Comprehensive Evaluation of the Rheological, Tribological, and Thermal Behavior of Cutting Oil and Water-Based Metalworking Fluids

Abstract

1. Introduction

2. Materials and Methods

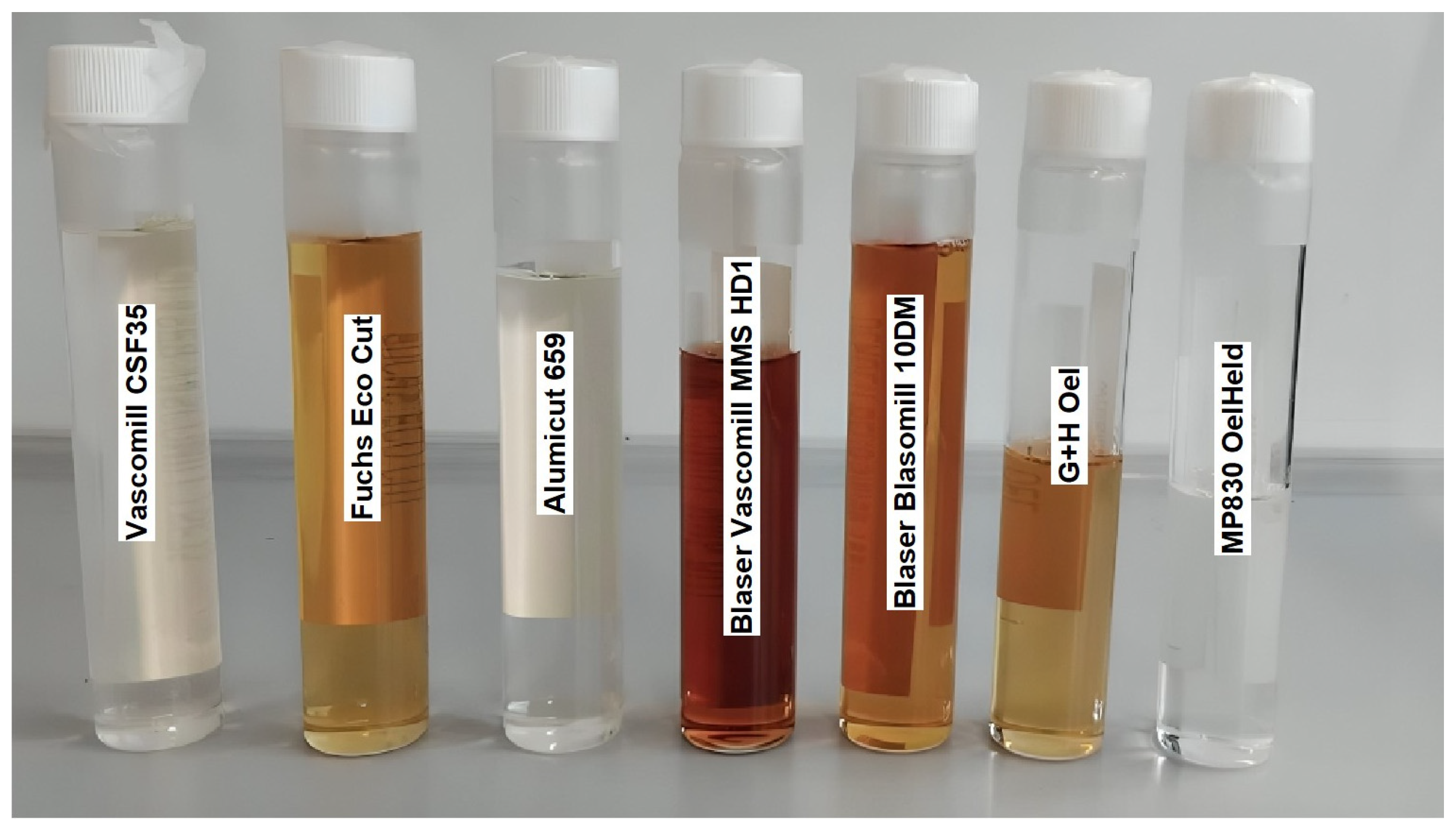

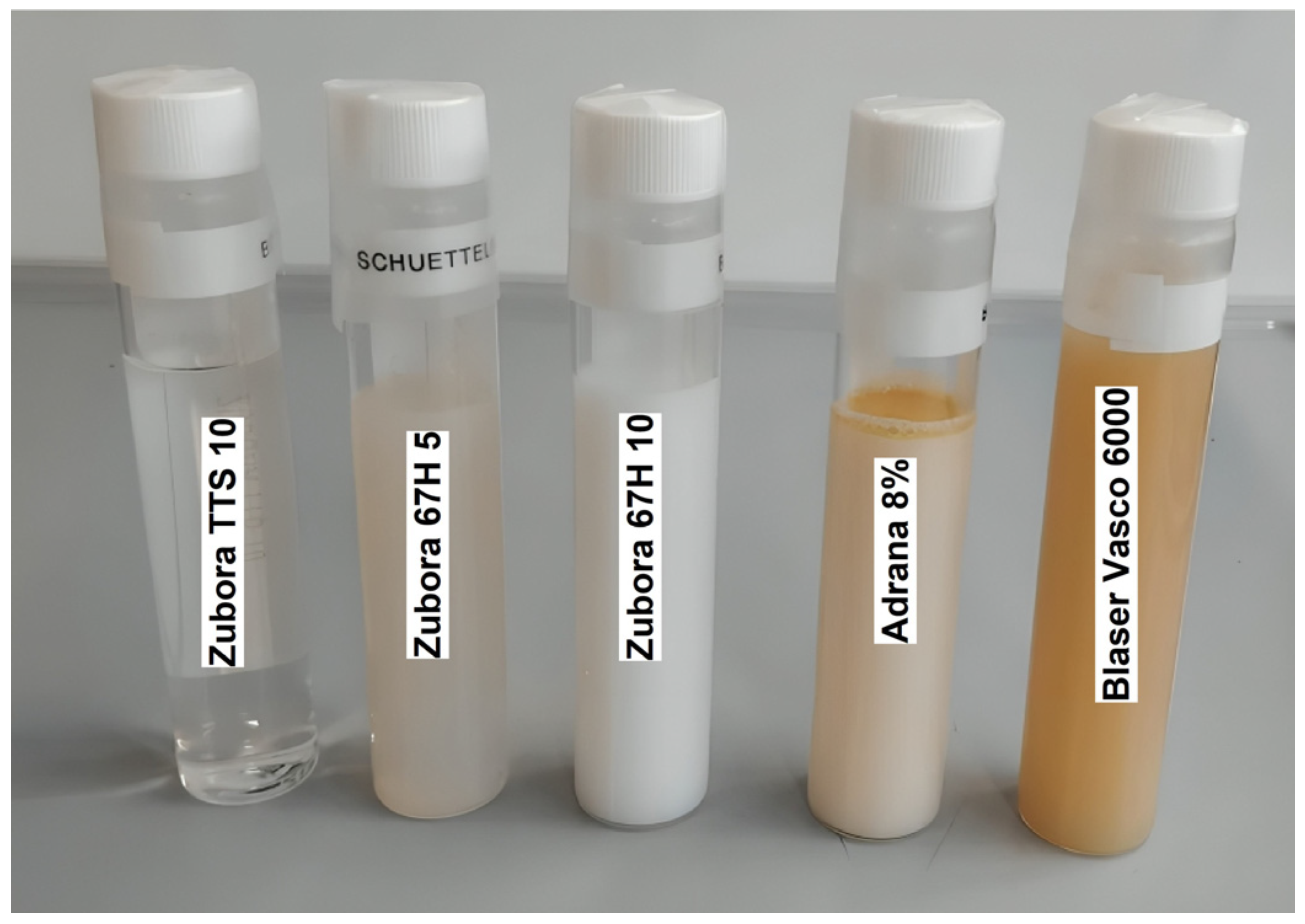

2.1. MWFs

2.2. Rheological and Tribological Characterization

2.3. Thermal Properties

3. Results and Discussion

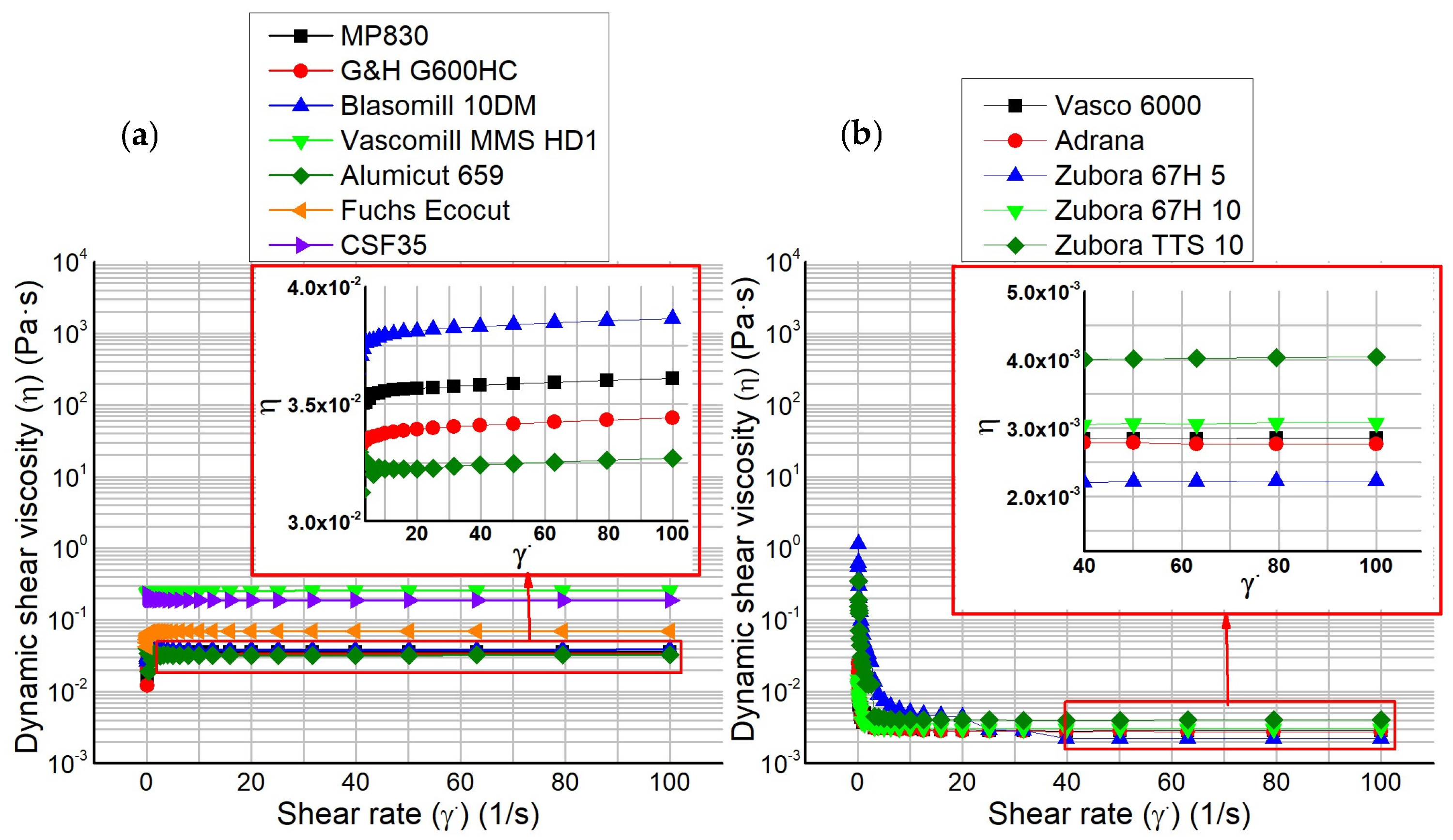

3.1. Rheological Behavior

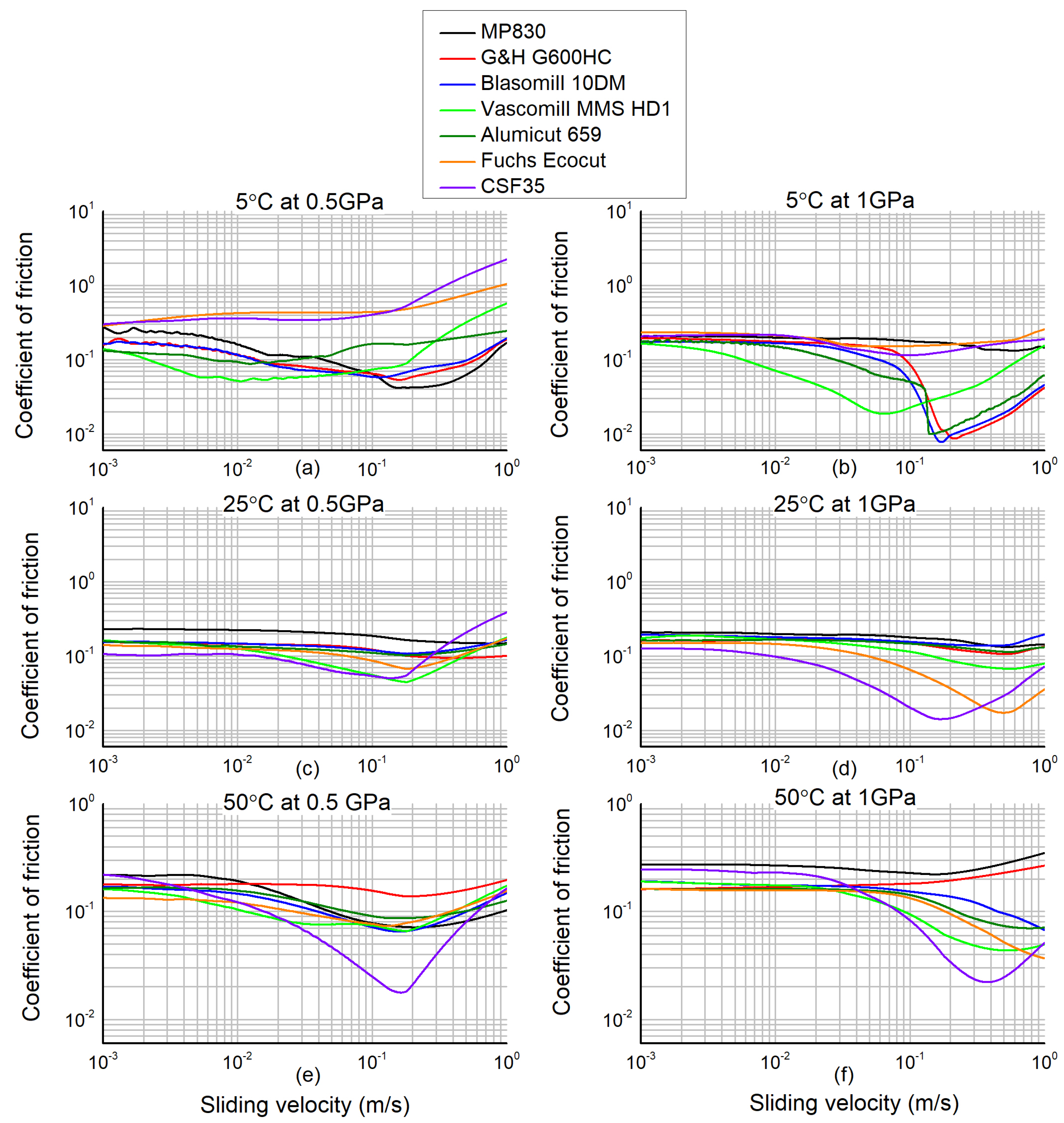

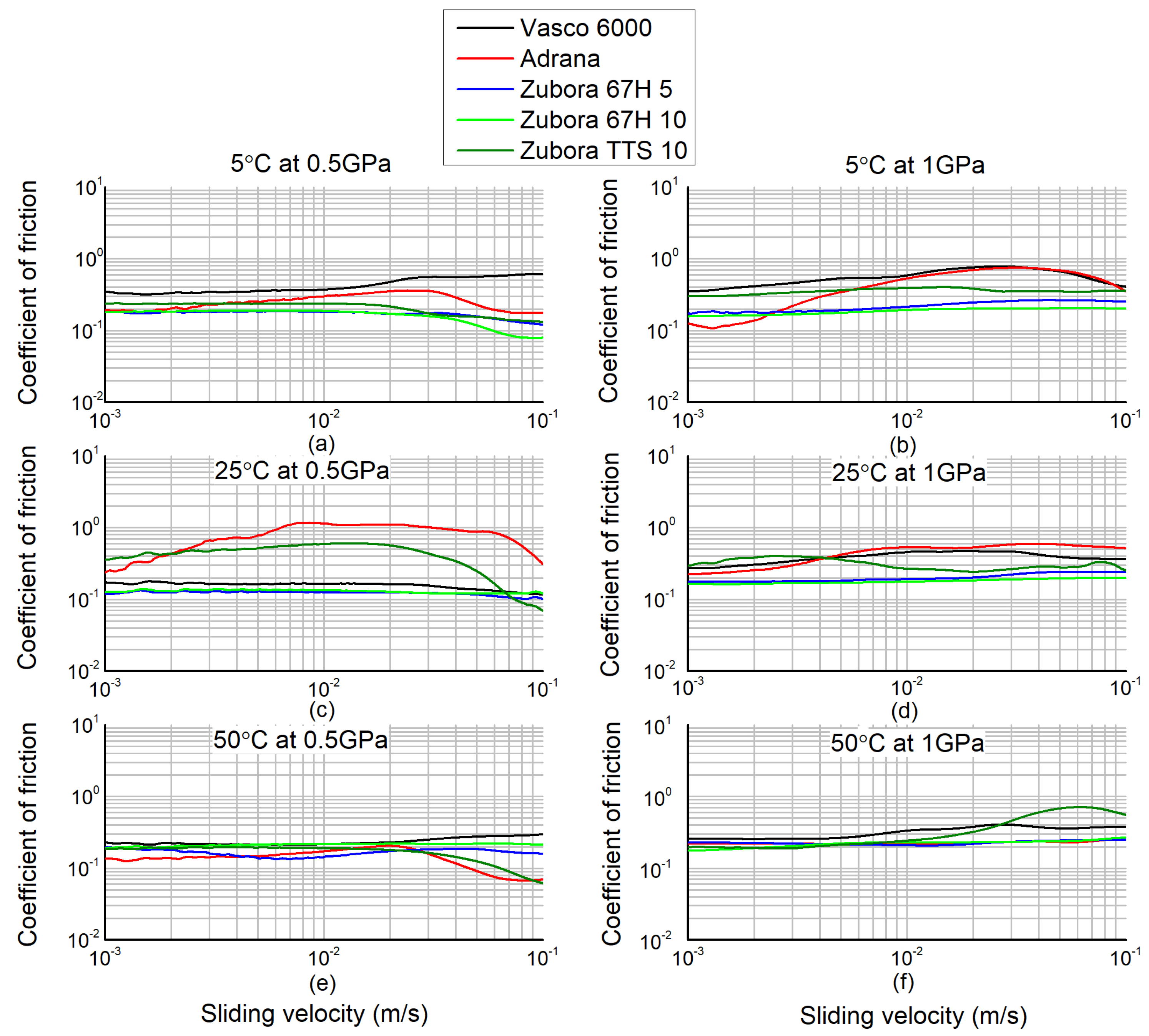

