The Influences of Surface Texture Topography and Orientation on Point-Contact Mixed Lubrication

Abstract

1. Introduction

2. Methods

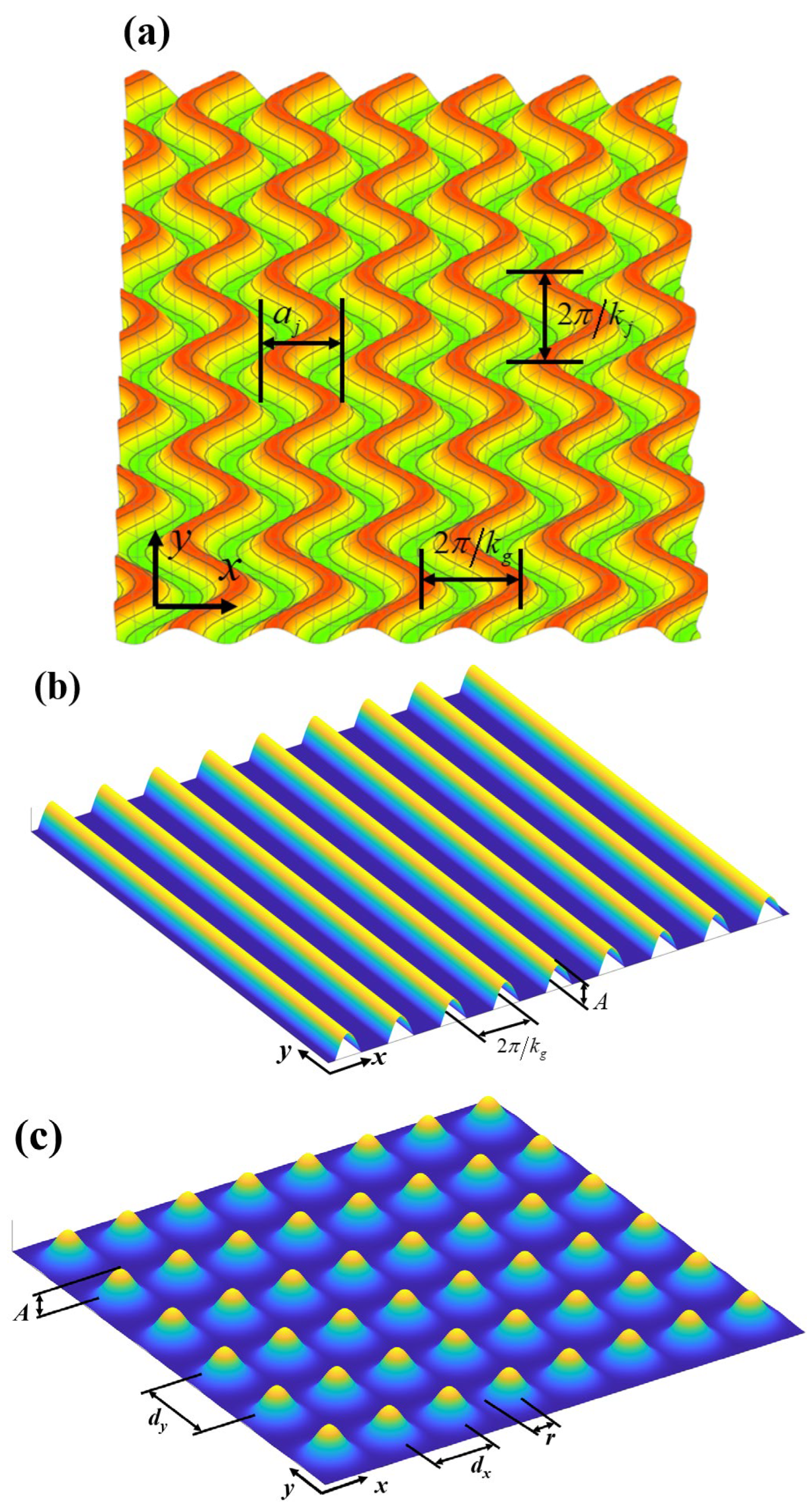

2.1. Surface Generation

2.2. EHL Solver

3. Results

3.1. EHL Results of Smooth Surfaces

3.2. EHL Results of the Bump Array Surfaces

- (1)

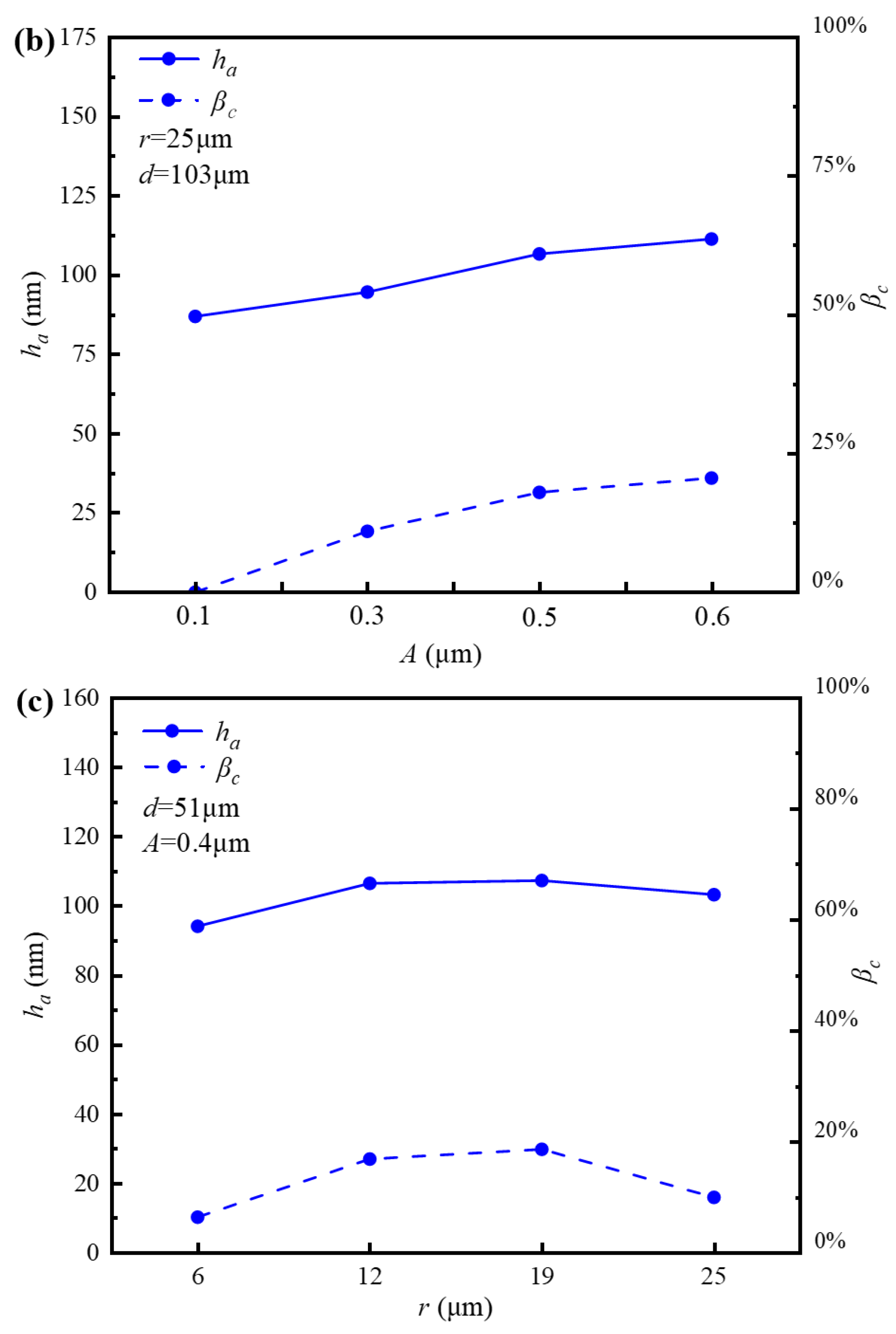

- Isotropic bump array surfaces

- (2)

