Improving Wear Resistance of DLC-Coated Metal Components During Service: A Review

Abstract

1. Introduction

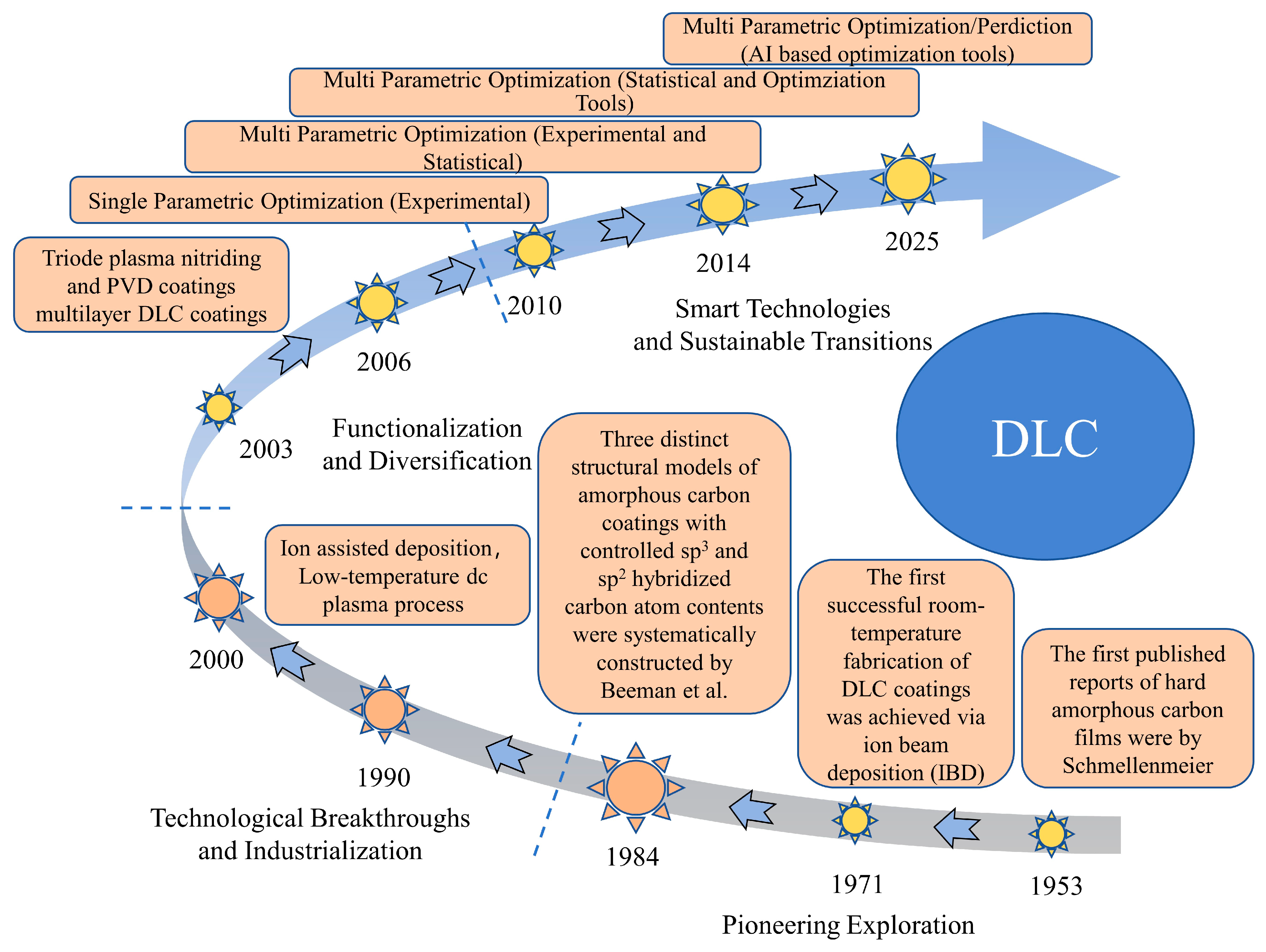

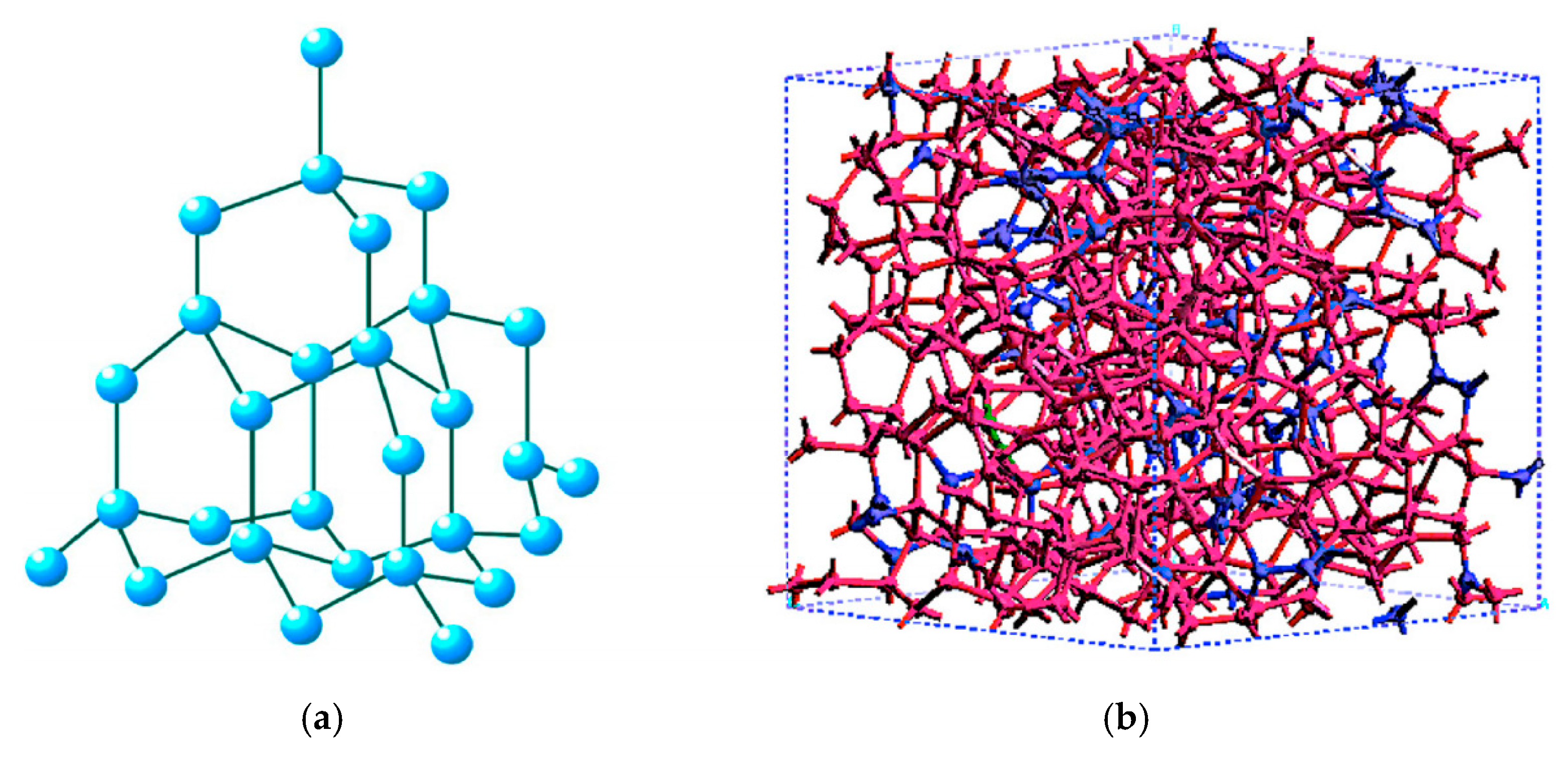

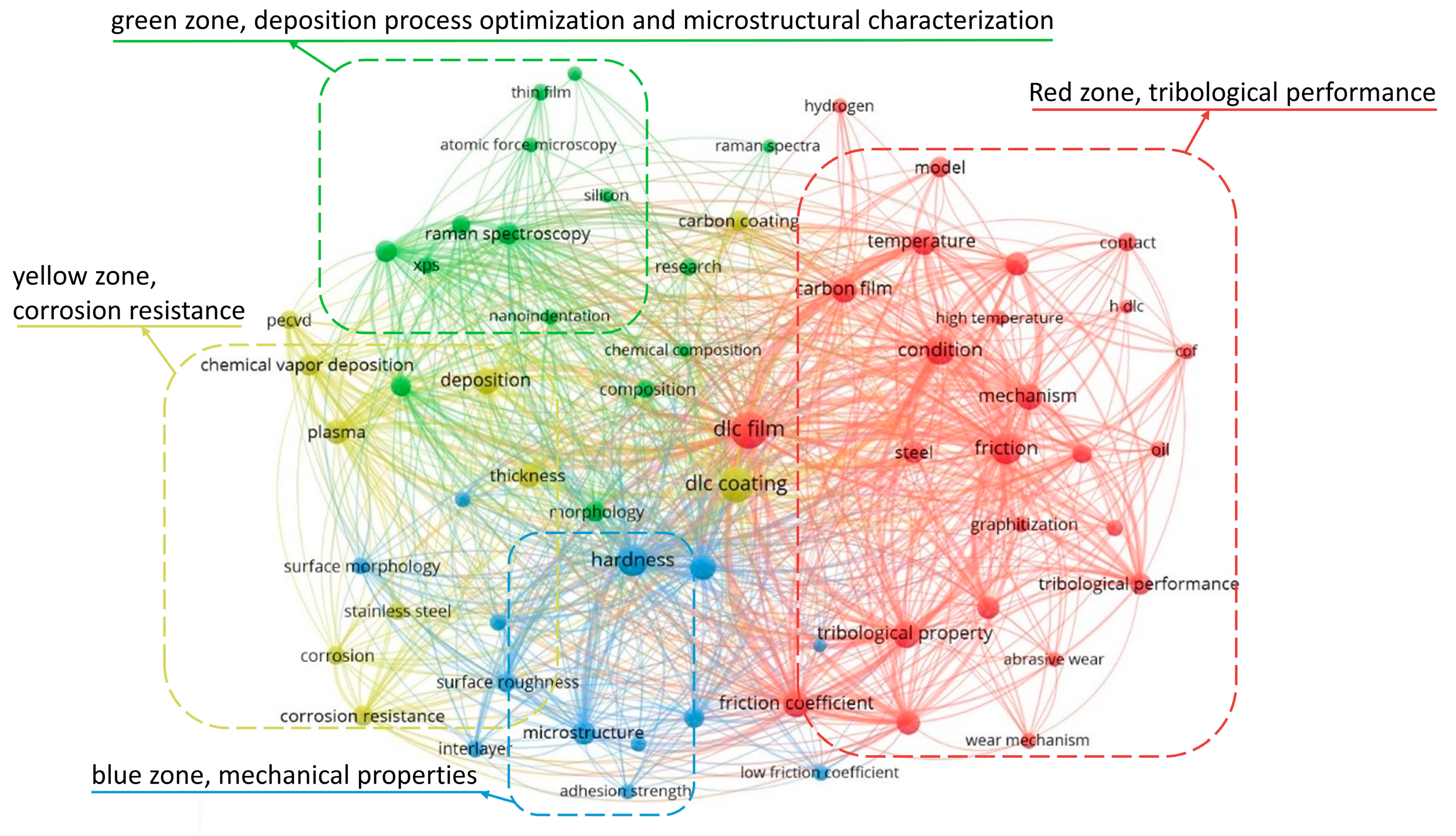

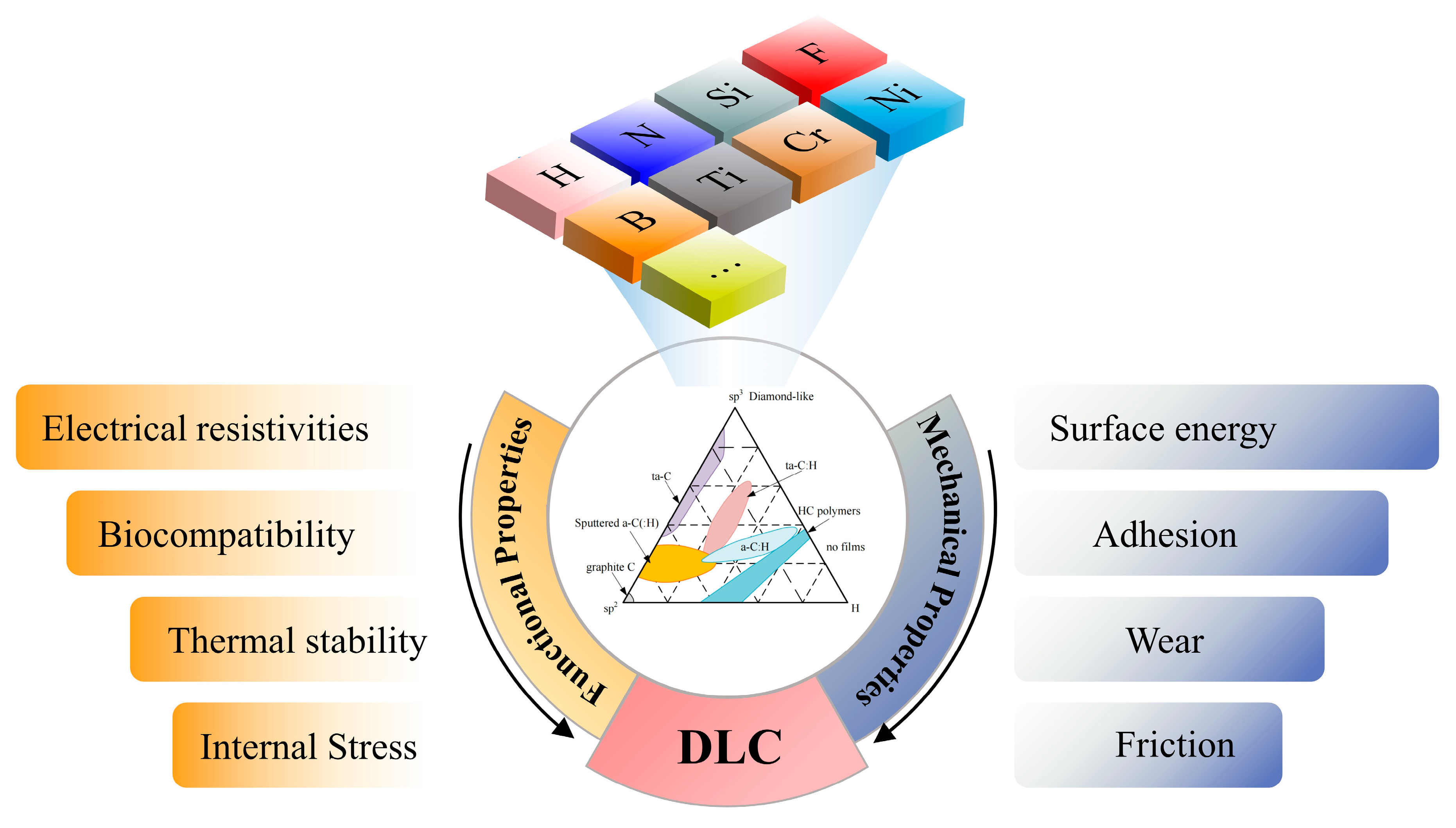

1.1. DLC Coatings

1.2. Purpose of the Review

2. Wear Mechanisms of DLC-Coated Metal Components

2.1. Wear Mechanisms of Metallic Substrates

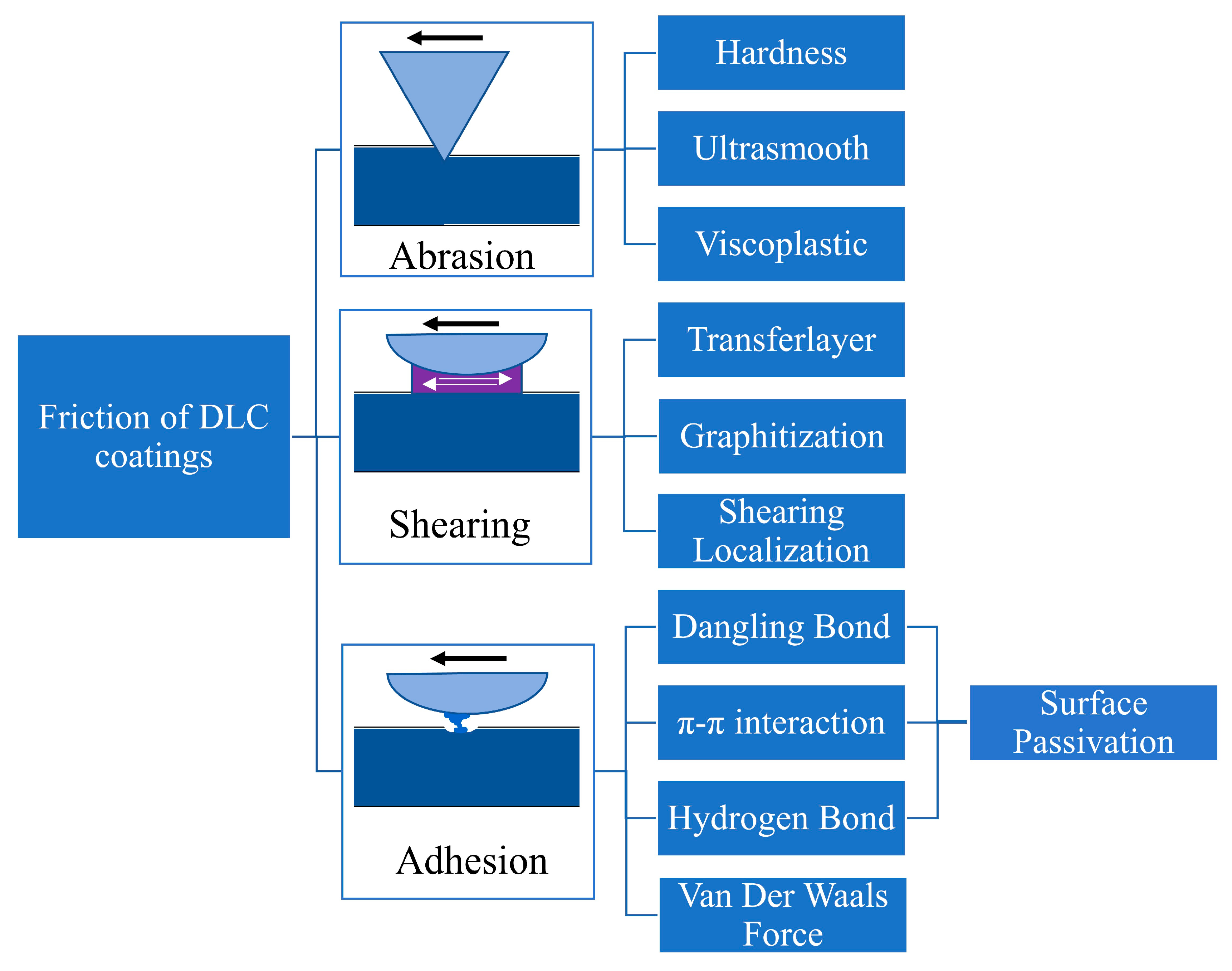

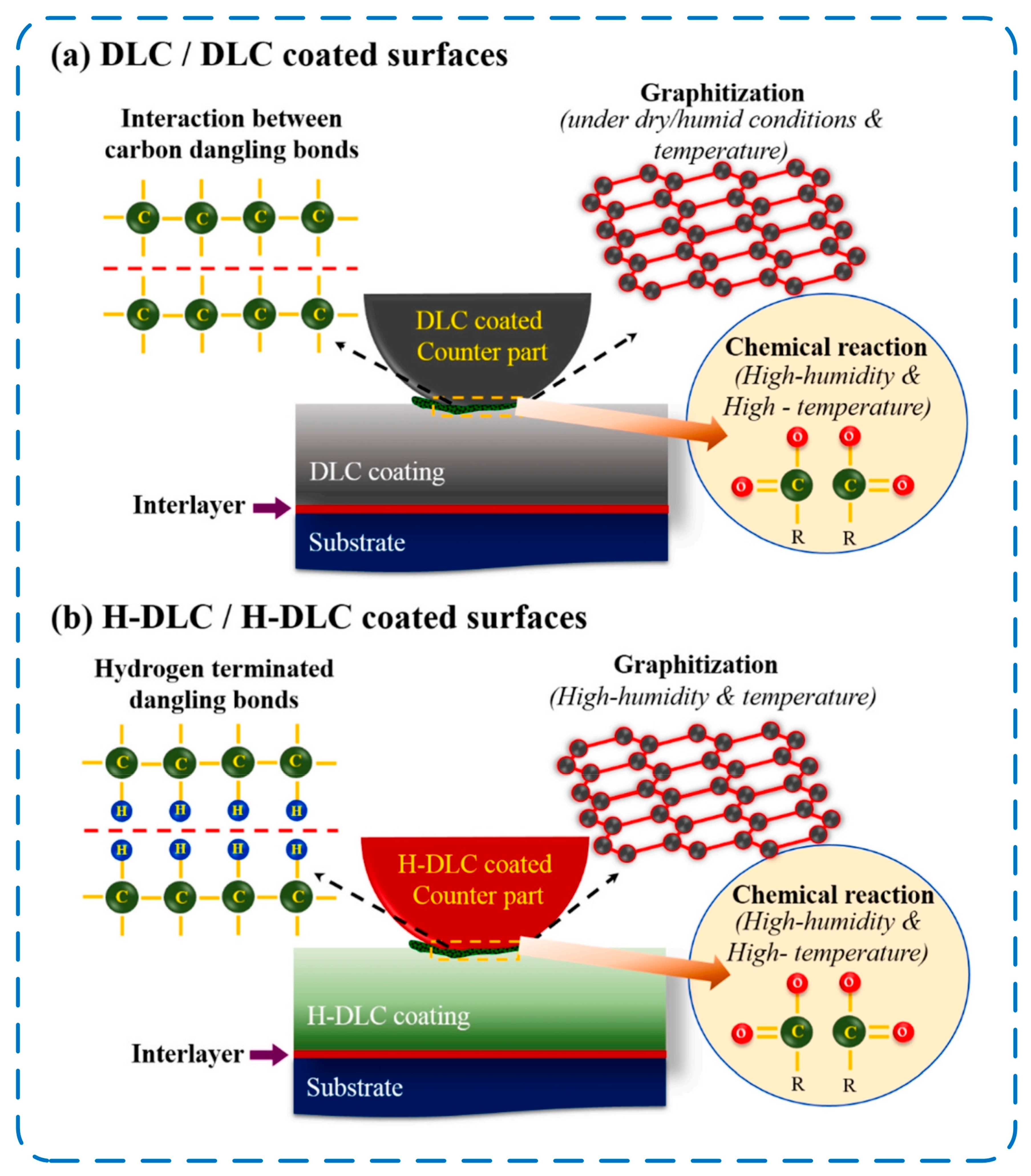

2.2. Wear Mechanisms of DLC Coatings

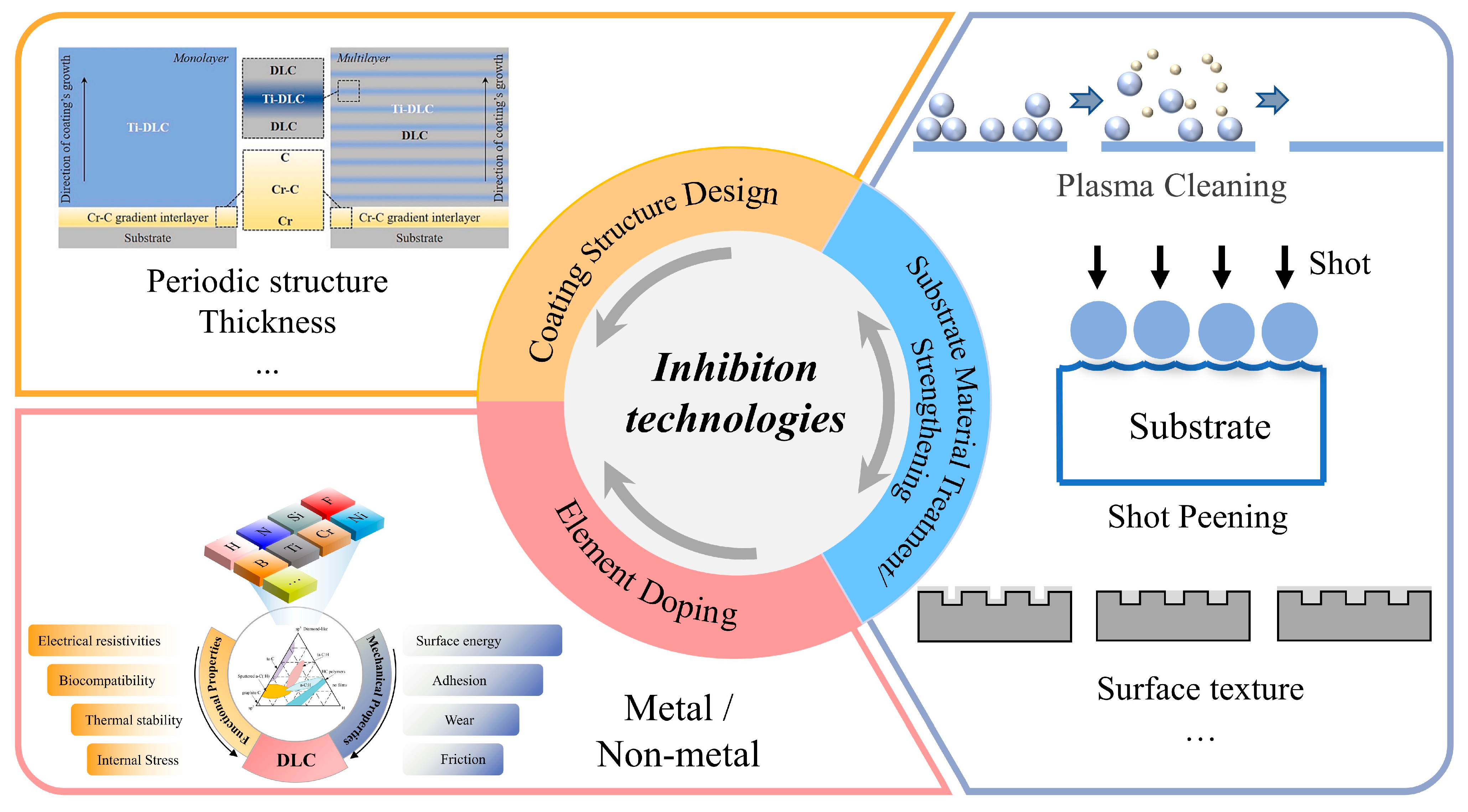

3. Wear Inhibition Technologies of DLC-Coated Metal Components

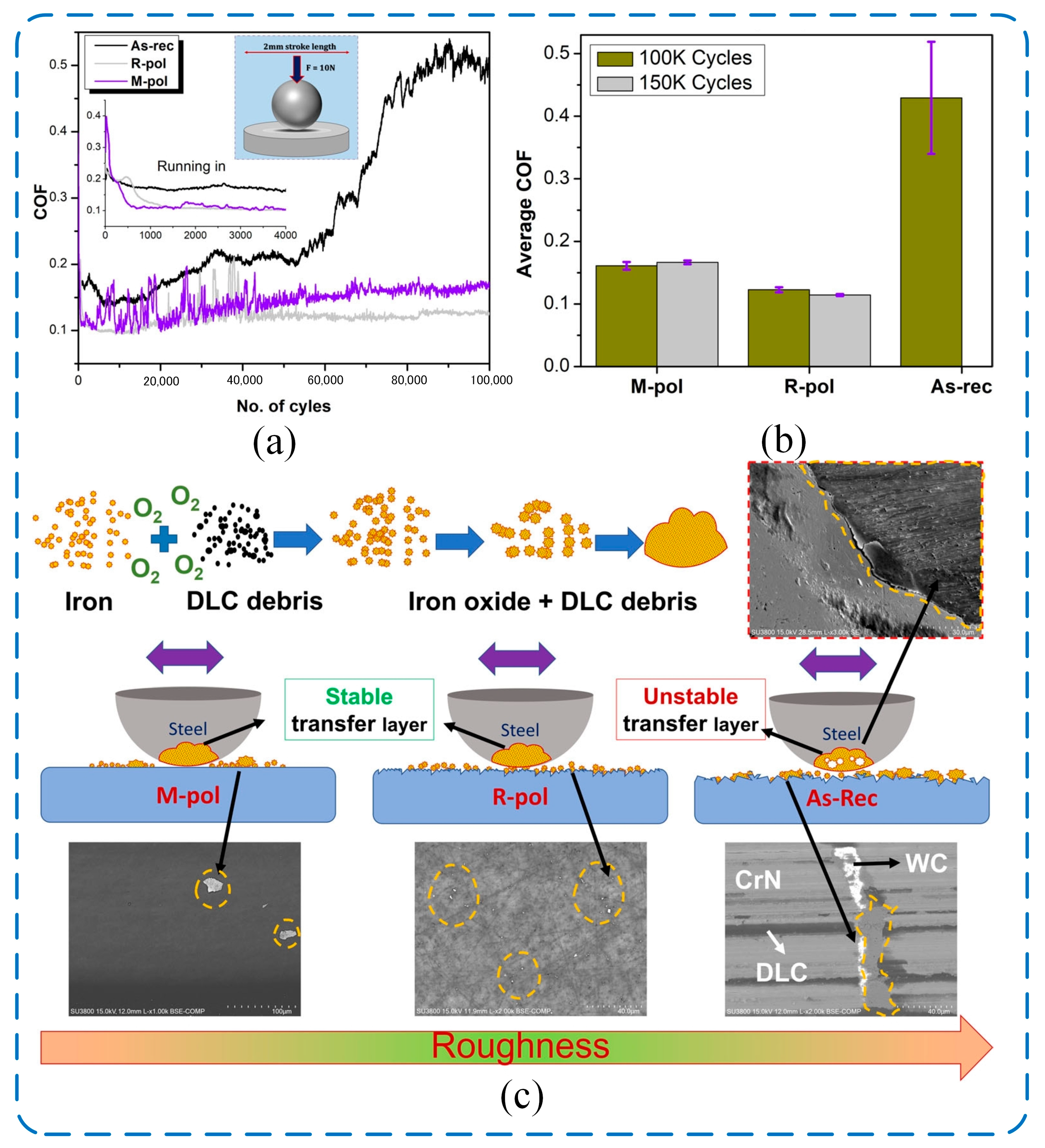

3.1. Substrate Material Treatment/Strengthening

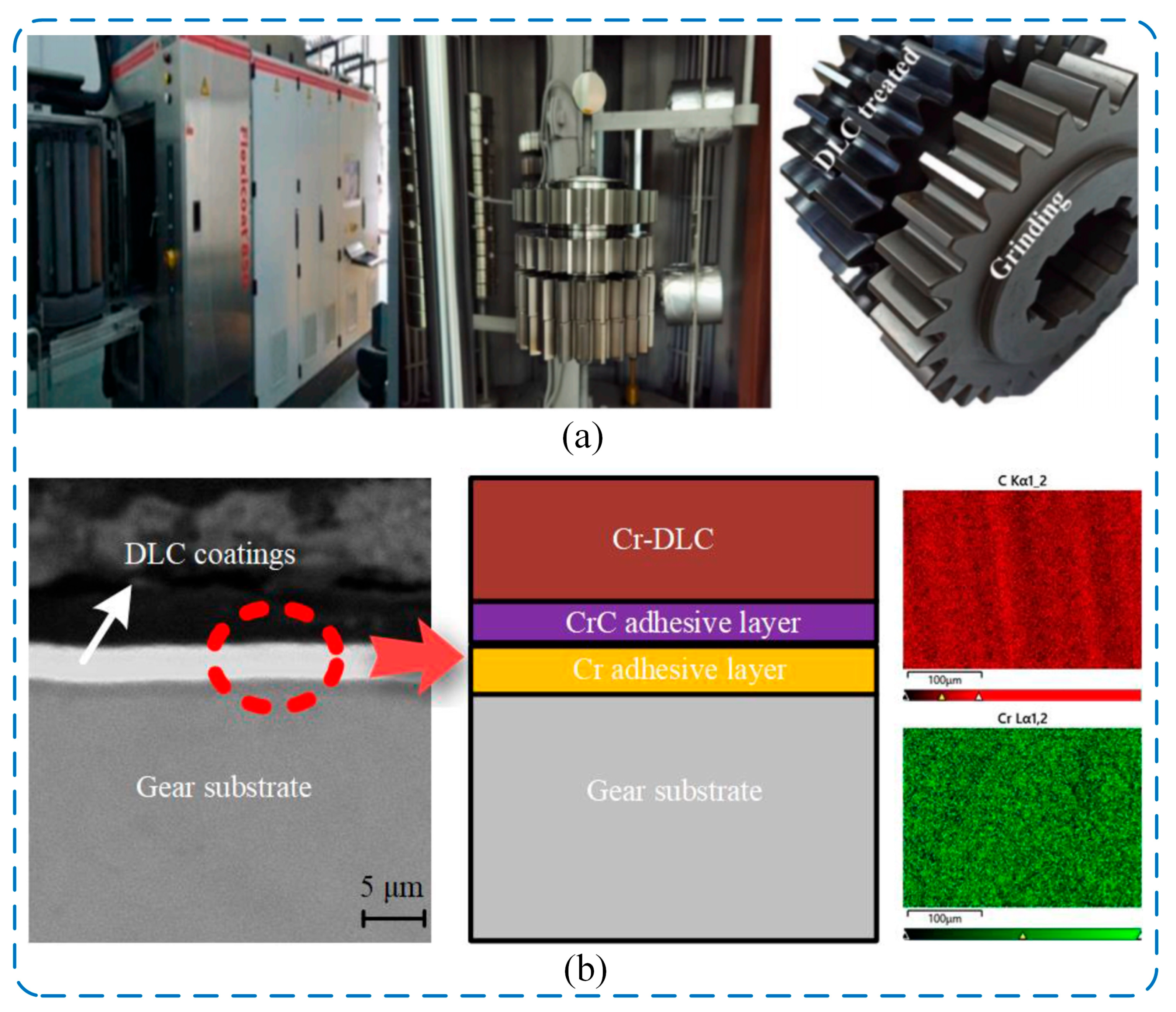

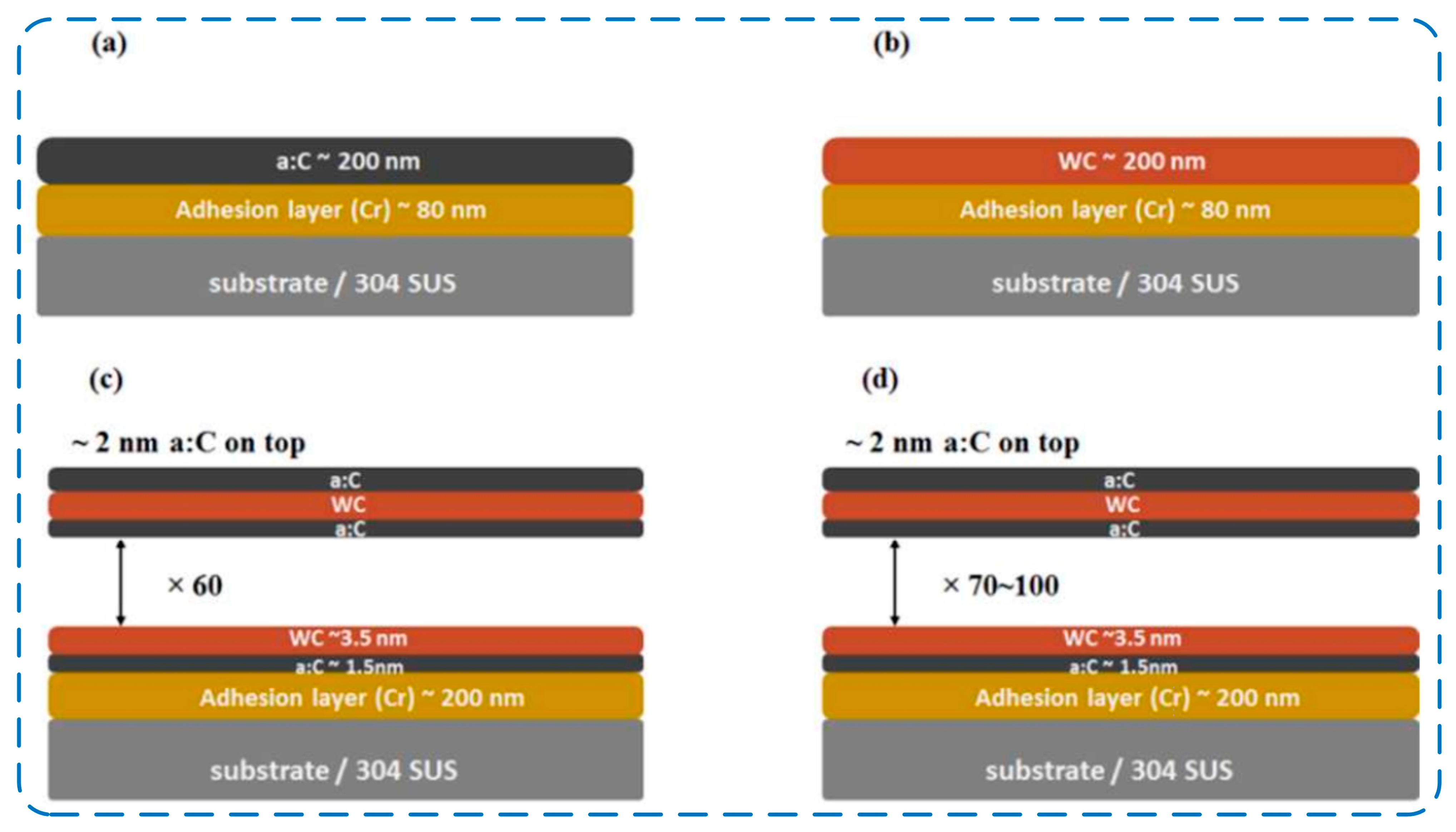

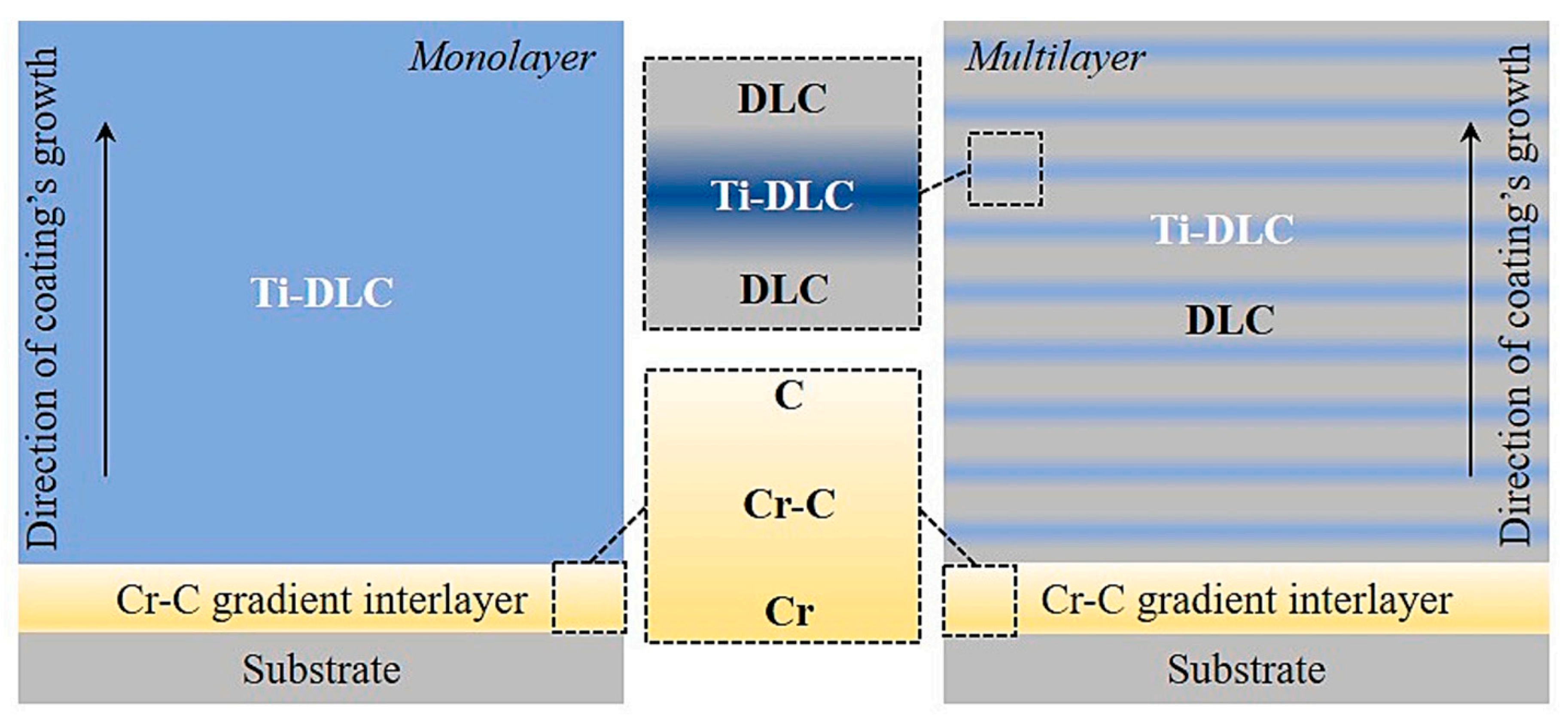

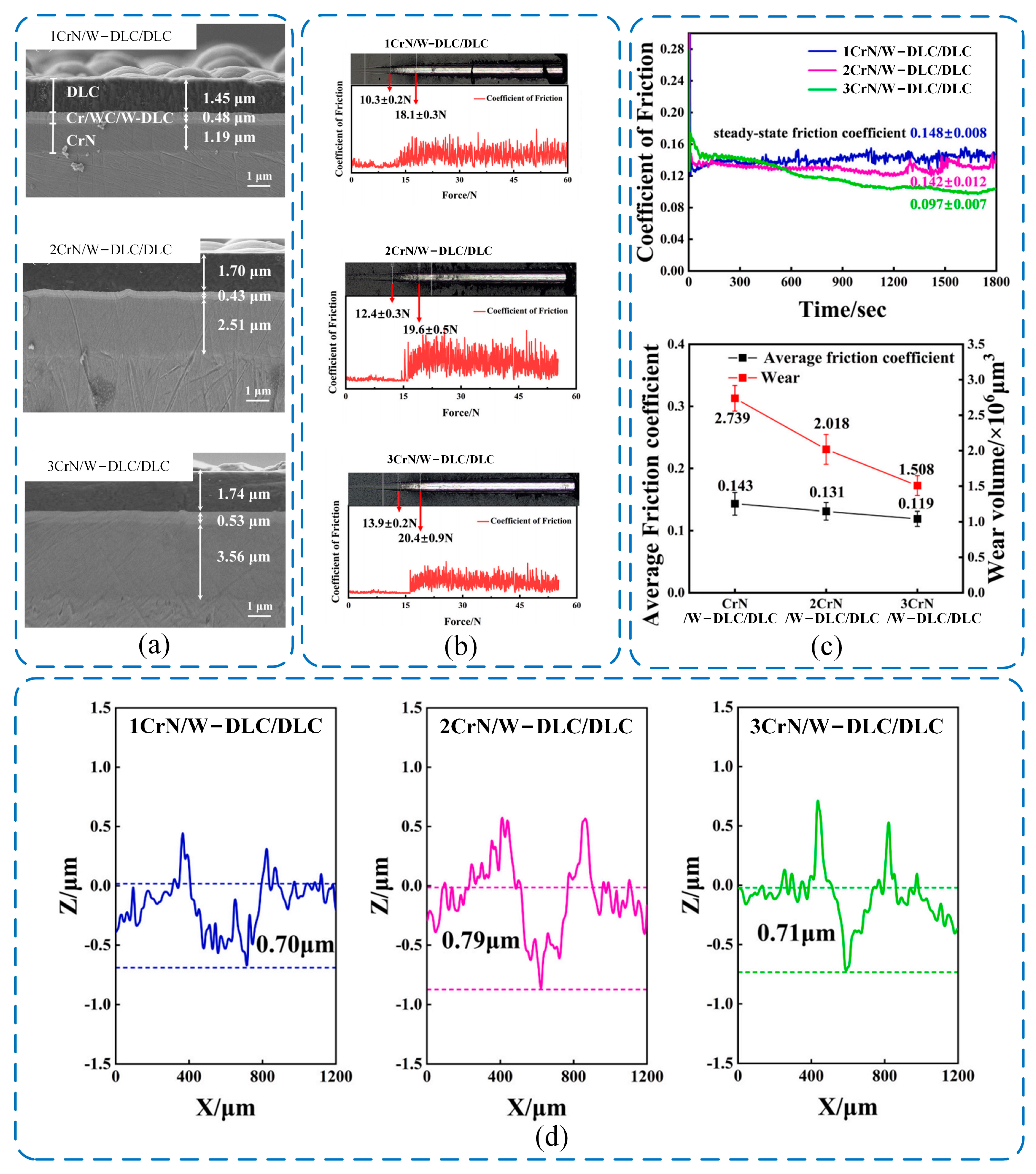

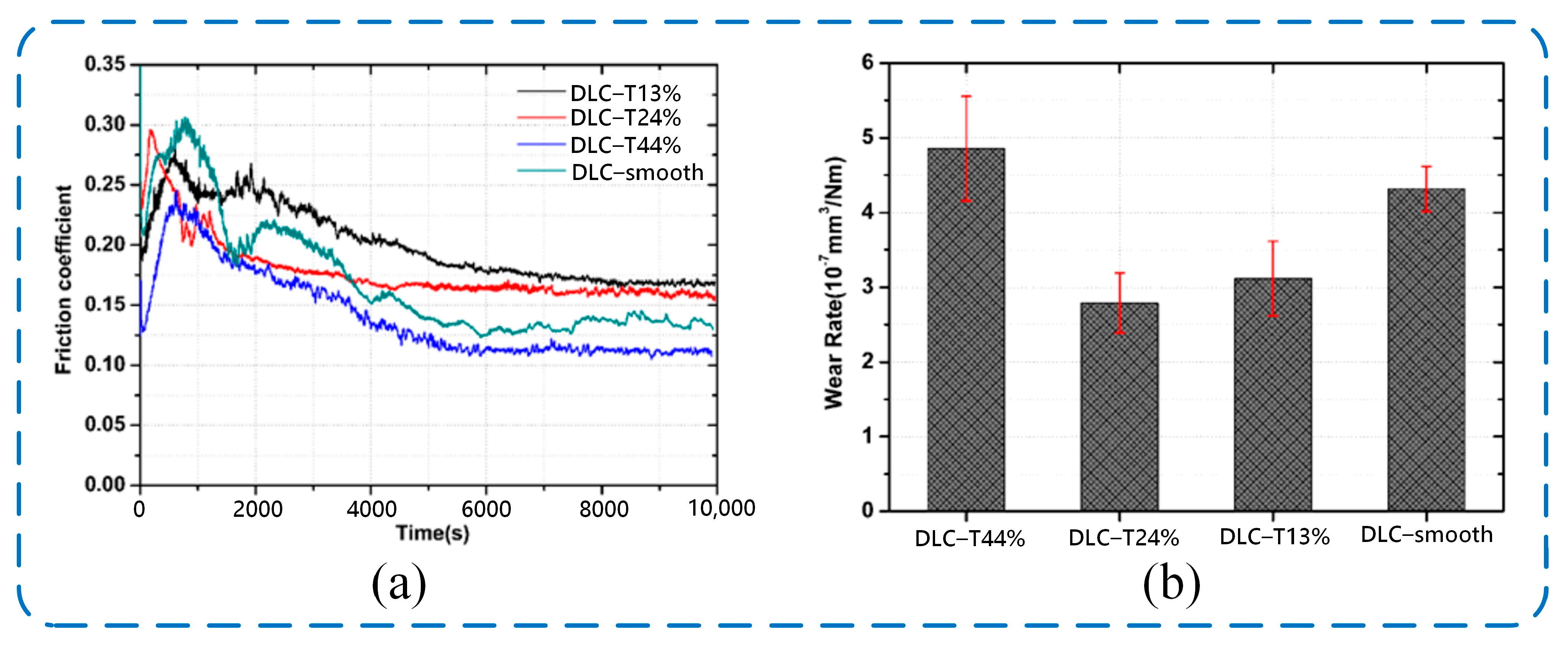

3.2. Coating Structure Design

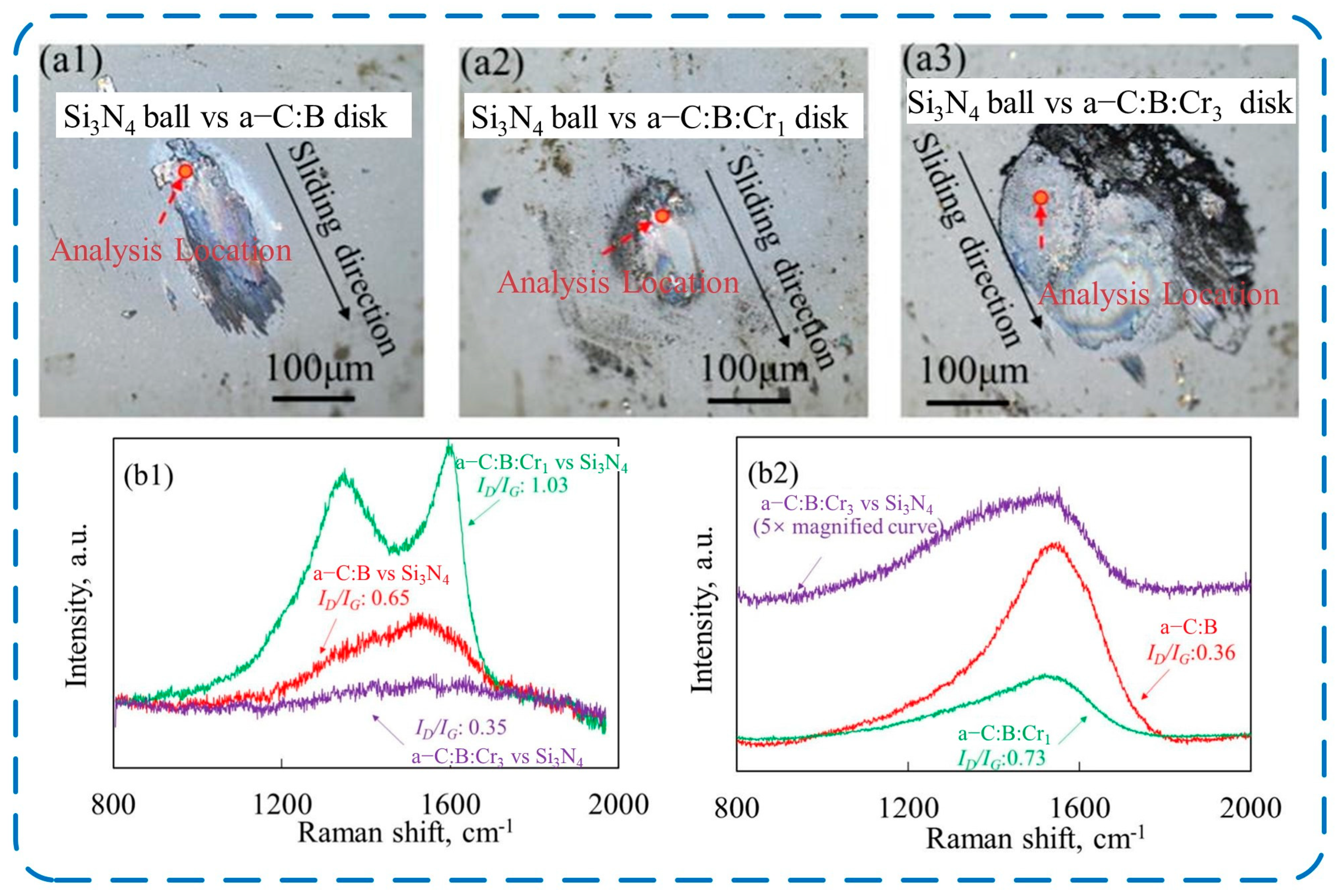

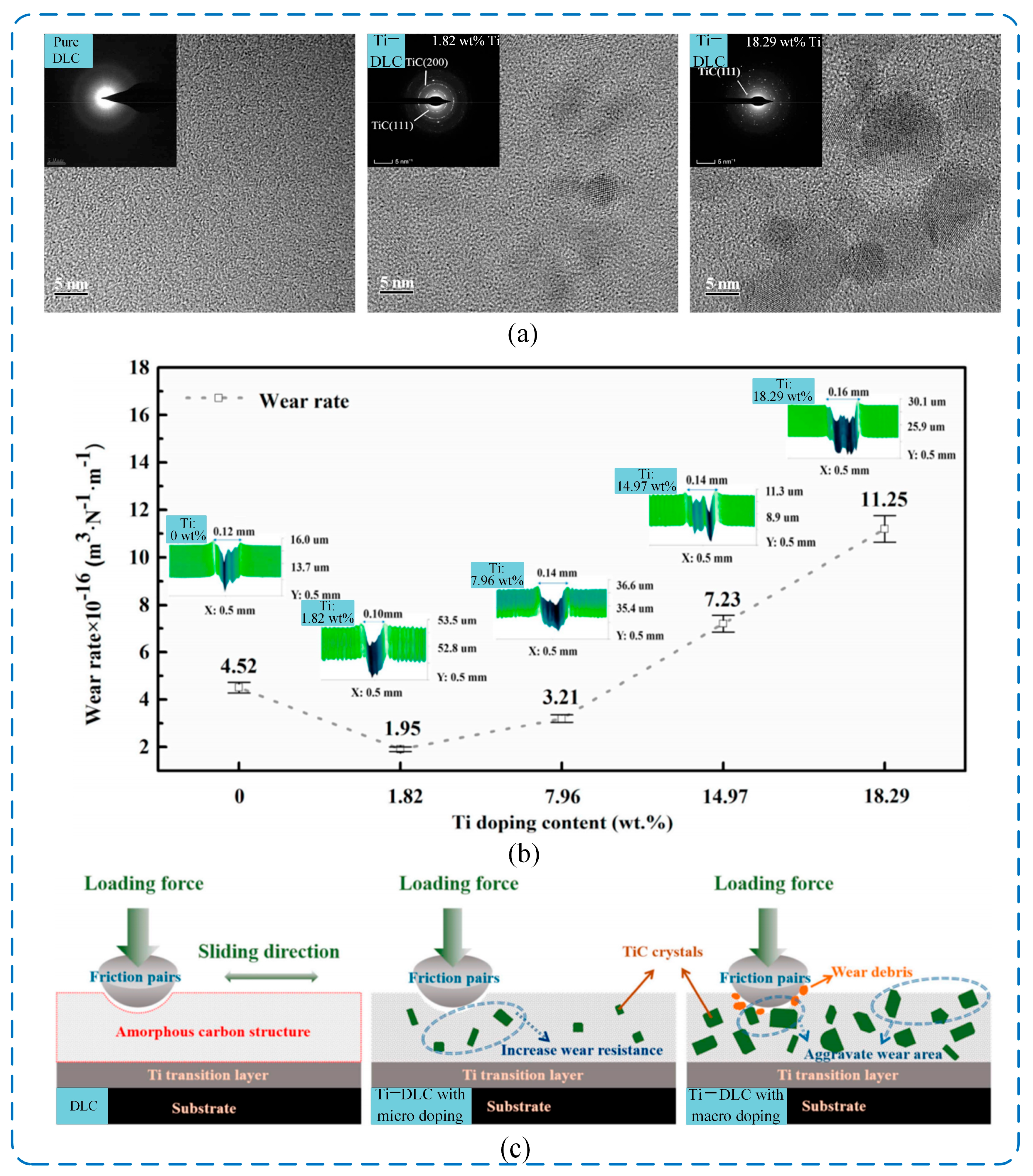

3.3. Elemental Doping

4. Synergistic Effect of Wear Inhibition Technologies for DLC-Coated Metal Components

4.1. Advantages and Limitations of Inhibition Technologies

4.2. Synergetic Effects of Inhibition Technologies

5. Conclusions and Outlook

5.1. Conclusions

5.2. Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Patrick, J.F.; Robb, M.J.; Sottos, N.R.; Moore, J.S.; White, S.R. Polymers with autonomous life-cycle control. Nature 2016, 540, 363–370. [Google Scholar] [CrossRef] [PubMed]

