Mechanistic Interpretation of Fretting Wear in Z10C13 Steel Under Displacement–Load Coupling

Abstract

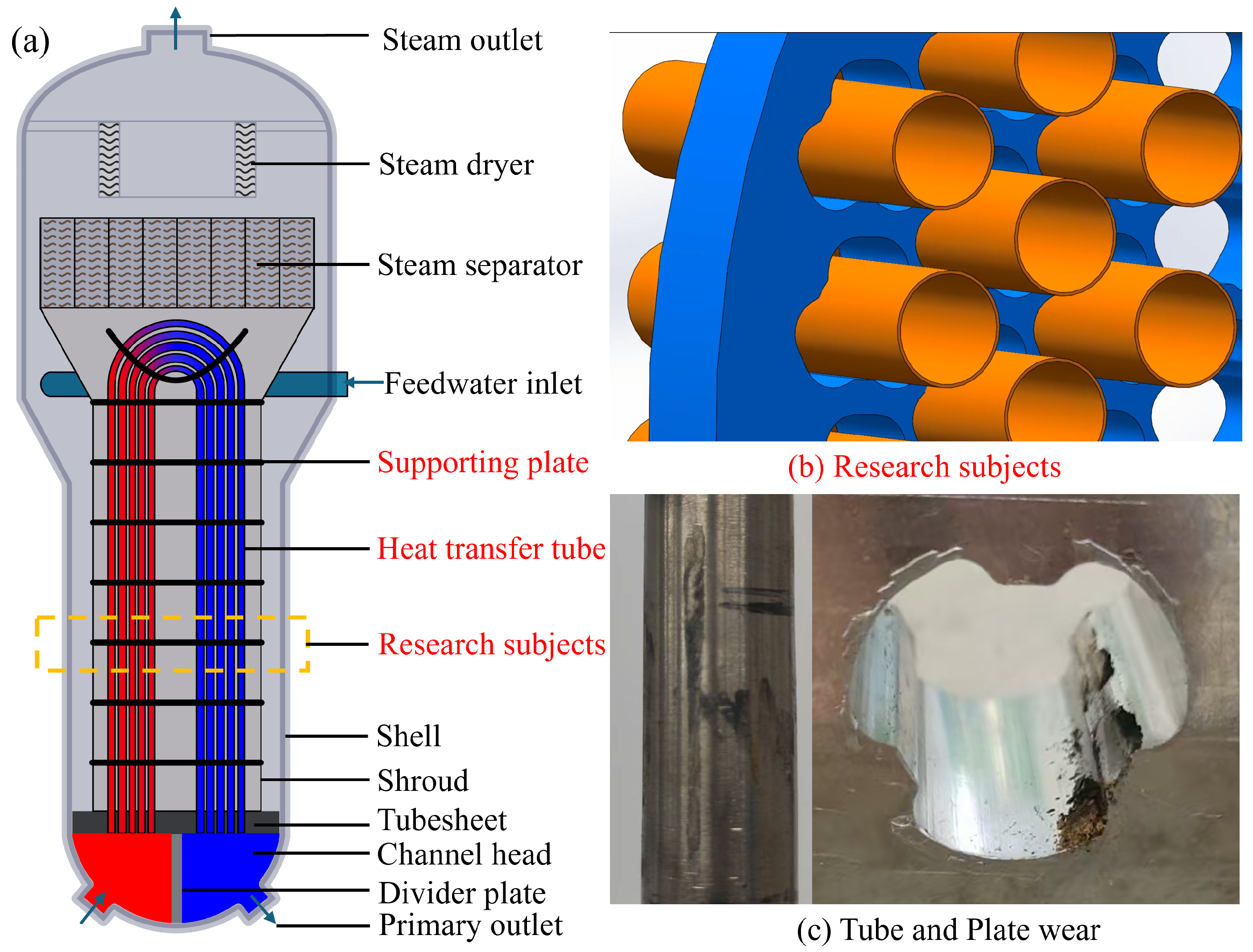

1. Introduction

2. Experimental Methods

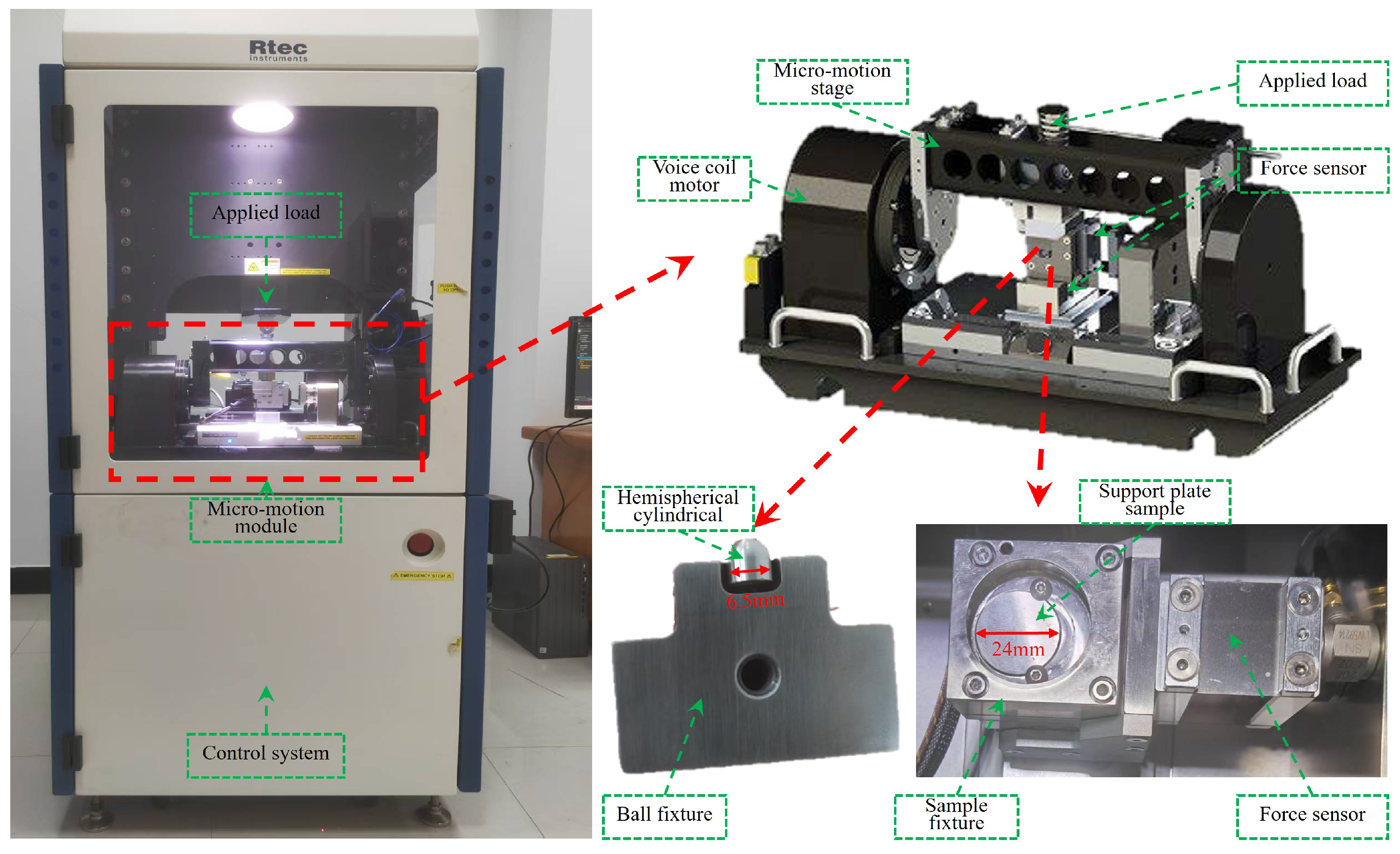

2.1. Material Selection and Test Apparatus

2.2. Experimental Design and Parameters