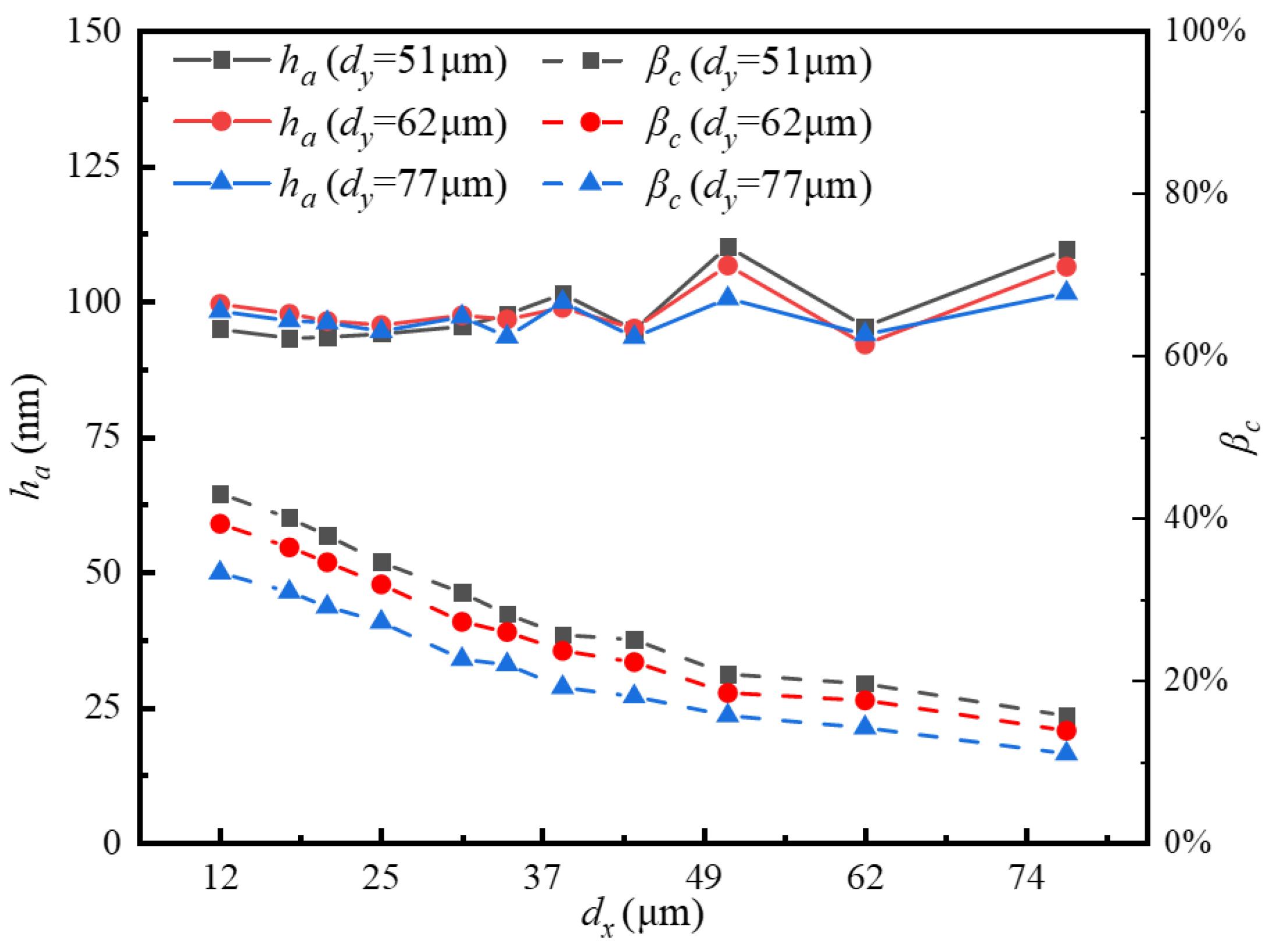

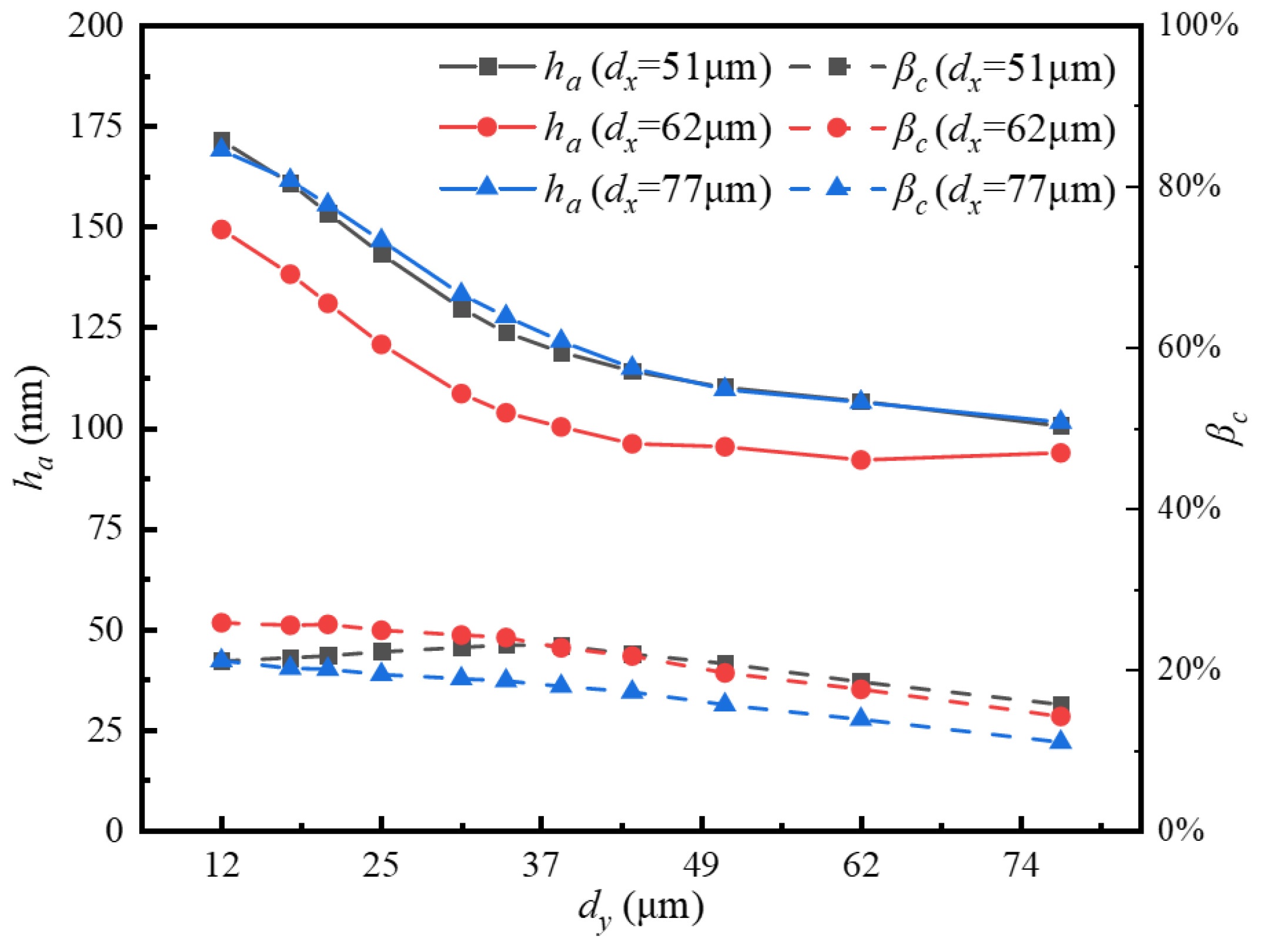

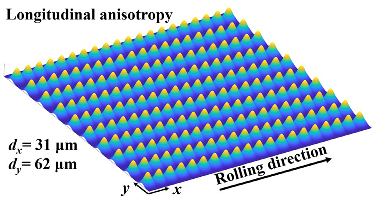

- Anisotropic bump array surfaces

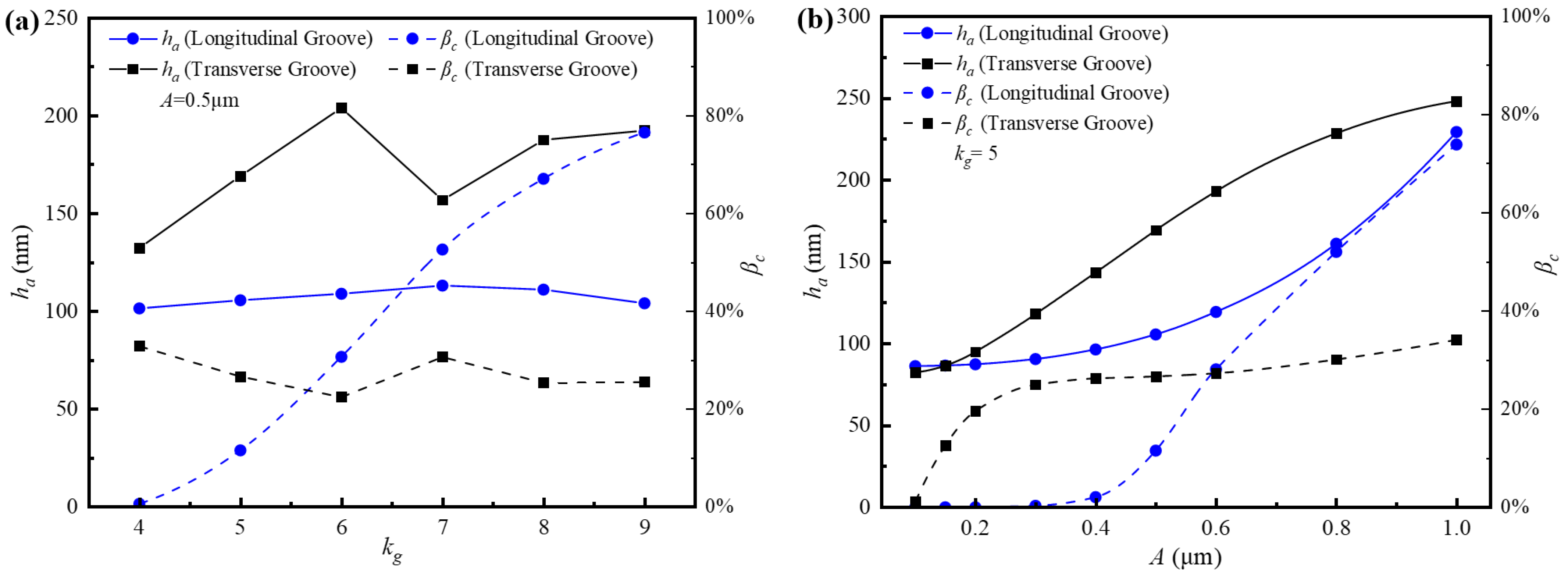

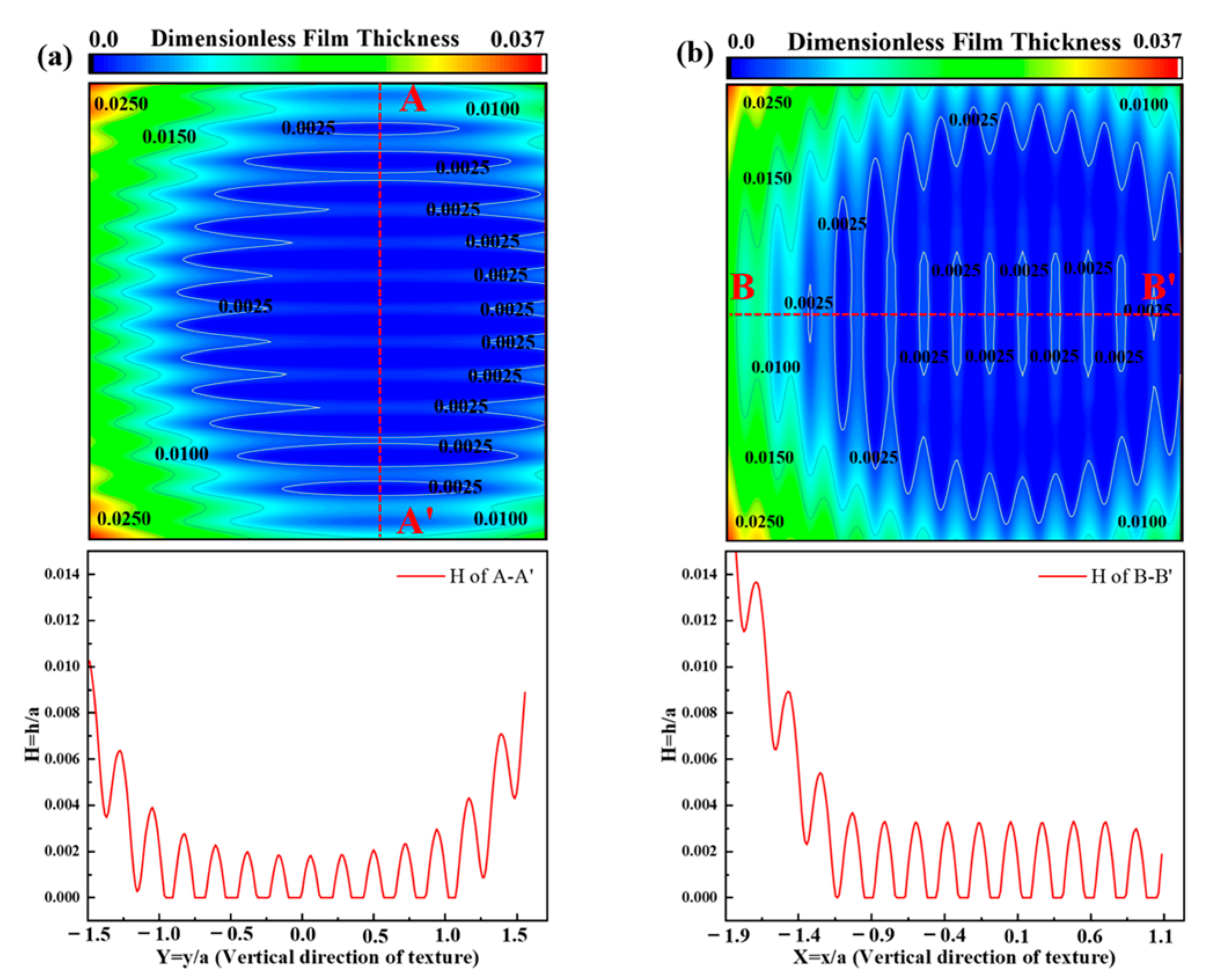

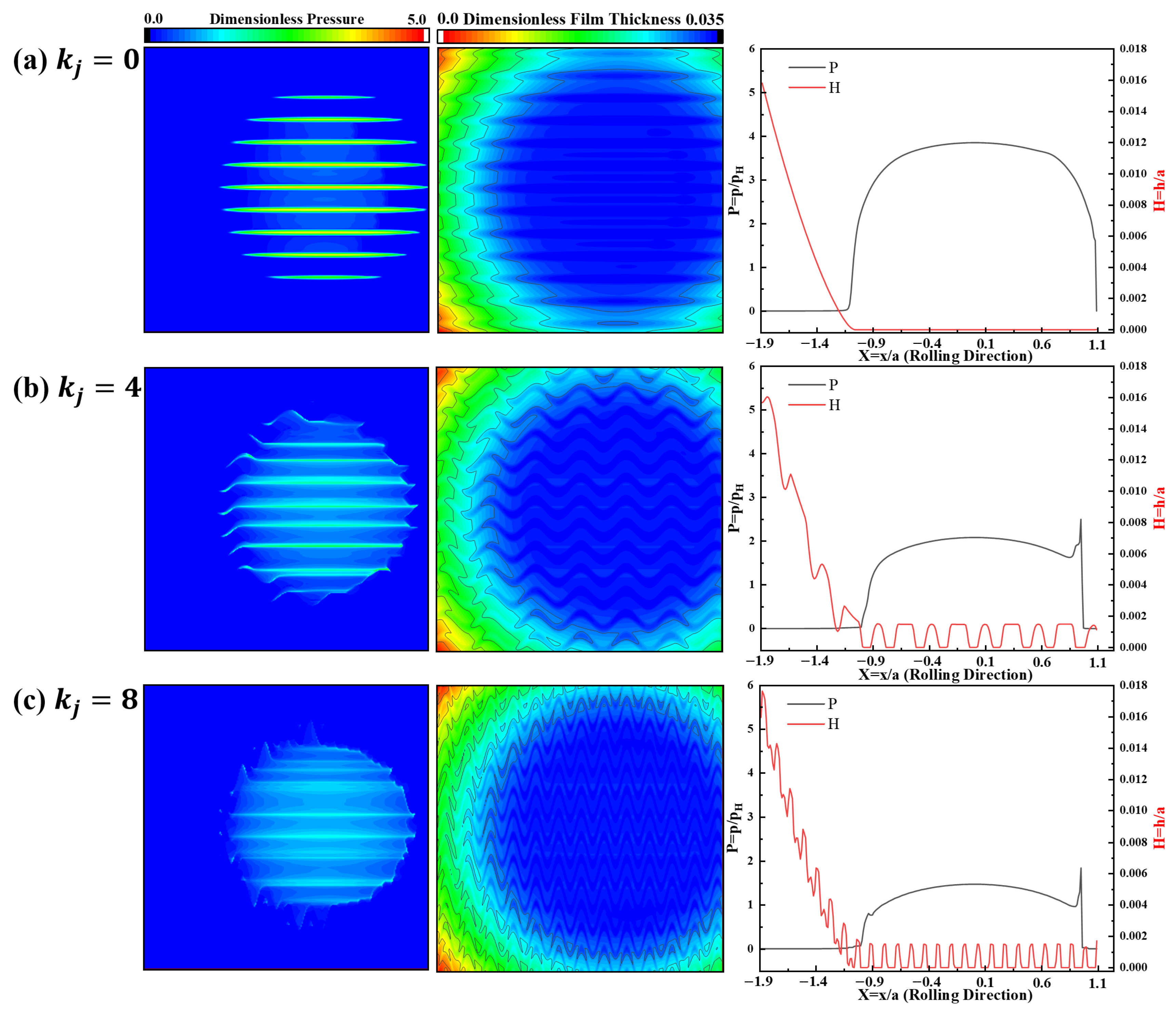

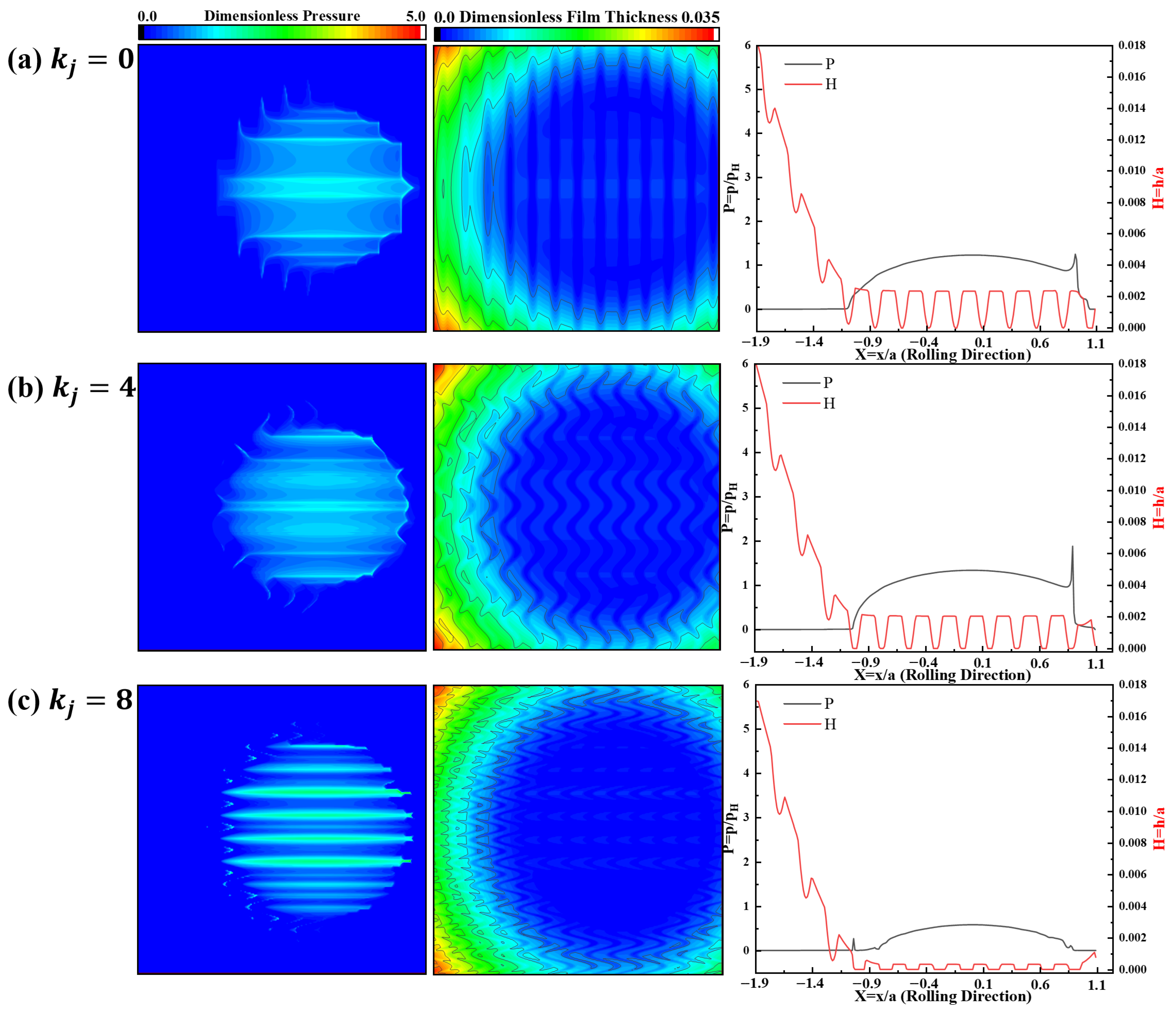

3.3. EHL Results of the Groove Surfaces

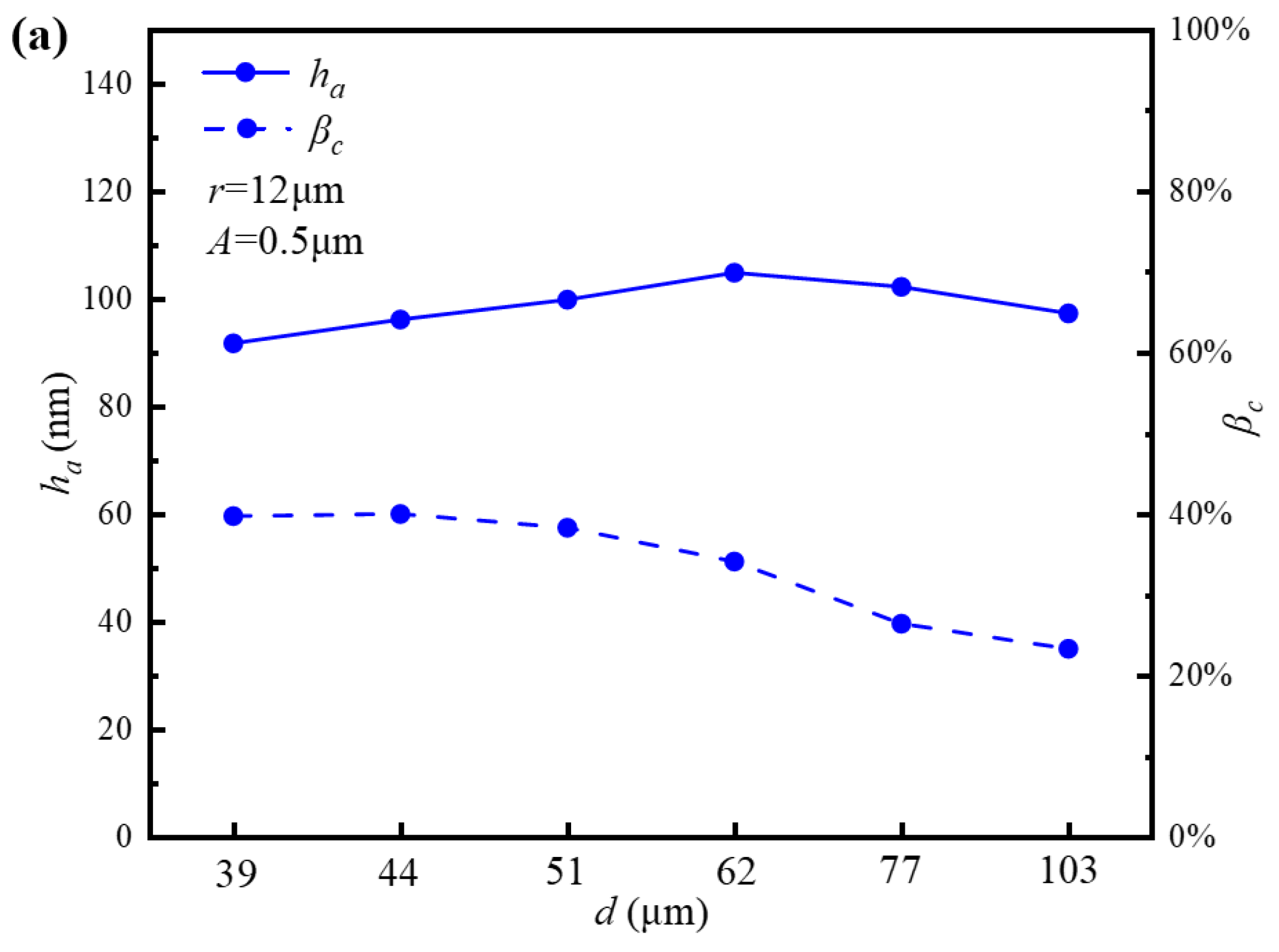

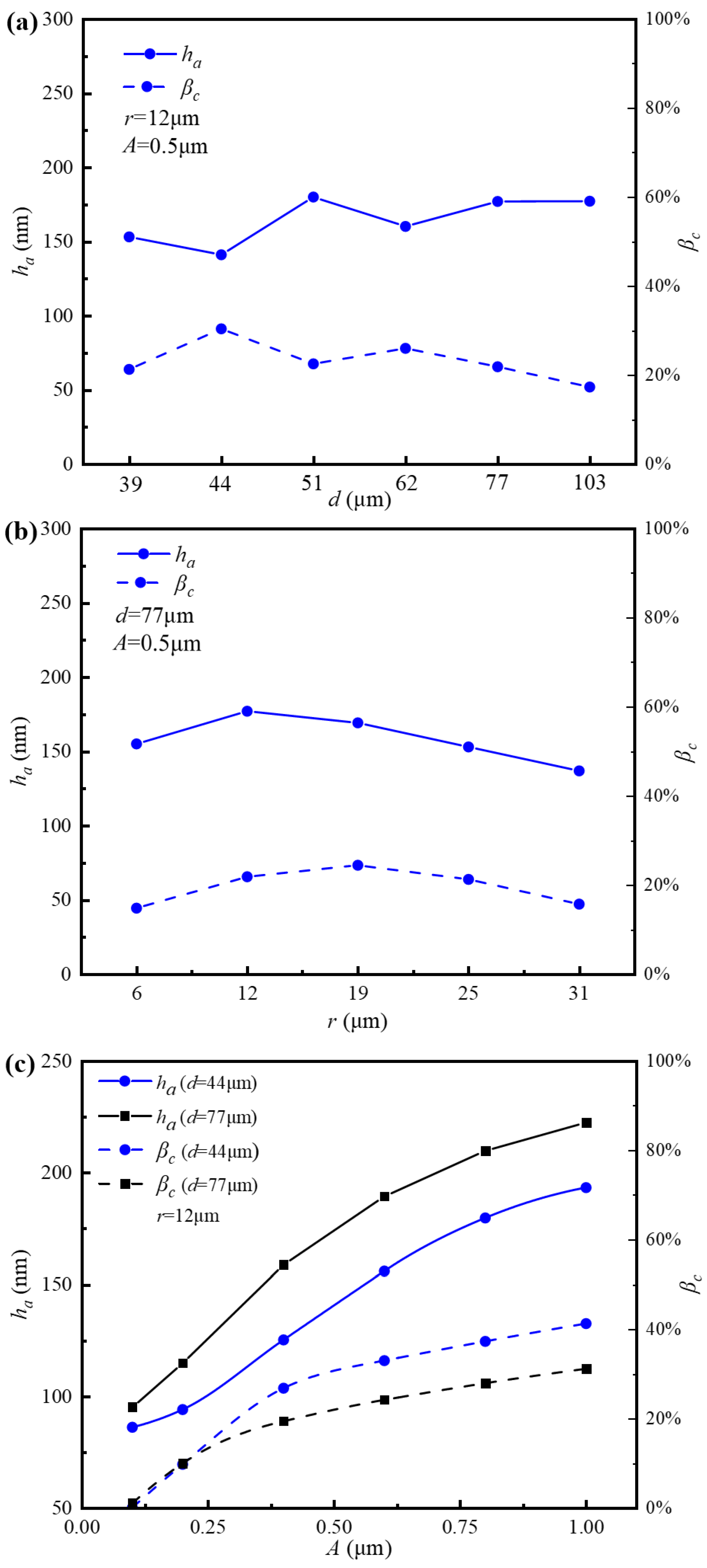

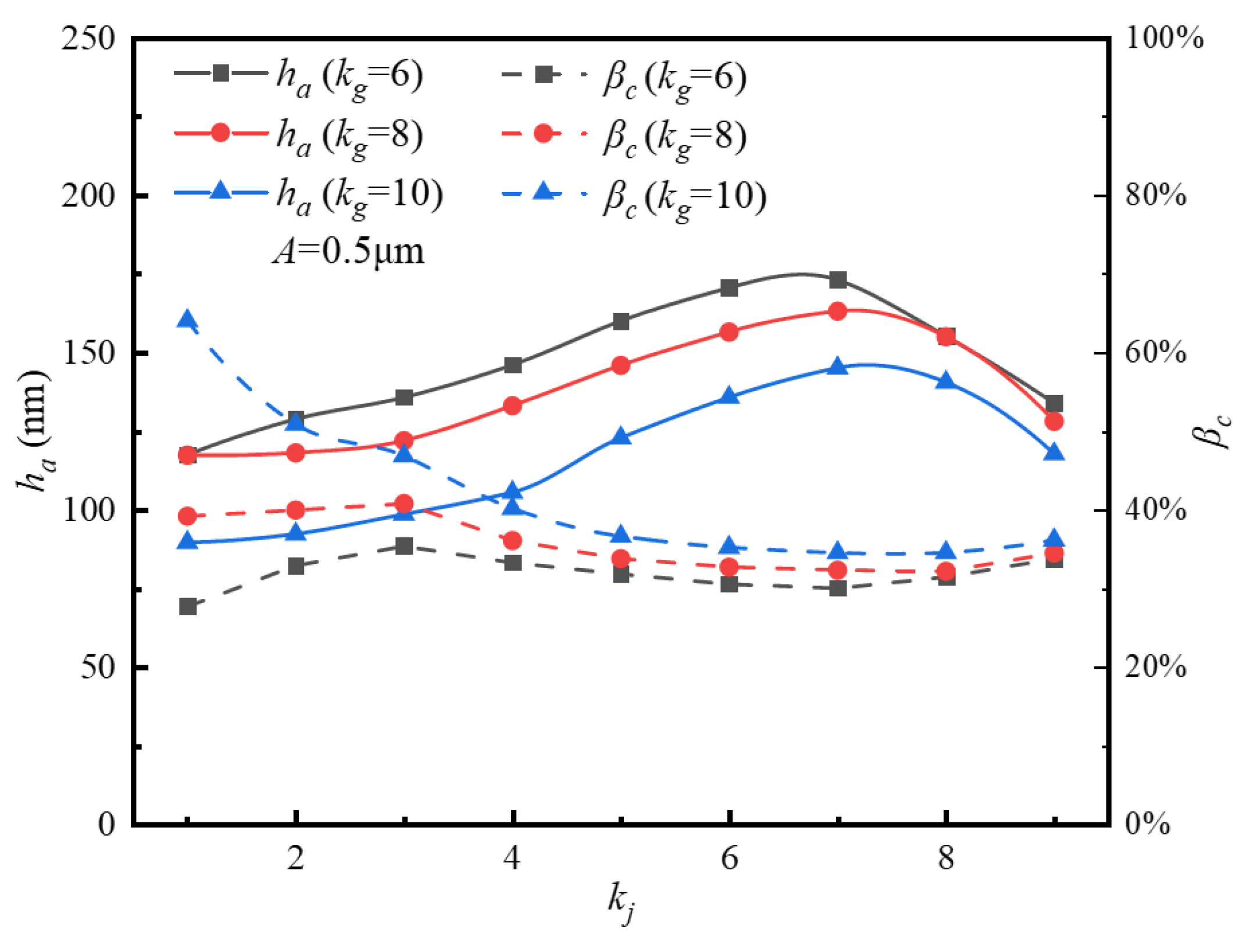

3.4. EHL Results of the Herringbone Surfaces

4. Discussions

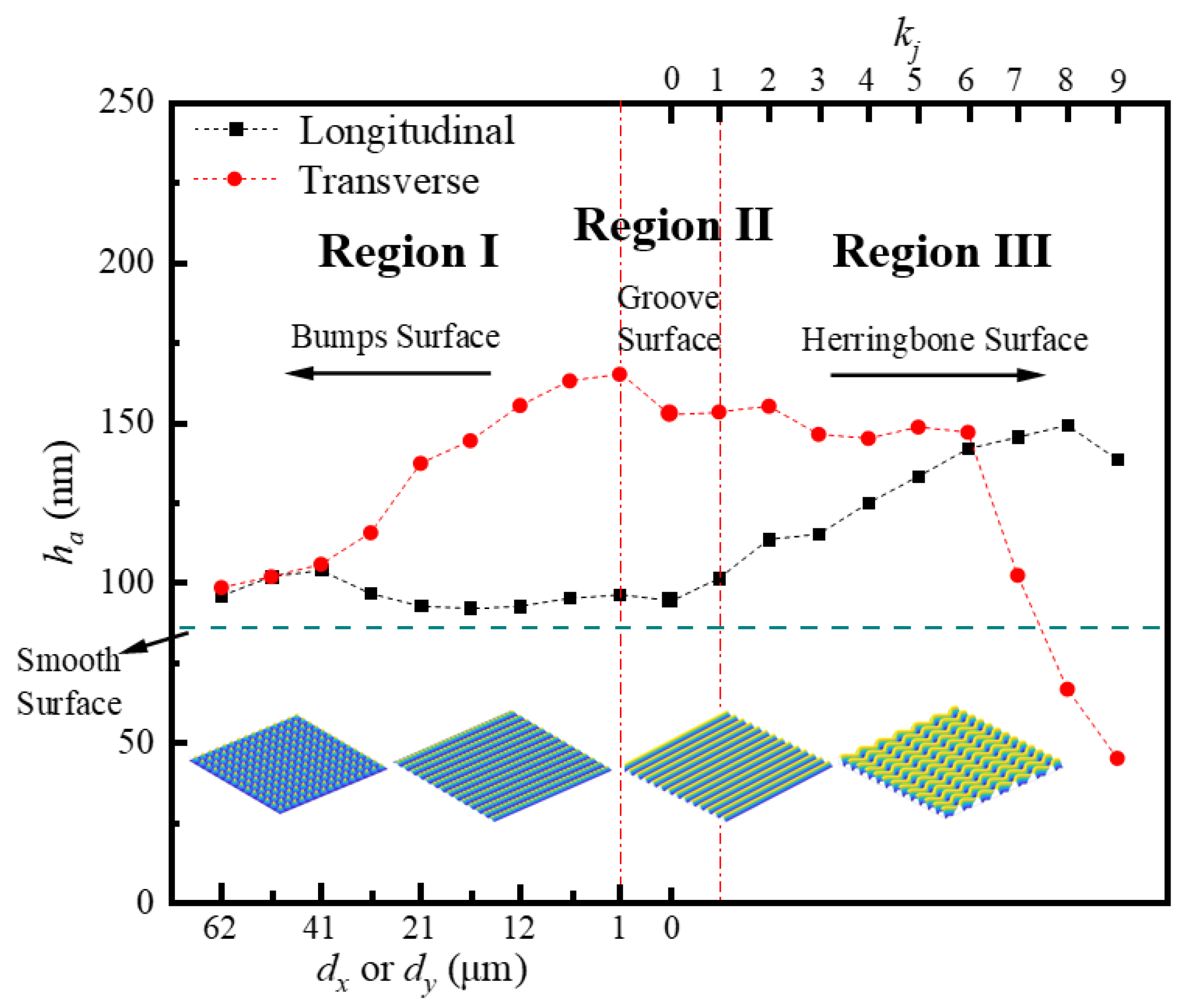

4.1. Influence of Surface Topology Variations on Film Thickness

4.2. The Effect of Sliding Velocity on Lubrication

5. Conclusions

- Isotropic bump arrays outperform anisotropic configurations in lubrication efficiency with lower contact load ratios (0–20%), primarily due to effective hydrodynamic pressure generation, which reduces the contact load of asperities.

