4.2.1. Taguchi Orthogonal Method

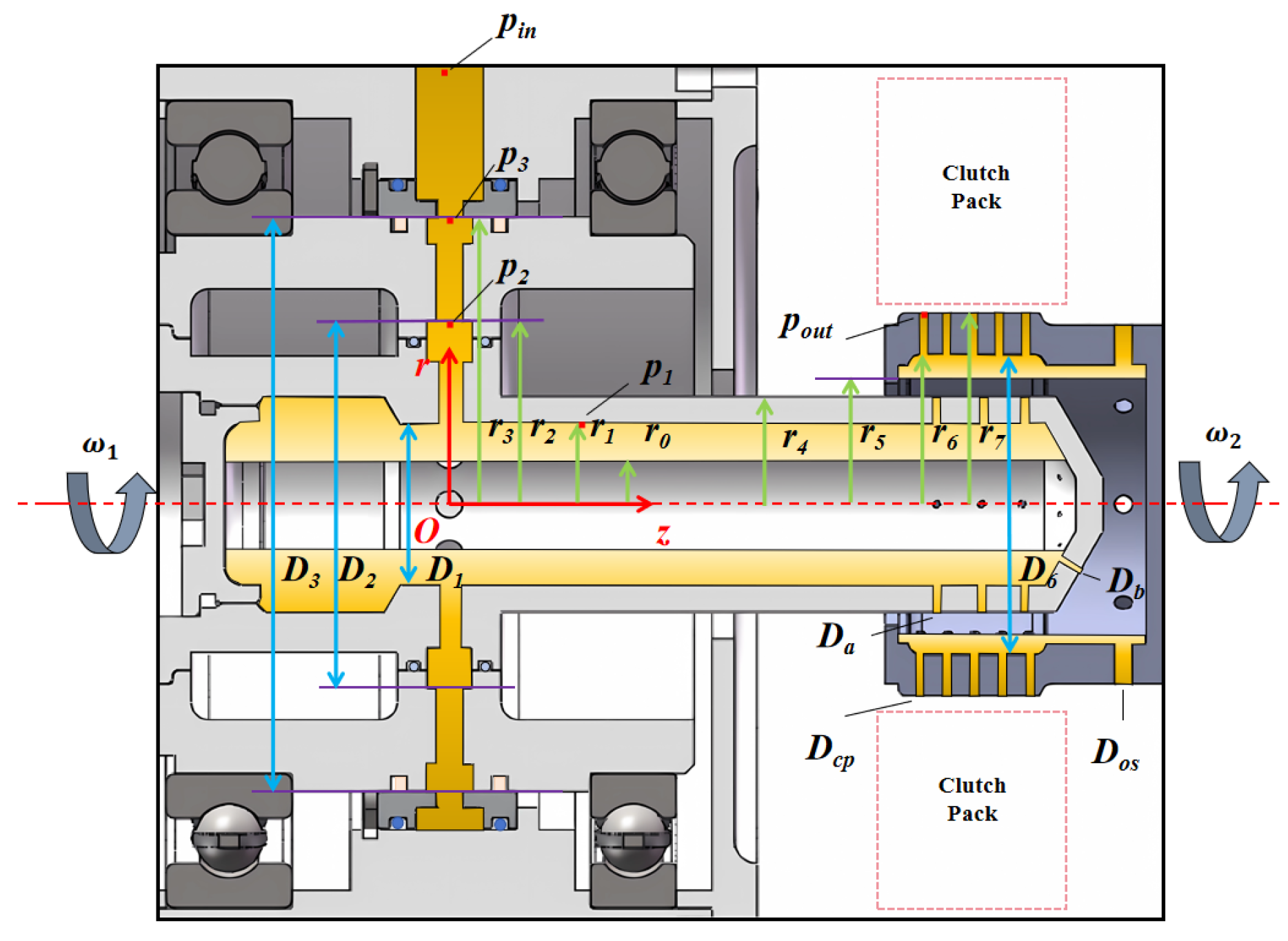

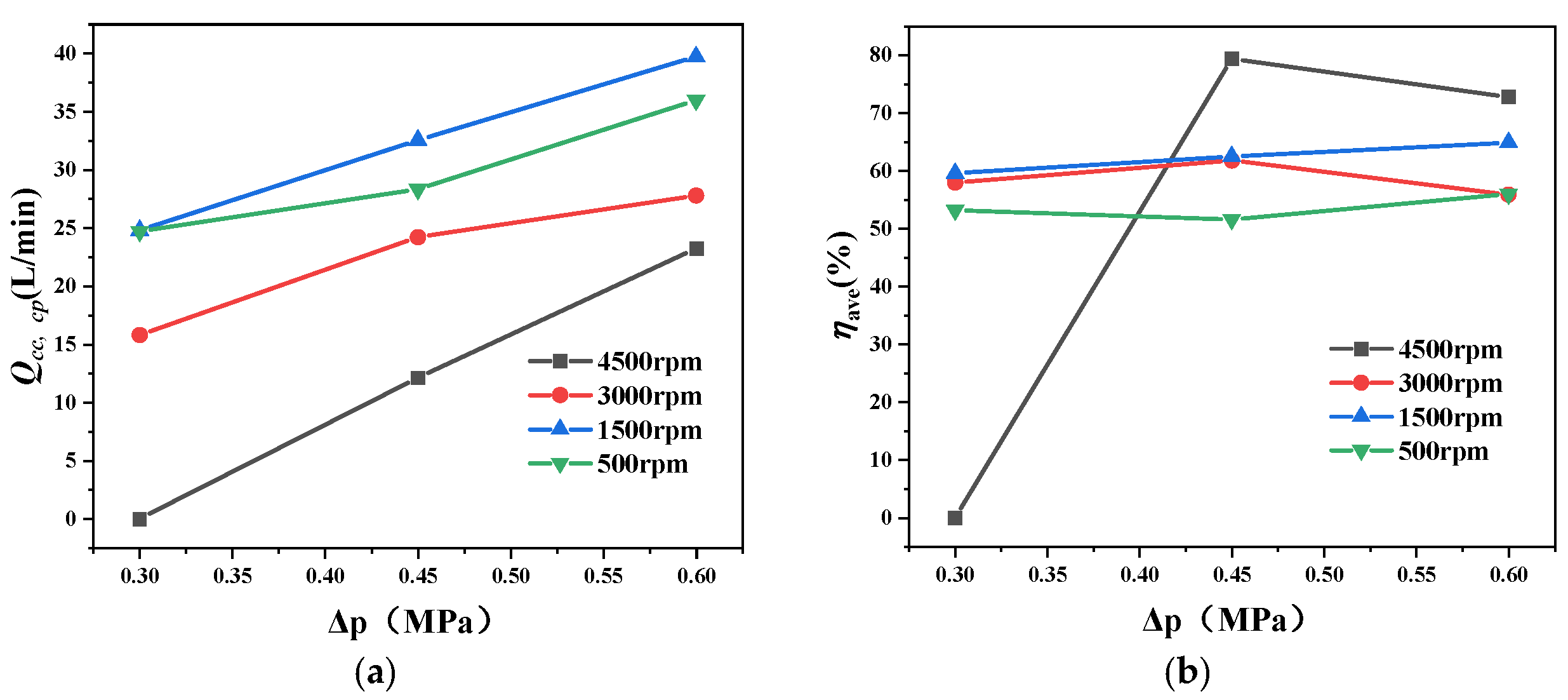

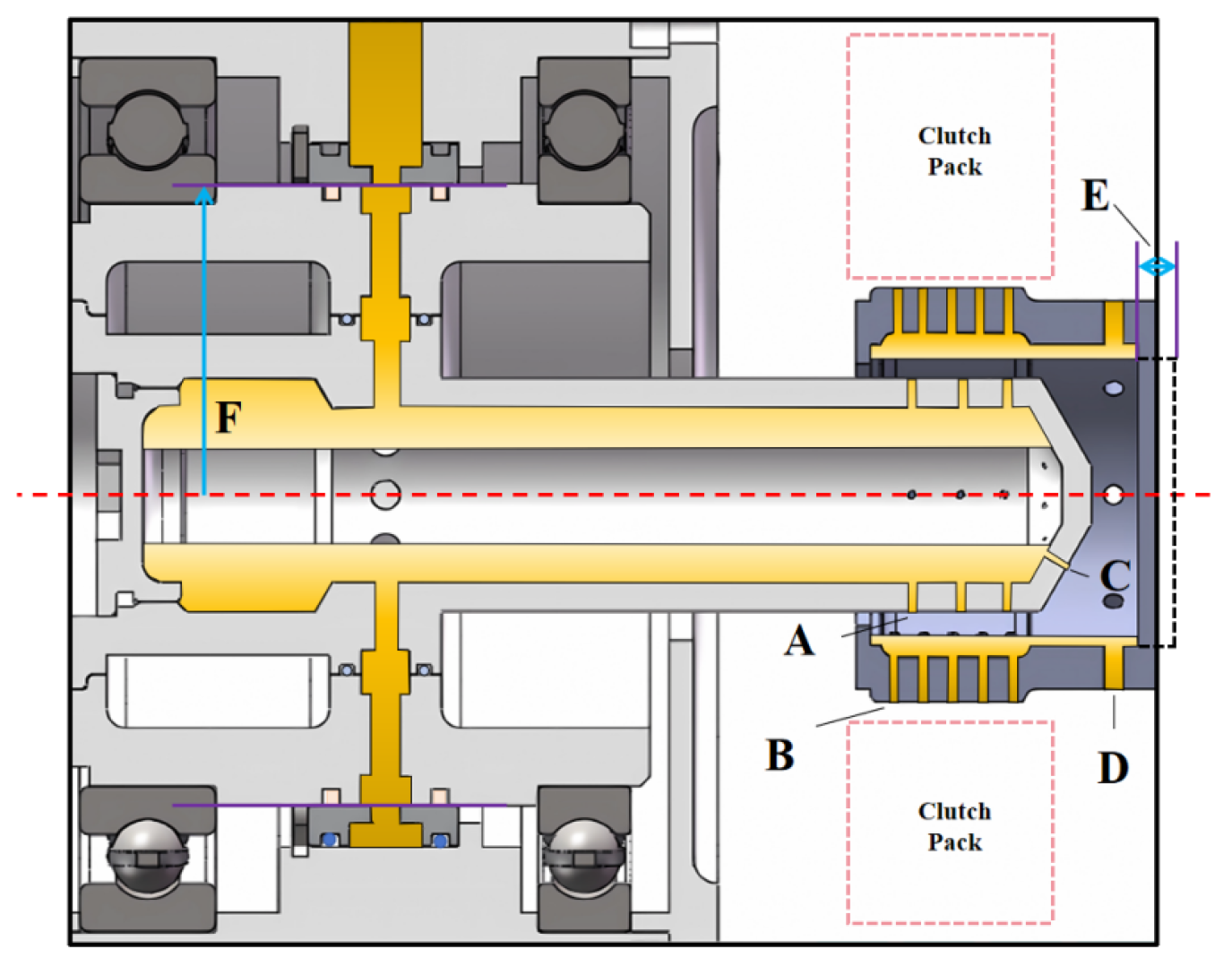

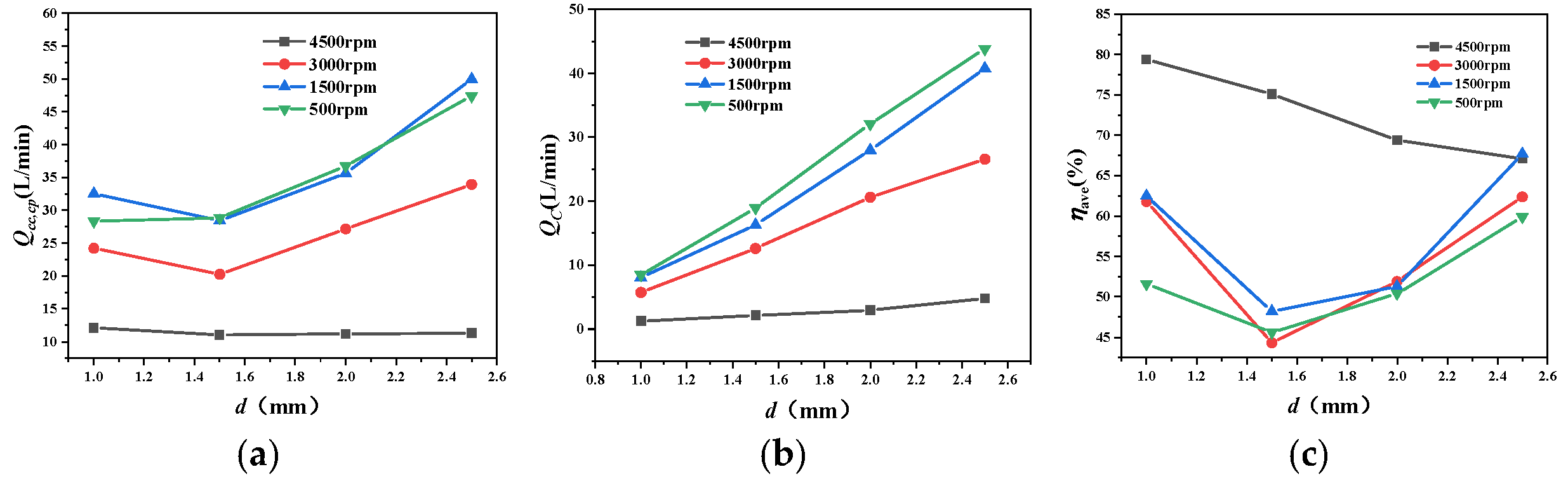

The parameters influencing the flow characteristics of the input unit are optimized as follows: A (Oil-slinging nozzle 1 diameter), B (Friction pair supply orifice diameter), C (Oil-slinging nozzle 2 diameter), D (Output shaft supply orifice diameter), E (Injection distance), and F (Input shaft radius), as illustrated in

Figure 9. The flow characteristics of a free liquid jet impacting a rotating disk are distance-dependent [

30,

31,

32]; hence, the oil injection distance E is introduced as an additional parameter. Considering structural mechanical strength requirements, the level values of the optimization parameters are specified in

Table 4.

