Abstract

The aim of this article is to simulate the distribution of oil or lubricants on the surface by the characterization of the R and S roughness parameters. It is considered that undesirable particles may appear in the oil due to friction, the wear of parts, or dirt in the lubrication circuit. One of the problems that can generate the appearance of particles in the oil is the poor distribution of this along the surface, using standards, standardised particle sizes, and following the standard. This research aims to implement effective algorithms for the calculation of profile and surface roughness parameters following existing standards, as well as the development of a morphological filter that will simulate particles on the surface. The analysis of the surface roughness of the surface in contact with the lubricant can help to decide the maximum particle size that is permissible in the system; therefore, analysing the oil will help to decide when it is necessary to filter or replace that lubricant. This research is carried out form the geometrical point of view of the morphological filter effect. This paper represents a first approach to researching the calculation of all standardized profile and surface roughness parameters. As a result, only a selection of parameters has been chosen from the full range of available ones, in order to improve effectiveness.

1. Introduction

Oils and lubricants serve various essential functions in industry, including reducing friction between moving parts, preventing overheating by acting as heat sinks, and enhancing energy efficiency through friction reduction.

The presence of particles in the oil can lead to increased friction between moving parts and the accumulation of particles in critical areas, which can result in increased wear or even the breakage of parts. It can also lead to an increase in machine temperature due to increased friction and poor heat dissipation, which can result in reduced system performance or increased energy consumption.

For this reason, it is essential to perform an analysis of industrial lubricants to ensure the correct operation of the machines and to extend their useful life. In one of the tests performed in the standards, automatic particle counters (APCs) are used, which are systems that measure the size of the particles and group the quantity of particles in the sample in different size ranges [1]. In this work, those ranges of sizes of particles standardized were used as the starting point for the filter characterization in the evaluation of the parameters.

This paper simulates the issues of oil distribution by applying a morphological filter to a surface, treating it as if it were a particle. Then, the surface is ‘virtually’ measured by the application of a morphological filter parametrized by the particle size. On the filtered ‘surface’, it is evaluated using each of the standardized parameters listed in the following clauses.

Although there are a multitude of standards, in this research, ISO standards have been used, mainly because they are widely accepted, especially in industry, because they provide a standardized and internationally recognized framework. This facilitates comparability of results between different laboratories, equipment, and works. In addition, ISO standards are the result of an international consensus among experts, which ensures that they are practical and effective. Therefore, future works may benefit from this fact, since it will be possible to compare their results with other precedents and, in this way, give more consistency to their own.

This paper does not take into account surface energy, oil temperature, material type, and possible wear on the oil. It is only evaluated from the point of view of the geometrical study of the morphological filter effect.

ISO/TC 213 is the technical committee in charge of creating, updating, and maintaining the ISO GPS standard for the geometrical product specifications and verification [2]. It was created in 1996. It is responsible for the standards ISO 21920, ISO 25178, and ISO 16610 used in this paper.

This research is a continuation of the Master’s Thesis in Metrology, referenced in [3].

Paper [4], by Bartkowiak et al., investigates the correlations between the build-up angle, surface fractal complexity, and wettability on additively manufactured surfaces fabricated with different technologies. This work uses surface data acquired using optical focusing variation, confocal microscopy, confocal fusion, and interferometry technologies. To investigate this correlation, it uses height, hybrid, and spatial parameters. Specifically, the parameters analysed are Sq, Sp, Sz, Sv, Sa, Sdq, Sdr, and Str. It does not consider the contacting surfaces and does not evaluate other parameters.

Grzesik’s work in chapters 4 and 20 of [5] have also been consulted on the surface integrity resulting from machining with cutting tools of various materials. An analysis of profile and surface roughness parameters calculated based on ISO 25178-2:2012 [6] and ISO 4287:1999 [7] is performed. Calculations of height, spatial, hybrid, and functional parameters are carried out in the paper. Specifically, the parameters evaluated are Sa, Sq, Ssk, Sku, Sp, Sv, Str, Sal, Std, Sdq, Sdr, Vvc, Vv, Vmp, and Vmc. Once more, R parameters are not evaluated.

Kim’s work in paper [8] describes the use of a microscope to capture images and evaluate the roughness parameter Ra, comparing the results obtained for shot-blasted and sand-blasted surfaces. In this case, there is no contact, and the S parameters are not measured.

Paper [9], by Lingadurai and Shunmugam, attempts to extend the 2D filter specified in ISO 16610-41:2006 [10] to a three-dimensional surface. Instead of using a spherical shape, as is the case in our study, a toroidal shape has been selected. That paper uses the filter to discriminate between surface waviness and shape defects.

Paper [11], by Lou et al., shows the application process of morphological filters including the scanning process, surface reconstruction, deviation evaluation, filtering for open and closed profiles, contact simulation, the establishment of the uncertainty zone, and the evaluation of the stratified surface. This study is focused on the application of the morphological filter; the roughness parameters are not evaluated as they are in our study.

Paper [12], by Lou et al., shows the application of a morphological filter of a closing disc and a linear segment filter and proposes an algorithm to implement the filter. In our work, we implement the morphological filter, and we evaluate and compare different parameters. Taking into account all the research conducted before, we have first of all selected the size of the morphological filter below the lubricant particle size (100 µm), designed a contacting filter, and evaluated not only the R parameter but also the S parameter. The new application of this paper will be the fictitious change in the surface that may appear when filtering the lubricant and removing bigger lubricant particles. The bigger the size, the smoother the surface will seem to be. That change in “smoothness” is evaluated by the change in some R and S parameters. In our work, we show which R and S parameters will show that change.

Paper [13], by Tóth et al., highlights the important role of anti-wear additives in protecting contact surfaces even with a thin film of lubricant. This study is carried out with particles between 1 nm and 100 nm. Tribological measurements reveal that the optimum particle concentration of 0.5 wt.% reduces the wear scarring produced by 45% and 90% of the pure wear volume compared to pure oil. This study complements the results of our study obtained from the comparison of the areal and profile roughness parameters, as it can be deduced from them that the smallest particles studied do not present major changes in the results of the calculated parameters.

The primary objective of this paper is to determine the critical impact of lubricant particle size behaviour and performance on the contacting surface by evaluating its effect on areal and roughness parameters.

2. Materials and Methods

2.1. Preliminary Research of the State-of-the-Art on Particle Size in Oils

In the last years, many industrial parts have been measured with roughness instruments fulfilling ISO requirements. Therefore, it is a fact that for the final user, it will be easier and competitive to improve their parts if they can take decisions from ISO parameters. It is out of the scope of this paper to define new parameters.

Thorough research has been performed into the current standards and regulations regarding the presence of particles in oils and lubricants. These are as follows:

- ISO 4406:2021 Hydraulic fluid power—Fluids—Method for coding the level of contamination by solid particles [14];

- NAS 1638:1964 (National Aerospace Standard)—International particle count standards [15,16,17];

- SAE AS4059 Rev. E. (2020) SAE Aerospace Standard [16,17,18];

- GOST 17216-2001 Gosudarstvenny Standard [16,17,19];

- NAV AIR 10-1A17 (1989) Navy Standard for Hydraulic Fluids used for aircraft hydraulic systems [16,17,20].

Table 1 shows the particle size defined by each standard and the calibration standard related to the first. In all of them, particle sizes for lubricants are somehow specified, and are therefore used as reference for this work.

Table 1.

Table of particle sizes for each of the standards.

It is noted that the particle size limit used in these standards is based on the standard used for the calibration of the particle measurement system. There are two types for use: ISO 4407:2002 [21] (MTD) and ISO 11171:2022 [22] (ACFTD). The first uses the diameter equivalent to the projected area of particles and the second uses the maximum length of the particles. This divergence approach needs to have very close size values, but not identical. Some standards refer to ISO 4402:1991 [24] instead of ISO 11171:1999 [26], as ISO 11171:1999 [26] replaced ISO 4402:1991 [24] in 1999.

All the values referenced Table 1 were used for this paper. In cases where the standards gave a range instead of a specific value, the limit values of the ranges were selected, as will be shown.

Therefore, the following particle sizes were selected: 2 µm, 4 µm, 5 µm, 6 µm, 14 µm, 15 µm, 21 µm, 25 µm, 38 µm, 50 µm, 70 µm, and 100 µm.

The 200 µm size has not been taken into account due to the high processing time necessary to apply the filtering. Because the filter size is too large for the chosen surface area, representing as much as 20% of the final surface, this was considered excessive. Moreover, normally, lubricated surfaces do not work under those extreme conditions.

2.2. Programmed Algorithms

The algorithms were developed using Matlab 2024B [27] programming and another numerical calculation platform. Matlab 2024B was selected because of its high flexibility and easy programming. Due to its computational power and high-level programming, it eases code debugging and high-quality graphical representation.

