Review on Tribological and Vibration Aspects in Mechanical Bearings of Electric Vehicles: Effect of Bearing Current, Shaft Voltage, and Electric Discharge Material Spalling Current

Abstract

1. Introduction

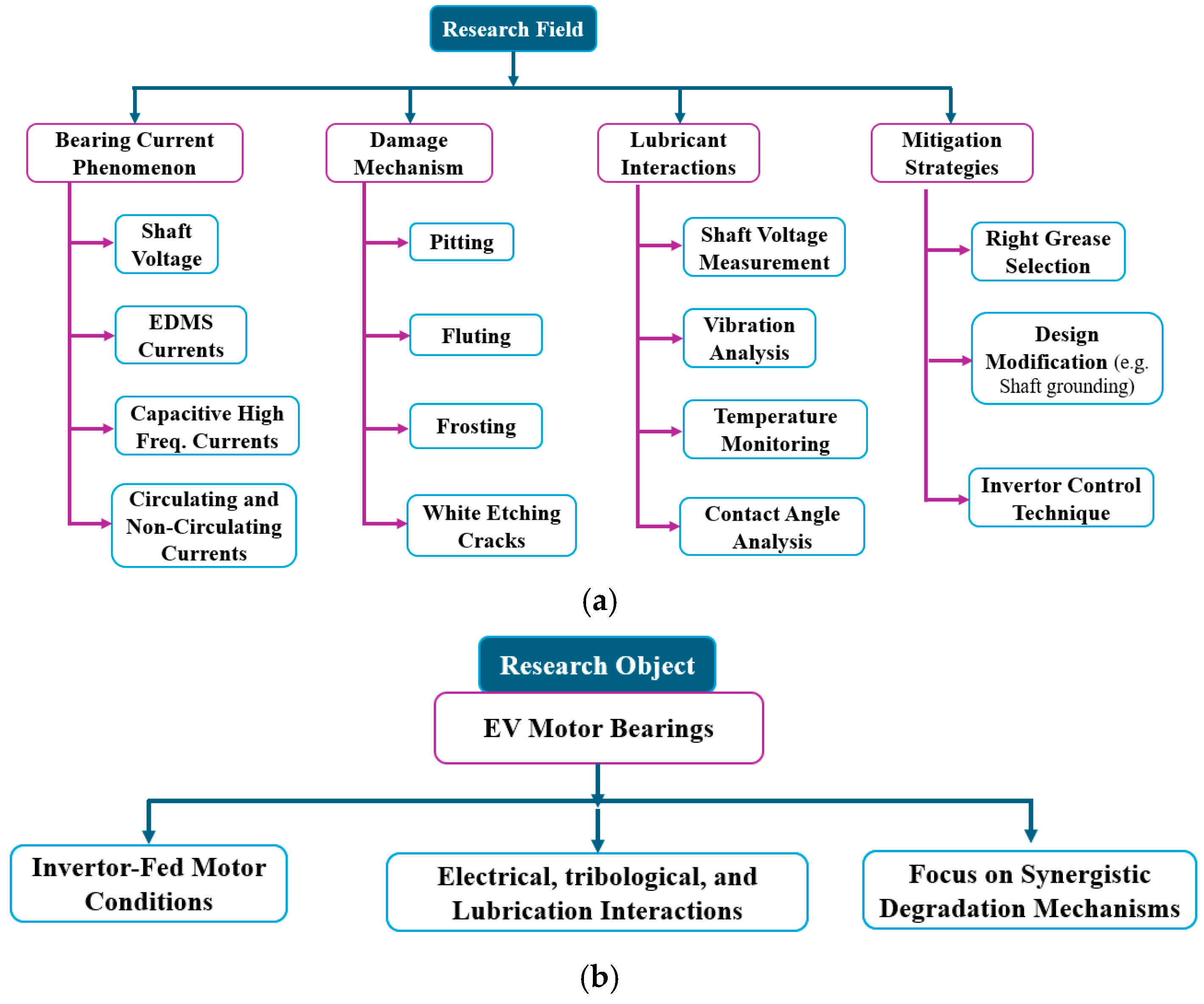

2. Bearing Current, Shaft Voltage, and Electric Discharge Material Spalling Current Mechanisms

2.1. Bearing Current Causes

- Electromagnetic interference (EMI) that is both conducted and radiated;

- Ground currents that flow to earth via stray capacitors are found inside motors;

- Bearing currents resulting from the motor shaft voltage;

- Overvoltage at motor terminals;

- Shorter motor insulating life.