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Wang, X.; Luo, C.; Jiang, D.; Wang, H.; Wang, Z. Improved design method for gas carburizing process through data-driven and physical information. Comput. Mater. Sci. 2025, 247, 113507. [Google Scholar] [CrossRef]

- Chen, J.; Liang, Y.; Li, S.; Yang, M.; Sun, Y. Rolling Contact Fatigue Behaviors of 20CrNi2Mo Steel by a New Carbon and Nitrogen Composite Infiltration Process. Fatigue Fract. Eng. Mater. Struct. 2025, 48, 296–311. [Google Scholar] [CrossRef]

- Visscher, G.T.; Bianconi, P.A. Synthesis and characterization of polycarbynes, a new class of carbon-based network polymers. J. Am. Chem. Soc. 1994, 116, 1805–1811. [Google Scholar] [CrossRef]

- Jacob, W.; Möller, W. On the structure of thin hydrocarbon films. Appl. Phys. Lett. 1993, 63, 1771–1773. [Google Scholar] [CrossRef]

- Ziegltrum, A.; Lohner, T.; Stahl, K. TEHL Simulation on the Influence of Lubricants on the Frictional Losses of DLC Coated Gears. Lubricants 2018, 6, 17. [Google Scholar] [CrossRef]

- Zia, A.W.; Hussain, S.A.; Rasul, S.; Bae, D.; Pitchaimuthu, S. Progress in diamond-like carbon coatings for lithium-based batteries. J. Energy Storage 2023, 72, 108803. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, F.; Yang, K.; Xiao, N.; Tang, J.; Xiong, Y.; Zhang, G.; Duan, M.; Chen, H. Important contributions of carbon materials in tribology: From lubrication abilities to wear mechanisms. J. Alloys Compd. 2024, 979, 173454. [Google Scholar] [CrossRef]

- Kolawole, F.O. Tribological behavior of duplex CrN/DLC and nano-multilayer DLC-W coatings on valve tappet under elevated temperature and varying load. Int. J. Refract. Met. Hard Mater. 2024, 121, 106660. [Google Scholar] [CrossRef]