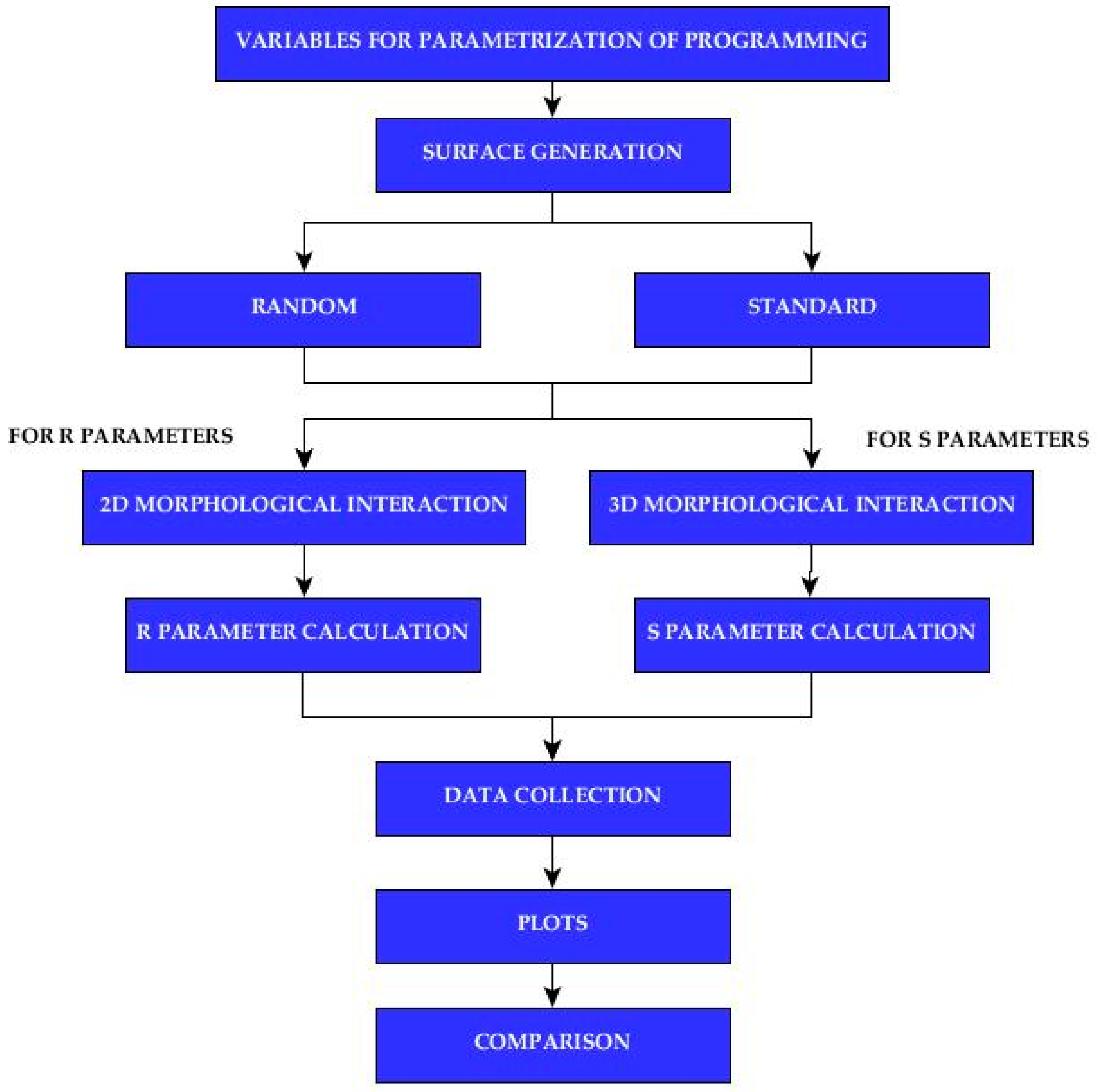

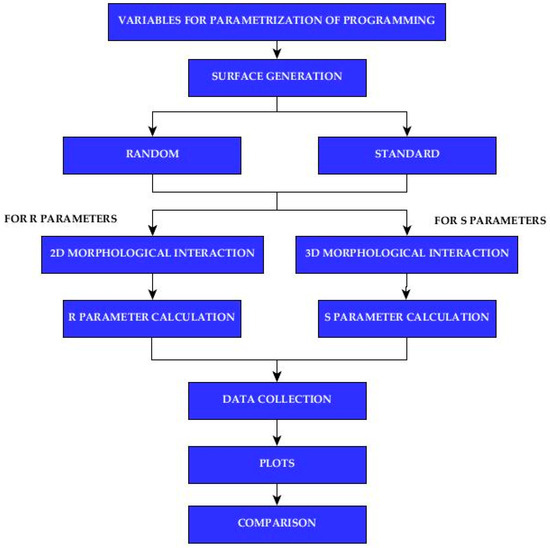

The general flow diagram of the programming it shown in Figure 1.

Figure 1.

Flowchart of the developed program.

The description of each box in the diagram above and the specific functions programmed are explained below.

- Variables of parametrization programming: The parameters of the point cloud and the standard are set.

- Surface generation: MySimLab is used to generate the point cloud and developed functions are used to generate the standards and combine point clouds. These were the functions:

- ○

- Gen_triangular_standard.m

- ○

- Gen_surface.m

- ○

- Gen_total_surface.m

- 2D morphological interaction: The surface is measured as a profile, which is filtered with a profile morphological closure disk filter, simulating the path of a disk over the profile. It was programmed using the scripts FPMCD.m and app_filter_profile.m.

- 3D morphological interaction: The surface is filtered with an areal morphological closure ball filter, simulating the path of a particle or stylus through the surface. It uses the scripts FAMCB.m and app_filter_surface.m.

- R parameter calculation: Profile roughness parameters were evaluated on the profile selected on the surface with the following scripts programmed as defined in the standards referenced at the end of the papers. These were the programmed functions:

- ○

- Calc_Rq.m

- ○

- Calc_Rsk.m

- ○

- Calc_Rku.m

- ○

- Calc_Rp.m

- ○

- Calc_Rv.m

- ○

- Calc_Rzt.m

- ○

- Calc_Ra.m

- ○

- Calc_Rmc.m

- ○

- Calc_Rcm.m

- ○

- Calc_Rdc.m

- ○

- Calc_Rdq.m

- ○

- Calc_Rdr.m

- ○

- Calc_Rk.m

- ○

- Calc_Rvkx.m

- ○

- Calc_Rvk.m

- ○

- Calc_Rpkx.m

- ○

- Calc_Rpk.m

- ○

- Calc_Rmrk1.m

- ○

- Calc_Rmrk2.m

- ○

- Calc_Rak1.m

- ○

- Calc_Rak2.m

- ○

- Calc_Rak.m

- ○

- Calc_step_p.m

- ○

- Profile_data_process.m

- S parameter calculation: Areal roughness parameters were evaluated on that surface with the following scripts:

- ○

- Calc_Sq.m

- ○

- Calc_Ssk.m

- ○

- Calc_Sku.m

- ○

- Calc_Sp.m

- ○

- Calc_Sv.m

- ○

- Calc_Szt.m

- ○

- Calc_Smr.m

- ○

- Calc_Smc.m

- ○

- Calc_Sdq.m

- ○

- Calc_Sdr.m

- ○

- Calc_Sk.m

- ○

- Calc_Svkx.m

- ○

- Calc_Svk.m

- ○

- Calc_Spkx.m

- ○

- Calc_Spk.m

- ○

- Calc_Smrk1.m

- ○

- Calc_Smrk2.m

- ○

- Calc_Sak1.m

- ○

- Calc_Sak2.m

- ○

- Calc_Sak.m

- ○

- Calc_step.m

- ○

- Data_process.m

- Data collection: Results were saved, and a report was generated as an xls file. Data collection was developed with the following scripts:

- ○

- Write_xls.m

- ○

- Parameter_initialize.m

- ○

- Parameter_initialize_standard.m

- ○

- Parameter_initialize_profile.m

- ○

- Delete_data.m

- Plots: Plots were generated using Matlab 2024B and excel programs. The following three scripts were developed:

- ○

- Material_ratio_curve.m

- ○

- Iterative_graphics.m

- ○

- Surface_graphic.m

- Comparison: Conclusions and results were studied to perform this work.

2.3. Surface Generation

A random surface was generated, and since we focused on the method, this was good enough. Triangular peak and grooves standards have been generated for analysis. A real surface could have been used instead of the random surface, but among all the standards specified, the triangular standard was shown to be the best for that.

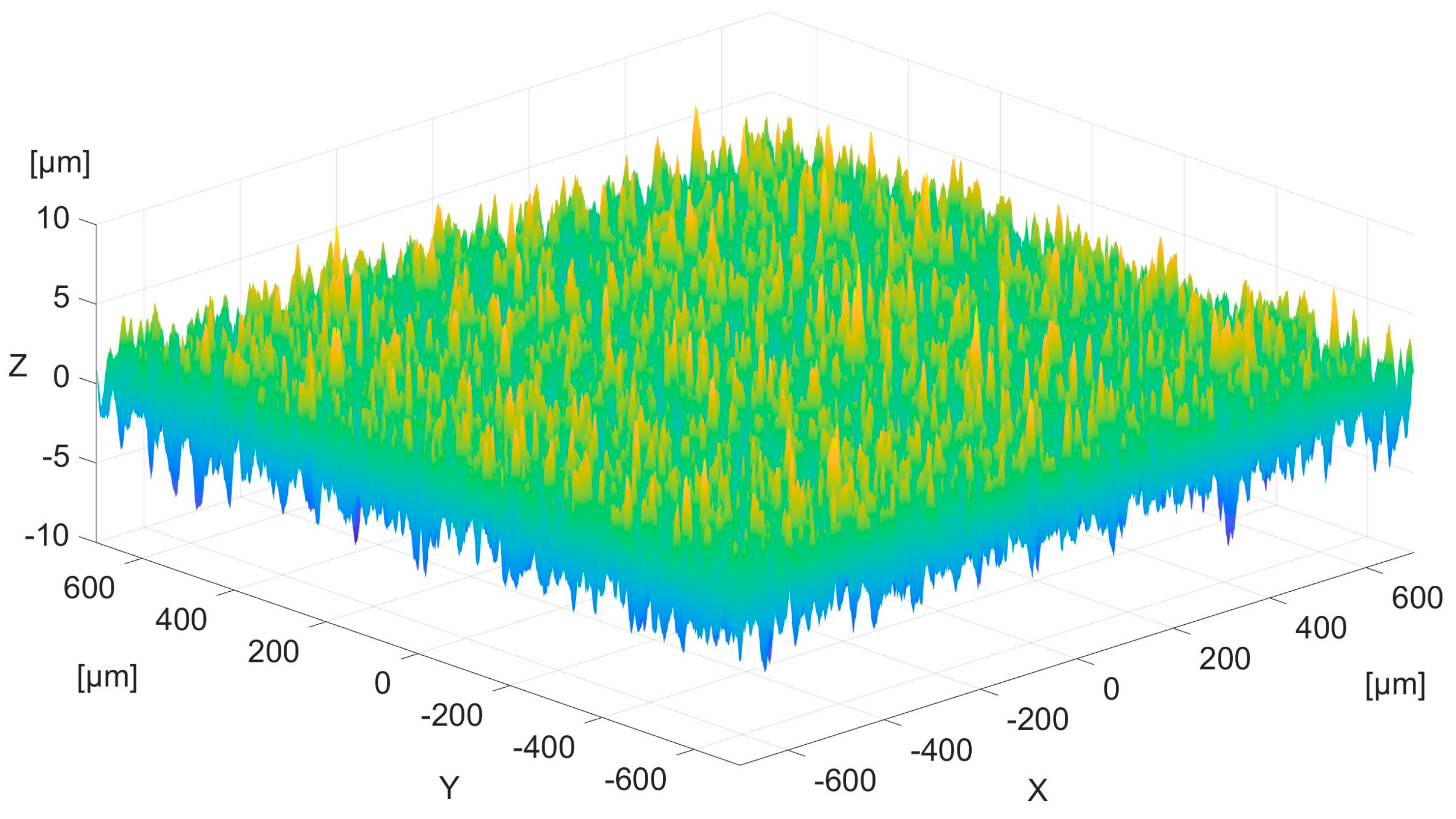

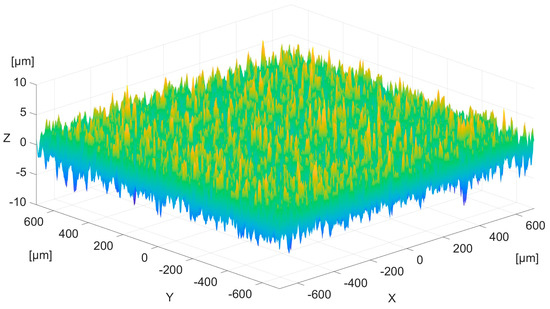

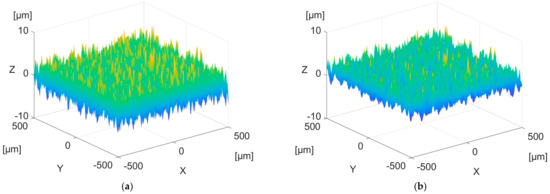

In order to carry out the research, a surface was generated using the MySimLabs [28] tool, executed in the Matlab environment. The script used to generate the surface was ‘rsgeng2D.m’. This script gives, as an output, a matrix with the data corresponding to the Z axis and two vectors with the data of the X and Y axes. To obtain two matrixes with the X and Y axes, the Matlab meshgrid function was used. The random surface was 1400.4 µm in X and Y axes and 14.2354 µm in the Z axis. However, after the filtering operation, only 1 mm was used in both the X and Y axes.

The point cloud has been generated, leaving a distance between the points of 0.2 µm, avoiding aliasing, because the diameter of the smallest filter to be evaluated is 2 µm.

The surface was generated by five surfaces with different amplitudes and filters, and they were added together to obtain the most realistic surface possible. In Appendix A, the parameters used to generate each of the surfaces and the correction factors applied prior to the summation of all the surfaces are detailed.

It should be noted that since the morphological filter has an end effect and in the case of the surfaces there is no standard for the compensation of this defect, it has been necessary to generate a larger surface than the one to be processed with the algorithms for the calculation of the evaluation. Currently, there is only one standard for the end effect compensation, and it is the UNE-EN ISO 16610-28:2018 [29] standard, but it is only applicable to profiles, not surfaces. Therefore, the only existing solution to avoid this distortion by filtering is to use a larger data sample than needed and then discard the data affected by this effect.