3.2. Frictional Performance

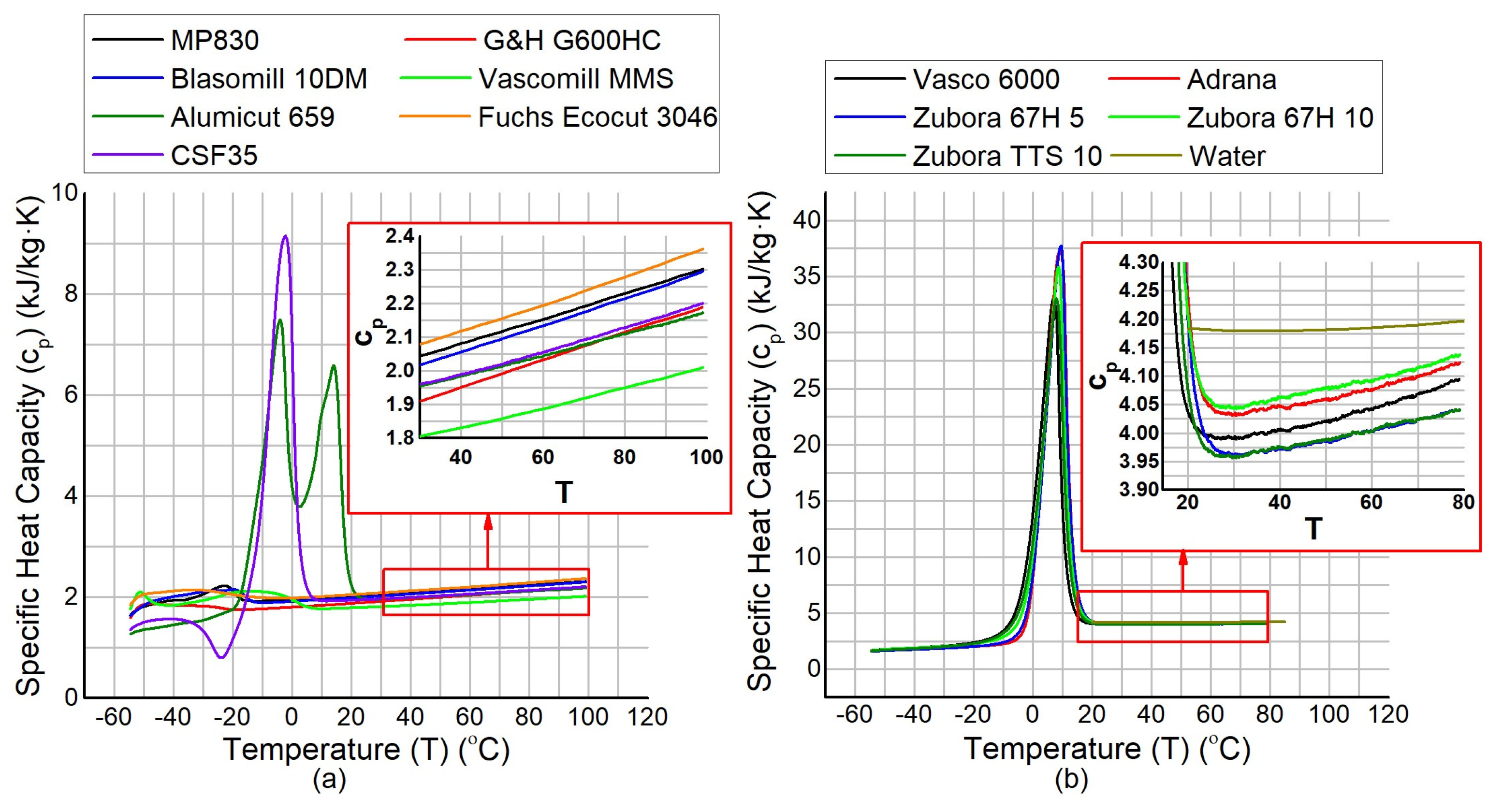

3.3. Thermal Behavior

4. Limitations of the Study

5. Summary and Outlook

- Temperature had a high influence on the tribological and thermal properties of the respective cutting fluids.

- The viscosity values of the emulsions were significantly lower than those of the oils, showing remarkable shear thinning behavior.

- The lubrication conditions for the emulsion remained in the mixed lubrication regime, as shown by Liu et al. [17], by performing