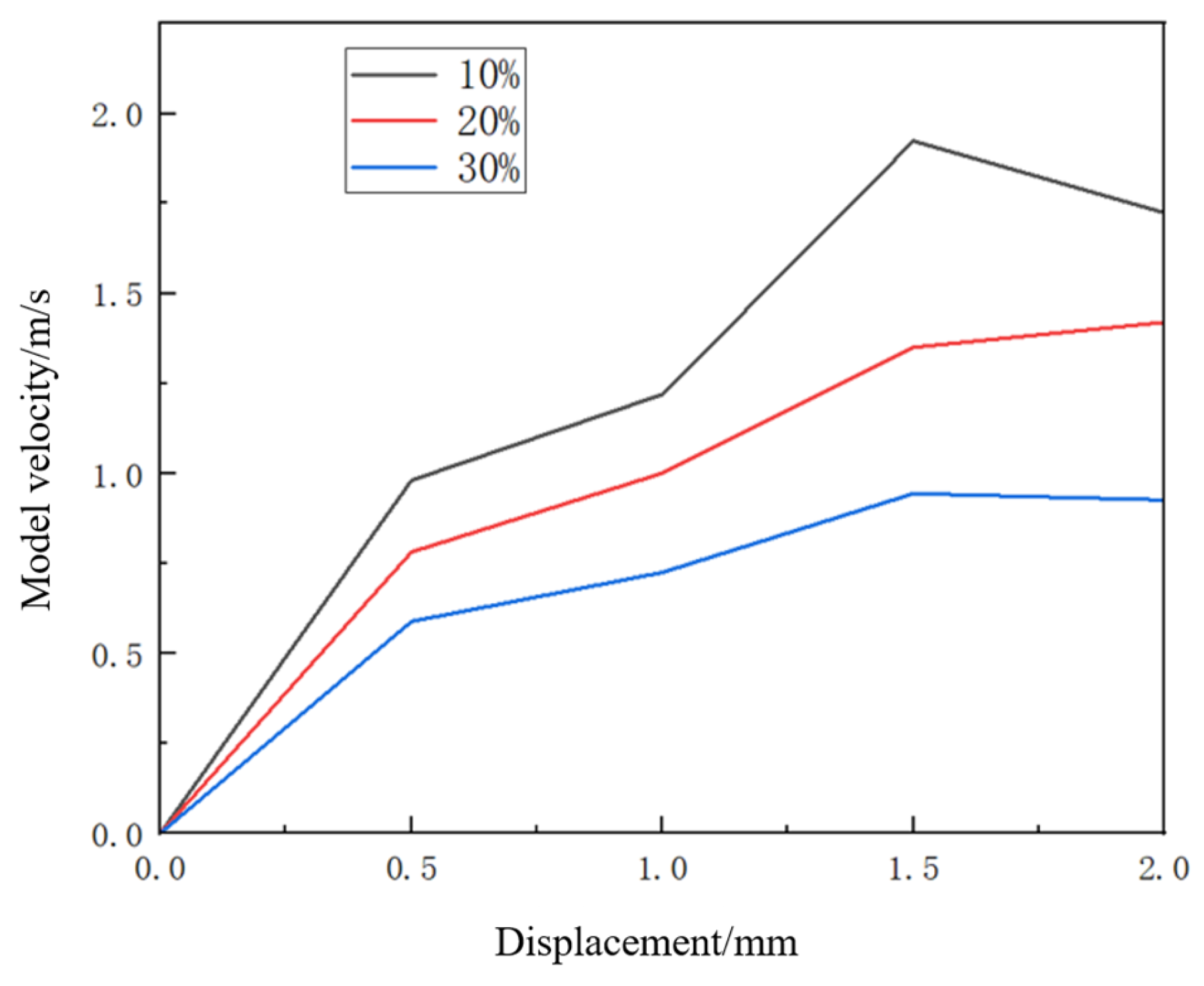

4.4. Speed Regulation Performance of Variable Friction Device

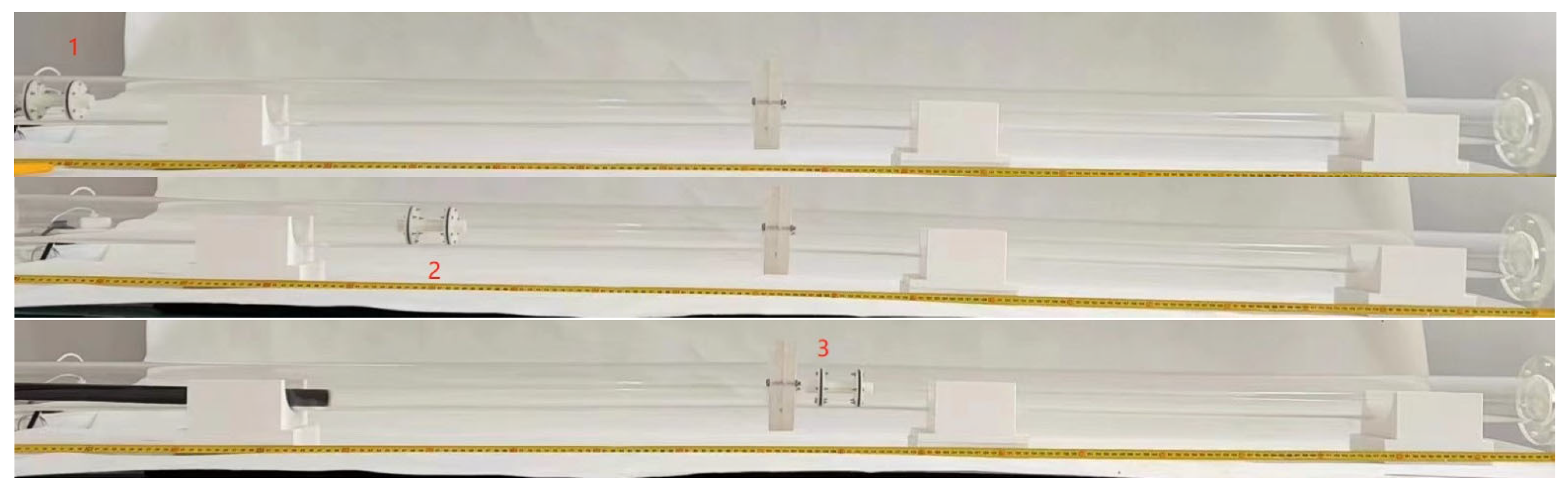

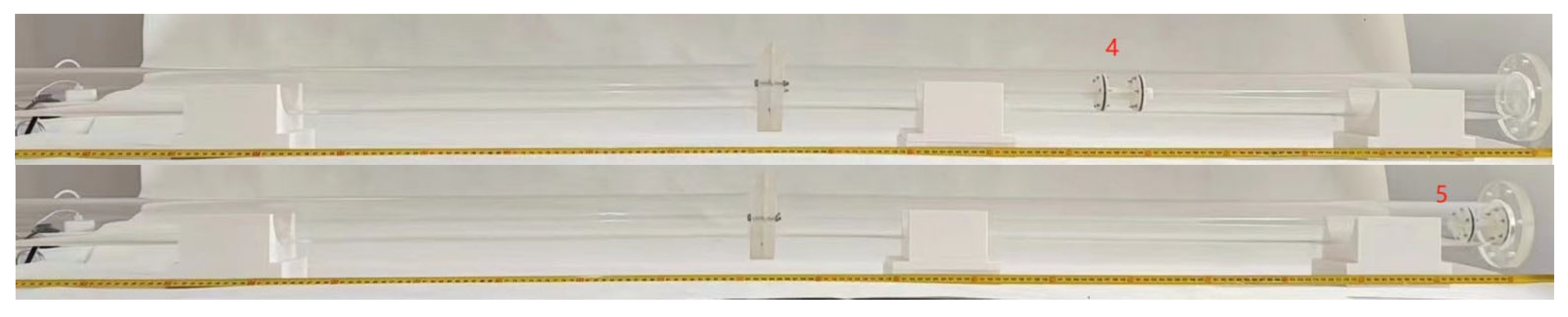

4.5. Experimental Results Analysis

5. Conclusions

- (1)

- The feasibility of the integrated design has been validated: A prototype featuring a synergistic control system integrating a rotary disk valve-type flow-discharge speed regulation device and a helical groove-driven variable friction device was successfully developed. Experiments demonstrated that this dual-mechanism system can effectively regulate the speed of the robot (achieving a speed adjustment range of approximately ±40% of the initial speed by varying the valve opening) and enable rapid stabilization (the coordinated strategy reduced the regulation time by about 66.7% compared to using the valve alone) under low-pressure gas drive conditions.