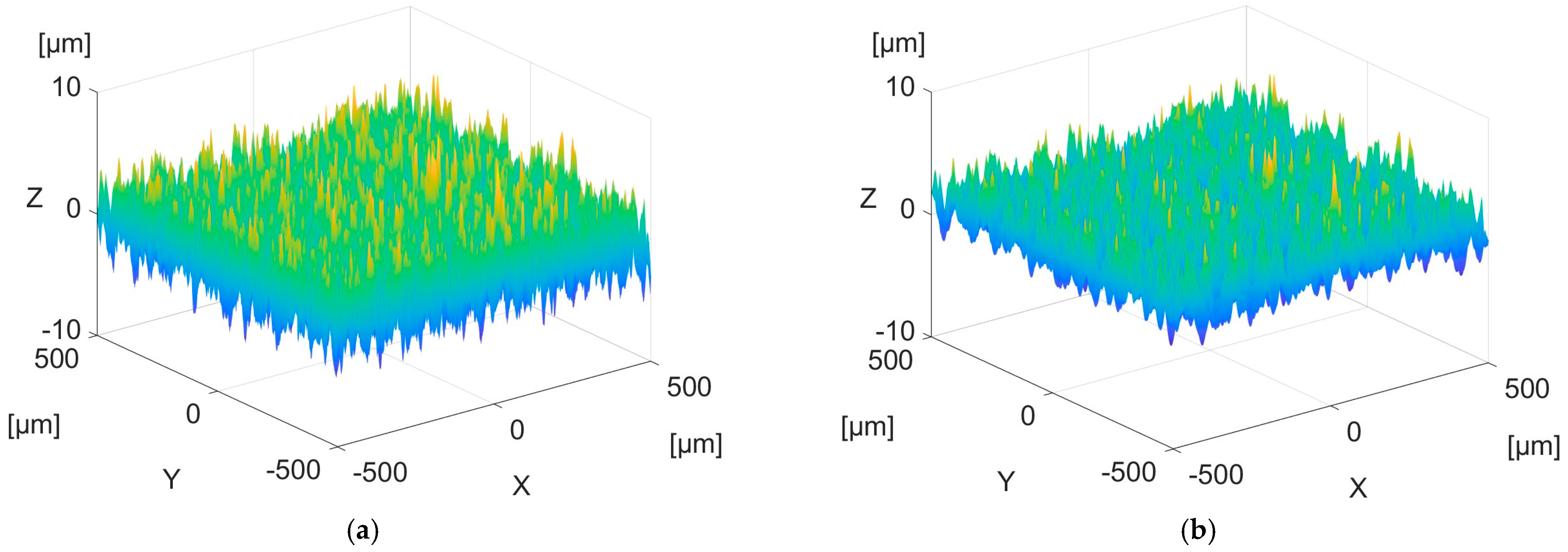

Figure 2 shows the point cloud generated for the surface analysis.

Figure 2.

The point cloud generated. Z (height in µm), X, and Y (horizontal displacement in µm).

2.4. Generation of the Standards

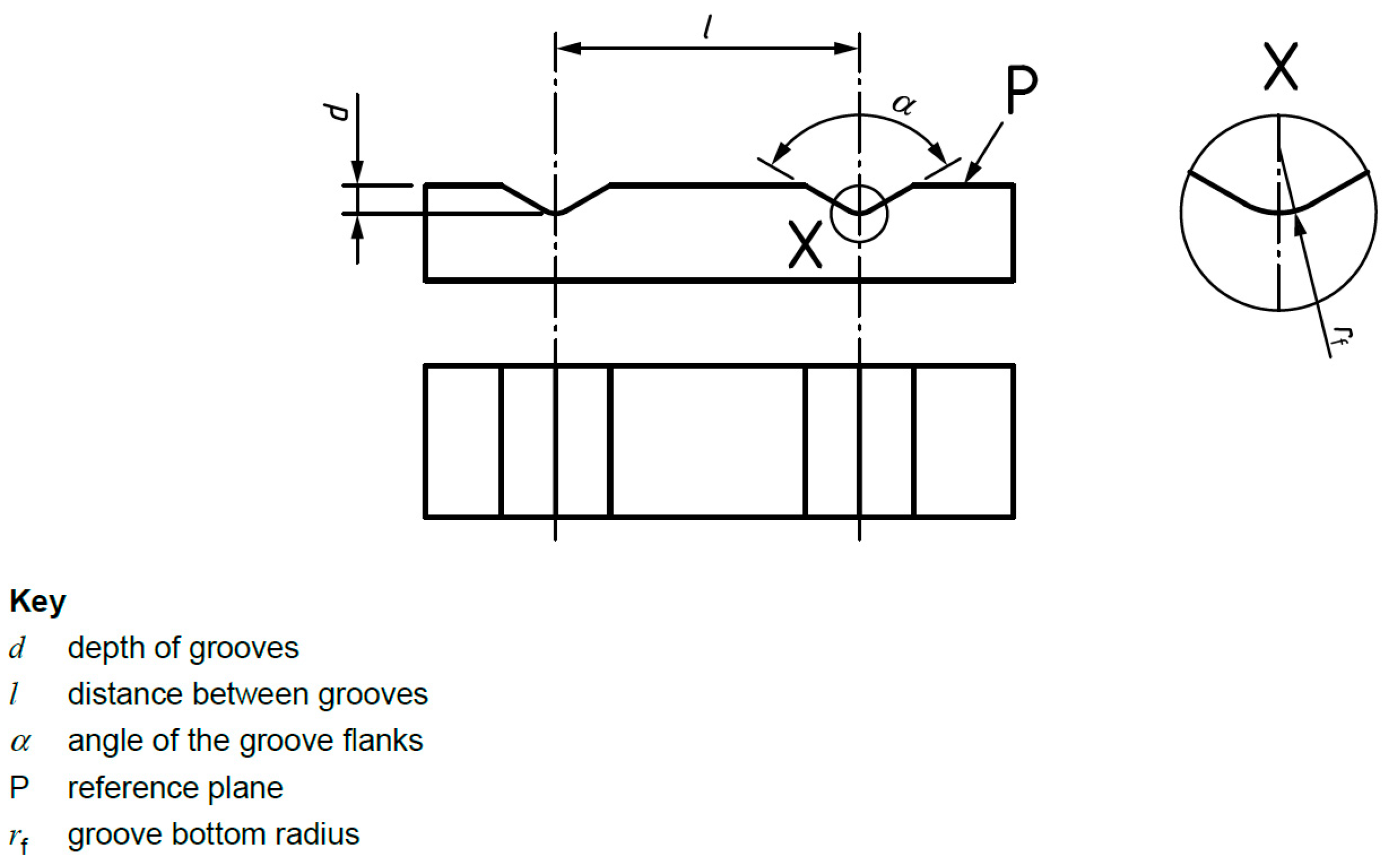

In addition to the random surface, a triangular groove standard has been used following the recommendations of the UNE-EN ISO 25178-701:2011 [30] standard; this was used in order to appreciate the influence of the program morphological filter on peaks and grooves.

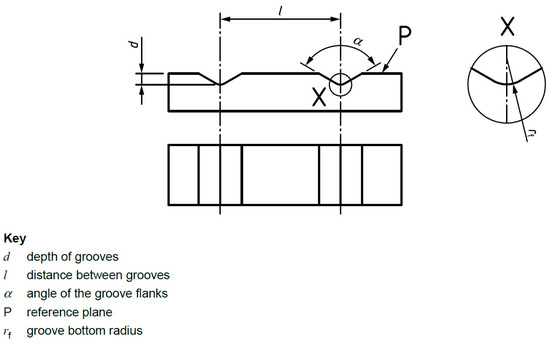

Figure 3 shows the ER1 standard of the standard used.

Figure 3.

The two-parallel-grooves standard (ER1) of the UNE-EN ISO 25178-701:2011 [30] standard.

As in the random surface, the standard surface has also been programmed with an inter-point distance of 0.2 µm. The standard has been developed with a depth (d) of 20 µm, an opening angle (α) of 130°, a rounding radius (rf) of 1 µm, and the plane (P) is defined at Z coordinate 0 µm. These parameters have been selected so that the largest stylus or filter diameter can enter the slot to test its influence.

The standard remarks that the rounding angle must be larger than the stylus radius for the standard to be used for calibration. However, in this case, the scope of using the standard is to evaluate the evolution of morphological filtering on the surface as the filter size increases, provided that the morphological filter resembles the contacting performance for the selected particle size with the surface.