2.3. Specimen Preparation and Characterization

3. Effects of Load and Amplitude on Fretting Behavior

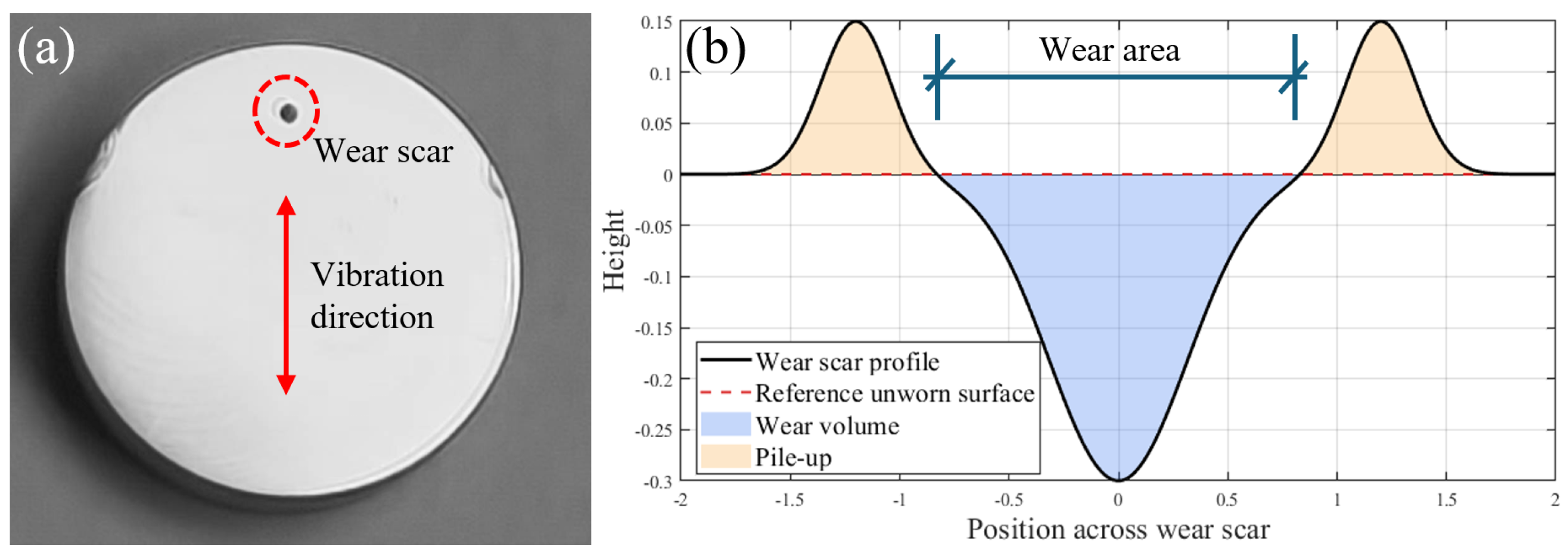

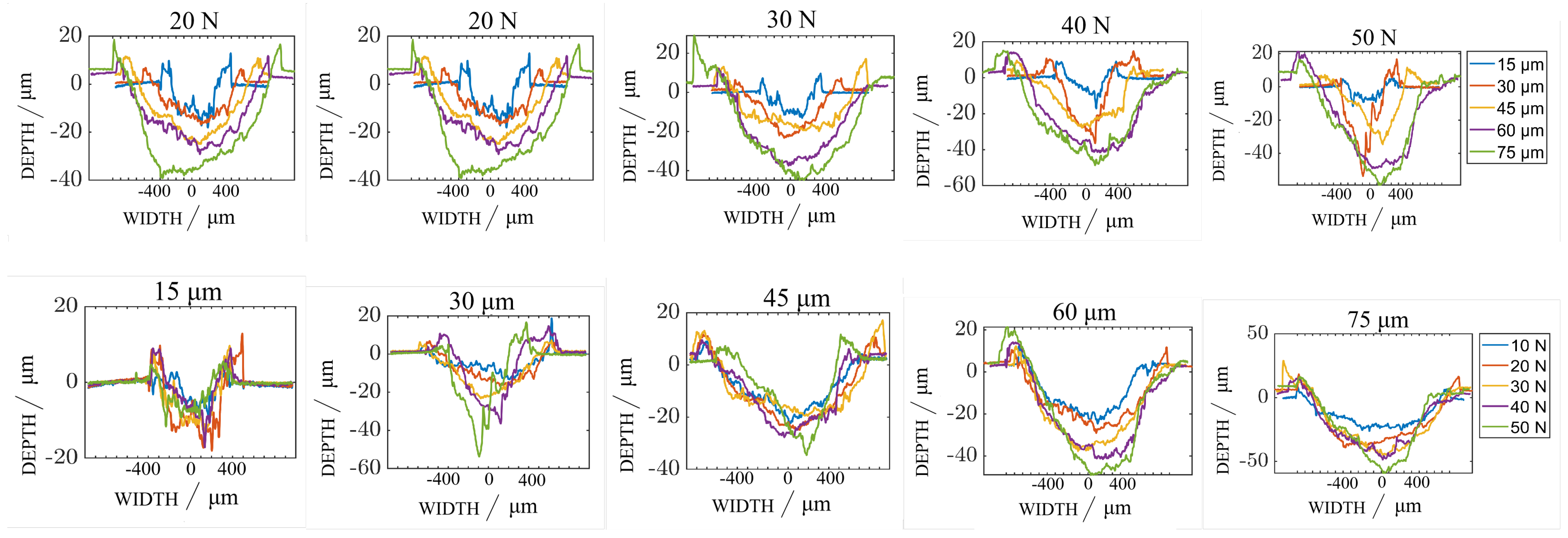

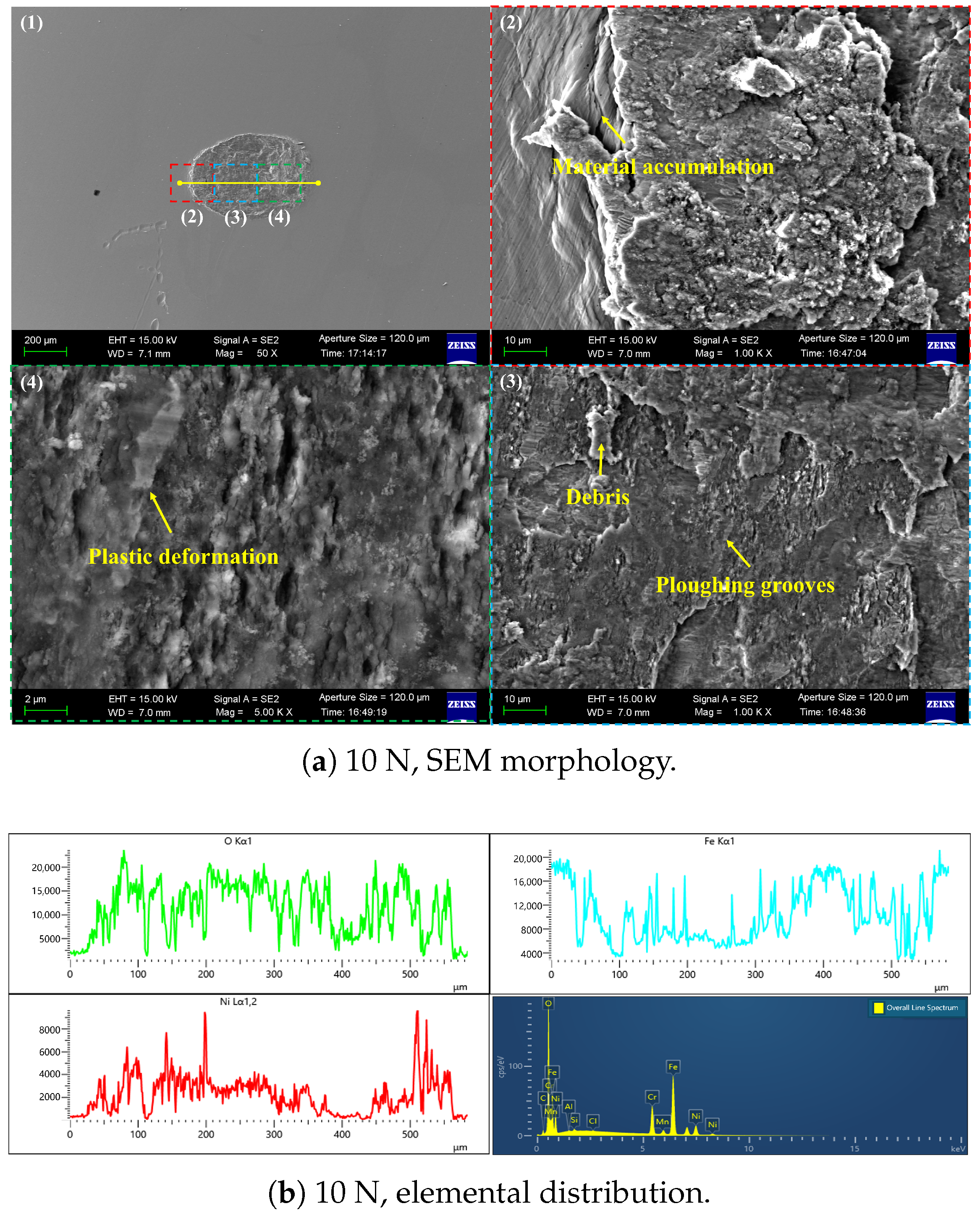

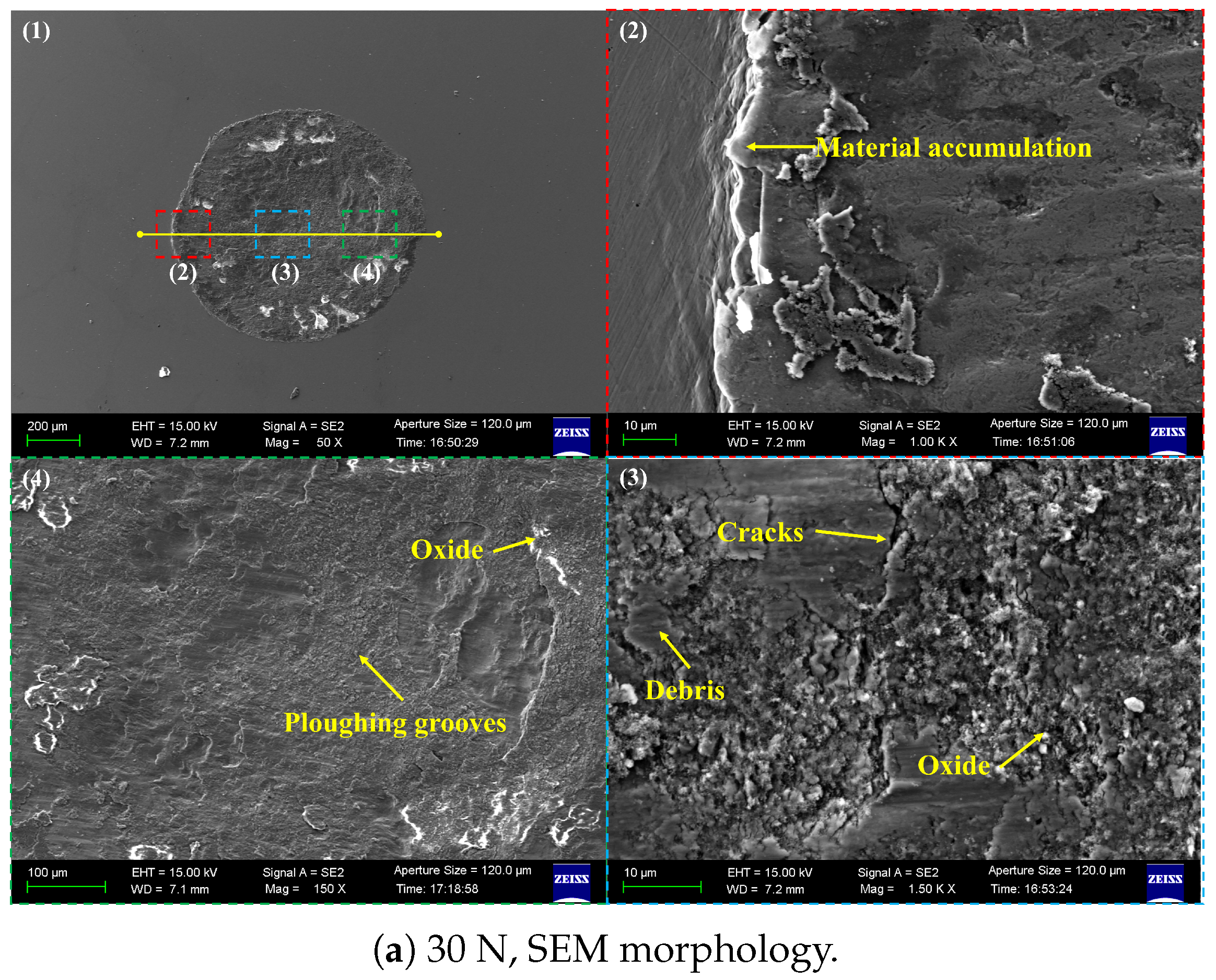