- Ogihara, H.; Iwata, T.; Mihara, Y.; Kano, M. The effects of DLC-coated journal on improving seizure limit and reducing friction under engine oil lubrication. Int. J. Engine Res. 2022, 23, 1267–1274. [Google Scholar] [CrossRef]

- Kabir, M.S.; Zhou, Z.; Xie, Z.; Munroe, P. Designing multilayer diamond like carbon coatings for improved mechanical properties. J. Mater. Sci. Technol. 2021, 65, 108–117. [Google Scholar] [CrossRef]

- Samiee, M.; Seyedraoufi, Z.-S.; Abbasi, M.; Eshraghi, M.J.; Abouei, V. Diamond-like carbon (DLC) coating on graphite: Investigating the achievement of maximum wear properties using the PECVD method. Ceram. Int. 2024, 50, 21439–21450. [Google Scholar] [CrossRef]

- Tian, J.; Jin, J.; Zhang, C.; Xu, J.; Qi, W.; Yu, Q.; Deng, W.; Wang, Y.; Li, X.; Chen, X.; et al. Shear-induced interfacial reconfiguration governing superlubricity of MoS2-Ag film enabled by diamond-like carbon. Appl. Surf. Sci. 2022, 578, 152068. [Google Scholar] [CrossRef]

- Malisz, K.; Świeczko-Żurek, B.; Sionkowska, A. Preparation and Characterization of Diamond-like Carbon Coatings for Biomedical Applications—A Review. Materials 2023, 16, 3420. [Google Scholar] [CrossRef]

- Das, D.; Banerjee, A. Anti-reflection coatings for silicon solar cells from hydrogenated diamond like carbon. Appl. Surf. Sci. 2015, 345, 204–215. [Google Scholar] [CrossRef]

- Zia, A.W.; Birkett, M. Deposition of diamond-like carbon coatings: Conventional to non-conventional approaches for emerging markets. Ceram. Int. 2021, 47, 28075–28085. [Google Scholar] [CrossRef]

