Comparative Analysis of Emulsion, Cutting Oil, and Synthetic Oil-Free Fluids on Machining Temperatures and Performance in Side Milling of Ti-6Al-4V

Abstract

1. Introduction

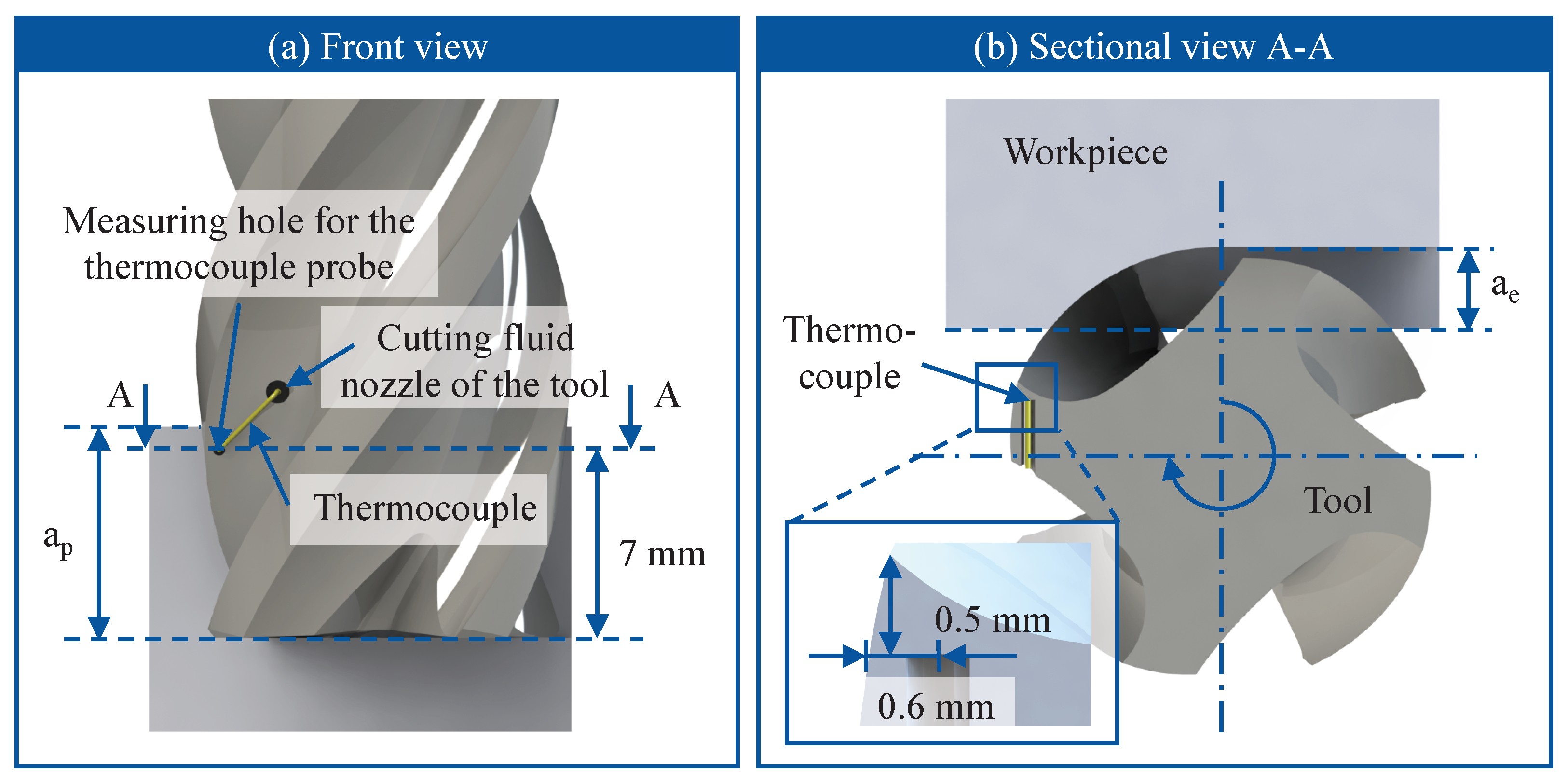

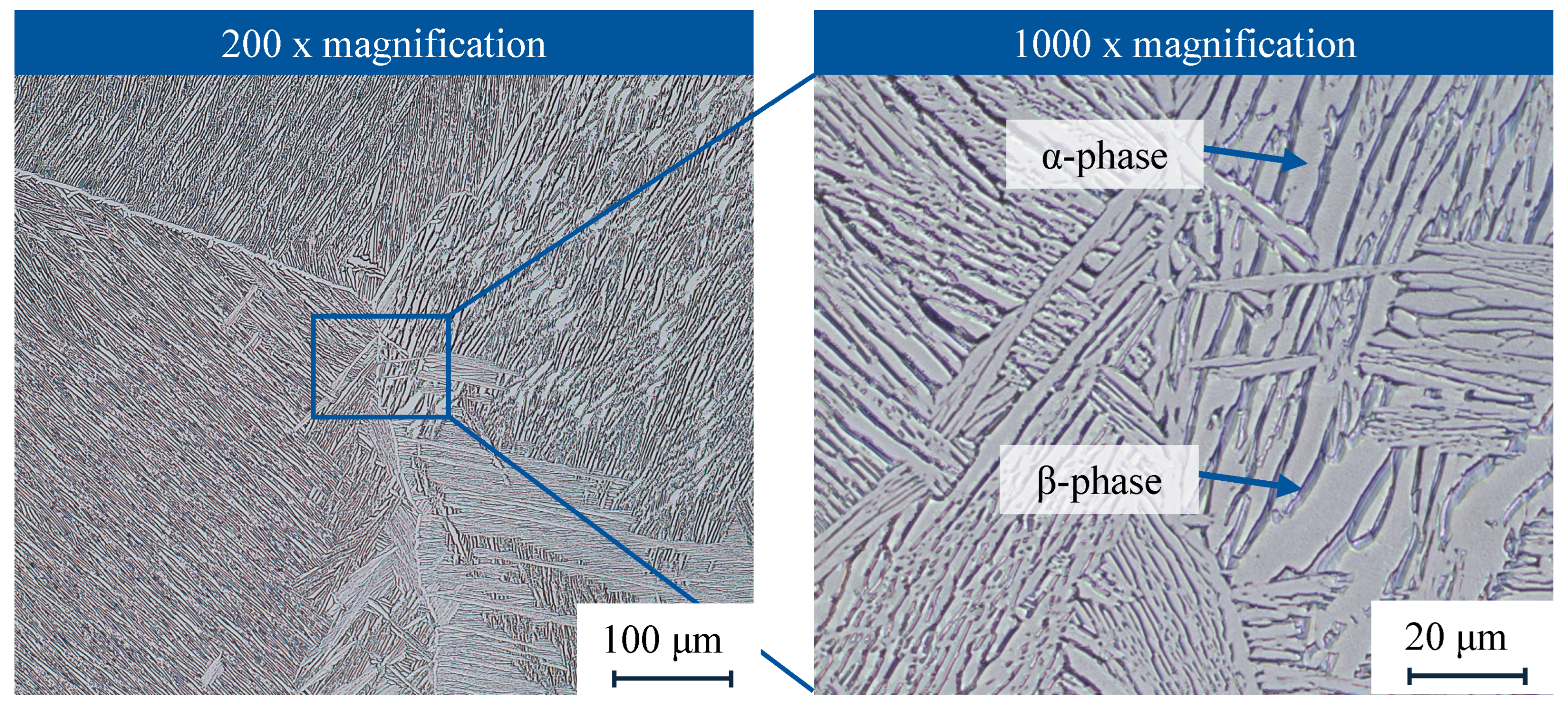

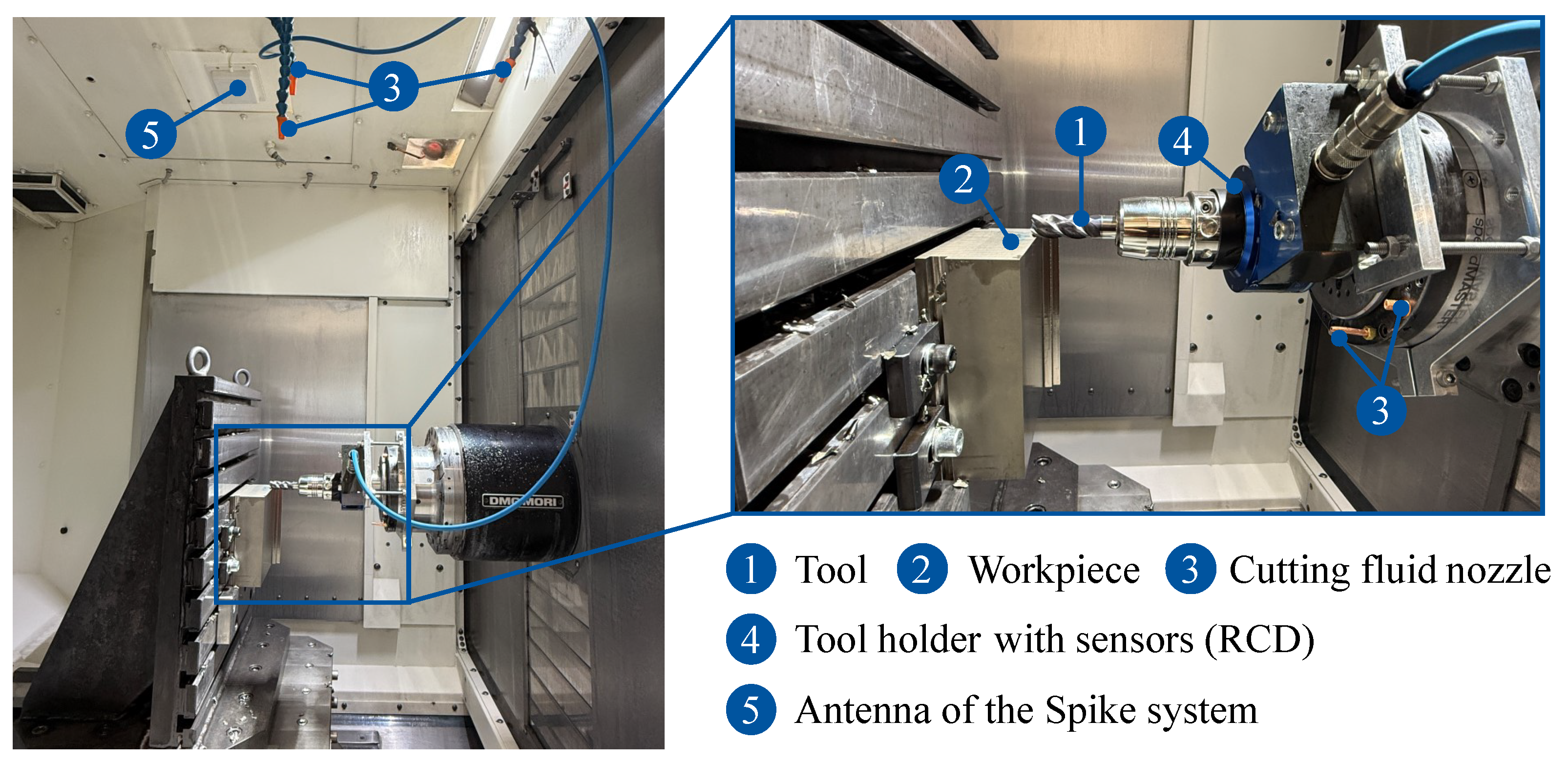

2. Material Characterization and Experimental Setup

2.1. Characterization of Cutting Tool and Workpiece Materials