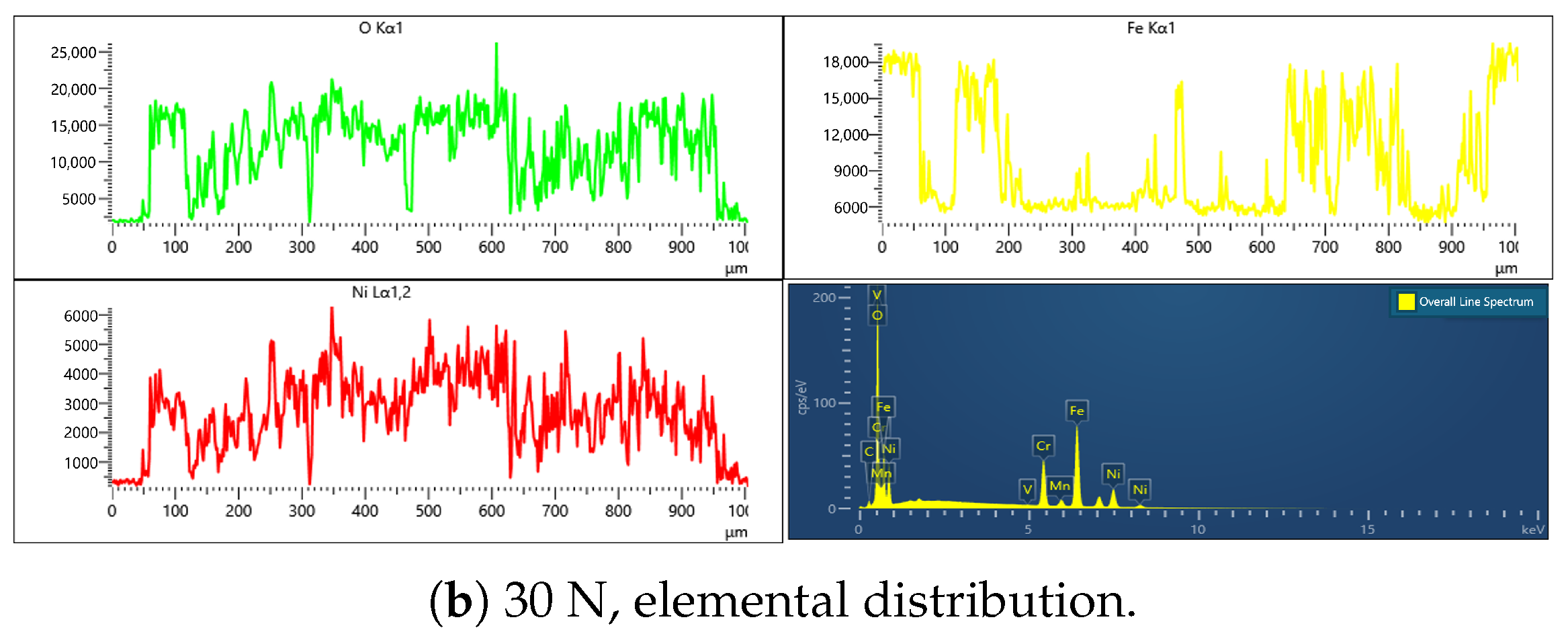

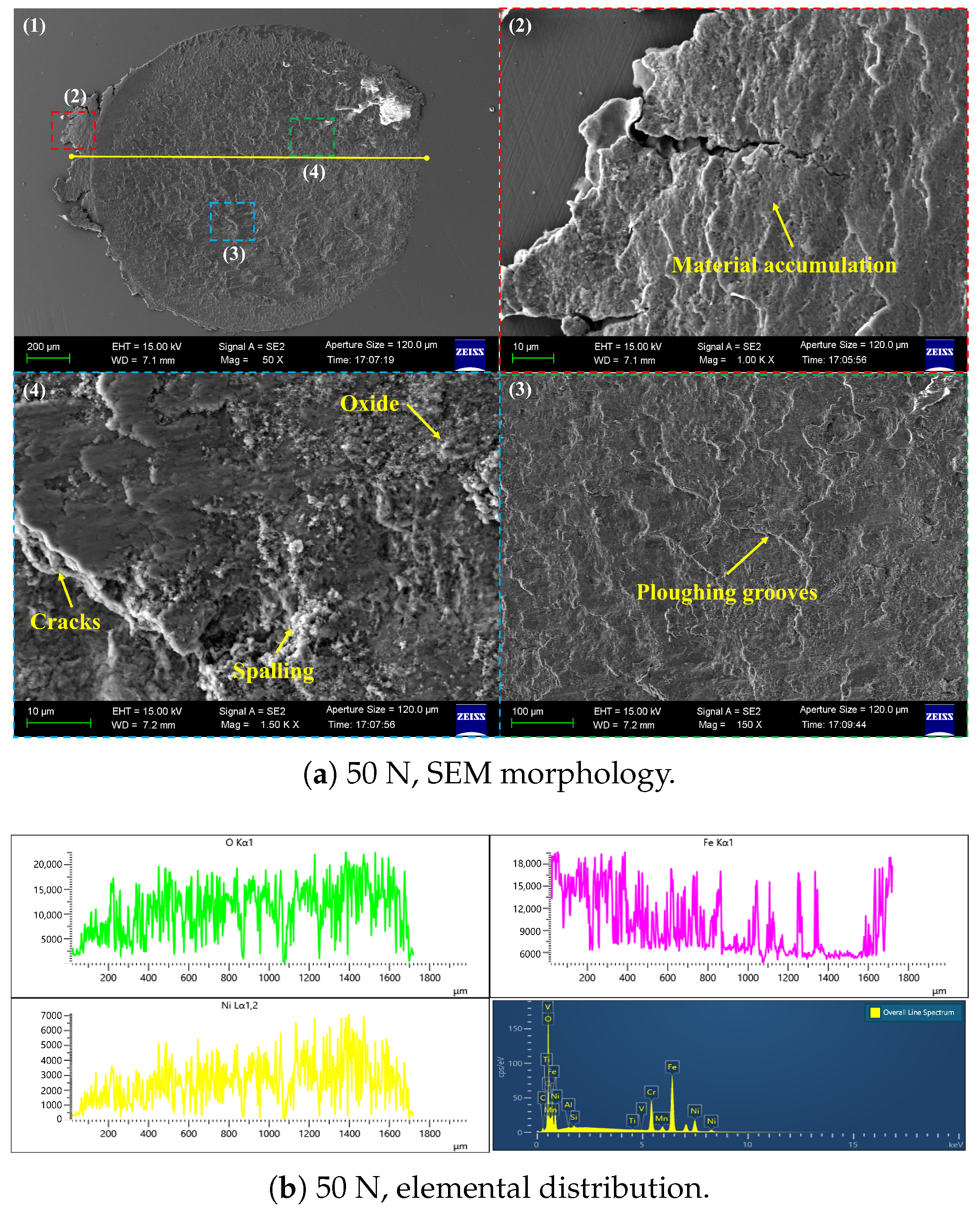

3.1. Wear Scar Morphology Analysis

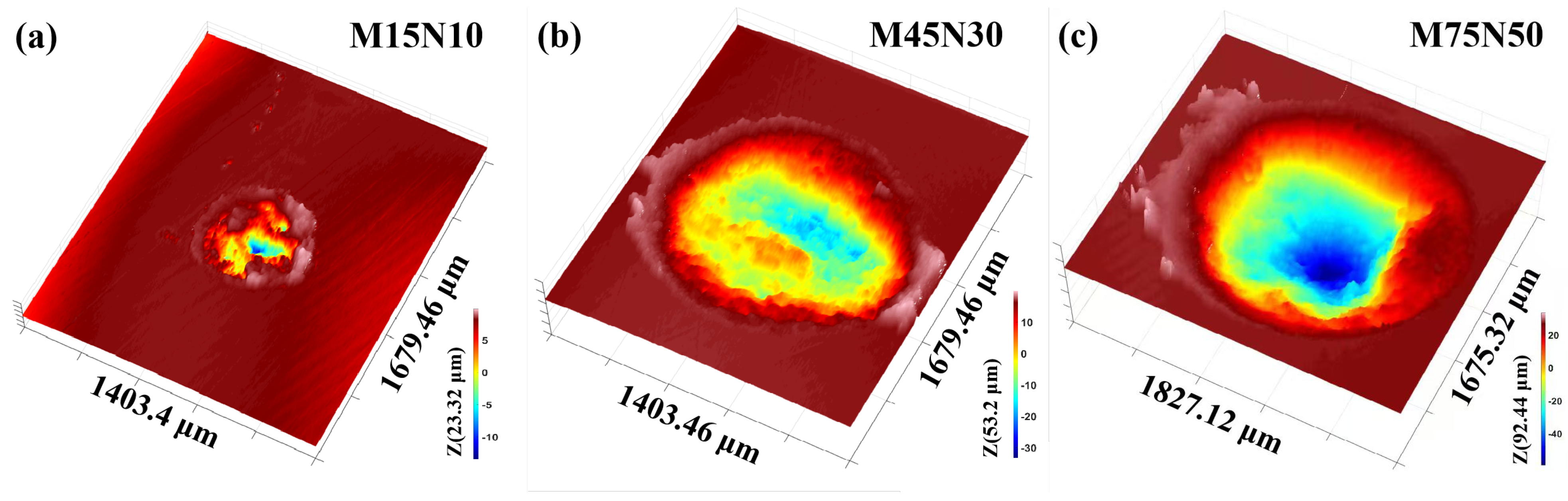

3.1.1. Macro-Scale Wear Scar Morphology

3.1.2. Localized Material Failure Modes

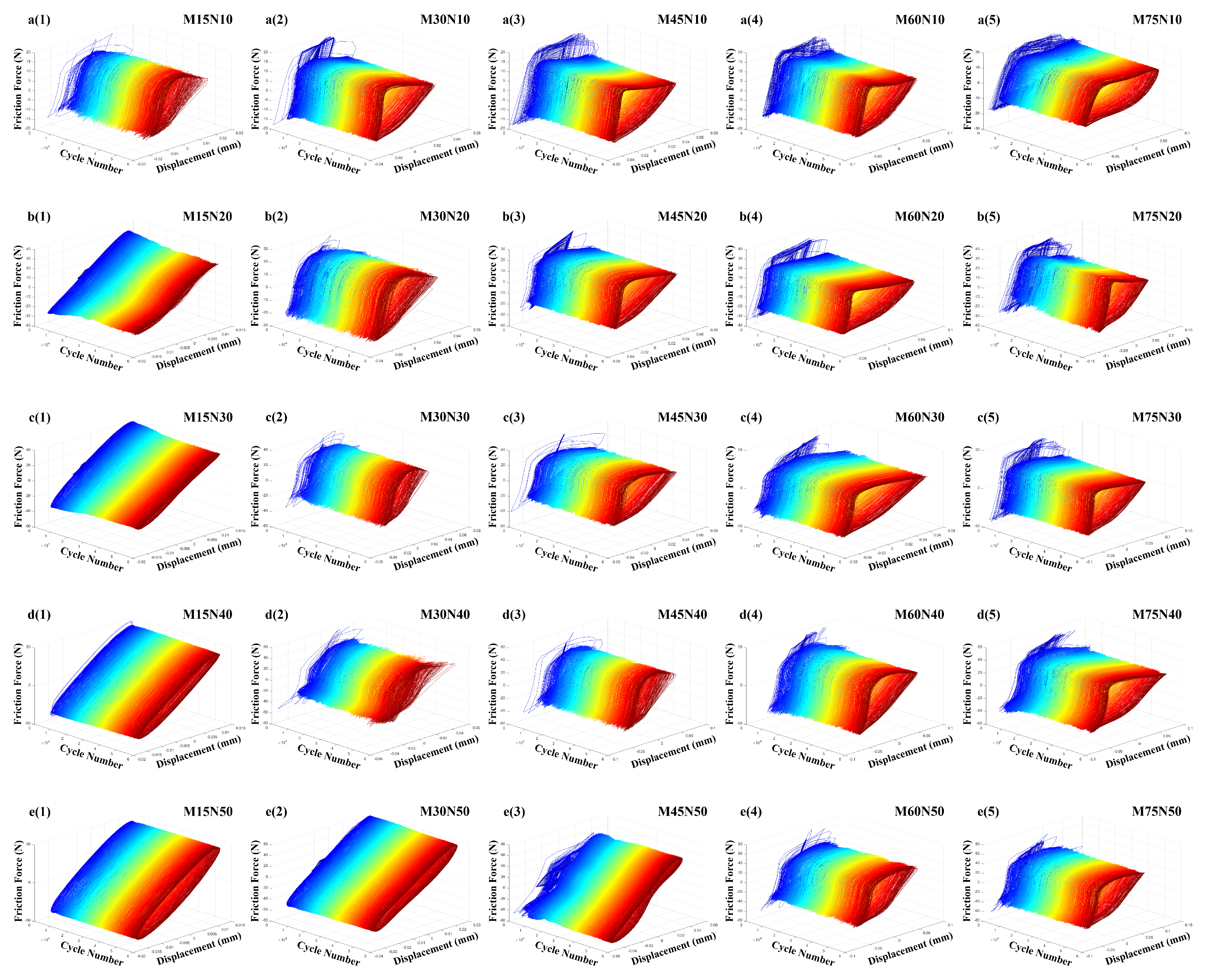

