The Mechanism of a High Fluid Pressure Differential on the Sealing Performance of Rotary Lip Seals

Abstract

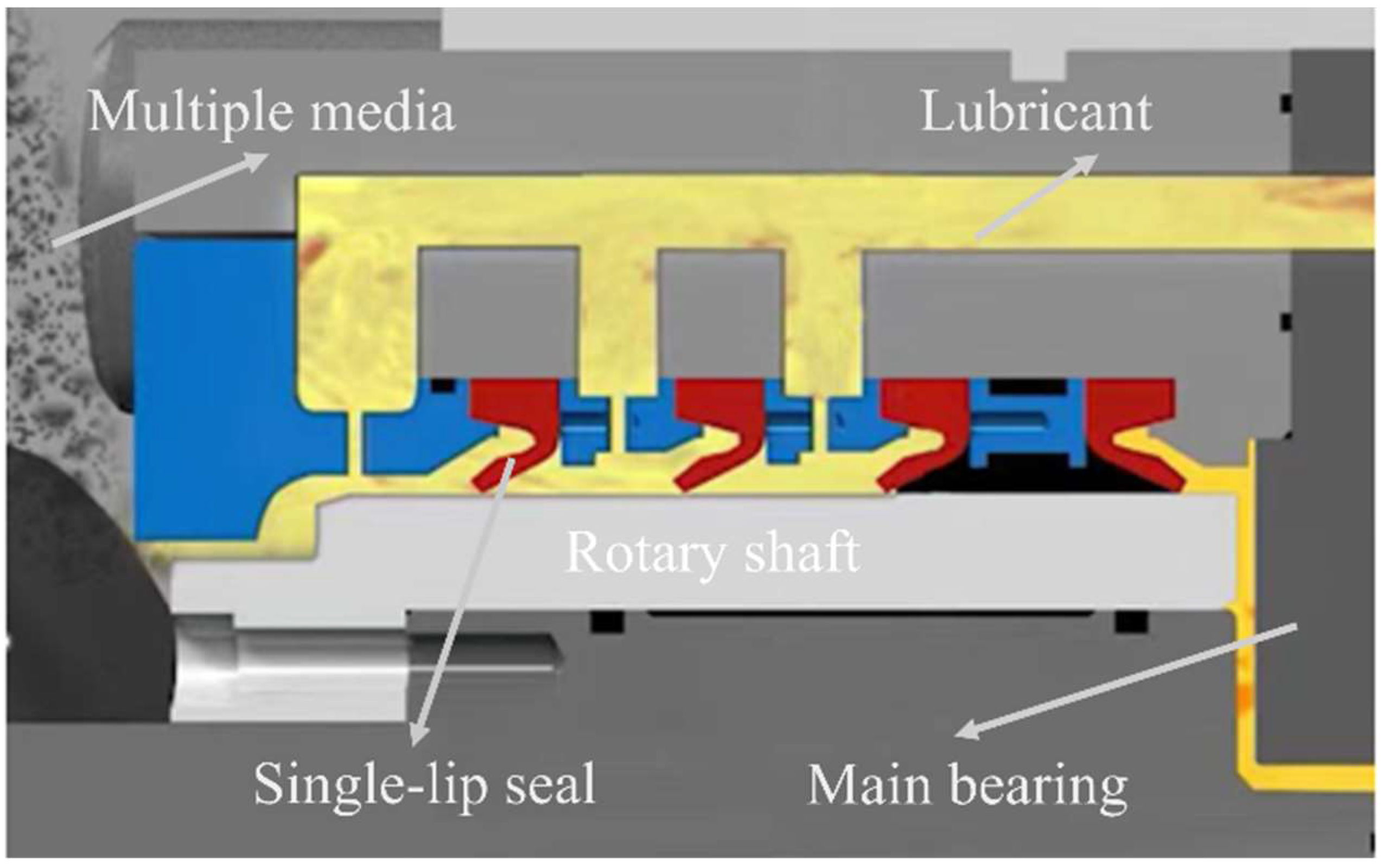

1. Introduction

2. Modeling of MTHL

- (1)

- The lubricant is modeled as an incompressible Newtonian fluid, exhibiting laminar flow characteristics in the sealing region.

- (2)

- The rotary lip seal functions consistently at a uniform velocity.

- (3)

- The thickness of the lubricant film has no influence on the overall deformation of the single-lip seal.

- (4)

- The rotary shaft is entirely smooth, and the single-lip seal’s surface asperity exhibits a Gaussian distribution along the axial direction, with a periodic arrangement in the circumferential orientation.

- (5)

- The effects of viscoelasticity on the single-lip seal, fluid inertia, gravity, and the lubricant film’s curvature are ignored.

- (6)

