Theoretical Modeling and Numerical Simulation of Current-Carrying Friction and Wear: State of the Art and Challenges

Abstract

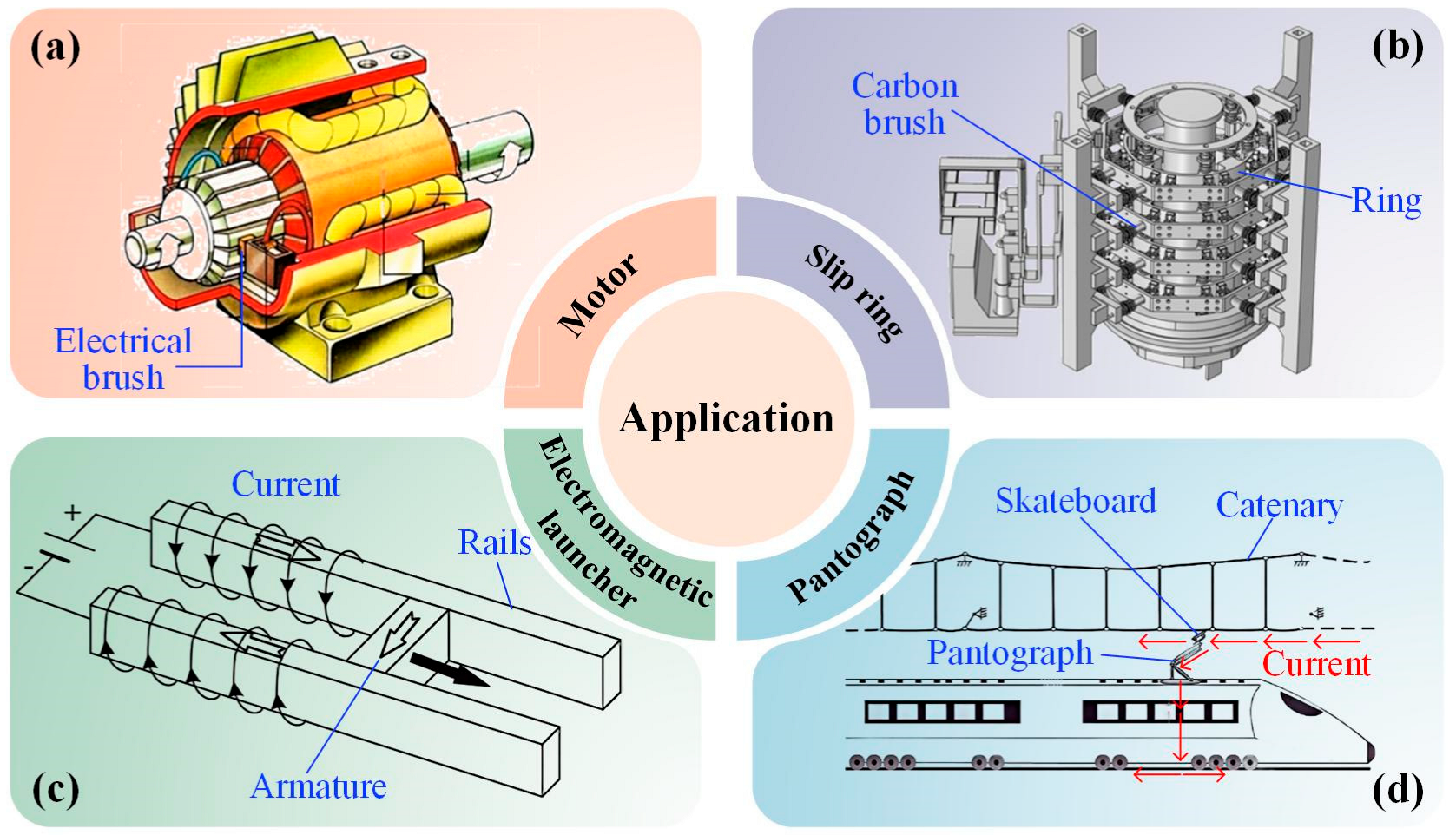

1. Introduction

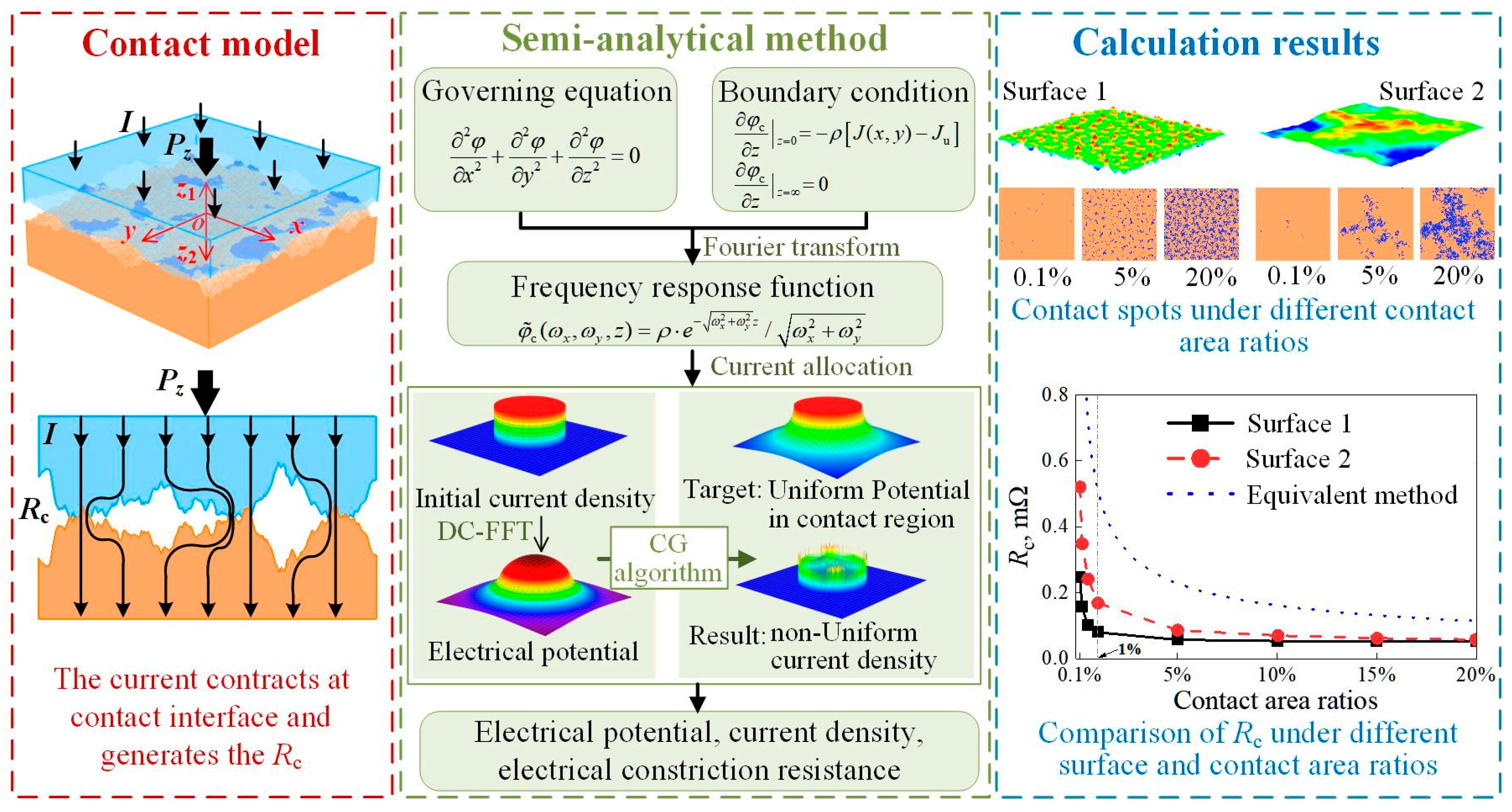

2. Solving Electrical Contact Resistance (ECR)

2.1. Constriction Resistance Rc

2.2. Film Resistance Rf

2.3. Total ECR