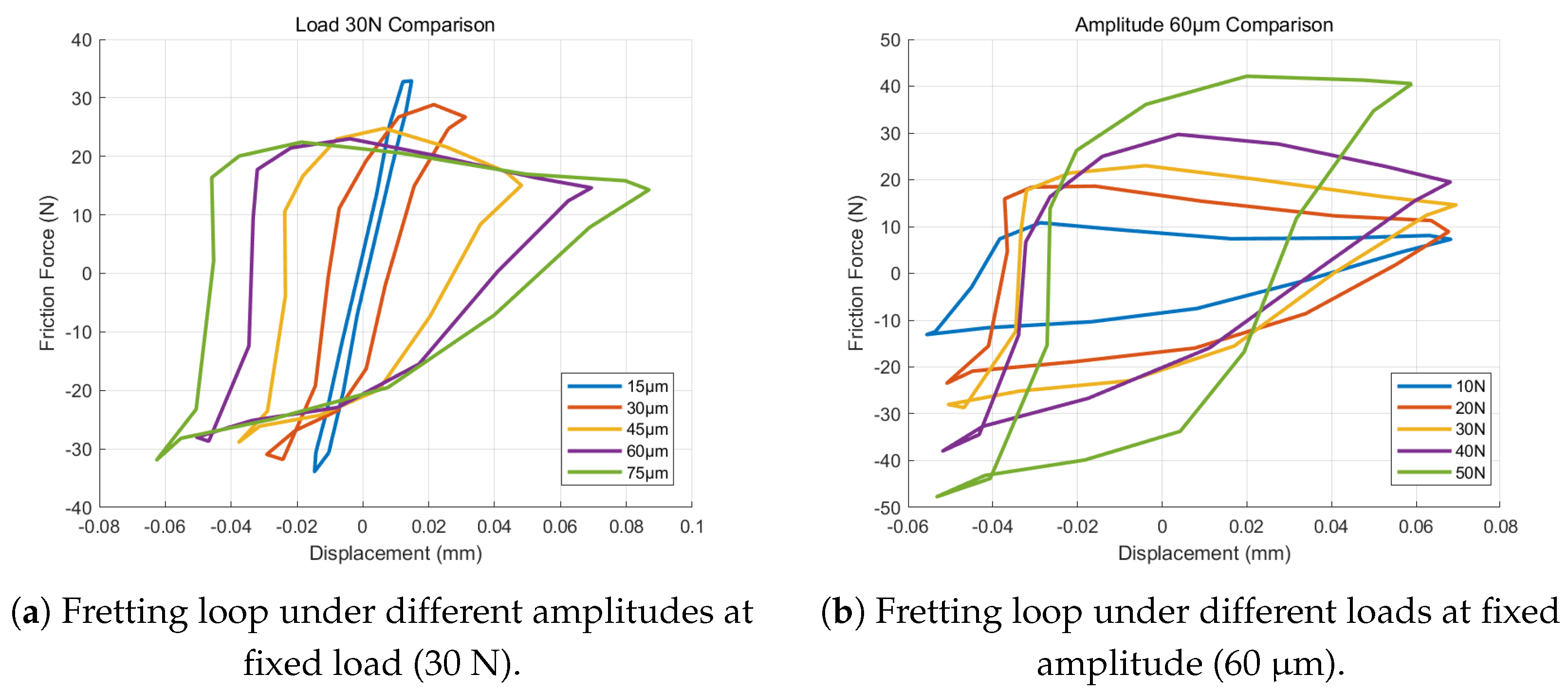

3.2. Characterization of Fretting Hysteresis Loops and Energy Dissipation

3.2.1. Analysis of Fretting Loop Evolution

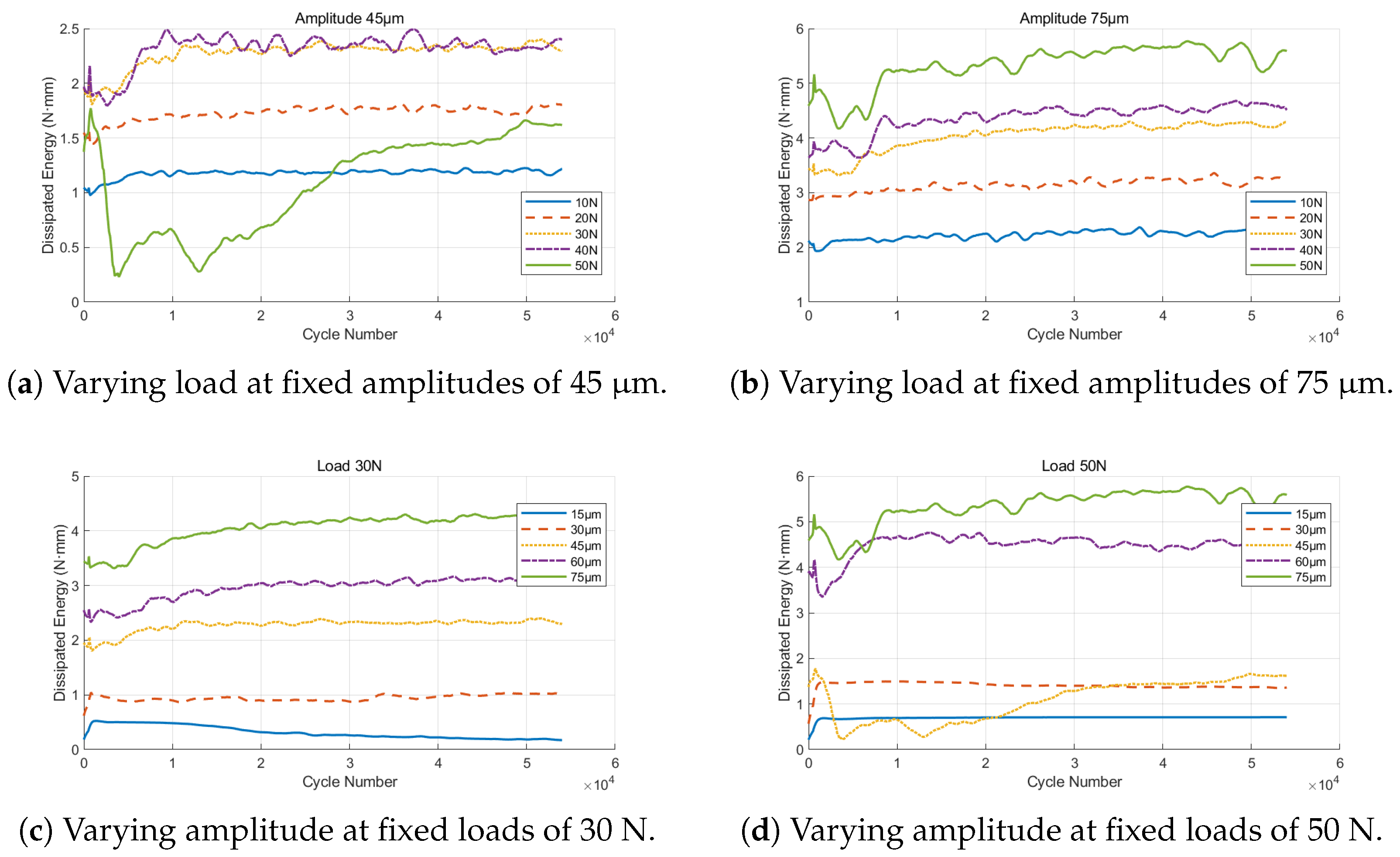

3.2.2. Dissipated Energy Response Analysis

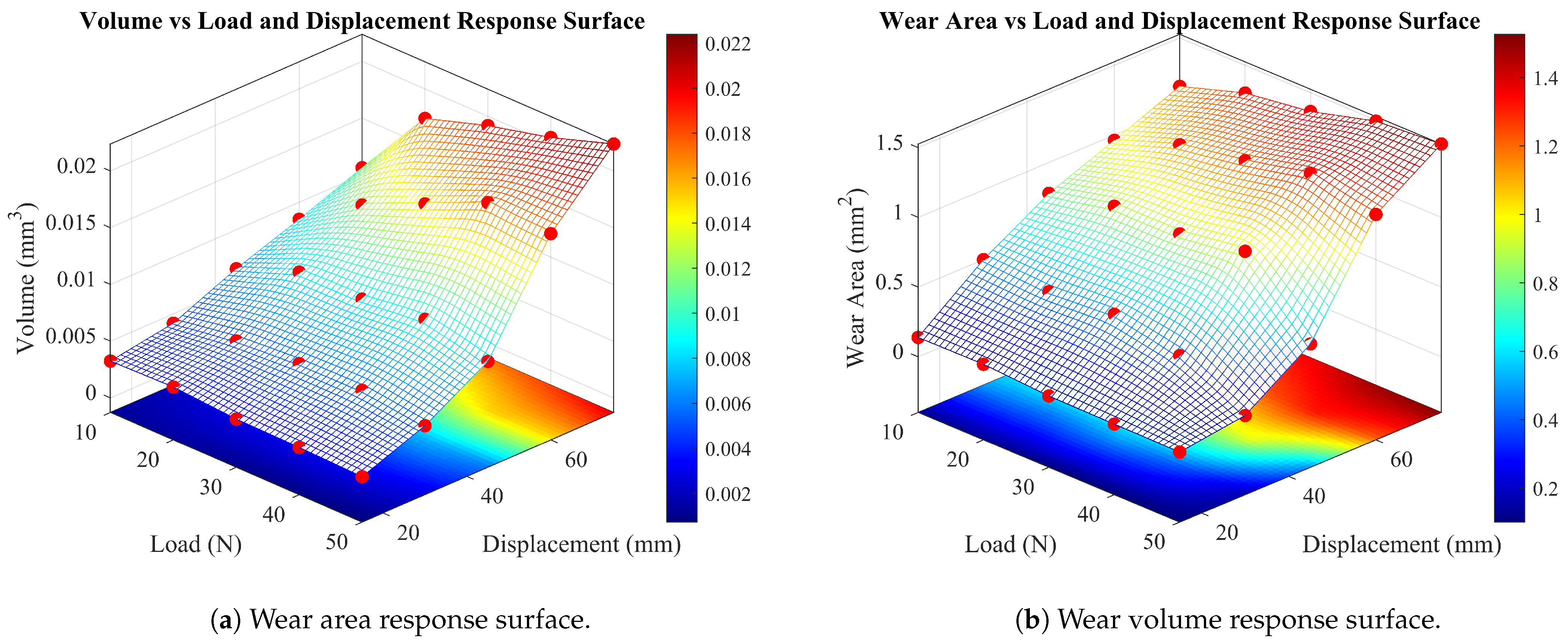

