Study on Transient Thermal Characteristics of Aviation Wet Clutches with Conical Separate Discs for Helicopters in Successive Shifting

Abstract

1. Introduction

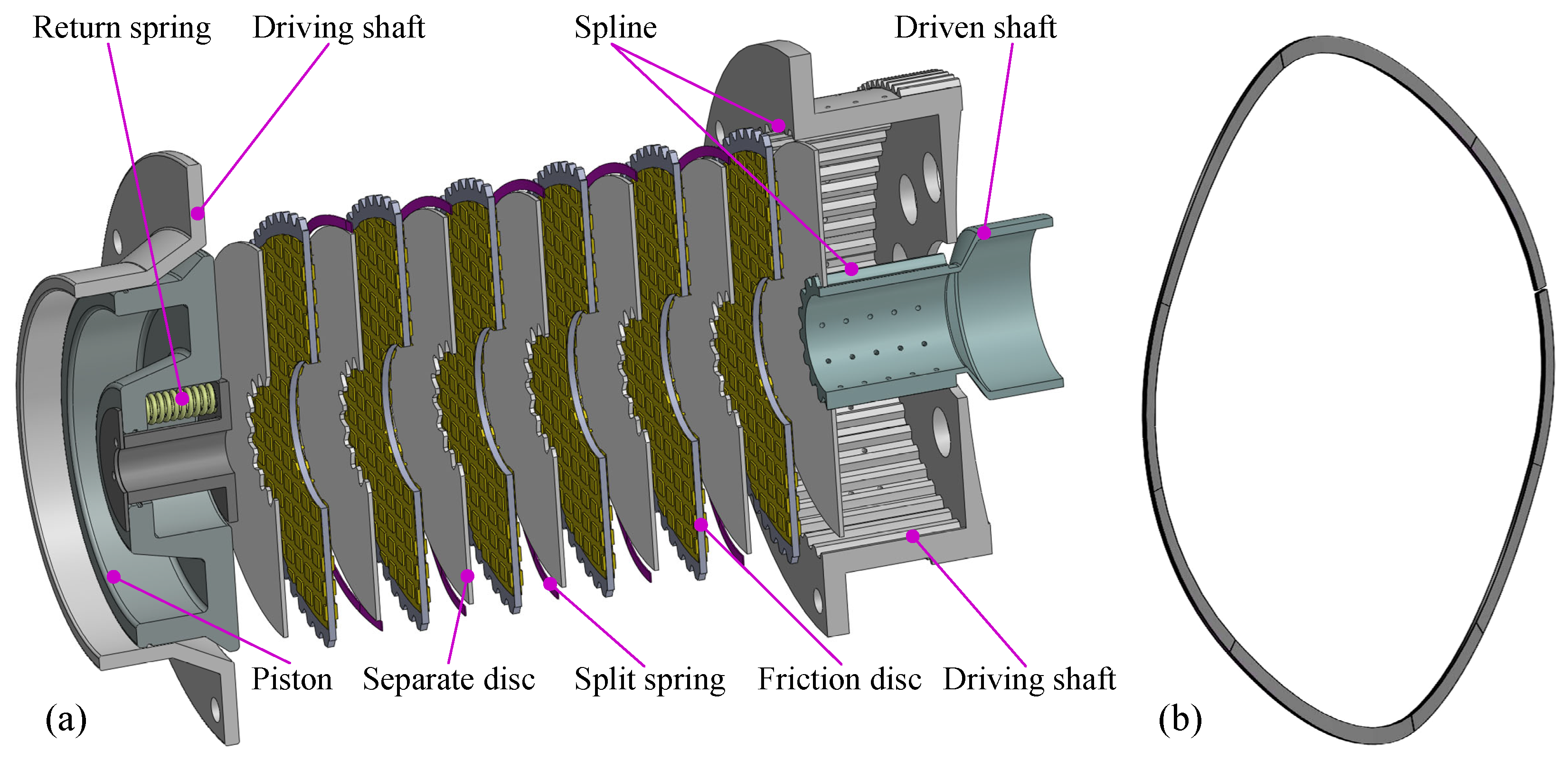

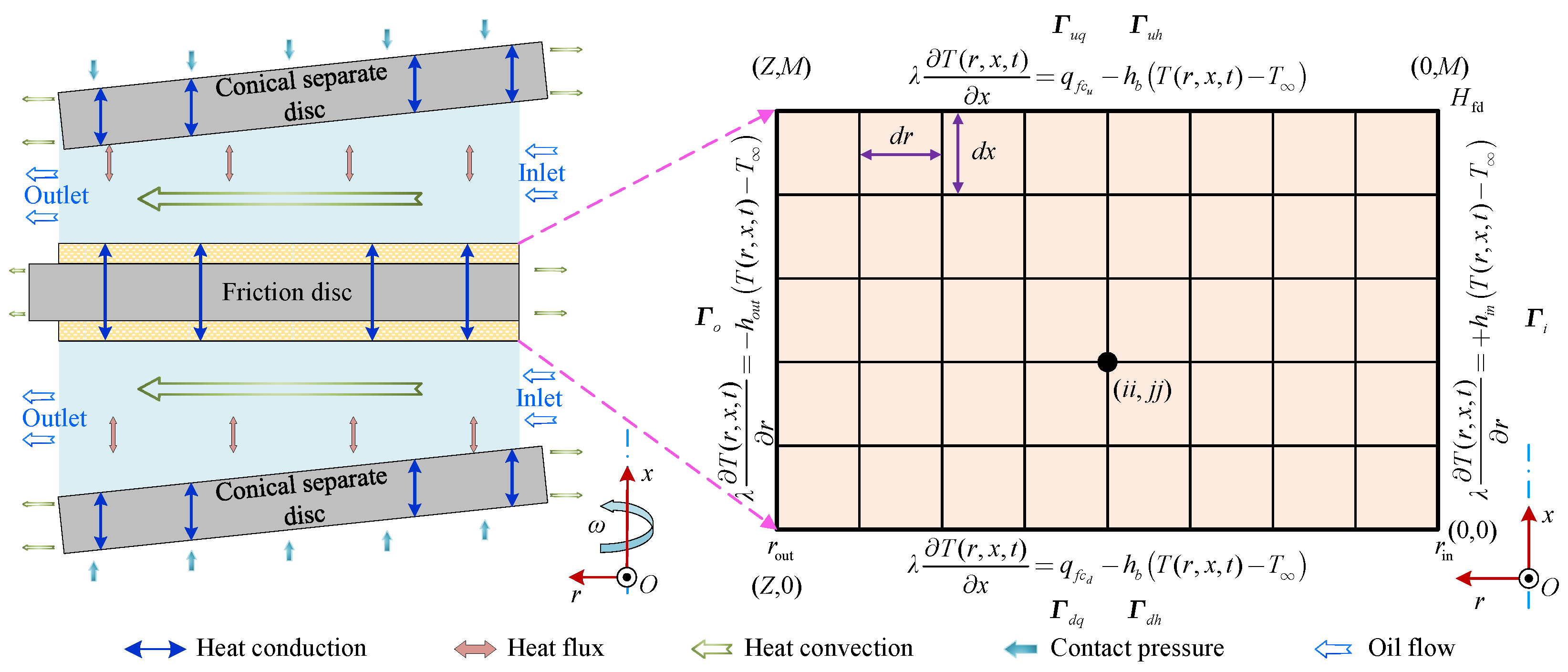

2. Mathematical Models of Dynamic and Heat Transfer

2.1. Conical Separate Disc Model