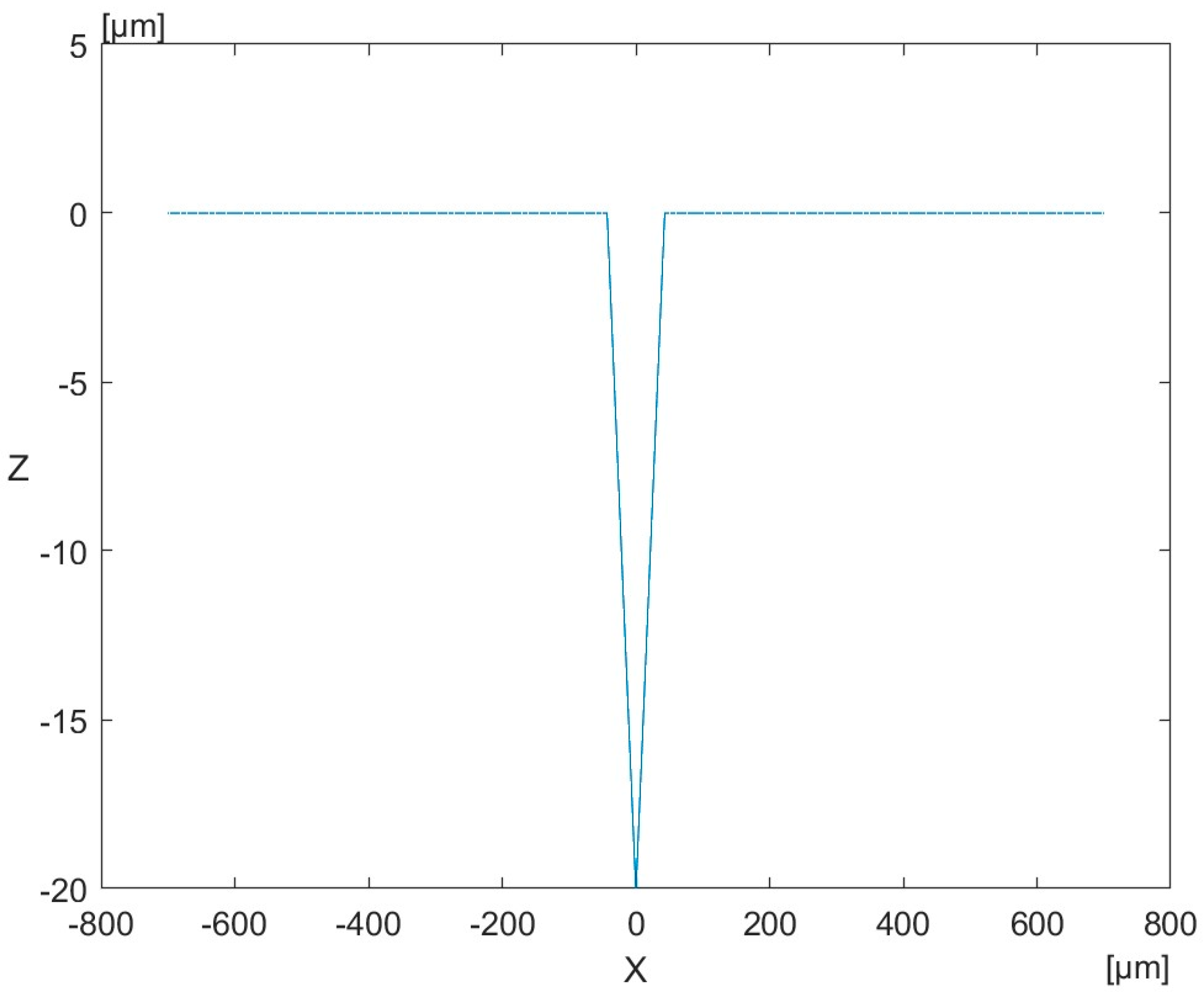

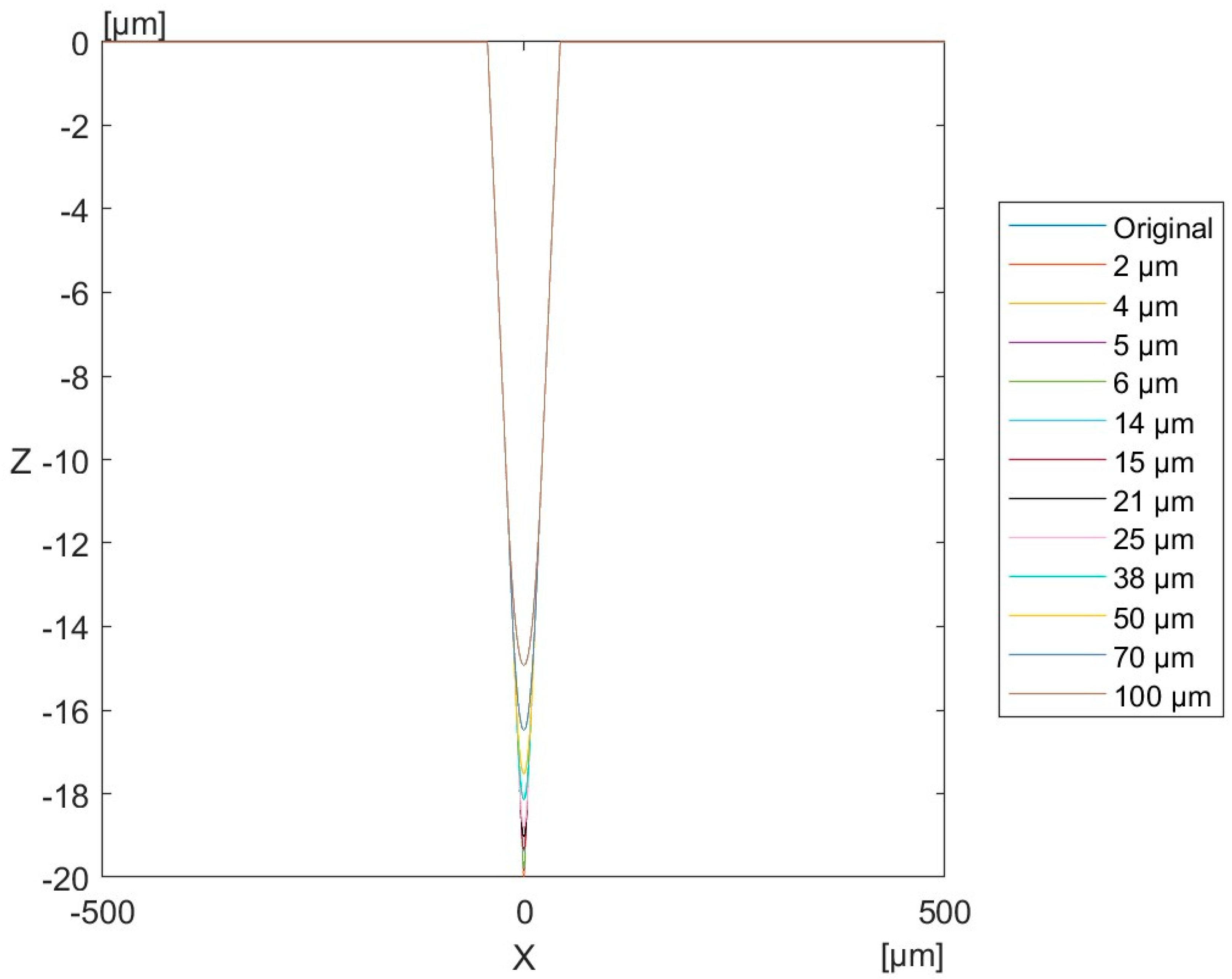

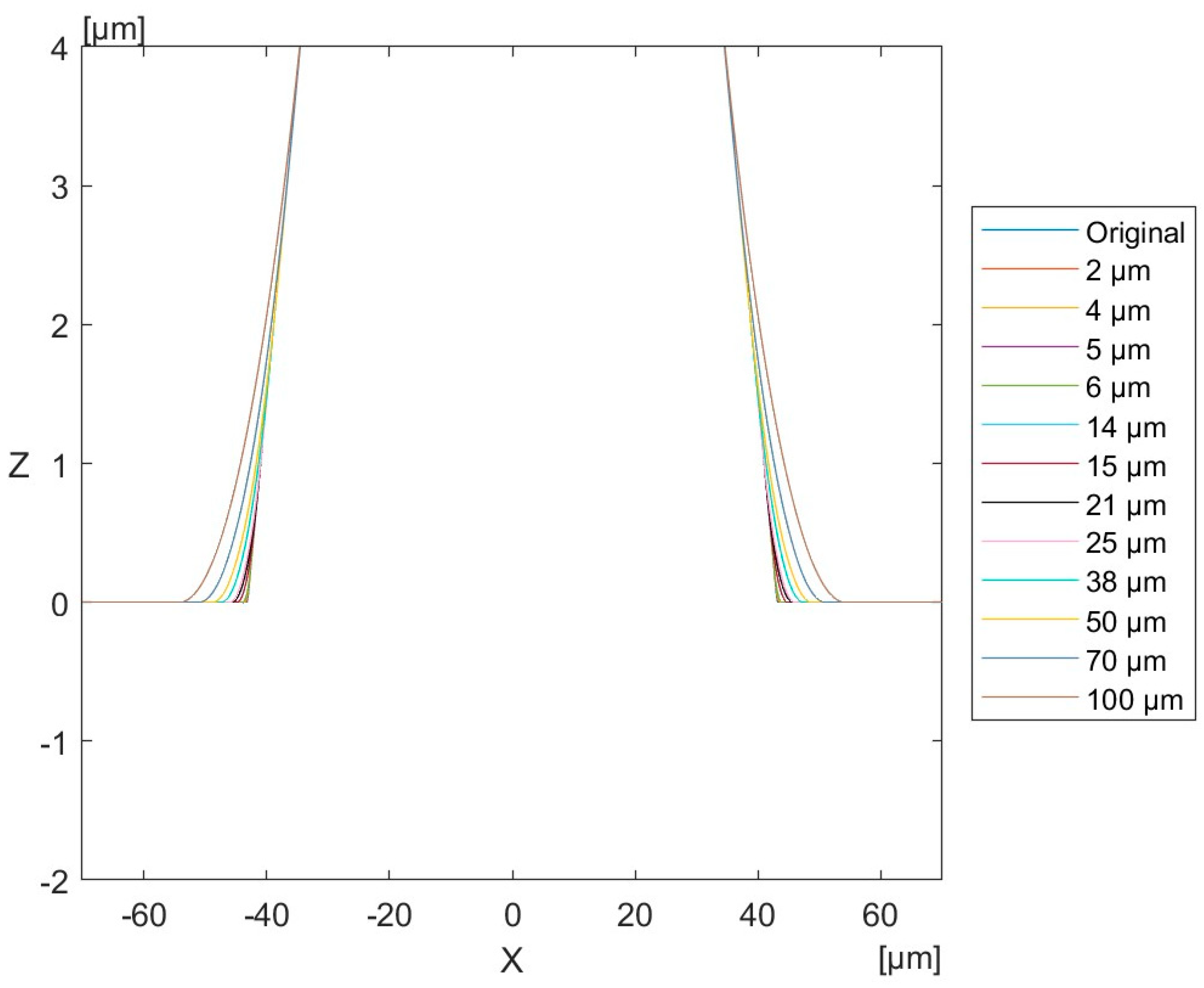

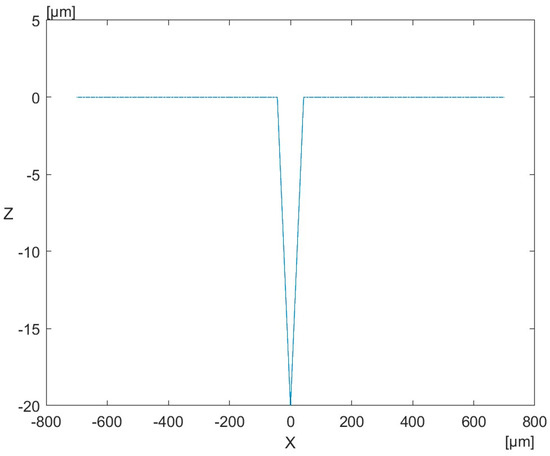

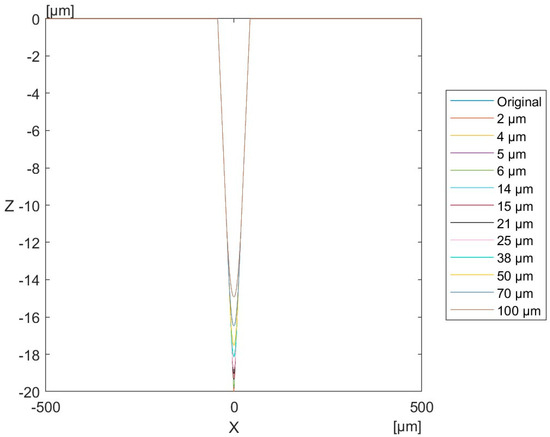

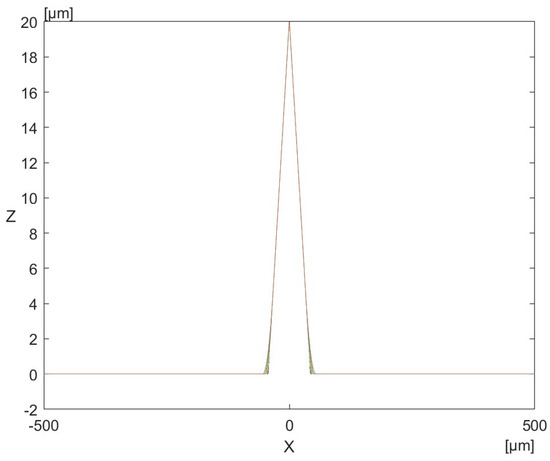

Figure 4 shows the profile of the first programmed standard.

Figure 4.

Profile of the groove standard. Z (height in µm) and X (Horizontal displacement in µm).