ball-on-disc tests using different optical interferometry. Thus, the influence of additives that form boundary films is particularly important.

- In general, a lower COF can be achieved with oil-based MWFs as they are able to form a separating lubrication film within the tribocontact.

- MP830 showed the highest COF at high contact pressures, while CSF35 performed similarly at elevated temperatures, excelling alongside Vascomill MMS and Fuchs Ecocut 3046 in the mixed and full-fluid film regimes.

- Adrana showed a significant increase in COF at intermediate velocities before stabilizing, while the Zubora 67H emulsions maintained a consistent and favorable frictional performance.

- At temperatures of 50 °C, both Adrana and Zubora TTS 10 showed a decrease in COF compared with their behavior at 25 °C.

- All water-based lubricants exhibited a phase transition from solid to liquid around 0 °C due to the high water content. Only two oils showed clear signs of phase transition.

- In the case of the thermophysical properties, the thermal conductivity as well as the heat capacity of the examined water-based MWFs were significantly higher than those of the cutting oils, enabling a more efficient heat dissipation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Taylor, F.W. On the Art of Cutting Metals; American Society of Mechanical Engineers: New York, NY, USA, 1906; Volume 23. [Google Scholar]

- Spherical Insights LLP. Global Lubricant Mark. 2022, p. 211. Available online: https://www.sphericalinsights.com/reports/lubricant-market (accessed on 31 March 2025).