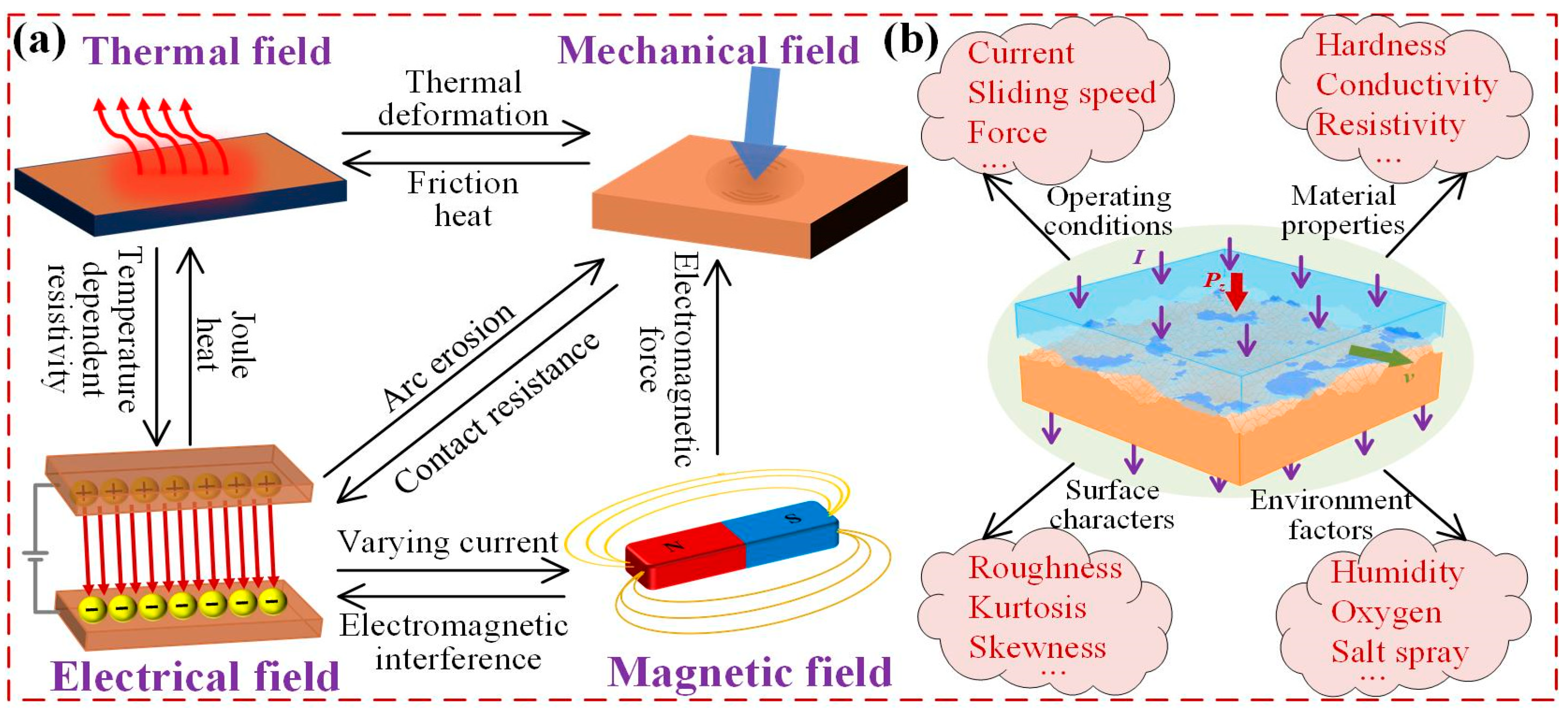

3. Modeling Current-Carrying Friction

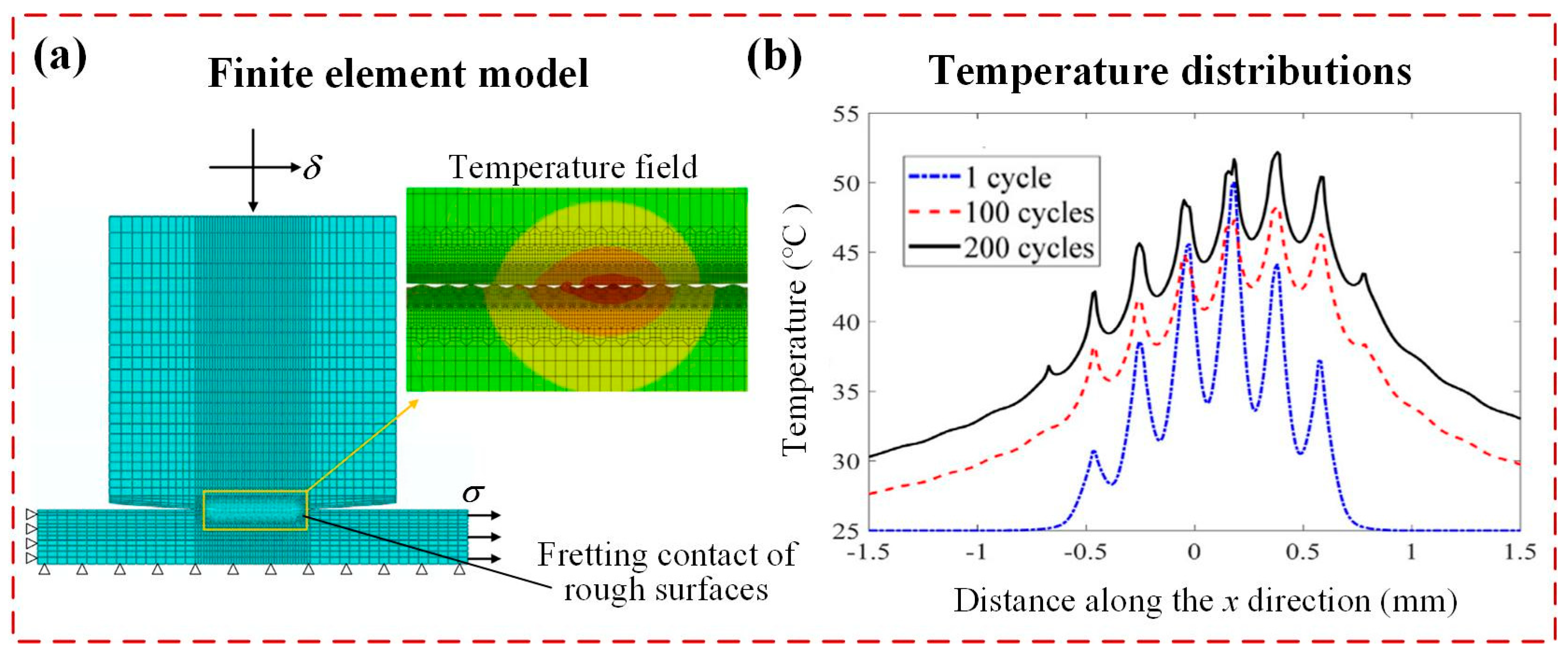

3.1. Thermal Field

3.2. Thermal-Mechanical-Electrical Coupling

3.3. Thermal-Mechanical-Electrical-Magnetic Coupling

4. Modeling Current-Carrying Wear

4.1. Mechanical Wear

4.2. Modeling Arc Erosion

5. Conclusions and Perspectives

- (1)