To ensure sufficient oil supply capacity of the input unit structure, the following variables were designated as optimization objectives: friction pair oil collection flow rate (

), oil delivery efficiency (

), and input shaft interface pressure (

). Minimizing

is prioritized, as lower pressure indicates reduced flow resistance and facilitates dynamic pressure sealing.

Operational conditions for Taguchi orthogonal experiments were standardized at identical rotational speeds and oil pressure differentials. The design rated speed of 4800 rpm is critically important due to its minimum oil supply condition, while 85% of rated speed (4080 rpm) represents a frequently used operational point requiring focused attention. Weighted processing of results from both speeds was implemented according to operational significance, calculated as follows:

where

,

, and

denote the weighting coefficients for the friction pair oil collection flow rate, efficiency, and pressure at 4800 rpm, respectively. The values were chosen to reflect operational criticality, with

= 0.65 (prioritizing flow at rated speed),

= 0.40 (emphasizing efficiency at a key operational point), and

= 0.25 (constraining pressure).

Following Taguchi’s orthogonal array design principles, an L

27(3

6) matrix (6 factors, 3 levels) was implemented. Twenty-seven sets of simulations were conducted at both 4819 rpm and 4080 rpm. Finite element analysis computed the three optimization variables, with results statistically weighted and averaged as summarized in

Table 5.

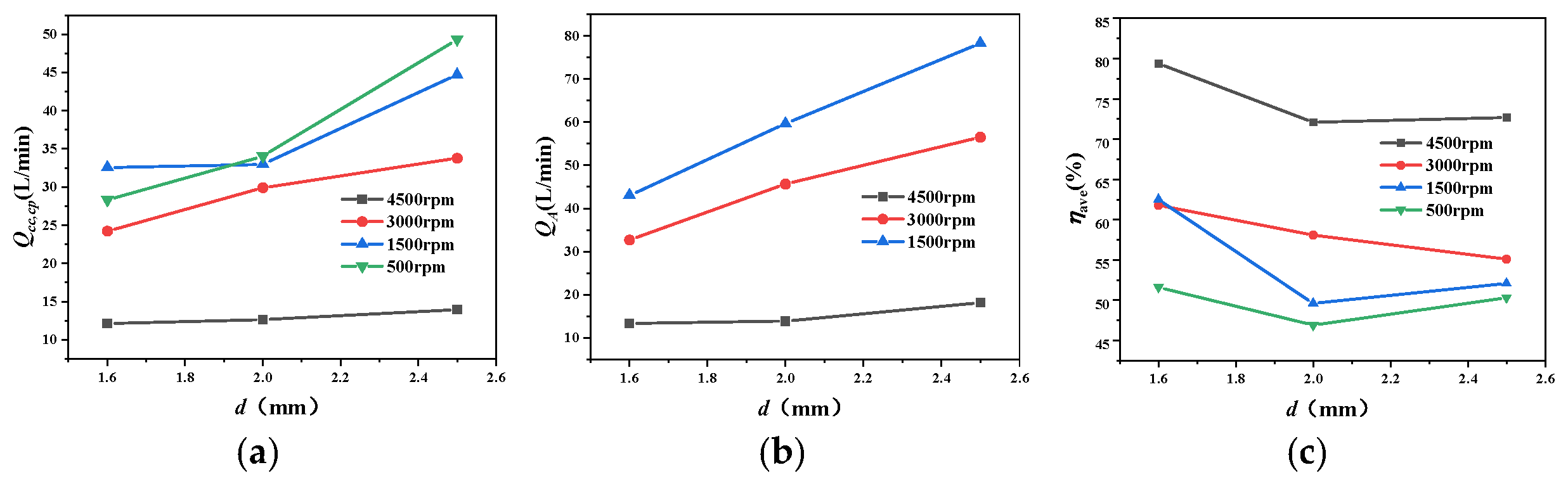

To compute the mean value m of an optimization objective under Level 1 of Parameter A, Equation (23) is applied. The mean values of each optimization objective across all parameter levels are illustrated in

Figure 16.

where

denotes the weighted friction pair oil collection flow rate in the

simulation at Level 1 of Parameter A.