4. Mechanism Analysis with Equivalent Hardness-Corrected Archard Model

4.1. Motivation

4.2. Theoretical Model Development and Derivation

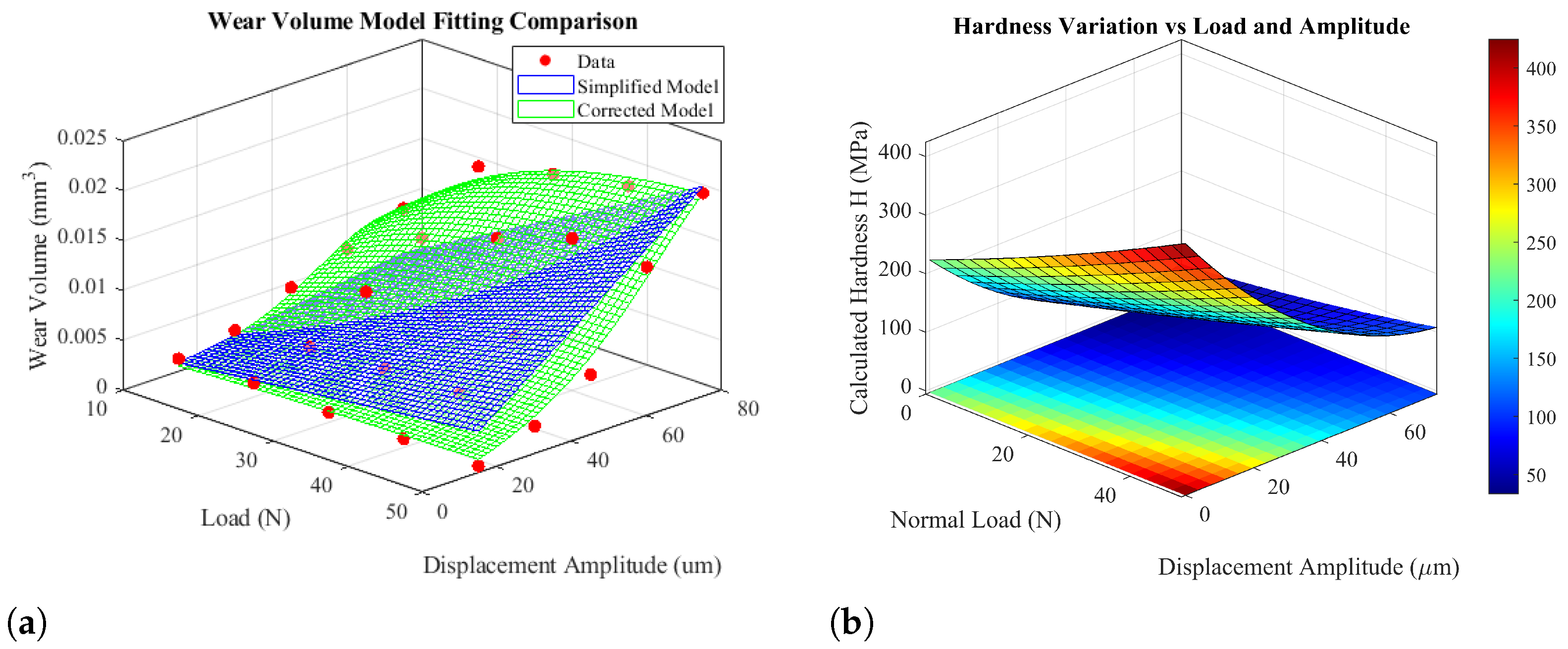

4.3. Model Fitting and Validation

5. Conclusions

- The energy dissipation and damage behavior of the fretting system are governed by the nonlinear coupling of normal load and displacement amplitude. Higher normal loads increase contact stress and promote adhesion, while larger amplitudes extend the slip path and stress cycles. Together, these factors synergistically enhance interfacial damage and result in greater wear volume.