- Theoretical formulas, FEM, and SAM are widely used in solving ECR. Among them, theoretical formulas are typically restricted to idealized scenarios, such as contact spots with regular shapes, resulting in low accuracy; FEM offers high accuracy but consumes a lot of computation time; SAM effectively balances precision and efficiency, making it better suited for more realistic rough surface contacts. Currently, research on the dynamic evolution of ECR during current-carrying friction remains limited. The primary challenge lies in capturing the evolution of the 3D geometry of the oxide film and subsequently determining the time-dependent behavior of film resistance. Modeling the evolution of 3D oxide film morphology via PFM, in combination with electron tunneling theory for film resistance prediction, presents a promising direction.

- (2)

- FEM, BEM, and SAM have proven effective in addressing multi-field coupling problems in current-carrying friction with high accuracy. FEM offers strong geometric adaptability and modeling flexibility but is limited due to high computational cost. BEM and SAM are more efficient; however, BEM struggles to obtain fundamental solutions under multi-field coupling, and SAM poorly accommodates the actual geometry of contact parts. Furthermore, their adaptability remains limited under complex conditions such as high-power, high-speed, and alternating current. The primary challenges lie in incorporating temperature-dependent material properties and modeling the effects of magnetic fields induced by alternating currents at the contact interface. To address these limitations, future efforts could focus on two aspects: capturing the spatial variability of material properties to account for temperature dependence; coupling magnetic field effects with thermal-mechanical-electrical fields. Additionally, to enhance the applicability of models across diverse operating environments, external factors such as humidity must also be integrated into the modeling framework.

- (3)

- FEM is widely employed to model current-carrying wear at the microscale, while energy dissipation principles provide an effective means to simulate macro wear amount. Effective methods for simulating long-distance surface wear evolution remain lacking. The main challenges include the absence of models capable of characterizing the 3D morphology of arc erosion and the low computational efficiency of existing approaches in capturing surface evolution. A key future research direction is developing an integrated model that couples the 3D arc erosion with mechanical wear under multi-field conditions. Such a model is essential for accurately identifying arc initiation criteria and predicting current-carrying wear by capturing the synergistic effects of mechanical and electrical degradation. Additionally, incorporating energy dissipation principles into wear models could enable efficient simulation of surface morphology evolution over extended wear durations.

- (4)

- The advances in artificial intelligence have made the application of ML to current-carrying friction and wear a central focus of future research. For instance, employ PINN to solve complex partial differential equations in multi-field coupling problems, establish quantitative relationships between wear characteristics and engineering parameters for friction pair design, and predict the remaining service life of components based on wear evolution. In the future, the primary challenge will be to integrate physical principles with ML techniques for multi-scale modeling, spanning contact damage analysis at the asperity level to wear evolution simulation at the rough-surface level, enabling real-time prediction of component performance and remaining service life.

Author Contributions

Funding

Conflicts of Interest

References

- Holle, M.J.; Misak, H.E.; Malik, R.A.; Alarifi, I.M.; Asmatulu, R. Structural analysis and wear behavior of different graphite-based brushes for aircraft starter generator application. Adv. Compos. Hybrid Mater. 2021, 4, 162–172. [Google Scholar] [CrossRef]

- Liu, B. Simulation analysis of alocal temperature field of electric propulsion slip ring. Vibroeng. Procedia 2024, 54, 1–7. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, P.; Li, H.; Zhang, H. The Influence of projectile shielding on the internal magnetic field during an electromagnetic launch. J. Vibroeng. 2022, 24, 966–982. [Google Scholar] [CrossRef]

- Song, Y.; Wang, Z.; Liu, Z.; Wang, R. A spatial coupling model to study dynamic performance of pantograph-catenary with vehicle-track excitation. Mech. Syst. Signal Process. 2021, 151, 107336. [Google Scholar] [CrossRef]

- Zuo, X.; Xie, W.; Zhou, Y. Influence of electric current on the wear topography of electrical contact surfaces. J. Tribol.-Trans. ASME 2022, 144, 071702. [Google Scholar] [CrossRef]

- Wen, D.; Zhang, M.; Zhu, R.; Zuo, X.; Zhou, Y. Improving signal transmission quality of wind turbine pitch slip ring with copper matrix composites. J. Tribol.-Trans. ASME 2024, 146, 101402. [Google Scholar] [CrossRef]

- Arish, N.; Kamper, M.J.; Wang, R.J. Advancements in electrical marine propulsion technologies: A comprehensive overview. SAIEE Afr. Res. J. 2025, 116, 14–29. [Google Scholar] [CrossRef]

- Lin, Q.; Li, B. Numerical simulation of interior ballistic process of railgun based on the multi-field coupled model. Def. Technol. 2016, 12, 101–105. [Google Scholar] [CrossRef]

- Zhu, C.; Li, B. Analysis of sliding electric contact characteristics in augmented railgun based on the combination of contact resistance and sliding friction coefficient. Def. Technol. 2020, 16, 747–752. [Google Scholar] [CrossRef]

- Li, S.; Yang, X.; Kang, Y.; Li, Z.; Li, H. Progress on current-carry friction and wear: An overview from measurements to mechanism. Coatings 2022, 12, 1345. [Google Scholar] [CrossRef]

- Wei, P.; Wang, X.; Jing, G.; Li, F.; Bai, P.; Tian, Y. Research progress on current-carrying friction with high stability and excellent tribological behavior. Lubricants 2024, 12, 349. [Google Scholar] [CrossRef]

- Huang, Q.; Song, C.; Liu, Z.; Hou, X.; Pang, X.; Sun, C.; Lu, H.; Wang, S.; Zhang, Y. Research progress on the characteristics of current-carrying tribology in electrical transmission. Space Sol. Power Wirel. Transm. 2024, 1, 37–47. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, W.; Zhang, S.; Zhao, Z. Semi-analytical solution of three-dimensional steady state thermoelastic contact problem of multilayered material under friction heating. Int. J. Therm. Sci. 2018, 127, 384–399. [Google Scholar] [CrossRef]

- Yasar, I.; Canakci, A.; Arslan, F. The effect of brush spring pressure on the wear behaviour of copper–graphite brushes with electrical current. Tribol. Int. 2007, 40, 1381–1386. [Google Scholar] [CrossRef]

- Chen, W.W.; Wang, Q.J.; Kim, W. Transient thermomechanical analysis of sliding electrical contacts of elastoplastic bodies, thermal softening, and melting inception. J. Tribol.-Trans. ASME 2009, 131, 021406. [Google Scholar] [CrossRef]

- He, W.; Feng, Y.; Wu, S.; Wang, W. Effect of elastoplastic thermal softening on electrical contact resistance based on the dual-iterative coupling method. IEEE Trans. Dielectr. Electr. Insul. 2023, 30, 11–19. [Google Scholar] [CrossRef]

- Ohkawa, F.J. Temperature dependence of electrical resistivity of metals. J. Phys. Soc. Jpn. 1978, 44, 1105–1111. [Google Scholar] [CrossRef]