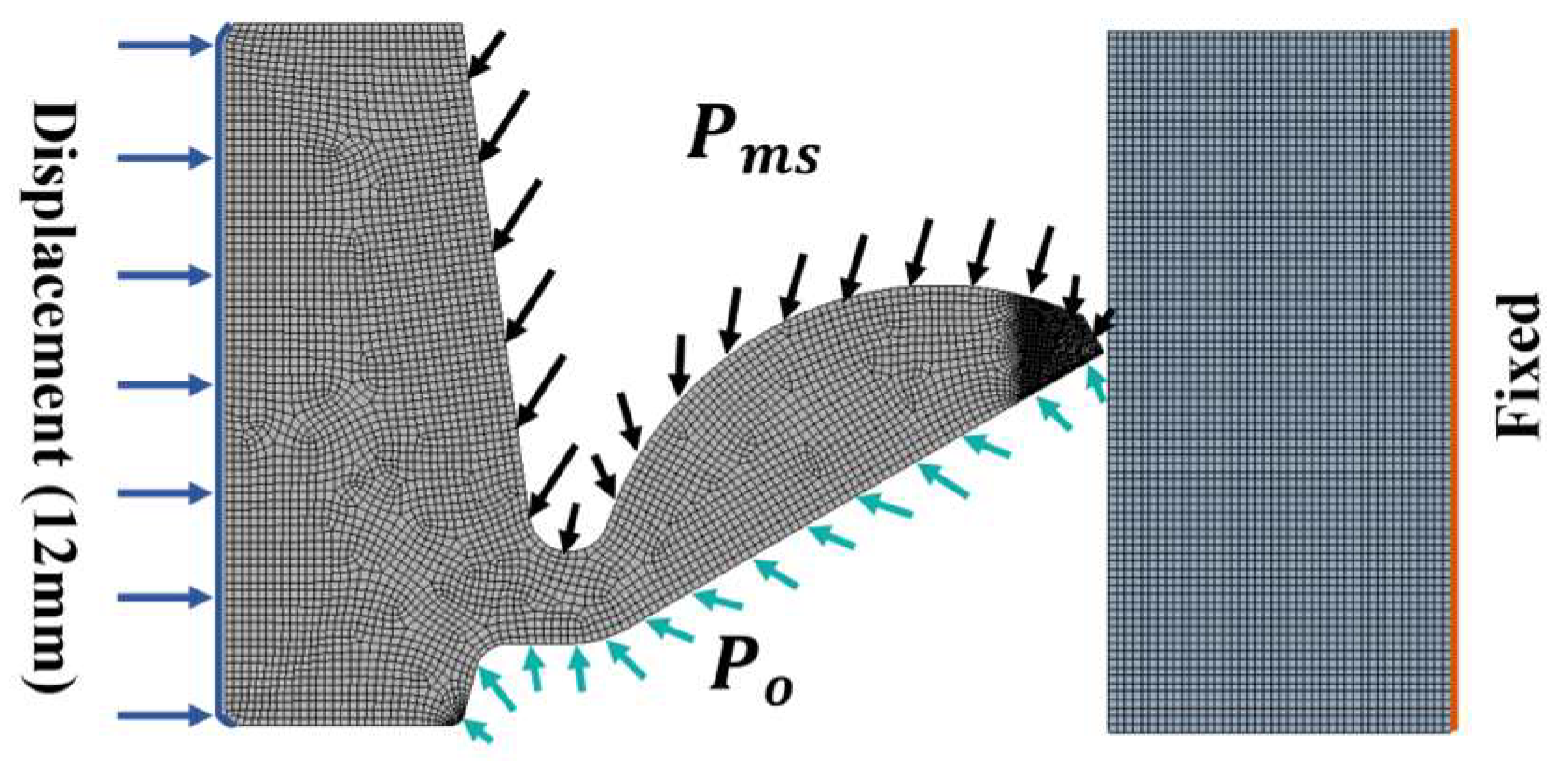

- Considering the axial symmetry of both the geometry and loads, the rotary lip seal is modeled as a two-dimensional (2D) axisymmetric finite element system.

2.1. Service Conditions

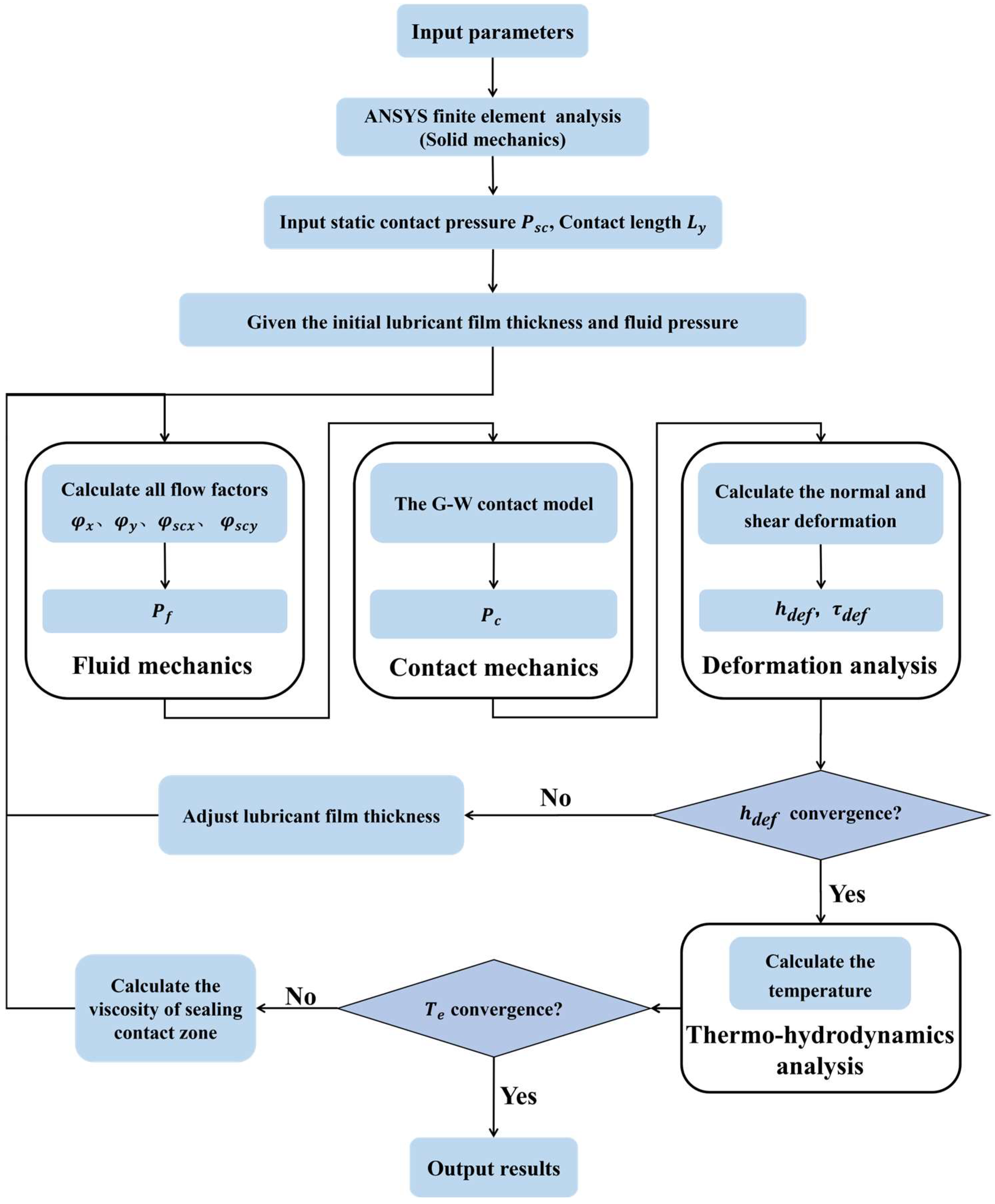

2.2. Process of MTHL Model

- (1)

- The operational data is input and ANSYS 2022 is utilized to determine the contact length and static contact pressure, .