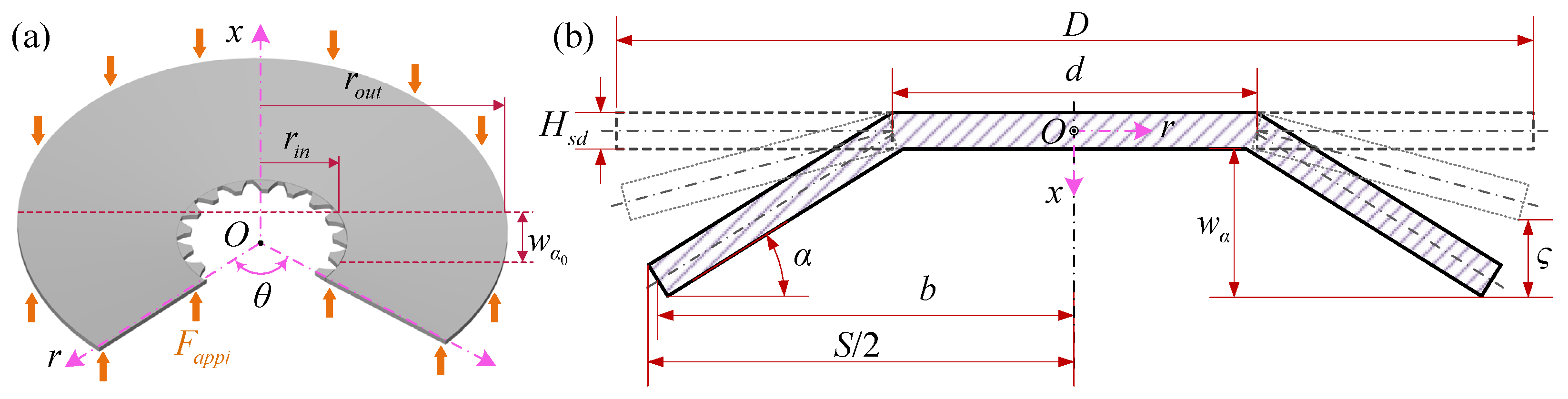

2.1.1. Geometric Description of Conical Separate Disc

2.1.2. Elastic Force Model of Conical Separate Disc

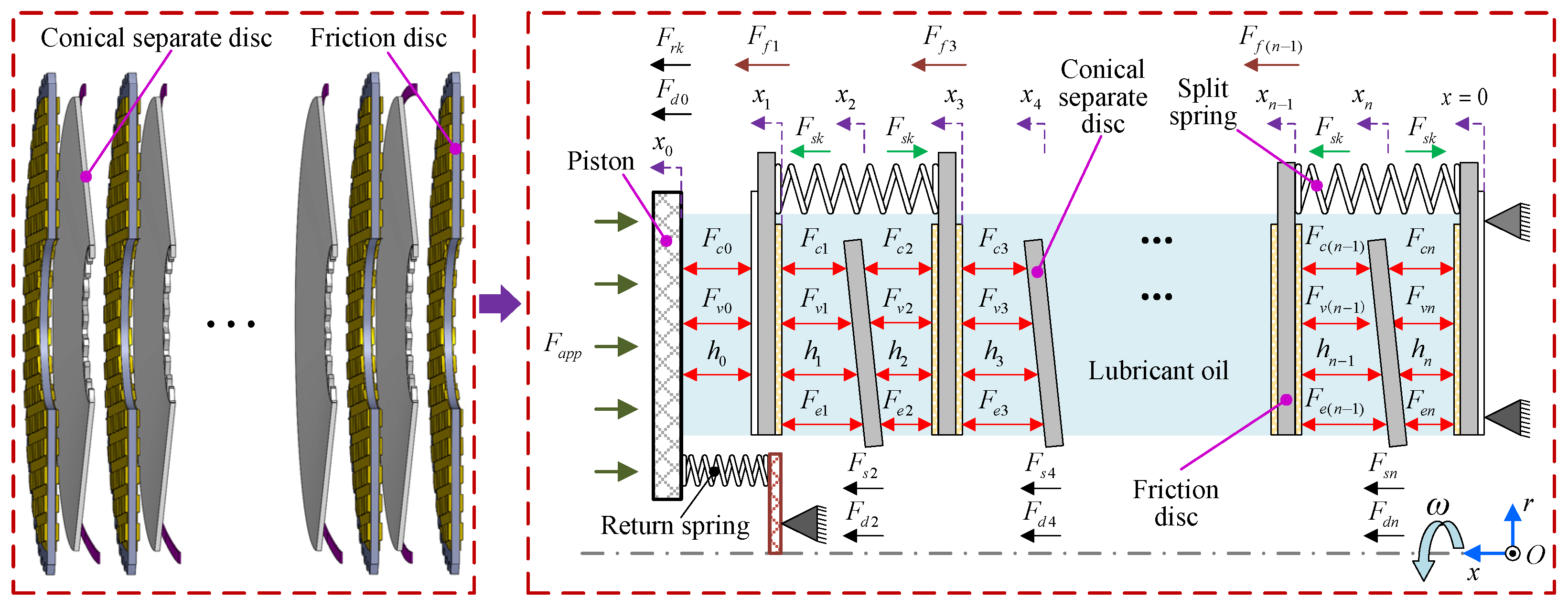

2.2. Axial Dynamic Model of Clutch System

2.3. Gap Model of Friction Pair

2.4. Lubrication and Asperity Model

2.4.1. Lubrication Model