- He, L.; Cai, Z.; Peng, J.; Deng, W.; Li, Y.; Yang, L.; Zhu, M. Effects of oxidation layer and roughness on the fretting wear behavior of copper under electrical contact. Mater. Res. Express 2020, 6, 1265e3. [Google Scholar] [CrossRef]

- Chen, G.; Yang, H.; Zhang, W.; Wang, X.; Zhang, S.; Zhou, Z. Experimental study on arc ablation occurring in a contact strip rubbing against a contact wire with electrical current. Tribol. Int. 2013, 61, 88–94. [Google Scholar] [CrossRef]

- Mei, G. Tribological performance of rigid overhead lines against pantograph sliders under DC passage. Tribol. Int. 2020, 151, 106538. [Google Scholar] [CrossRef]

- Guo, F.; Wang, Z.; Zheng, Z.; Zhang, J.; Wang, H. Electromagnetic noise of pantograph arc under low current conditions. Int. J. Appl. Electromagn. Mech. 2017, 53, 397–408. [Google Scholar] [CrossRef]

- He, Z.; Ni, Z.; Wang, H.; Yang, Z.; Wei, W.; Wang, X.; Deng, L.; Wu, G. Effect of magnetic field on the current-carrying friction and wear performance of C/Cu contact pairs. In Proceedings of the International Conference on Electrical Materials and Power Equipment, Chongqing, China, 11–15 April 2021; pp. 1–4. [Google Scholar]

- Shin, W.G.; Lee, S.H. An analysis of the main factors on the wear of brushes for automotive small brush-type DC motor. J. Mech. Sci. Technol. 2010, 24, 37–41. [Google Scholar] [CrossRef]

- Lin, Y.; Li, J.Z.; Pan, J.; Zhang, C.; Ni, D.R.; Chen, Q.; Song, W.L.; Lu, J.Y.; Li, B.; Liu, L. Current-carrying wear behavior and the interface evolution of the Cu/Al tribological pair. Eng. Fail. Anal. 2023, 153, 107549. [Google Scholar] [CrossRef]

- Wang, X.; Song, K.; Duan, J.; Feng, J.; Huang, T.; Xing, J. Current-carrying tribological behavior and wear mechanism of CuW composites with different W content. Tribol. Int. 2024, 200, 110125. [Google Scholar] [CrossRef]

- Yi, F.; Zhang, M.; Xu, Y. Effect of the electric current on the friction and wear properties of the CNT–Ag–G composites. Carbon 2005, 43, 2685–2692. [Google Scholar] [CrossRef]

- Bouchoucha, A.; Chekroud, S.; Paulmier, D. Influence of the electrical sliding speed on friction and wear processes in an electrical contact copper–stainless steel. Appl. Surf. Sci. 2004, 223, 330–342. [Google Scholar] [CrossRef]

- Ma, W.; Lu, J. Effect of sliding speed on surface modification and tribological behavior of copper–graphite composite. Tribol. Lett. 2010, 41, 363–370. [Google Scholar] [CrossRef]

- Findik, F.; Uzun, H. Microstructure, hardness and electrical properties of silver-based refractory contact materials. Mater. Des. 2003, 24, 489–492. [Google Scholar] [CrossRef]

- Liu, X.; Cai, Z.; Liu, S.; Peng, J.; Zhu, M. Effect of roughness on electrical contact performance of electronic components. Microelectron. Reliab. 2017, 74, 100–109. [Google Scholar] [CrossRef]

- Hu, Z.; Chen, Z.; Xia, J. Study on surface film in the wear of electrographite brushes against copper commutators for variable current and humidity. Wear 2008, 264, 11–17. [Google Scholar] [CrossRef]

- Ni, Z.; He, Z.; Wang, H.; Gao, G.; Yang, Z.; Wei, W. Effect of oxygen concentration on the current-carrying friction and wear performance of C/Cu contact pairs. In Proceedings of the 16th Annual Conference of China Electrotechnical Society, Singapore, 24–26 September 2021; pp. 443–450. [Google Scholar]

- Holm, R. Electric Contacts: Theory and Application, 4th ed.; Springer: New York, NY, USA, 1967. [Google Scholar] [CrossRef]

- Timsit, R.S. The potential distribution in a constricted cylinder. J. Phys. D Appl. Phys. 1977, 10, 2011. [Google Scholar] [CrossRef]

- Rosenfeld, A.M.; Timsit, R.S. The potential distribution in a constricted cylinder: An exact solution. Q. Appl. Math. 1981, 39, 405–417. [Google Scholar] [CrossRef]

- Greenwood, J. Constriction resistance and the real area of contact. Br. J. Appl. Phys. 1966, 17, 1621–1632. [Google Scholar] [CrossRef]

- Barber, J.R. Bounds on the electrical resistance between contacting elastic rough bodies. Proc. R. Soc. London Ser. A Math. Phys. Eng. Sci. 2003, 459, 53–66. [Google Scholar] [CrossRef]

- Kogut, L.; Komvopoulos, K. Electrical contact resistance theory for conductive rough surfaces. J. Appl. Phys. 2003, 94, 3153–3162. [Google Scholar] [CrossRef]

- Li, B.; Hong, J.; Shao, G.; Du, F. An integrated mechanical–electrical predictive model of eectrical contact resistance between two rough surfaces. Tribol. Trans. 2015, 58, 537–548. [Google Scholar] [CrossRef]

- Ta, W.; Qiu, S.; Wang, Y.; Yuan, J.; Gao, Y.; Zhou, Y. Volumetric contact theory to electrical contact between random rough surfaces. Tribol. Int. 2021, 160, 107007. [Google Scholar] [CrossRef]

- Talukder, S.; Yeo, C.D.; Hong, Y.K.; Choi, M.; Flicek, R.C.; Bishop, J.E. Analytical modeling and simulation of electrical contact resistance for elastic rough electrode surface contact including frictional temperature rise. AIP Adv. 2022, 12, 025204. [Google Scholar] [CrossRef]

- Zhang, M.; Zuo, X.; Zhou, Y. Fractal contact resistance model of wind pitch slip ring considering wear and self-excited vibration. Ind. Lubr. Tribol. 2024, 76, 214–230. [Google Scholar] [CrossRef]

- Nakamura, M.; Minowa, I. Computer simulation for the conductance of a contact interface. IEEE Trans. Compon. Hybrids Manuf. Technol. 1986, 9, 150–155. [Google Scholar] [CrossRef]

- Ren, W.; Chen, Y.; Wang, Z.; Xue, S.; Zhang, X. Electrical contact resistance of coated spherical contacts. IEEE Trans. Electron Devices 2016, 63, 4373–4379. [Google Scholar] [CrossRef]

- Korchevnik, O.; Goltsberg, R.; Kligerman, Y.; Etsion, I. Electrical resistance model of a bilayer-coated spherical contact. IEEE Trans. Compon. Packag. Manuf. Technol. 2018, 8, 1614–1620. [Google Scholar] [CrossRef]

- Riba, J.R.; Mancini, A.G.; Abomailek, C.; Capelli, F. A 3D-FEM-based model to predict the electrical constriction resistance of compressed contacts. Measurement 2018, 114, 44–50. [Google Scholar] [CrossRef]

- Ren, W.; Zhang, C.; Sun, X. Electrical contact resistance of contact bodies with cambered surface. IEEE Access 2020, 8, 93857–93867. [Google Scholar] [CrossRef]