- Among textures with pronounced anisotropy, transverse grooves exhibit superior lubrication performance compared with longitudinal grooves, because of strong micro-EHL effects due to enhanced lubricant entrapment behind ridges. The transverse surfaces achieve up to about 50% thicker average films than longitudinal counterparts for the conditions studied.

- For herringbone surfaces, an increase in the short wavelength intensifies surface wrinkling and alters the direction of surface anisotropy. For instance, as increases, longitudinal herringbone surfaces tend to transition toward transverse orientations, thereby increasing film thickness and reducing surface contact load.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| The amplitude of surface topography | |

| The amplitude of jog wave | |

| The spacing of surface topography | |

| The spacing between transversely distributed textures | |

| The spacing between longitudinally distributed textures | |

| Young’s modulus of the ball material | |

| Young’s modulus of the substrate material | |

| Local dimensional oil film thickness | |

| H | Dimensionless oil film thickness in dimensionless computational domain |

| Average film thickness | |

| Central film thickness | |

| Maximum film thickness | |

| Minimum film thickness | |

| The wave number of the groove wave | |

| The wave number of the jog wave | |

| Dimensionless pressure in dimensionless computational domain | |

| Maximum contact pressure in Hertzian contact | |

| Dimensionless contact pressure at the position where film thickness is zero | |

| The radius of surface bump | |

| Hertzian contact radius | |

| The radius of the ball | |

| Slip velocity | |

| Poisson’s ratio of the ball material | |

| Poisson’s ratio of the substrate material | |