2.4.2. Asperity Model

2.5. Torque Model

2.6. Transient Thermal Model and Solution Method

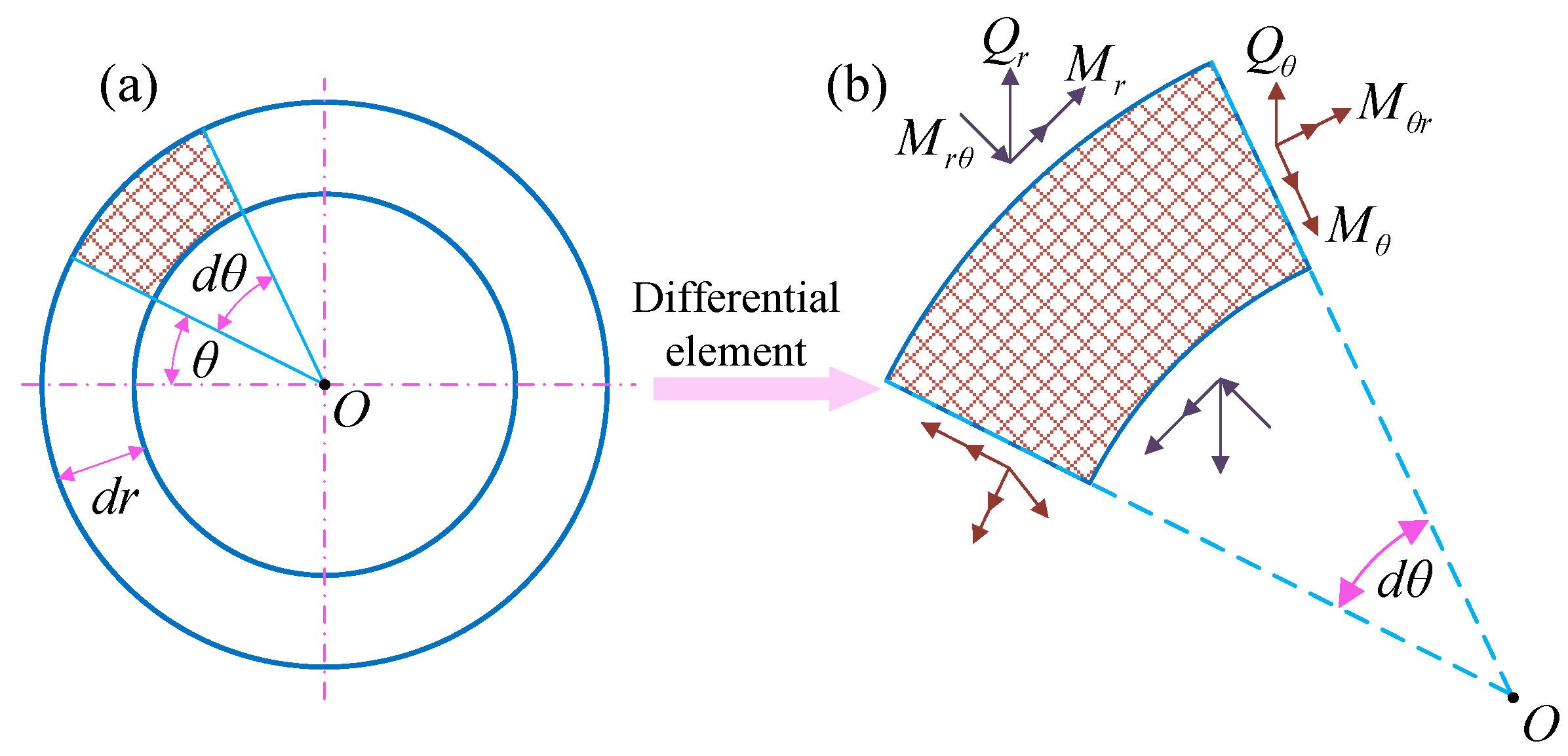

2.6.1. Transient Thermal Model

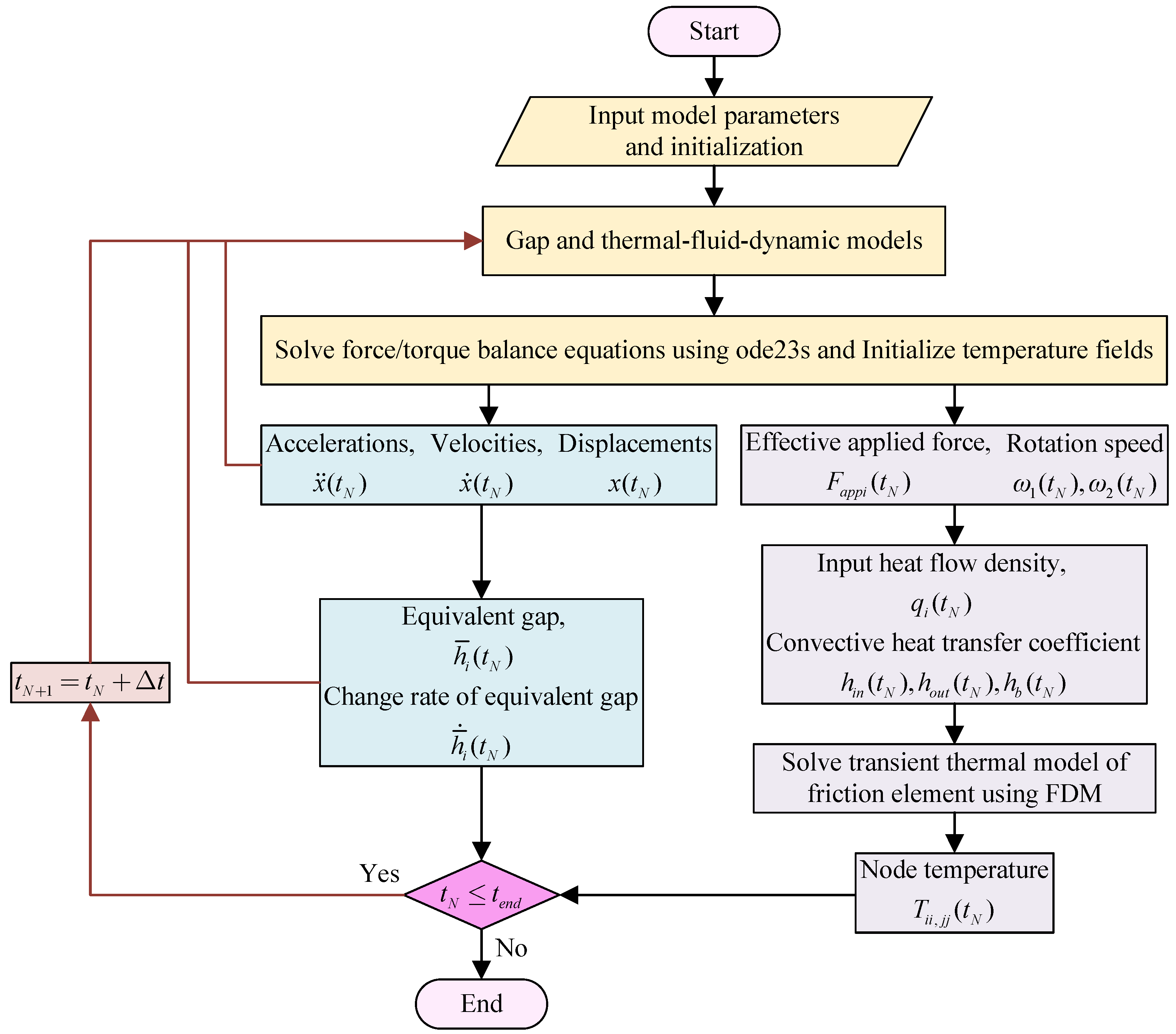

2.6.2. Solution Method for Transient Thermal Model

3. Numerical Simulation

3.1. Model Parameters and Simulation Method

