Biomimetic Hexagonal Texture with Dual-Orientation Groove Interconnectivity Enhances Lubrication and Tribological Performance of Gear Tooth Surfaces

Abstract

1. Introduction

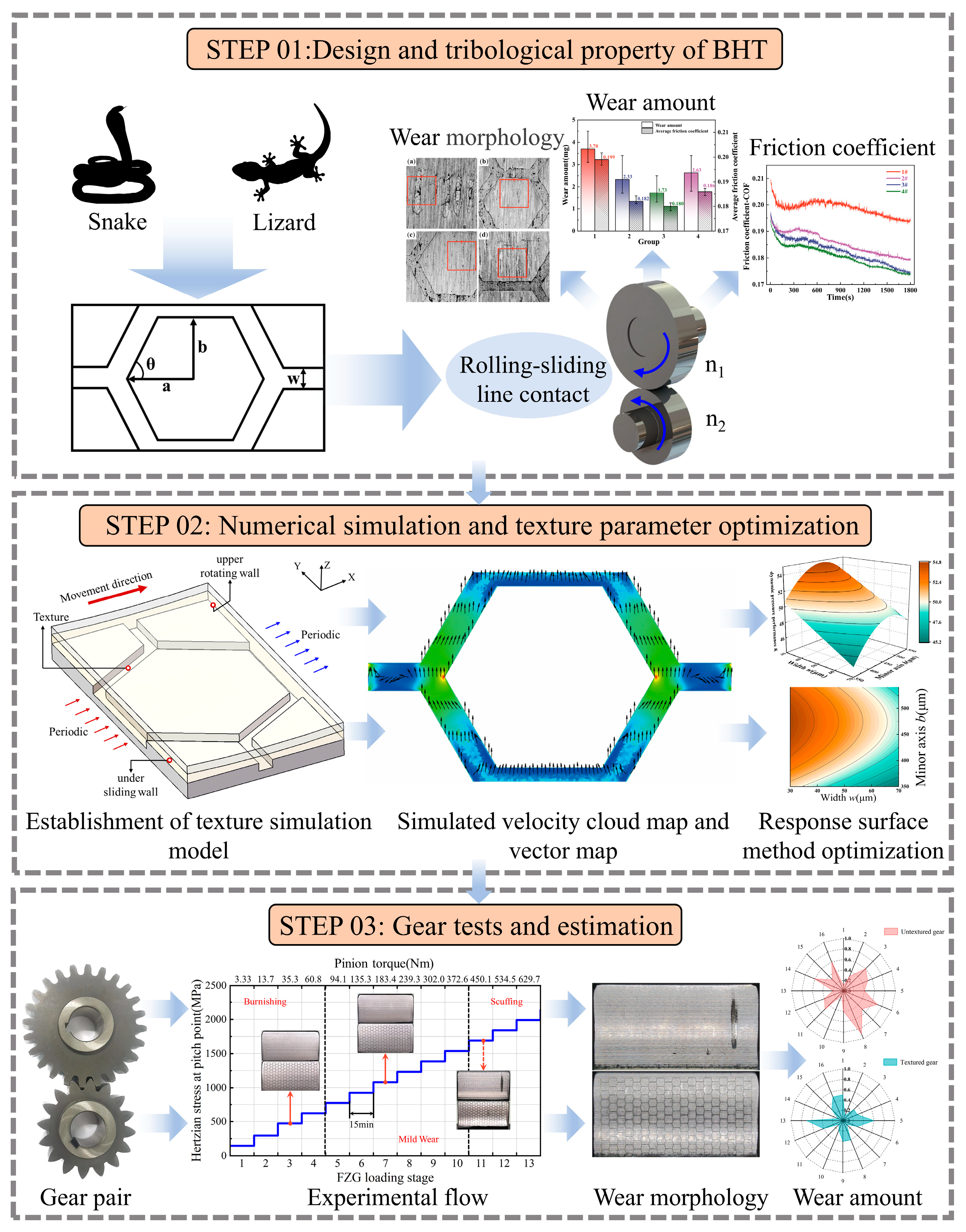

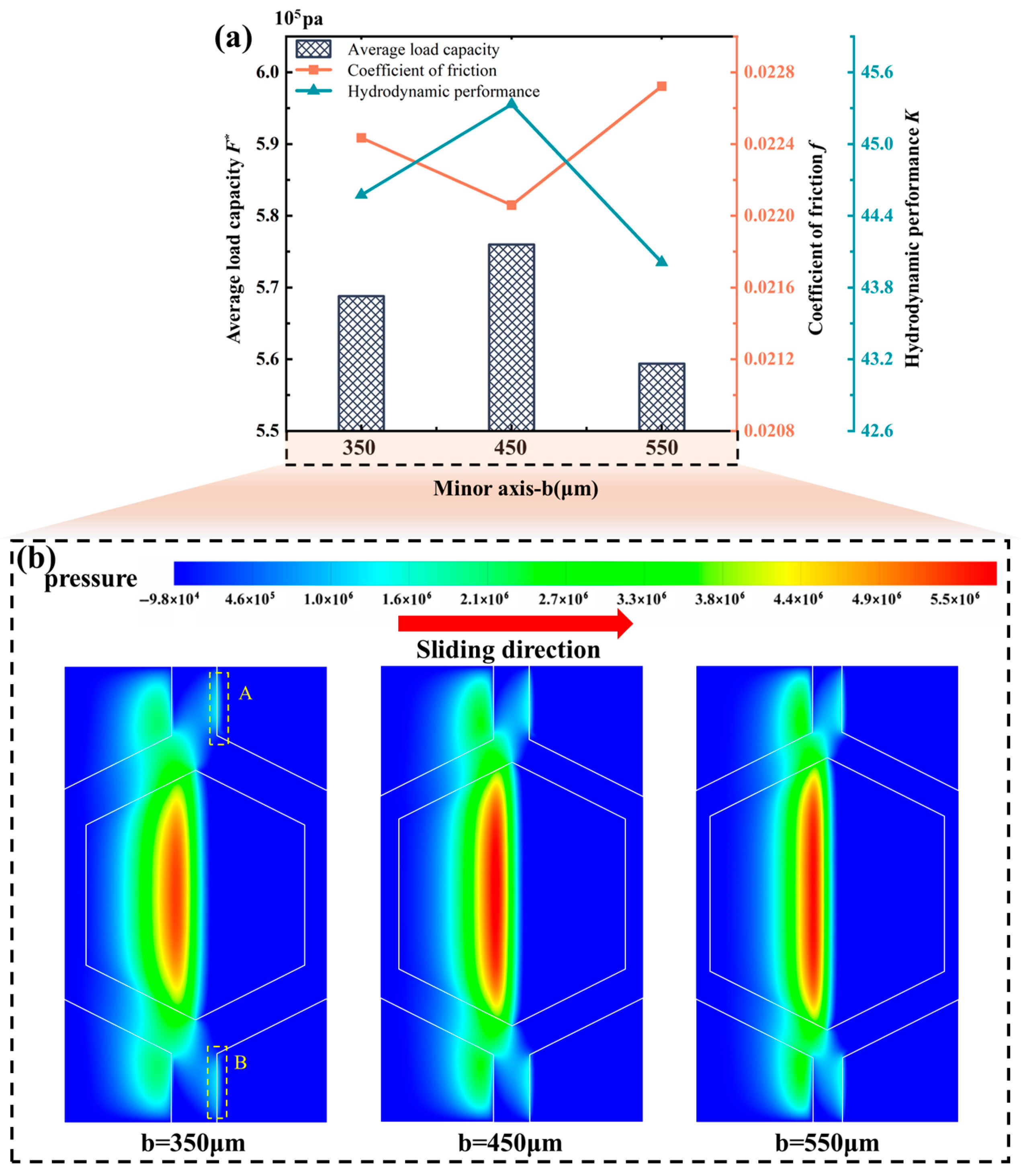

2. Design and Tribological Property of Biomimetic Texture

2.1. Texture Design

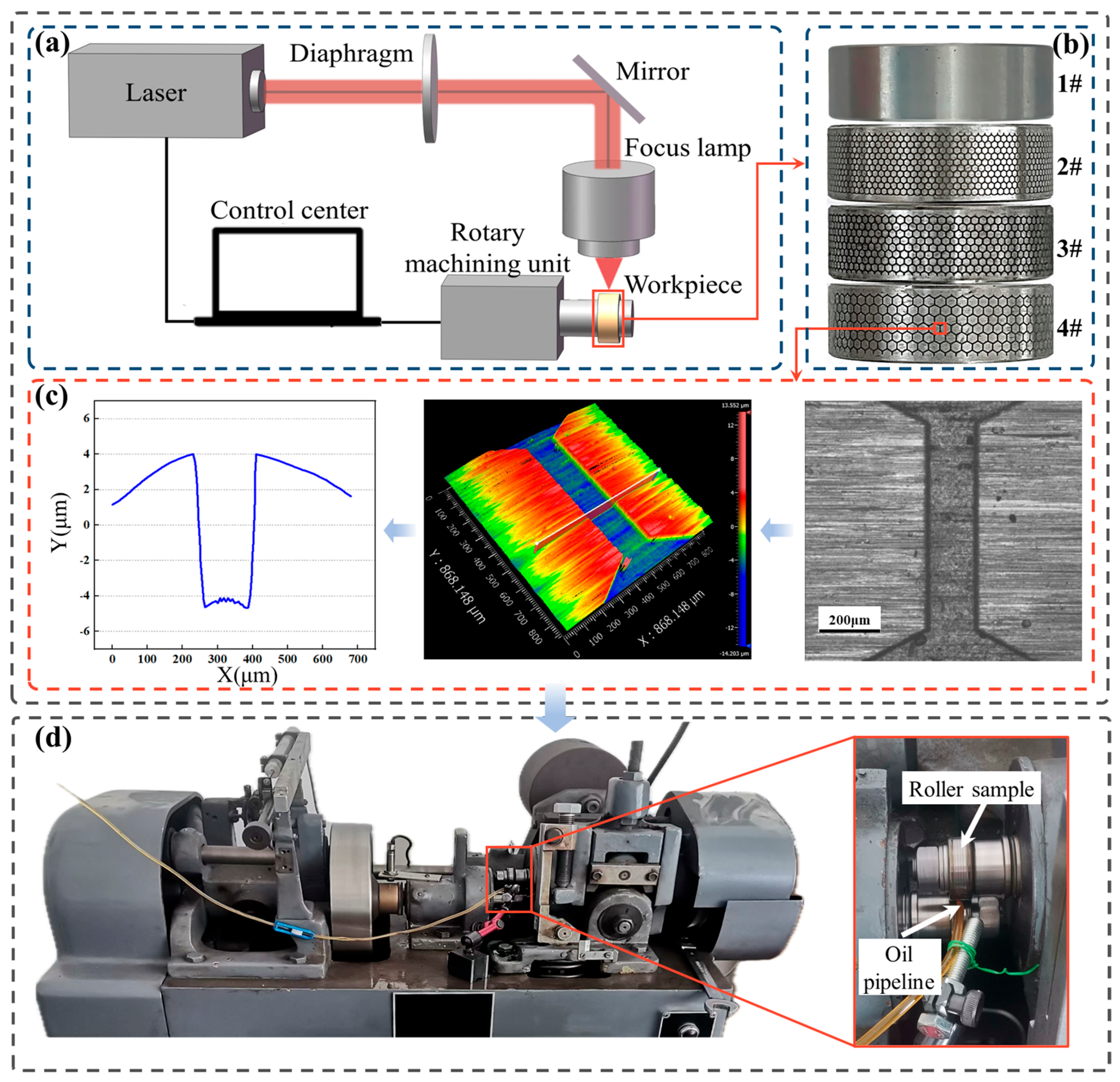

2.2. Tribological Test

2.2.1. Experimental Configuration