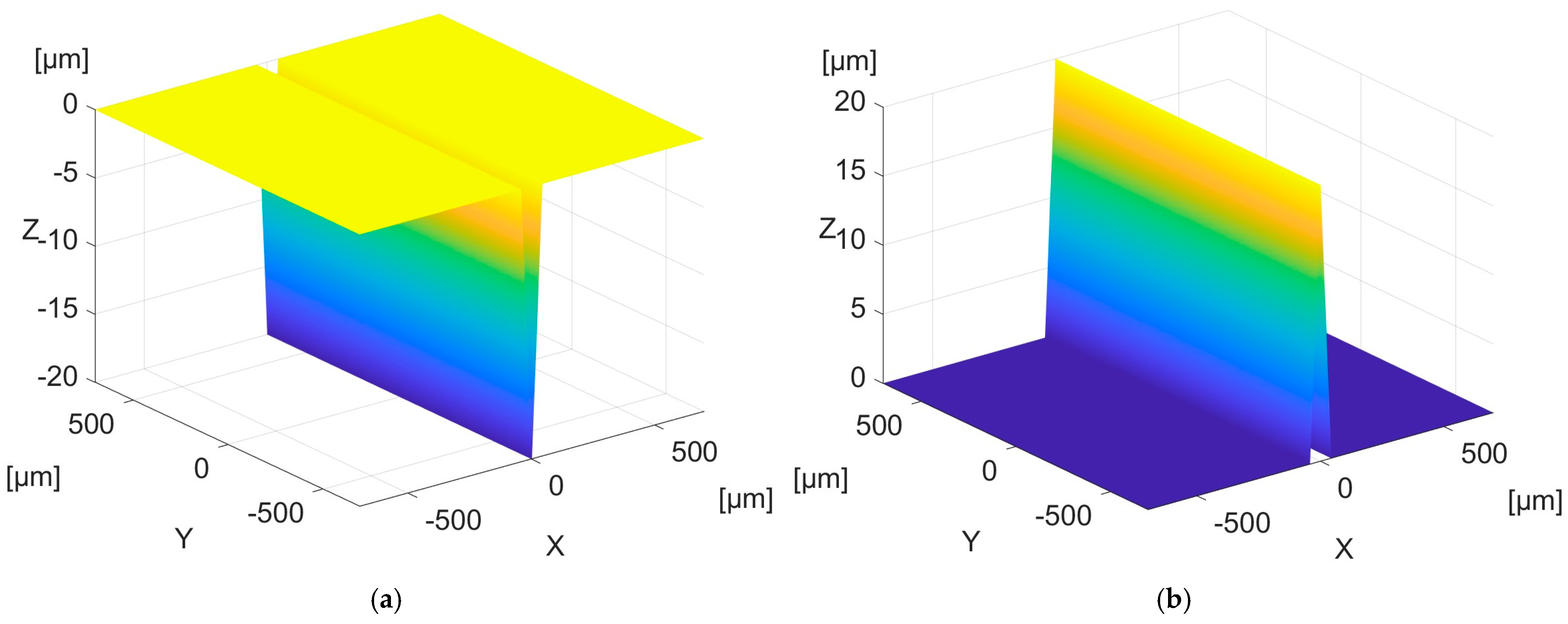

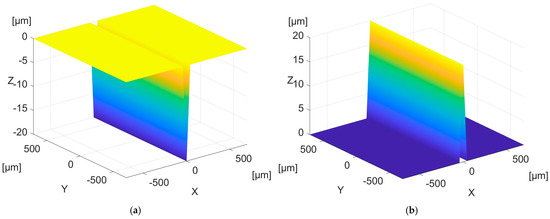

Subsequently, the programmed standard has been inverted to have a peak upwards, and the performance of the R or S roughness parameters is checked, because for an ideal surface, as stated in these standards, the result of R or S parameters is the same. Figure 5 shows the groove (a) and peak (b) standard.

Figure 5.

(a) Groove standard. Z (height in µm), X, and Y (horizontal displacement in µm). (b) Triangular peak standard. Z (height in µm), X, and Y (horizontal displacement in µm).

It is important to note that since the standards have ideal surfaces without roughness, only the height parameters and the hybrid parameters have been calculated. Since the functional and bearing rate parameters depend on the material ratio curve, there is no benefit from calculating them in this case. Due to the shape of the standard, the evaluated material ratio curve does not have the inverted s-shape with a single inflection point necessary to calculate these parameters.

2.5. Morphological Interaction/Filtering

In order to evaluate the influence of particles or the stylus contacting a surface, it was decided to use a closing morphological filter. For this work, the morphological filter consists of a series of mathematical operations that relate a virtual measured surface to a contact measurement system (matching the size of the filter to the size of the stylus).

Although the particles present in the lubricant can have different shapes, for this study, it is assumed that these particles are perfect spheres. Further work may consider that effect.

Whenever a measurement is made with a stylus, morphological filtering is applied automatically, as the spherical shape of the stylus cannot be in contact with every single point on the surface. In small dales, the stylus does not reach the bottom, acquiring a slightly reduced depth. However, it can measure all the peaks correctly.

The same is true for the particle as for the stylus. If the particle has a diameter larger than the width of the dale, it will not be able to penetrate completely. If there is a large difference between the filtered surface and the original surface, it means that the particle may have been left behind to block the passage of the lubricant and thus leave the lubricant unevenly distributed.

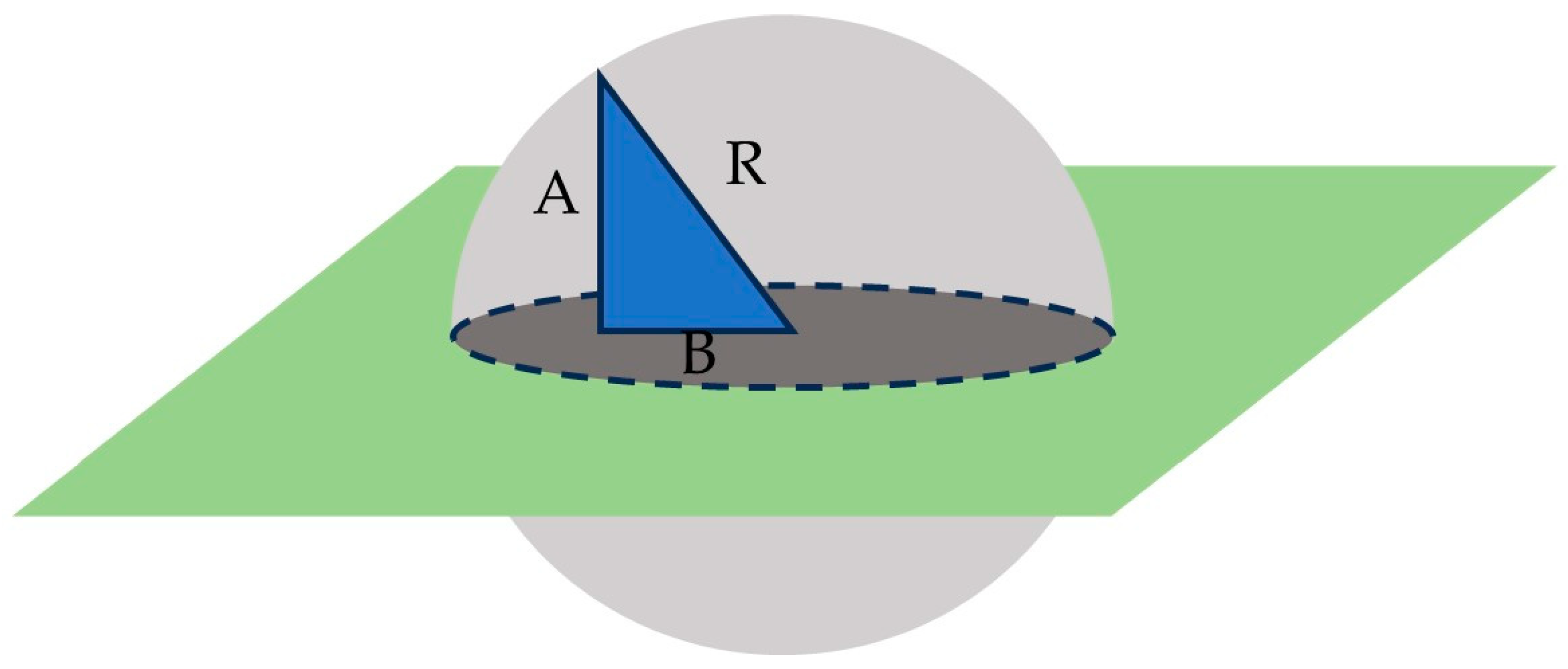

This behaviour of the sphere with the surface can be simulated for a particle in a mathematical way using an FAMCB (Filter Areal Morphological Closing Ball) filter. In fact, a morphological filter with a closing disc was selected for the profile and a closing sphere was selected for the surface filtering. In the case of the profile, the guidelines explained in the UNE-EN ISO 16610-41:2015 [31] standard have been used. There are still no published standards for morphological areal filtering.

The filters used do not present an end effect in the case of profiles or closed surfaces, but they do in the case of profiles and open surfaces. As there are no end effect compensation techniques for surfaces as in the case of profiles (UNE-EN ISO 16610-28:2018 [29]), larger surfaces and standards are generated than those that are going to be used.

It should be noted that the end effect depends on the size of the filter used; the larger the filter, the more data will be affected by it. Therefore, the larger the filter used, more data have to be discarded. In order not to have a bad influence on our evaluation by the end effect and the size of the surface used, the same amount of data have been discarded for all filter sizes. In the case of profiles, the techniques explained in the UNE-EN ISO 16610-28:2018 [29] standard could be used. In order to be consistent, the same technique has been used as for the surface.