Figure 15 identifies the parameter combinations maximizing each objective: A (3), B (3), C (3), D (1), E (1), F (1) for

; A (1), B (3), C (2), D (1), E (1), F (2) for

; and A (1), B (1), C (1), D (2), E (2), F (3) for

. Analysis of variance (ANOVA) and multiple linear regression evaluated parameter significance. Using Parameter A’s adjusted sum of squares (Adj SS), adjusted mean square (Adj MS), and F-value as examples (Equations (24)–(28)), the proportional influence of each parameter on optimization objectives was calculated, with results detailed in

Table 6 and

Table 7 (showing Adj SS, DF, and

p-value).

where

denotes the number of levels for Factor A (here

)

represents the sum of all

values at the

level of Factor A

indicates the occurrence count of Factor A at level i (here

)

is the grand sum of all

values

N signifies the total number of experiments (N = 27).

The degrees of freedom for Factor A (

) equal k − 1 (i.e.,

).

The adjusted mean square error (

) is calculated via Equation (22),

The total sum of squares (Total SS) is computed using Equation (23), where

denotes the

weighted flow rate value.

For Parameter E, one-way ANOVA performed on each optimization objective yielded p-values exceeding 0.05 in all three cases, indicating statistically insignificant influence on the objectives. Consequently, this parameter was excluded from the multiple linear regression model and fixed at Level 1 (0 mm), which maximizes flow rate and efficiency.

The impact proportion of each parameter is analyzed through ANOVA calculations. A larger Adjusted Sum of Squares (Adj SS) indicates that the parameter contributes more significantly to the variation in the optimization objective, implying a greater degree of influence. A p-value < 0.05 indicates that the parameter’s effect on the optimization objective is statistically significant; otherwise, there is insufficient evidence to conclude significance.

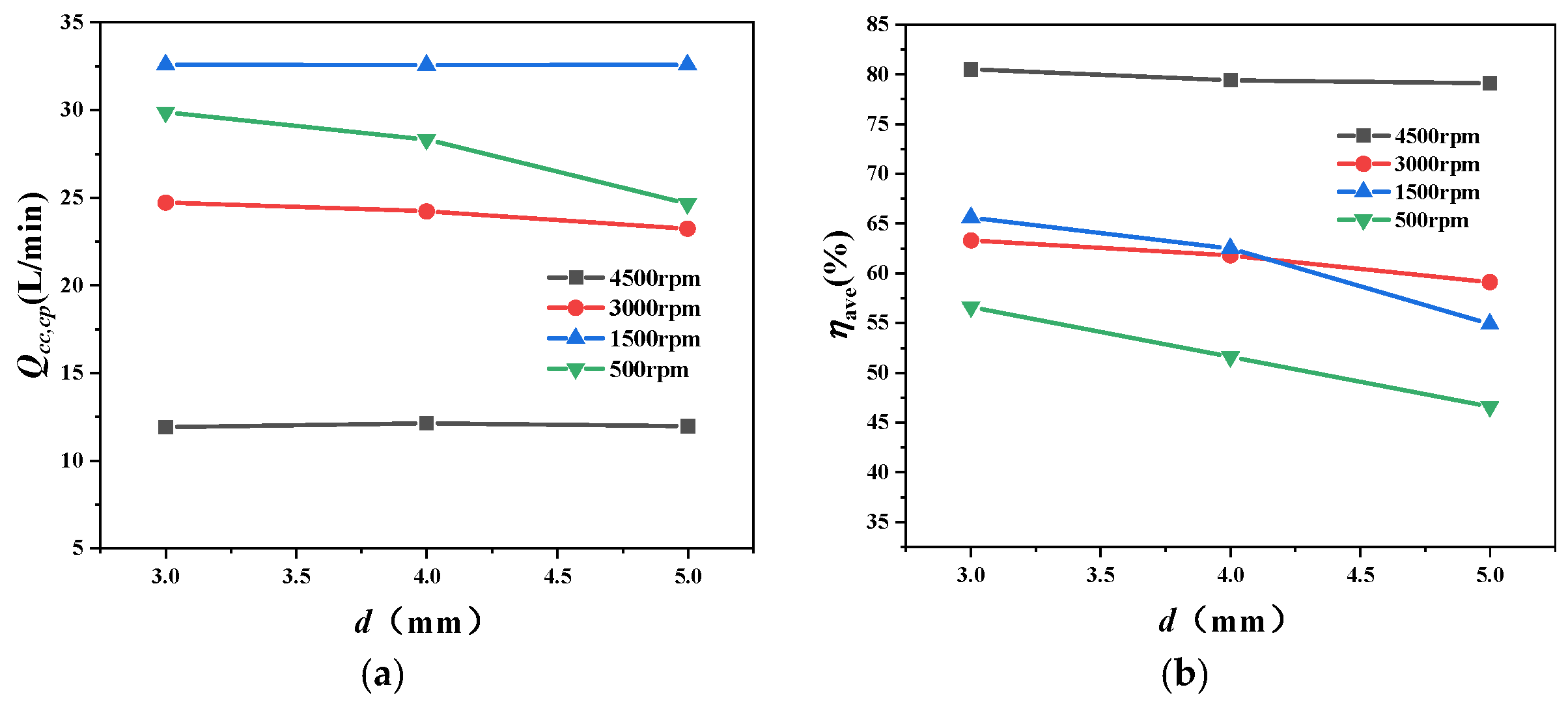

For the weighted friction pair oil collection flow rate (

), parameters C and D have p-values greater than 0.05, indicating their influence is not significant, and the ranking of parameter influence magnitude is F > A > B > (C, D). For the weighted oil delivery efficiency (

), the influence of parameter C is not significant, and the ranking is B > D > F > A > (C). For the weighted input shaft interface pressure (

), the influence of parameters B and D is not significant, and the ranking is F > A > C > (B, D). It is evident that for each optimization objective, parameters F, A, and B exhibit significantly higher influence magnitudes than C and D. Therefore, parameters F, A, and B will be the focus for further optimization. Since parameter D has a relatively significant influence on the optimization target (particularly efficiency), it is fixed at Level 1 (3 mm), the value yielding the highest efficiency based on average calculation results. Simultaneously, as parameter C significantly impacts the interface pressure, it is fixed at Level 3 (2 mm), the value resulting in the lowest interface pressure.