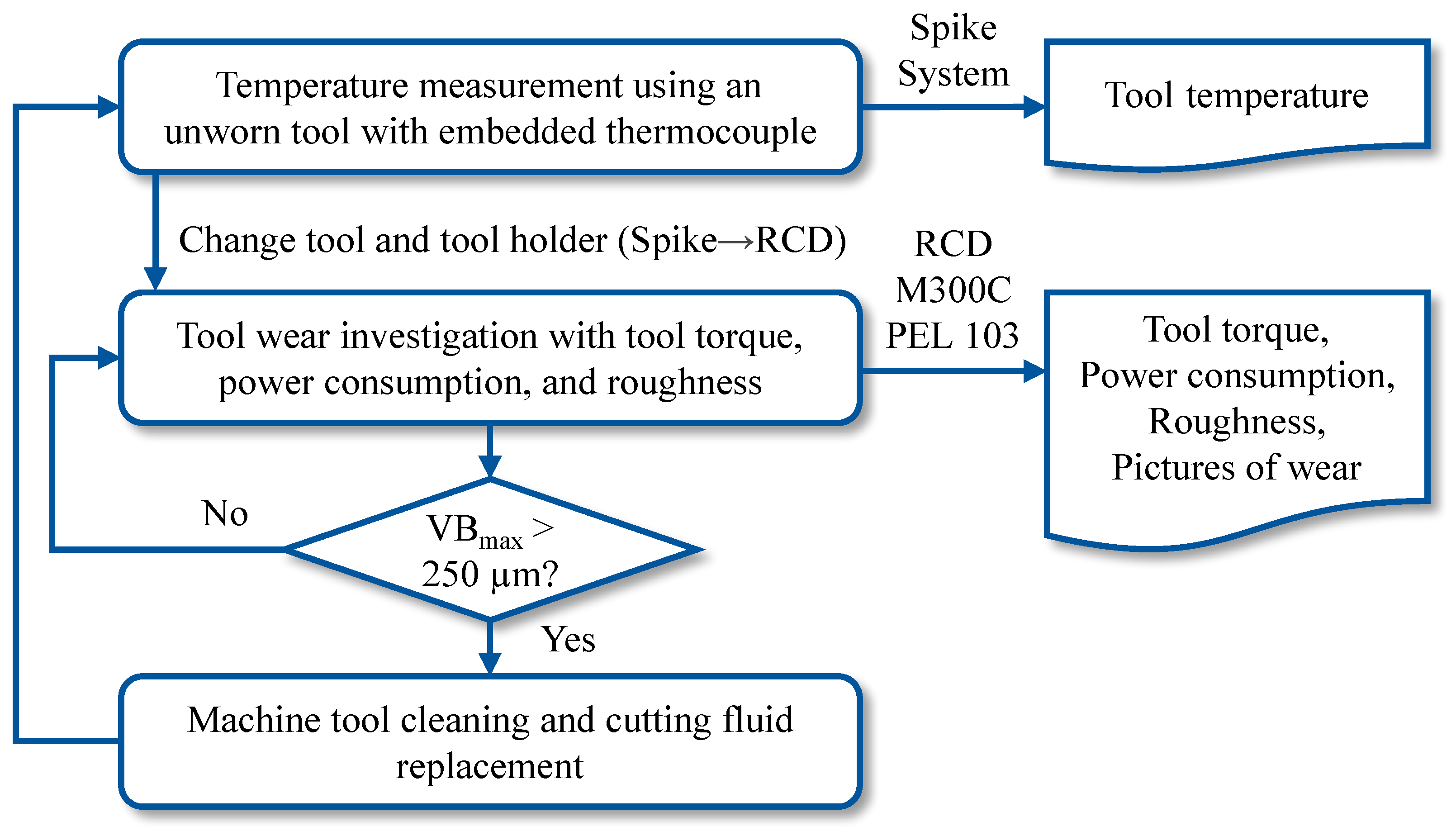

2.2. Experimental Design and Procedure

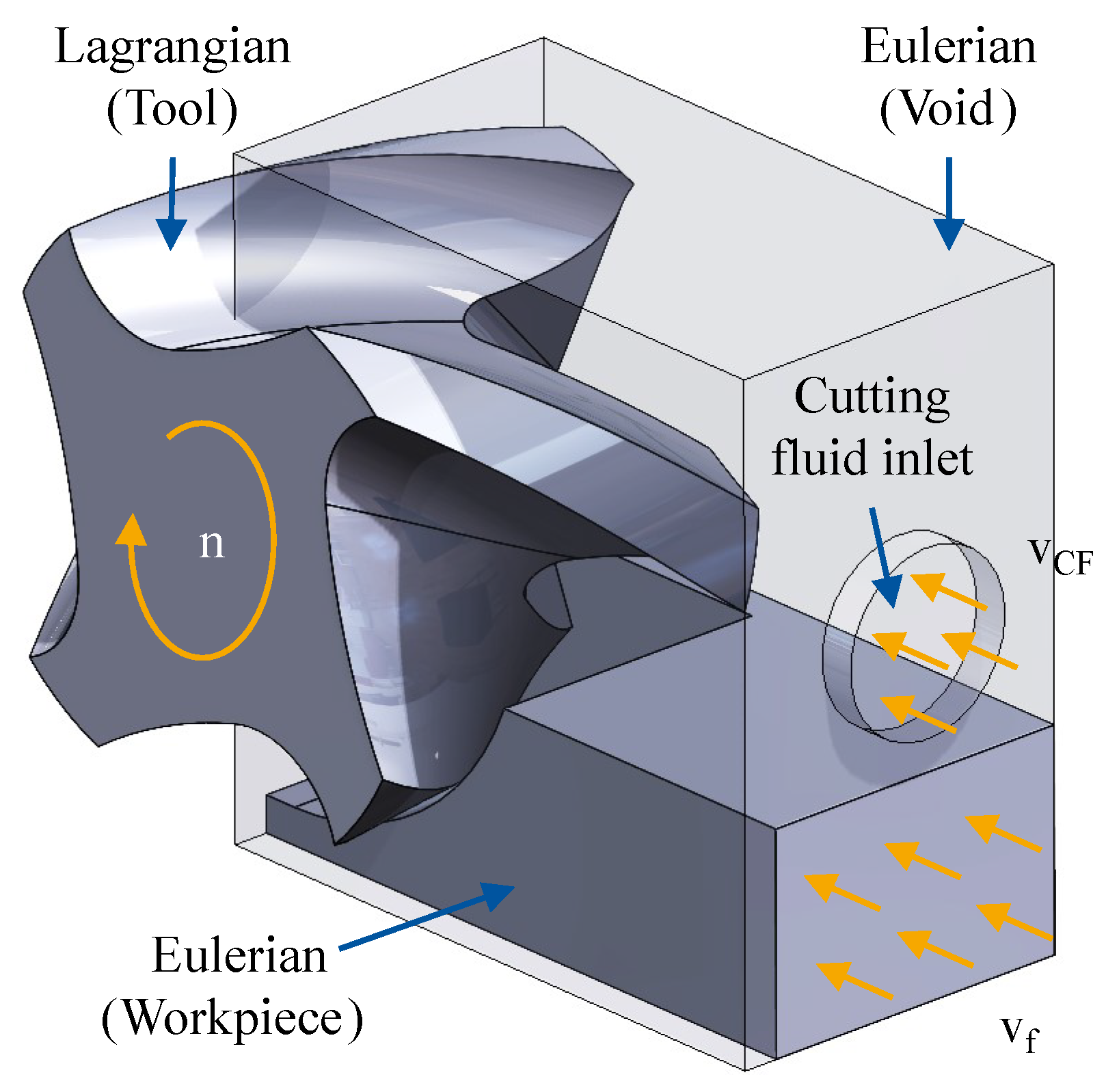

3. Model Setup for Process and Temperature Simulation

3.1. Simulation Approach for Tool Temperature Prediction

3.2. Process Simulation Considering Cutting Fluid Effects

4. Experimental and Simulation Results and Discussion

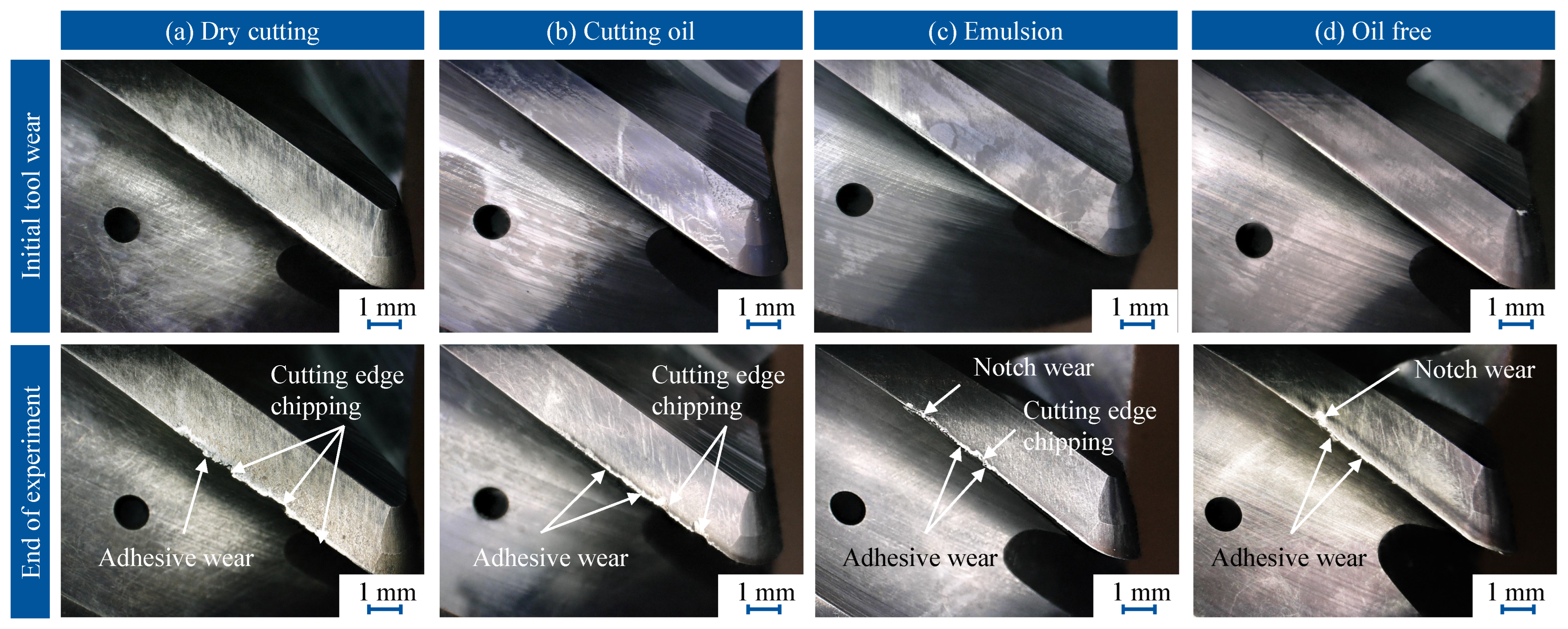