- (2)

- The initial lubricant film and fluid pressures are set; then the hydrodynamic fluid pressure and asperity contact pressure are determined through calculations in fluid mechanics analysis and contact mechanics analysis, respectively.

- (3)

- The normal deformation magnitude () is determined via deformation analysis, and the lubricant film thickness is iteratively adjusted until the convergence criterion of 0.01 mm for is satisfied.

- (4)

- Through calculations involving viscous friction and asperity contact friction, the temperature within the sealing zone is ascertained, and subsequently, the lubricant viscosity corresponding to this temperature is derived. This process is repeated iteratively until the temperature error () fulfills the convergence criteria (1 °C), signifying the end of the computational process.

- (5)

- The essential sealing performance metrics are presented: the torque due to friction and the rate of reverse pumping.

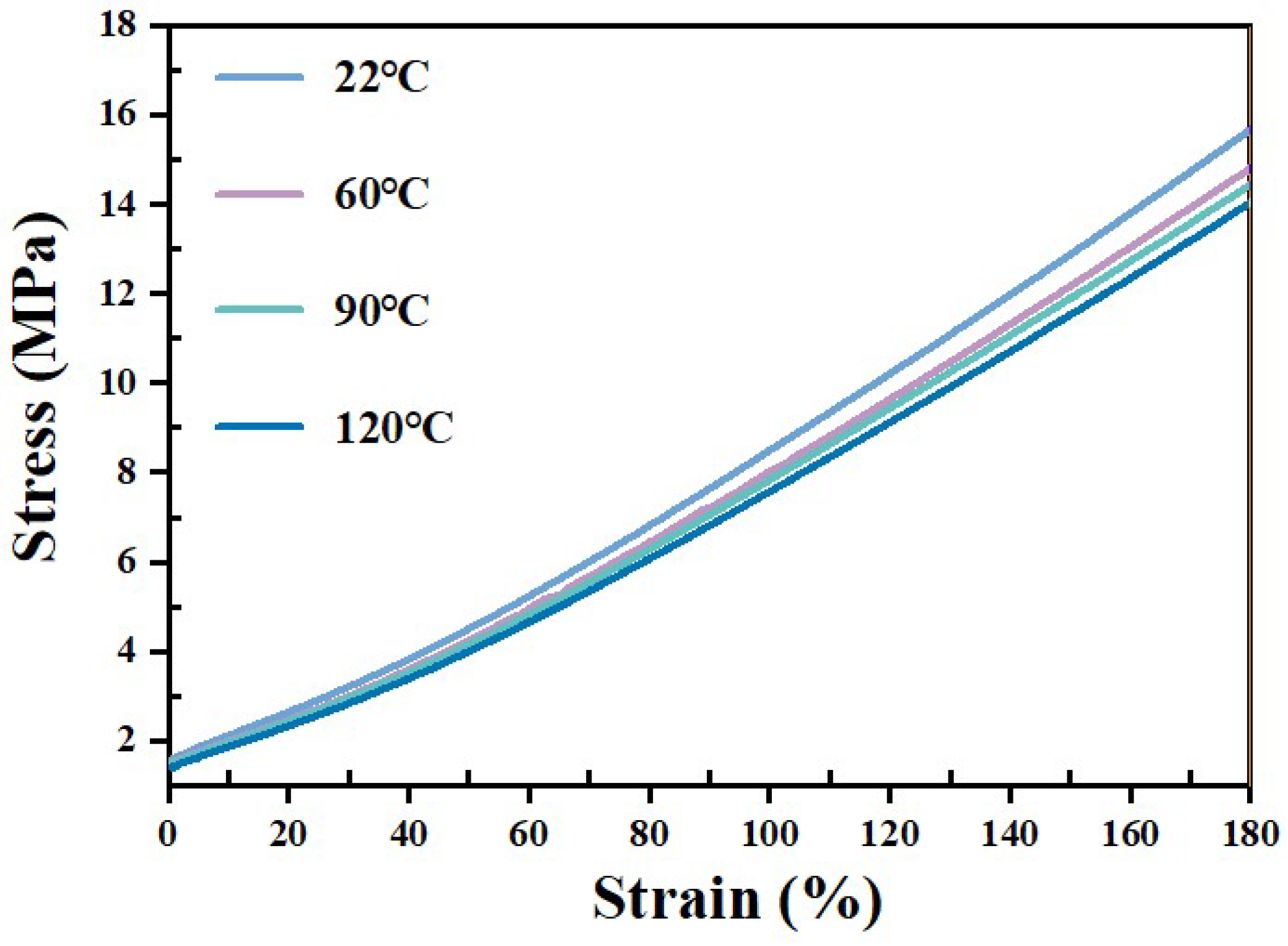

2.3. Solid Mechanics

3. Results and Discussion

3.1. Model Validation

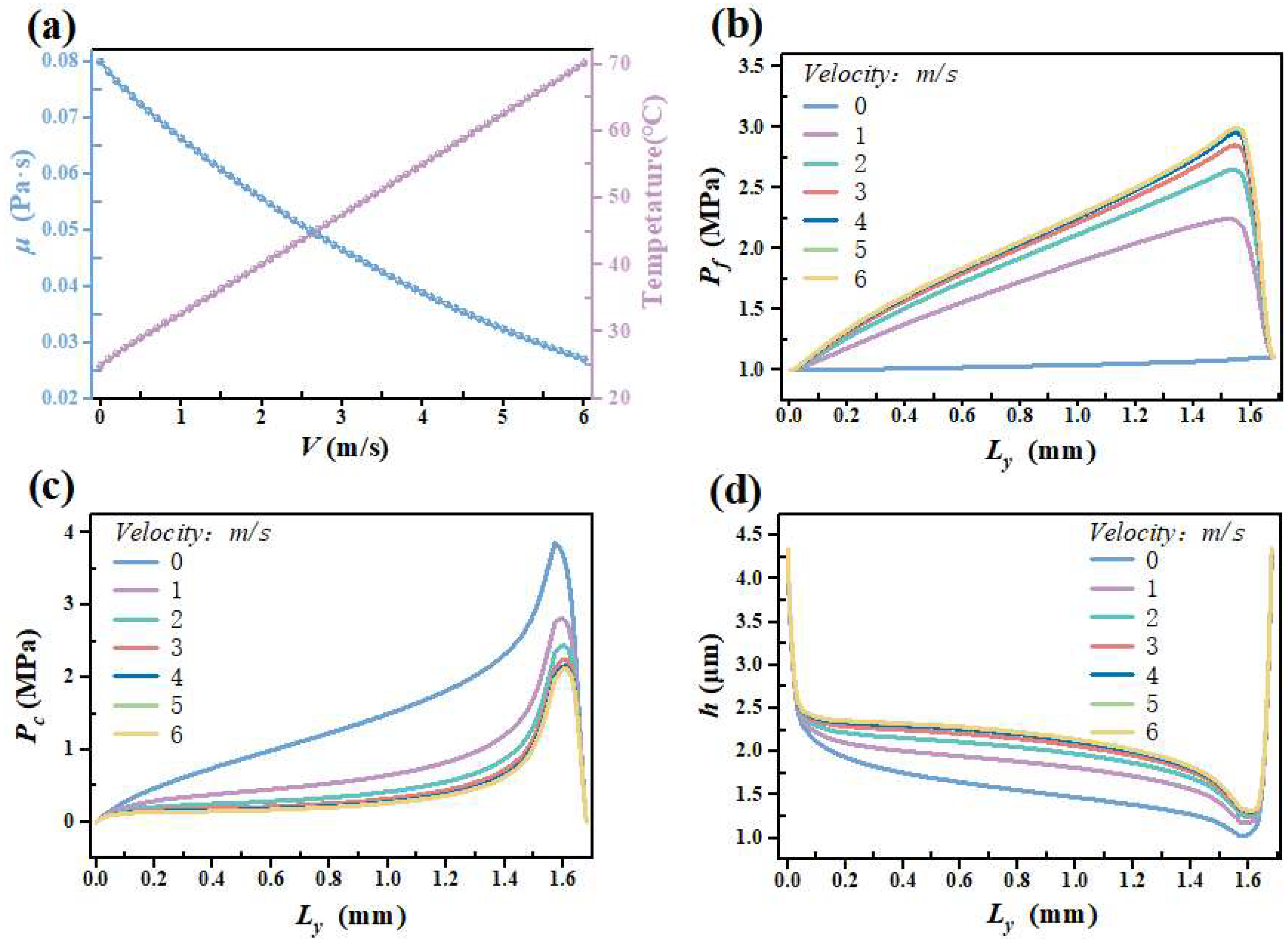

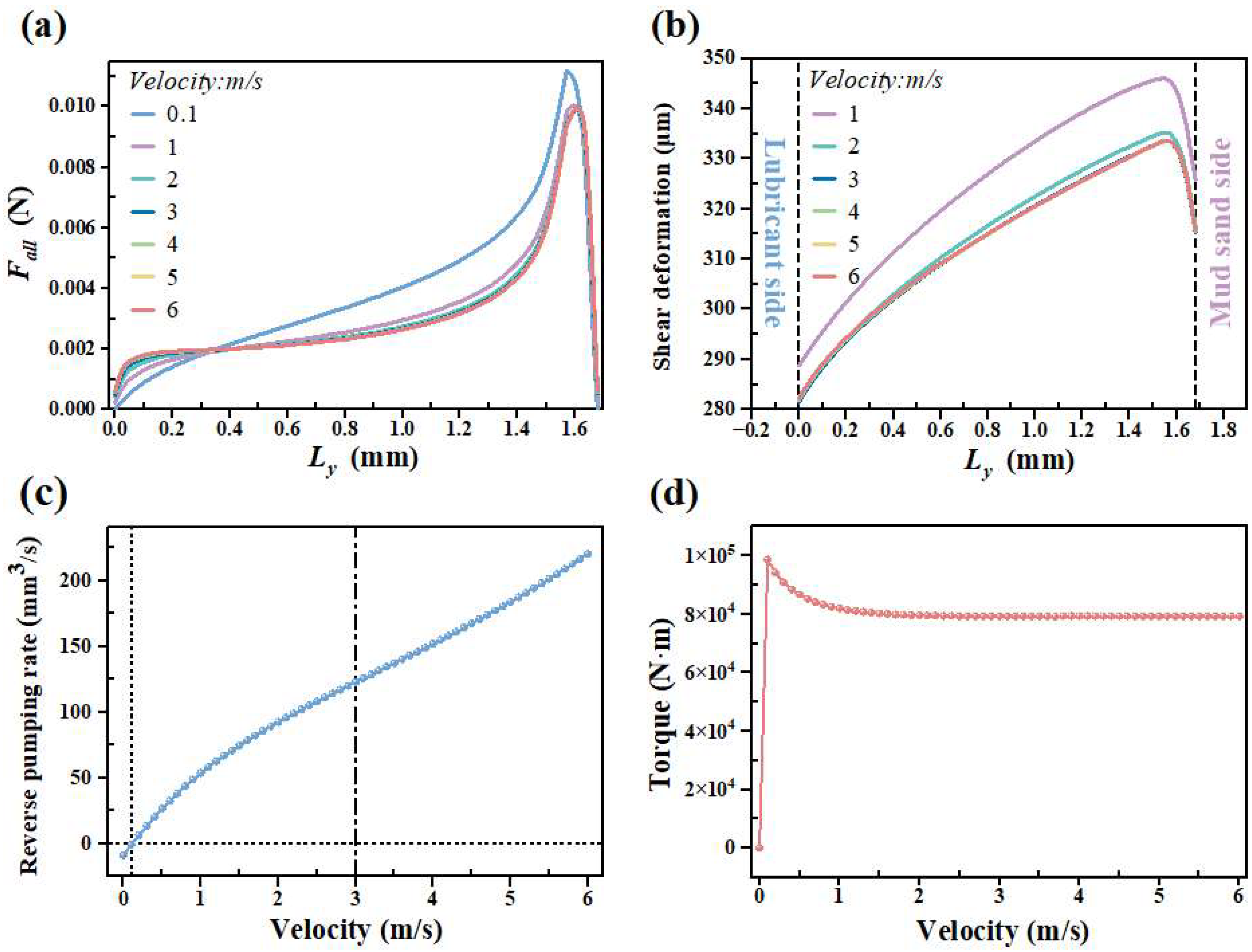

3.2. Effect of Velocity

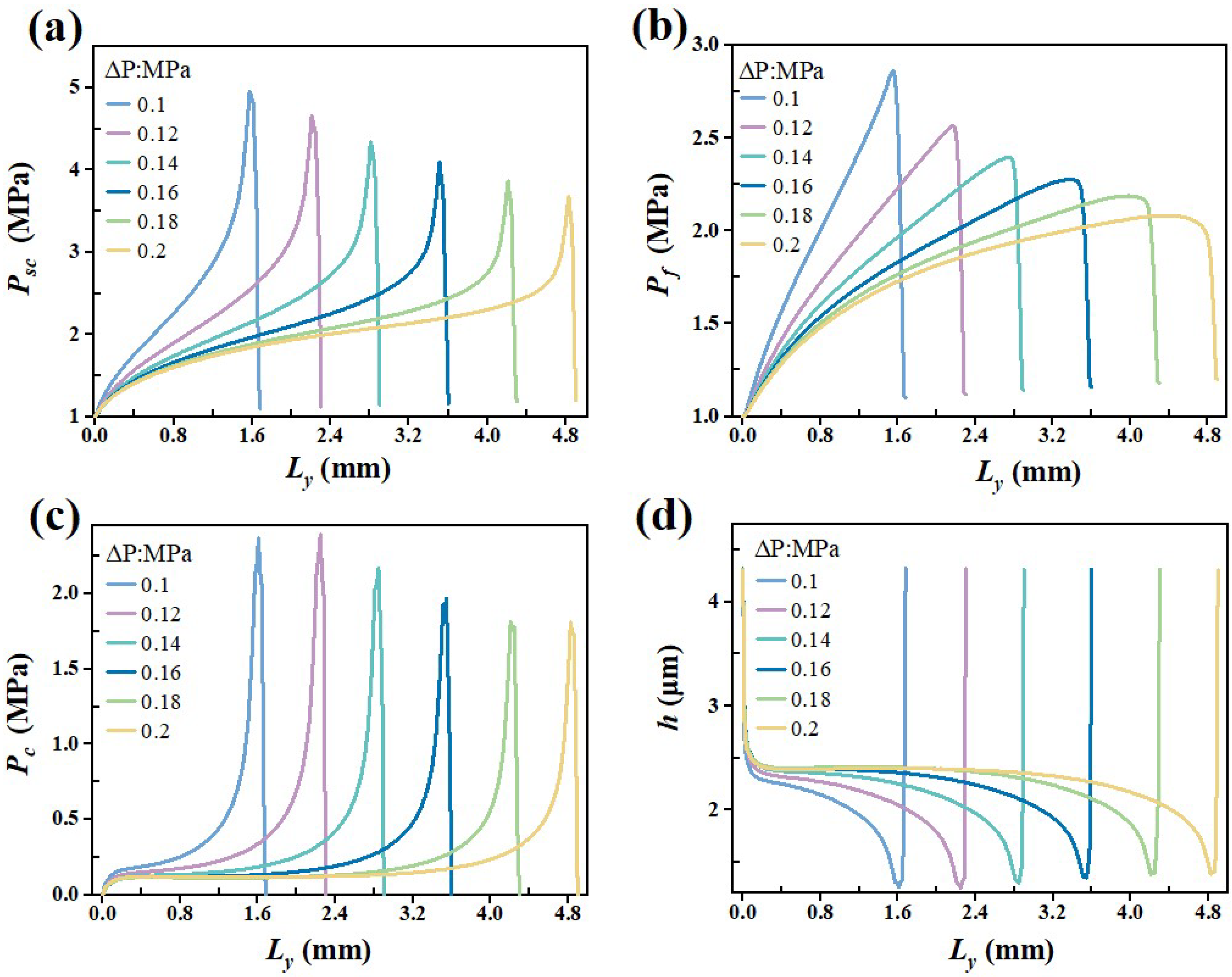