2.2.2. Experimental Result

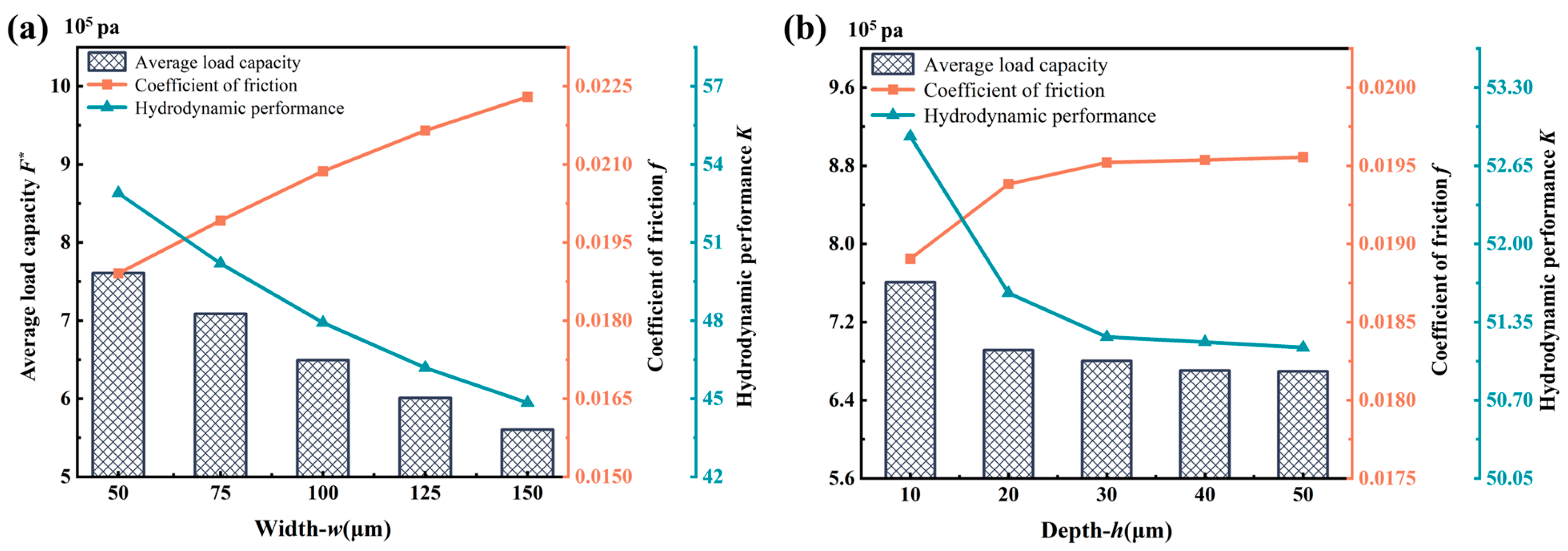

3. Parameters Optimization of BHT

3.1. Simulation Models

3.2. Validation of CFD Model

3.3. Lubrication Mechanism of BHT

3.4. The Effect of Parameters on Hydrodynamic Lubrication

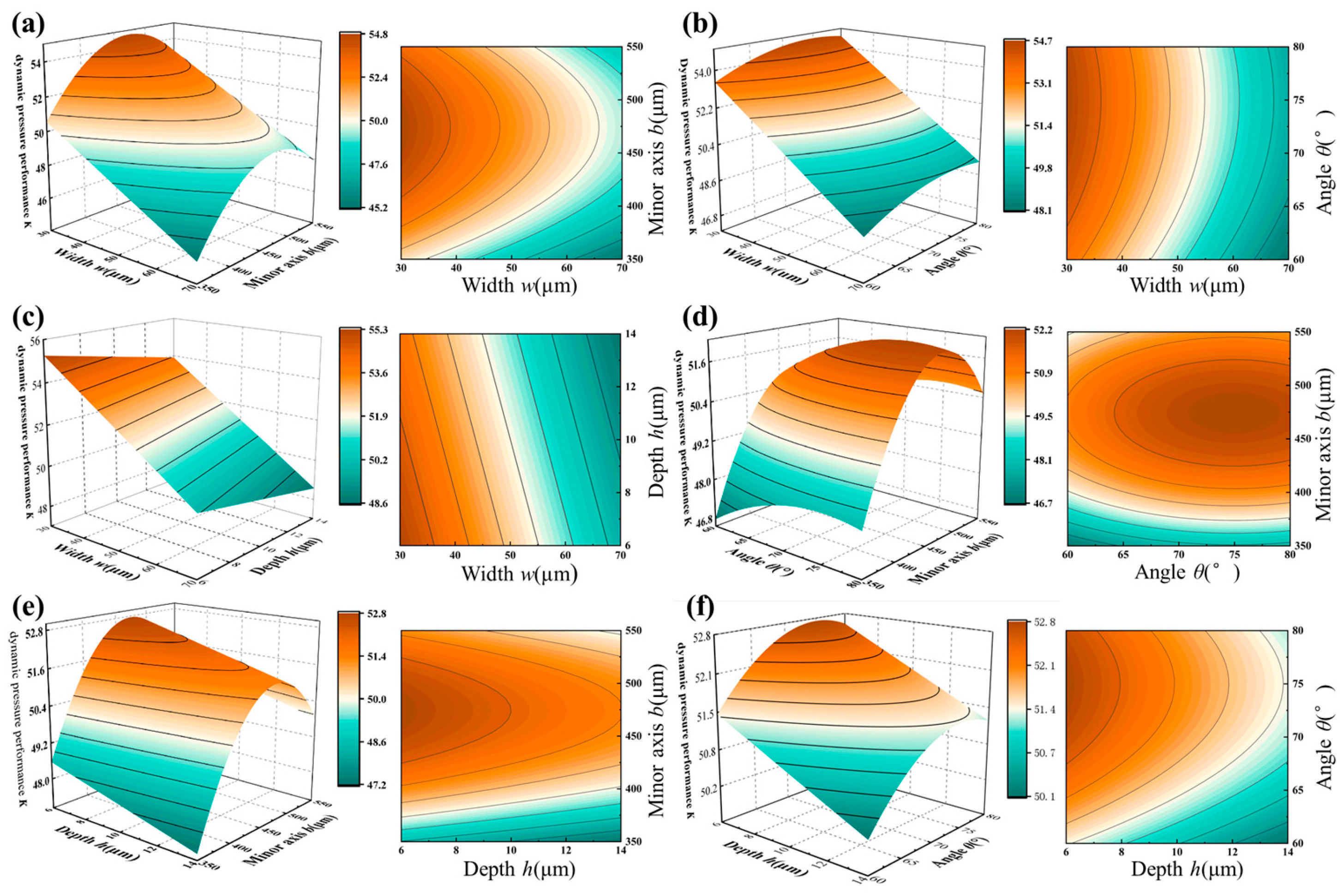

3.5. Parameters Optimization Based on RSM

4. Gear Experiments

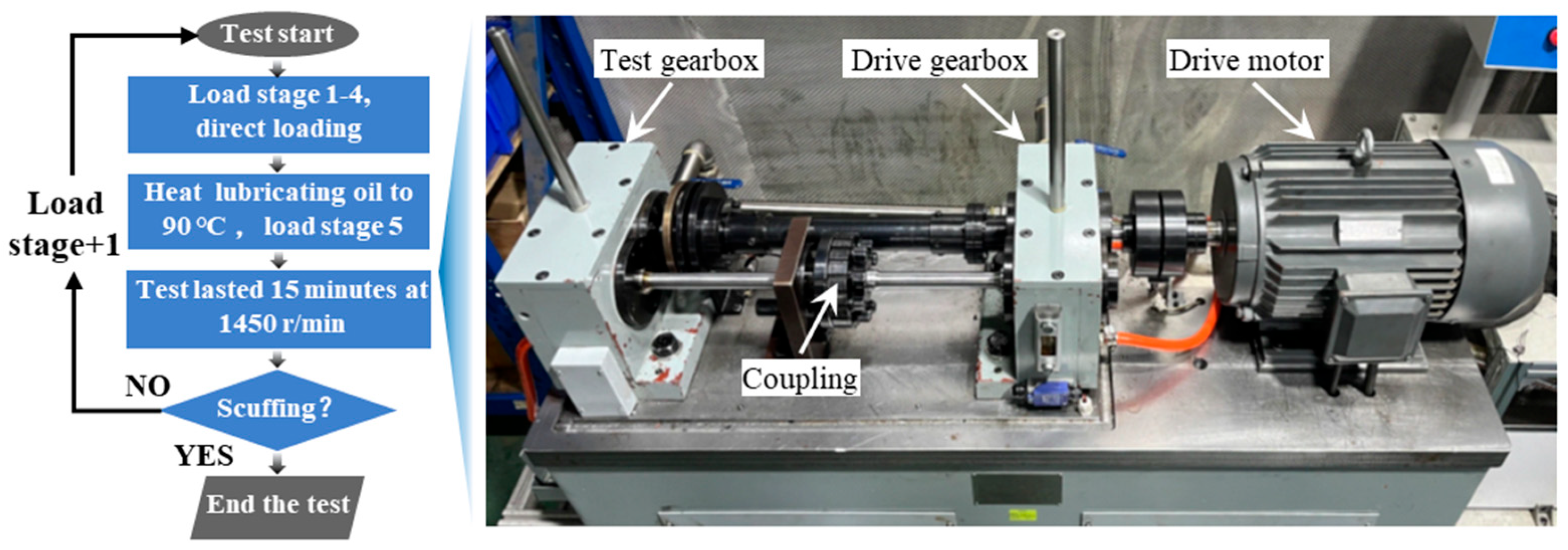