- Hovsepian, P.E.; Ehiasarian, A.P. Six strategies to produce application tailored nanoscale multilayer structured PVD coatings by conventional and High Power Impulse Magnetron Sputtering (HIPIMS). Thin Solid Films 2019, 688, 137409. [Google Scholar] [CrossRef]

- Zhang, S.-W. Green tribology: Fundamentals and future development. Friction 2013, 1, 186–194. [Google Scholar] [CrossRef]

- Kalin, M.; Polajnar, M.; Kus, M.; Majdič, F. Green Tribology for the Sustainable Engineering of the Future. Stroj. Vestn.—J. Mech. Eng. 2019, 65, 709–727. [Google Scholar] [CrossRef]

- Schmellenmeier, H. Die Beeinflussung von festen Oberflachen durch eine ionisierte. Exp. Tech. Phys. 1953, 1, 49–68. [Google Scholar]

- Long, H.M.; Notaro, J. Ion-Beam Deposition of Thin Films of Diamondlike Carbon. J. Appl. Phys. 1971, 42, 155–162. [Google Scholar] [CrossRef]

- Dai, W.; Li, X.; Wu, L.; Wang, Q. Influences of target power and pulse width on the growth of diamond-like/graphite-like carbon coatings deposited by high power impulse magnetron sputtering. Diam. Relat. Mater. 2021, 111, 108232. [Google Scholar] [CrossRef]

- Donnet, C.; Erdemir, A. Tribology of Diamond-like Carbon Films: Fundamentals and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Zheng, J.; Shang, J.; Zhuang, W.; Ding, J.C.; Mei, H.; Yang, Y.; Ran, S. Structural and tribomechanical properties of Cr-DLC films deposited by reactive high power impulse magnetron sputtering. Vacuum 2024, 230, 113611. [Google Scholar] [CrossRef]

- Robertson, J. Deposition mechanisms for promoting sp3 bonding in diamond-like carbon. Diam. Relat. Mater. 1993, 2, 984–989. [Google Scholar] [CrossRef]