| Applied normal load | |

| The dimensionless coordinates of the computational domain | |

| The dimensional coordinates of the surface | |

| Lower boundary in dimensionless coordinates | |

| Upper boundary in dimensionless coordinates | |

| Pressure viscosity coefficient | |

| Contact load ratio | |

| The grid width of the dimensionless computational domain | |

| Lubrication oil viscosity | |

| Lubricant density | |

| The entire integral domain of the dimensionless computational domain |

References

- Guegan, J.; Kadiric, A.; Spikes, H. A Study of the Lubrication of EHL Point Contact in the Presence of Longitudinal Roughness. Tribol. Lett. 2015, 59, 22. [Google Scholar] [CrossRef][Green Version]

- Ren, N.; Zhu, D.; Chen, W.W.; Liu, Y.; Wang, Q.J. A Three-Dimensional Deterministic Model for Rough Surface Line-Contact EHL Problems. J. Tribol. 2008, 131, 011501. [Google Scholar] [CrossRef]

- Krupka, I.; Sperka, P.; Hartl, M. Effect of surface roughness on lubricant film breakdown and transition from EHL to mixed lubrication. Tribol. Int. 2016, 100, 116–125. [Google Scholar] [CrossRef]

- Aymard, A.; Delplanque, E.; Dalmas, D.; Scheibert, J. Designing metainterfaces with specified friction laws. Science 2024, 383, 200–204. [Google Scholar] [CrossRef]

- Tzanakis, I.; Hadfield, M.; Thomas, B.; Noya, S.M.; Henshaw, I.; Austen, S. Future perspectives on sustainable tribology. Renew. Sustain. Energy Rev. 2012, 16, 4126–4140. [Google Scholar] [CrossRef]

- Long, R.; Ma, Q.; Shang, Q.; Wang, H.; Yao, Y.; Wang, Y.; Zong, L. Parameter Optimization for the Improvement of Tribological Behavior of Textured Tapered Roller Bearings. Lubricants 2025, 13, 165. [Google Scholar] [CrossRef]

- Kaneta, M.; Cameron, A. Effects of Asperities in Elastohydrodynamic Lubrication. J. Lubr. Technol. 1980, 102, 374–378. [Google Scholar] [CrossRef]

- Choo, J.W.; Glovnea, R.P.; Olver, A.V.; Spikes, H.A. The Effects of Three-Dimensional Model Surface Roughness Features on Lubricant Film Thickness in EHL Contacts. J. Tribol. 2003, 125, 533–542. [Google Scholar] [CrossRef]

- Zheng, C.; Yang, Y.; Cheng, S.; Wang, W.; Liu, K.; Xu, J. Friction reduction and anti-wear mechanisms of surface-textured graphite under water lubrication. Wear 2025, 562–563, 205665. [Google Scholar] [CrossRef]

- Wang, H.-J.; Huang, J.-D.; Wang, B.; Zhang, Y.; Wang, J. Study on the Tribological Behavior of Laser Surface Texturing on Silicon Nitride Ceramic Under Water Lubrication. Lubricants 2025, 13, 21. [Google Scholar] [CrossRef]

- Chen, X.; Huang, Y.; Rong, Y.; Wu, C. Two-step laser processing of micro/nano-composite structures on PS-SiC surfaces for superior friction performance under water-lubrication. Ceram. Int. 2025, 51, 26171–26184. [Google Scholar]