4.1. Experimental Setup

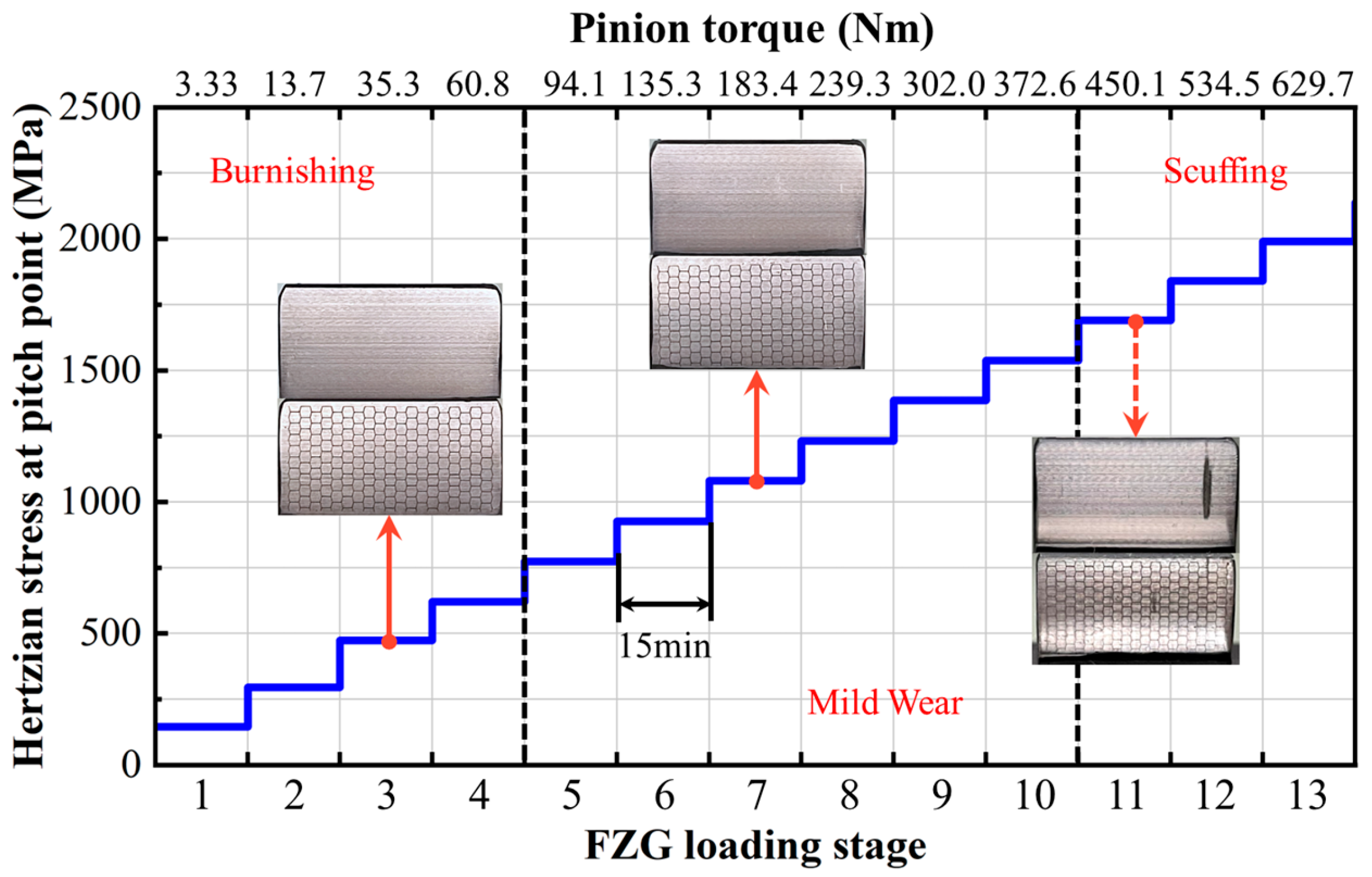

4.2. Result and Discussion

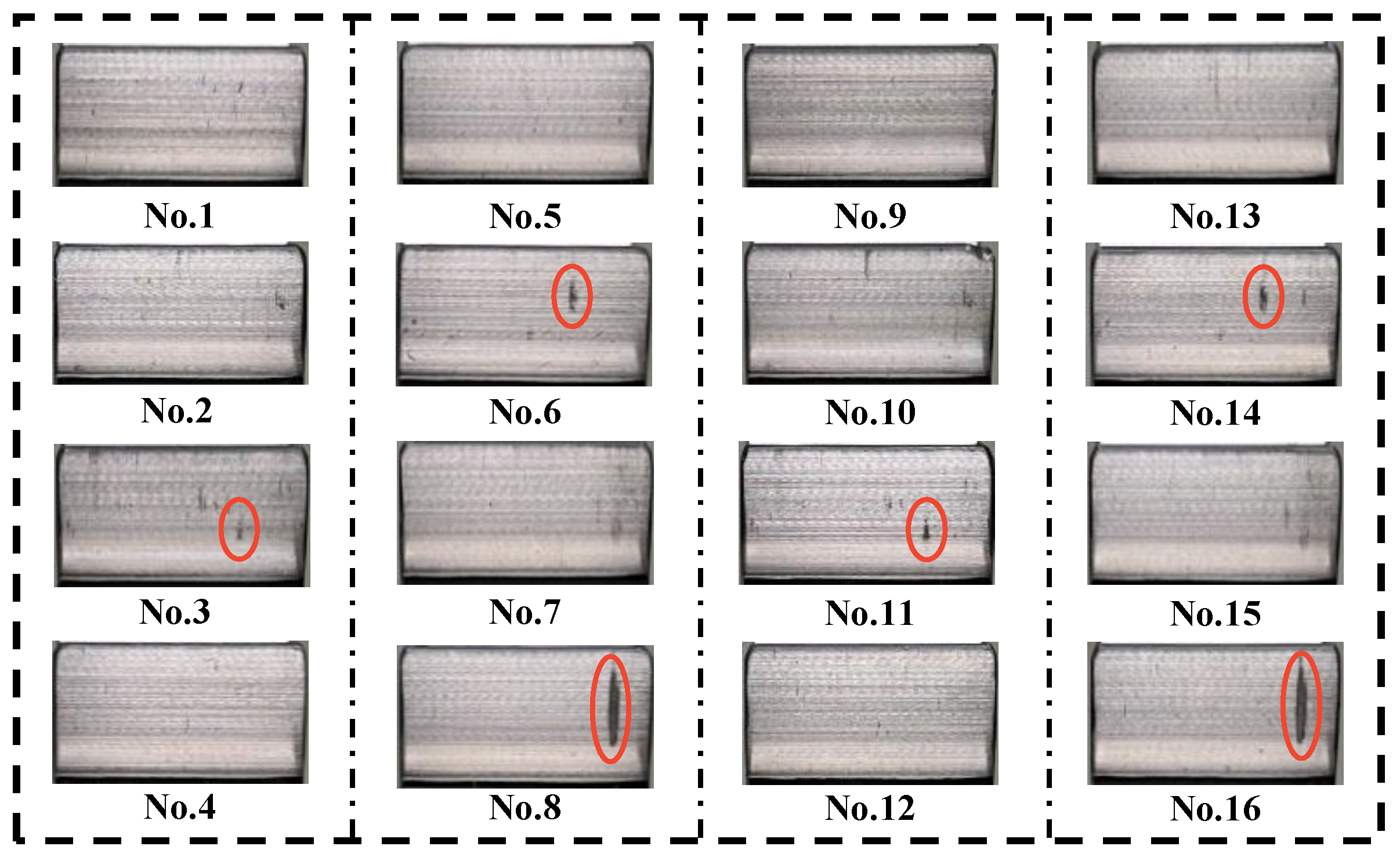

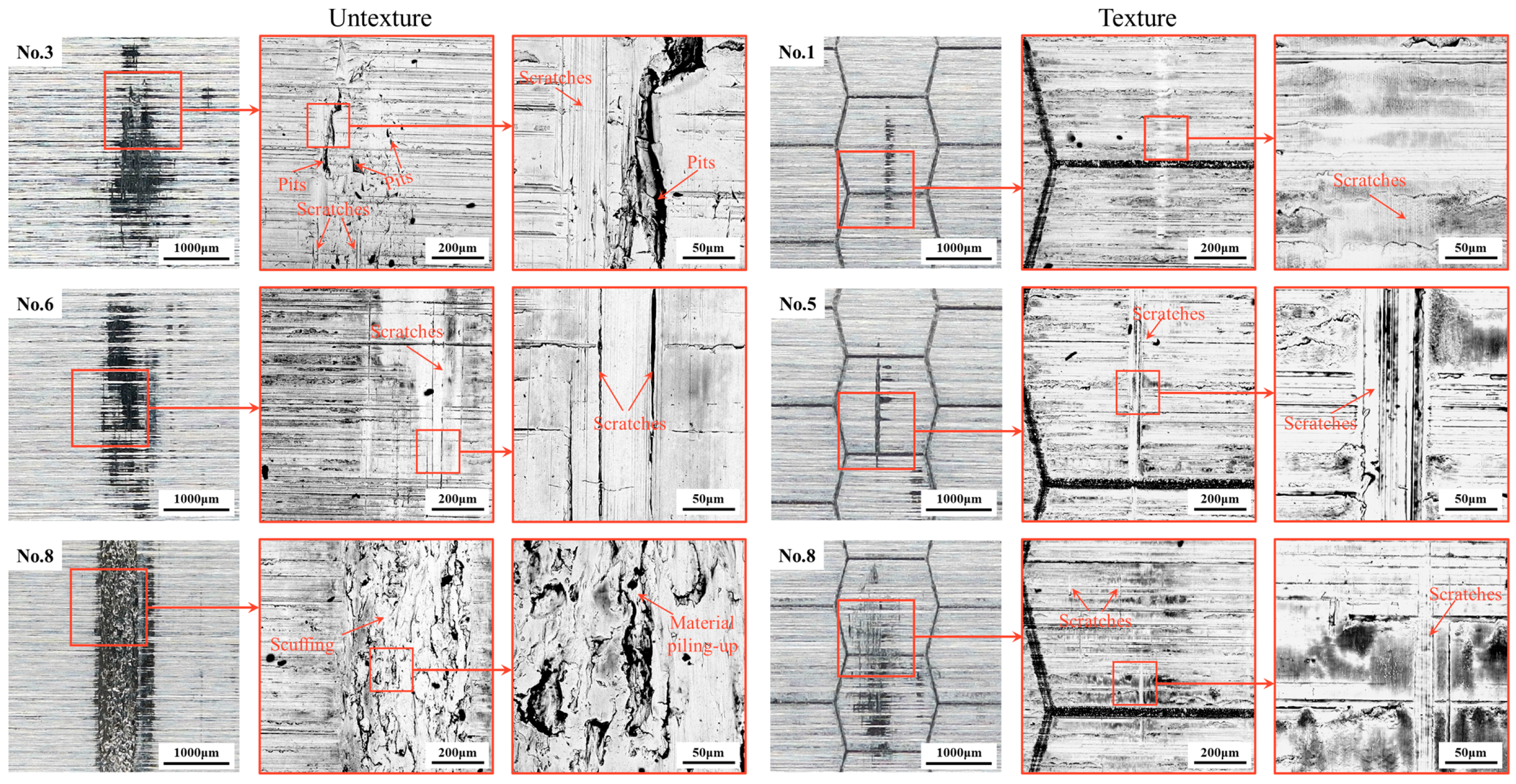

4.2.1. Wear Morphology

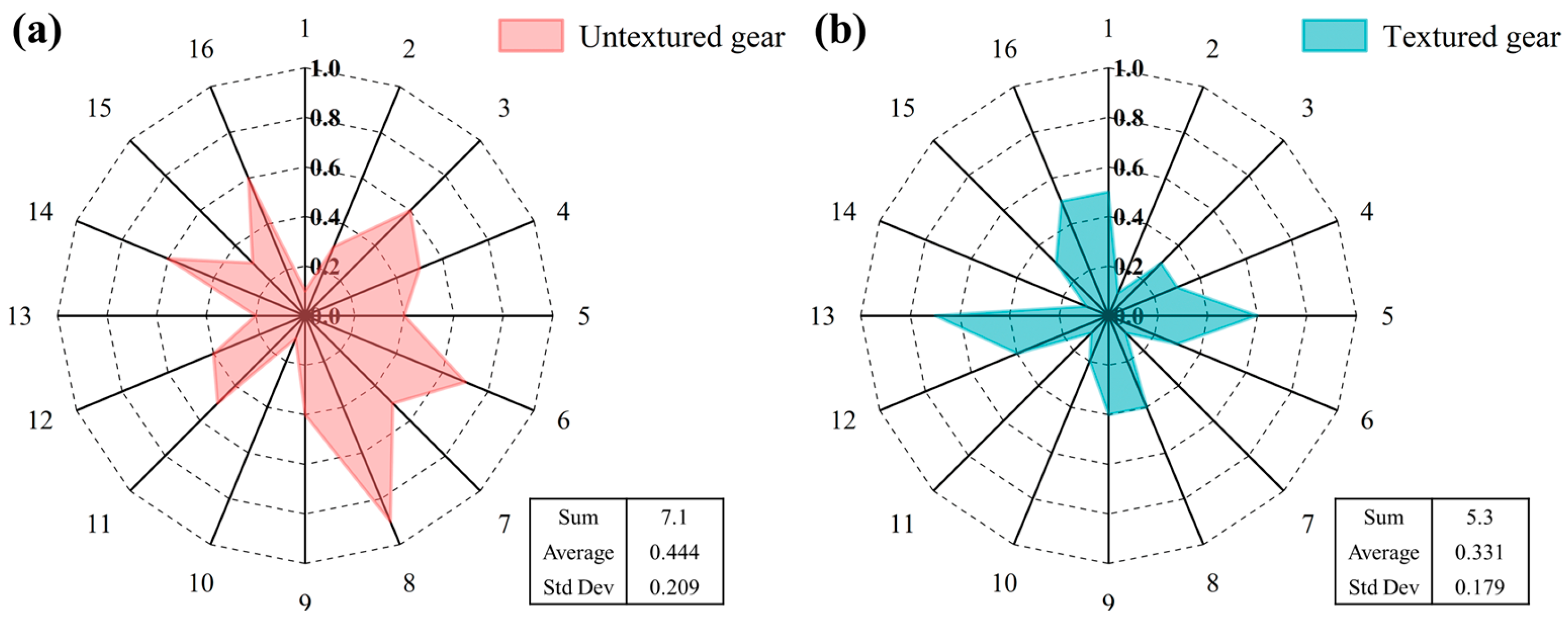

4.2.2. Wear Area

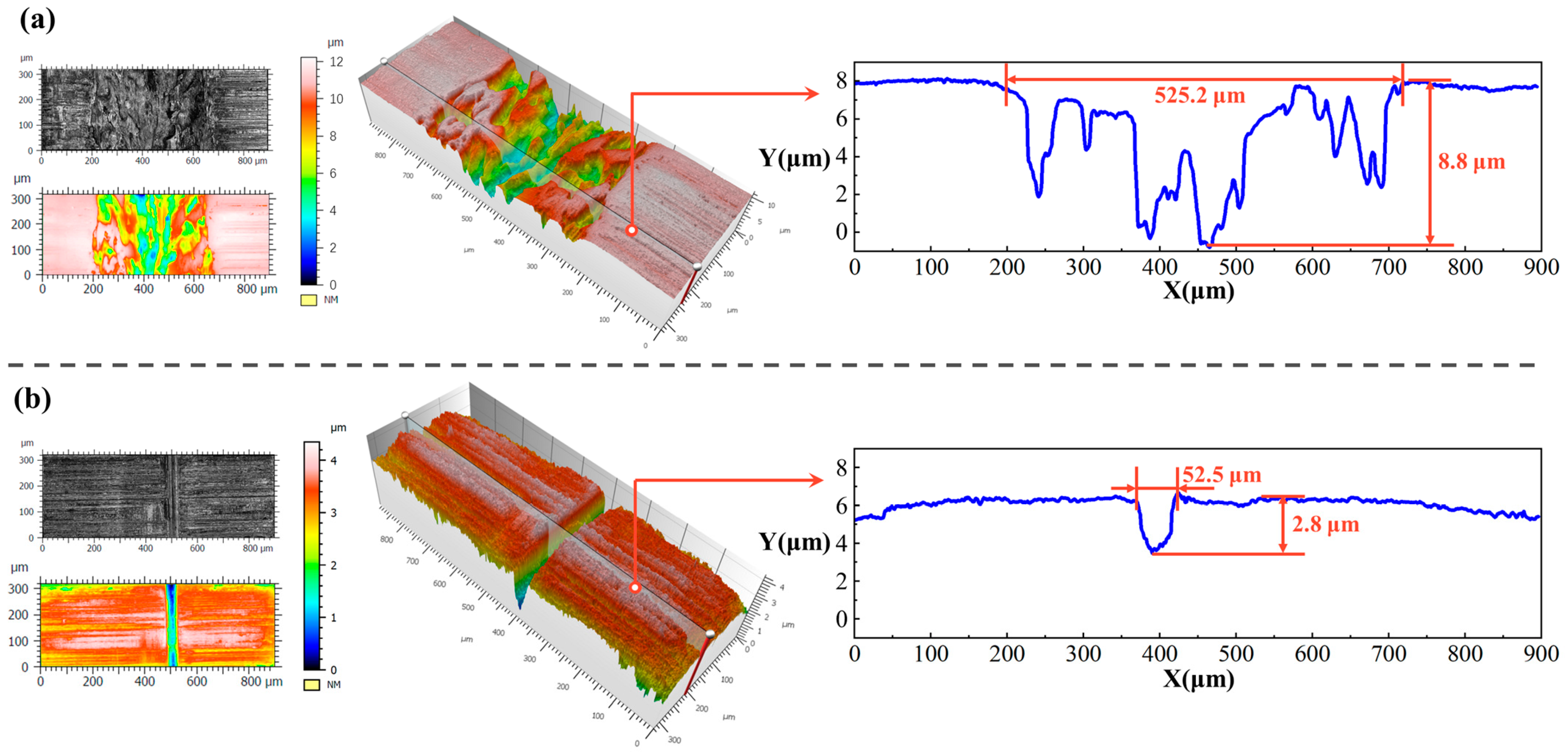

4.2.3. Wear Amount

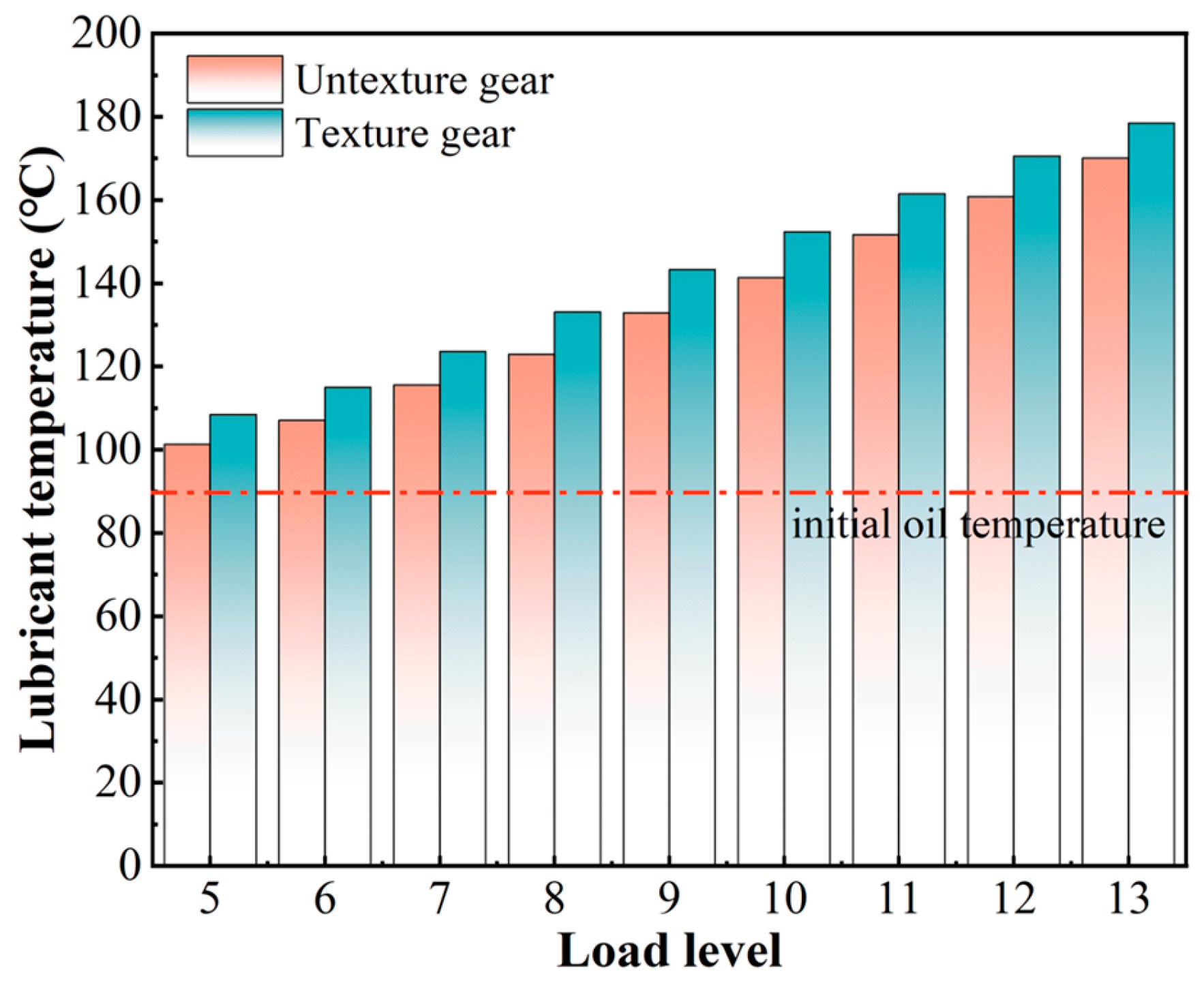

4.2.4. Lubricant Temperature

5. Conclusions