4.2.2. Response Surface Methodology

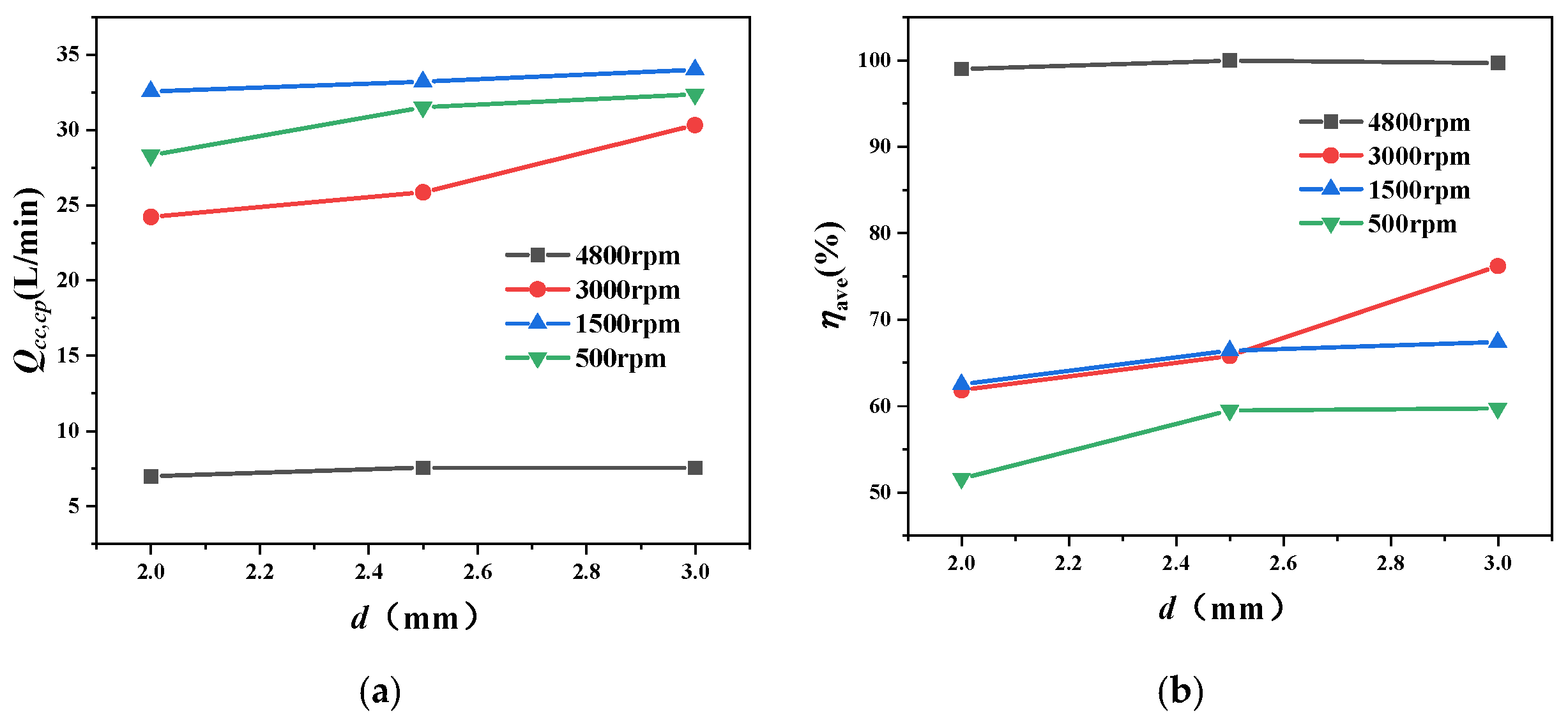

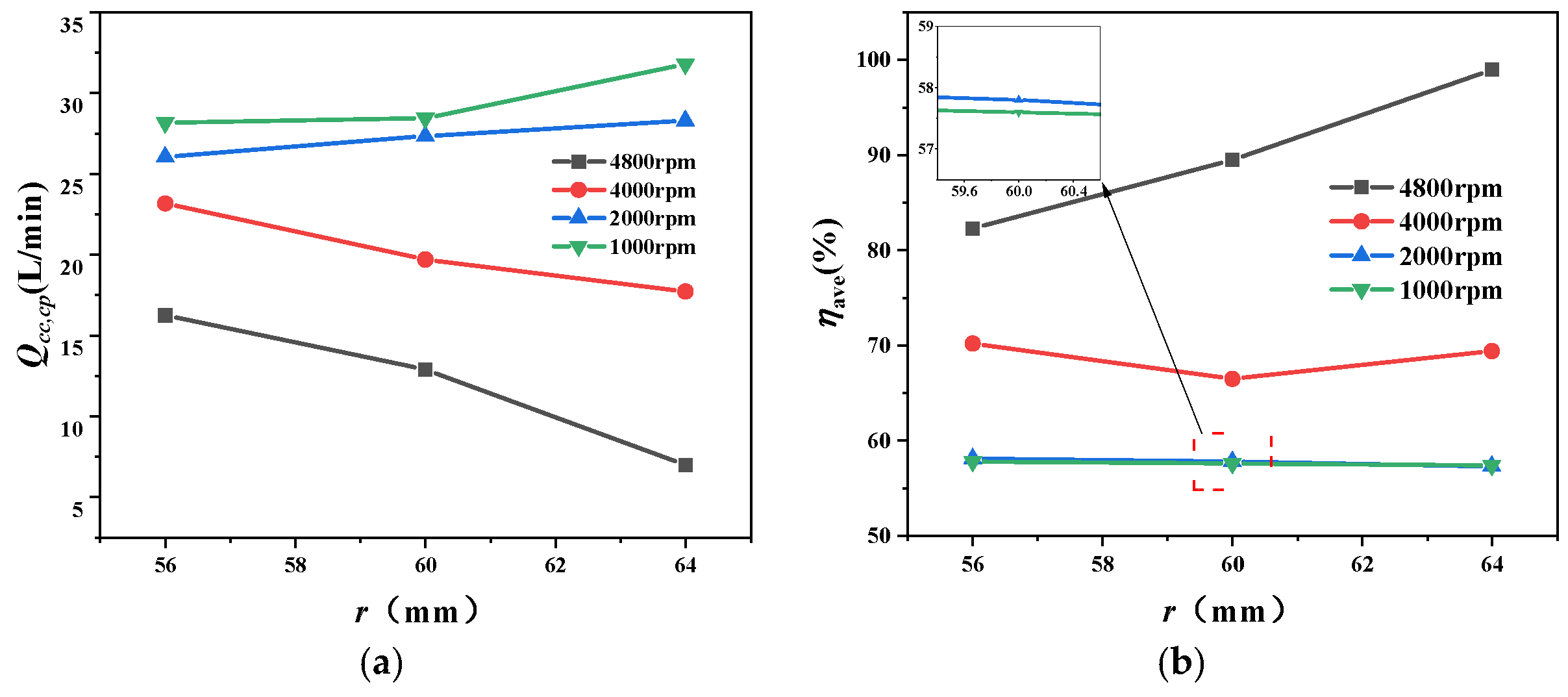

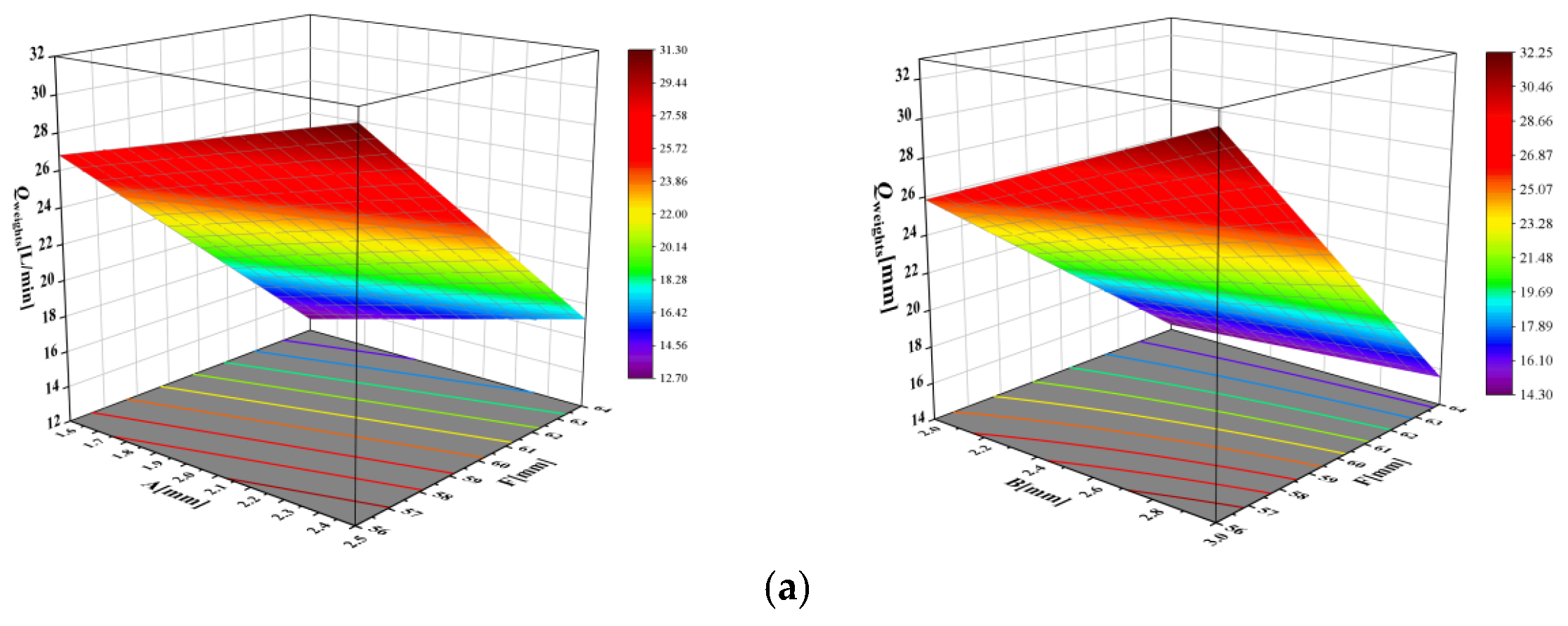

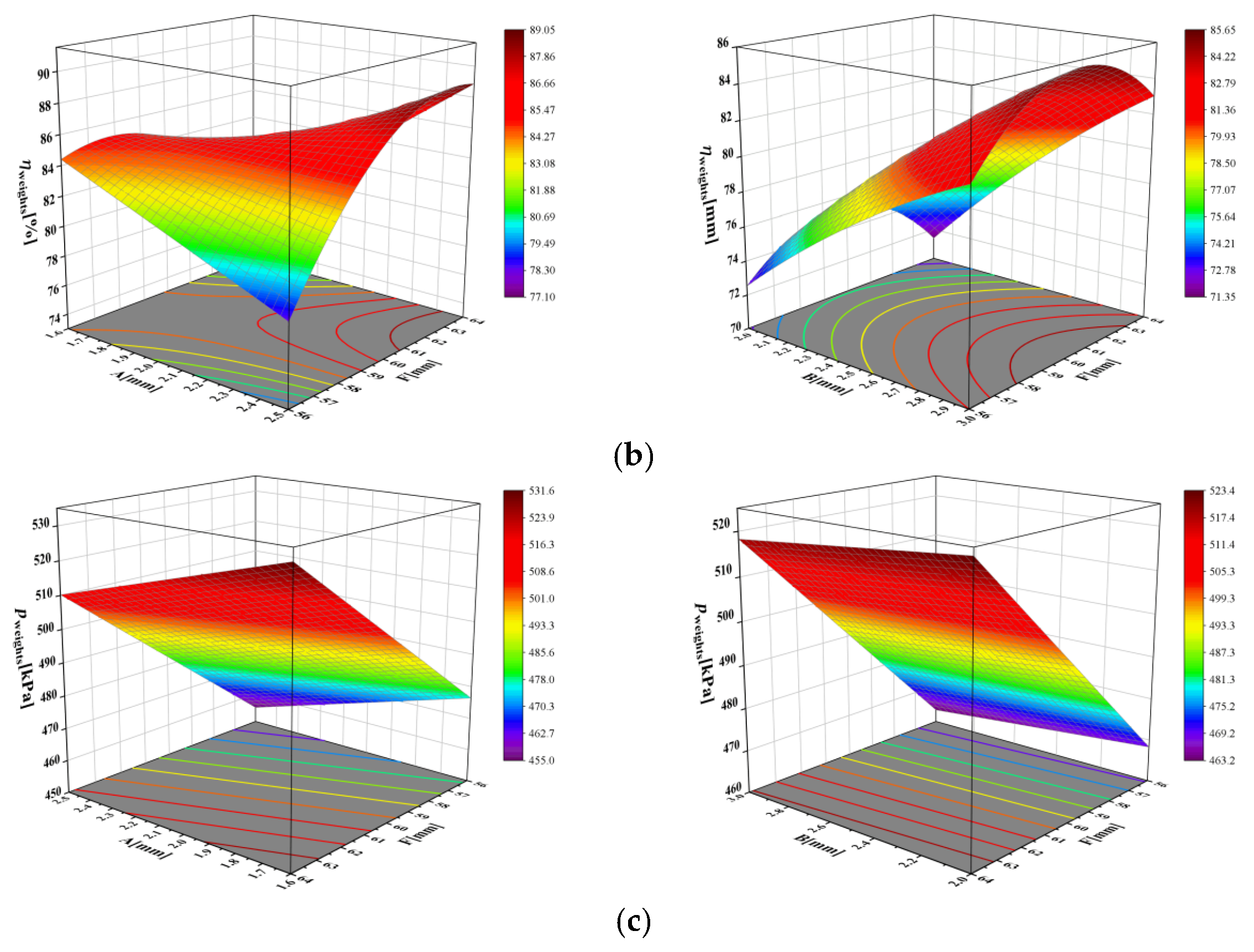

Response Surface Methodology (RSM) was employed to intuitively visualize the influence trends of the optimized parameters (F, A, B) on the objectives, enabling further refinement to obtain the optimal parameter combination. RSM primarily includes Central Composite Design (CCD) and Box–Behnken Design (BBD) methods. Considering the number of parameters and their levels, the BBD method was utilized. The level values for each optimization parameter are shown in the corresponding table. Each parameter’s three level values were coded as −1, 0, and 1 from low to high, where −1 and 1 represent the lower and higher-level values, respectively; the correspondence between codes and actual values is detailed in

Table 8. Accounting for differences across rotational speeds, 17 speed values were designed for both 4000 rpm and 4800 rpm. The results for the three optimization objectives (

,

,

) were obtained through weighted averaging. The response surface simulation results are presented in

Figure 17.

Figure 17 indicates that orifice diameter B and shaft radius F significantly influence the oil collection flow rate, showing positive and negative correlations, respectively. Effects on efficiency are nonlinear: parabolic with F, synergistic with simultaneous increases in F and A, and positive with B. Interface pressure negatively correlates with A and positively with F. To maximize flow rate and efficiency while minimizing pressure, the optimized parameters are: F = 60 mm (balanced value), A = 2.5 mm (maximized), B = 3 mm (maximized), as specified in

Table 9. This combination reflects design trade-offs among competing objectives. These optimized values translate directly into practical design guidelines: maximize critical orifice diameters (A, B) to enhance flow capacity, select an intermediate shaft radius (F) to balance centrifugal effects, and fix secondary parameters (C, D) at values that prioritize key performance metrics. This approach provides a validated framework for designing high-performance centrifugal oil supply systems.