- Jiang, S.; Liu, Q.; Ji, H.; Wang, W.; Meng, Z.; Wang, J.; Dong, G. Modeling and analysis for surface texturing on soft sliders in mixed lubrication. Friction 2025, 13, 9440917. [Google Scholar] [CrossRef]

- Wu, Z.; Gao, L.; Huang, X.; Hua, Z. Simulation Study on the Surface Texturing Design of COC Hip Joints Based on Elastohydrodynamic Lubrication Model. Lubricants 2025, 13, 217. [Google Scholar] [CrossRef]

- Guangteng, G.; Cann, P.M.; Olver, A.V.; Spikes, H.A. Lubricant Film Thickness in Rough Surface, Mixed Elastohydrodynamic Contact. J. Tribol. 1999, 122, 65–76. [Google Scholar] [CrossRef]

- Patir, N.; Cheng, H.S. An Average Flow Model for Determining Effects of Three-Dimensional Roughness on Partial Hydrodynamic Lubrication. J. Lubr. Technol. 1978, 100, 12–17. [Google Scholar] [CrossRef]

- Venner, C.H.; Lubrecht, A.A. Numerical Simulation of a Transverse Ridge in a Circular EHL Contact Under Rolling/Sliding. J. Tribol. 1994, 116, 751–761. [Google Scholar] [CrossRef]

- Wedeven, L.D.; Cusano, C. Elastohydrodynamic Film Thickness Measurements of Artificially Produced Surface Dents and Grooves. ASLE Trans. 1979, 22, 369–381. [Google Scholar] [CrossRef]

- Choo, J.W.; Olver, A.V.; Spikes, H.A.; Dumont, M.-L.; Ioannides, E. The Influence of Longitudinal Roughness in Thin-Film, Mixed Elastohydrodynamic Lubrication. Tribol. Trans. 2006, 49, 248–259. [Google Scholar] [CrossRef]

- Choo, J.W.; Olver, A.V.; Spikes, H.A. The influence of transverse roughness in thin film, mixed elastohydrodynamic lubrication. Tribol. Int. 2007, 40, 220–232. [Google Scholar] [CrossRef]

- Pei, X. Scale Effects of Surface-Texture Distribution on Lubrication and Friction. Tribol. Lett. 2025, 73, 86. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.; Du, J.; Morina, A. Understanding the Influences of Multiscale Waviness on the Elastohydrodynamic Lubrication Performance, Part I: The Full-Film Condition. Lubricants 2022, 10, 368. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Y. Understanding the Influences of Multiscale Waviness on the Elastohydrodynamic Lubrication Performance, Part II: The Partial-Film Condition. Lubricants 2024, 12, 190. [Google Scholar] [CrossRef]

- Peng, F.; Jabbarzadeh, A. The Effect of Geometrical Shape of Surface Texture on the Rheology and Tribology of Confined Lubricants. Lubricants 2025, 13, 13. [Google Scholar] [CrossRef]

- Boidi, G.; Tertuliano, I.S.; Profito, F.J.; de Rossi, W.; Machado, I.F. Effect of laser surface texturing on friction behaviour in elastohydrodynamically lubricated point contacts under different sliding-rolling conditions. Tribol. Int. 2020, 149, 105613. [Google Scholar] [CrossRef]

- Lu, P.; Wood, R.J.K.; Gee, M.G.; Wang, L.; Pfleging, W. A Novel Surface Texture Shape for Directional Friction Control. Tribol. Lett. 2018, 66, 51. [Google Scholar] [CrossRef]

- Choi, W.M.; Song, J.; Khang, D.-Y.; Jiang, H.; Huang, Y.Y.; Rogers, J.A. Biaxially Stretchable “Wavy” Silicon Nanomembranes. Nano Lett. 2007, 7, 1655–1663. [Google Scholar] [CrossRef]

- Wang, Z.; Yu, C.; Wang, Q. Model for Elastohydrodynamic Lubrication of Multilayered Materials. J. Tribol. 2015, 137, 011501. [Google Scholar] [CrossRef]

- Pu, W.; Wang, J.; Zhu, D. Progressive Mesh Densification Method for Numerical Solution of Mixed Elastohydrodynamic Lubrication. J. Tribol. 2015, 138, 021502. [Google Scholar] [CrossRef]

- Zhu, D.; Hu, Y. The study of transition from full film elastohydrodynamic to mixed and boundary lubrication. In The Advancing Frontier of Engineering Tribology, Proceedings of the 1999 STLE/ASME HS Cheng Tribology Surveillance; Society of Tribologists and Lubrication Engineers: Park Ridge, IL, USA, 1999; pp. 150–156. [Google Scholar]

- Liu, S.; Wang, Q.; Liu, G. A versatile method of discrete convolution and FFT (DC-FFT) for contact analyses. Wear 2000, 243, 101–111. [Google Scholar] [CrossRef]

- Kaneta, M.; Sakai, T.; Nishikawa, H. Effects of Surface Roughness on Point Contact EHL. Tribol. Trans. 1993, 36, 605–612. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Velocity u/(m/s) | 0.1 |

| Radius of the ball /(mm) | 12.9 |

| Load /(N) | 100 |

| Young’s modulus of the ball /(GPa) | 200 |

| Young’s modulus of the flat material /(GPa) | 200 |

| Poisson’s ratio of the ball | 0.3 |

| Poisson’s ratio of the flat material | 0.3 |

| Lubrication oil viscosity /(Pa∙s) | 0.096 |

| Pressure viscosity coefficient /(Pa−1) | 18.2 × 10−9 |

| Lubricant density /(g/cm3) | 0.8 |

| Hertzian contact radius /(μm) | 206 |

| Hertzian contact pressure /(Mpa) | 1120 |

| Hamrock–Dowson analytical central film thickness /(nm) | 101.83 |

| Hamrock–Dowson analytical minimum film thickness /(nm) | 58.91 |

| Parameters | Transverse Configuration | Longitudinal Configuration |

|---|---|---|

| 12 μm | 12 μm | |

| 0.5 μm | 0.5 μm | |

| Fixed, selected from 51 μm, 62 μm, and 77 μm | Variable, ranged from 12 μm to 77 μm | |

| Variable, ranged from12 μm to 77 μm | Fixed, selected from 51 μm, 62 μm, and 77 μm | |

| Example |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, C.; Cheng, R.; Zhang, H.; Ma, C.; Yu, S. The Influences of Surface Texture Topography and Orientation on Point-Contact Mixed Lubrication. Lubricants 2025, 13, 409. https://doi.org/10.3390/lubricants13090409

Yu C, Cheng R, Zhang H, Ma C, Yu S. The Influences of Surface Texture Topography and Orientation on Point-Contact Mixed Lubrication. Lubricants. 2025; 13(9):409. https://doi.org/10.3390/lubricants13090409

Chicago/Turabian StyleYu, Chengjiao, Rui Cheng, Hongwei Zhang, Chicheng Ma, and Shuangcheng Yu. 2025. "The Influences of Surface Texture Topography and Orientation on Point-Contact Mixed Lubrication" Lubricants 13, no. 9: 409. https://doi.org/10.3390/lubricants13090409

APA StyleYu, C., Cheng, R., Zhang, H., Ma, C., & Yu, S. (2025). The Influences of Surface Texture Topography and Orientation on Point-Contact Mixed Lubrication. Lubricants, 13(9), 409. https://doi.org/10.3390/lubricants13090409