6. Limitations and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liang, X.; Zuo, M.; Feng, Z. Dynamic modeling of gearbox faults: A review. Mech. Syst. Signal Process. 2018, 98, 852–876. [Google Scholar] [CrossRef]

- Miler, D.; Hoic, M. Optimisation of cylindrical gear pairs: A review. Mech. Mach. Theory 2020, 156, 104156. [Google Scholar] [CrossRef]

- Feng, K.; Ji, J.; Ni, Q.; Beer, M. A review of vibration-based gear wear monitoring and prediction techniques. Mech. Syst. Signal Process. 2023, 182, 109605. [Google Scholar] [CrossRef]

- Liu, J.; Liu, H.; Zhu, C.; Parker, R. Effects of lubrication on gear performance: A review. Mech. Mach. Theory 2020, 145, 103701. [Google Scholar] [CrossRef]

- Li, Z.; Guan, Q.; Liu, S.; Bao, J.; Ding, H.; Wang, W. Friction-reducing and anti-wear performance of SiO2-Coated TiN nanoparticles in gear oil. Wear 2024, 538, 205219. [Google Scholar] [CrossRef]

- Marian, M.; Almqvist, A.; Rosenkranz, A.; Fillon, M. Numerical micro-texture optimization for lubricated contacts—A critical discussion. Friction 2022, 10, 1772–1809. [Google Scholar] [CrossRef]

- Wang, H.; Deng, D.; Zhai, Z.; Yao, Y. Laser-processed functional surface structures for multi-functional applications-a review. J. Manuf. Process. 2024, 116, 247–283. [Google Scholar] [CrossRef]