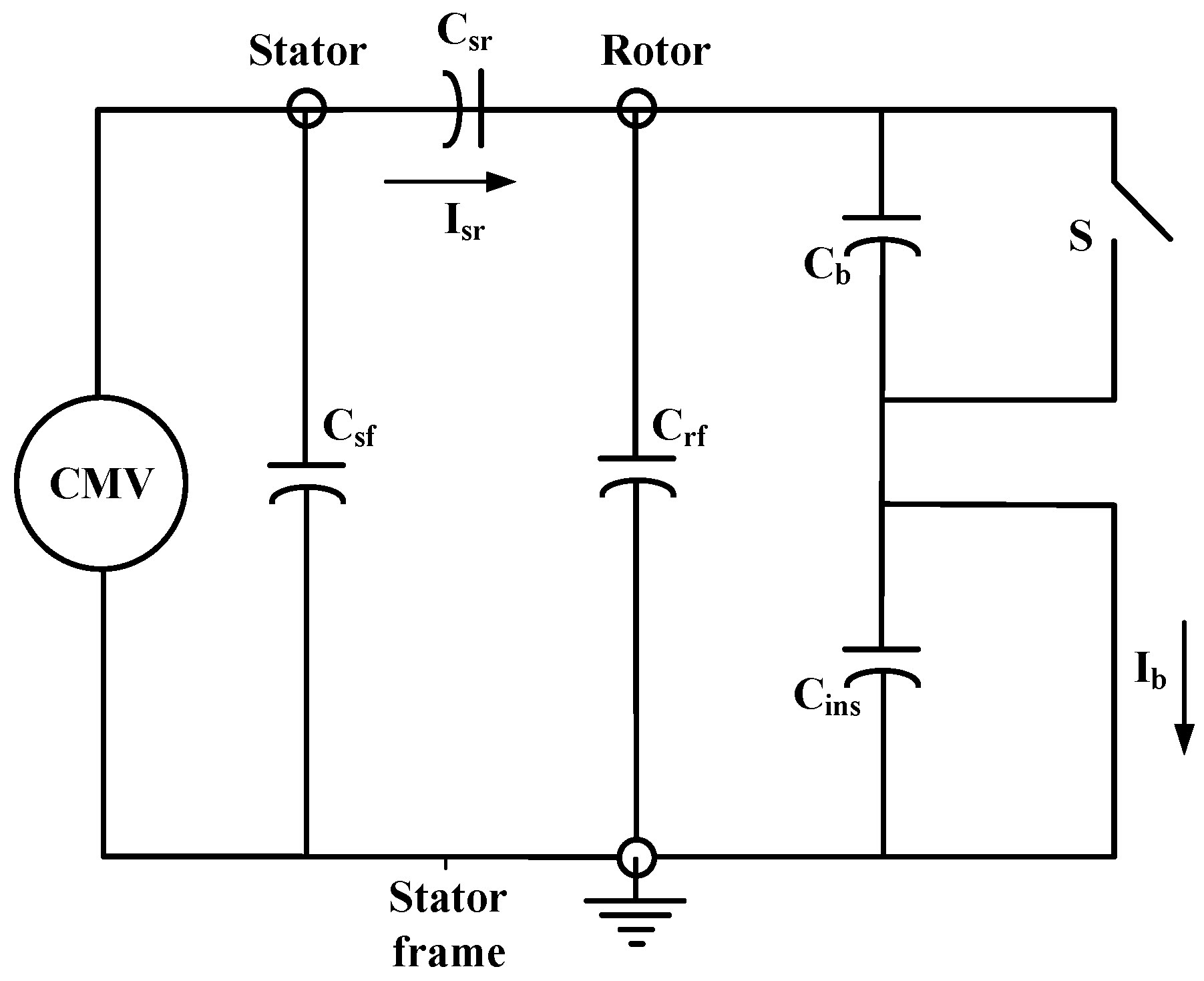

2.2. Bearing Currents, Common Mode Voltages, and Shaft Voltages

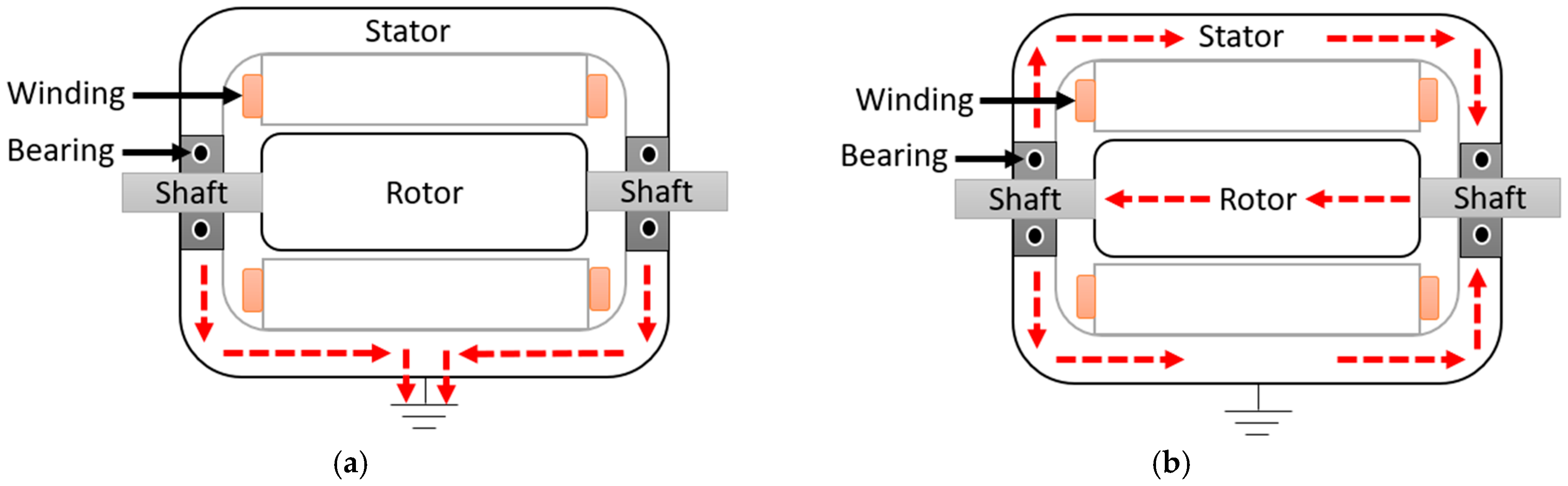

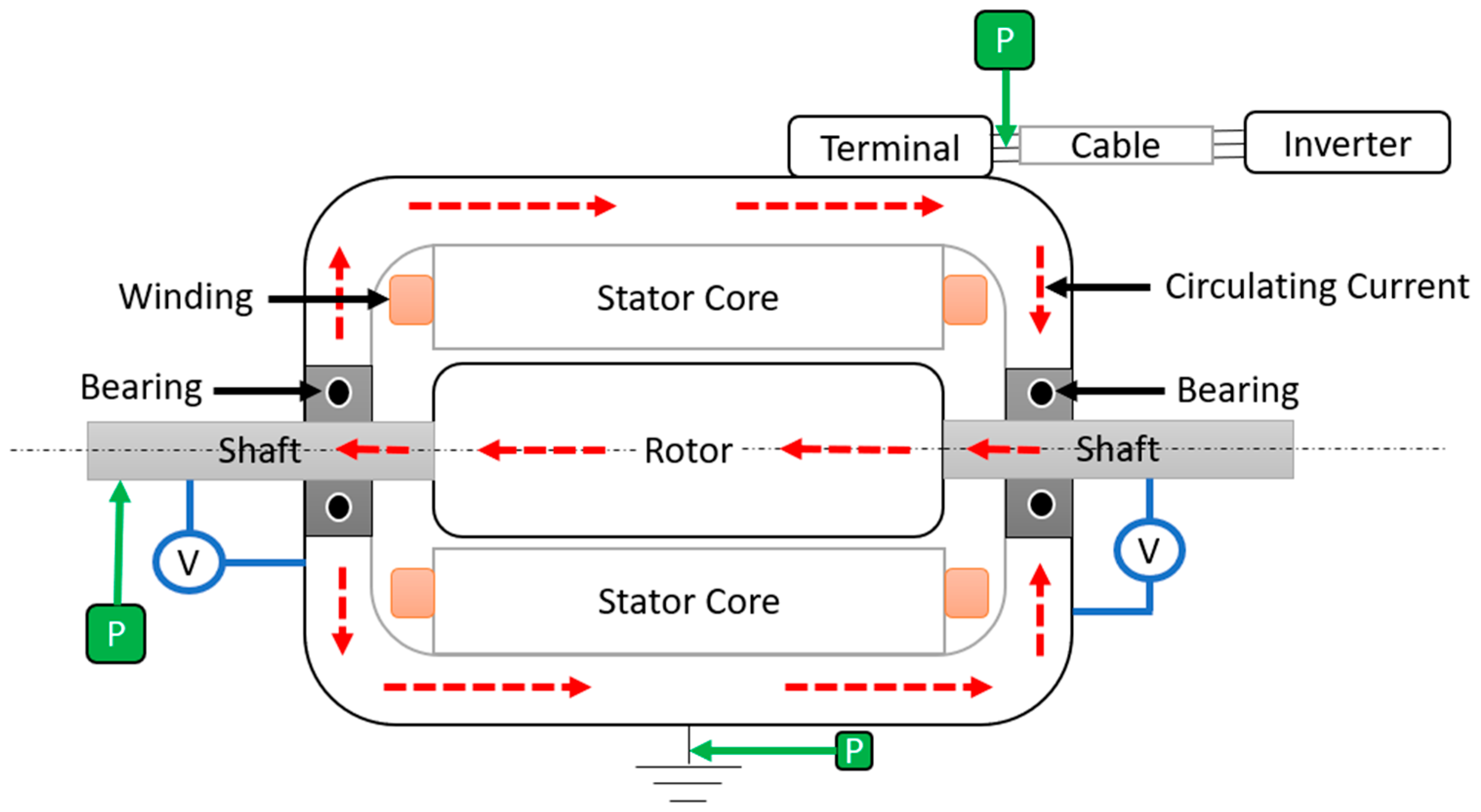

2.3. Flow of Circulating Current

- The first path involves the current flowing directly from the motor shaft, passing through bearings, then travelling through the motor or load frame, and eventually grounding itself, as shown in Figure 3a;

- An alternative path for current flow involves the current travelling from one side of the shaft to the other, passing through one bearing, then the motor frame, and back through the opposing bearing, as shown in Figure 3b.