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Luo, J. Investigation on the origin of friction and superlubricity. Chin. Sci. Bull. 2020, 65, 2966–2978. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Meyer, D.; Huesmann-Cordes, A.; Herrmann, C. Metalworking fluids—Mechanisms and performance. CIRP J. Manuf. Sci. Technol. 2015, 64, 605–628. [Google Scholar] [CrossRef]

- Ogedengbe, T.S.; Abdulkareem, S.; Aweda, J. Effect of coolant temperature on machining characteristics of high carbon steel. Cov. J. Eng. Technol. 2018, 1, 73–86. [Google Scholar]

- Kui, G.W.A.; Islam, S.; Reddy, M.M.; Khandoker, N.; Chen, V.L.C. Recent progress and evolution of coolant usages in conventional machining methods: A comprehensive review. Int. J. Adv. Manuf. Technol. 2022, 119, 3–40. [Google Scholar] [CrossRef]

- Antonicelli, M.; Piccininni, A.; Cusanno, A.; Lacedra, V.; Palumbo, G. Evaluation of the effectiveness of natural origin metalworking fluids in reducing the environmental impact and the tool wear. J. Clean. Prod. 2023, 385, 135679. [Google Scholar] [CrossRef]

- Yan, P.; Rong, Y.; Wang, G. The effect of cutting fluids applied in metal cutting process. Proc. Inst. Mech. Eng. Part B. 2015, 230, 19–37. [Google Scholar] [CrossRef]

- ISO 6743-7; Lubricants, Industrial Oils and Related Products (Class L)—Classification—Part 7: Family M (Metalworking). International Organization for Standardization: Geneva, Switzerland, 1986.

- DIN 51385:2013-12; Lubricants—Processing Fluids for Forming and Machining of Materials—Terms. German Institute for Standardization: Berlin, Germany, 2013.

- Clark, P.E.; Pilehvari, A. Characterization of crude oil-in-water emulsions. J. Petrol. Sci. Eng. 1993, 9, 165–181. [Google Scholar] [CrossRef]

- Iowa Waste Reduction Center. Cutting Fluid Management: Small Machining Operations; National Center for Manufacturing Sciences: Ann Arbor, MI, USA, 2003; pp. 1–61. [Google Scholar]

- Singh, J.; Gill, S.S.; Dogra, M.; Singh, R. A review on cutting fluids used in machining processes. Eng. Res. Express 2021, 3, 012002. [Google Scholar] [CrossRef]

- McCoy, J.S. Tracing the Historical Development of Metalworking Fluids, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2017; pp. 1–17. [Google Scholar]

- Pape, F.; Poll, G.; Ellersiek, L.; Denkena, B.; Liu, H. Tribological Effects of Metalworking Fluids in Cutting Processes Lubricants. Lubricants 2023, 11, 224. [Google Scholar] [CrossRef]

- Liu, H.C.; Pape, F.; Zhao, Y.; Ellersiek, L.; Denkena, B.; Poll, G. On the Elastohydrodynamic Film-Forming Properties of Metalworking Fluids and Oil-in-Water Emulsions. Tribol. Lett. 2022, 71, 10. [Google Scholar] [CrossRef]

- Anand, A.; Vohra, K.; Haq, M.U.; Raina, A.; Wani, M.F. In Tribological Considerations of Cutting Fluids in Machining Environment: A Review. Tribol. Ind. 2016, 38, 463. [Google Scholar]

- Yang, K.Z.; Pramanik, A.; Basak, A.K.; Dong, Y.; Prakash, C.; Shankar, S.; Dixit, S.; Kumar, K.; Ivanovich Vatin, N. Application of coolants during tool-based machining—A review. Ain Shams Eng. J. 2023, 14, 101830. [Google Scholar] [CrossRef]

- Radulescu, I.; Radulescu, A.V.; Ramalchanov, S.; Yankov, S.; Rupetsov, V.S. Experimental Researches concerning the Rheology of Cutting Fluids. IOP Conf. Ser. Mater. Sci. Eng. 2019, 514, 012007. [Google Scholar] [CrossRef]

- Nassef, B.G.; Pape, F.; Poll, G.; Schenzel, J.; Bergmann, B.; Denkena, B. Evaluating the Tribological Behaviour in Cutting Operations Using a Modified Ball-on-Disc Open Tribotester. Lubricants 2024, 12, 77. [Google Scholar] [CrossRef]

- Bavoh, C.B.; Adam, J.M.; Lal, B. Specific heat capacity of xanthan gum/PAC polymer-based drilling fluids: An experimental and correlation study. Mater. Today Proc. 2022, 57, 1002–1007. [Google Scholar] [CrossRef]

- Singh, R.K.; Sharma, A.K.; Dixit, A.R.; Mandal, A.; Tiwari, A.K. Experimental investigation of thermal conductivity and specific heat of nanoparticles mixed cutting fluids. Mater. Today Proc. 2017, 4, 8587–8596. [Google Scholar] [CrossRef]