- Wang, W.; Sui, Y.; Ge, X.; Zhang, H. An efficient method for solving electrical constriction resistance of rough surfaces. Tribol. Int. 2024, 197, 109808. [Google Scholar] [CrossRef]

- Braunovic, M.; Konchits, V.; Myshkin, N. Electrical Contacts: Fundamentals, Applications and Technology; Taylor & Francis Group, LLC.: Boca Raton, FL, USA, 2006; pp. 1–645. [Google Scholar] [CrossRef]

- Li, Y.; Shen, F.; Ke, L. Multi-physics electrical contact analysis considering the electrical resistance and Joule heating. Int. J. Solids Struct. 2022, 256, 111975. [Google Scholar] [CrossRef]

- Simmons, J.G. Generalized formula for the electric tunnel effect between similar electrodes separated by a thin insulating film. J. Appl. Phys. 1963, 34, 1793–1803. [Google Scholar] [CrossRef]

- Kogut, L.; Komvopoulos, K. Electrical contact resistance theory for conductive rough surfaces separated by a thin insulating film. J. Appl. Phys. 2004, 95, 576–585. [Google Scholar] [CrossRef]

- Jackson, R.L.; Kogut, L. Electrical contact resistance theory for anisotropic conductive films considering electron tunneling and particle flattening. IEEE Trans. Compon. Packag. Technol. 2007, 30, 59–66. [Google Scholar] [CrossRef]

- Ma, T.; Yu, Z.; Song, A.; Zhao, J.; Zhang, H.; Lu, H.; Han, D.; Wang, X.; Wang, W. Intermittent failure mechanism and stabilization of microscale electrical contact. Friction 2022, 11, 538–545. [Google Scholar] [CrossRef]

- Kondo, T.; Nakata, H.; Sekikawa, J.; Kubota, Y.; Hayakawa, K.; Nakamura, T. An analysis of relationship between contact resistance and fracture of oxide film for connector contacts using finite element method. In Proceedings of the 2014 IEEE 60th Holm Conference on Electrical Contacts (Holm), New Orleans, LA, USA, 12–15 October 2014; pp. 1–6. [Google Scholar]

- Yang, F.; Fang, D.; Liu, B. A theoretical model and phase field simulation on the evolution of interface roughness in the oxidation process. Model. Simul. Mater. Sci. Eng. 2012, 20, 015001. [Google Scholar] [CrossRef]

- Wang, R.; Ji, Y.; Cheng, T.; Xue, F.; Chen, L.; Wen, Y. Phase-field modeling of alloy oxidation at high temperatures. Acta Mater. 2023, 248, 118776. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, Q.; Guo, F.; Tang, A.; Wang, X.; Chen, X. Mathematical model of contact resistance in pantograph-catenary system considering rough surface characteristics. IEEE Trans. Transp. Electrif. 2022, 8, 455–465. [Google Scholar] [CrossRef]

- Cai, Z.; Li, C.; You, L.; Chen, X.; He, L.; Cao, Z.; Zhang, Z. Prediction of contact resistance of electrical contact wear using different machine learning algorithms. Friction 2024, 12, 1250–1271. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Q. A three-dimensional thermomechanical model of contact between non-conforming rough surfaces. J. Tribol.-Trans. ASME 2000, 123, 17–26. [Google Scholar] [CrossRef]

- Liu, S.; Rodgers, M.; Wang, Q.; Keer, L.; Cheng, H. Temperature distributions and thermoelastic displacements in moving bodies. Comput. Model. Eng. Sci. 2002, 3, 465–481. [Google Scholar] [CrossRef]

- Shen, F.; Zhou, K. Investigation on thermal response in fretting sliding with the consideration of plastic dissipation, surface roughness and wear. Int. J. Mech. Sci. 2018, 148, 94–102. [Google Scholar] [CrossRef]

- Greenwood, J.A.; Williamson, J.B.P.; Bowden, F.P. Electrical conduction in solids II. Theory of temperature-dependent conductors. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1958, 246, 13–31. [Google Scholar] [CrossRef]

- Nituca, C. Thermal analysis of electrical contacts from pantograph–catenary system for power supply of electric vehicles. Electr. Power Syst. Res. 2013, 96, 211–217. [Google Scholar] [CrossRef]

- Plesca, A. Thermal analysis of sliding electrical contacts with mechanical friction in steady state conditions. Int. J. Therm. Sci. 2014, 84, 125–133. [Google Scholar] [CrossRef]

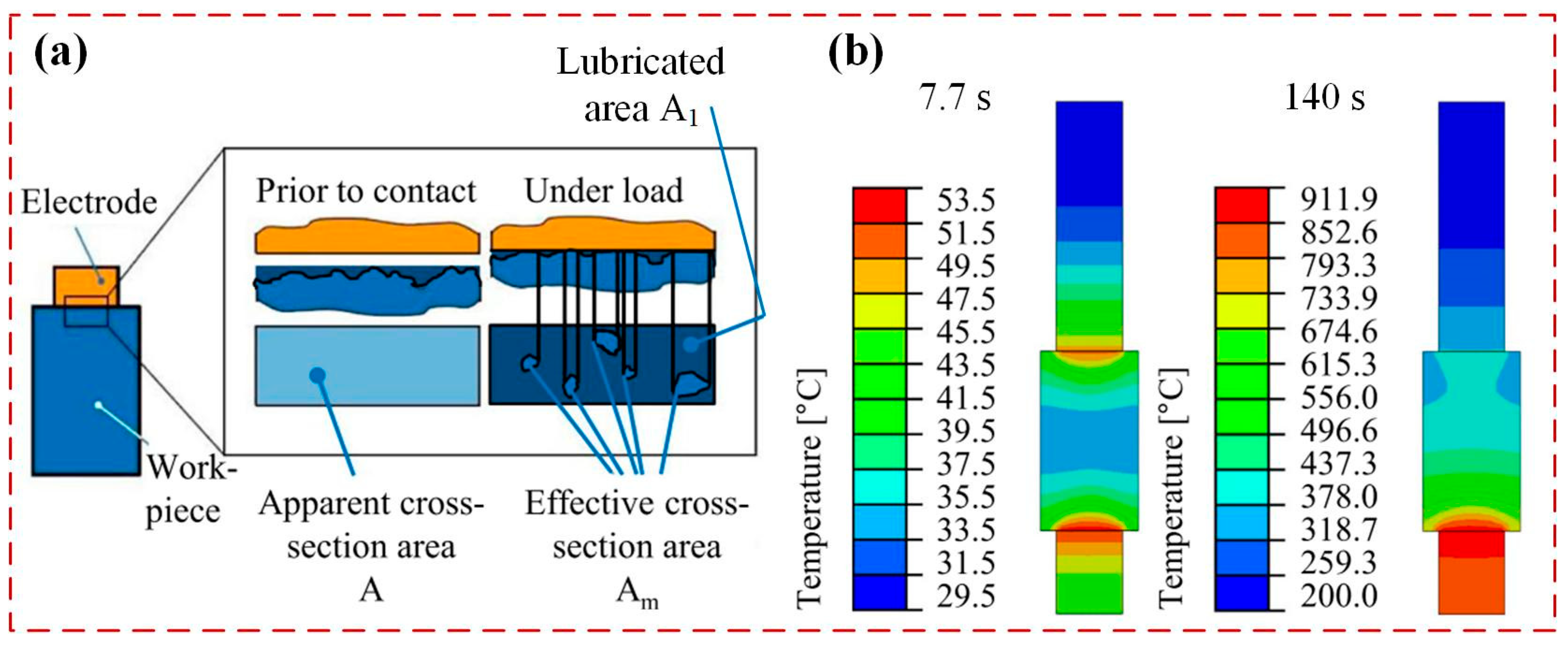

- Terhorst, M.; Ozhoga-Maslovskaja, O.; Trauth, D.; Shirobokov, A.; Mattfeld, P.; Solf, M.; Klocke, F. Electro-thermo-mechanical contact model for bulk metal forming under application of electrical resistance heating. Int. J. Adv. Manuf. Technol. 2016, 89, 3601–3618. [Google Scholar] [CrossRef]