- (2)

- Key design parameters were quantified and determined: Based on the established mechanical model of the sealing cup, the quantitative relationship between the frictional force and structural parameters was clarified. By balancing the sealing reliability against frictional resistance, an optimal thickness of 30 mm was determined. Furthermore, integrating fluid simulation results with internal spatial constraints led to an optimized discharge area ratio of 30%, providing a concrete basis for engineering implementation.

- (3)

- Anti-jamming performance was supported by both mechanism analysis and experiments: The variable friction device provides a “soft-pass” capability against sudden pipeline diameter changes by actively retracting the sealing cup radially. Scaled-model experiments visually verified the effectiveness of this function, demonstrating that proactively reducing the seal diameter can effectively prevent jamming when encountering simulated local protrusions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Glossary, Scheme and Nomenclature

| Abbreviation | Full Term | Description |

| MFL | Magnetic Flux Leakage | Non-destructive testing method based on magnetic flux leakage |

| PIG | Pipeline Inspection Gauge | Device used for pipeline inspection and maintenance |

| CFD | Computational Fluid Dynamics | Numerical simulation of fluid flow |

| GMR | Giant Magneto-Resistance | High-sensitivity magnetic sensing technology |

| CNN | Convolutional Neural Network | Deep learning model for feature extraction |

| RL | Reinforcement Learning | Machine learning method based on reward mechanisms |

| PSO | Particle Swarm Optimization | Swarm intelligence optimization algorithm |

| SVM | Support Vector Machine | Supervised learning model for classification |

| SSA | Sparrow Search Algorithm | Swarm intelligence optimization algorithm |

| Symbols | Description | |

| m | net mass of the robot | |

| g | gravity acceleration | |

| Δp | pressure differential of the fluid medium across the robot | |

| A | cross-sectional area | |

| Ff | frictional force acting on the robot | |

| θ | angle between the robot’s central axis and horizontal plane | |

| Fz | resistance force from pipeline impurities | |

| P1 | pressure at inlet | |

| P2 | pressure at outlet | |

| v1 | velocity at inlet | |

| v2 | velocity at outlet | |

| ζ1 | local pressure loss due to sudden contraction at entrance | |

| ζi | frictional pressure loss | |

| ζ2 | local pressure loss due to sudden expansion at exit | |

| ξ1 | localized pressure loss coefficient for sudden fluid contraction | |

| ξ2 | localized pressure loss coefficient for sudden fluid expansion | |

| Ai | cross-section of fluid within the valve orifice | |

| A1 | cross-section of fluid at inlet | |

| A2 | cross-section of fluid at outlet | |

| Fd | driving force exerted by fluid pressure differential on the robot | |

| A′ | thrust-applicable area | |

| Ff | total frictional force between sealing cup and pipe wall | |

| μ | friction coefficient | |

| FG | gravity-induced deformation force | |

| FN1 | interference fit force | |

| FN2 | cantilever beam reaction force | |

| dG | gravitational force on an infinitesimal sector | |

| G | total robot weight | |

| r | sealing cup radius | |

| dφ | angular span of infinitesimal sector | |

| dFG | normal reaction force on an infinitesimal sector | |

| δ | deformation of the sealing cup under compressive force | |

| D | inner diameter of the pipe wall | |

| E | elastic modulus of the cup material | |

| t | thickness of the sealing cup | |

| σN1 | compressive stress on the sealing cup | |

| ω | cantilever beam deflection | |

| M(x) | bending moment | |

| Iz | moment of inertia | |

| FS | pressure per unit cup segment | |

| L | length of the inclined cup segment | |

| α | inclination angle of the cup | |

| dβ | angular span of an infinitesimal sector | |

| b | axial contact length | |

| S | contact area between cup and pipe wall | |

| i | number of sealing cups installed | |

References

- Nguyen, H.-H.; Park, J.-H.; Jeong, H.-Y. A Simultaneous Pipe-Attribute and PIG-Pose Estimation (SPPE) Using 3-D Point Cloud in Compressible Gas Pipelines. Sensors 2023, 23, 1196. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wang, J.; Zhou, Q.; Feng, S.; Wang, X. Mechanism design and mechanical analysis of pipeline inspection robot. Ind. Robot.-Int. J. Robot. Res. Appl. 2025, 52, 137–143. [Google Scholar] [CrossRef]