- Chiguma, J.; Johnson, E.; Shah, P.; Gornopolskaya, N.; Jones, W.E., Jr. Thermal diffusivity and thermal conductivity of epoxy-based nanocomposites by the laser flash and differential scanning calorimetry techniques. Open J. Compos. Mater. 2013, 3, 51–62. [Google Scholar] [CrossRef]

- Pereira, O.; Martín-Alfonso, J.E.; Rodríguez, A.; Calleja, A.; Fernández-Valdivielso, A.; De Lacalle, L.L. Sustainability analysis of lubricant oils for minimum quantity lubrication based on their tribo-rheological performance. J. Clean. Prod. 2017, 164, 1419–1429. [Google Scholar] [CrossRef]

- Suárez, A.; López de Lacalle, L.N.; Polvorosa, R.; Veiga, F.; Wretland, A. Effects of high-pressure cooling on the wear patterns on turning inserts used on alloy IN718. Mater. Manuf. Process. 2017, 32, 678–686. [Google Scholar] [CrossRef]

- Pereira, O.; Rodríguez, A.; Calleja-Ochoa, A.; Celaya, A.; de Lacalle, L.N.L.; Fernández-Valdivielso, A.; González, H. Simulation of Cryo-cooling to Improve Super Alloys Cutting Tools. Int. J. Precis. Eng. Manuf. Green Technol. 2022, 9, 73–82. [Google Scholar] [CrossRef]

- Amigo, F.J.; Urbikain, G.; Pereira, O.; Fernández-Lucio, P.; Fernández-Valdivielso, A.; de Lacalle, L.L. Combination of high feed turning with cryogenic cooling on Haynes 263 and Inconel 718 superalloys. J. Manuf. Process. 2020, 58, 208–222. [Google Scholar] [CrossRef]

- Pusavec, F.; Kramar, D.; Krajnik, P.; Kopac, J. Transitioning to sustainable production–part II: Evaluation of sustainable machining technologies. J. Clean. Prod. 2010, 18, 1211–1221. [Google Scholar] [CrossRef]

- Biermann, D.; Saelzer, J.; Bergmann, B.; Schenzel, J.; Menze, C.J.; Gerken, J.F.; Wolf, T.; Denkena, B.; Möhring, H.-C.; Zabel, A. Fundamental characterization of lubrication effects through various cooling lubricants in the chip formation zone. Prod. Eng. Res. Dev. 2025, 19, 173–185. [Google Scholar] [CrossRef]

- Nassef, B.G.; Moradi, A.; Bayer, G.; Pape, F.; Abouelkasem, Z.A.; Rummel, F.; Schmölzer, S.; Poll, G.; Marian, M. Biogenic palm oil-based greases with glycerol monostearate and soy wax: A rheological and tribological study. Results Eng. 2025, 25, 103728. [Google Scholar] [CrossRef]

- Läuger, J.; Pondicherry, K. New insights into the use of a rotational rheometer as tribometer. Annu. Trans. Nord. Rheol. Soc. 2017, 25, 333–340. [Google Scholar]

- Nassef, B.G.; Pape, F.; Poll, G. Enhancing the Performance of Rapeseed Oil Lubricant for Machinery Component Applications through Hybrid Blends of Nanoadditives. Lubricants 2023, 11, 479. [Google Scholar] [CrossRef]

- ASTM E1269; Standard Test Method for Determining Specific Heat Capacity by Differential Scanning Calorimetry. ASTM International: West Conshohocken, PA, USA, 2018.

- DIN 51007; Thermal Analysis—Differential Thermal Analysis (DTA) and Differential Scanning Calorimetry (DSC)—General Principles. German Institute for Standardization: Berlin, Germany, 2019.

- ISO 11357; Plastics—Differential Scanning Calorimetry (DSC). International Organization for Standardization: Geneva, Switzerland, 2023.

- DIN 53765; Testing of Plastics and Elastomeres; Thermal Analysis; DSC-Method. German Institute for Standardization: Berlin, Germany, 1994.

- ASTM E793; Standard Test Method for Enthalpies of Fusion and Crystallization by Differential Scanning Calorimetry. ASTM International: West Conshohocken, PA, USA, 2018.

- Nadolny, Z.; Dombek, G. Thermal properties of mixtures of mineral oil and natural ester in terms of application in the transformer. Int. Conf. Energy Environ. Mater. Syst. 2017, 19, 01040. [Google Scholar] [CrossRef]

| Item | Density (g/cm3) at 20 °C | Viscosity (mm2/s) at 40 °C | Structure |

|---|---|---|---|

| Oelheld Sinto Grind MP830 | 0.82 | 15.0 | Synthetic |

| G&H Oel Variocut G600HC | 0.85 | 9.2 | Non-water-miscible cutting fluid based on hydrocrack oil |

| Swisslube Blaser Blasomill 10DM | 0.85 | 10.0 | Mineral oil-based |

| Swisslube Blaser Vascomill MMS HD1 | 1.00 | 40.0 | Mineral oil-free with 80% ester oil content |