2.4. Electric Discharge Material Spalling Current and Its Breakdowns

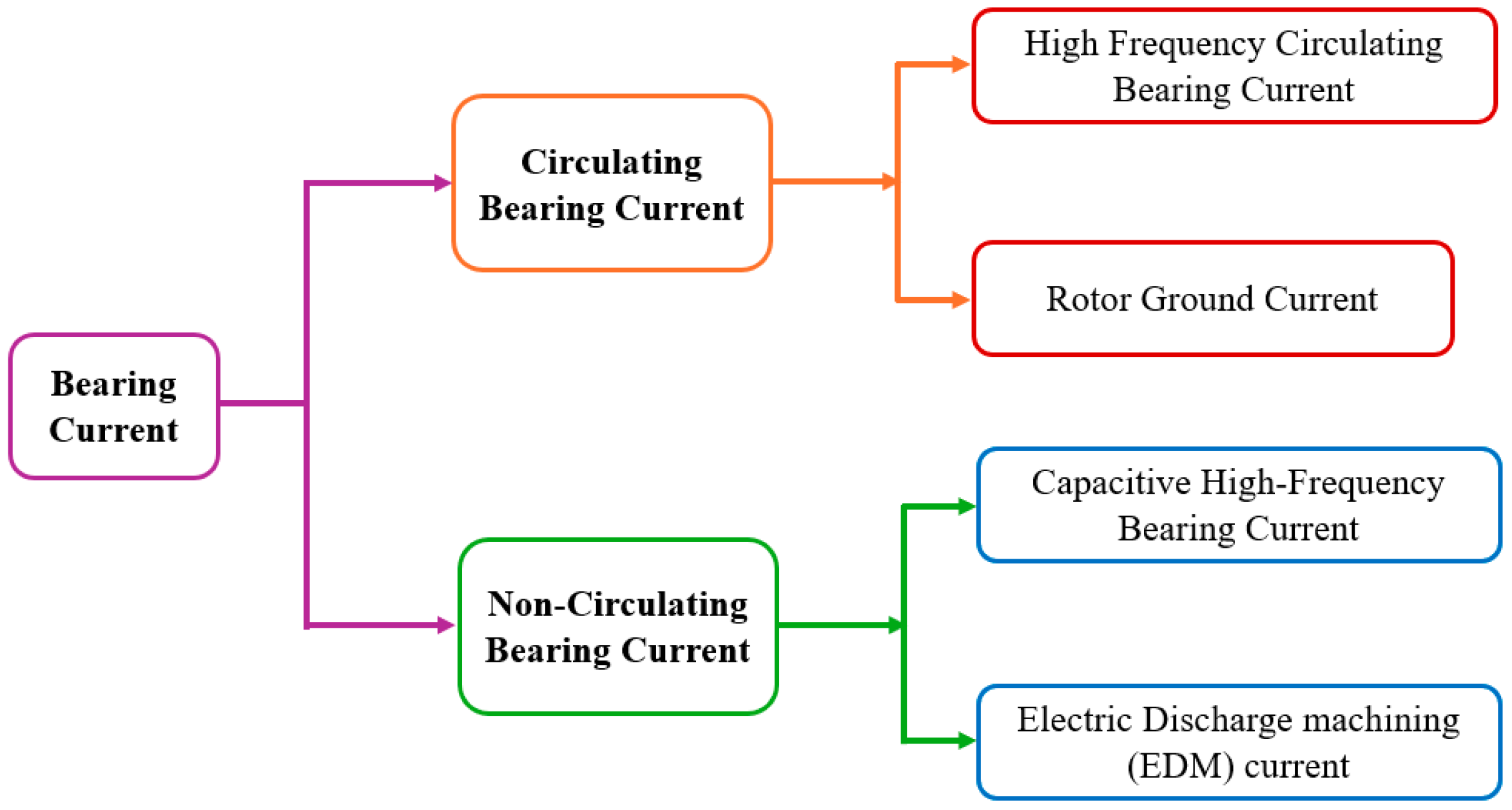

2.5. Non-Circulating and Circulating Bearing Currents

3. Morphological Damages to Bearings Due to Bearing Currents

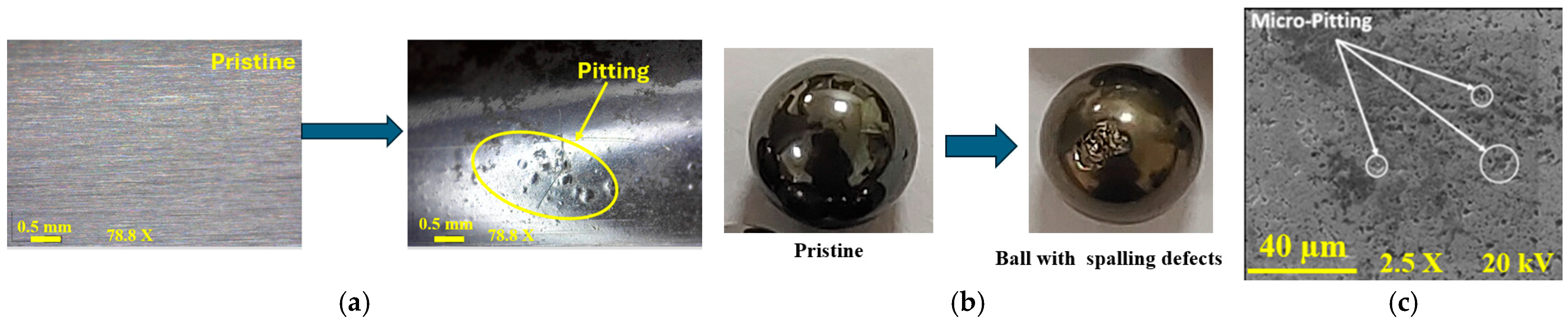

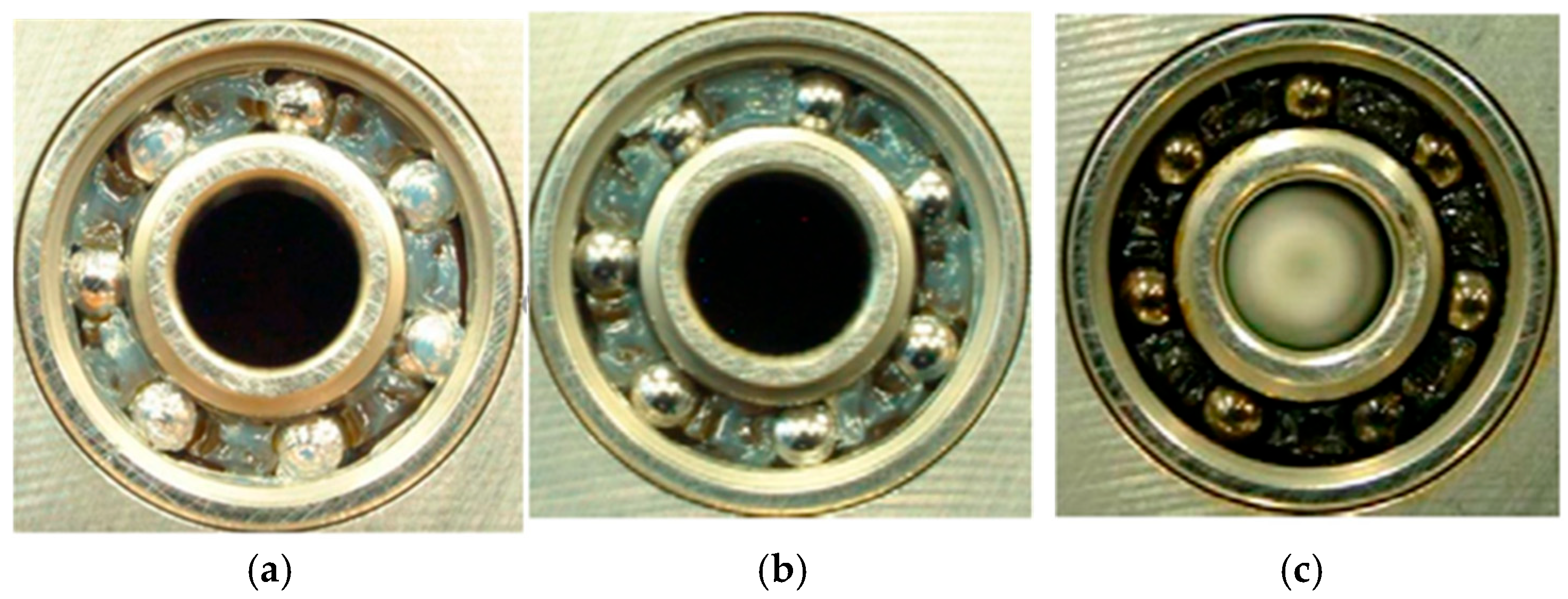

3.1. Electrically Induced Surface Pitting

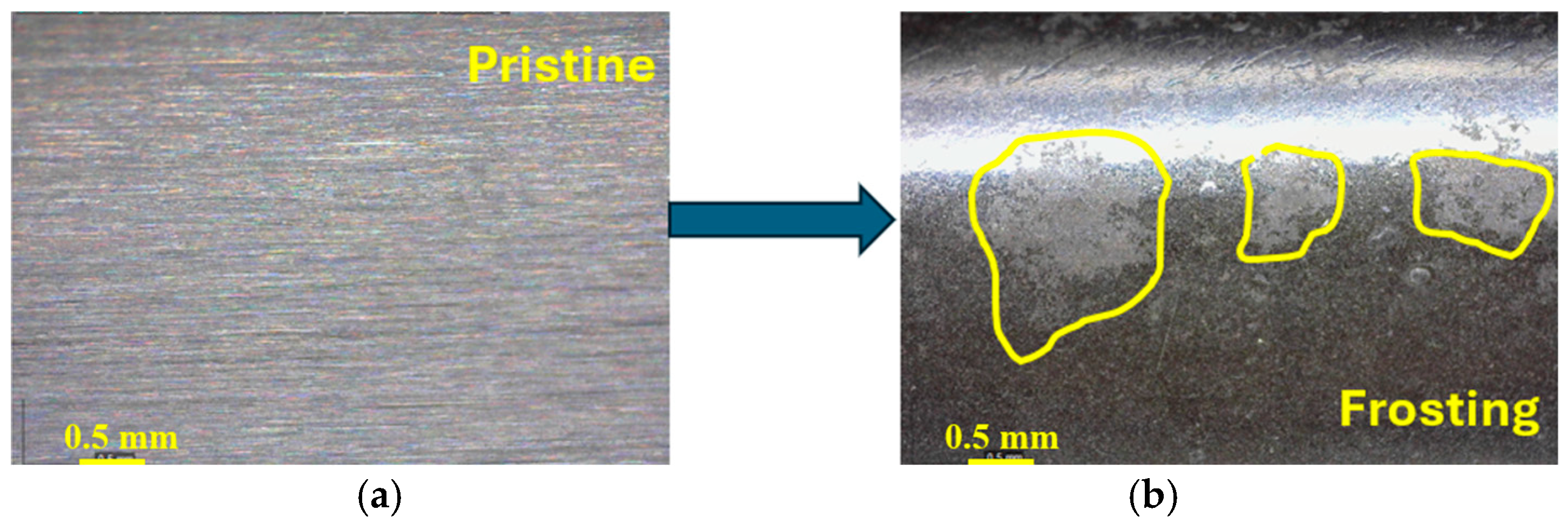

3.2. Micro-Scale Arc-Induced Surface Texturing (Frosting)

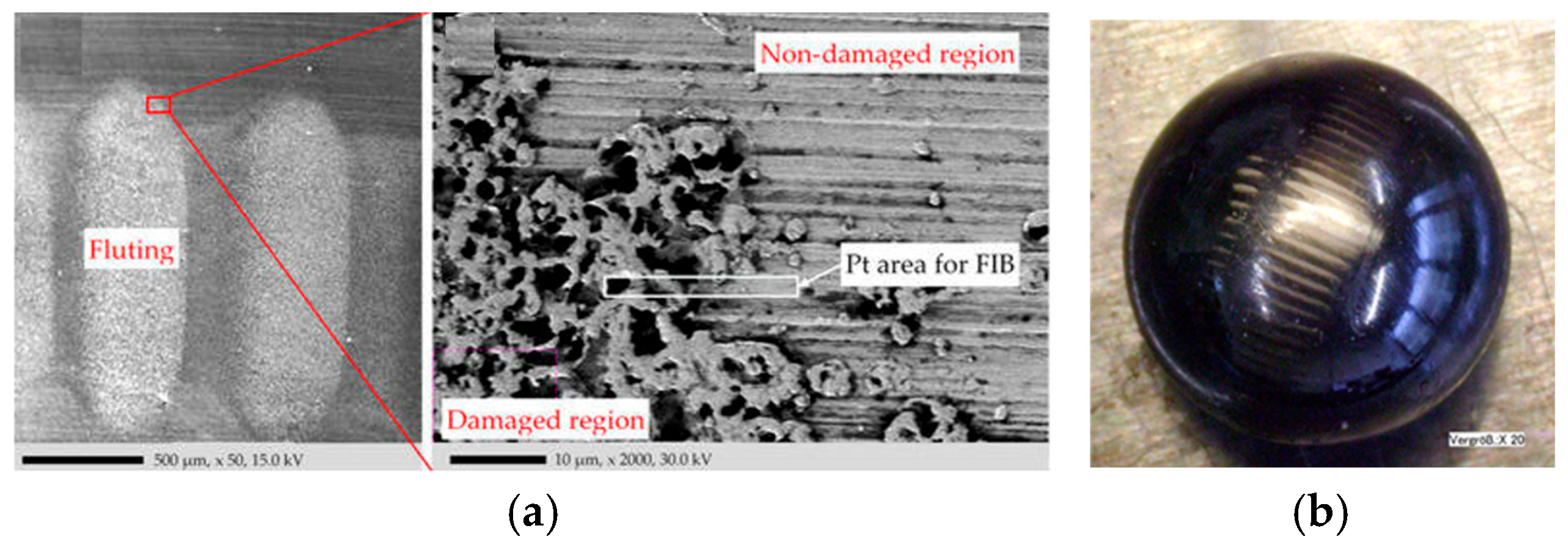

3.3. Fluting and Spark Tracks

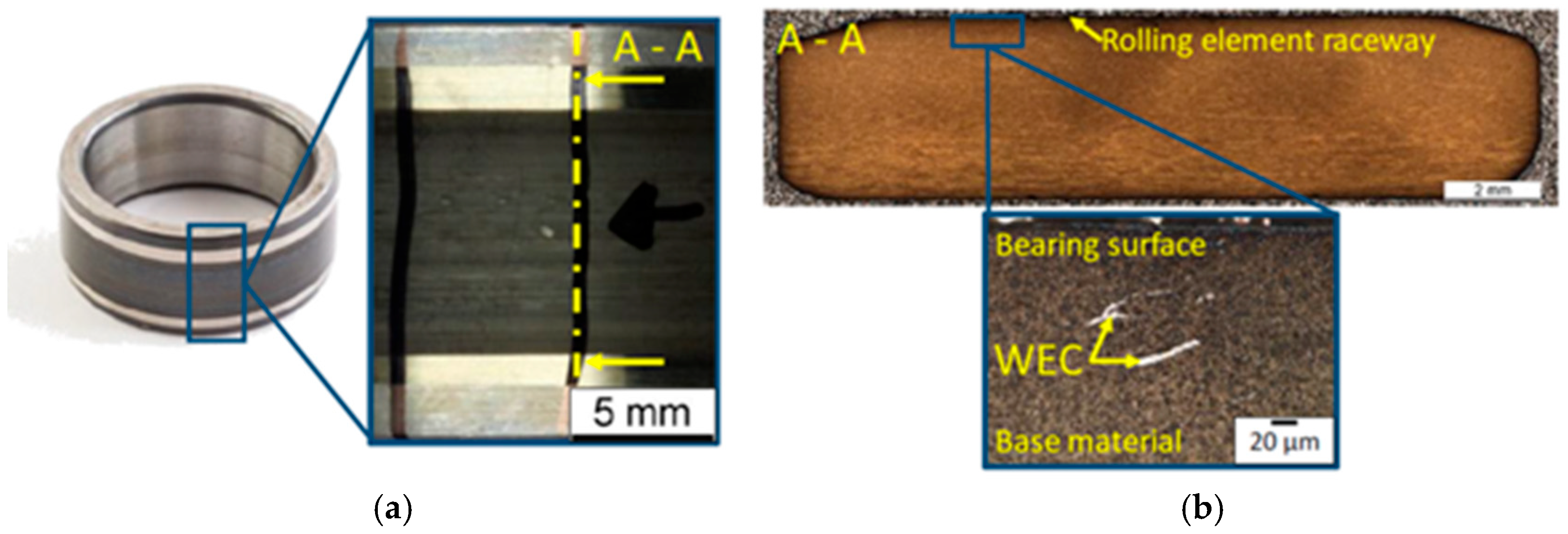

3.4. Subsurface White Etching Crack Formation

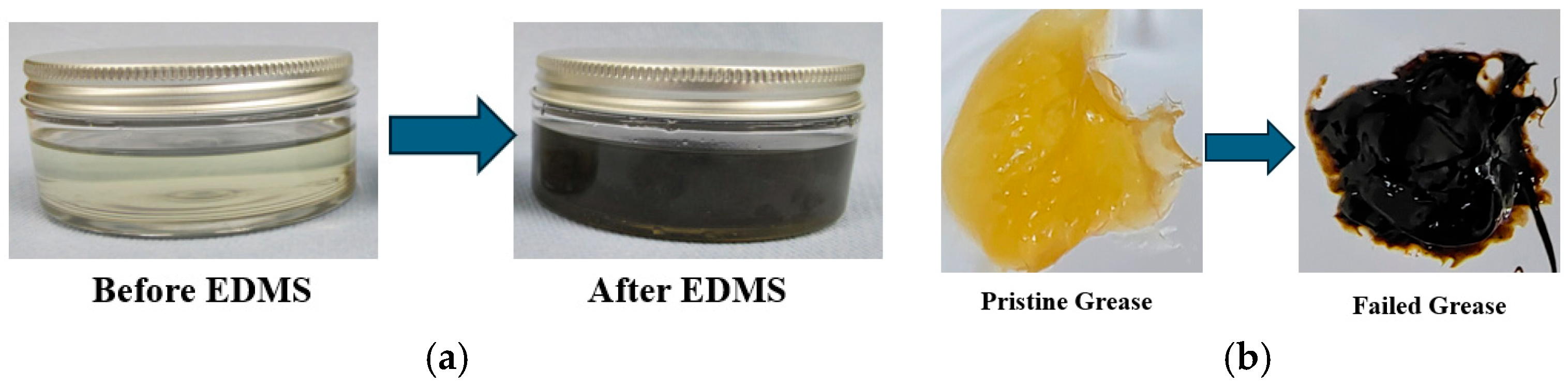

3.5. Dielectric Breakdown and Thermochemical Degradation of Lubricants Lubricant Degradation

4. Measurement, Diagnostics, and Mitigation

4.1. Vibration and Signal-Based Diagnostics of Bearing Faults

4.2. Electrical and Thermal Indicators of Bearing Health

4.3. Lubricant Condition Monitoring and Grease Degradation Assessment

4.4. Mitigation or Solution to the Bearing Currents Problem

5. Influence of Mechanical and Electrical Properties of Lubricants on Bearing Current and Shaft Voltage

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AC | Alternating Current |

| BEV | Battery Electric Vehicle |

| BPFI | Ball Pass Frequency Inner |

| BPFO | Ball Pass Frequency Outer |

| BSF | Ball Spin Frequency |

| BVR | Bearing Voltage Ratio |

| CDF | Characteristics Defect Frequency |

| CFRP | Carbon Fiber-Reinforced Plastic |

| CMV | Common Mode Voltage |

| EDMS | Electric Discharge Material Spalling Current |

| EMI | Electromagnetic Interference |

| EV | Electric Vehicle |

| FCEV | Fuel Cell Electric Vehicle |

| FFT | Fast Fourier Transform |

| FTF | Frequency Train Frequency |

| HEV | Hybrid Electric Vehicle |

| IC | Internal Combustion |

| IGBT | Insulated Gate Bipolar Transistor |

| MOSFET | Metal-Oxide-Semiconductor Field-Effect Transistors |

| PWM | Pulse Width Modulation |

| PHEV | Plug-In Hybrid Electric Vehicle |

| RPS | Revolution Per Second |

| SEM | Scanning Electron Microscope |

| SEV | Solar Electric Vehicle |

| VFD | Variable Frequency Drive |

| WEC | White Etching Current |

References