- Xiao, Q.; Wang, X.; Wang, Y.; Zheng, W.; Xu, J.; Luo, X.; Sun, J.; Zhang, L. Beyond smoothness: The art of surface texturing battling against friction. Int. J. Extrem. Manuf. 2025, 7, 022014. [Google Scholar] [CrossRef]

- Lin, O.; Xiao, G.; Liu, S.; Zhou, Y.; Liu, Z.; Huang, J.; Yin, K. Rapid multiscale surface texture manufacturing process using hybrid laser belt machining. J. Mater. Process. Technol. 2024, 319, 118092. [Google Scholar] [CrossRef]

- Wang, H.; Huang, J.; Wang, B.; Zhang, Y.; Wang, J. Study on the tribological behavior of laser surface texturing on silicon nitride ceramic under water lubrication. Lubricants 2025, 13, 21. [Google Scholar] [CrossRef]

- Huang, Q.; Wu, C.; Shi, X.; Zhang, K. Topology optimization of AISI 4140 steel with surface texture filled by multi-solid lubricants for enhancing tribological properties. Friction 2024, 12, 2033–2051. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, Y. Tribological and dynamic performance analysis of rolling bearings with varied surface textures operating under lubricant contamination. Wear 2023, 532, 205109. [Google Scholar] [CrossRef]

- Xue, L.; Yan, Z.; Jiang, Y.; Sun, T. Influences of Sharkskin Texture on Lubrication Performance of Elastic Bearing Friction Pairs. Tribol. Lett. 2024, 72, 103. [Google Scholar] [CrossRef]

- Wang, X.; Li, C.; Zhang, Y.; Said, Z.; Debnath, S.; Sharma, S.; Yang, M.; Gao, T. Influence of texture shape and arrangement on nanofluid minimum quantity lubrication turning. Int. J. Adv. Manuf. Technol. 2022, 119, 631–646. [Google Scholar] [CrossRef]

- Long, R.; Shang, Q.; Sun, S.; Wang, S.; Ma, C.; Zhang, J.; Marian, M. Influence of Monstera riedrichsthalii bionic textures on the tribological and vibration behavior of rolling bearings. Friction 2025, 13, 9440949. [Google Scholar] [CrossRef]

- Liu, Z.; Shen, Y.; Liu, J.; Qu, J.; Xu, J.; Li, C. Effects of double-sided textures matching on friction and wear performance in reciprocating contact interface. Wear 2024, 556, 205522. [Google Scholar] [CrossRef]

- Wu, D.; Liang, X.; Wen, X.; Meng, Z.; Yu, Z.; He, Y.; Dai, P.; Yu, Y.; Li, N. Experimental study of diesel engine deposits on failure of honed cylinder liner surface texture. Eng. Fail. Anal. 2025, 174, 109476. [Google Scholar] [CrossRef]

- He, Z.; Guo, Y.; Si, J.; Li, N.; Jia, L.; Zou, Y.; Wang, H. Numerical optimization analysis of floating ring seal performance based on surface texture. Lubricants 2024, 12, 241. [Google Scholar] [CrossRef]

- Lu, P.; Wood, R. Tribological performance of surface texturing in mechanical applications—A review. Surf. Topogr. Metrol. Prop. 2020, 8, 043001. [Google Scholar] [CrossRef]

- Bian, B.; Zhang, Z.; Li, L.; Chao, Q.; Yuan, H.; Liu, Z. Lubrication, friction and wear characteristics of textured surface slipper pairs in axial piston pumps. Lubricants 2024, 12, 370. [Google Scholar] [CrossRef]

- Andreas, R.; Philipp, G.; Carsten, G.; Henara, L. Surface texturing in machine elements a critical discussion for rolling and sliding contacts. Adv. Eng. Mater. 2019, 1099, 194. [Google Scholar] [CrossRef]

- Gupta, N.; Tandon, N.; Pandey, R. An exploration of the performance behaviors of lubricated textured and conventional spur gearsets. Tribol. Int. 2018, 128, 376–385. [Google Scholar] [CrossRef]

- Gupta, N.; Tandon, N.; Pandey, R.; Vidyasagar, K.; Kalyanasundaram, D. Tribological and vibration studies of textured spur gear pairs under fully flooded and starved lubrication conditions. Tribol. Trans. 2020, 63, 1103–1120. [Google Scholar] [CrossRef]

- Chang, X.; Renqing, D.; Liao, L.; Zhu, P.; Lin, B.; Huang, Y.; Luo, S. Study on hydrodynamic lubrication and friction reduction performance of spur gear with groove texture. Tribol. Int. 2023, 177, 107978. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Zou, T.; Hou, W.; An, Y.; Liu, J. Effect of bionic texture on the lubrication efficiency and mechanical efficiency loss for rotating gears. Surf. Topogr. Metrol. Prop. 2024, 12, 035004. [Google Scholar] [CrossRef]

- Renqing, D.; Luo, S.; Chang, X. Study on hydrodynamic lubrication and friction reduction performance of cylindrical rolls with tesla valve texture. Tribol. Trans. 2023, 66, 981–991. [Google Scholar] [CrossRef]

- Li, J.; Zhang, G.; Du, C.; Song, T.; Wu, Y.; Zhou, Y. Various multi-scale textures morphology fabricated by combining femtosecond laser and molding process: Friction and wetting behavior. Surf. Topogr. Metrol. Prop. 2025, 13, 035006. [Google Scholar] [CrossRef]

- Zhu, X.; Yang, X.; Zhao, A.; Cheng, X.; Zhang, Q.; Liu, D. Tribological Characteristics of Laser Multi-scale Composite Textures for YT-15 Cemented Carbide Surface. Tribol. Lett. 2025, 73, 60. [Google Scholar] [CrossRef]

- Hou, Q.; Yang, X.; Cheng, J.; Wang, S.; Duan, D.; Xiao, J.; Li, W. Optimization of performance parameters and mechanism of bionic texture on friction surface. Coatings 2020, 10, 171. [Google Scholar] [CrossRef]

- Sharma, S.; Grewal, H. Tribological behavior of bioinspired surfaces. Biomimetics 2023, 8, 62. [Google Scholar] [CrossRef]

- Abdel-Aal, H.; Vargiolu, R.; Zahouani, H.; El Mansori, M. Preliminary investigation of the frictional response of reptilian shed skin. Wear 2012, 290, 51–60. [Google Scholar] [CrossRef][Green Version]

- Qi, C.; Jiang, F.; Yang, S. Advanced honeycomb designs for improving mechanical properties: A review. Compos. B Eng. 2021, 227, 109393. [Google Scholar] [CrossRef]

- Kumar, R.; Rezapourian, M.; Rahmani, R.; Maurya, H.; Kamboj, N.; Hussainova, I. Bioinspired and multifunctional tribological materials for sliding, erosive, machining, and energy-absorbing conditions: A Review. Biomimetics 2024, 9, 209. [Google Scholar] [CrossRef]

- Cans, C.; Baic, D. Regional specialization of reptilian scale surfaces: Relation of texture and biologic role. Science 1977, 195, 1348–1350. [Google Scholar] [CrossRef]

- Sanchez, J.; Estupinan, H.; Toro, A. Friction response of bioinspired AISI 52100 steel surfaces texturized by photochemical machining. Surf. Topogr. Metrol. Prop. 2021, 9, 014001. [Google Scholar] [CrossRef]

- Zhong, Y.; Zheng, L.; Gao, Y.; Liu, Z. Numerical simulation and experimental investigation of tribological performance on bionic hexagonal textured surface. Tribol. Int. 2019, 129, 151–161. [Google Scholar] [CrossRef]

- Rahmani, H.; Taghavi, S. A comprehensive model for viscoplastic flows in channels with a patterned wall: Longitudinal, transverse and oblique flows. J. Fluid Mech. 2024, 984, A32. [Google Scholar] [CrossRef]