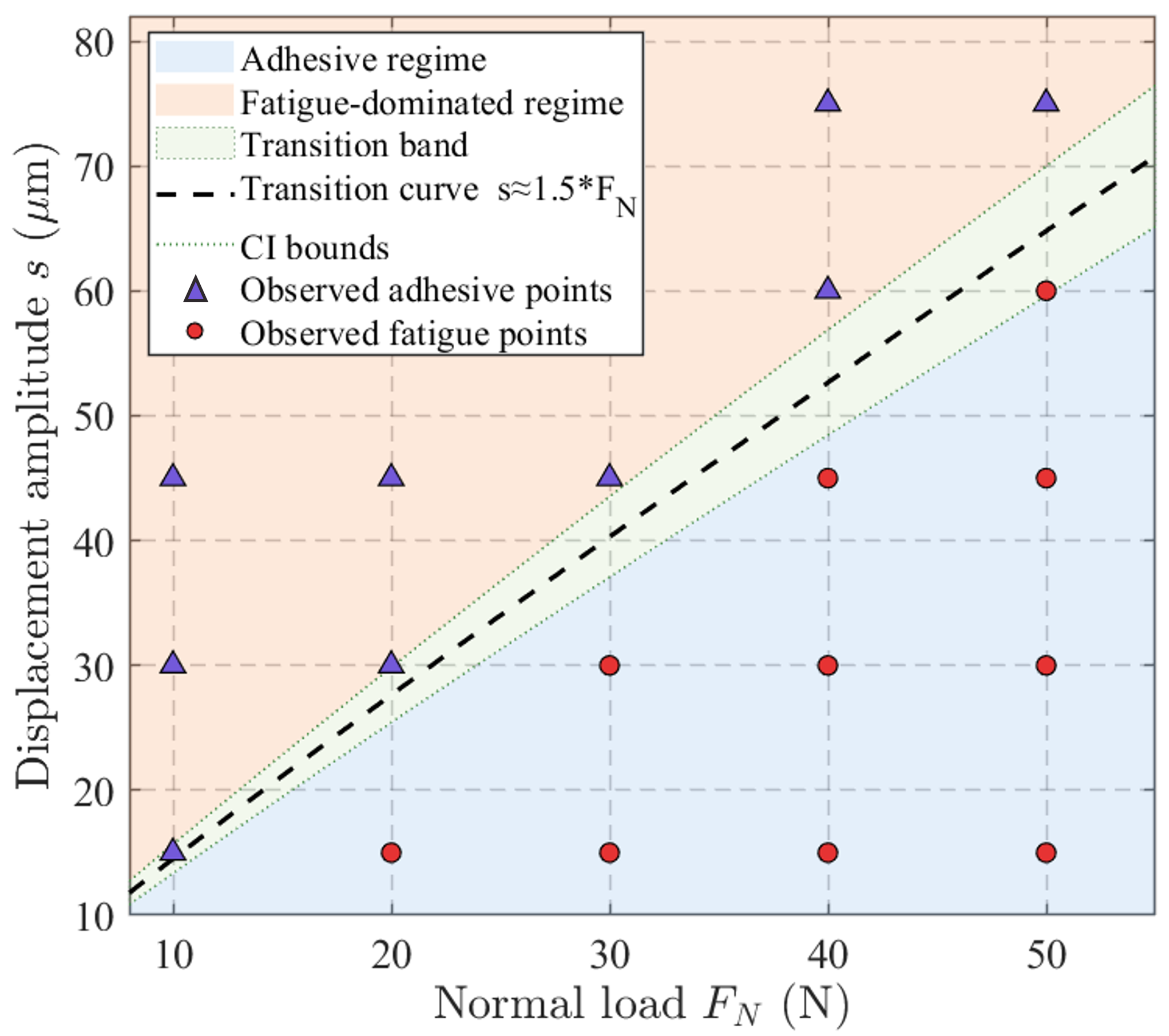

- Systematic analysis shows that when the load-to-amplitude ratio exceeds approximately 1:1.5, the wear mechanism rapidly shifts from adhesive sliding to fatigue spalling. This transition is accompanied by a dramatic increase in the asymmetry of the wear scar depth profile, indicating a critical change in the interfacial damage mode and confirming the nonlinear transition of material removal mechanisms.

- The hardness-corrected Archard model proposed in this work effectively captures the nonlinear influence of load and amplitude on wear volume. Its prediction accuracy () is significantly higher than that of the traditional Archard model (), making it a useful tool for rapid prediction of fretting wear and service life assessment.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PWR | pressurized water reactor |

| FIV | flow induced vibrations |

| PSR | partial slip regime |

| MFR | mixed fretting regime |

| GSR | gross slip regime |

| TBL | third body layer |

| PDL | plastic deformation layer |

| TSPs | tube support plates |

References

- Kang, K.S.; Kupca, L. Assessment and Management of Ageing of Major Nuclear Power Plant Components Important to Safety: Steam Generators (2011 Update); International Atomic Energy Agency: Vienna, Austria, 2011. [Google Scholar]

- Bian, W.W.; Liu, X.; Wang, F.; Xiao, J.; Zhang, X.F.; Han, Y.Q.; Cheng, Z.Y.; Shoji, T. Insights into the fretting corrosion behavior and damage mechanism of Inconel 690TT in water and steam environments containing different dissolved oxygen levels. Corros. Sci. 2025, 253, 113018. [Google Scholar] [CrossRef]

- Yun, J.Y.; Shin, G.S.; Kim, D.I.; Lee, H.S.; Kang, W.S.; Kim, S.J. Effect of carbide size and spacing on the fretting wear behavior of Inconel 690 SG tube mated with SUS 409. Wear 2015, 338–339, 252–257. [Google Scholar] [CrossRef]

- Cai, Z.B.; Li, Z.Y.; Yin, M.G.; Zhu, M.H.; Zhou, Z.R. A review of fretting study on nuclear power equipment. Tribol. Int. 2020, 144, 106095. [Google Scholar] [CrossRef]

- Gru, O. Technical Specifications Task Force; EXCEL Services Corporation: Rockville, MD, USA, 2005. [Google Scholar]

- Sollier, T.; Le Calvar, M.; Balestreri, F.; Mermaz, F. Recent safety issues concerning steam generators in France and their analysis by IRSN. In Proceedings of the 6th CNS International Steam Generator Conference, Toronto, ON, Canada, 8–11 November 2009. [Google Scholar]

- Dow, B.L., Jr. Steam Generator Progress Report: Revision 12; Technical Report EPRI TR-106365; Electric Power Research Institute (EPRI): Palo Alto, CA, USA, 1996. [Google Scholar]

- Xie, W.; Ding, S.; Rong, B.; Wang, X.; Xu, L.; Peng, J. Study on the Effect of Normal Loads on the Fretting Wear Performance of Zr-4 Alloy Tubes Under Three Fretting Modes. Tribol. Lett. 2025, 73, 34. [Google Scholar] [CrossRef]

- Li, Y.; Xie, G.; Sun, X.; Jingcao, C.; Wu, X.; Zhang, Y.; Yu, C.; Du, P. A review on fretting wear/fatigue behavior, protective measures, and application examples of typical alloy materials. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2025, 239, 1261–1290. [Google Scholar] [CrossRef]

- Chen, H.; Mei, G.; Wang, G.; Tan, W.; Zhu, G. Fretting wear and corrosion in liquid lead-bismuth eutectic: A review of current state and prospect. Eng. Sci. 2025, 35, 1594. [Google Scholar] [CrossRef]

- Xin, L.; Huang, Q.; Han, Y.; Lu, Y.; Zhang, W.; Shoji, T. The damage mechanism of Alloy 690TT against Alloy 600 caused by fretting wear in room temperature pure water. Mater. Charact. 2020, 161, 110176. [Google Scholar] [CrossRef]

- Wang, J.; Li, H.; Li, Z.; Lei, Y.; Ren, Q.; Jiao, Y.; Cai, Z. Fretting wear characteristics of nuclear fuel cladding in high-temperature pressurized water. Chin. J. Mech. Eng. 2023, 36, 101. [Google Scholar] [CrossRef]

- Ding, H.; Cao, Y.; Hua, K.; Tong, Y.; Li, N.; Sun, L.; Li, X.; Wu, H.; Wang, H. Fretting wear resistance at ambient and elevated temperatures of 316 stainless steel improved by laser cladding with Co-based alloy/WC/CaF2 composite coating. Opt. Laser Technol. 2023, 163, 109428. [Google Scholar] [CrossRef]

- Xu, Z.; Li, D.; Lu, Z.; Lv, X.; Liu, Y.; Liu, J.; He, C. Study on the fretting wear behavior over a wide temperature range of an Inconel 718 superalloy deposited by laser cladding. Eng. Fail. Anal. 2023, 143, 106864. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, B.; Ming, H.; Wang, J.; Wang, J.; Han, E.H. Effects of displacement amplitude and normal force on fretting wear behavior of zirconium alloy tube in simulated primary water of PWR. Wear 2024, 542–543, 205271. [Google Scholar] [CrossRef]

- Winter, T.; Neu, R.W.; Singh, P.M.; Kolaya, L.E.; Vizoso, D.; Deo, C.S. Coefficient of friction evolution with temperature under fretting wear for FeCrAl fuel cladding candidate. J. Nucl. Mater. 2019, 520, 140–151. [Google Scholar] [CrossRef]

- Wang, Z.; Xu, J.; Li, J.; Xin, L.; Lu, Y.; Shoji, T.; Takeda, Y.; Otsuka, Y.; Mutoh, Y. The synergy of corrosion and fretting wear process on Inconel 690 in the high temperature high pressure water environment. J. Nucl. Mater. 2018, 502, 255–262. [Google Scholar] [CrossRef]