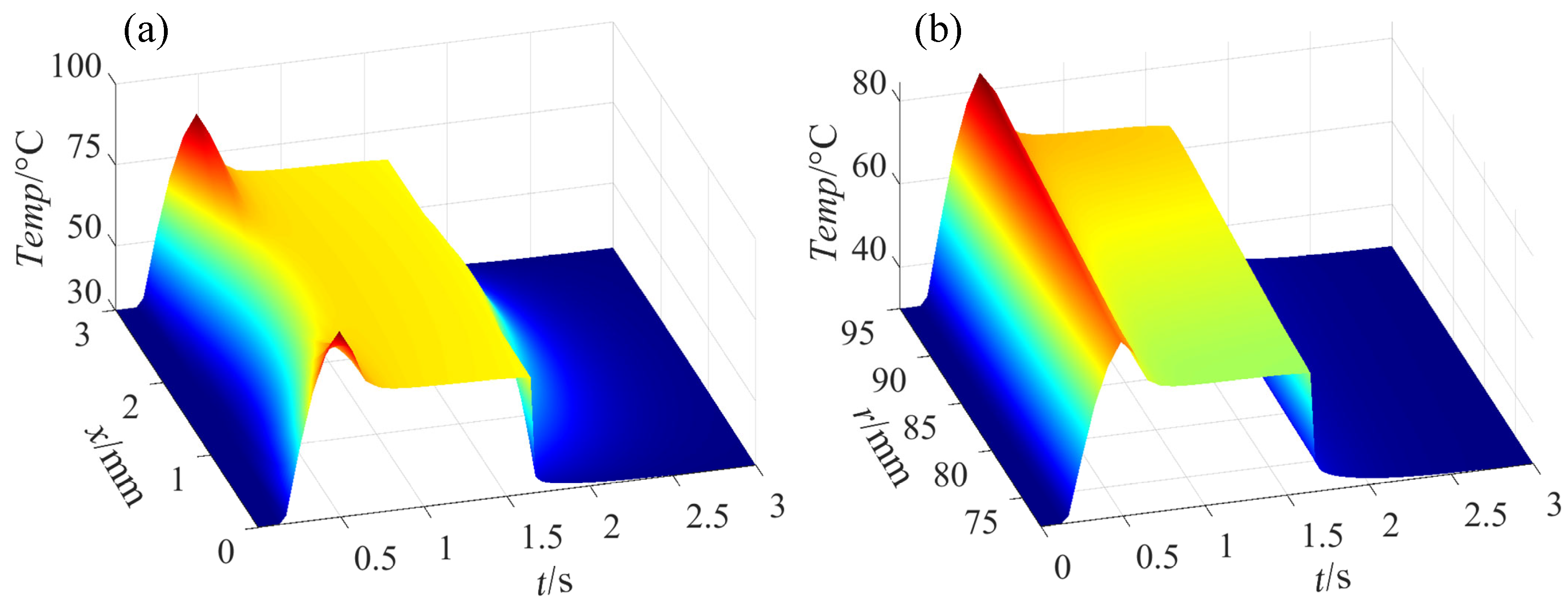

3.2. Dynamic and Thermodynamic Response

4. Results Analysis and Discussion

4.1. Effect of Shifting Interval

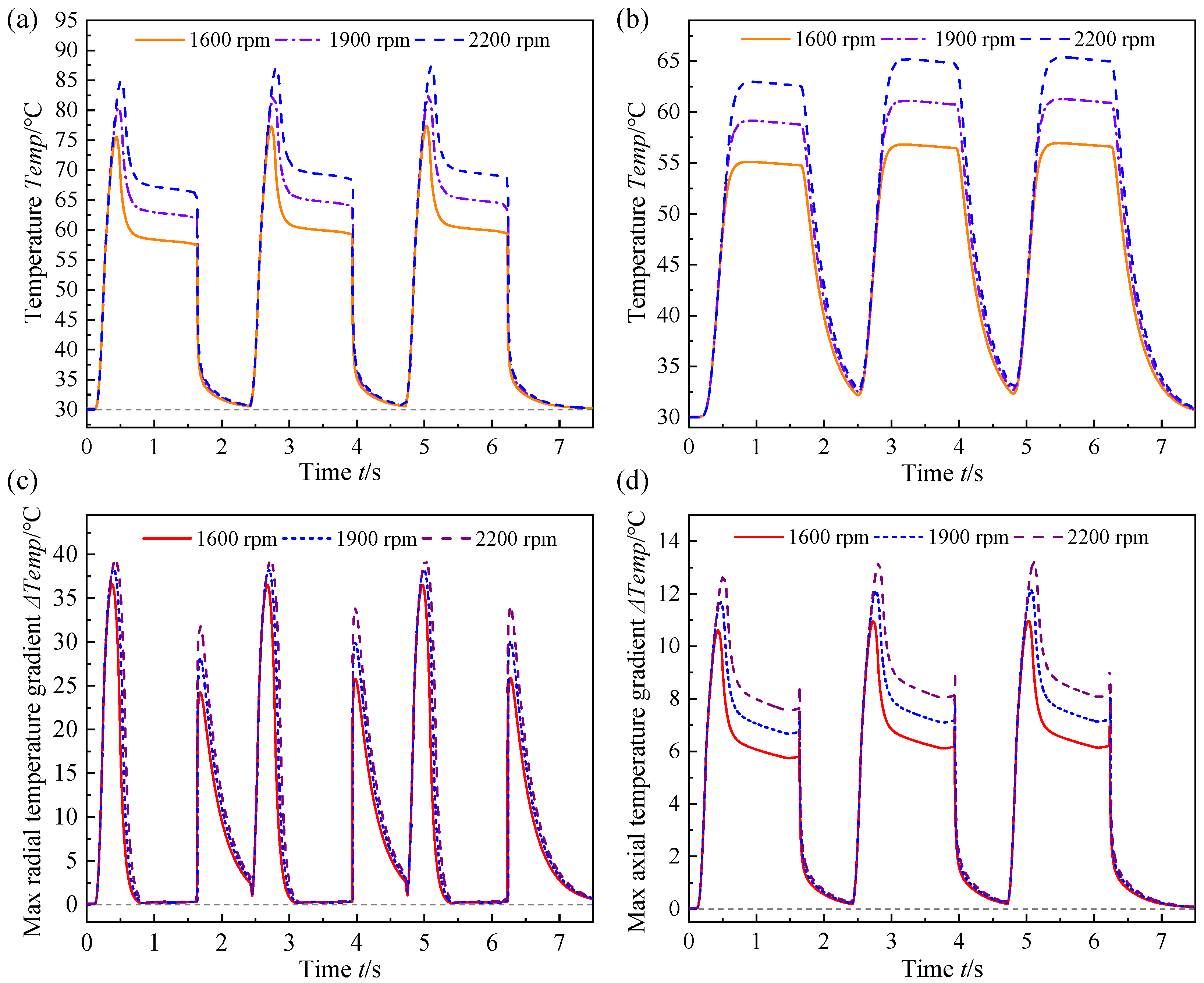

4.2. Effect of Rotation Speed

4.3. Effect of Control Oil Pressure

4.4. Discussion

5. Conclusions

- (1)

- In a single shifting operation of the aviation wet clutch, the temperature field of the friction elements successively rises and then decreases. Additionally, the radial temperature gradient initially increases, then decreases, increases again, and finally decreases, while the axial temperature gradient experiences an initial increase followed by a decrease.