- Guo, F.; Gu, X.; Li, L.; Wang, Z.; Wang, T.; Jia, S. Effect of surface microparameters on contact temperature of sliding electrical contact. IEEE Trans. Ind. Inform. 2022, 18, 5972–5981. [Google Scholar] [CrossRef]

- Hu, J.; Tsai, H.L. Heat and mass transfer in gas metal arc welding. Part I: The arc. Int. J. Heat Mass Transf. 2007, 50, 833–846. [Google Scholar] [CrossRef]

- Kharin, S.N. Mathematical models of heat and mass transfer in electrical contacts. In Proceedings of the 2015 IEEE 61st Holm Conference on Electrical Contacts (Holm), San Diego, CA, USA, 11–14 October 2015; pp. 1–21. [Google Scholar]

- Zhu, G.-y.; Gao, G.-q.; Wu, G.-n.; Gu, Z.; Wu, J.; Hao, J. Modeling pantograph–catenary arcing. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2016, 230, 1687–1697. [Google Scholar] [CrossRef]

- Komvopoulos, K. A multiscale theoretical analysis of the mechanical, thermal, and electrical characteristics of rough contact interfaces demonstrating fractal behavior. Front. Mech. Eng. 2020, 6, 36. [Google Scholar] [CrossRef]

- Michopoulos, J.G.; Young, M.; Iliopoulos, A. A multiphysics theory for the static contact of deformable conductors with fractal rough surfaces. IEEE Trans. Plasma Sci. 2015, 43, 1597–1610. [Google Scholar] [CrossRef]

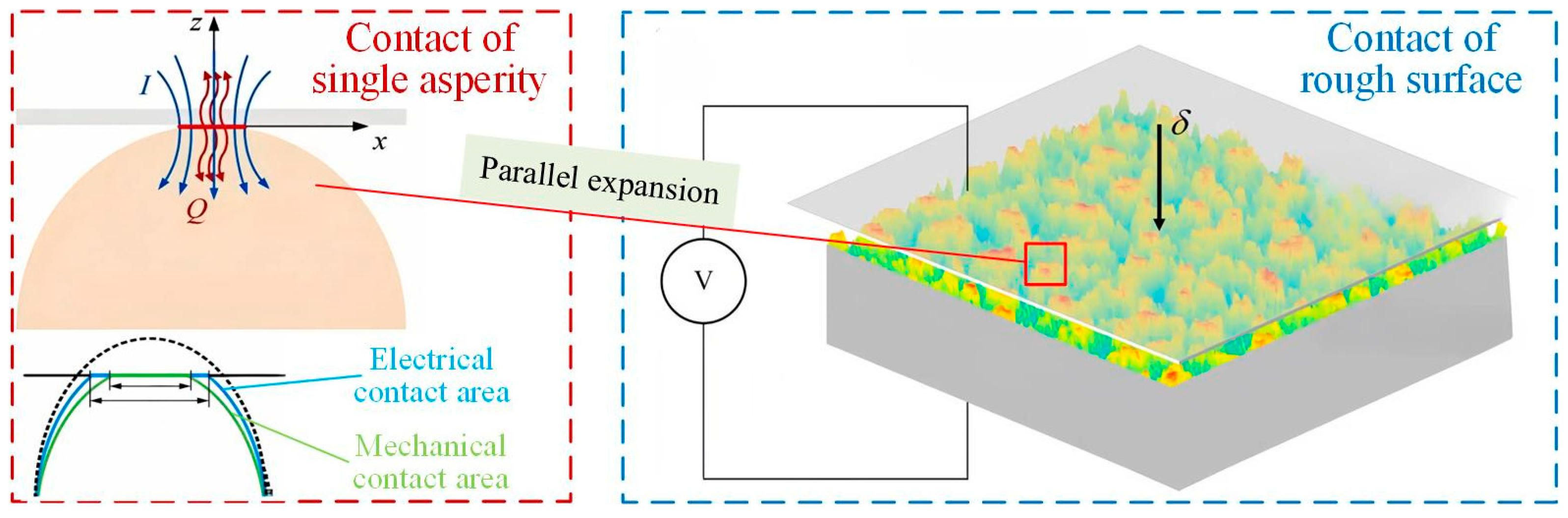

- Li, Y.; Shen, F.; Güler, M.A.; Ke, L. A rough surface electrical contact model considering the interaction between asperities. Tribol. Int. 2023, 190, 109044. [Google Scholar] [CrossRef]

- Li, Y.; Shen, F.; Güler, M.A.; Ke, L. Modeling multi-physics electrical contact on rough surfaces considering elastic-plastic deformation. Int. J. Mech. Sci. 2024, 269, 109066. [Google Scholar] [CrossRef]

- Li, Y.; Shen, F.; Güler, M.A.; Ke, L. An efficient method for electro-thermo-mechanical coupling effect in electrical contact on rough surfaces. Int. J. Heat Mass Transf. 2024, 226, 125492. [Google Scholar] [CrossRef]