- Chan, C.C. The state of the art of electric, hybrid, and fuel cell vehicles. Proc. IEEE 2007, 95, 704–718. [Google Scholar] [CrossRef]

- He, F.; Xie, G.; Luo, J. Electrical bearing failures in electric vehicles. Friction 2020, 8, 4–28. [Google Scholar] [CrossRef]

- Guo, L.; Mol, H.; Nijdam, T.; de Vries, L.; Bongaerts, J. Study on the electric discharge behaviour of a single contact in EV motor bearings. Tribol. Int. 2023, 187, 108743. [Google Scholar] [CrossRef]

- Ahmed Abdalglil Mustafa, W.; Dassenoy, F.; Sarno, M.; Senatore, A. A review on potentials and challenges of nanolubricants as promising lubricants for electric vehicles. Lubr. Sci. 2022, 34, 1–29. [Google Scholar] [CrossRef]

- Pei, T.; Zhang, H.; Hua, W.; Zhang, F. Comprehensive Review of Bearing Currents in Electrical Machines: Mechanisms, Impacts, and Mitigation Techniques. Energies 2025, 18, 517. [Google Scholar] [CrossRef]

- Chan, C.C.; Bouscayrol, A.; Chen, K. Electric, hybrid, and fuel-cell vehicles: Architectures and modeling. IEEE Trans. Veh. Technol. 2009, 59, 589–598. [Google Scholar] [CrossRef]

- Ma, J.; Xue, Y.; Han, Q.; Li, X.; Yu, C. Motor bearing damage induced by bearing current: A Review. Machines 2022, 10, 1167. [Google Scholar] [CrossRef]

- Bleger, A.; Leighton, M.; Morris, N. Automotive e-motor bearing electrical discharge phenomena: An experimental and numerical investigation. Tribol. Int. 2024, 191, 109140. [Google Scholar] [CrossRef]

- Lee, P.M.; Sanchez, C.; Frazier, C.; Velasquez, A.; Kostan, T. Tribological evaluation of electric vehicle driveline lubricants in an electrified environment. Front. Mech. Eng. 2023, 9, 1215352. [Google Scholar] [CrossRef]

- Song, C.; Ren, Y.; Huang, Q.; Zhang, Y.; Li, Y.; Cheng, J.; Pang, X.; Zhang, Y. Effect of shaft voltage on electric damage of GCr15 bearing material. Tribol. Int. 2024, 200, 110139. [Google Scholar] [CrossRef]

- Busse, D.; Erdman, J.; Kerkman, R.J.; Schlegel, D.; Skibinski, G. Bearing currents and their relationship to PWM drives. IEEE Trans. Power Electron. 1997, 12, 243–252. [Google Scholar] [CrossRef]

- Alger, P.; Samson, H. Shaft currents in electric machines. Trans. Am. Inst. Electr. Eng. 2009, 43, 235–245. [Google Scholar]