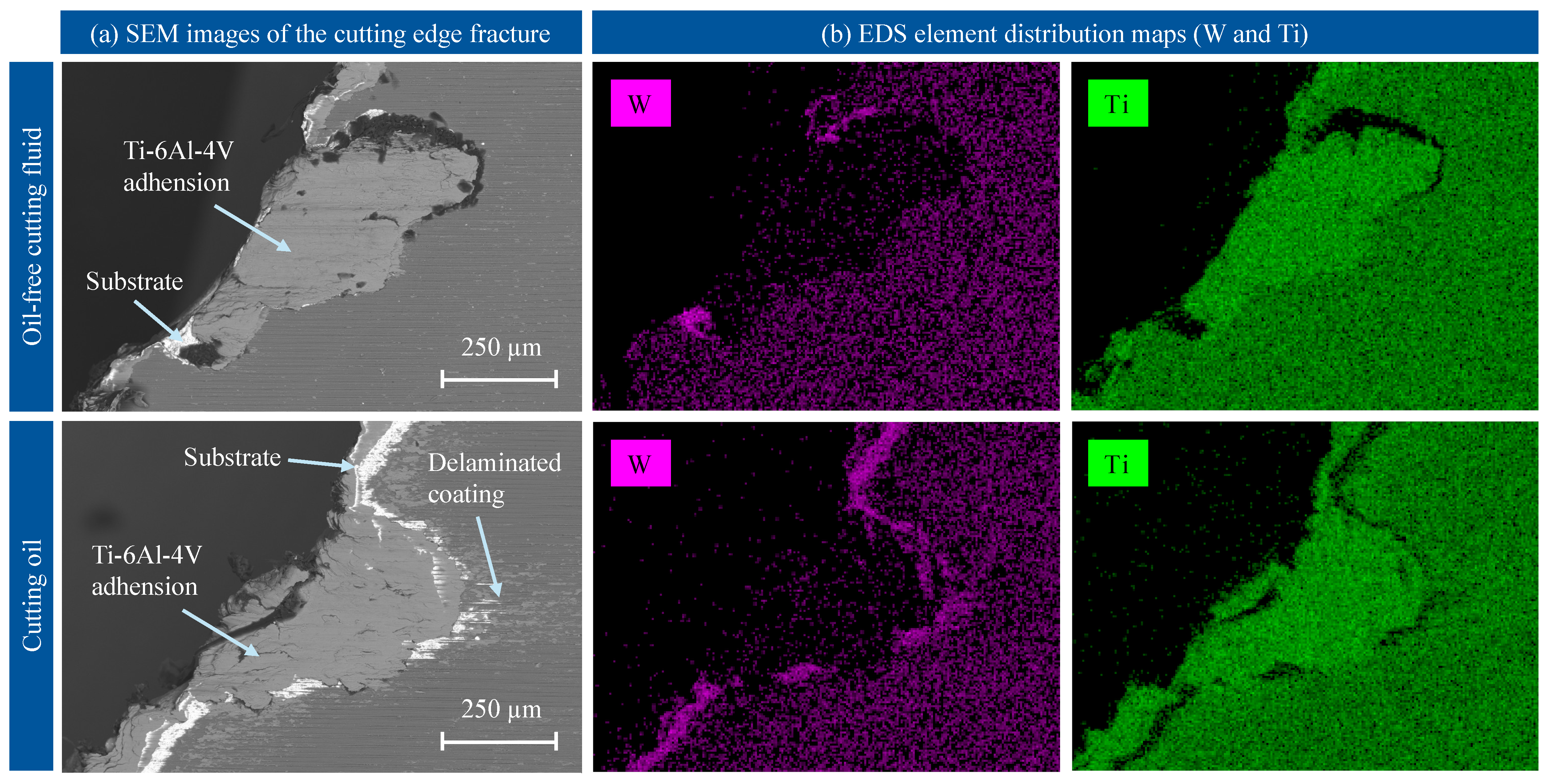

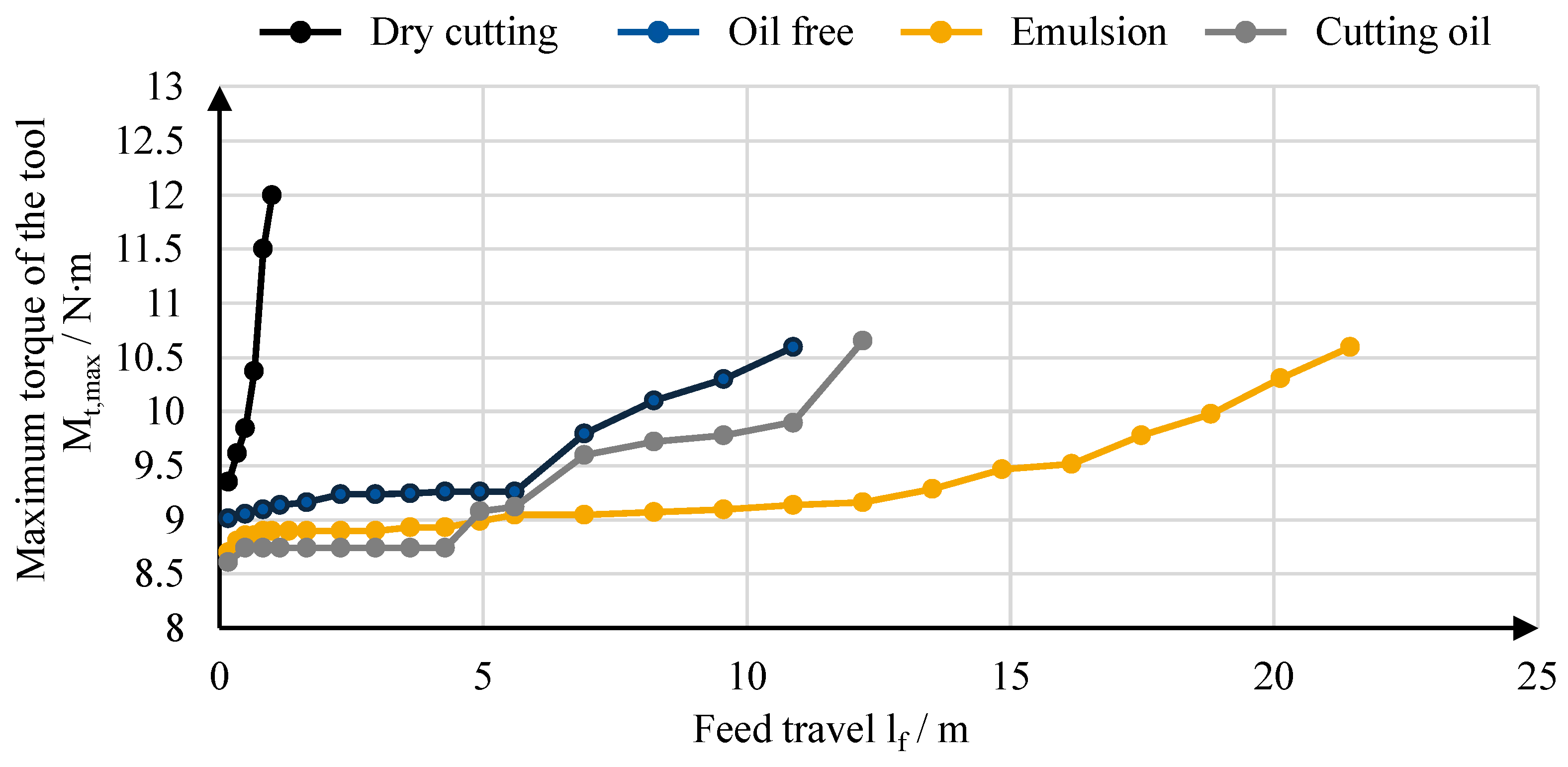

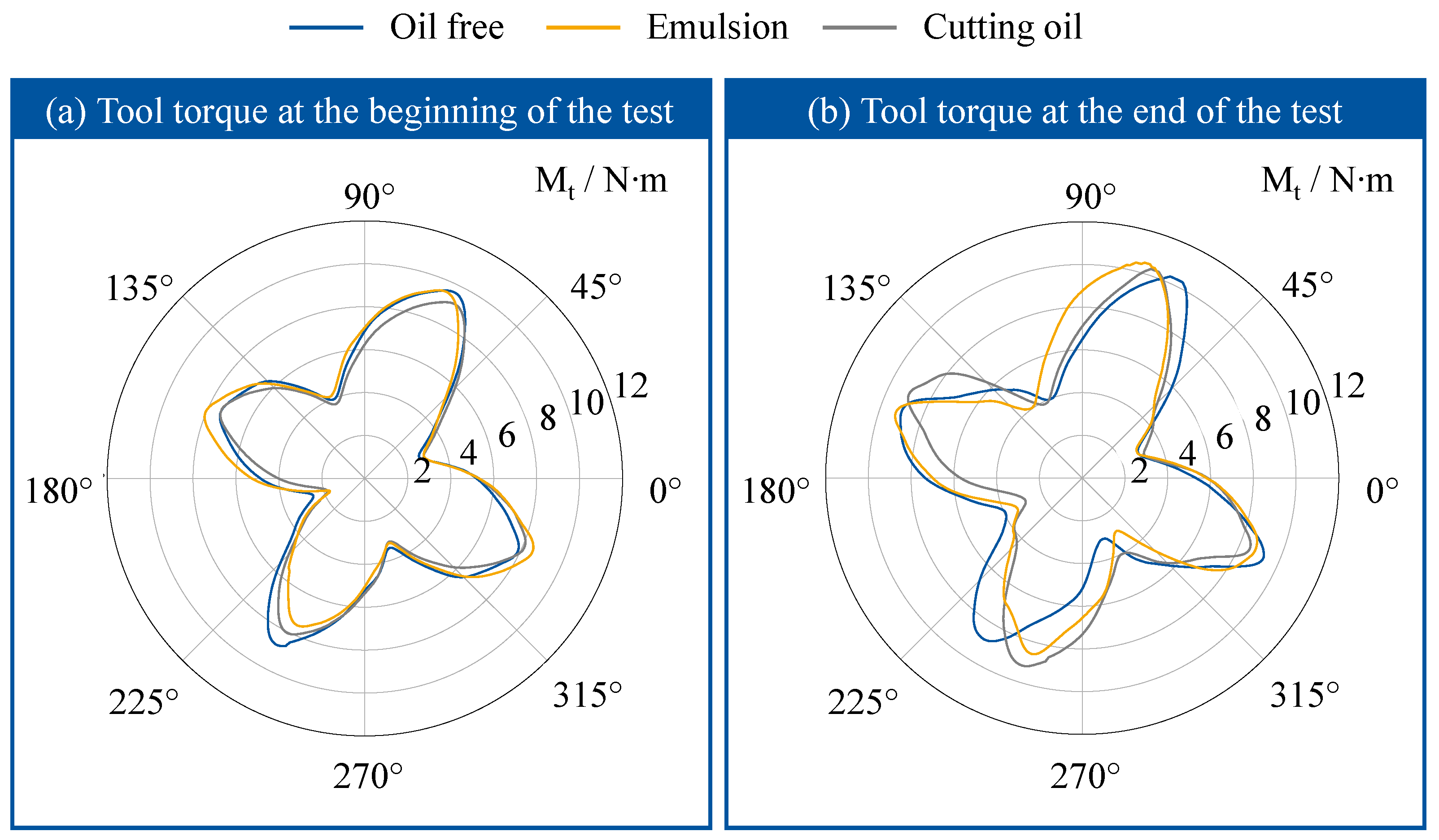

4.1. Evaluation and Interpretation of Experimental Results

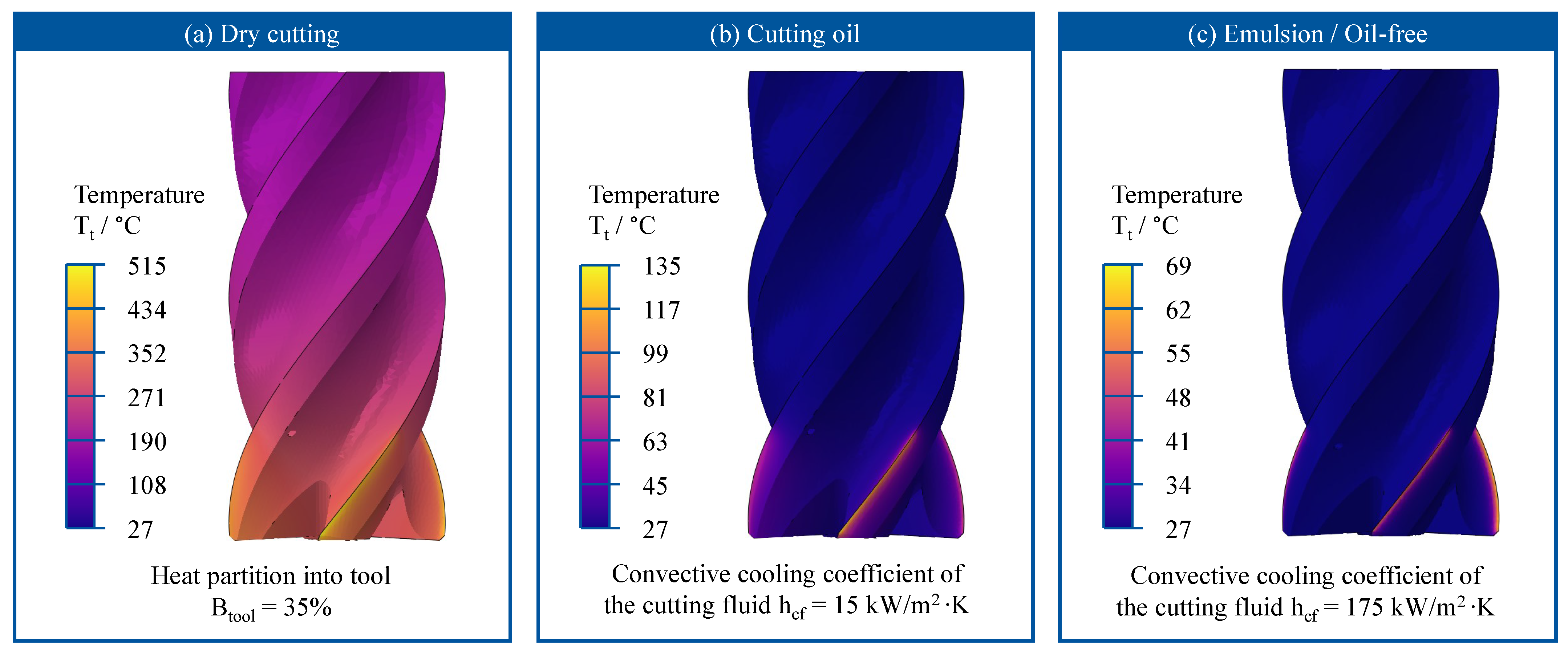

4.2. Evaluation and Interpretation of Simulation Results

5. Conclusions and Outlook

- Performance comparison of cutting fluids:Among the fluids tested, the emulsion delivered the most favorable performance. It achieved a tool life corresponding to a feed travel length of = 12.21 m, which was approximately 200% longer than the = 6.3 m and 6.1 m recorded for cutting oil and the oil-free fluid, respectively. This indicates that the emulsion provided the best balance of cooling and lubrication under the given process conditions.

- Characteristics and limitations of cutting oil:Cutting oil showed good lubricating properties in the early phase of machining, effectively suppressing adhesive wear. However, its limited cooling capacity made it less effective in maintaining thermal stability, which contributed to localized edge chipping. This finding suggests that lubrication alone is insufficient to ensure tool stability during high thermal loading in titanium milling.