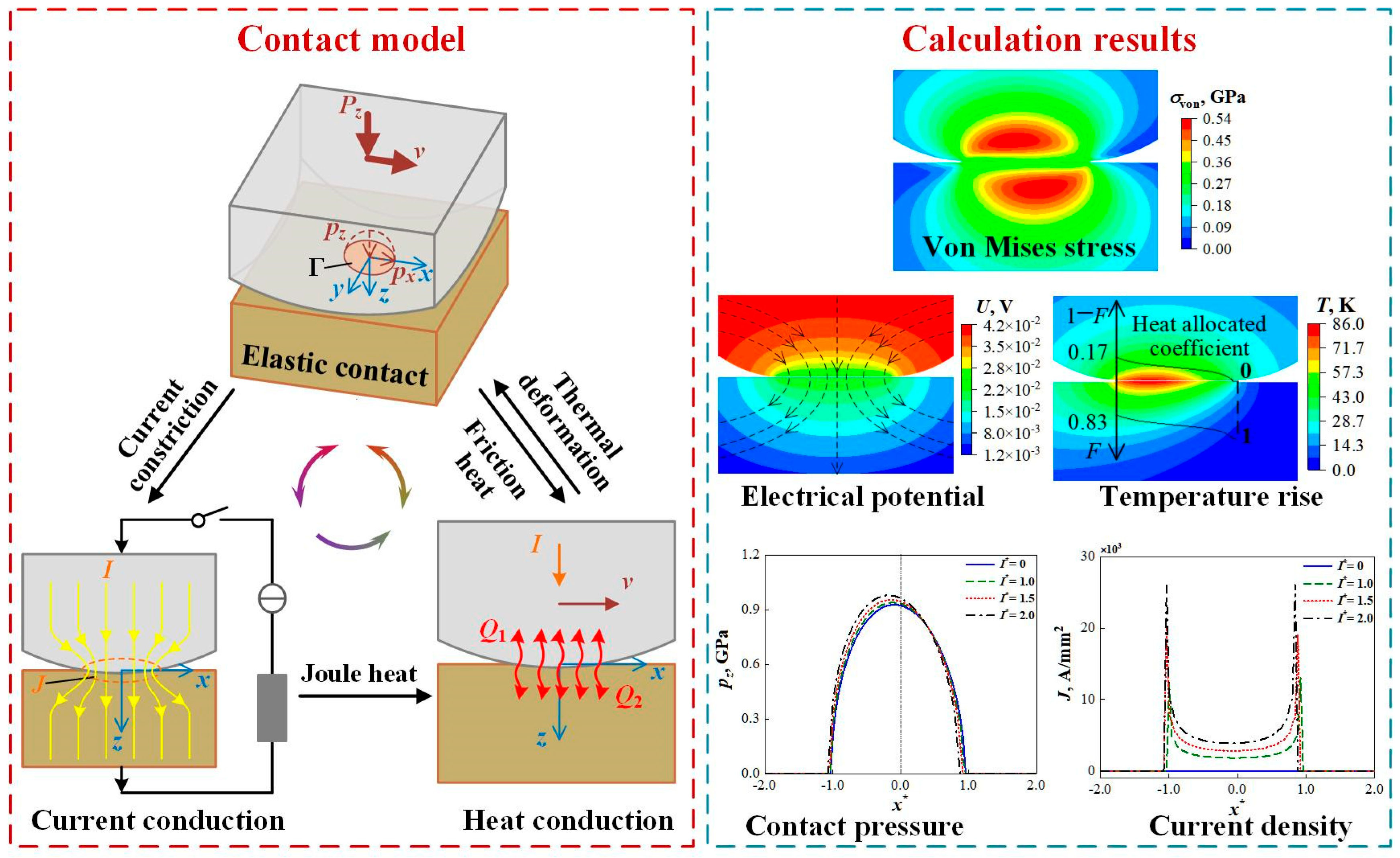

- Sui, Y.; Wang, W.; Zhang, H.; Xie, Y. Modeling 3D sliding electrical contact considering fully coupled thermal-mechanical-electrical effects. Tribol. Int. 2023, 184, 108491. [Google Scholar] [CrossRef]

- Zhao, Y.; Wu, G.; Gao, G.; Wang, W.; Zhou, L. Study on electromagnetic force of pantograph-catenary system. J. China Railw. Soc. 2014, 36, 28–32. [Google Scholar] [CrossRef]

- Liu, X.; Yang, Z.; Xiao, S.; Duan, X.; Gao, G.; Wei, W.; Wu, G.; Rotaru, M.; Sykulski, J.K. Multi-physics analysis and optimisation of high-speed train pantograph-catenary systems allowing for velocity skin effect. High Volt. 2020, 5, 654–661. [Google Scholar] [CrossRef]

- Raissi, M.; Perdikaris, P.; Karniadakis, G.E. Physics-informed neural networks: A deep learning framework for solving forward and inverse problems involving nonlinear partial differential equations. J. Comput. Phys. 2019, 378, 686–707. [Google Scholar] [CrossRef]

- Sahin, T.; von Danwitz, M.; Popp, A. Solving forward and inverse problems of contact mechanics using physics-informed neural networks. Adv. Model. Simul. Eng. Sci. 2024, 11, 11. [Google Scholar] [CrossRef]

- Xia, Y.; Meng, Y. Physics-informed neural network (PINN) for solving frictional contact temperature and inversely evaluating relevant input parameters. Lubricants 2024, 12, 62. [Google Scholar] [CrossRef]

- Oh, H.; Jo, G. Physics-informed neural network for the heat equation under imperfect contact conditions and its error analysis. AIMS Math. 2025, 10, 7920–7940. [Google Scholar] [CrossRef]

- Zhou, Y.; Song, H. Physics-informed neural network approach to randomly rough surface contact mechanics. Tribol. Lett. 2025, 73, 88. [Google Scholar] [CrossRef]

- Bai, J.; Lin, Z.; Wang, Y.; Wen, J.; Liu, Y.; Rabczuk, T.; Gu, Y.; Feng, X. Energy-based physics-informed neural network for frictionless contact problems under large deformation. Comput. Methods Appl. Mech. Eng. 2025, 437, 117787. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Archard, J.F.; Hirst, W.; Allibone, T.E. The wear of metals under unlubricated conditions. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1956, 236, 397–410. [Google Scholar] [CrossRef]

- Rabinowicz, E. The effect of size on the looseness of wear fragments. Wear 1958, 2, 4–8. [Google Scholar] [CrossRef]

- Aghababaei, R.; Warner, D.H.; Molinari, J.-F. Critical length scale controls adhesive wear mechanisms. Nat. Commun. 2016, 7, 11816. [Google Scholar] [CrossRef]

- Frérot, L.; Aghababaei, R.; Molinari, J.-F. A mechanistic understanding of the wear coefficient: From single to multiple asperities contact. J. Mech. Phys. Solids 2018, 114, 172–184. [Google Scholar] [CrossRef]

- Brink, T.; Frérot, L.; Molinari, J.-F. A parameter-free mechanistic model of the adhesive wear process of rough surfaces in sliding contact. J. Mech. Phys. Solids 2021, 147, 104238. [Google Scholar] [CrossRef]

- Cao, H.; Tian, Y.; Meng, Y. A fracture-induced adhesive wear criterion and its application to the simulation of wear process of the point contacts under mixed lubrication condition. Facta Univ. Ser. Mech. Eng. 2021, 19, 23–38. [Google Scholar] [CrossRef]

- Weißenfels, C.; Wriggers, P. Numerical modeling of electrical contacts. Comput. Mech. 2009, 46, 301–314. [Google Scholar] [CrossRef]

- Jiang, X.; Pan, F.; Shao, G.; Huang, J.; Hong, J.; Zhou, A. Prediction of electrical contact endurance subject to micro-slip wear using friction energy dissipation approach. Friction 2018, 7, 537–550. [Google Scholar] [CrossRef]

- Shen, F.; Ke, L. Numerical study of coupled electrical-thermal-mechanical-wear behavior in electrical contacts. Metals 2021, 11, 955. [Google Scholar] [CrossRef]

- Yang, X.; Li, X.; Wang, S. Study on simulation of multifield coupled wear in reciprocating electrical contact. Ind. Lubr. Tribol. 2022, 75, 98–109. [Google Scholar] [CrossRef]