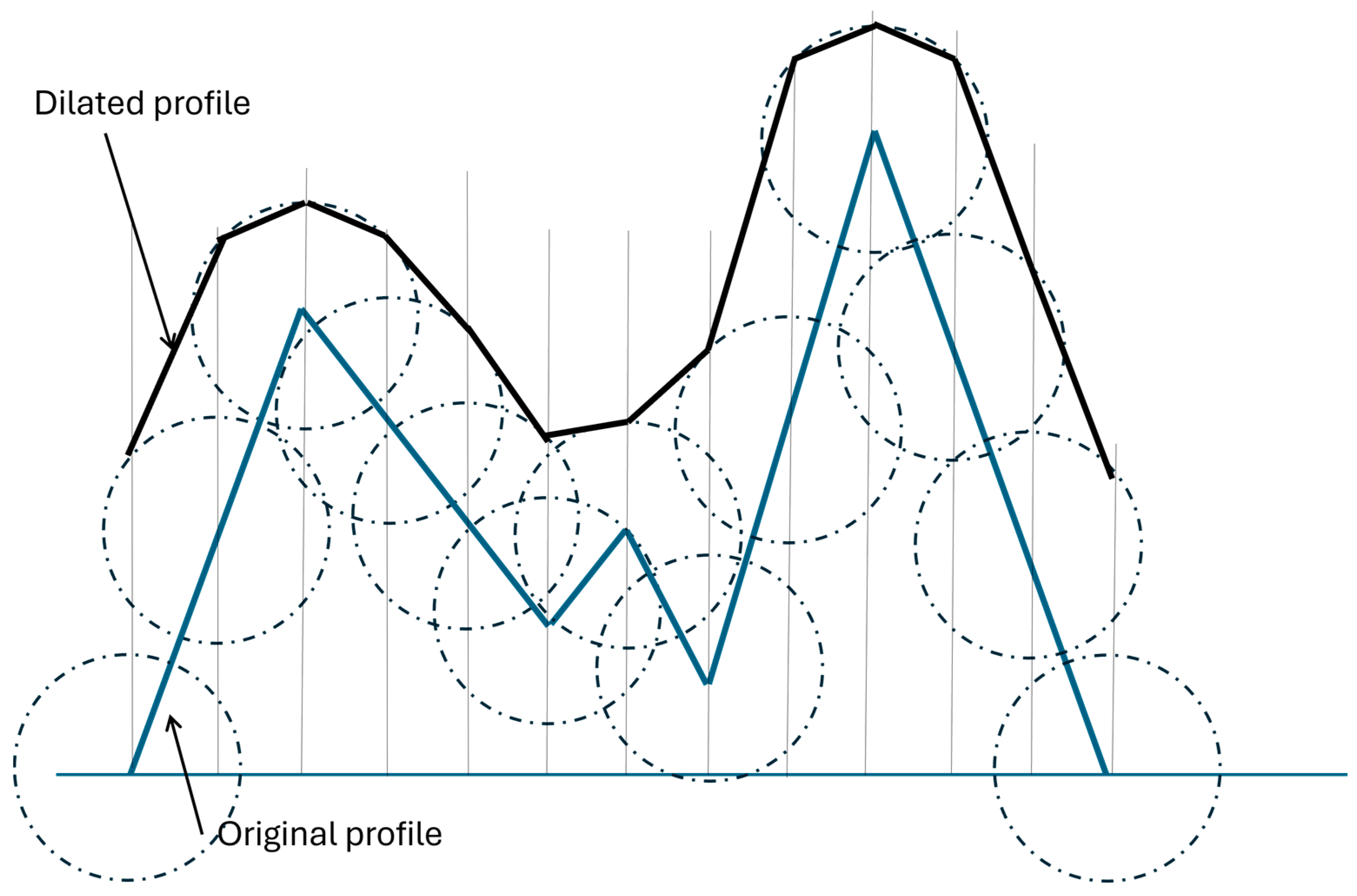

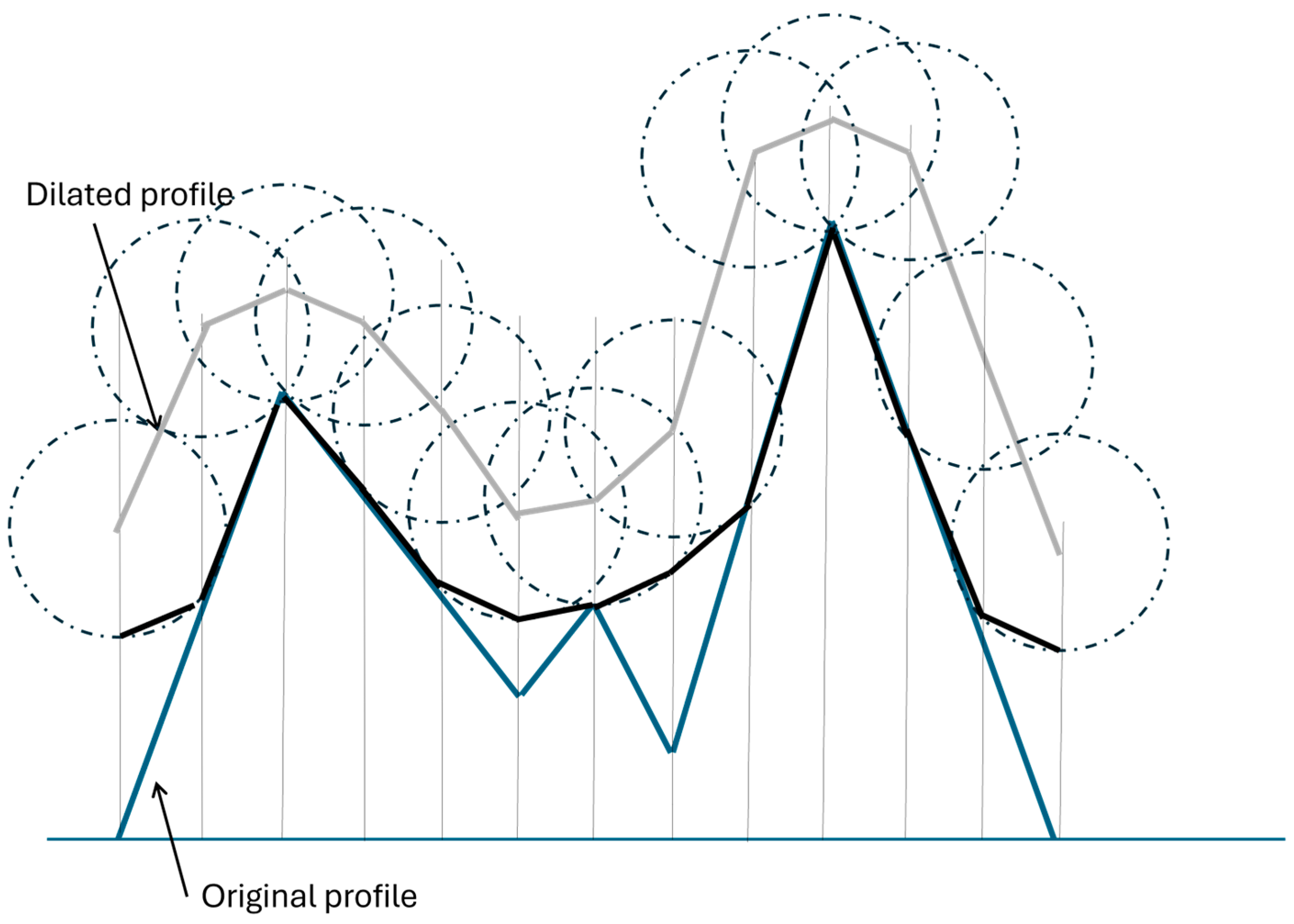

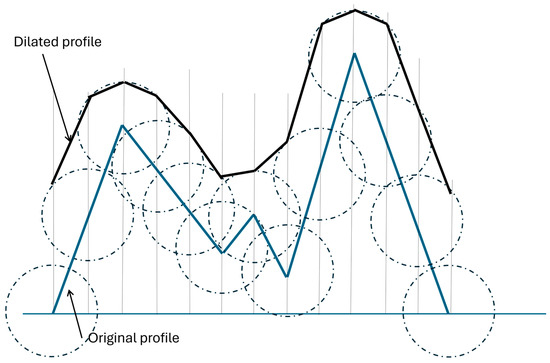

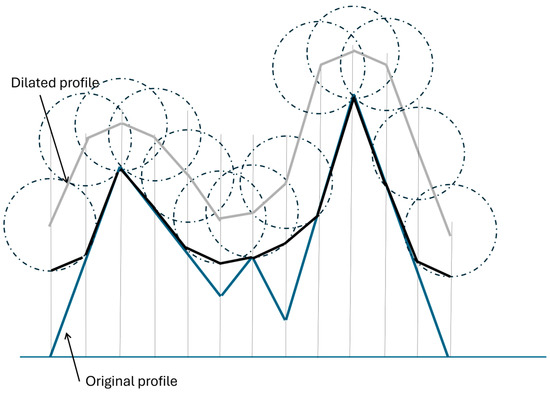

These filters are based on two types of primary operations, namely, dilation (Figure 6) and erosion [32]. Depending on the order in which these operations are performed, the filter is either opening or closing (Figure 7). The application of the dilation operations followed by the erosion operation, using a circular disc, would highly approximate what a morphological filter would do with a closing disc.

Figure 6.

Morphological dilation operation based on [9].

Figure 7.

Morphological closing operation based on [9].

Figure 6 and Figure 7 show graphically how a filtered profile evolves with an FPMCD filter. In Figure 6, the blue profile is the original, and the black profile is the profile resulting from the first morphological operation applied, which is dilation. In Figure 7, the dilated profile is shown in grey, and the filtered profile is shown in black. Comparing the filtered profile with the original one, it can be seen that due to the large diameter of the disc used, it does not come into contact with the bottom of the dales; therefore, in the final profile, these are reduced. It can also be seen that at the beginning and end of the filtered profile in Figure 7, there is an end effect in which there is a big difference between the original profile and the filtered profile due to the fact that there is no continuity in the data. This causes a distortion in the resulting profile; therefore, it is necessary to correct or discard these data.

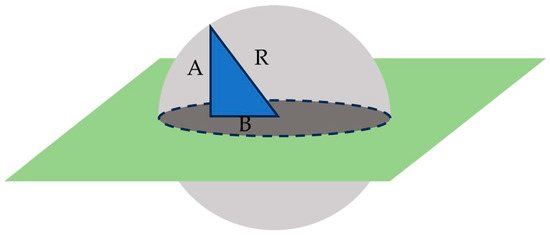

A matrix has been generated to implement the filtering, knowing that in this case the distribution between the data in the X and Y axis is constant. This matrix was used as a mobile window along the surface to apply the filter. It depends on the diameter of the filter to be applied, it simulates the shape of the sphere with trigonometric operations or Pythagorean Theorem, and its size depends on the diameter of the filter to be used. The matrix keeps the same distance between the data in the X and Y axis. The matrix used for filtering stores the distance between the diametric plane of a sphere (of the filter sphere) and the contour of the hemisphere of the sphere.

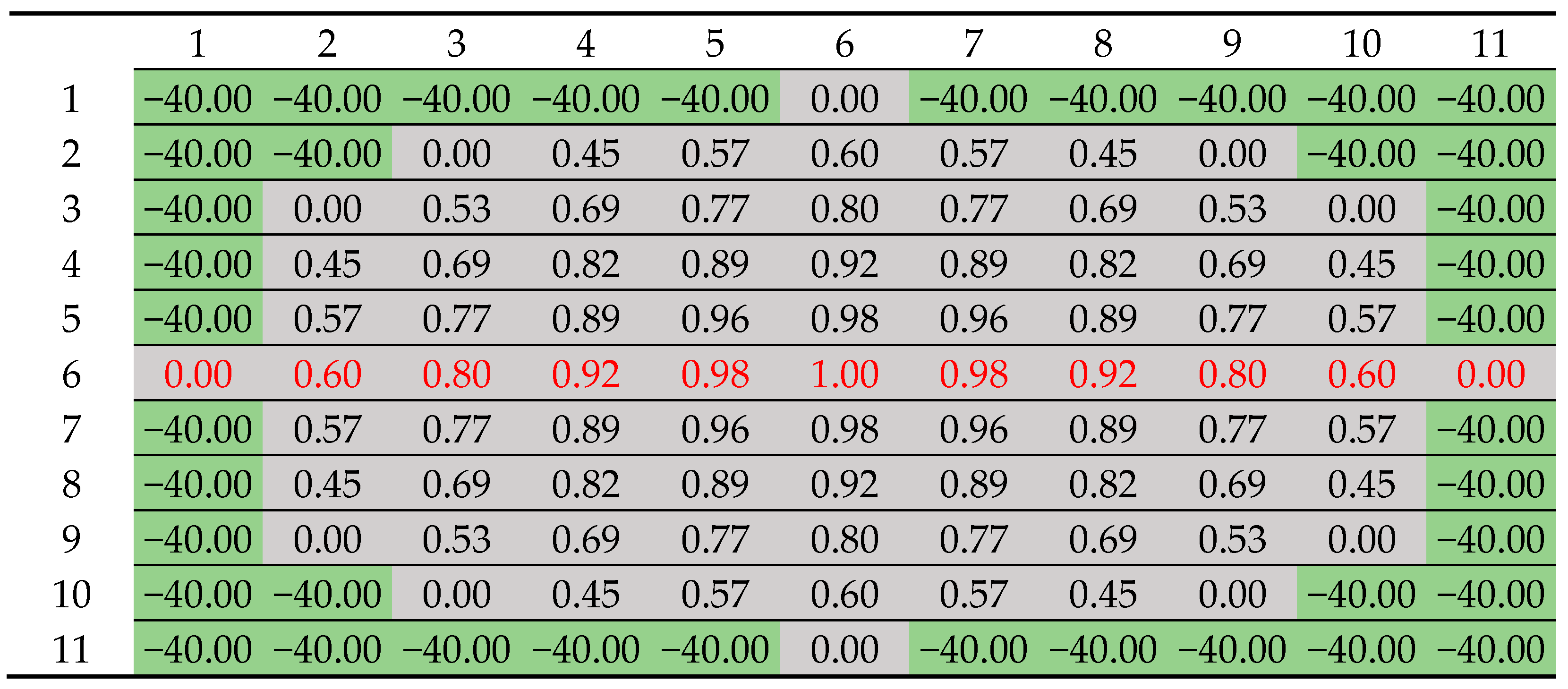

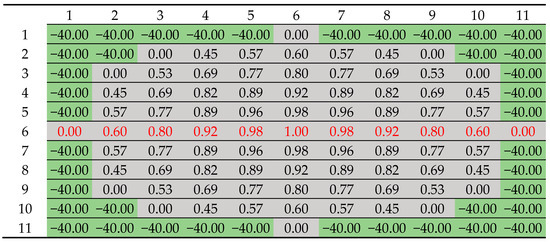

Figure 8 shows the values of the mask used for the 2 µm filter, and the groove standard for the surface morphological filter (FAMCB). The numbers in red represent the mask used for the morphological profile filter (FPMCD) of the same size.