- Weiler, M.; Sattel, S.; Jung, K.; Ehrhardt, H.; Veerasamy, V.S.; Robertson, J. Highly tetrahedral, diamond-like amorphous hydrogenated carbon prepared from a plasma beam source. Appl. Phys. Lett. 1994, 64, 2797–2799. [Google Scholar] [CrossRef]

- Robertson, J. Diamond-like amorphous carbon. Mater. Sci. Eng. R Rep. 2002, 37, 129–281. [Google Scholar] [CrossRef]

- Casado, R.; Younas, M. Emerging trends and technologies in big data processing. Concurr. Comput. Pract. Exp. 2015, 27, 2078–2091. [Google Scholar] [CrossRef]

- Zia, A.W.; Hussain, S.A.; Baig, M.M.F.A. Optimizing diamond-like carbon coatings—From experimental era to artificial intelligence. Ceram. Int. 2022, 48, 36000–36011. [Google Scholar] [CrossRef]

- Beeman, D.; Silverman, J.; Lynds, R.; Anderson, M. Modeling studies of amorphous carbon. Phys. Rev. B 1984, 30, 870. [Google Scholar] [CrossRef]

- Aisenberg, S. The role of ion assisted deposition in the formation of diamond-like carbon films. J. Vac. Sci. Technol. A Vac. Surf. Films 1990, 8, 2150–2154. [Google Scholar] [CrossRef]

- Ham, M.; Lou, K.A. Diamond-like carbon films grown by a large-scale direct current plasma chemical vapor deposition reactor: System design, film characteristics, and applications. J. Vac. Sci. Technol. A Vac. Surf. Films 1990, 8, 2143–2149. [Google Scholar] [CrossRef]

- Avelar-Batista, J.C.; Spain, E.; Fuentes, G.G.; Sola, A.; Rodriguez, R.; Housden, J. Triode plasma nitriding and PVD coating: A successful pre-treatment combination to improve the wear resistance of DLC coatings on Ti6Al4V alloy. Surf. Coat. Technol. 2006, 201, 4335–4340. [Google Scholar] [CrossRef]