- Kalaiselvi, J.; Srinivas, S. Bearing currents and shaft voltage reduction in dual-inverter-fed open-end winding induction motor with reduced CMV PWM methods. IEEE Trans. Ind. Electron. 2014, 62, 144–152. [Google Scholar] [CrossRef]

- Busse, D.; Erdman, J.; Kerkman, R.; Schlegal, D.; Skibinski, G. Characteristics of shaft voltage and bearing currents. IEEE Ind. Appl. Mag. 1997, 3, 21–32. [Google Scholar] [CrossRef]

- Son, D.W.; Zhang, T.; Lee, G. Study on Electrical Pitting Prevention Device of a Rotating Shaft Using Automatic Control Potential Balancing. Materials 2022, 15, 4510. [Google Scholar] [CrossRef]

- Schneider, V.; Behrendt, C.; Höltje, P.; Cornel, D.; Becker-Dombrowsky, F.M.; Puchtler, S.; Gutiérrez Guzmán, F.; Ponick, B.; Jacobs, G.; Kirchner, E. Electrical bearing damage, a problem in the nano-and macro-range. Lubricants 2022, 10, 194. [Google Scholar] [CrossRef]

- Oh, H.W.; Willwerth, A.H. New motor design with conductive micro fiber shaft grounding ring prevents bearing failure in PWE inverter driven motors. In Proceedings of the 2007 Electrical Insulation Conference and Electrical Manufacturing Expo, Nashville, Tennessee, 22–24 October 2007; IEEE: Piscataway, NJ, USA, 2007; pp. 240–246. [Google Scholar]

- Tawfiq, K.B.; Güleç, M.; Sergeant, P. Bearing current and shaft voltage in electrical machines: A comprehensive research review. Machines 2023, 11, 550. [Google Scholar] [CrossRef]

- Prudhom, A.; Antonino-Daviu, J.; Razik, H.; Climente-Alarcon, V. Time-frequency vibration analysis for the detection of motor damages caused by bearing currents. Mech. Syst. Signal Process. 2017, 84, 747–762. [Google Scholar] [CrossRef]

- Chen, S.; Lipo, T.A.; Fitzgerald, D. Source of induction motor bearing currents caused by PWM inverters. IEEE Trans. Energy Convers. 2002, 11, 25–32. [Google Scholar] [CrossRef]

- Qiu, J.; He, Y.; Xu, L.; Jiao, Q. A Novel SVPWM Technique for Leakage Current Reduction and Neutral-Point Voltage Balance in Transformerless Three-Level Inverters. In Proceedings of the 2020 4th International Conference on HVDC (HVDC), Xi’an, China, 6–9 November 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 560–565. [Google Scholar]

- Heino, T. Bearing Currents and Their Mitigation in Frequency Converter-Driven Induction Motors. Bachelor’s Thesis, Electrical Engineering, Vaasa, Finland, 2014. [Google Scholar]

- Plazenet, T.; Boileau, T.; Caironi, C.; Nahid-Mobarakeh, B. An overview of shaft voltages and bearing currents in rotating machines. In Proceedings of the 2016 IEEE Industry Applications Society Annual Meeting, Portland, ON, USA, 2–6 October 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1–8. [Google Scholar]

- Wang, F. Motor shaft voltages and bearing currents and their reduction in multilevel medium-voltage PWM voltage-source-inverter drive applications. IEEE Trans. Ind. Appl. 2000, 36, 1336–1341. [Google Scholar] [CrossRef]

- Im, J.-H.; Kang, J.-K.; Lee, Y.-K.; Hur, J. Shaft voltage elimination method to reduce bearing faults in dual three-phase motor. IEEE Access 2022, 10, 81042–81053. [Google Scholar] [CrossRef]

- Liu, S.; Lv, J.; Yang, Z.; Kuang, L.; Zhao, L.; Liu, C. The discharge characteristics and damages in the EV motor bearings: Influenced by the rotational speeds and lubricating oil viscosities. Wear 2025, 571, 205863. [Google Scholar] [CrossRef]

- Prashad, H. Appearance of craters on track surface of rolling element bearings by spark erosion. Tribol. Int. 2001, 34, 39–47. [Google Scholar] [CrossRef]

- Chin, J.-W.; Kim, D.-J.; Park, S.; Yu, T.; Jung, H.-C. Sensitivity Analysis on Shaft Voltage according to Variables of Inverter and Motor for Electric Vehicle Powertrain. In Proceedings of the 2023 IEEE Energy Conversion Congress and Exposition (ECCE), Nashville, TN, USA, 29 October 2023; IEEE: Piscataway, NJ, USA, 2023. [Google Scholar]

- Jonjo, E.R.; Ali, I.; Megahed, T.F.; Nassef, M.G. Mitigation of Electrical Discharge Damage in Electric Vehicle Bearings: Comparative Study of Multi-Walled Carbon Nanotubes and Alumina Nanoparticles in Lubricating Grease. Vehicles 2025, 7, 19. [Google Scholar] [CrossRef]

- Song, Y.; Yan, P.; Zhao, W.; Sha, T.; Dai, Z.; Li, S.; Gu, H.; Wang, X. Finite Element Simulation Method for Fretting Wear Considering Double-Side Wear Behavior. Tribol. Lett. 2025, 73, 57. [Google Scholar] [CrossRef]

- Notay, R.S. A Brief Review on the Tribological Effects of Electrically Induced Bearing Damage. J. Tribol. 2025, 147, 1–27. [Google Scholar] [CrossRef]

- Thorsen, O.; Dalva, M. Failure identification and analysis for high voltage induction motors in petrochemical industry. In Proceedings of the Conference Record of 1998 IEEE Industry Applications Conference. Thirty-Third IAS Annual Meeting (Cat. No. 98CH36242), St. Louis, MO, USA, 12–15 October 1998; IEEE: Piscataway, NJ, USA, 1998. [Google Scholar]

- Thorsen, O.V.; Dalva, M. A survey of faults on induction motors in offshore oil industry, petrochemical industry, gas terminals, and oil refineries. IEEE Trans. Ind. Appl. 2002, 31, 1186–1196. [Google Scholar] [CrossRef]

- Schiferl, R.; Melfi, M. Bearing current remediation options. IEEE Ind. Appl. Mag. 2004, 10, 40–50. [Google Scholar] [CrossRef]

- Tong, W. Mechanical Design and Manufacturing of Electric Motors; CRC Press: Boca Raton, FL, USA, 2022. [Google Scholar]

- Park, J.-K.; Jeong, C.-L.; Bianchi, N.; Hur, J. Frame-to-shaft voltage and end-to-end shaft voltage analysis according to eccentricity in IPMSMs. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition (ECCE), Portland, ON, USA, 23–27 September 2018; IEEE: Piscataway, NJ, USA, 2018. [Google Scholar]

- Quabeck, S.; Grau, V.; De Doncker, R.W. Modeling and mitigation of bearing currents in electrical traction drives. In Proceedings of the 2020 23rd International Conference on Electrical Machines and Systems (ICEMS), Hamamatsu, Japan, 24–27 November 2020; IEEE: Piscataway, NJ, USA, 2020. [Google Scholar]

- Shami, U.T.; Akagi, H. Identification and discussion of the origin of a shaft end-to-end voltage in an inverter-driven motor. IEEE Trans. Power Electron. 2009, 25, 1615–1625. [Google Scholar] [CrossRef]

- Eull, M.; Preindl, M. A soft switching inverter minimizing bearing currents in 800V electric vehicle drives. In Proceedings of the 2021 IEEE 13th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), Dallas, TX, USA, 22–25 August 2021; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Krein, P.T. Electrostatic discharge issues in electric vehicles. IEEE Trans. Ind. Appl. 2002, 32, 1278–1284. [Google Scholar] [CrossRef]

- Abu-Rub, H.; Bayhan, S.; Moinoddin, S.; Malinowski, M.; Guzinski, J. Medium-voltage drives: Challenges and existing technology. IEEE Power Electron. Mag. 2016, 3, 29–41. [Google Scholar] [CrossRef]

- Zhu, J.; Kim, H.; Chen, H.; Erickson, R.; Maksimović, D. High efficiency SiC traction inverter for electric vehicle applications. In Proceedings of the 2018 IEEE Applied Power Electronics Conference and Exposition (APEC), San Antonio, TX, USA, 26–30 March 2018; IEEE: Piscataway, NJ, USA, 2018. [Google Scholar]

- Arora, T.; Renge, M.; Aware, M. Effects of switching frequency and motor speed on common mode voltage, common mode current and shaft voltage in PWM inverter-fed induction motors. In Proceedings of the 2017 12th IEEE Conference on Industrial Electronics and Applications (ICIEA), Siem Reap, Cambodia, 18–20 June 2017; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar]

- Ronanki, D.; Perumal, P. A SVPWM for reduction in common mode and bearing currents applied to diode clamped three-level inverter fed induction motor. In Proceedings of the 2016 IEEE International Power Electronics and Motion Control Conference (PEMC), Varna, Bulgaria, 25–28 September 2016; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar]

- Kalaiselvi, J.; Srinivas, S. Bearing current profiles in a 3-phase VSI fed induction motor drive using a simplified measurement approach. In Proceedings of the 2012 IEEE International Conference on Power Electronics, Drives and Energy Systems (PEDES), Mangalore, India, 18–21 December 2012; IEEE: Piscataway, NJ, USA, 2012. [Google Scholar]

- Loh, P.C.; Holmes, D.G.; Fukuta, Y.; Lipo, T.A. Reduced common-mode modulation strategies for cascaded multilevel inverters. IEEE Trans. Ind. Appl. 2003, 39, 1386–1395. [Google Scholar]