- Tang, C.; Du, B.; Jiang, S.; Shao, Q.; Dong, X.; Liu, X.-J.; Zhao, H. A pipeline inspection robot for navigating tubular environments in the sub-centimeter scale. Sci. Robot. 2022, 7, eabm8597. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Li, R.; Zhang, J.; Zhang, P. Development of a Pipeline Inspection Robot for the Standard Oil Pipeline of China National Petroleum Corporation. Appl. Sci. 2020, 10, 2853. [Google Scholar] [CrossRef]

- Kakogawa, A.; Ma, S. Design of a multilink-articulated wheeled pipeline inspection robot using only passive elastic joints. Adv. Robot. 2018, 32, 37–50. [Google Scholar] [CrossRef]

- Guo, Z.; Liu, Y.; Zhou, F.; Zhang, P.; Song, Z.; Tan, H. Design of hexapod robot equipped with omnidirectional vision sensor for defect inspection of pipeline’s inner surface. Meas. Sci. Technol. 2024, 35, 115901. [Google Scholar] [CrossRef]

- Yin, J.; Liu, X.; Wang, Y.; Wang, Y. Design and motion mechanism analysis of screw-driven in-pipe inspection robot based on novel adapting mechanism. Robotica 2024, 42, 1297–1319. [Google Scholar] [CrossRef]

- Elankavi, R.S.; Dinakaran, D.; Doss, A.S.A.; Chetty, R.M.K.; Ramya, M.M. Design of a wheeled-type In-Pipe Inspection Robot to overcome motion singularity in curved pipes. J. Ambient. Intell. Smart Environ. 2023, 16, 43–55. [Google Scholar] [CrossRef]

- Ma, Q.; Yang, Z.; Yue, C.; Liu, S. Investigation on mechanical behaviour of underwater launching process of bidirectional pigging robot in the subsea oil pipeline using Coupled Eulerian-Lagrangian method. Proc. Inst. Mech. Eng. Part M-J. Eng. Marit. Environ. 2024, 238, 847–864. [Google Scholar] [CrossRef]

- Venkateswaran, S.; Chablat, D. Stability analysis of tensegrity mechanism coupled with a bio-inspired piping inspection robot. arXiv 2022, arXiv:2206.01433. [Google Scholar] [CrossRef]

- Jeon, K.-W.; Jung, E.-J.; Bae, J.-H.; Park, S.-H.; Kim, J.-J.; Chung, G.; Chung, H.-J.; Yi, H. Development of an In-Pipe Inspection Robot for Large-Diameter Water Pipes. Sensors 2024, 24, 3470. [Google Scholar] [CrossRef]

- Jang, M.-W.; Lee, J.-Y.; Jeong, M.-S.; Hong, S.-H.; Shin, D.-H.; Seo, K.-H.; Suh, J.-H. Development of Spiral Driving Type Pipe Inspection Robot System for Magnetic Flux Leakage. J. Korean Soc. Precis. Eng. 2022, 39, 603–613. [Google Scholar] [CrossRef]

- Kim, H.M.; Yoo, H.R.; Park, G.S. A New Design of MFL Sensors for Self-Driving NDT Robot to Avoid Getting Stuck in Curved Underground Pipelines. IEEE Trans. Magn. 2018, 54, 1–5. [Google Scholar] [CrossRef]

- Wang, R.; Kawamura, Y. An Automated Sensing System for Steel Bridge Inspection Using GMR Sensor Array and Magnetic Wheels of Climbing Robot. J. Sens. 2016, 2016, 8121678. [Google Scholar] [CrossRef]

- Kim, J.-W.; Choi, J.-S.; Lee, E.-C.; Park, S.-H. Field Application of a Cable NDT System for Cable-Stayed Bridge Using MFL Sensors Integrated Climbing Robot. J. Korean Soc. Nondestruct. Test. 2014, 34, 60–67. [Google Scholar] [CrossRef]