- (2)

- In the successive shifting, extending the shift interval from 2 s to 2.3 s yielded a maximum temperature of 87.338 °C. Increasing the input shaft speed from 1600 rpm to 2200 rpm also elevates the maximum temperature to 87.338 °C. Raising the control oil pressure from 1.5 MPa to 1.9 MPa further increases the maximum temperature to 93.146 °C. Corresponding results indicate that the control oil pressure exerts the most prominent influence on the maximum temperature among the three parameters.

- (3)

- Throughout the successive shifting of the aviation clutch, the control oil pressure exerts the most significant influence on the maximum radial temperature gradient, which surges by 42.65%. The value substantially exceeds the increments induced by the extended shifting interval (9.44%) and elevated rotation speed (7.54%). For the maximum axial temperature gradient, the control oil pressure results in a relative increase of 24.35%, followed by the rotation speed (20.49%) and the shifting interval (14.93%).

- (4)

- To mitigate overheating and enhance the temperature uniformity of wet clutches with conical discs during helicopter successive shifting operation, the operation parameters are optimized by rationally adjusting the relative rotational speeds, appropriately shortening the shift intervals, and calibrating the minimum required control oil pressure. Critical to these modifications is that they must align with the specified operational performance requirements of the aviation clutch to preserve functional integrity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| asperity contact area coefficient | specific heat of friction disc (J/kg°C) | ||

| specific heat of the lubricant oil (J/kg°C) | specific heat of separate disc (J/kg°C) | ||

| damping coefficient (N·s/m) | friction lining thickness (m) | ||

| equivalent Young’s modulus (Pa) | bearing capacity of asperity and oil film (N) | ||

| elastic force of conical separate disc (N) | , | spline friction force (N) | |

| damping force (N) | , | spring force (N) | |

| exerted force of piston (N) | friction coefficient | ||

| initial and equivalent gap of friction pairs (m) | , | convective coefficients at inner and outer (W/m2°C) | |

| , | convective coefficients at friction pairs (W/m2°C) | friction and separate disc thickness (m) | |

| driven shaft inertia (kg·m2) | , | spring stiffness (N/m) | |

| piston, separate and friction disc mass (kg) | n | friction pairs number | |

| heat flow density of friction disc (W/m2) | heat flow density of separate disc (W/m2) | ||

| inner and outer radius of conical friction pair (m) | pitch circle radius of spline (m) | ||

| inner and outer radius of friction element (m) | , | friction and viscous torque (N·m) | |

| load torque (N·m) | x | clutch element position (m) | |

| clutch element velocity (m/s) | clutch element acceleration (m/s2) | ||

| rotation speed (r/min) | relative speed (r/min) | ||

| deformation height (m) | cone angle (°) | ||

| asperity density (m−2) | friction material permeability (m2) | ||

| thermal conductivity of friction disc (W/m°C) | thermal conductivity of lubricant oil (W/m°C) | ||

| thermal conductivity of separate disc (W/m°C) | friction disc density (kg/m3) | ||

| lubricant oil density (kg/m3) | separate disc density (kg/m3) | ||

| compression height of conical separate disc (m) | dynamic viscosity (Pa·s) | ||

| roughness (m) | flow factors |

Appendix A

References

- Tan, W.Z.; Chen, Z.; Li, Z.Z.; Yan, H.Z. Thermal-Fluid-Solid Coupling Simulation and Oil Groove Structure Optimization of Wet Friction Clutch for High-Speed Helicopter. Machines 2023, 11, 296. [Google Scholar] [CrossRef]

- Zhang, Y.N.; Wang, D.Q.; Du, Y.F.; Wen, C.K.; Wang, L.Z.; Wu, Z.K. Sensorless wet clutch pressure control method for high-power tractors using physical and digital twins. Biosyst. Eng. 2026, 261, 104322. [Google Scholar] [CrossRef]

- Bao, H.Y.; Kong, W.D.; Hou, X.N.; Zhu, R.P. Analysis on temperature field of friction pair of aviation friction clutch based on different groove shapes of friction disk. J. Mech. Sci. Technol. 2021, 35, 3735–3742. [Google Scholar] [CrossRef]

- Bian, J.N.; Wu, H.M.; Yang, X.Y.; Ye, G.; Zhu, X.; Dai, Y. Thermal Characteristics Analysis of an Aerospace Friction Clutch Based on Thermal-Fluid-Solid Coupling. Lubricants 2025, 13, 469. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, Y.; Chen, H.; Chen, Y.; Xie, D. An investigation into the failure mechanism of severe abrasion of high-speed train brake discs on snowy days. Eng. Fail. Anal. 2019, 101, 121–134. [Google Scholar] [CrossRef]

- Schneider, T.; Voelkel, K.; Pflaum, H.; Stahl, K. Investigating Failure Modes and Performance Impacts of Wet Clutches in Automotive Limited Slip Differentials. Lubricants 2024, 12, 70. [Google Scholar] [CrossRef]

- Li, X.K.; Wei, D.H.; Wang, H.; Yan, Y.X.; Yan, H.Z.; Yin, M.; Xiao, Y.X. Investigation on the Effects of Operating Parameters on the Transient Thermal Behavior of the Wet Clutch in Helicopters. Appl. Sci. 2025, 15, 10412. [Google Scholar] [CrossRef]