3.3. Effect of Fluid Pressure Differential

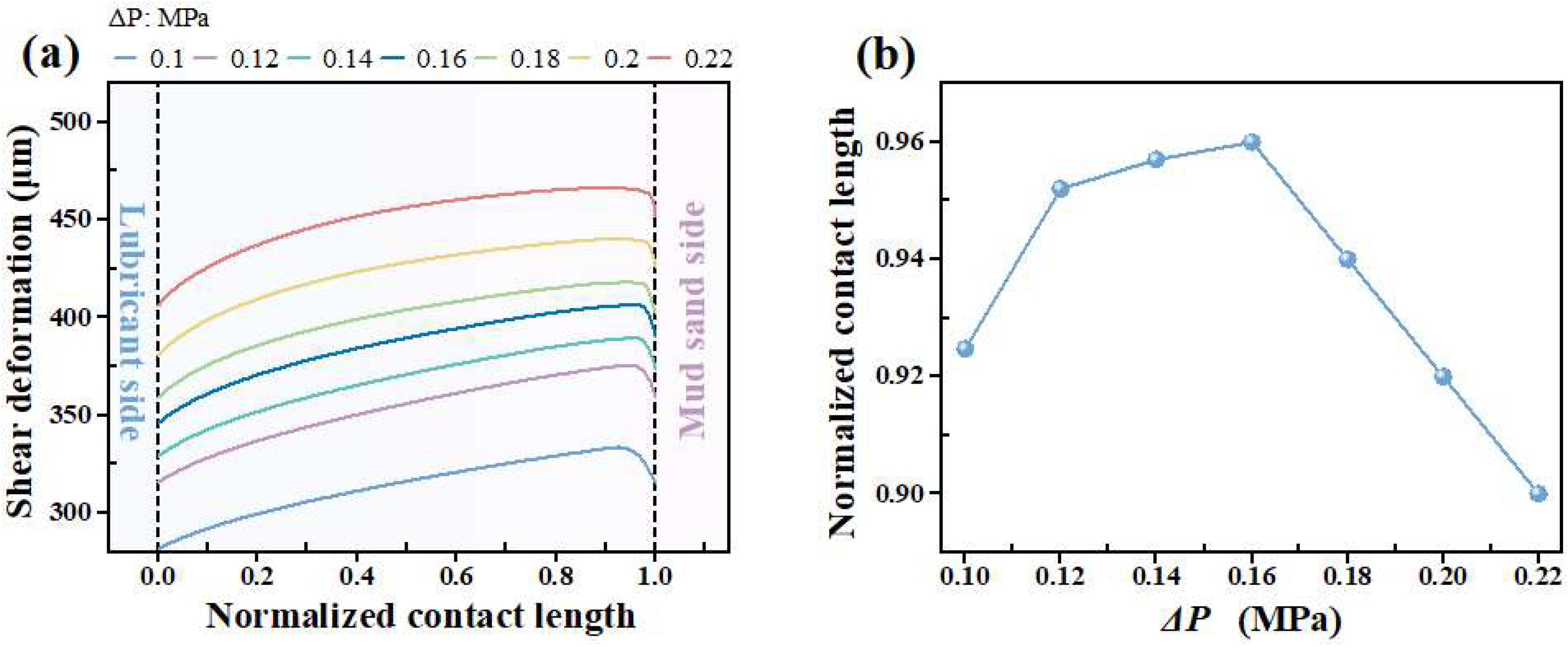

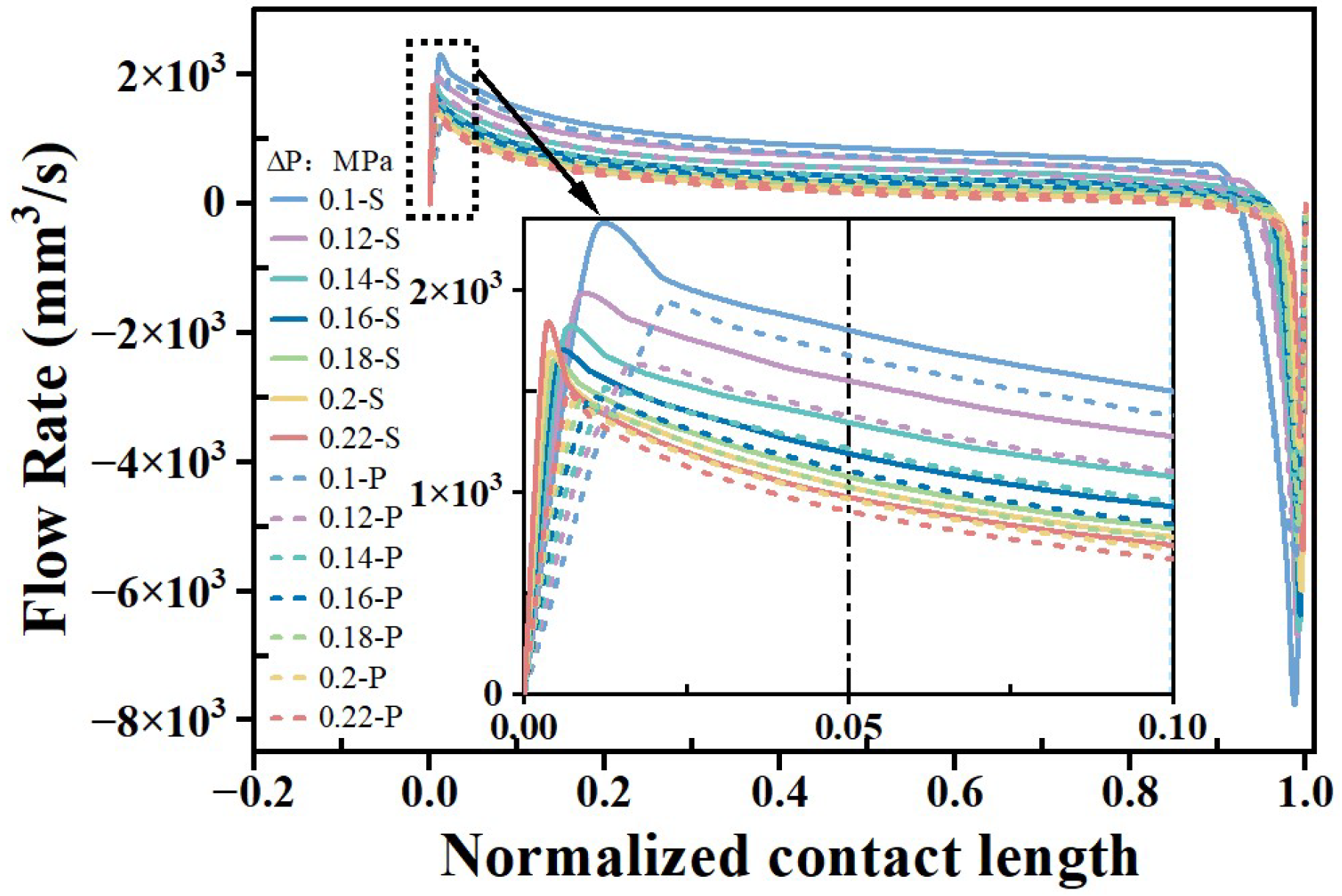

4. Conclusions

- As speed increases, the peak shear deformation shifts nearer to the mud sand side and the rate of reverse pumping increases markedly, which aligns with the classical reverse pumping mechanism. Meanwhile, the torque due to friction first rises sharply, then decreases, and finally stabilizes.