- Lynch, A.J. Magnetic Flux Leakage Robotic Pipe Inspection: Internal and External Methods. Master’s Thesis, Rice University, Houston, TX, USA, 2009. [Google Scholar]

- Pan, J.; Gao, L. A novel method for defects marking and classifying in MFL inspection of pipeline. Int. J. Press. Vessel. Pip. 2023, 202, 104892. [Google Scholar] [CrossRef]

- Feng, J.; Zhang, X.; Lu, S.; Yang, F. A Single-Stage Enhancement-Identification Framework for Pipeline MFL Inspection. IEEE Trans. Instrum. Meas. 2022, 71, 1–13. [Google Scholar] [CrossRef]

- Wu, Z.; Deng, Y.; Liu, J.; Wang, L. A Reinforcement Learning-Based Reconstruction Method for Complex Defect Profiles in MFL Inspection. IEEE Trans. Instrum. Meas. 2021, 70, 1–10. [Google Scholar] [CrossRef]

- Chen, J.; Kang, X.; Zhang, X.; He, R.; Meng, T.; Song, K. A novel identification approach for corrosion and gouging of oil and gas pipelines based on low magnetisation level MFL inspection. Insight 2022, 64, 270–278. [Google Scholar] [CrossRef]

- Shi, P.; Zhang, P.; Hao, S.; Wang, W.; Gou, X. Classification and evaluation for nearside/backside defect via magnetic flux leakage: A dual probe design with SVM and PSO intelligence algorithms. NDT E Int. 2024, 144, 103100. [Google Scholar] [CrossRef]

- Shen, Y.; Zhou, W. Development of a convolutional neural network model to predict the size and location of corrosion defects on pipelines based on magnetic flux leakage signals. Int. J. Press. Vessel. Pip. 2024, 207, 105123. [Google Scholar] [CrossRef]

| Sealing Cup | Interference Ratio | Contact Length | Thickness | Inclination Angle | Inclined Segment Length |

|---|---|---|---|---|---|

| numerical value | 3% | 20 mm | 30 mm | 55° | 80 mm |

| Number of Grids/Million | Pressure Difference/MPa |

|---|---|

| 100 | 0.051 |

| 150 | 0.042 |

| 200 | 0.0299 |

| 250 | 0.0366 |

| 300 | 0.0378 |

| 350 | 0.0382 |

| 400 | 0.0384 |

| 450 | 0.0381 |

| 500 | 0.0383 |

| Percentage | 10% | 20% | 30% |

|---|---|---|---|

| 1 | 0.51 | 0.64 | 0.85 |

| 2 | 0.92 | 1.04 | 1.54 |

| 3 | 1.18 | 1.41 | 2.07 |

| 4 | 1.51 | 1.83 | 2.61 |

| Metric | Value |

|---|---|

| Speed regulation range | ±40% |

| Regulation time (coordinated control) | ~0.5 s |

| Speed fluctuation reduction | ~37% |

| Valve torque range | 20–69 MPa |

| Optimal discharge area ratio | 30% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Liu, H.; Cao, D.; Yuan, S.; Liu, J.; Li, Y. Design and Performance Analysis of a New Variable Friction Pipeline Magnetic Flux Leakage Detection Robot. Lubricants 2026, 14, 20. https://doi.org/10.3390/lubricants14010020

Liu H, Cao D, Yuan S, Liu J, Li Y. Design and Performance Analysis of a New Variable Friction Pipeline Magnetic Flux Leakage Detection Robot. Lubricants. 2026; 14(1):20. https://doi.org/10.3390/lubricants14010020

Chicago/Turabian StyleLiu, Haichao, Dongliang Cao, Shining Yuan, Jie Liu, and Yufang Li. 2026. "Design and Performance Analysis of a New Variable Friction Pipeline Magnetic Flux Leakage Detection Robot" Lubricants 14, no. 1: 20. https://doi.org/10.3390/lubricants14010020

APA StyleLiu, H., Cao, D., Yuan, S., Liu, J., & Li, Y. (2026). Design and Performance Analysis of a New Variable Friction Pipeline Magnetic Flux Leakage Detection Robot. Lubricants, 14(1), 20. https://doi.org/10.3390/lubricants14010020