- Xie, L.; Guan, Y.; Lu, J.; Zhu, P.; Chen, R.; Lin, H. Fretting wear behavior test and numerical simulation of Inconel 690 alloy. J. Nucl. Sci. Technol. 2023, 60, 1100–1115. [Google Scholar] [CrossRef]

- Mace, A.O.; Kurtz, M.A.; Gilbert, J.L. Fretting and fretting corrosion behavior of additively manufactured Ti-6Al-4V and Ti-Nb-Zr alloys in air and physiological solutions. J. Funct. Biomater. 2024, 15, 38. [Google Scholar] [CrossRef]

- He, J.; Peng, J.; Ren, Y.; Cai, Z.; Liu, J.; Zhu, M. Study on improving fretting wear properties of AISI 4135 steel via diverse surface modifications under grease lubrication. Wear 2022, 490, 204210. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, S.; Ming, H.; Wang, J.; Han, E.H. Study of fretting wear behavior of 690TT heat exchanger tube under three fretting regimes in high temperature pressurized water. J. Nucl. Mater. 2025, 605, 155559. [Google Scholar] [CrossRef]

- Bian, W.W.; Hong, C.; Xin, L.; Kang, L.Z.; Han, Y.M.; Liu, H.; Shoji, T.; Lu, Y.H. Effect of the cycle number on fretting wear behavior of alloy 690TT tube in high-temperature pressurized water. J. Nucl. Mater. 2022, 567, 153828. [Google Scholar] [CrossRef]

- Lai, P.; Gao, X.; Tang, L.; Guo, X.; Zhang, L. Effect of temperature on fretting wear behavior and mechanism of alloy 690 in water. Nucl. Eng. Des. 2018, 327, 51–60. [Google Scholar] [CrossRef]

- Tassone, A.; Meeusen, J.; Serafini, A.; Caruso, G. Numerical study of liquid metal turbulent heat transfer in cross-flow tube banks. Energies 2023, 16, 387. [Google Scholar] [CrossRef]

- Xie, X.; Ma, A.; Zhao, H.; Li, X.; Wu, X. Experimental investigation and analysis on the cross flow characteristics over inline tube bundles with S/D = 1.875. Int. J. Heat Mass Transf. 2023, 203, 1006. [Google Scholar] [CrossRef]

- Fessler, G.; Sadeghi, A.; Glatzel, T.; Goedecker, S.; Meyer, E. Atomic friction: Anisotropy and asymmetry effects. Tribol. Lett. 2019, 67, 2. [Google Scholar] [CrossRef]

- Fantetti, A.; Tamatam, L.R.; Volvert, M.; Lawal, I.; Liu, L.; Salles, L.; Brake, M.R.; Schwingshackl, C.W.; Nowell, D. The impact of fretting wear on structural dynamics: Experiment and simulation. Tribol. Int. 2019, 138, 111–124. [Google Scholar] [CrossRef]

- Rustamov, I.; Guo, F.; Wang, Z. Experimental investigations into fretting wear and damage mechanisms of Inconel X-750 alloy. J. Mech. Sci. Technol. 2019, 33, 4701–4713. [Google Scholar] [CrossRef]

- Souilliart, T.; Rigaud, E.; Le Bot, A.; Phalippou, C. Energy-based wear law for oblique impacts in dry environment. Tribol. Int. 2017, 105, 241–249. [Google Scholar] [CrossRef]

- Attia, M.H.; Magel, E. Experimental investigation of long-term fretting wear of multi-span steam generator tubes with U-bend sections. Wear 1999, 225–229, 563–574. [Google Scholar] [CrossRef]

- Lin, X.; Xu, Y. An equivalent damage model to fretting fatigue initiation life considering wear. Int. J. Fatigue 2022, 163, 107048. [Google Scholar] [CrossRef]

- Blau, P.J. Friction Science and Technology, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Archard, J.F. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

| Material | C | Si | Mn | P | S | Cr | Al | Cu | Ni | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Z10C13 | 0.12 | 0.5 | 1.0 | 0.04 | 0.03 | 12 | Nan | Nan | 0.60 | Bal. |

| Inconel 690 | 0.023 | 0.30 | 0.23 | 0.008 | 0.002 | 30.3 | 0.25 | 0.50 | Bal. | 9.6 |

| Parameter | Unit | Value |

|---|---|---|

| Flat sample | ||

| Material | – | Z10C13 ferritic stainless steel |

| Dimension | mm | ⌀24 × 8 |

| Designation | – | M15N10–M75N50 |

| Hemispherical cylindrical | ||

| Material | – | Inconel 690 |

| Dimension | mm | ⌀6.5 |

| Designation | – | M15N10–M75N50 |

| Displacement amplitude | m | 15, 30, 45, 60, 75 |

| Applied normal load | N | 10, 20, 30, 40, 50 |

| Frequency | Hz | 30 |

| Ambient temperature | °C | 25 |

| Specimen | Load (N) | Amplitude (m) | Wear Area (mm2) | Wear Volume (mm3) |

|---|---|---|---|---|

| M15N10 | 10 | 15 | 0.137 | 0.00125 |

| M30N10 | 10 | 30 | 0.498 | 0.00217 |

| M45N10 | 10 | 45 | 0.777 | 0.00456 |

| M60N10 | 10 | 60 | 0.961 | 0.00650 |

| M75N10 | 10 | 75 | 1.151 | 0.00863 |

| M15N20 | 20 | 15 | 0.141 | 0.00138 |

| M30N20 | 20 | 30 | 0.465 | 0.00302 |

| M45N20 | 20 | 45 | 0.881 | 0.00668 |

| M60N20 | 20 | 60 | 1.126 | 0.01017 |

| M75N20 | 20 | 75 | 1.300 | 0.01539 |

| M15N30 | 30 | 15 | 0.110 | 0.00097 |

| M30N30 | 30 | 30 | 0.499 | 0.00344 |

| M45N30 | 30 | 45 | 0.879 | 0.00671 |

| M60N30 | 30 | 60 | 1.207 | 0.01268 |

| M75N30 | 30 | 75 | 1.364 | 0.01717 |

| M15N40 | 40 | 15 | 0.105 | 0.00089 |

| M30N40 | 40 | 30 | 0.399 | 0.00350 |

| M45N40 | 40 | 45 | 0.951 | 0.00734 |

| M60N40 | 40 | 60 | 1.314 | 0.01521 |

| M75N40 | 40 | 75 | 1.491 | 0.01854 |

| M15N50 | 50 | 15 | 0.101 | 0.00072 |

| M30N50 | 50 | 30 | 0.167 | 0.00280 |

| M45N50 | 50 | 45 | 0.483 | 0.00605 |

| M60N50 | 50 | 60 | 1.216 | 0.01490 |

| M75N50 | 50 | 75 | 1.524 | 0.02039 |

| Model | RSS | R2 | AIC | BIC |

|---|---|---|---|---|

| Archard | 0.0003 | 0.7258 | 285.65 | −284.43 |

| Hardness-corrected | 0.0000 | 0.9838 | −346.40 | −339.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, R.; Sun, B.; Meng, Z.; Wang, Y.; Ni, J.; Zhang, H. Mechanistic Interpretation of Fretting Wear in Z10C13 Steel Under Displacement–Load Coupling. Lubricants 2025, 13, 421. https://doi.org/10.3390/lubricants13090421

Li R, Sun B, Meng Z, Wang Y, Ni J, Zhang H. Mechanistic Interpretation of Fretting Wear in Z10C13 Steel Under Displacement–Load Coupling. Lubricants. 2025; 13(9):421. https://doi.org/10.3390/lubricants13090421

Chicago/Turabian StyleLi, Ruizhi, Bozhen Sun, Zhen Meng, Yigang Wang, Jing Ni, and Haohan Zhang. 2025. "Mechanistic Interpretation of Fretting Wear in Z10C13 Steel Under Displacement–Load Coupling" Lubricants 13, no. 9: 421. https://doi.org/10.3390/lubricants13090421

APA StyleLi, R., Sun, B., Meng, Z., Wang, Y., Ni, J., & Zhang, H. (2025). Mechanistic Interpretation of Fretting Wear in Z10C13 Steel Under Displacement–Load Coupling. Lubricants, 13(9), 421. https://doi.org/10.3390/lubricants13090421