| Setral Alumicut 659 | 0.90 | 9.1 | Non-water-soluble synthetic oil |

| Fuchs Ecocut 3046 | 0.86 | 45.0 | Mineral oil-based |

| Swisslube Vascomill CSF35 | 0.90 | 35.0 | Synthetic oil |

| Item | Density (g/cm3) at 20 °C | Viscosity (mm2/s) at 40 °C | Structure |

|---|---|---|---|

| Swisslube Vasco 6000 | 0.99 | 15 at 40 °C | Fully synthetic emulsion with 10% ester oil and 88% deionized water |

| Houghton Adrana 8% AY401 | 0.99 | 120 at 20 °C | 92% water-miscible 8% mineral oil based cooling lubricant |

| Zeller & Gmelin Zubora 67H5 | 1.00 | 125 at 20 °C | Semi-synthetic MWF with 5% mineral oil content and 95% deionized water |

| Zeller & Gmelin Zubora 67H10 | 1.00 | 142 at 20 °C | Semi-synthetic MWF with 10% mineral oil content and 90% deionized water |

| Zeller & Gmelin Zubora TTS | 1.00 | 155 at 20 °C | Fully synthetic MWF with 90% water |

| Vasco 6000 | Adrana | 67H5 | 67H10 | TTS | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Temperature [°C] | ||||||||||

| 25 | 3.996 | 0.536 | 4.047 | 0.526 | 3.983 | 0.561 | 4.057 | 0.553 | 3.969 | 0.542 |

| 40 | 4.006 | 0.555 | 4.046 | 0.550 | 3.973 | 0.584 | 4.063 | 0.579 | 3.975 | 0.566 |

| 60 | 4.043 | 0.567 | 4.076 | 0.569 | 4.004 | 0.830 | 4.092 | 0.616 | 4.004 | 0.604 |

| 80 | 4.096 | 0.599 | 4.124 | 0.568 | 4.041 | 8.805 | 4.138 | 0.696 | 4.042 | 0.619 |

| MP830 | G600HC | 10DM | MMS | Alumicut 659 | EcoCut | CSF35 | |

|---|---|---|---|---|---|---|---|

| Temperature [°C] | |||||||

| 25 | 2.026 | 1.889 | 1.999 | 1.793 | 1.953 | 2.061 | 1.945 |

| 40 | 2.081 | 1.951 | 2.056 | 1.830 | 1.985 | 2.118 | 1.989 |

| 60 | 2.152 | 2.032 | 2.133 | 1.886 | 2.044 | 2.194 | 2.055 |

| 80 | 2.226 | 2.111 | 2.211 | 1.947 | 2.107 | 2.274 | 2.126 |

| 100 | 2.302 | 2.190 | 2.295 | 2.009 | 2.173 | 2.361 | 2.201 |

| 25 | 0.131 | 0.108 | 0.124 | 0.137 | 0.135 | 0.130 | 0.153 |

| 40 | 0.128 | 0.106 | 0.125 | 0.137 | 0.137 | 0.121 | 0.137 |

| 60 | 0.132 | 0.108 | 0.128 | 0.140 | 0.135 | 0.126 | 0.131 |

| 80 | 0.131 | 0.109 | 0.130 | 0.149 | 0.123 | 0.133 | 0.129 |

| 100 | 0.134 | 0.112 | 0.138 | 0.153 | 0.126 | 0.129 | 0.133 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pape, F.; Nassef, B.G.; Schmölzer, S.; Stobitzer, D.; Taubmann, R.; Rummel, F.; Stegmann, J.; Gerke, M.; Marian, M.; Poll, G.; et al. Comprehensive Evaluation of the Rheological, Tribological, and Thermal Behavior of Cutting Oil and Water-Based Metalworking Fluids. Lubricants 2025, 13, 219. https://doi.org/10.3390/lubricants13050219

Pape F, Nassef BG, Schmölzer S, Stobitzer D, Taubmann R, Rummel F, Stegmann J, Gerke M, Marian M, Poll G, et al. Comprehensive Evaluation of the Rheological, Tribological, and Thermal Behavior of Cutting Oil and Water-Based Metalworking Fluids. Lubricants. 2025; 13(5):219. https://doi.org/10.3390/lubricants13050219

Chicago/Turabian StylePape, Florian, Belal G. Nassef, Stefan Schmölzer, Dorothea Stobitzer, Rebekka Taubmann, Florian Rummel, Jan Stegmann, Moritz Gerke, Max Marian, Gerhard Poll, and et al. 2025. "Comprehensive Evaluation of the Rheological, Tribological, and Thermal Behavior of Cutting Oil and Water-Based Metalworking Fluids" Lubricants 13, no. 5: 219. https://doi.org/10.3390/lubricants13050219

APA StylePape, F., Nassef, B. G., Schmölzer, S., Stobitzer, D., Taubmann, R., Rummel, F., Stegmann, J., Gerke, M., Marian, M., Poll, G., & Kabelac, S. (2025). Comprehensive Evaluation of the Rheological, Tribological, and Thermal Behavior of Cutting Oil and Water-Based Metalworking Fluids. Lubricants, 13(5), 219. https://doi.org/10.3390/lubricants13050219