- Wang, L.; Nie, X.; Lukitsch, M.J.; Jiang, J.C.; Cheng, Y.T. Effect of tribological media on tribological properties of multilayer Cr(N)/C(DLC) coatings. Surf. Coat. Technol. 2006, 201, 4341–4347. [Google Scholar] [CrossRef]

- Erdemir, A.; Martin, J.M. Superior wear resistance of diamond and DLC coatings. Curr. Opin. Solid State Mater. Sci. 2018, 22, 243–254. [Google Scholar] [CrossRef]

- Bouchet, M.D.B.; Matta, C.; Le-Mogne, T.; Martin, J.M.; Zhang, Q.; Goddard, W., III; Kano, M.; Mabuchi, Y.; Ye, J. Superlubricity mechanism of diamond-like carbon with glycerol. Coupling of experimental and simulation studies. In Proceedings of the International Conference on Science of Friction, Aichi, Japan, 9–13 September 2007; p. 012003. [Google Scholar]

- Schall, J.D.; Gao, G.; Harrison, J.A. Effects of Adhesion and Transfer Film Formation on the Tribology of Self-Mated DLC Contacts. J. Phys. Chem. C 2009, 114, 5321–5330. [Google Scholar] [CrossRef]

- He, Z.; Shi, P.; Zhong, X.; Zhang, H.; Zhuo, P.; Li, J.; Chen, X.; Qian, L.; Wang, Y. Friction condition switching two-type transfer layers of hydrogenated amorphous carbon with distinct tribological behaviors. Carbon 2025, 238, 120198. [Google Scholar] [CrossRef]

- Song, H.; Ji, L.; Li, H.; Wang, J.; Liu, X.; Zhou, H.; Chen, J. Self-forming oriented layer slip and macroscale super-low friction of graphene. Appl. Phys. Lett. 2017, 110, 073101. [Google Scholar] [CrossRef]

- Shi, S.; Wei, X.; Li, X.; Li, Q.; Ding, S.; Fan, C.; Zhang, G.; Lu, Z. A Comparative Study on Impact Wear of Diamond-like Carbon Films on H62 and GCr15 Steel. J. Mater. Eng. Perform. 2022, 31, 6722–6735. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, G.; Zhu, L.; Wang, H.; Han, C.; Li, Z.; Wang, H.; Yong, Q.; Huang, Y. Structure–performance evolution mechanism of the wear failure process of coated spherical plain bearings. Eng. Fail. Anal. 2022, 135, 106097. [Google Scholar] [CrossRef]

- Wu, S.; Tang, Y.; Gu, J.; Li, R.; Liang, Y.; Liu, P.; Wang, H.; An, C.; Deng, Q.; Zhao, L.; et al. Controllable preparation of metal-based lubrication coatings in extreme environmental applications. Mater. Des. 2024, 241, 112922. [Google Scholar] [CrossRef]

- Hao, Y.; Huang, L.; Wang, L. Theoretical Research on Solid Lubrication Coatings: From Classical Models to Quantum-mechanical Simulations. Zhongguo Biaomian Gongcheng China Surf. Eng. 2024, 37, 64–78. [Google Scholar] [CrossRef]

- Bai, L.; Yu, Y. Fatigue behaviors of diamond-like carbon films. Diam. Relat. Mater. 2022, 124, 108892. [Google Scholar] [CrossRef]

- Vanossi, A.; Manini, N.; Urbakh, M.; Zapperi, S.; Tosatti, E. Colloquium: Modeling friction: From nanoscale to mesoscale. Rev. Mod. Phys. 2013, 85, 529–552. [Google Scholar] [CrossRef]

- He, Y.; She, D.; Liu, Z.; Wang, X.; Zhong, L.; Wang, C.; Wang, G.; Mao, S.X. Atomistic observation on diffusion-mediated friction between single-asperity contacts. Nat. Mater. 2021, 21, 173–180. [Google Scholar] [CrossRef]

- Dong, Y.; Vadakkepatt, A.; Martini, A. Analytical models for atomic friction. Tribol. Lett. 2011, 44, 367–386. [Google Scholar] [CrossRef]

- Archard, J. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Moore, M.A. Abrasive wear. Int. J. Mater. Eng. Appl. 1978, 1, 97–111. [Google Scholar] [CrossRef]

- Sadeghi, F.; Jalalahmadi, B.; Slack, T.S.; Raje, N.; Arakere, N.K. A Review of Rolling Contact Fatigue. J. Tribol. 2009, 131, 041403. [Google Scholar] [CrossRef]

- Cao, S.; Mischler, S. Modeling tribocorrosion of passive metals—A review. Curr. Opin. Solid State Mater. Sci. 2018, 22, 127–141. [Google Scholar] [CrossRef]

- Wang, B.; Qiu, F.; Barber, G.C.; Pan, Y.; Cui, W.; Wang, R. Microstructure, wear behavior and surface hardening of austempered ductile iron. J. Mater. Res. Technol. 2020, 9, 9838–9855. [Google Scholar] [CrossRef]

- Markov, D.P. Adhesion at friction and wear. Friction 2022, 10, 1859–1878. [Google Scholar] [CrossRef]

- Svetlizky, I.; Fineberg, J. Classical shear cracks drive the onset of dry frictional motion. Nature 2014, 509, 205–208. [Google Scholar] [CrossRef]

- Zhang, J.; Alpas, A. Transition between mild and severe wear in aluminium alloys. Acta Mater. 1997, 45, 513–528. [Google Scholar] [CrossRef]

- Marian, M.; Tremmel, S. Current Trends and Applications of Machine Learning in Tribology-A Review. Lubricants 2021, 9, 86. [Google Scholar] [CrossRef]

- Frérot, L.; Aghababaei, R.; Molinari, J.-F. A mechanistic understanding of the wear coefficient: From single to multiple asperities contact. J. Mech. Phys. Solids 2018, 114, 172–184. [Google Scholar] [CrossRef]

- Fontaine, J.; Donnet, C.; Erdemir, A. Fundamentals of the tribology of DLC coatings. In Tribology of Diamond-like Carbon Films: Fundamentals and Applications; Springer: Boston, MA, USA, 2008; pp. 139–154. [Google Scholar] [CrossRef]

- Zhang, R.; Lee, W.Y.; Umehara, N.; Tokoroyama, T.; Murashima, M.; Takimoto, Y. The development of B/Cr co-doped DLC coating by FCVA deposition system and its tribological properties at 300 °C. Surf. Coat. Technol. 2024, 487, 130968. [Google Scholar] [CrossRef]

- Khan, S.A.; Ferreira, F.; Oliveira, J.; Emami, N.; Ramalho, A. A comparative study in the tribological behaviour of different DLC coatings sliding against titanium alloys. Wear 2024, 554–555, 205468. [Google Scholar] [CrossRef]

- Kim, D.-W.; Kim, K.-W. Effects of sliding velocity and normal load on friction and wear characteristics of multi-layered diamond-like carbon (DLC) coating prepared by reactive sputtering. Wear 2013, 297, 722–730. [Google Scholar] [CrossRef]

- Li, X.; Luo, Y.; Li, J.; Cao, X.; Wang, L.; Zhang, G.; Luo, Z. Predominant role of fatigue crack evolution and tribo-chemistry on tribological behavior of Si-DLC film under different relative humidity. Tribol. Int. 2023, 181, 108326. [Google Scholar] [CrossRef]

- Helen Xu, G.; Liang, H.; Woodford, J.B.; Johnson, J.A. Temperature Dependence of Diamondlike Carbon Film Tribological Characteristics. J. Am. Ceram. Soc. 2005, 88, 3110–3115. [Google Scholar] [CrossRef]

- Fu, Z.-Q.; Wang, C.-B.; Zhang, W.; Wang, W.; Yue, W.; Yu, X.; Peng, Z.-J.; Lin, S.-S.; Dai, M.-J. Influence of W content on tribological performance of W-doped diamond-like carbon coatings under dry friction and polyalpha olefin lubrication conditions. Mater. Des. 2013, 51, 775–779. [Google Scholar] [CrossRef]

- Zou, Y.; Wang, X.; Wang, L. Microstructure and high-temperature tribological properties of Ti/Si co-doped diamond-like carbon films fabricated by twin-targets reactive HiPIMS. Diam. Relat. Mater. 2024, 141, 110573. [Google Scholar] [CrossRef]

- Jaroenapibal, P.; Seekumbor, E.; Triroj, N. Adsorption of polar molecules on diamond-like carbon films with different trapped charge densities. Diam. Relat. Mater. 2016, 65, 125–130. [Google Scholar] [CrossRef]

- Ahmed, M.H.; Byrne, J.A. Effect of surface structure and wettability of DLC and N-DLC thin films on adsorption of glycine. Appl. Surf. Sci. 2012, 258, 5166–5174. [Google Scholar] [CrossRef]

- Yang, M.; Marino, M.J.; Bojan, V.J.; Eryilmaz, O.L.; Erdemir, A.; Kim, S.H. Quantification of oxygenated species on a diamond-like carbon (DLC) surface. Appl. Surf. Sci. 2011, 257, 7633–7638. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, H.; Wang, X.; Luo, Y. Exploring the Key Mechanism of Superlubricity Behavior of DLC Film in Vacuum Environment Based on First-Principles Calculations and Molecular Dynamics Simulation. Tribol. Lett. 2023, 71, 113. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Xiao, C. The synergistic mechanism between transfer layer and surface passivation of diamond-like carbon film under different gas pressure environments. Appl. Surf. Sci. 2022, 587, 152874. [Google Scholar] [CrossRef]

- Erdemir, A.; Eryilmaz, O. Achieving superlubricity in DLC films by controlling bulk, surface, and tribochemistry. Friction 2014, 2, 140–155. [Google Scholar] [CrossRef]

- Wang, Y.; Yin, Z.; Fan, D.; Bai, L. Friction behaviors of DLC films in an oxygen environment: An atomistic understanding from ReaxFF simulations. Tribol. Int. 2022, 168, 107448. [Google Scholar] [CrossRef]

- Srinivasan, N.; Bhaskar, L.K.; Kumar, R.; Baragetti, S. Residual stress gradient and relaxation upon fatigue deformation of diamond-like carbon coated aluminum alloy in air and methanol environments. Mater. Des. 2018, 160, 303–312. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.; Chen, Q.; Su, Y.; Bai, S.; Ootani, Y.; Ozawa, N.; Adachi, K.; Kubo, M. Environment-dependent tribochemical reaction and wear mechanisms of Diamond-like carbon: A reactive molecular dynamics study. Carbon 2025, 231, 119713. [Google Scholar] [CrossRef]

- Ronkainen, H.; Holmberg, K. Environmental and thermal effects on the tribological performance of DLC coatings. In Tribology of Diamond-like Carbon Films: Fundamentals and Applications; Springer: Boston, MA, USA, 2008; pp. 155–200. [Google Scholar]

- Miyoshi, K.; Wu, R.L.C.; Garscadden, A. Friction and wear of diamond and diamondlike carbon coatings. Surf. Coat. Technol. 1992, 54–55, 428–434. [Google Scholar] [CrossRef]

- Oguri, K.; Arai, T. Two different low friction mechanisms of diamond-like carbon with silicon coatings formed by plasma-assisted chemical vapor deposition. J. Mater. Res. 1992, 7, 1313–1316. [Google Scholar] [CrossRef]

- Koskinen, J.; Hirvonen, J.P.; Hannula, S.P.; Pischow, K.; Kattelus, H.; Suni, I. Nanolayered gradient structures as an intermediate layer for diamond coatings. Diam. Relat. Mater. 1994, 3, 1107–1111. [Google Scholar] [CrossRef]

- Ronkainen, H.; Koskinen, J.; Likonen, J.; Varjus, S.; Vihersalo, J. Characterization of wear surfaces in dry sliding of steel and alumina on hydrogenated and hydrogen-free carbon films. Diam. Relat. Mater. 1994, 3, 1329–1336. [Google Scholar] [CrossRef]

- Grill, A. Tribology of diamondlike carbon and related materials: An updated review. Surf. Coat. Technol. 1997, 94–95, 507–513. [Google Scholar] [CrossRef]

- Harris, S.J.; Weiner, A.M.; Meng, W.-J. Tribology of metal-containing diamond-like carbon coatings. Wear 1997, 211, 208–217. [Google Scholar] [CrossRef]

- Gangopadhyay, A. Mechanical and tribological properties of amorphous carbon films. Tribol. Lett. 1998, 5, 25–39. [Google Scholar] [CrossRef]

- Voevodin, A.A.; Zabinski, J.S. Supertough wear-resistant coatings with ‘chameleon’ surface adaptation. Thin Solid Films 2000, 370, 223–231. [Google Scholar] [CrossRef]

- Ronkainen, H.; Varjus, S.; Koskinen, J.; Holmberg, K. Differentiating the tribological performance of hydrogenated and hydrogen-free DLC coatings. Wear 2001, 249, 260–266. [Google Scholar] [CrossRef]

- Andersson, J.; Erck, R.A.; Erdemir, A. Frictional behavior of diamondlike carbon films in vacuum and under varying water vapor pressure. Surf. Coat. Technol. 2003, 163–164, 535–540. [Google Scholar] [CrossRef]