- Gupta, A.K.; Khambadkone, A.M. A space vector modulation scheme to reduce common mode voltage for cascaded multilevel inverters. IEEE Trans. Power Electron. 2007, 22, 1672–1681. [Google Scholar] [CrossRef]

- Espina, J.; Ortega, C.; De Lillo, L.; Empringham, L.; Balcells, J.; Arias, A. Reduction of output common mode voltage using a novel SVM implementation in matrix converters for improved motor lifetime. IEEE Trans. Ind. Electron. 2014, 61, 5903–5911. [Google Scholar] [CrossRef]

- Hussain, H.A.; Toliyat, H.A. Reduction of shaft voltages and bearing currents in five-phase induction motors. In Proceedings of the 2012 IEEE Energy Conversion Congress and Exposition (ECCE), Raleigh, NC, USA, 15–20 September 2012; IEEE: Piscataway, NJ, USA, 2012. [Google Scholar]

- Erdman, J.M.; Kerkman, R.J.; Schlegel, D.W.; Skibinski, G.L. Effect of PWM inverters on AC motor bearing currents and shaft voltages. IEEE Trans. Ind. Appl. 2002, 32, 250–259. [Google Scholar] [CrossRef]

- Adabi, J.; Zare, F.; Ledwich, G.; Ghosh, A. Leakage current and common mode voltage issues in modern AC drive systems. In Proceedings of the 2007 Australasian Universities Power Engineering Conference, Perth, Australia, 9–12 December 2007; IEEE: Piscataway, NJ, USA, 2007. [Google Scholar]

- Muetze, A.; Binder, A. Practical rules for assessment of inverter-induced bearing currents in inverter-fed AC motors up to 500 kW. IEEE Trans. Ind. Electron. 2007, 54, 1614–1622. [Google Scholar] [CrossRef]

- Han, P.; Heins, G.; Patterson, D.; Thiele, M.; Ionel, D.M. Evaluation of Bearing Voltage Reduction in Electric Machines by Using Insulated Shaft and Bearings. In Proceedings of the 2020 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 11–15 October 2020; pp. 5584–5589. [Google Scholar]

- Xiao, Z.; Hu, M.; Chen, S.; Cao, K. Bearing electrical-erosion damage in electrical drive systems: A review. IEEE Trans. Transp. Electrif. 2023, 7, 3428–3442. [Google Scholar] [CrossRef]

- Puchtler, S.; Maier, R.; Kuhn, M.; Burkhardt, Y. The Influence of Load and Speed on the Initial Breakdown of Rolling Bearings Exposed to Electrical Currents. Lubricants 2023, 12, 1. [Google Scholar] [CrossRef]

- von Jouanne, A.; Collin, R.; Stephens, M.; Phillips, B.; Chen, H.; Li, C.; Agamloh, E.; Yokochi, A. Development of Inverter Duty Motor Bearings for Si and SiC-Based Variable Frequency Drive Applications Including Advanced 4D Finite Element Modeling. In Proceedings of the 2021 IEEE Energy Conversion Congress and Exposition (ECCE), Vancouver, BC, Canada, 10–14 October 2021; IEEE: Piscataway, NJ, USA, 2021. [Google Scholar]

- Yang, M.; Cheng, Y.; Du, B.; Li, Y.; Wang, S.; Cui, S. Research on Analysis and Suppression Methods of the Bearing Current for Electric Vehicle Motor Driven by SiC Inverter. Energies 2024, 17, 1109. [Google Scholar] [CrossRef]

- Bechev, D.; Capan, R.; Gonda, A.; Sauer, B. Method for the investigation of the EDM breakdown voltage of grease and oil on rolling bearings. Bear World J. 2019, 4, 83–91. [Google Scholar]

- Lokhande, R. Development of a Novel Test Rig for Quantifying Motor Bearing Failures due to Electric Discharge Machining Current in EVs. In Department of Mechanical Engineering; Indian Institute of Technology Madras: Chennai, India, 2025; pp. 1–92. [Google Scholar]

- Beroual, A.; Khaled, U.; Mbolo Noah, P.S.; Sitorus, H. Comparative study of breakdown voltage of mineral, synthetic and natural oils and based mineral oil mixtures under AC and DC voltages. Energies 2017, 10, 511. [Google Scholar] [CrossRef]

- Gonda, A.; Capan, R.; Bechev, D.; Sauer, B. The influence of lubricant conductivity on bearing currents in the case of rolling bearing greases. Lubricants 2019, 7, 108. [Google Scholar] [CrossRef]

- Klenk, T.; Colineau, F.; Morgenstern, S. Conductive Simmerrings help prevent electrical discharge machining in modern electrical powertrains. Bear. World J. 2019, 4, 7–13. [Google Scholar]

- Plazenet, T.; Boileau, T.; Caironi, C.; Nahid-Mobarakeh, B. A comprehensive study on shaft voltages and bearing currents in rotating machines. IEEE Trans. Ind. Appl. 2018, 54, 3749–3759. [Google Scholar] [CrossRef]

- Chen, S.; Lipo, T.A. Circulating type motor bearing current in inverter drives. IEEE Ind. Appl. Mag. 1998, 4, 32–38. [Google Scholar] [CrossRef]

- Patro, B.D.K.; Suvin, P.; Dalimba, U.; Kreivaitis, R. Effect of temperature on tribological behavior of L–proline–based green deep eutectic solvents for Ti6Al4V interfaces: A study of novel potential lubricant. Tribol. Int. 2025, 208, 110667. [Google Scholar] [CrossRef]

- Asefi, M.; Nazarzadeh, J. Survey on high-frequency models of PWM electric drives for shaft voltage and bearing current analysis. IET Electr. Syst. Transp. 2017, 7, 179–189. [Google Scholar] [CrossRef]

- Mütze, A.; Binder, A. Don’t lose your bearings. IEEE Ind. Appl. Mag. 2006, 12, 22–31. [Google Scholar] [CrossRef]

- Chiou, Y.-C.; Lee, R.-T.; Lin, C.-M. Formation criterion and mechanism of electrical pitting on the lubricated surface under AC electric field. Wear 1999, 236, 62–72. [Google Scholar] [CrossRef]

- Lin, C.-M.; Chiou, Y.-C.; Lee, R.-T. Effect of MoS2 additive on electrical pitting mechanism of lubricated surface for Babbitt alloy/bearing steel pair under ac electric field. Wear 2004, 257, 833–842. [Google Scholar] [CrossRef]

- Suzumura, J. Prevention of electrical pitting on rolling bearings by electrically conductive grease. Q. Rep. RTRI 2016, 57, 42–47. [Google Scholar] [CrossRef]

- Kaufman, H.; Boyd, J. The conduction of current in bearings. ASLE Trans. 1959, 2, 67–77. [Google Scholar] [CrossRef]

- Prashad, H. Theoretical analysis of the effects of instantaneous charge leakage on roller tracks of roller bearings lubricated with high resistivity lubricants under the influence of electric current. J. Tribol. 1990, 112, 37–43. [Google Scholar] [CrossRef]

- Tischmacher, H.; Gattermann, S. Bearing currents in converter operation. In Proceedings of the The XIX International Conference on Electrical Machines-ICEM 2010, Rome, Italy, 6–8 September 2010; IEEE: Piscataway, NJ, USA, 2010. [Google Scholar]

- Costello, M.J. Shaft voltages and rotating machinery. IEEE Trans. Ind. Appl. 2002, 29, 419–426. [Google Scholar] [CrossRef]

- Ost, W.; De Baets, P. Failure analysis of the deep groove ball bearings of an electric motor. Eng. Fail. Anal. 2005, 12, 772–783. [Google Scholar] [CrossRef]

- Tischmacher, H.; Gattermann, S.; Kriese, M.; Wittek, E. Bearing wear caused by converter-induced bearing currents. In Proceedings of the IECON 2010-36th Annual Conference on IEEE Industrial Electronics Society, Glendale, AZ, USA, 7–10 November 2010; IEEE: Piscataway, NJ, USA, 2010. [Google Scholar]

- Raadnui, S.; Kleesuwan, S. Electrical pitting wear debris analysis of grease-lubricated rolling element bearings. Wear 2011, 271, 1707–1718. [Google Scholar] [CrossRef]

- Didenko, T.; Pridemore, W.D. Electrical fluting failure of a Tri-lobe roller bearing. J. Fail. Anal. Prev. 2012, 12, 575–580. [Google Scholar] [CrossRef]

- Safdarzadeh, O.; Farahi, A.; Binder, A.; Sezen, H.; Hofmann, J.P. WLI, XPS and SEM/FIB/EDS surface characterization of an electrically fluted bearing raceway. Lubricants 2024, 12, 148. [Google Scholar] [CrossRef]

- Liu, W. The prevalent motor bearing premature failures due to the high frequency electric current passage. Eng. Fail. Anal. 2014, 45, 118–127. [Google Scholar] [CrossRef]

- Romanenko, A.; Muetze, A.; Ahola, J. Effects of electrostatic discharges on bearing grease dielectric strength and composition. IEEE Trans. Ind. Appl. 2016, 52, 4835–4842. [Google Scholar] [CrossRef]

- Loos, J.; Bergmann, I.; Goss, M. Influence of high electrical currents on WEC formation in rolling bearings. Tribol. Trans. 2021, 64, 708–720. [Google Scholar] [CrossRef]

- Gould, B.; Greco, A.; Stadler, K.; Vegter, E.; Xiao, X. Using advanced tomography techniques to investigate the development of White Etching Cracks in a prematurely failed field bearing. Tribol. Int. 2017, 116, 362–370. [Google Scholar] [CrossRef]

- Romanenko, A.; Ahola, J.; Muetze, A. Influence of electric discharge activity on bearing lubricating grease degradation. In Proceedings of the 2015 IEEE Energy Conversion Congress and Exposition (ECCE), Montreal, QC, Canada, 20–24 September 2015; IEEE: Piscataway, NJ, USA, 2015. [Google Scholar]