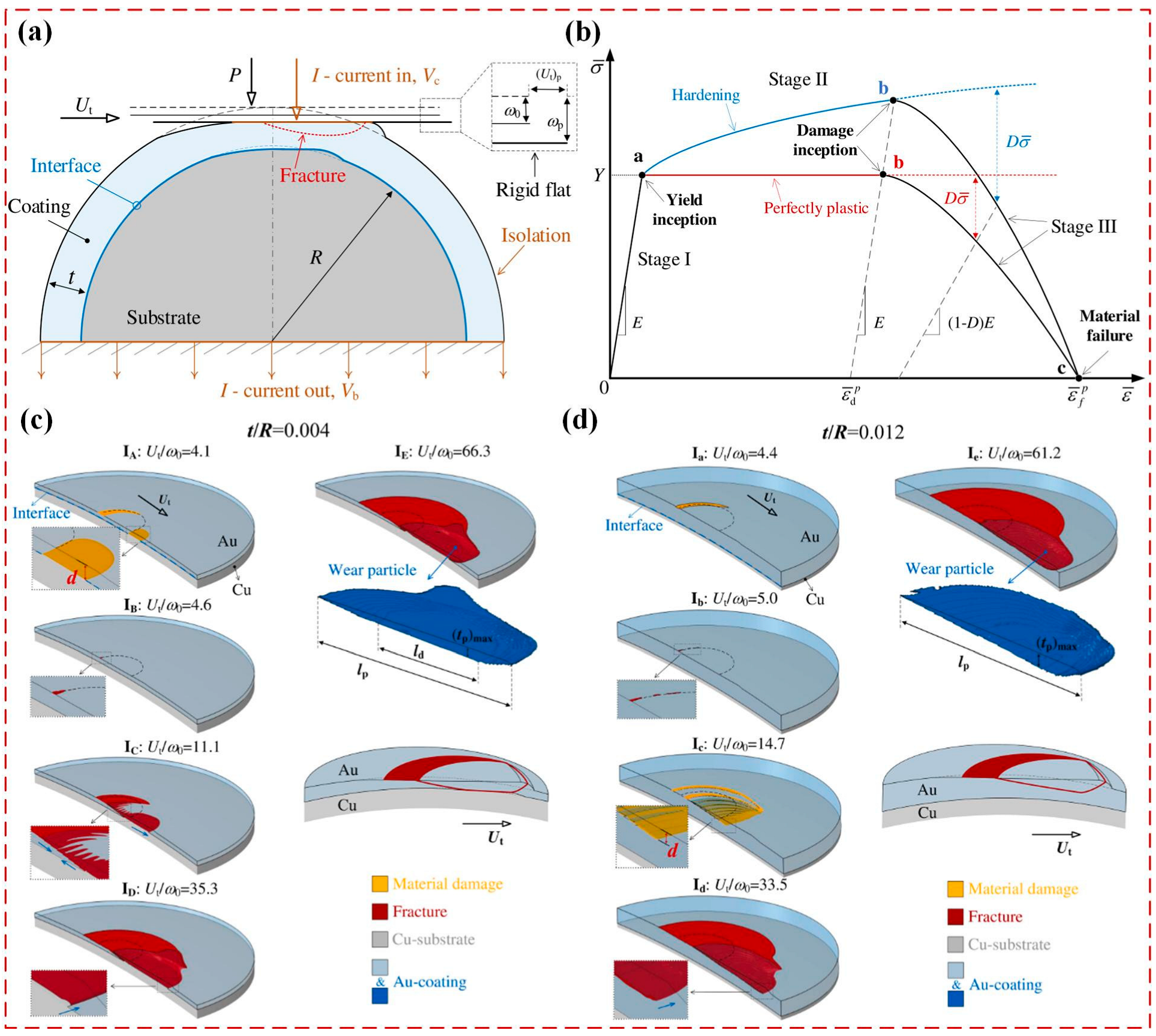

- Zhang, H.; Wu, X.; Wang, W. Modeling contact of Au-coated sphere with rigid flat: Electrical contact resistance, adhesive wear and friction. Int. J. Mech. Sci. 2023, 246, 108152. [Google Scholar] [CrossRef]

- Doelling, K.L.; Ling, F.F.; Bryant, M.D.; Heilman, B.P. An experimental study of the correlation between wear and entropy flow in machinery components. J. Appl. Phys. 2000, 88, 2999–3003. [Google Scholar] [CrossRef]

- Lijesh, K.P.; Khonsari, M.M. On the degradation of tribo-components in boundary and mixed lubrication regimes. Tribol. Lett. 2018, 67, 12. [Google Scholar] [CrossRef]

- Song, C.; Liu, Z.; Zhang, Y.; Sun, C.; Liu, Z.; Zhang, Y. Generation conditions of rolling current-carrying associated arc on Cu-Cu pairs and the surface damage mechanisms. Eng. Fail. Anal. 2024, 159, 108103. [Google Scholar] [CrossRef]

- Xu, Y.; Wu, Y.; Jackson, R.L. Electrical contact with dielectric breakdown of interfacial gap. J. Tribol.-Trans. ASME 2025, 147, 051109. [Google Scholar] [CrossRef]

- Bucca, G.; Collina, A. Electromechanical interaction between carbon-based pantograph strip and copper contact wire: A heuristic wear model. Tribol. Int. 2015, 92, 47–56. [Google Scholar] [CrossRef]

- Wei, X.K.; Meng, H.F.; He, J.H.; Jia, L.M.; Li, Z.G. Wear analysis and prediction of rigid catenary contact wire and pantograph strip for railway system. Wear 2020, 442–443, 203118. [Google Scholar] [CrossRef]

- Mesyats, G.A.; Uimanov, I.V. Hydrodynamics of the molten metal during the crater formation on the cathode surface in a vacuum arc. IEEE Trans. Plasma Sci. 2015, 43, 2241–2246. [Google Scholar] [CrossRef]

- Cunha, M.D.; Kaufmann, H.T.C.; Benilov, M.S.; Hartmann, W.; Wenzel, N. Detailed numerical simulation of cathode spots in vacuum arcs—I. IEEE Trans. Plasma Sci. 2017, 45, 2060–2069. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, L.; Jia, S.; Shmelev, D.L. Modeling of cathode spot crater formation and development in vacuum arc. J. Phys. D Appl. Phys. 2017, 50, 455203. [Google Scholar] [CrossRef]

| Methods | Efficiency | Accuracy | Coupling Degree | Scale (Spatial, Temporal) | |

|---|---|---|---|---|---|

| ECR | Theoretical formulas | +++ | + | + | Regular spots, static |

| FEM | + | +++ | ++ | Simple case, static | |

| SAM | +++ | +++ | +++ | Rough surfaces, static | |

| ML | ++ | ++ | ++ | Rough surfaces, static | |

| Friction | Fractal theory | +++ | + | + | Fractal surfaces, steady |

| FEM | + | +++ | ++ | Rough surfaces, transient | |

| BEM | ++ | ++ | ++ | Rough surfaces, steady | |

| SAM | +++ | +++ | +++ | Rough surfaces, steady | |

| Wear | FEM | + | + | + | Asperity level, short time |

| Energy dissipation theory | +++ | ++ | ++ | Rough surfaces, long time |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sui, Y.; Xing, P.; Li, G.; Zhang, H.; Wang, W.; Zhang, H. Theoretical Modeling and Numerical Simulation of Current-Carrying Friction and Wear: State of the Art and Challenges. Lubricants 2025, 13, 370. https://doi.org/10.3390/lubricants13080370

Sui Y, Xing P, Li G, Zhang H, Wang W, Zhang H. Theoretical Modeling and Numerical Simulation of Current-Carrying Friction and Wear: State of the Art and Challenges. Lubricants. 2025; 13(8):370. https://doi.org/10.3390/lubricants13080370

Chicago/Turabian StyleSui, Yijin, Pengfei Xing, Guobin Li, Hongpeng Zhang, Wenzhong Wang, and Haibo Zhang. 2025. "Theoretical Modeling and Numerical Simulation of Current-Carrying Friction and Wear: State of the Art and Challenges" Lubricants 13, no. 8: 370. https://doi.org/10.3390/lubricants13080370

APA StyleSui, Y., Xing, P., Li, G., Zhang, H., Wang, W., & Zhang, H. (2025). Theoretical Modeling and Numerical Simulation of Current-Carrying Friction and Wear: State of the Art and Challenges. Lubricants, 13(8), 370. https://doi.org/10.3390/lubricants13080370