- Grillo, S.E.; Field, J.E. The friction of natural and CVD diamond. Wear 2003, 254, 945–949. [Google Scholar] [CrossRef]

- Svahn, F.; Kassman-Rudolphi, Å.; Wallén, E. The influence of surface roughness on friction and wear of machine element coatings. Wear 2003, 254, 1092–1098. [Google Scholar] [CrossRef]

- Erdemir, A. Genesis of superlow friction and wear in diamondlike carbon films. Tribol. Int. 2004, 37, 1005–1012. [Google Scholar] [CrossRef]

- Field, S.K.; Jarratt, M.; Teer, D.G. Tribological properties of graphite-like and diamond-like carbon coatings. Tribol. Int. 2004, 37, 949–956. [Google Scholar] [CrossRef]

- Fontaine, J.; Loubet, J.L.; Mogne, T.L.; Grill, A. Superlow Friction of Diamond-like Carbon Films: A Relation to Viscoplastic Properties. Tribol. Lett. 2004, 17, 709–714. [Google Scholar] [CrossRef]

- Park, S.J.; Lee, K.-R.; Ko, D.-H. Tribochemical reaction of hydrogenated diamond-like carbon films: A clue to understand the environmental dependence. Tribol. Int. 2004, 37, 913–921. [Google Scholar] [CrossRef]

- Tanaka, A.; Nishibori, T.; Suzuki, M.; Maekawa, K. Characteristics of friction surfaces with DLC films in low and high humidity air. Wear 2004, 257, 297–303. [Google Scholar] [CrossRef]

- Konca, E.; Cheng, Y.T.; Weiner, A.M.; Dasch, J.M.; Alpas, A.T. Effect of test atmosphere on the tribological behaviour of the non-hydrogenated diamond-like carbon coatings against 319 aluminum alloy and tungsten carbide. Surf. Coat. Technol. 2005, 200, 1783–1791. [Google Scholar] [CrossRef]

- Donnet, C. Recent progress on the tribology of doped diamond-like and carbon alloy coatings: A review. Surf. Coat. Technol. 1998, 100–101, 180–186. [Google Scholar] [CrossRef]

- Yin, Z.; Wu, H.; Zhang, G.; Mu, C.; Bai, L. Wear Estimation of DLC Films Based on Energy-Dissipation Analysis: A Molecular Dynamics Study. Materials 2022, 15, 893. [Google Scholar] [CrossRef] [PubMed]

- Huang, T.; Yang, M.; Su, Y.; Han, Y.; Li, Q.; Zhang, S.; Goto, T.; Tu, R.; Zhang, L. Molecular dynamics study on nano sliding behavior at DLC/AISI 304 interface. Carbon 2025, 240, 120371. [Google Scholar] [CrossRef]

- Bai, L.; Srikanth, N.; Korznikova, E.A.; Baimova, J.A.; Dmitriev, S.V.; Zhou, K. Wear and friction between smooth or rough diamond-like carbon films and diamond tips. Wear 2017, 372–373, 12–20. [Google Scholar] [CrossRef]

- Kayode, J.F.; Lawal, S.L.; Afolalu, S.A. An Overview of Tribology and its Industrial Applications. In Proceedings of the 2023 International Conference on Science, Engineering and Business for Sustainable Development Goals (SEB-SDG), Omu-Aran, Nigeria, 5–7 April 2023; pp. 1–15. [Google Scholar]

- Kayode, J.F.; Lawal, S.L.; Afolalu, S.A. Overview of Green Tribology in Recent World: Fundamentals and Future Development. In Proceedings of the 2023 International Conference on Science, Engineering and Business for Sustainable Development Goals (SEB-SDG), Omu-Aran, Nigeria, 5–7 April 2023; pp. 1–11. [Google Scholar]

- Forest, S.; Sievert, R. Nonlinear microstrain theories. Int. J. Solids Struct. 2006, 43, 7224–7245. [Google Scholar] [CrossRef]

- Haneef, M.; Evaristo, M.; Morina, A.; Yang, L.; Trindade, B. New nanoscale multilayer magnetron sputtered Ti-DLC/DLC coatings with improved mechanical properties. Surf. Coat. Technol. 2024, 480, 130595. [Google Scholar] [CrossRef]

- Rauschenbach, B. Ion Beam Deposition and Cleaning. In Low-Energy Ion Irradiation of Materials: Fundamentals and Application; Springer: Cham, Switzerland, 2022; pp. 407–480. [Google Scholar]

- Jiang, J.; Arnell, R.D. The effect of substrate surface roughness on the wear of DLC coatings. Wear 2000, 239, 1–9. [Google Scholar] [CrossRef]

- Khan, S.A.; Oliveira, J.; Ferreira, F.; Emami, N.; Ramalho, A. Surface roughness influence on tribological behavior of HIPIMS DLC coatings. Tribol. Trans. 2023, 66, 565–575. [Google Scholar] [CrossRef]

- Kovacı, H.; Baran, Ö.; Yetim, A.F.; Bozkurt, Y.B.; Kara, L.; Çelik, A. The friction and wear performance of DLC coatings deposited on plasma nitrided AISI 4140 steel by magnetron sputtering under air and vacuum conditions. Surf. Coat. Technol. 2018, 349, 969–979. [Google Scholar] [CrossRef]

- Morita, T.; Andatsu, K.; Hirota, S.; Kumakiri, T.; Ikenaga, M.; Kagaya, C. Effect of Hybrid Surface Treatment Composed of Plasma Nitriding and DLC Coating on Friction Coefficient and Fatigue Strength of Stainless Steel. Mater. Trans. 2013, 54, 732–737. [Google Scholar] [CrossRef]

- Yetim, A.F.; Kovacı, H.; Uzun, Y.; Tekdir, H.; Çelik, A. A comprehensive study on the fatigue properties of duplex surface treated Ti6Al4V by plasma nitriding and DLC coating. Surf. Coat. Technol. 2023, 458, 129367. [Google Scholar] [CrossRef]

- Yamauchi, N.; Demizu, K.; Ueda, N.; Sone, T.; Tsujikawa, M.; Hirose, Y. Effect of peening as pretreatment for DLC coatings on magnesium alloy. Thin Solid Films 2006, 506–507, 378–383. [Google Scholar] [CrossRef]

- Wu, J.; Wei, P.; Liu, G.; Chen, D.; Zhang, X.; Chen, T.; Liu, H. A comprehensive evaluation of DLC coating on gear bending fatigue, contact fatigue, and scuffing performance. Wear 2024, 536–537, 205177. [Google Scholar] [CrossRef]

- Suh, N.P.; Mosleh, M.; Howard, P.S. Control of friction. Wear 1994, 175, 151–158. [Google Scholar] [CrossRef]

- Arslan, A.; Masjuki, H.H.; Quazi, M.M.; Kalam, M.A.; Varman, M.; Jamshaid, M.; Rahman, S.M.A.; Imran, M.; Zulfattah, Z.M.; Anwar, M.T.; et al. Experimental investigation of tribological properties of laser textured tungsten doped diamond like carbon coating under dry sliding conditions at various loads. Mater. Res. Express 2019, 6, 106444. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, W.; Sun, G. The influence of textured interface on DLC films prepared by vacuum arc. Surf. Coat. Technol. 2019, 365, 143–151. [Google Scholar] [CrossRef]

- Geng, J.; Yao, Q.; Yang, L.; Wei, X.; Wang, H.; Fu, G. Alleviating internal stress in diamond-like carbon films for enhanced tribological performance under high contact pressure via interface texturing. Surf. Coat. Technol. 2024, 490, 131164. [Google Scholar] [CrossRef]

- Yu, S.; Li, D.; Ye, Y.; Ye, Z.; Xu, F.; Lang, W.; Liu, J.; Yu, X.; Qin, Q.H. Tribological and corrosive performance of functional gradient DLC coatings prepared by a hybrid HiPIMS/CVD techniques. Vacuum 2025, 238, 114160. [Google Scholar] [CrossRef]

- Viswanathan, S.; Mohan, L.; Bera, P.; Shanthiswaroop, S.; Muniprakash, M.; Barshilia, H.C.; Anandan, C. Corrosion and wear resistance properties of multilayered diamond-like carbon nanocomposite coating. Surf. Interface Anal. 2018, 50, 265–276. [Google Scholar] [CrossRef]

- Wu, Y.; Qi, J.; Li, K.; Zhou, X.; Yu, S.; Zhang, C.; Liu, Y. Preparation and tribological properties of Ni/DLC multilayer film. J. Vac. Sci. Technol. A Vac. Surf. Films 2024, 42, 023419. [Google Scholar] [CrossRef]

- Nemati, N.; Bozorg, M.; Penkov, O.V.; Shin, D.-G.; Sadighzadeh, A.; Kim, D.-E. Functional Multi-Nanolayer Coatings of Amorphous Carbon/Tungsten Carbide with Exceptional Mechanical Durability and Corrosion Resistance. ACS Appl. Mater. Interfaces 2017, 9, 30149–30160. [Google Scholar] [CrossRef] [PubMed]

- Ramírez-Reyna, O.; Pérez-Alvarez, J.; Flores-Martínez, M.; Rodríguez-Castro, G.A.; Rodil, S.E. Evaluation of mechanical properties and tribological behavior of DLC/WC/WCN/W multilayer coatings deposited by HiPIMS. Mater. Lett. 2024, 357, 135737. [Google Scholar] [CrossRef]

- Bertran, E.; Corbella, C.; Pinyol, A.; Vives, M.; Andújar, J.L. Comparative study of metal/amorphous-carbon multilayer structures produced by magnetron sputtering. Diam. Relat. Mater. 2003, 12, 1008–1012. [Google Scholar] [CrossRef]

- Wang, J.; Misra, A. An overview of interface-dominated deformation mechanisms in metallic multilayers. Curr. Opin. Solid State Mater. Sci. 2011, 15, 20–28. [Google Scholar] [CrossRef]

- Fujii, M.; Ananth Kumar, M.; Yoshida, A. Influence of DLC coating thickness on tribological characteristics under sliding rolling contact condition. Tribol. Int. 2011, 44, 1289–1295. [Google Scholar] [CrossRef]

- Sahoo, P.; Kumar, S.; Singh, R.K.; Srinivas, G.; Bonu, V.; Barshilia, H.C. Effect of arc-deposited diamond-like carbon (DLC) coating thickness on friction and size effects in high-speed micromilling of Ti6Al4V. Tribol. Int. 2024, 192, 109223. [Google Scholar] [CrossRef]

- Wang, P.; Wang, X.; Xu, T.; Liu, W.; Zhang, J. Comparing internal stress in diamond-like carbon films with different structure. Thin Solid Films 2007, 515, 6899–6903. [Google Scholar] [CrossRef]

- Qiang, L.; Zhang, B.; Zhou, Y.; Zhang, J. Improving the internal stress and wear resistance of DLC film by low content Ti doping. Solid State Sci. 2013, 20, 17–22. [Google Scholar] [CrossRef]

- Sharifahmadian, O.; Pakseresht, A.; Amirtharaj Mosas, K.K.; Galusek, D. Doping effects on the tribological performance of diamond-like carbon coatings: A review. J. Mater. Res. Technol. 2023, 27, 7748–7765. [Google Scholar] [CrossRef]

- Chen, Y.; Su, F.; Sun, J.; Lin, S. Improved high-temperature friction and wear behavior of diamond-like carbon films via boron carbide doping. Wear 2025, 564–565, 205726. [Google Scholar] [CrossRef]

- Hongxi, L.; Yehua, J.; Rong, Z.; Baoyin, T. Wear behaviour and rolling contact fatigue life of Ti/TiN/DLC multilayer films fabricated on bearing steel by PIIID. Vacuum 2012, 86, 848–853. [Google Scholar] [CrossRef]

- Niu, X.; Zhou, Y.; Zhang, T.; Ding, M.; Xing, X.; Yang, Q.; Wang, D.; Xiao, J.; Shi, Z. Atomic insight into residual stress and microstructure evolution of amorphous carbon heterostructured films induced by multi-stage phase transformation of high-entropy alloys. Surf. Sci. Technol. 2024, 2, 23. [Google Scholar] [CrossRef]

- Kametani, N.; Nakamura, M.; Yashiro, K.; Takaki, T. Impact of temperature on residual stress and bonding in diamond-like carbon film: A molecular dynamics study under various deposition conditions. Comput. Mater. Sci. 2024, 238, 112950. [Google Scholar] [CrossRef]

- Cao, H.; Qi, F.; Ouyang, X.; Zhao, N.; Zhou, Y.; Li, B.; Luo, W.; Liao, B.; Luo, J. Effect of Ti Transition Layer Thickness on the Structure, Mechanical and Adhesion Properties of Ti-DLC Coatings on Aluminum Alloys. Materials 2018, 11, 1742. [Google Scholar] [CrossRef]

- Sánchez-López, J.; Fernández, A. Doping and alloying effects on DLC coatings. In Tribology of Diamond-like Carbon Films: Fundamentals and Applications; Springer: Boston, MA, USA, 2008; pp. 311–338. [Google Scholar] [CrossRef]