- Li, M.Y.; Ma, B.; Li, H.Y.; Li, H.Z.; Yu, L. Analysis of the thermal buckling of annular disks in clutches under the condition of radial temperature gradient. J. Therm. Stresses 2017, 40, 1275–1284. [Google Scholar] [CrossRef]

- Koranteng, K.; Shaahu, J.-S.; Ma, C.N.; Li, H.Y.; Yi, Y.B. The performance of Cu-based friction material in dry clutch engagement. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 235, 1114–1123. [Google Scholar] [CrossRef]

- Gong, Y.B.; Ge, W.C.; Yi, Y.B. Finite element analysis of thermal buckling characteristics of automotive 430 dry clutch pressure plate. Int. J. Vehicle. Des. 2018, 78, 108–130. [Google Scholar] [CrossRef]

- Yu, L.; Ma, B.; Chen, M.; Li, H.Y.; Liu, J.K.; Li, M.Y. Investigation on the failure mechanism and safety mechanical-thermal boundary of a multi-disc clutch. Eng. Fail. Anal. 2019, 103, 319–334. [Google Scholar] [CrossRef]

- Wang, Q.L.; Wang, J.M.; Cui, H.W.; Wang, J.; Zhang, F. Numerical investigation into thermal buckling of friction pairs in hydro-viscous drive under nonlinear radial temperature distribution. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 1081–1090. [Google Scholar] [CrossRef]

- Chen, Z.; Yi, Y.B.; Bao, K. Prediction of thermally induced postbuckling of clutch disks using the finite element method. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 235, 303–314. [Google Scholar] [CrossRef]

- Xiong, C.B.; Ma, B.O.; Li, H.Y.; Zhang, F.L.; Wu, D. Experimental Study and Thermal Analysis on the Buckling of Friction Components in Multi-Disc Clutch. J. Therm. Stresses 2015, 38, 1325–1345. [Google Scholar] [CrossRef]

- Wu, J.P.; Ding, A.; Yang, C.B.; Zhang, H.S.; Wang, L.Y.; Li, H.Y. Data-driven thermal safety threshold analysis of friction component based on macro-micro interaction model. Case. Stud. Therm. Eng. 2025, 74, 106821. [Google Scholar] [CrossRef]

- Cui, J.Z.; Hou, P.L.; Zhang, B.G.; Zhao, X.Y. Investigation of flow between deformed disks in hydro-viscous drive. Tribol. Int. 2018, 121, 287–301. [Google Scholar] [CrossRef]

- Cui, J.Z.; Zhang, D.; Xu, Y.W.; Ma, S.X.; Chen, G.T. A Coupling Model for Tribodynamic Behavior of the Hydroviscous Flexible Drive With Consideration of Saucer-Warping Deformation. Tribol. Trans. 2023, 66, 73–91. [Google Scholar] [CrossRef]

- Xue, J.Q.; Ma, B.; Xiong, C.B.; Yu, L.; Feng, Y.Q. The effect of disc deformation on the dynamic response of multi-disc systems: A tilting-impact model originating from the wet clutch. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2025, 239, 5735–5751. [Google Scholar] [CrossRef]

- Xue, J.Q.; Ma, B.; Chen, M.; Yu, L.; Zheng, L.J. On the Effects of Disc Deformation on the Tilting-Induced Vibration of a Spline-Guided Spinning Disc with an Axial-Fixed Boundary. Appl. Sci. 2022, 12, 3637. [Google Scholar] [CrossRef]

- Yu, L.; Ma, B.; Chen, M.; Li, H.Y.; Liu, J.K. Investigation on the thermodynamic characteristics of the deformed separate plate in a multi-disc clutch. Eng. Fail. Anal. 2020, 110, 104385. [Google Scholar] [CrossRef]

- Cui, H.W.; Suo, Y.R.; Mei, B.Z.; Li, D.H.; Jiang, Y.Y.; Sun, H.; Zhang, L.Q. Research on the nonuniform contact characteristics and thermal behavior of friction pairs involving the radial conical buckling deformation in hydro-viscous drive. Numer. Heat Transf. Part A Appl. 2025, 86, 3211–3232. [Google Scholar] [CrossRef]

- Zhao, Q.; Ma, B.; Xiong, C.B.; Yu, L.; Fu, B.; Yan, S.F. Modeling of the Dynamics of Conical Separate Plates in a Wet Multi-Disc Clutch. Lubricants 2025, 13, 262. [Google Scholar] [CrossRef]

- Wu, J.P.; Cui, J.H.; Shu, W.Y.; Wang, L.Y.; Li, H.Y. Coupling mechanism and data-driven approaches for high power wet clutch torque modeling and analysis. Tribol. Int. 2024, 191, 109166. [Google Scholar] [CrossRef]

- Zhao, Q.; Ma, B.; Yu, L.; Dong, Y.; Yin, H.; Li, H.Y.; Liu, Y.J. Influence of buckled separate plate on the contact pressure and thermal properties in a multi-disc clutch. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2025, 1–19. [Google Scholar] [CrossRef]

- Chen, Z.; Yi, Y.B.; Zhao, J.X. Fourier finite element model for prediction of thermal buckling in disc clutches and brakes. J. Therm. Stress. 2016, 39, 1241–1251. [Google Scholar] [CrossRef]

- Ozaki, S.; Tsuda, K.; Tominaga, J. Analyses of static and dynamic behavior of coned disk springs: Effects of friction boundaries. Thin-Walled Struct. 2012, 59, 132–143. [Google Scholar] [CrossRef]

- Li, X.K.; Yan, H.Z.; Wei, D.H.; Wu, J.M.; Yin, M.; Xiao, Y.X.; Li, K.F. Study on the Effect of Operating Conditions on the Friction Pair Gap in a Wet Multi-Disc Clutch in a Helicopter Transmission System. Appl. Sci. 2024, 14, 7751. [Google Scholar] [CrossRef]