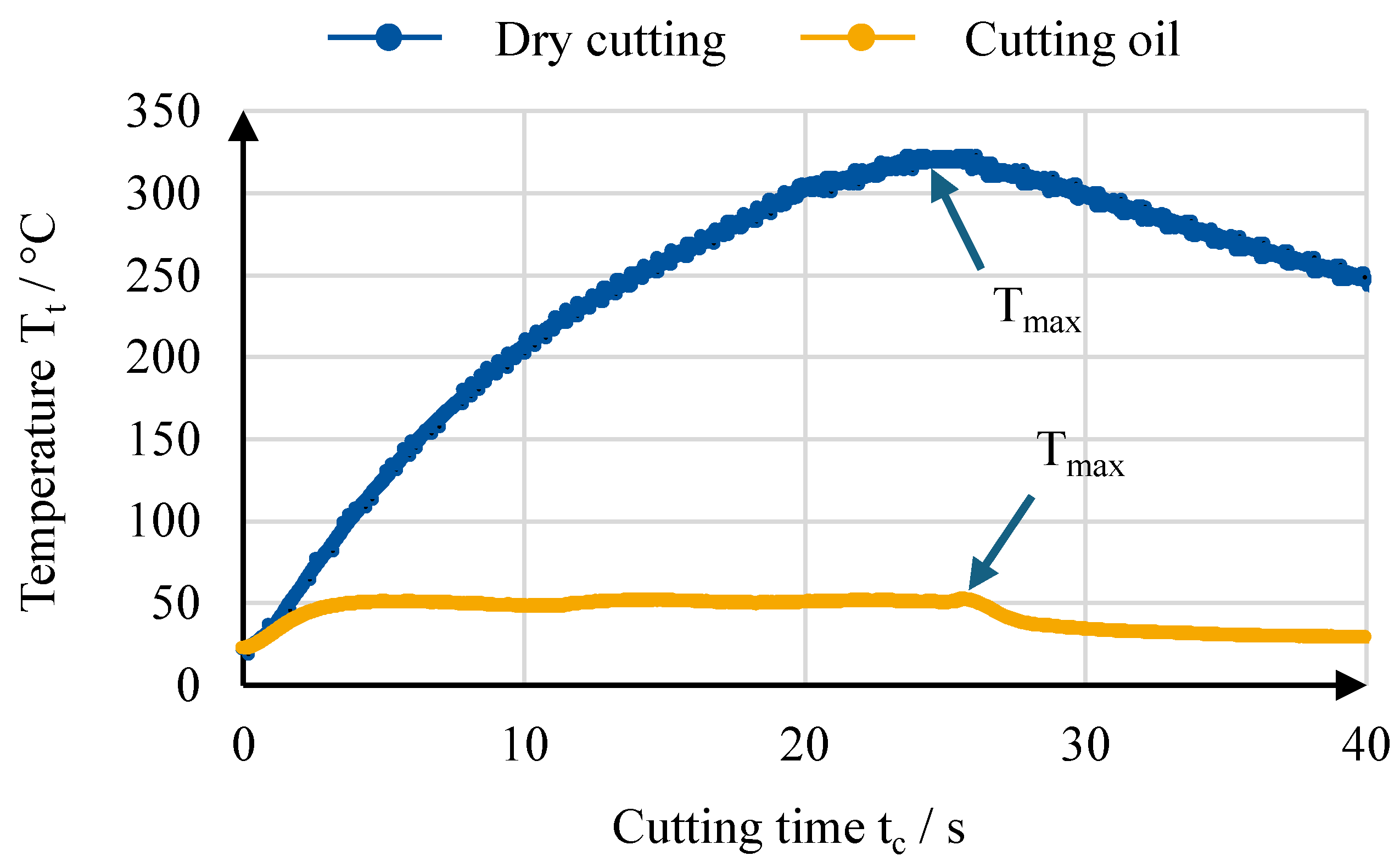

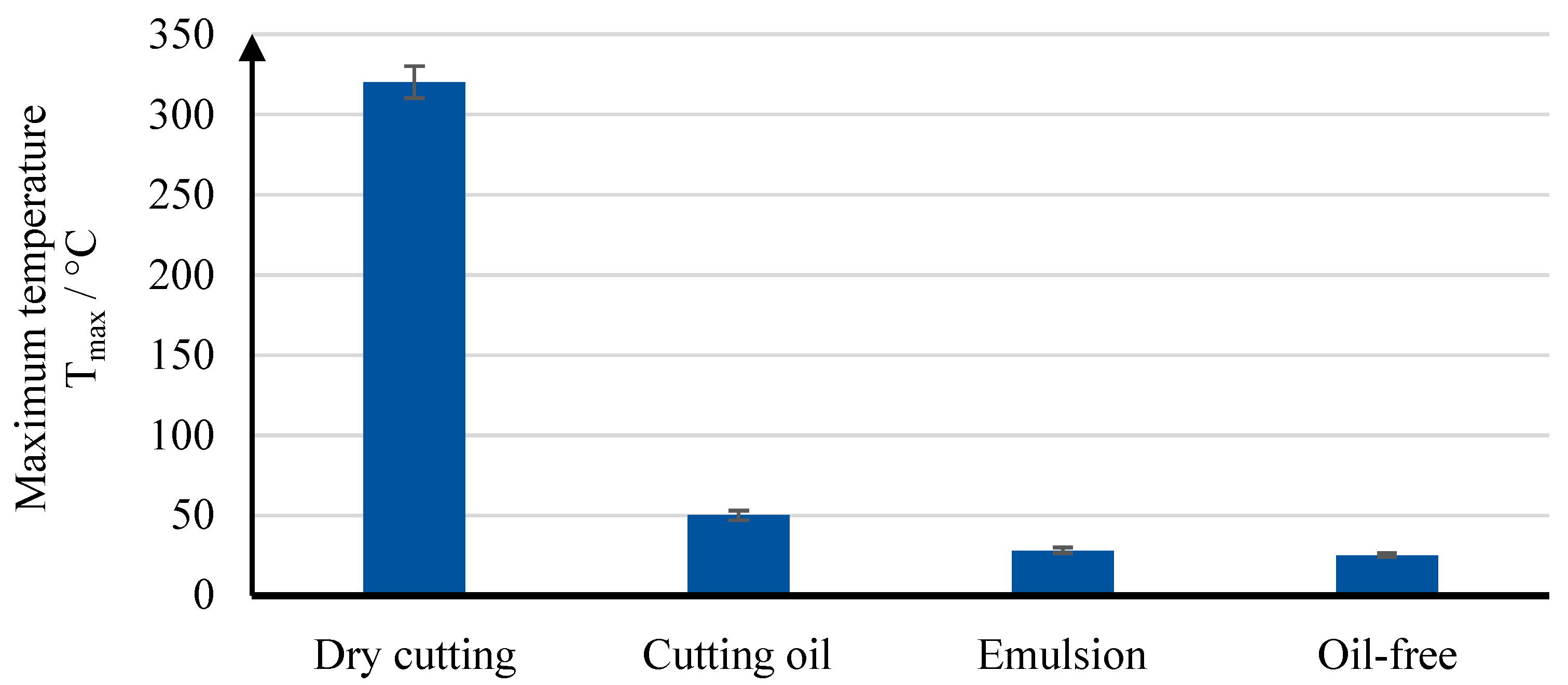

- Thermal performance of water-based fluids:The water-based fluids, including the emulsion and oil-free coolant, significantly lowered the tool temperature to approximately 28 °C due to improved convective heat transfer. Simulations confirmed that their heat transfer coefficients were more than ten times higher than those of cutting oil. Nevertheless, the aggressive cooling at the tool entry zone increased notch wear, likely due to diminished thermal softening of the workpiece material, which elevated mechanical stresses on the cutting edge.