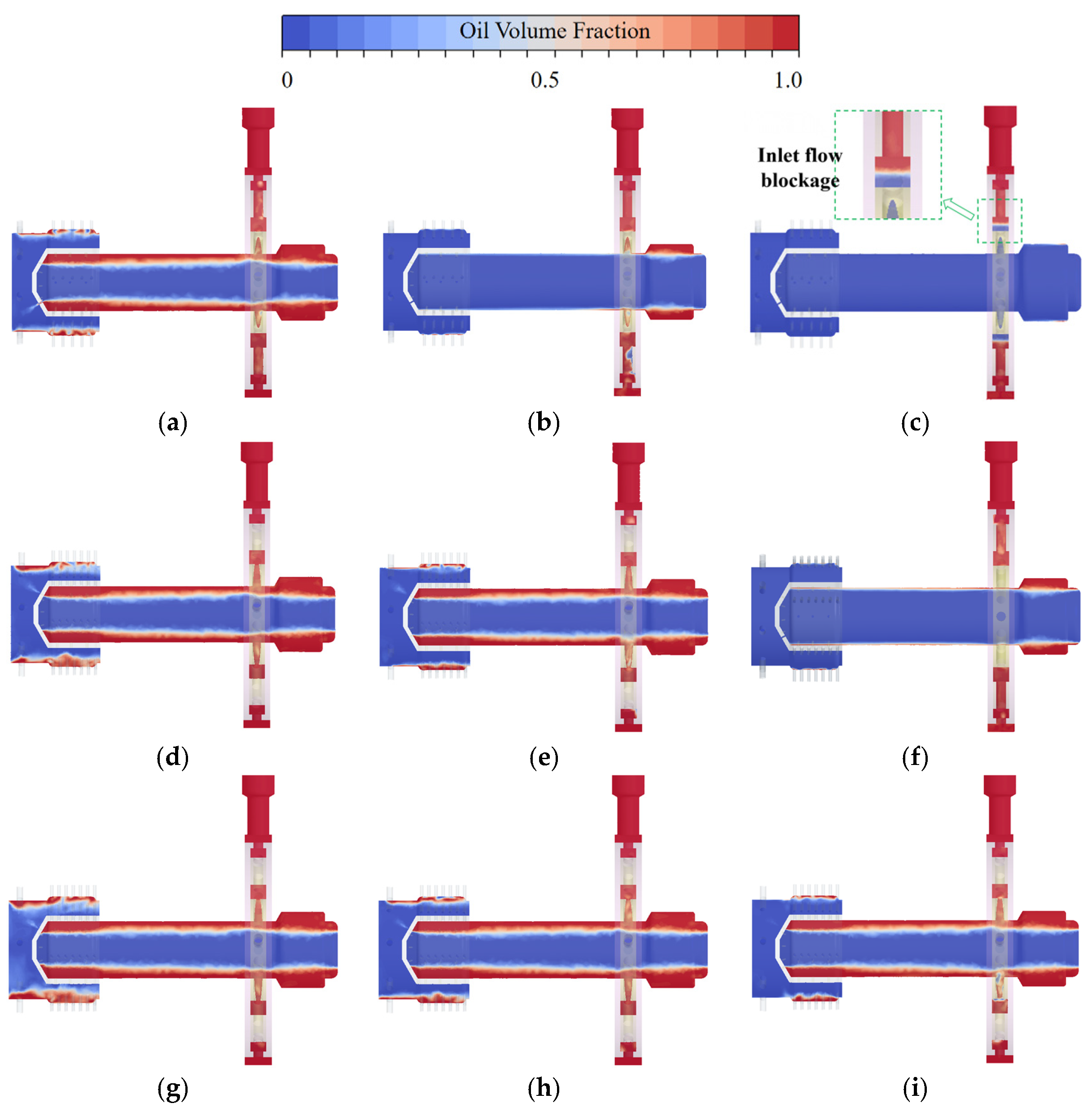

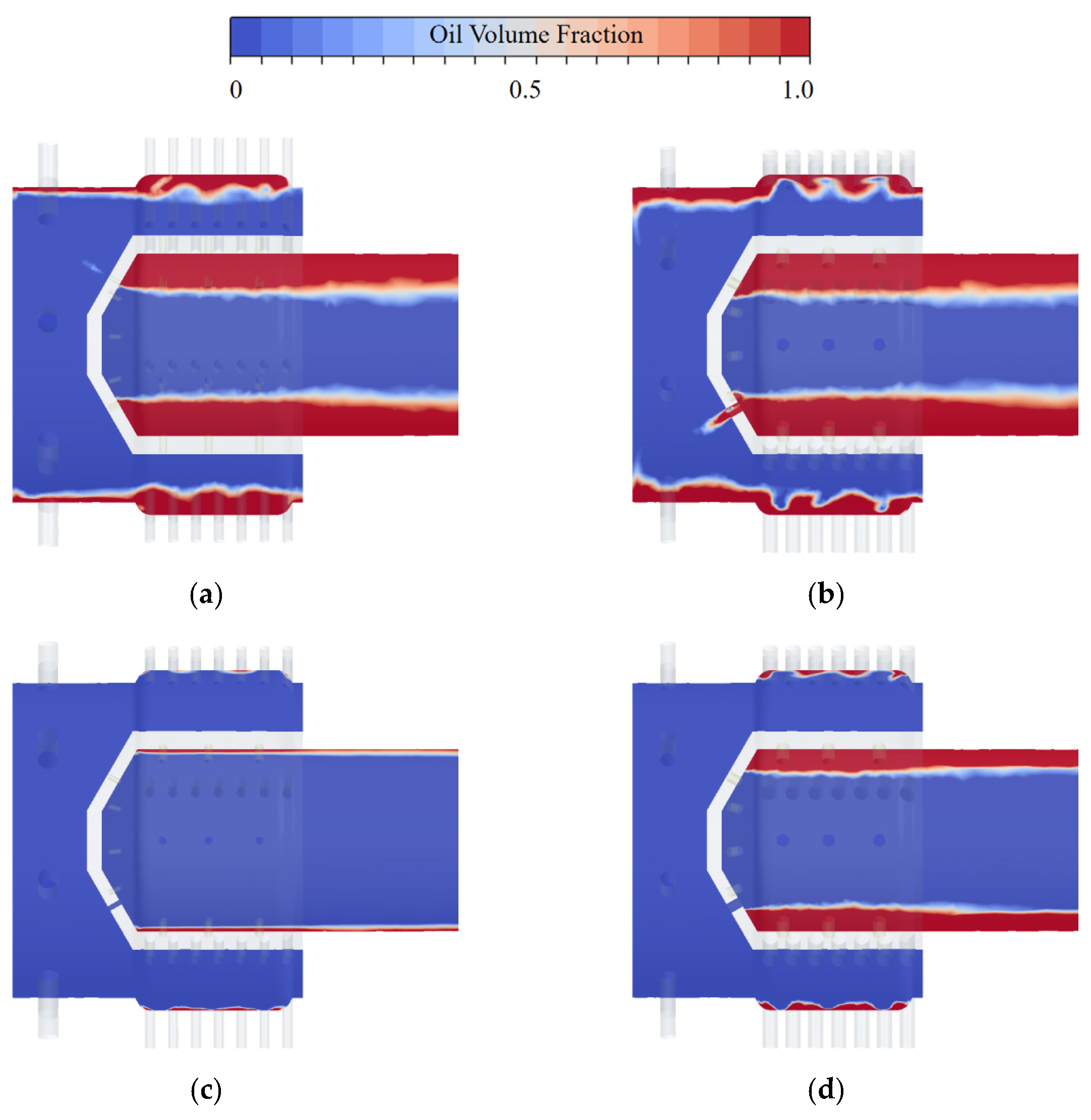

Optimized oil–air distribution is shown in

Figure 18. At both critical speeds of 4800 rpm and 4080 rpm, the optimized structure significantly increases the liquid level height within the oil-slinging nozzle and enhances the oil flow capacity of the friction pair supply orifice. Concurrently, it reduces the maximum total pressure at the rotor–stator interface, thereby lowering the difficulty of maintaining dynamic pressure sealing. Specific values are detailed in

Table 10.