- Mufazzal, S.; Muzakkir, S.; Khanam, S. On the importance of modeling ball raceway impact force for evaluating the plastic deformation at spall edge of rolling element bearing: Theoretical modeling. J. Vib. Eng. Technol. 2024, 12, 1309–1322. [Google Scholar] [CrossRef]

- Malec, D.; Bley, V.; Talbi, F.; Lalam, F. Contribution to the understanding of the relationship between mechanical and dielectric strengths of Alumina. J. Eur. Ceram. Soc. 2010, 30, 3117–3123. [Google Scholar] [CrossRef]

- Noguchi, S.; Kakinuma, S.-N.; Kanada, T. Measurement of direct current voltage causing electrical pitting. J. Adv. Mech. Des. Syst. Manuf. 2010, 4, 1084–1094. [Google Scholar] [CrossRef]

- Schoen, R.R.; Habetler, T.G.; Kamran, F.; Bartfield, R.G. Motor bearing damage detection using stator current monitoring. In Proceedings of the 1994 IEEE Industry Applications Society Annual Meeting, Denver, CO, USA, 2–5 October 1994; IEEE: Piscataway, NJ, USA, 1994. [Google Scholar]

- Huan, J.; Li, S.; Xia, Z.; Wang, Y.; Wang, W.; Shi, G. Experimental Study on Electric Corrosion Damage of Bearing and Solution. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 10349–10358. [Google Scholar] [CrossRef]

- Joshi, A. Electrical Characterisations of Bearings. Ph.D. Thesis, Chalmers University of Technology, Göteborg, Sweden, 2019. (In Sweden). [Google Scholar]

- Park, J.-K.; Wellawatta, T.R.; Ullah, Z.; Hur, J. New equivalent circuit of the IPM-type BLDC motor for calculation of shaft voltage by considering electric and magnetic fields. IEEE Trans. Ind. Appl. 2016, 52, 3763–3771. [Google Scholar] [CrossRef]

- Han, P.; Heins, G.; Patterson, D.; Thiele, M.; Ionel, D.M. Modeling of bearing voltage in electric machines based on electromagnetic FEA and measured bearing capacitance. IEEE Trans. Ind. Appl. 2021, 57, 4765–4775. [Google Scholar] [CrossRef]

- Burda, E.A.; Zusman, G.V.; Kudryavtseva, I.S.; Naumenko, A.P. An overview of vibration analysis techniques for the fault diagnostics of rolling bearings in machinery. Shock Vib. 2022, 2022, 6136231. [Google Scholar] [CrossRef]

- Singh, S.; Howard, C.Q.; Hansen, C.H. An extensive review of vibration modelling of rolling element bearings with localised and extended defects. J. Sound Vib. 2015, 357, 300–330. [Google Scholar] [CrossRef]

- Janjarasjitt, S.; Ocak, H.; Loparo, K. Bearing condition diagnosis and prognosis using applied nonlinear dynamical analysis of machine vibration signal. J. Sound Vib. 2008, 317, 112–126. [Google Scholar] [CrossRef]

- Mufazzal, S.; Muzakkir, S.; Khanam, S. A dynamic model for simulating vibration response of ball bearings with extended outer race defects for precise spall size estimation. J. Sound Vib. 2023, 552, 117606. [Google Scholar] [CrossRef]

- McFadden, P.; Smith, J. Vibration monitoring of rolling element bearings by the high-frequency resonance technique—A review. Tribol. Int. 1984, 17, 3–10. [Google Scholar] [CrossRef]

- Allen, J. Short term spectral analysis, synthesis, and modification by discrete Fourier transform. IEEE Trans. Acoust. Speech Signal Process. 2003, 25, 235–238. [Google Scholar] [CrossRef]

- Polikar, R. The wavelet tutorial second edition part i. In Fundamental Concepts & An Overview of The Wavelet Theory; Rowan University: Glassboro, NJ, USA, 1996. [Google Scholar]

- Ayenu-Prah, A.; Attoh-Okine, N. Comparative study of Hilbert–Huang transform, Fourier transform and wavelet transform in pavement profile analysis. Veh. Syst. Dyn. 2009, 47, 437–456. [Google Scholar] [CrossRef]

- Kan, M.S.; Tan, A.C.; Mathew, J. A review on prognostic techniques for non-stationary and non-linear rotating systems. Mech. Syst. Signal Process. 2015, 62, 1–20. [Google Scholar] [CrossRef]

- Huang, N.E.; Shen, Z.; Long, S.R.; Wu, M.C.; Shih, H.H.; Zheng, Q.; Yen, N.-C.; Tung, C.C.; Liu, H.H. The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis. Proc. R. Soc. Lond. Ser. A Math. Phys. Eng. Sci. 1998, 454, 903–995. [Google Scholar] [CrossRef]

- Lei, Y.; He, Z.; Zi, Y. EEMD method and WNN for fault diagnosis of locomotive roller bearings. Expert Syst. Appl. 2011, 38, 7334–7341. [Google Scholar] [CrossRef]

- Wu, Z.; Huang, N.E. Ensemble empirical mode decomposition: A noise-assisted data analysis method. Adv. Adapt. Data Anal. 2009, 1, 1–41. [Google Scholar] [CrossRef]

- Shami, U.T.; Akagi, H. Experimental discussions on a shaft end-to-end voltage appearing in an inverter-driven motor. IEEE Trans. Power Electron. 2009, 24, 1532–1540. [Google Scholar] [CrossRef]

- Mäki-Ontto, P. Modeling and reduction of shaft voltages in AC motors fed by frequency converters. In Doctoral thesis 2006; Helsinki University of Technology: Helsinki, Finland, 2006; p. 74. [Google Scholar]

- Ong, R.; Dymond, J.H.; Findlay, R.D. Comparison of techniques for measurement of shaft currents in rotating machines. IEEE Trans. Energy Convers. 2002, 12, 363–367. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, G.; Xia, Z.; Bao, Z.; Yao, J.; Fang, X.; Zhang, Z.; Guan, R. Research on the friction, lubrication and temperature rise characteristics of silicon nitride full ceramic ball bearing at low temperature. Ind. Lubr. Tribol. 2023, 75, 432–447. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhang, C.; Ni, W.; Li, S. A study on the temperature rise characteristics of high-speed ball bearings under starvation lubrication. Ind. Lubr. Tribol. 2024, 76, 1214–1224. [Google Scholar] [CrossRef]

- Qu, J.; Truhan, J.J. An efficient method for accurately determining wear volumes of sliders with non-flat wear scars and compound curvatures. Wear 2006, 261, 848–855. [Google Scholar] [CrossRef]

- Jakubek, B.; Grochalski, K.; Rukat, W.; Sokol, H. Thermovision measurements of rolling bearings. Measurement 2022, 189, 110512. [Google Scholar] [CrossRef]

- Hong, D.-P.; Kim, D.-Y.; Lee, J.-W.; Yu, C.-H.; Kim, W.-T.; Choi, M.-Y. A study on the temperature characteristic of the rotation element is the Ball bearing by the lubrication condition using the infrared thermography camera. In Proceedings of the Korean Society for Noise and Vibration Engineering Conference, Seoul, Republic of Korea, 23–26 August 2010; The Korean Society for Noise and Vibration Engineering: Seoul, Republic of Korea, 2010; pp. 262–263. [Google Scholar]

- Amooie, M.A.; Lijesh, K.; Mahmoudi, A.; Azizian-Farsani, E.; Khonsari, M.M. On the characteristics of fatigue fracture with rapid frequency change. Entropy 2023, 25, 840. [Google Scholar] [CrossRef] [PubMed]

- Naderi, M.; Amiri, M.; Khonsari, M. On the thermodynamic entropy of fatigue fracture. Proc. R. Soc. A Math. Phys. Eng. Sci. 2010, 466, 423–438. [Google Scholar] [CrossRef]

- Shah, R.; Sridharan, N.V.; Mahanta, T.K.; Muniyappa, A.; Vaithiyanathan, S.; Ramteke, S.M.; Marian, M. Ensemble deep learning for wear particle image analysis. Lubricants 2023, 11, 461. [Google Scholar] [CrossRef]

- Khonsari, M.; Beaman, J. Thermohydrodynamic analysis of laminar incompressible journal bearings. ASLE Trans. 1986, 29, 141–150. [Google Scholar] [CrossRef]

- Chybowski, L.; Szczepanek, M.; Sztangierski, R.; Brożek, P. A Quantitative and Qualitative Analysis of the Lubricity of Used Lubricating Oil Diluted with Diesel Oil. Appl. Sci. 2024, 14, 4567. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhou, X.; Huang, Q.; Liu, X.; Wang, L.; Xing, S. Impact of oil-water emulsions on lubrication performance of ship stern bearings. Sci. Rep. 2024, 14, 31478. [Google Scholar] [CrossRef]

- Rounds, F.G. Effects of base oil viscosity and type on bearing ball fatigue. ASLE Trans. 1962, 5, 172–182. [Google Scholar] [CrossRef]

- Shah, R.; Tung, S.; Chen, R.; Miller, R. Grease performance requirements and future perspectives for electric and hybrid vehicle applications. Lubricants 2021, 9, 40. [Google Scholar] [CrossRef]

- Andrew, J.M. The future of lubricating greases in the electric vehicle era. Tribol. Lubr. Technol. 2019, 75, 38–44. [Google Scholar]

- Chen, Y.; Jha, S.; Raut, A.; Zhang, W.; Liang, H. Performance characteristics of lubricants in electric and hybrid vehicles: A review of current and future needs. Front. Mech. Eng. 2020, 6, 571464. [Google Scholar] [CrossRef]