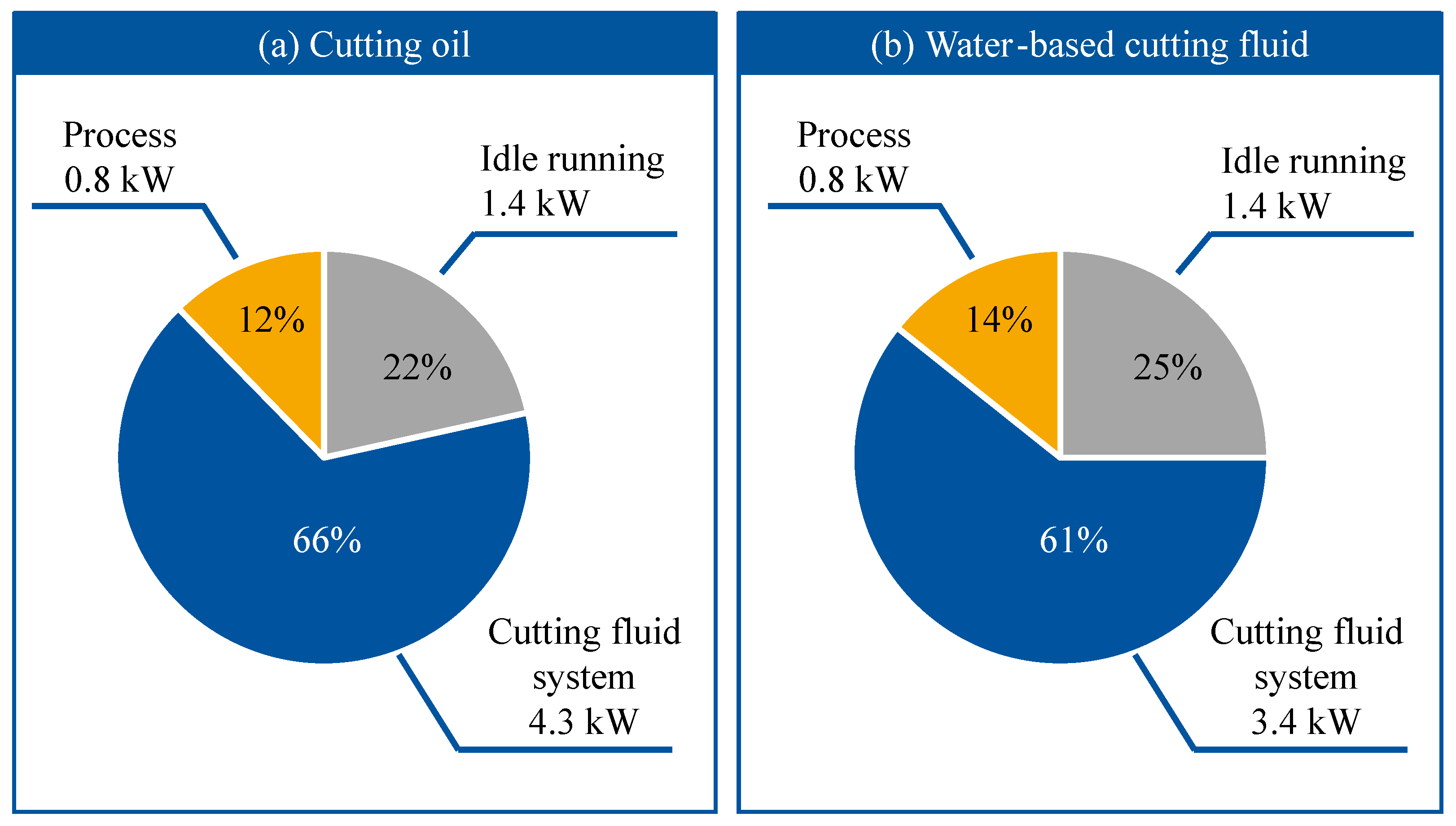

- Energy consumption and supply system impact:The energy analysis identified the cutting fluid supply system as the primary contributor to total machine energy use. When using high-viscosity fluids such as cutting oil, the supply system accounted for up to 66% of the total energy consumption. These findings highlight the importance of selecting not only effective but also energy-efficient cooling systems.

- Scope and applicability of the findings:The conclusions drawn in this study are based on a specific set of semi-finishing conditions and may not directly apply to other machining scenarios. Under different setups, such as higher cutting speeds, deeper depths of cut, or interrupted machining, the relative performance of the fluids may vary. Further research is recommended to validate these findings across a broader range of process conditions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CFD | Computational Fluid Dynamics |

| CNC | Computerized Numerical Control |

| EDM | Electrical Discharge Machining |

| EDS | Energy-Dispersive X-ray Spectroscopy |

| EP | Extreme Pressure |

| FEM | Finite Element Method |

| RCD | Rotating Dynamometer |

| SEM | Scanning Electron Microscope |

References

- Arrazola, P.J.; Garay, A.; Iriarte, L.M.; Armendia, M.; Marya, S.; Le Maître, F. Machinability of titanium alloys (Ti6Al4V and Ti555.3). J. Mater. Process. Technol. 2009, 209, 2223–2230. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Wang, Z.M. Titanium alloys and their machinability—A review. J. Mater. Process. Technol. 1997, 68, 262–274. [Google Scholar] [CrossRef]

- Pramanik, A. Problems and solutions in machining of titanium alloys. Int. J. Adv. Manuf. Technol. 2014, 70, 919–928. [Google Scholar] [CrossRef]

- Namb, M.; Paulo, D. Influence of Coolant in Machinability of Titanium Alloy (Ti-6Al-4V). J. Surf. Eng. Mater. Adv. Technol. 2011, 1, 9–14. [Google Scholar] [CrossRef]

- Sørby, K.; Tønnessen, K. High-pressure cooling of face-grooving operations in Ti6Al4V. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2006, 220, 1621–1627. [Google Scholar] [CrossRef]

- Su, Y.; He, N.; Li, L.; Li, X.L. An experimental investigation of effects of cooling/lubrication conditions on tool wear in high-speed end milling of Ti-6Al-4V. Wear 2006, 261, 760–766. [Google Scholar] [CrossRef]

- Klocke, F. Manufacturing Processes 1; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar] [CrossRef]

- Vieira, J.M.; Machado, A.R.; Ezugwu, E.O. Performance of cutting fluids during face milling of steels. J. Mater. Process. Technol. 2001, 116, 244–251. [Google Scholar] [CrossRef]

- Mittal, R.K.; Kulkarni, S.S.; Singh, R.K. Effect of lubrication on machining response and dynamic instability in high-speed micromilling of Ti-6Al-4V. J. Manuf. Processes 2017, 28, 413–421. [Google Scholar] [CrossRef]

- Li, S.; Li, Y.; Li, Y.; Chen, D. Study of different cutting fluids effect on the coupling characteristics of milling noise-vibration and surface roughness of TA2 pure titanium. J. Manuf. Processes 2024, 118, 103–115. [Google Scholar] [CrossRef]

- Tanaka, R.; Hosokawa, A.; Furumoto, T.; Okada, M.; Ueda, T. Influence of cutting fluid on tool edge temperature in end milling titanium alloy. J. Adv. Mech. Des. Syst. Manuf. 2015, 9, JAMDSM0074. [Google Scholar] [CrossRef]

- Karaguzel, U.; Bakkal, M.; Budak, E. Modeling and Measurement of Cutting Temperatures in Milling. Procedia CIRP 2016, 46, 173–176. [Google Scholar] [CrossRef]

- Praetzas, C.; Teppernegg, T.; Mayr, J.; Czettl, C.; Schäfer, J.; Abele, E. Investigation of Tool Core Temperature and Mechanical Tool Load in Milling of Ti6Al4V. Procedia CIRP 2018, 77, 118–121. [Google Scholar] [CrossRef]

- Augspurger, T.; Koch, M.; Klocke, F.; Döbbeler, B. Investigation of transient temperature fields in the milling cutter under CO2 cooling by means of an embedded thermocouple. Procedia CIRP 2019, 79, 33–38. [Google Scholar] [CrossRef]