- As the fluid pressure differential increases, the friction torque exhibits a gradual increasing trend. The reverse pumping rate demonstrates a pattern of an initial increase, followed by a decrease, and then a subsequent increase. Meanwhile, the axial position of the maximum shear deformation of the rotary lip seal first moves closer to the mud sand side (0.1–0.16 MPa) and then moves away from the mud sand side (0.16–0.22 MPa). This phenomenon cannot be explained by the classical reverse pumping mechanism.

- The MTHL model established in this paper separately calculates the flow rates generated by shear flow and pressure flow. By comparing the relative magnitude of these two flow rates, it reasonably predicts the sealing performance, thus supplementing the classical reverse pumping mechanism. This also provides critical insights for optimizing seal performance under varying operational conditions.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hand, B.P.; Erdogan, N.; Murray, D.; Cronin Doran, P.J.; Murphy, J. Experimental testing on the influence of shaft rotary lip seal misalignment for a marine hydro-kinetic turbine. Sustain. Energy Technol. Assess. 2022, 50, 101874. [Google Scholar] [CrossRef]

- Jagger, E.T. Rotary shaft seals: The sealing mechanism of synthetic rubber seals running at atmospheric pressure. Proc. Inst. Mech. Eng. 1957, 171, 597–616. [Google Scholar] [CrossRef]

- Hirano, F.; Ishiwata, H.; Kambayashi, H. Friction and Sealing Characteristics of Oil Seals. Available online: https://cir.nii.ac.jp/crid/1572824499808583168?lang=en (accessed on 16 July 2025).

- Kuzma, D.C. Theory of the mechanism of sealing with application to face seals. J. Lubr. Technol. 1969, 91, 704–712. [Google Scholar] [CrossRef]

- Kawahara, Y.; Abe, M.; Hirabayashi, H.; Matsushima, A. Effect of Surface Condition of Lip on Sealing Phenomena of Oil Seals; No. 780405; SAE International: Warrendale, PA, USA, 1978. [Google Scholar] [CrossRef]

- Kawahara, Y.; Abe, M.; Hirabayashi, H. An analysis of sealing characteristics of oil seals. Tribol. Trans. 1980, 23, 93–102. [Google Scholar] [CrossRef]

- Qian, D.S. The sealing mechanism and design factors of radial lip seals for crankshafts. Intern. Combust. Engine Eng. 1984, 5, 10–13. [Google Scholar] [CrossRef]

- Kammuller, M. On the Sealing Mechanism of Radial Shaft Seals. Ph.D. Thesis, Technical University of Munich, München, Germany, 1986. Available online: https://puma.ub.uni-stuttgart.de/bibtex/36b18ec71004289bcc84a184b349dd61 (accessed on 16 July 2025).

- Sponagel, S.; Kilthau, G.; Spies, K.H. Sealing mechanisms of lip seals. In Proceedings of the 11th International Conference on Fluid Sealing, Cannes, France, 8–10 April 1987; pp. 748–772. Available online: https://www.abebooks.de/9781851661008/11th-International-Conference-Fluid-Sealing-185166100X/plp (accessed on 16 July 2025).

- Stakenborg, M.J.L. On the Sealing and Lubrication Mechanism of Radial Lip Seals. Ph.D. Thesis, Technische Universiteit Eindhoven, Eindhoven, The Netherlands, 1988. [Google Scholar] [CrossRef]

- Salant, R.F. Numerical analysis of the flow field within lip seals containing microundulations. J. Tribol. 1992, 114, 485–492. [Google Scholar] [CrossRef]

- Salant, R.F.; Flaherty, A.L. Elastohydrodynamics of lip seals. Lubr. Sci. 1995, 8, 15–26. [Google Scholar] [CrossRef]

- Salant, R.F. Elastohydrodynamics of the rotary lip seal. Lubr. Sci. 1997, 9, 111–125. [Google Scholar] [CrossRef]

- Hajjam, M.; Bonneau, D. Influence of the roughness model on the thermoelastohydrodynamic performances of lip seals. Tribol. Int. 2006, 39, 198–205. [Google Scholar] [CrossRef]

- Guo, F.; Jia, X.; Suo, S.; Salant, R.F.; Wang, Y. A mixed lubrication model of a rotary lip seal using flow factors. Tribol. Int. 2013, 57, 195–201. [Google Scholar] [CrossRef]

- Patir, N.; Cheng, H.S. An average flow model for determining effects of three-dimensional roughness on partial hydrodynamic lubrication. J. Lubr. Technol. 1978, 100, 12–17. [Google Scholar] [CrossRef]

- Elrod, H.G. A cavitation algorithm. J. Lubr. Technol. 1981, 103, 350–354. [Google Scholar] [CrossRef]

- Lo, S.W. On the effects of roughness orientation—A mapping and double scale analysis of flow factors. J. Tribol. 1992, 114, 747–754. [Google Scholar] [CrossRef]

- Liu, D.; Wang, S.; Shi, J.; Zhang, C.; Tomovic, M. Numerical analysis of rotary lip seal performance deterioration. In Proceedings of the 2016 IEEE 11th Conference on Industrial Electronics and Applications, Hefei, China, 5–7 June 2016; pp. 1078–1083. [Google Scholar] [CrossRef]

- Yan, C.X.; Jia, X.H.; Jiang, B.Q.; Gao, L.F.; Guo, F. Influence of oil temperature on the lip seal’s performance. Tribol. Trans. 2019, 62, 739–746. [Google Scholar] [CrossRef]

- Chen, S.; Guo, F.; Wang, W.; Wang, Y. An improved mixed lubrication model for revealing the mechanism of high speed and frictional heat on sealing performance. Tribol. Int. 2024, 191, 109147. [Google Scholar] [CrossRef]