Figure 8.

FAMCB filter matrix for 2 µm stylus size (values in µm).

The data represented in grey are the data corresponding to the inside or edge of the plane inside the sphere, and the values in green are the values on the outside. The grey values of the mask correspond to the heights of A (Figure 9) for all the points inside the sphere. It is important to remember that the inter-point distance in the mask must be the same as that of the surface or profile used. To ensure that the filter does not take into account the values represented in green, the parameter Sz, representing the distance between the highest peak and the deepest dale, has been calculated and multiplied with the value −2, to ensure that those values will not take in account values outside the sphere. Multiplying the surface Sz value or profile Rzt value by −2, any value outside the sphere is going to be lower than any point in the surface or profile.

Figure 9.

Sphere (particle) and diametric plane.

In order to be able to use the mask, it is important that the advance of the data on the X and Y axes coincides with that of the mask. Another important aspect is that the size of the mask must be odd to perform the operations, since the result of the mathematical operations will be stored in the position of the data that coincides with the centre of the mask. Due to do mathematical operations, it is necessary to have a value in the centre of the mask.

To apply the dilation and closure operations, it is necessary to go through the complete point cloud with the filter. First, dilation is applied, and after, closure operation is applied.

One way to perform the dilation operation is to add the filter matrix with the matching values in the data, to calculate the maximum value between them. For the closing operation, the data to which the dilation has already been applied are subtracted from the filter values and the minimum is calculated.

2.6. Parameters Evaluated

This paper deals with a first approximation of research that aims to calculate all the standardized roughness profile and surface parameters; therefore, only some parameters have been selected among all the existing ones. Particularly, parameters that are more widely used in the industry are selected.

For the calculation of the parameters, the guidelines of the UNE-EN ISO 25178-2:2023 [6] standards have been followed for the surface parameters and UNE-EN ISO 21920-2:2023 [33] for the profile parameters.

Table 2 lists all the parameters used for the paper. These are grouped into height, hybrid, material ratio parameters, and parameters for stratified surfaces.

Table 2.

Parameters evaluated.

2.7. Collection

Results were saved in the Matlab workspace and the same program that stored data was used to create the reports with the results of all parameters.

2.8. Analysis

These data will be specified in the results section.

3. Results

This section shows the results obtained for the profile and surface roughness parameters after filtering the surface and the profile with different stylus or particle sizes.

The units recommended by UNE-EN ISO 25178-3:2013 [34] and UNE-EN ISO 21920-3:2023 [35] have been used to represent the results obtained.

As the areal material ratio and length bearing rate height parameters depend on another data besides the surface or profile. For the calculation of the and parameters, a value of c = 10 % (which is the value that UNE-EN ISO 25178-3:2013 [34] establishes for the p parameter for the calculation of ) has been used as input, and for the calculation of and , the previously calculated value of and has been used.

In the tables in this section, some parameters are shown in red and others in orange. In red are shown parameters with large variations and in orange parameters with significant but not so large variations.

3.1. Evaluation for the Random Surface

Table 3 and Table 4 show the results for the areal roughness parameters for particle sizes from 2 µm to 100 µm.

Table 3.

Results of the surface roughness of the original and filtered clouds (2–15 µm).

Table 4.

Results of the surface roughness parameters of the filtered clouds (21–100 µm).

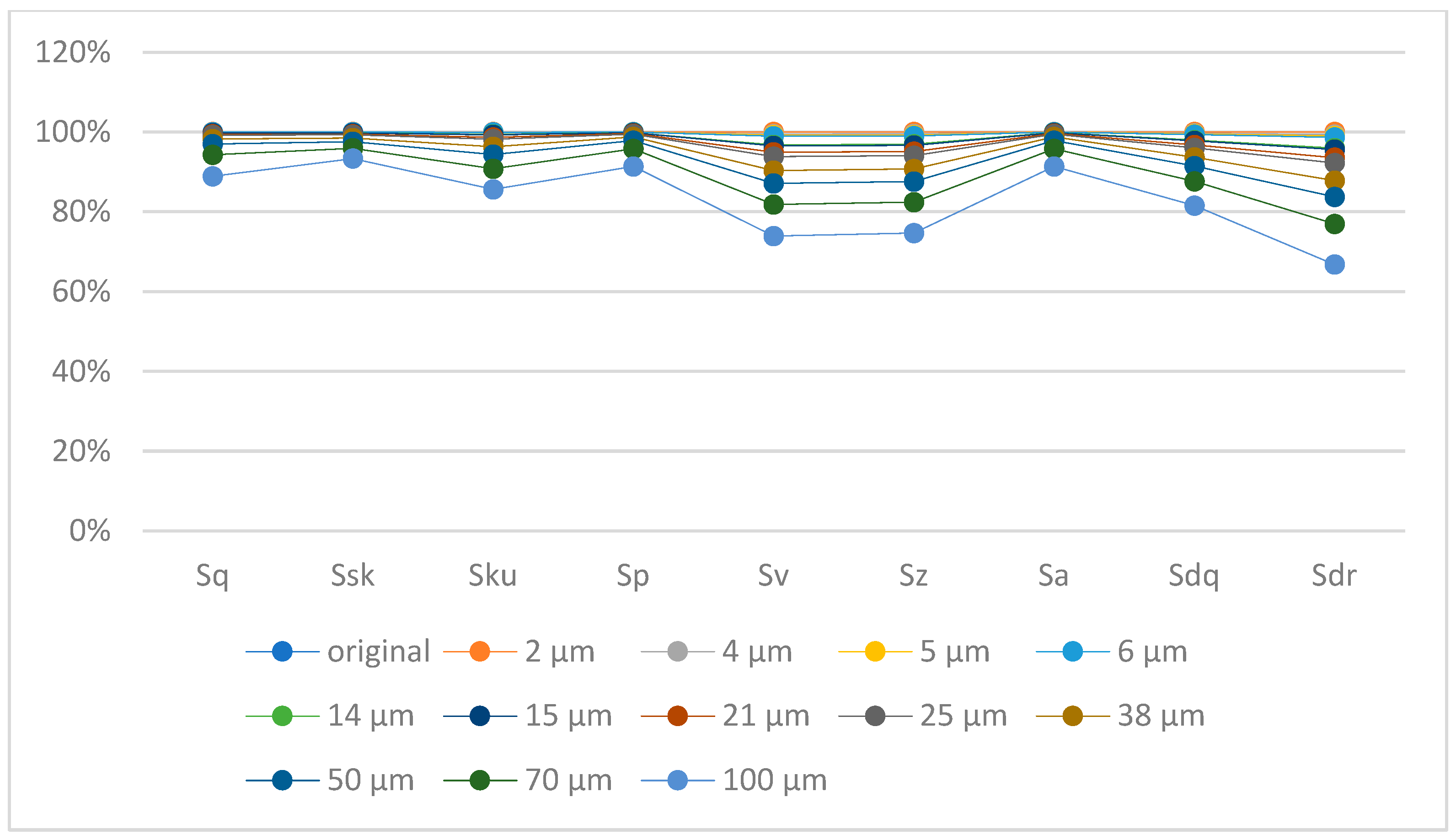

Looking at the results in the tables above, it is evident that the parameter most affected by the increasing particle size is the Sdr parameter. This parameter exhibits the greatest variation on the unfiltered surface, a value of 8.6407%, which decreases to 1.41301% on the 100 µm filter. The Sdr parameter is the ratio between the interfacial surface and the projected surface; therefore, it makes sense that when a filtering operation is applied, it is considerably reduced, since the variation between peaks and dales will be reduced. Therefore, the interfacial surface will be reduced as well.

Another parameter that has a large variation is Sdq, which on the unfiltered surface is 0.4304 rad, and for the 100 µm filter, it is 0.169 rad. The parameter calculation is based on the gradient of the surface when enlarging the filter size.

The Ssk parameter varies from −0.0056 to 0.3102. This parameter evaluates the level of asymmetry in the surface height distribution.

The parameters Svk, Svkx, and Sak2 also have a remarkable variation. Svkx ranges from 4.4962 µm to 2.2335 µm, and Sv is reduced to almost half of its initial value.

Some parameters increase with an increasing particle size, and others are reduced. The Sku parameter is one of the parameters that increases with the size of the filter, but the most curious thing is that it exceeds the limit of 3. When Sku has a value of 3, the distribution of the surface in height is normal; when it has a value below 3, the distribution is uniform, and above 3, it is sharp [36].

The graphs in Figure 10 show two point clouds; the one on the left is the original one and the one on the right is the one resulting from applying a 70 µm FAMCB filter. A clear reduction in the depth of the pits is observed.

Figure 10.

(a) Original point cloud discarding the points that, once filtered, are affected by the end effect. Z (height in µm), X, and Y (horizontal displacement in µm). (b) Point cloud resulting from filtering with the 70 µm filter. Z (height in µm), X, and Y (horizontal displacement in µm).