- Liu, H.; Meurer, M.; Bergs, T. Modeling and Monitoring of the Tool Temperature During Continuous and Interrupted Turning with Cutting Fluid. Metals 2024, 14, 1292. [Google Scholar] [CrossRef]

- Helmig, T.; Liu, H.; Winter, S.; Bergs, T.; Kneer, R. Development of a Tool Temperature Simulation During Side Milling. In Proceedings of the 3rd International Conference on Thermal Issues in Machine Tools (ICTIMT2023), Dresden, Germany, 21–23 March 2023; Ihlenfeldt, S., Ed.; Lecture Notes in Production Engineering. Springer International Publishing: Cham, Switzerland, 2023; pp. 308–317. [Google Scholar] [CrossRef]

- Liu, H.; Helmig, T.; Gerhard, N.; Kneer, R.; Bergs, T. Numerical and experimental determination of contact heat transfer during orthogonal cutting. Procedia CIRP 2023, 117, 329–334. [Google Scholar] [CrossRef]

- Tismer, A.; Menze, C.; Straub, P.; Stegmann, J.; Riedelbauch, S.; Möhring, H.C.; Kabelac, S. Simulation-based evaluation of the 3D fluid dynamics of a coolant lubricant in the narrow-closed cutting gap during circular sawing. Procedia CIRP 2023, 117, 402–407. [Google Scholar] [CrossRef]

- Liu, H.; Meurer, M.; Schraknepper, D.; Bergs, T. Investigation of the cutting fluid’s flow and its thermomechanical effect on the cutting zone based on fluid–structure interaction (FSI) simulation. Int. J. Adv. Manuf. Technol. 2022, 121, 267–281. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A Constitutive Model and Data for Metals Subjected to Large Strains, High Strain Rates and High Temperatures. In Proceedings of the 7th International Symposium On Ballistics, Hague, The Netherlands, 19–21 April 2018. [Google Scholar]

- Johnson, G.R.; Cook, W.H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

- Abouridouane, M.; Klocke, F.; Lung, D.; Veselovac, D. The Mechanics of Cutting: In-situ Measurement and Modelling. Procedia CIRP 2015, 31, 246–251. [Google Scholar] [CrossRef]

- Puls, H.; Klocke, F.; Lung, D. Experimental investigation on friction under metal cutting conditions. Wear 2014, 310, 63–71. [Google Scholar] [CrossRef]

- Klocke, F.; Peng, B.X.; Lakner, T.; Döbbeler, B. Identification of friction and material model parameters for finite element simulation of TiAl6V4. In Reibung, Schmierung und Verschleiß: Forschung und Praktische Anwendungen; 57. Tribologie-Fachtagung; GfT Gesellschaft für Tribologie e.V.: Göttingen, Germany, 2016. [Google Scholar]

- Dassault Systèmes Simulia Corp. Abaqus 6.11 Analysis User’s Guide; Dassault Systèmes: Providence, RI, USA, 2011. [Google Scholar]

- Trostmann, E. Water Hydraulics Control Technology; M. Dekker: New York, NY, USA; Basel, Switzerland; Hong Kong, China, 1996. [Google Scholar]

- Abbas, A.T.; Al Bahkali, E.A.; Alqahtani, S.M.; Abdelnasser, E.; Naeim, N.; Elkaseer, A. Fundamental Investigation into Tool Wear and Surface Quality in High-Speed Machining of Ti6Al4V Alloy. Materials 2021, 14, 7128. [Google Scholar] [CrossRef] [PubMed]

- Brecher, C. (Ed.) Effizienzsteigerung von Werkzeugmaschinen durch Optimierung der Technologien zum Komponentenbetrieb—EWOTeK: Verbundprojekt im Rahmenkonzept “Forschung für die Produktion von morgen”, “Ressourceneffizienz in der Produktion” des Bundesministeriums für Bildung und Forschung (BMBF), 1st ed.; Apprimus: Aachen, Germany, 2012; White Paper. [Google Scholar]

- DMG MORI Aktiengesellschaft. GreenMode—Energieeffizienz in der Produktion; Technical Report; DMG MORI Aktiengesellschaft: Bielefeld, Germany, 2023; White Paper. [Google Scholar]

| Ti | Al | V | Fe | C | Sn | Zr | Mo |

|---|---|---|---|---|---|---|---|

| 89 | 6.3 | 4.16 | 0.227 | 0.0806 | 0.0084 | 0.0046 | 0.0112 |

| Si | Mn | Cr | Ni | Cu | Nb | Pd | Y |

| 0.0129 | 0.0041 | 0.042 | 0.0289 | 0.0111 | 0.0431 | 0.0108 | 0.0063 |

| /m/min | /mm/z | /mm | /mm | Process Type |

|---|---|---|---|---|

| 60 | 0.08 | 5 | 8 | Down Milling |

| Emulsion | Ester oil-based, highly additivated, water-emulsifiable cutting fluid |

| Oil-free | Full synthetic, water-soluble cutting fluid with EP additives |

| Cutting oil | Mineral oil-based, non-water-miscible cutting oil with EP additives |

| Temperature T/°C | Density /kg/m3 | Thermal Conductivity /W/m·K | Specific Heat /J/kg·K |

|---|---|---|---|

| 25 | 14,800 | 115.17 | 198 |

| 100 | - | 106.25 | 215 |

| 200 | - | 96.17 | 229 |

| 300 | - | 88.44 | 238 |

| 400 | - | 81.78 | 243 |

| 500 | - | 75.92 | 246 |

| 1500 | - | - | 250 |

| Johnson–Cook material constitutive model of Ti-6Al-4V | |||||||

| A/MPa | B/MPa | C | m | n | /°C | /°C | / |

| 1098 | 1092 | 0.014 | 1.3 | 0.93 | 1630 | 20 | 1 |

| Johnson–Cook damage model of Ti-6Al-4V | Friction model of Ti-6Al-4V | ||||||

| −0.072 | 0.324 | 0.576 | 0.0168 | 4.644 | 0.425 | 0.4 | 110 |

| Density /kg/m3 | Thermal Conductivity /W/m·K | Specific Heat /J/kg·K | Kinematic Viscosity /mm2/s | Speed of Sound /mm/s | |

|---|---|---|---|---|---|

| Cutting oil | 850.5 | 0.129 | 2006.9 | 11 | 1.30 × 106 |

| Water | 992.2 | 0.629 | 4073.7 | 0.6579 | 1.45 × 106 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Meurer, M.; Bergs, T. Comparative Analysis of Emulsion, Cutting Oil, and Synthetic Oil-Free Fluids on Machining Temperatures and Performance in Side Milling of Ti-6Al-4V. Lubricants 2025, 13, 396. https://doi.org/10.3390/lubricants13090396

Liu H, Meurer M, Bergs T. Comparative Analysis of Emulsion, Cutting Oil, and Synthetic Oil-Free Fluids on Machining Temperatures and Performance in Side Milling of Ti-6Al-4V. Lubricants. 2025; 13(9):396. https://doi.org/10.3390/lubricants13090396

Chicago/Turabian StyleLiu, Hui, Markus Meurer, and Thomas Bergs. 2025. "Comparative Analysis of Emulsion, Cutting Oil, and Synthetic Oil-Free Fluids on Machining Temperatures and Performance in Side Milling of Ti-6Al-4V" Lubricants 13, no. 9: 396. https://doi.org/10.3390/lubricants13090396

APA StyleLiu, H., Meurer, M., & Bergs, T. (2025). Comparative Analysis of Emulsion, Cutting Oil, and Synthetic Oil-Free Fluids on Machining Temperatures and Performance in Side Milling of Ti-6Al-4V. Lubricants, 13(9), 396. https://doi.org/10.3390/lubricants13090396