- Yuan, S.; Huang, W.; Wang, X. Orientation effects of micro-grooves on sliding surfaces. Tribol. Int. 2011, 44, 1047–1054. [Google Scholar] [CrossRef]

- Li, L.; Li, B.; Wei, X.; Gao, Z.; Lu, Z.; Guo, H. Multi-dimensional tool wear detection using non-subsampled shearlet transform and enhanced pulse coupled neural network in optical microscopy reconstruction. Opt. Laser Technol. 2025, 187, 112849. [Google Scholar] [CrossRef]

- Luo, Q. Electron microscopy and spectroscopy in the analysis of friction and wear mechanisms. Lubricants 2018, 6, 58. [Google Scholar] [CrossRef]

- Zochowski, T.; Olszewski, A.; Fillon, M.; Galda, L.; Smykla, J. Accurate dimensional characterization of the textured inner surface of the bearing bushing by the mean of a new measurement instrument. Measurement 2025, 250, 117068. [Google Scholar] [CrossRef]

- Peta, K.; Stemp, W.; Stocking, T.; Chen, R.; Love, G.; Gleason, M.; Houk, B.; Brown, C. Multiscale geometric characterization and discrimination of dermatoglyphs (fingerprints) on hardened clay—A novel archaeological application of the gelsight max. Materials 2025, 18, 2939. [Google Scholar] [CrossRef]

- Chen, T.; Zhu, C.; Chen, J.; Liu, H. A review on gear scuffing studies: Theories, experiments and design. Tribol. Int. 2024, 196, 109741. [Google Scholar] [CrossRef]

- Zhang, N.; Guo, S.; He, G.; Jiang, B.; Zhou, L.; Chen, Y.; Liu, Y. Failure analysis of the carburized 20MnCr5 gear in fatigue working condition. Int. J. Fatigue 2022, 161, 106938. [Google Scholar] [CrossRef]

- Chen, T.; Wei, P.; Zhu, C.; Zeng, P.; Li, D.; Parker, R.; Liu, H. Experimental investigation of gear scuffing for various tooth surface treatments. Tribol. Trans. 2023, 66, 35–46. [Google Scholar] [CrossRef]

| Elements | C | Si | Mn | Cr | S |

|---|---|---|---|---|---|

| Weight % | 0.17~0.22 | ≤0.4 | 1.00~1.40 | 1.00~1.30 | ≤0.035 |

| Levels | Minor Axis b (μm) | Width w (μm) | Depth h (μm) | Angle θ (°) |

|---|---|---|---|---|

| −2 | 350 | 30 | 6 | 60 |

| −1 | 400 | 40 | 8 | 65 |

| 0 | 450 | 50 | 10 | 70 |

| 1 | 500 | 60 | 12 | 75 |

| 2 | 550 | 70 | 14 | 80 |

| No. | Independent Variable | Response Value | |||

|---|---|---|---|---|---|

| b (μm) | w (μm) | h (μm) | θ (°) | K | |

| 1 | 400 | 60 | 8 | 65 | 48.7954 |

| 2 | 450 | 50 | 10 | 80 | 52.2020 |

| 3 | 500 | 40 | 8 | 75 | 53.8057 |

| 4 | 450 | 50 | 10 | 70 | 52.0688 |

| 5 | 400 | 60 | 12 | 65 | 48.4337 |

| 6 | 400 | 40 | 12 | 65 | 51.4747 |

| 7 | 500 | 40 | 12 | 65 | 52.4014 |

| 8 | 400 | 40 | 8 | 65 | 51.6537 |

| 9 | 500 | 40 | 8 | 65 | 53.1905 |

| 10 | 400 | 60 | 12 | 75 | 49.1945 |

| 11 | 500 | 60 | 8 | 65 | 50.5708 |

| 12 | 500 | 60 | 12 | 75 | 50.7184 |

| 13 | 450 | 50 | 6 | 70 | 53.5461 |

| 14 | 450 | 50 | 10 | 70 | 52.1983 |

| 15 | 350 | 50 | 10 | 70 | 48.4517 |

| 16 | 450 | 50 | 10 | 60 | 51.0894 |

| 17 | 400 | 40 | 12 | 75 | 51.7179 |

| 18 | 400 | 40 | 8 | 75 | 52.3394 |

| 19 | 450 | 50 | 14 | 70 | 51.3411 |

| 20 | 450 | 50 | 10 | 70 | 51.8583 |

| 21 | 400 | 60 | 8 | 75 | 49.2929 |

| 22 | 450 | 30 | 10 | 70 | 54.6773 |

| 23 | 550 | 50 | 10 | 70 | 50.5640 |

| 24 | 500 | 60 | 12 | 65 | 50.0887 |

| 25 | 450 | 50 | 10 | 70 | 51.8083 |

| 26 | 450 | 70 | 10 | 70 | 49.3598 |

| 27 | 450 | 50 | 10 | 70 | 52.1283 |

| 28 | 500 | 60 | 8 | 75 | 51.1719 |

| 29 | 500 | 40 | 12 | 75 | 53.0292 |

| 30 | 450 | 50 | 10 | 70 | 52.2983 |

| 31 | 450 | 50 | 10 | 70 | 51.8583 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | Note |

|---|---|---|---|---|---|---|

| Model | 72.11 | 6 | 12.02 | 140.71 | <0.0001 | Significant |

| b | 11.07 | 1 | 11.07 | 129.59 | <0.0001 | |

| w | 42.62 | 1 | 42.62 | 498.92 | <0.0001 | |

| h | 2.78 | 1 | 2.78 | 32.57 | <0.0001 | |

| θ | 1.98 | 1 | 1.98 | 23.13 | <0.0001 | |

| b2 | 13.46 | 1 | 13.46 | 157.57 | <0.0001 | |

| θ2 | 0.61 | 1 | 7.14 | 0.013 | 0.6100 | |

| Residual | 2.05 | 24 | 0.09 | |||

| Lack of Fit | 1.83 | 18 | 0.10 | 2.78 | 0.1050 | Not Significant |

| Pure Error | 0.22 | 6 | 0.04 | |||

| Cor total | 74.17 | 30 | ||||

| R-squared | 0.9724 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Luo, S.; Gao, T.; Mo, J.; Wang, D.; Chang, X. Biomimetic Hexagonal Texture with Dual-Orientation Groove Interconnectivity Enhances Lubrication and Tribological Performance of Gear Tooth Surfaces. Lubricants 2025, 13, 420. https://doi.org/10.3390/lubricants13090420

Wang Y, Luo S, Gao T, Mo J, Wang D, Chang X. Biomimetic Hexagonal Texture with Dual-Orientation Groove Interconnectivity Enhances Lubrication and Tribological Performance of Gear Tooth Surfaces. Lubricants. 2025; 13(9):420. https://doi.org/10.3390/lubricants13090420

Chicago/Turabian StyleWang, Yan, Shanming Luo, Tongwang Gao, Jingyu Mo, Dongfei Wang, and Xuefeng Chang. 2025. "Biomimetic Hexagonal Texture with Dual-Orientation Groove Interconnectivity Enhances Lubrication and Tribological Performance of Gear Tooth Surfaces" Lubricants 13, no. 9: 420. https://doi.org/10.3390/lubricants13090420

APA StyleWang, Y., Luo, S., Gao, T., Mo, J., Wang, D., & Chang, X. (2025). Biomimetic Hexagonal Texture with Dual-Orientation Groove Interconnectivity Enhances Lubrication and Tribological Performance of Gear Tooth Surfaces. Lubricants, 13(9), 420. https://doi.org/10.3390/lubricants13090420