- Cui, J.Z.; Xie, F.W.; Li, H.; Zhao, X.Y. Influences of deformed film gaps on dynamic torque behavior of hydroviscous drive. Tribol. Trans. 2021, 64, 477–500. [Google Scholar] [CrossRef]

- Patir, N.; Cheng, H.S. Application of Average Flow Model to Lubrication Between Rough Sliding Surfaces. J. Lubr. Technol. 1979, 101, 220–229. [Google Scholar] [CrossRef]

- Wu, B.Z.; Qin, D.T.; Hu, J.J.; Wang, X.; Wang, Y.; Lv, H. Analysis of influencing factors and changing laws on friction behavior of wet clutch. Tribol. Int. 2021, 162, 107125. [Google Scholar] [CrossRef]

- Yang, X.G.; Bao, H.Y.; Zhang, C.; Tan, W.Z.; Zhu, R.P. Influence of Groove Type on Friction Coefficient of Wet Friction Clutch Pair. Int. J. Automot. Technol. 2024, 25, 13–21. [Google Scholar] [CrossRef]

- Wu, J.P.; Zhao, P.; Yang, J.; Shu, W.Y.; Wang, L.Y. Digital twin transient temperature field of wet friction components based on the hybrid model optimizing dynamic parameters. Therm. Sci. Eng. Prog. 2025, 64, 103803. [Google Scholar] [CrossRef]

- Kakac, S.; Yener, Y.; Naveira-Cotta, C.P. Heat Conduction; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar] [CrossRef]

- Wu, J.P.; Zhao, P.; Shu, W.Y.; Yang, J.; Wang, L.Y.; Li, P.P. Self-adaptive physics-informed neural networks for solving the heat transfer problem in wet friction components of transmission system. Int. J. Therm. Sci. 2025, 220, 110390. [Google Scholar] [CrossRef]

- Wang, Q.L.; Zhang, X.B.; Wang, D.G.; Cui, H.W.; Zhang, S.; Wang, J.M. Numerical simulation and experimental investigation on the thermal-fluid-solid multi-physical field coupling characteristics of wet friction pairs considering cavitation effect. Appl. Therm. Eng. 2025, 260, 124955. [Google Scholar] [CrossRef]

- Jin, Y.C.; Chen, L.; Cheng, C. Thermal behavior of friction discs in dry clutches based on a non-uniform pressure model. Case Stud. Therm. Eng. 2022, 32, 101895. [Google Scholar] [CrossRef]

- Wu, J.P.; Yang, C.B.; Zhang, H.S.; Wang, L.Y.; Li, H.Y. Numerical analysis of micro-textured friction element interface temperature fields under mixed lubrication. Int. Commun. Heat Mass 2025, 163, 108743. [Google Scholar] [CrossRef]

- Yu, L.; Ma, B.; Li, H.Y.; Liu, J.K.; Li, M.Y. Numerical and Experimental Studies of a Wet Multidisc Clutch on Temperature and Stress Fields Excited by the Concentrated Load. Tribol. Trans. 2019, 62, 8–21. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value | Parameter | Value |

|---|---|---|---|---|---|

| n | 10 | ||||

| R | |||||

| Shifting Interval | Maximum Radial Temperature Gradient | Maximum Axial Temperature Gradient |

|---|---|---|

| 2 s | 35.853 °C () | 11.482 °C () |

| 2.2 s | 39.026 °C () | 13.159 °C () |

| 2.3 s | 39.237 °C () | 13.196 °C () |

| Rotation Speed | Maximum Radial Temperature Gradient | Maximum Axial Temperature Gradient |

|---|---|---|

| 1600 rpm | 36.486 °C () | 10.952 °C () |

| 1900 rpm | 38.218 °C () | 12.134 °C () |

| 2200 rpm | 39.237 °C () | 13.196 °C () |

| Control Oil Pressure | Maximum Radial Temperature Gradient | Maximum Axial Temperature Gradient |

|---|---|---|

| 1.5 MPa | 32.237 °C () | 11.719 °C () |

| 1.7 MPa | 39.237 °C () | 13.196 °C () |

| 1.9 MPa | 45.987 °C () | 14.572 °C () |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Li, X.; Wei, D.; Yan, Y.; Yan, H.; Yin, M.; Xiao, Y. Study on Transient Thermal Characteristics of Aviation Wet Clutches with Conical Separate Discs for Helicopters in Successive Shifting. Lubricants 2026, 14, 10. https://doi.org/10.3390/lubricants14010010

Li X, Wei D, Yan Y, Yan H, Yin M, Xiao Y. Study on Transient Thermal Characteristics of Aviation Wet Clutches with Conical Separate Discs for Helicopters in Successive Shifting. Lubricants. 2026; 14(1):10. https://doi.org/10.3390/lubricants14010010

Chicago/Turabian StyleLi, Xiaokang, Dahuan Wei, Yixiong Yan, Hongzhi Yan, Mei Yin, and Yexin Xiao. 2026. "Study on Transient Thermal Characteristics of Aviation Wet Clutches with Conical Separate Discs for Helicopters in Successive Shifting" Lubricants 14, no. 1: 10. https://doi.org/10.3390/lubricants14010010

APA StyleLi, X., Wei, D., Yan, Y., Yan, H., Yin, M., & Xiao, Y. (2026). Study on Transient Thermal Characteristics of Aviation Wet Clutches with Conical Separate Discs for Helicopters in Successive Shifting. Lubricants, 14(1), 10. https://doi.org/10.3390/lubricants14010010