- Uddin, M.S.; Ibatan, T.; Shankar, S. Influence of surface texture shape, geometry and orientation on hydrodynamic lubrication performance of plane-to-plane slider surfaces. Lubr. Sci. 2017, 29, 153–181. [Google Scholar] [CrossRef]

- Lahjouji, I.; El Gadari, M.H.; Radouani, M. Numerical Investigation of Grooved Shaft Effects on the Rotary Lip Seal Performance with Relative Lip Motion. Lubricants 2019, 7, 16. [Google Scholar] [CrossRef]

- Zhang, F.; Yang, J.; Shui, H.; Dong, C. Effect of roughness on sealing performance of oil seals with surface texture. Ind. Lubr. Tribol. 2020, 72, 525–532. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, Y. Research on sealing performance of oil seals with micro-dimple texture on lips. Ind. Lubr. Tribol. 2021, 73, 113–119. [Google Scholar] [CrossRef]

- Guo, F.; Jia, X.H.; Wang, L.K.; Salant, R.F.; Wang, Y.M. The Effect of Wear on the Performance of a Rotary Lip Seal. J. Tribol. 2014, 136, 041703. [Google Scholar] [CrossRef]

- Huang, T.C.; Tsai, J.W.; Liao, K.C. Wear and leakage assessments of canted oil Spring-Energized polytetrafluoroethylene seals under Ultra-High cycle operations. Eng. Fail. Anal. 2022, 135, 106110. [Google Scholar] [CrossRef]

- Jiang, B.; Guo, F.; Ma, T.; Jia, X.; Zhao, N.; Wang, Y. A mixed lubrication model for lip seals based on deterministic surface micro-deformation. Tribol. Trans. 2021, 65, 153–163. [Google Scholar] [CrossRef]

- GB/T 528-2009; Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties. Standardization Administration of China (SAC): Beijing, China, 2009.

- Patir, N.; Cheng, H.S. Application of the average flow model to lubrication between rough sliding surfaces. J. Lubr. Technol. 1979, 101, 220–229. [Google Scholar] [CrossRef]

- Payva, R.P.; Salant, R.F. A computational method for cavitation in a wavy mechanical seal. J. Tribol. 1992, 114, 199–204. [Google Scholar] [CrossRef]

- Rocke, A.H.; Salant, R.F. Elastohydrodynamic Analysis of a Rotary Lip Seal using flow factors. Tribol. Trans. 2005, 48, 308–316. [Google Scholar] [CrossRef]

- Liu, D.; Wang, S.; Zhang, C.; Tomovic, M.M. Numerical study of the effects of textured shaft on the wear of rotary lip seals. Tribol. Int. 2019, 138, 215–238. [Google Scholar] [CrossRef]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1985. [Google Scholar] [CrossRef]

- Salant, R.F.; Flaherty, A.L. Elastohydrodynamic analysis of reverse pumping in rotary lip seals with micro-undulations. J. Tribol. 1994, 116, 56–62. [Google Scholar] [CrossRef]

- Roelands, C.J.; Vlugter, J.C.; Waterman, H.I. The viscosity-temperature-pressure relationship for lubricating oils and its correlation with the chemical constitution. J. Basic Eng. 1963, 85, 601–610. [Google Scholar] [CrossRef]

- Liu, D.; Wang, S.; Shi, J. Mixed elastohydrodynamic lubrication model of rotary lip seal with nonGaussian surfaces: Experimentation verification and numerical analysis on effects of sealed pressure. Sci. Prog. 2021, 104, 00368504211017010. [Google Scholar] [CrossRef]

| Variables | Meaning | Value | Unit |

|---|---|---|---|

| Lubricant side pressure | 1.0 | MPa | |

| Mud sand side pressure | 1.1 | MPa | |

| Reference pressure | 1.0 | MPa | |

| Cavitation pressure | 0.0 | MPa | |

| Shaft speed | 3 | m/s | |

| Friction coefficient | 0.2 | ||

| Elastic modulus of the rotary shaft | 210 | GPa | |

| Poisson’s ratio for the rotating shaft | 0.29 | ||

| The elastic modulus for the sealing lip | 6.93 | MPa | |

| Poisson’s ratio for the sealing lip | 0.499 | ||

| Radius of the rotary shaft | 6 | m | |

| Lubricant viscosity | 0.08 | Pa·s | |

| Lubricant density | 0.89 | g/cm3 | |

| Surface topography parameters of the lip seal | 1/3 | ||

| Axial correlation length of the lip seal | 5 | μm | |

| Circumferential correlation length of the lip seal | 1.667 | μm | |

| The lip seal’s RMS roughness | 1 | μm | |

| The rotary shaft’s RMS roughness | 0 | μm | |

| Reference temperature | 25 | °C | |

| Heat transfer coefficient for the lubricant | 200 | W/(m2·K) | |

| Specific heat capacity for the lubricant | 2000 | J/(kg·K) | |

| Viscosity–temperature coefficient | 0.024 | K−1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, B.; Li, X.; He, W.; Dong, Z.; Yang, K.; Lu, Z.; Wang, Q. The Mechanism of a High Fluid Pressure Differential on the Sealing Performance of Rotary Lip Seals. Lubricants 2025, 13, 413. https://doi.org/10.3390/lubricants13090413

He B, Li X, He W, Dong Z, Yang K, Lu Z, Wang Q. The Mechanism of a High Fluid Pressure Differential on the Sealing Performance of Rotary Lip Seals. Lubricants. 2025; 13(9):413. https://doi.org/10.3390/lubricants13090413

Chicago/Turabian StyleHe, Bo, Xia Li, Wenhao He, Zhiyu Dong, Kang Yang, Zhibin Lu, and Qihua Wang. 2025. "The Mechanism of a High Fluid Pressure Differential on the Sealing Performance of Rotary Lip Seals" Lubricants 13, no. 9: 413. https://doi.org/10.3390/lubricants13090413

APA StyleHe, B., Li, X., He, W., Dong, Z., Yang, K., Lu, Z., & Wang, Q. (2025). The Mechanism of a High Fluid Pressure Differential on the Sealing Performance of Rotary Lip Seals. Lubricants, 13(9), 413. https://doi.org/10.3390/lubricants13090413