- Lugt, P.M. Modern advancements in lubricating grease technology. Tribol. Int. 2016, 97, 467–477. [Google Scholar] [CrossRef]

- Lijesh, K.; Khonsari, M. On the assessment of mechanical degradation of grease using entropy generation rate. Tribol. Lett. 2019, 67, 50. [Google Scholar] [CrossRef]

- Rezasoltani, A.; Khonsari, M. An engineering model to estimate consistency reduction of lubricating grease subjected to mechanical degradation under shear. Tribol. Int. 2016, 103, 465–474. [Google Scholar] [CrossRef]

- Brooksbank, A.; Latchford, J.; Mudge, S. Degradation and modification of fats, oils and grease by commercial microbial supplements. World J. Microbiol. Biotechnol. 2007, 23, 977–985. [Google Scholar] [CrossRef]

- Lijesh, K.; Miller, R.A.; Shah, R.; Shirvani, K.; Khonsari, M.M. The standard for assessing water resistance properties of lubricating grease using contact angle measurements. Lubricants 2023, 11, 440. [Google Scholar] [CrossRef]

- Lijesh, K.; Khonsari, M.; Miller, R.A. Assessment of water contamination on grease using the contact angle approach. Tribol. Lett. 2020, 68, 103. [Google Scholar] [CrossRef]

- IEEE Std 112-2017 (Revision IEEE Std 112-953, 2004); IEEE Standard Test Procedure for Polyphase Induction Motors and Generators. IEEE: Piscataway, NJ, USA, 2018; pp. 1–115.

- Fan, F.; See, K.Y.; Banda, J.K.; Liu, X.; Gupta, A.K. Investigation and mitigation of premature bearing degradation in motor drive system. IEEE Electromagn. Compat. Mag. 2019, 8, 75–81. [Google Scholar] [CrossRef]

- Busse, D.F.; Erdman, J.M.; Kerkman, R.J.; Schlegel, D.W.; Skibinski, G.L. The effects of PWM voltage source inverters on the mechanical performance of rolling bearings. IEEE Trans. Ind. Appl. 2002, 33, 567–576. [Google Scholar] [CrossRef]

- Muetze, A.; Tamminen, J.; Ahola, J. Influence of motor operating parameters on discharge bearing current activity. IEEE Trans. Ind. Appl. 2011, 47, 1767–1777. [Google Scholar] [CrossRef]

- Särkimäki, V. Radio Frequency Measurement Method for Detecting Bearing Currents in Induction Motors. Ph.D. Thesis, Lappeenranta University of Technology, Lappeenranta, Finland, 2009. [Google Scholar]

- Bubert, A.; Zhang, J.; De Doncker, R.W. Modeling and measurement of capacitive and inductive bearing current in electrical machines. In Proceedings of the 2017 Brazilian Power Electronics Conference (COBEP), Juiz de Fora, Brazil,, 19–22 November 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–6. [Google Scholar]

- Muetze, A.; Binder, A. Experimental evaluation of mitigation techniques for bearing currents in inverter-supplied drive-systems-investigations on induction motors up to 500 kW. In Proceedings of the IEEE International Electric Machines and Drives Conference, IEMDC’03, Madison, WI, USA, 1–4 June 2003; IEEE: Piscataway, NJ, USA, 2003. [Google Scholar]

- Tischmacher, H.; Gattermann, S. Investigations on bearing currents in converter-fed electrical motors. In Proceedings of the 2012 XXth International Conference on Electrical Machines, Marseille, France, 2–5 September 2012; IEEE: Piscataway, NJ, USA, 2012. [Google Scholar]

- Prashad, H. The effects of current leakage on electroadhesion forces in rolling friction and magnetic flux density distribution on the surface of rolling element bearings. J. Tribol. 1988, 110, 448–455. [Google Scholar] [CrossRef]

- Zheng, J.; Xiang, D.; Li, H.; Quach, D.-C. An Investigation into the Effect of Bearing Grease Degradation on the High-frequency dv/dt Bearing Current in an Inverter-fed Motor System. In Proceedings of the 2021 6th International Conference on Power and Renewable Energy (ICPRE), Shanghai, China, 17–20 September 2021; IEEE: Piscataway, NJ, USA, 2021. [Google Scholar]

- Khan, K.; Gyllensten, F. Experimental investigation of bearing currents in low voltage motors. In Proceedings of the 2018 XIII International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018; IEEE: Piscataway, NJ, USA, 2018. [Google Scholar]

| Method | Category | Functionality | Advantages | Limitations |

|---|---|---|---|---|

| Insulated Bearings | Break Current Path | Interrupts current path through high electrical resistance | Simple to implement, widely available | May not prevent high-frequency discharge |

| Hybrid Ceramic Bearings | Break Current Path | Prevents current flow due to insulating ceramic elements | Highly effective, durable under harsh conditions | Higher cost, complex manufacturing |

| Shaft Grounding Brushes | Break Current Path | Provides a low-impedance path to ground | Cost-effective, easily retrofitted | Brush wear and maintenance needed |

| Electrostatic Shielding | Break Current Path | Blocks electric fields along shaft | Minimizes electrostatic charging | Design complexity, less commonly applied |

| Common-Mode Choke | Reduce Source | Suppresses high-frequency common-mode currents | Reduces EMI, improves reliability | Added cost, may require tuning |

| dv/dt Filter | Reduce Source | Limits voltage slope (dv/dt) to reduce common-mode voltage | Protects insulation system | Voltage drop, space requirement |

| Shielded Cables | Reduce Source | Prevents electromagnetic interference and leakage currents | Reduces noise and leakage currents | May not fully filter high-frequency harmonics |

| Sinusoidal Filter | Reduce Source | Smooths PWM waveform to reduce electrical noise and CMV | Improves motor performance, extends bearing life | Bulkier, expensive for compact systems |

| Ref No. | Focus Area | Contribution | Limitation |

|---|---|---|---|

| [2] | EV bearing current failures | Comprehensive review of failure modes | Limited discussion on lubricant degradation |

| [3] | Discharge behavior in EV bearings | Experimental study on single-contact discharges | Specific to single contact, not system-level |

| [4] | Nano-lubricants for EVs | Review of nano-lubricants potential | Limited focus on bearing currents |

| [6] | Bearing current mechanisms | Detailed mechanisms and mitigation techniques | Minimal lubricant-related discussion |

| [7] | Bearing current damage | Morphological damage review (frosting, fluting) | Limited lubricant property analysis |

| [8] | E-motor bearing discharges | Experimental + numerical approach | Focused on electrical effects, less on tribology |

| [9] | Tribology of EV driveline lubes | Tribological evaluation in electrified setups | Lacks electrical discharge focus |

| [10] | Shaft voltage effects | Impact on GCr15 bearing material | Material specific, not broad motor systems |

| [11] | PWM drive and bearing currents | Early study linking PWM to bearing currents | No lubrication analysis |

| [16] | Micro/nano damage, measurement | Microstructural damage from currents | Limited lubricant comparison |

| [18] | Industrial motor mitigation | Mitigation techniques for shaft voltage | General motors, not EV-focused |

| [24] | Non-conductive lube effect on bearings | Discusses arcing from film breakdown | Not experimental |

| [26] | Speed/lube viscosity & pitting | Links speed, viscosity to pitting, fluting | Context specific to EVs |

| [27] | Bearing current variables | Highlights role of film thickness, impedance | Theoretical focus |

| [28] | Shaft voltage sensitivity | Sensitivity to inverter/motor params | Lacks tribological/lubricant integration |

| [29] | Nanoparticle grease in bearings | Shows effectiveness on discharge damage | Focused on two nanoparticle types |

| [30] | Electrical pitting prevention | Preventative device study | Device-specific, not generalizable |

| [31] | Tribological effects of damage | Tribology under electrical damage | Lacks lubricant chemistry evaluation |

| [56] | Lube conductivity/bearing currents | Experimental lube conductivity results | No long-term lube stability analysis |

| [66] | Conductive grease | Prevent electrical pitting using grease | Focused on grease, not whole system |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lokhande, R.; Mishra, S.K.; Ronanki, D.; Shakya, P.; Edachery, V.; Koottaparambil, L. Review on Tribological and Vibration Aspects in Mechanical Bearings of Electric Vehicles: Effect of Bearing Current, Shaft Voltage, and Electric Discharge Material Spalling Current. Lubricants 2025, 13, 349. https://doi.org/10.3390/lubricants13080349

Lokhande R, Mishra SK, Ronanki D, Shakya P, Edachery V, Koottaparambil L. Review on Tribological and Vibration Aspects in Mechanical Bearings of Electric Vehicles: Effect of Bearing Current, Shaft Voltage, and Electric Discharge Material Spalling Current. Lubricants. 2025; 13(8):349. https://doi.org/10.3390/lubricants13080349

Chicago/Turabian StyleLokhande, Rohan, Sitesh Kumar Mishra, Deepak Ronanki, Piyush Shakya, Vimal Edachery, and Lijesh Koottaparambil. 2025. "Review on Tribological and Vibration Aspects in Mechanical Bearings of Electric Vehicles: Effect of Bearing Current, Shaft Voltage, and Electric Discharge Material Spalling Current" Lubricants 13, no. 8: 349. https://doi.org/10.3390/lubricants13080349

APA StyleLokhande, R., Mishra, S. K., Ronanki, D., Shakya, P., Edachery, V., & Koottaparambil, L. (2025). Review on Tribological and Vibration Aspects in Mechanical Bearings of Electric Vehicles: Effect of Bearing Current, Shaft Voltage, and Electric Discharge Material Spalling Current. Lubricants, 13(8), 349. https://doi.org/10.3390/lubricants13080349