- Hakovirta, M.; Tiainen, V.M.; Pekko, P. Techniques for filtering graphite macroparticles in the cathodic vacuum arc deposition of tetrahedral amorphous carbon films. Diam. Relat. Mater. 1999, 8, 1183–1192. [Google Scholar] [CrossRef]

- Farfan-Cabrera, L.I.; Cao-Romero-Gallegos, J.A.; Lee, S.; Komurlu, M.U.; Erdemir, A. Tribological behavior of H-DLC and H-free DLC coatings on bearing materials under the influence of DC electric current discharges. Wear 2023, 522, 204709. [Google Scholar] [CrossRef]

- Kumar, D.D.; Kuppusami, P.; Kaliaraj, G.S.; Sana, S.S.; Kirubaharan, A.K. Tribological Properties of Carbon-Based Coatings. In Tribology and Characterization of Surface Coatings; Wiley: Hoboken, NJ, USA, 2022; pp. 115–137. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, X.; Wang, C.; Lu, Y.; Hao, J. High temperature tribology behavior of silicon and nitrogen doped hydrogenated diamond-like carbon (DLC) coatings. Tribol. Int. 2022, 175, 107845. [Google Scholar] [CrossRef]

- Nakazawa, H.; Okuno, S.; Magara, K.; Nakamura, K.; Miura, S.; Enta, Y. Tribological properties and thermal stability of hydrogenated, silicon/nitrogen-coincorporated diamond-like carbon films prepared by plasma-enhanced chemical vapor deposition. Jpn. J. Appl. Phys. 2016, 55, 125501. [Google Scholar] [CrossRef]

- Saha, B.; Liu, E.; Tor, S.; Khun, N.; Hardt, D.; Chun, J. Replication performance of Si-N-DLC-coated Si micro-molds in micro-hot-embossing. J. Micromech. Microeng. 2010, 20, 045007. [Google Scholar] [CrossRef]

- Jongwannasiri, C.; Li, X.; Watanabe, S. Improvement of thermal stability and tribological performance of diamond-like carbon composite thin films. Mater. Sci. Appl. 2013, 4, 630–636. [Google Scholar] [CrossRef][Green Version]

- Nakazawa, H.; Miura, S.; Kamata, R.; Okuno, S.; Suemitsu, M.; Abe, T. Effects of pulse bias on structure and properties of silicon/nitrogen-incorporated diamond-like carbon films prepared by plasma-enhanced chemical vapor deposition. Appl. Surf. Sci. 2013, 264, 625–632. [Google Scholar] [CrossRef]

- Ru, L.; Wang, Y.; Liu, J.; Tao, S.; Xiao, J. Hydrophobic, anticorrosion, and frictional properties of F-DLC films prepared by magnetron sputtering. Vacuum 2023, 217, 112567. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, L.; Shao, W.; Chen, Z.; Wang, S.; Xing, X.; Yang, Q. Mechanical and tribological behaviors of Ti-DLC films deposited on 304 stainless steel: Exploration with Ti doping from micro to macro. Diam. Relat. Mater. 2020, 107, 107870. [Google Scholar] [CrossRef]

- Amanov, A.; Watabe, T.; Tsuboi, R.; Sasaki, S. Fretting wear and fracture behaviors of Cr-doped and non-doped DLC films deposited on Ti–6al–4V alloy by unbalanced magnetron sputtering. Tribol. Int. 2013, 62, 49–57. [Google Scholar] [CrossRef]

- Zhang, S.; Wu, S.; Huang, T.; Yang, X.; Guo, F.; Zhang, B.; Ding, W. The Effects of Ti/Ni Doping on the Friction and Wear Properties of DLC Coatings. Coatings 2023, 13, 1743. [Google Scholar] [CrossRef]

- Dovydaitis, V.; Marcinauskas, L.; Ayala, P.; Gnecco, E.; Chimborazo, J.; Zhairabany, H.; Zabels, R. The influence of Cr and Ni doping on the microstructure of oxygen containing diamond-like carbon films. Vacuum 2021, 191, 110351. [Google Scholar] [CrossRef]

- Sahay, S.; Pandey, M.K.; Kar, A.K. Nickel concentration dependent mechanical and tribological properties of subsurface layer of electrodeposited Ni-C nanocomposite thin films. Thin Solid Films 2023, 773, 139818. [Google Scholar] [CrossRef]

- Deng, X.; Kousaka, H.; Tokoroyama, T.; Umehara, N. Tribological behavior of tetrahedral amorphous carbon (ta-C) coatings at elevated temperatures. Tribol. Int. 2014, 75, 98–103. [Google Scholar] [CrossRef]

- Yu, W.; Mei, Q.; Huang, W.; Wang, J.; Su, Y. Tailoring the mechanical and high-temperature tribological properties of Si-DLC films by controlling the Si content. Surf. Interface Anal. 2024, 56, 498–511. [Google Scholar] [CrossRef]

- Beake, B.D.; McMaster, S.J.; Liskiewicz, T.W.; Neville, A. Influence of Si- and W- doping on micro-scale reciprocating wear and impact performance of DLC coatings on hardened steel. Tribol. Int. 2021, 160, 107063. [Google Scholar] [CrossRef]

- Jing, P.P.; Gong, Y.L.; Deng, Q.Y.; Zhang, Y.Z.; Huang, N.; Leng, Y.X. The formation of the “rod-like wear debris” and tribological properties of Ag-doped diamond-like carbon films fabricated by a high-power pulsed plasma vapor deposition technique. Vacuum 2020, 173, 109125. [Google Scholar] [CrossRef]

- Sani-Taiariol, T.; Martins, G.; Hurtado, C.; Tada, D.; Corat, E.; Trava-Airoldi, V. Effect of individual and multiple incorporation of Ag and TiO2 on the properties of DLC films. Diam. Relat. Mater. 2025, 154, 112119. [Google Scholar] [CrossRef]

- Shi, J.; Ma, G.; Li, G.; Li, Z.; Zhao, H.; Han, C.; Wang, H. Evolution of high vacuum tribological performance of lead-doped hydrogenated diamond-like carbon coatings after atomic oxygen and ultraviolet irradiation. Tribol. Int. 2025, 202, 110356. [Google Scholar] [CrossRef]

- Li, N.; Zhang, L.; Bai, X.; Zhang, G. Tribological properties of graphene additive in steel/DLC composite lubrication systems. Diam. Relat. Mater. 2025, 152, 111872. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, C.; Li, H.; Dong, B.; Guo, X.; Liu, Y. Study on the substrate surface micro-texturing/carburizing regulating the film-substrate adhesion and wear behavior of DLC coatings. Diam. Relat. Mater. 2022, 130, 109535. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, Z.; Guo, W.; Bao, C. Effect of diamond-like carbon self-lubricant coatings on wear resistance of powder metallurgy products. Fenmo Yejin Jishu 2024, 42, 503–509. [Google Scholar] [CrossRef]

- Hua, L.; Su, F.; Li, J.; Lin, S. Effect of Cr/CrxCy Gradient Transition Layer Prepared with HiPIMS on Properties of DLC Films. Surf. Technol. 2025, 54, 62–73. [Google Scholar] [CrossRef]

- Tang, X.; Wang, J.; Li, W.; Hu, Y.; Lu, Z.; Zhang, G.a. Research Progress and Prospects on Tribological Properties of DLC Based Nano-multilayer Films. Surf. Technol. 2024, 53, 52–62. [Google Scholar] [CrossRef]

- Luo, G.; Xu, X.; Dong, H.; Wei, Q.; Tian, F.; Qin, J.; Shen, Q. Enhance the tribological performance of soft AISI 1045 steel through a CrN/W-DLC/DLC multilayer coating. Surf. Coat. Technol. 2024, 485, 130916. [Google Scholar] [CrossRef]

- Yamada, Y.; Murashima, M.; Umehara, N.; Tokoroyama, T.; Lee, W.-Y.; Takamatsu, H.; Tanaka, Y.; Utsumi, Y. Effect of fracture properties and surface morphology on wear of DLC coatings at severe contact condition. Tribol. Int. 2022, 169, 107486. [Google Scholar] [CrossRef]

- He, D.; Zheng, S.; Pu, J.; Zhang, G.; Hu, L. Improving tribological properties of titanium alloys by combining laser surface texturing and diamond-like carbon film. Tribol. Int. 2015, 82, 20–27. [Google Scholar] [CrossRef]

| Diamond Coatings [77,78,79,80,81,82] | Hydrogen Free DLC (H-Free DLC) [83,84,85,86,87,88,89,90,91,92,93,94] | Hydrogenated DLC (H-DLC) [77,85,86,89,91,92] | Modified/Doped DLC [84,89,90,91,92,95] | |

|---|---|---|---|---|

| Structure | CVD diamond | a-C ta-C | a-C:H ta-C:H | a-C:Me a-C:H:Me a-C:H:X |

| Atomic structure | sp3 | sp2 and sp3 | sp2 and sp3 | sp2 and sp3 |

| Hydrogen content | - | >1% | 10–50% | |

| µ in vacuum | 0.02–1 | 0.3–0.8 | 0.007–0.005 | 0.03 |

| µ in dry N2 | 0.03 | 0.6–0.7 | 0.01–0.15 | 0.007 |

| µ in dry N2 5–15% RH | 0.08–0.1 | 0.6 | 0.025–0.22 | 0.03 |

| µ in humid air 15–95% | 0.05–0.15 | 0.05–0.23 | 0.02–0.5 | 0.03–0.4 |

| µ in water | 0.002–0.08 | 0.007–0.1 | 0.01–0.7 | 0.06 |

| µ in oil | - | 0.03 | 0.1 | 0.1 |

| K in vacuum | 1–1000 | 60–400 | 0.0001 | - |

| K in dry N2 | 0.1–0.2 | 0.1–0.7 | 0.00001–0.1 | - |

| K in dry air 5–15% RH | 1–5 | 0.3 | 0.01–0.4 | - |

| K in humid air 15–95% | 0.04–0.06 | 0.0001–400 | 0.01–1 | 0.1–1 |

| K in water | 0.0001–1 | - | 0.002–0.2 | 0.15 |

| K in oil | - | - | - | 0.1 |

| Technologies | Advantages and Limitations | Reference |

|---|---|---|

| Substrate Material Treatment/Strengthening | Advantages: Enhanced load-bearing capacity of the substrate and reduced plastic deformation of coatings under mechanical loading. Limitations: High-temperature treatments (e.g., carburization) may induce substrate deformation or grain coarsening. | [110,154,155] |

| Coating Structure Design | Advantages: Stress distribution optimization and mitigation of thermal expansion mismatch at interfaces via gradient coatings. Limitations: Balancing high hardness with high toughness remains challenging. | [156,157] |

| Element Doping | Advantages: Internal stress regulation to improve coating adhesion and reduce friction coefficients. Limitations: Difficulty in achieving uniform doping, leading to localized performance degradation (e.g., brittle phase formation). | [126] |

| Coating Type | Deposition Technique/ Substrate | Wear Test Conditions | Wear Rate | Reference | |

|---|---|---|---|---|---|

| Substrate material treatment/strengthening | Cr/CrN-DLC | HiPIMS/ cemented carbide, WC-Co | A total of 100 K cycles, under dry condition with a stroke length of 2 mm and applied force of 10 N using a 100Cr6 steel ball of 10 mm diameter as a counterbody | Ra = 0.260 µm, 4.73 × 10⁻7 mm3/(N·m) Ra = 0.017 µm, 2.41 × 10⁻8 mm3/(N·m) Ra = 0.008 µm, 1.74 × 10⁻8 mm3/(N·m) | [105] |

| Coating structure design | WC-Cr-DLC | DC magnetron sputtering/304 stainless steel | A load of 10–50 mN, speed set to 2 mm/s with a stroke of 2 mm, counter surface is a stainless steel ball with a diameter of 1 mm | 10−9 mm3/(N·m) | [118] |

| Elemental doping | Ti-DLC (Ti, 1.82 wt%) | DC magnetron sputtering/304 stainless steel | A load of 5 N, reciprocating distance of 4 mm (frequency = 5 Hz), and a GCr15 grinding pair steel ball (diameter = 3 mm) | 1.95 × 10⁻3 mm3/(N·m) | [142] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, L.; Bai, Z.; Hao, Q.; Qin, J. Improving Wear Resistance of DLC-Coated Metal Components During Service: A Review. Lubricants 2025, 13, 257. https://doi.org/10.3390/lubricants13060257

Wu L, Bai Z, Hao Q, Qin J. Improving Wear Resistance of DLC-Coated Metal Components During Service: A Review. Lubricants. 2025; 13(6):257. https://doi.org/10.3390/lubricants13060257

Chicago/Turabian StyleWu, Luji, Zhongchao Bai, Qingle Hao, and Jiayin Qin. 2025. "Improving Wear Resistance of DLC-Coated Metal Components During Service: A Review" Lubricants 13, no. 6: 257. https://doi.org/10.3390/lubricants13060257

APA StyleWu, L., Bai, Z., Hao, Q., & Qin, J. (2025). Improving Wear Resistance of DLC-Coated Metal Components During Service: A Review. Lubricants, 13(6), 257. https://doi.org/10.3390/lubricants13060257