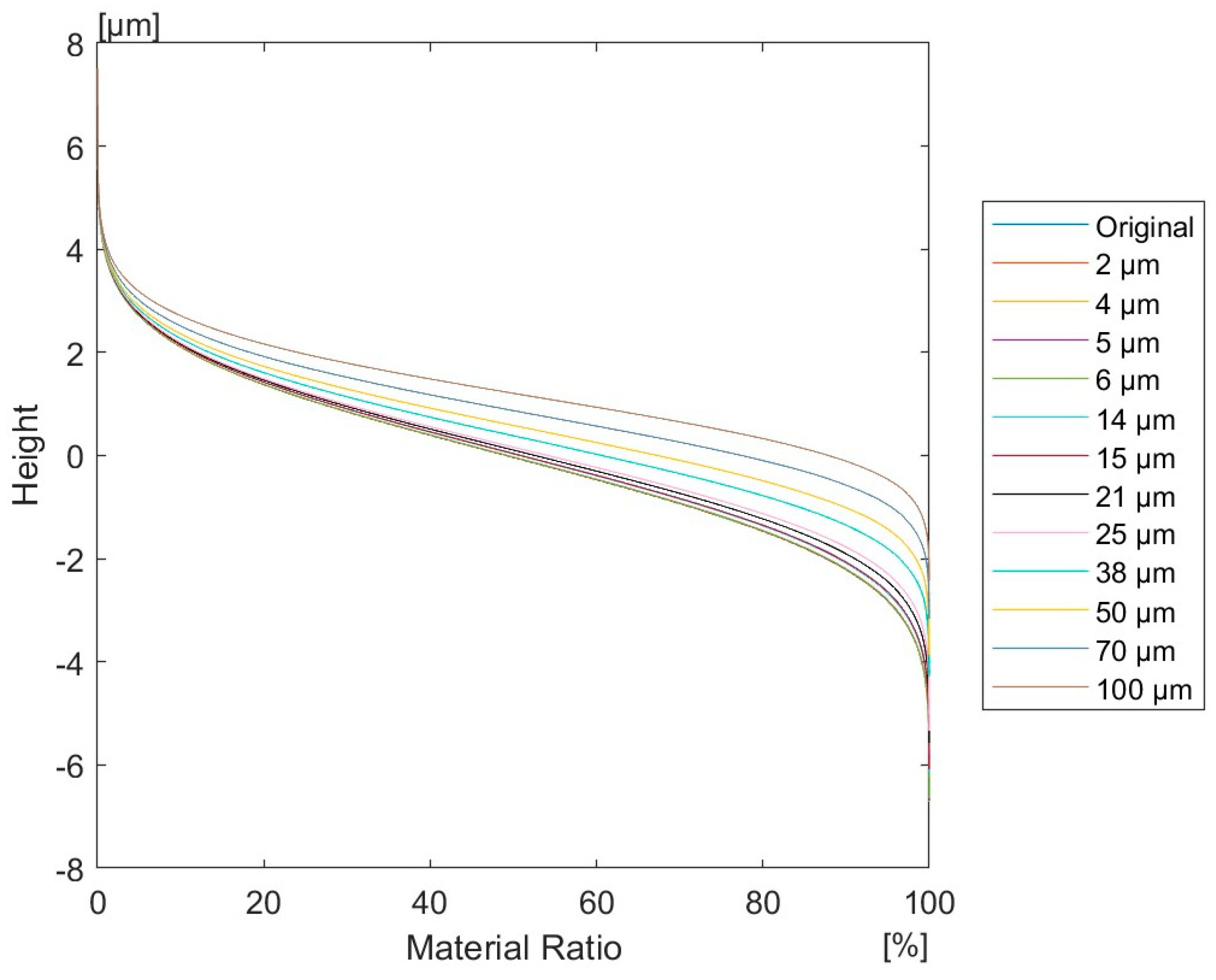

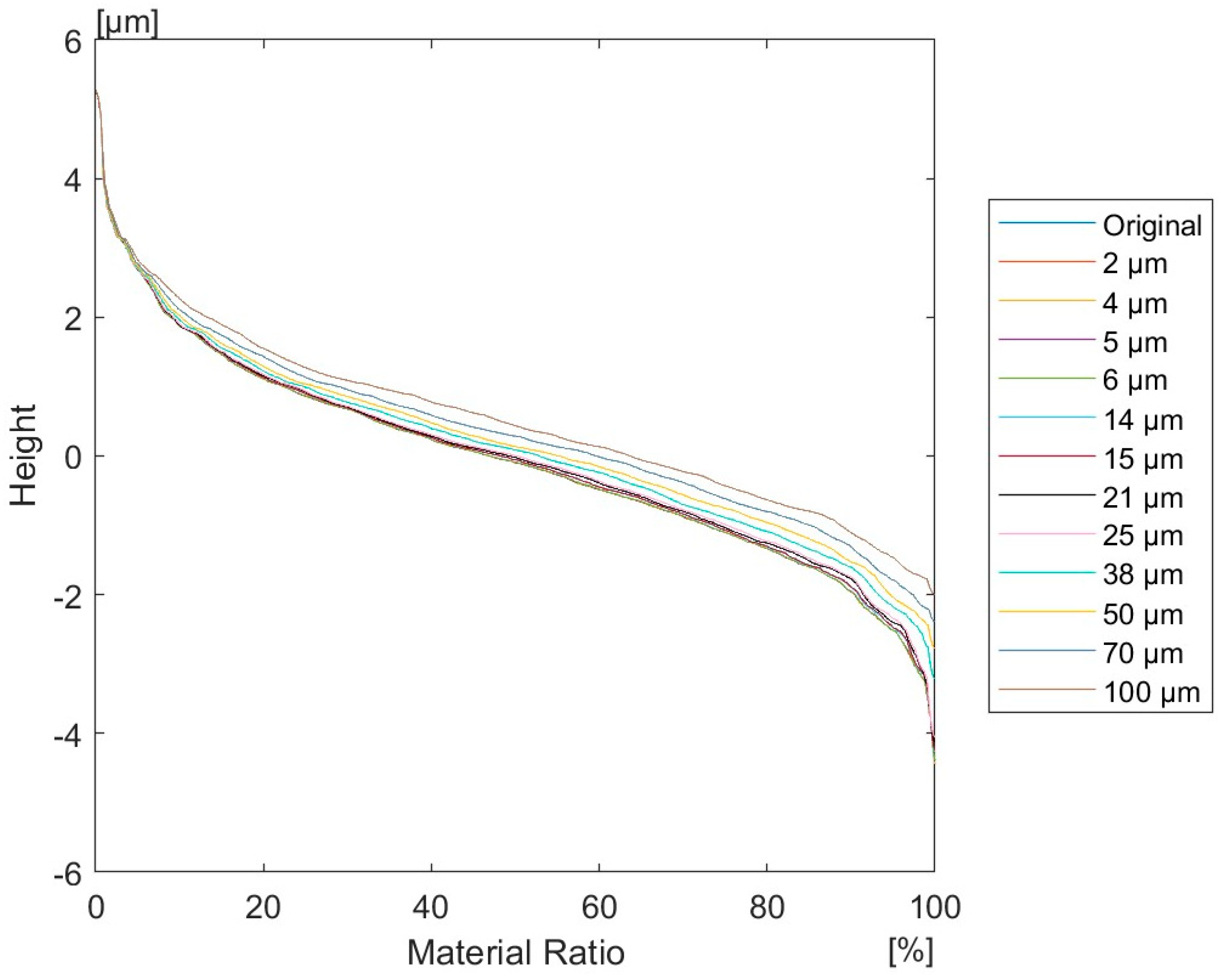

The material ratio curve describes the surface texture. It is a graphical representation of the surface or profile material ratio of the scale-limited surface or profile as a function of an intersection level. This curve represents the percentage of points (horizontal axis) above a given height (vertical axis). The left side of the curve corresponds to the highest points of the surface and the right side to the lowest points. Therefore, it makes sense that the right part of the curve is more affected with an increasing filter or particle size.

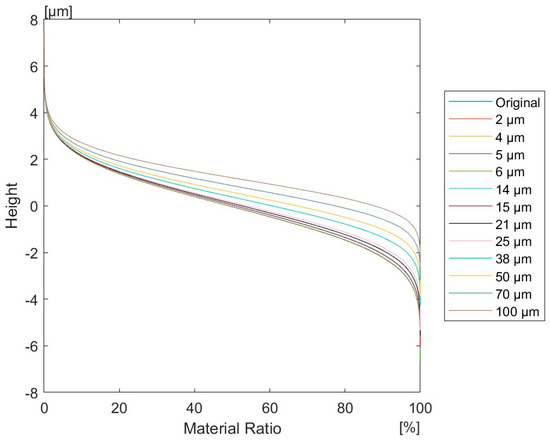

Figure 11 shows the areal material ratio curve for the created surface. It is shown that the secant of the curve becomes smaller with an increasing filter size. The reduction in this curve results in a reduction in the Sk parameter. The curve shows a reduction in the size of the dales at around 2 µm.

Figure 11.

Material ratio curves of the original and filtered point cloud with various filter sizes. Vertical axis (height in µm) and horizontal axis (Material ratio in %).

In the original curve for a height of 0 µm, there is 49.1694% of the surface data above this intersection level. But once the morphological filter of 100 µm is applied, the dales are reduced and 87.7874 % of the data are above that height. The Smc and Smr functions are the ones that relate the height to the material ratio curves.

In Smr, a height is given as a datum and gives the material ratio as a result, and in the case of Smc, a probability is given as a parameter and calculates the height to which it corresponds.

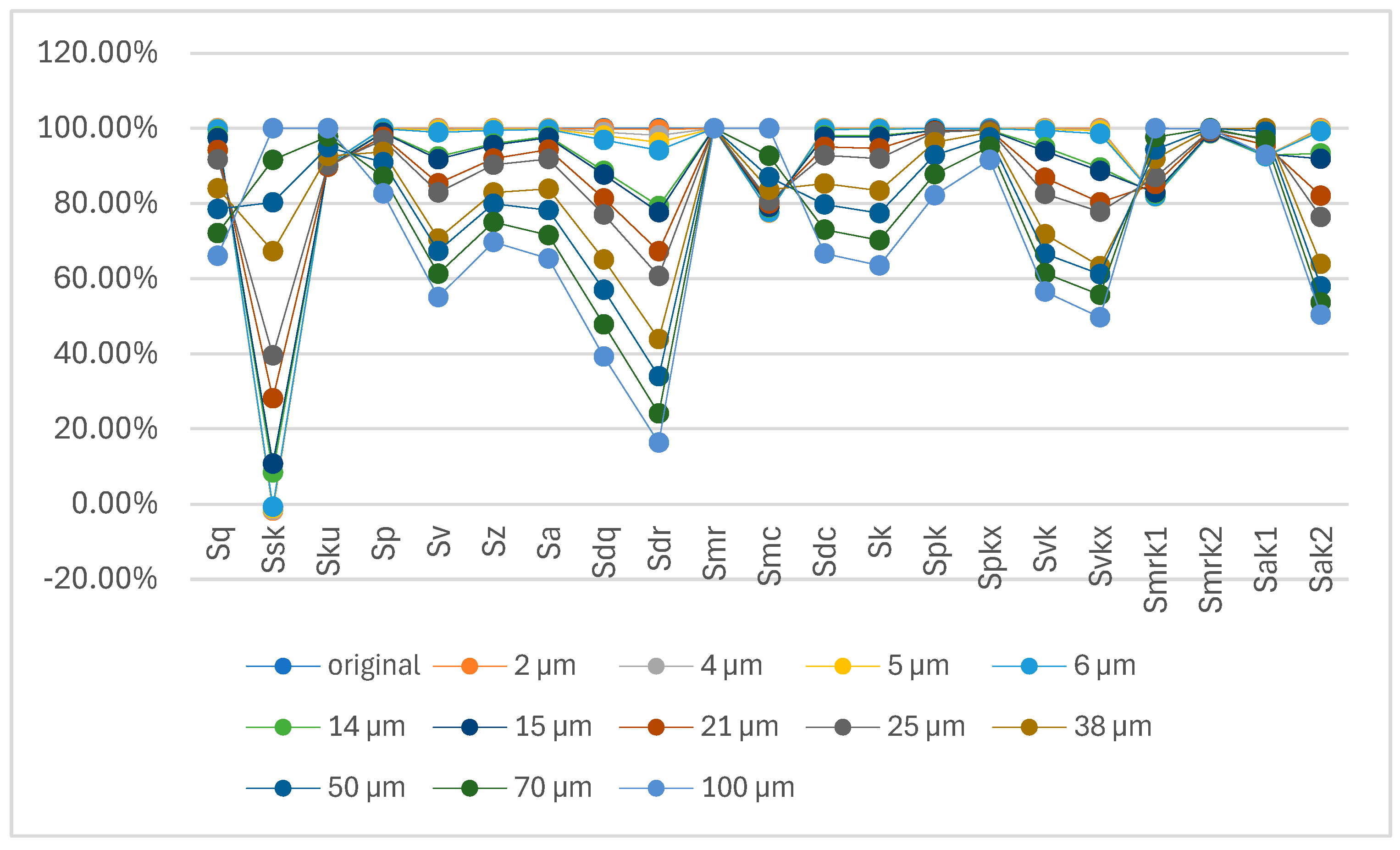

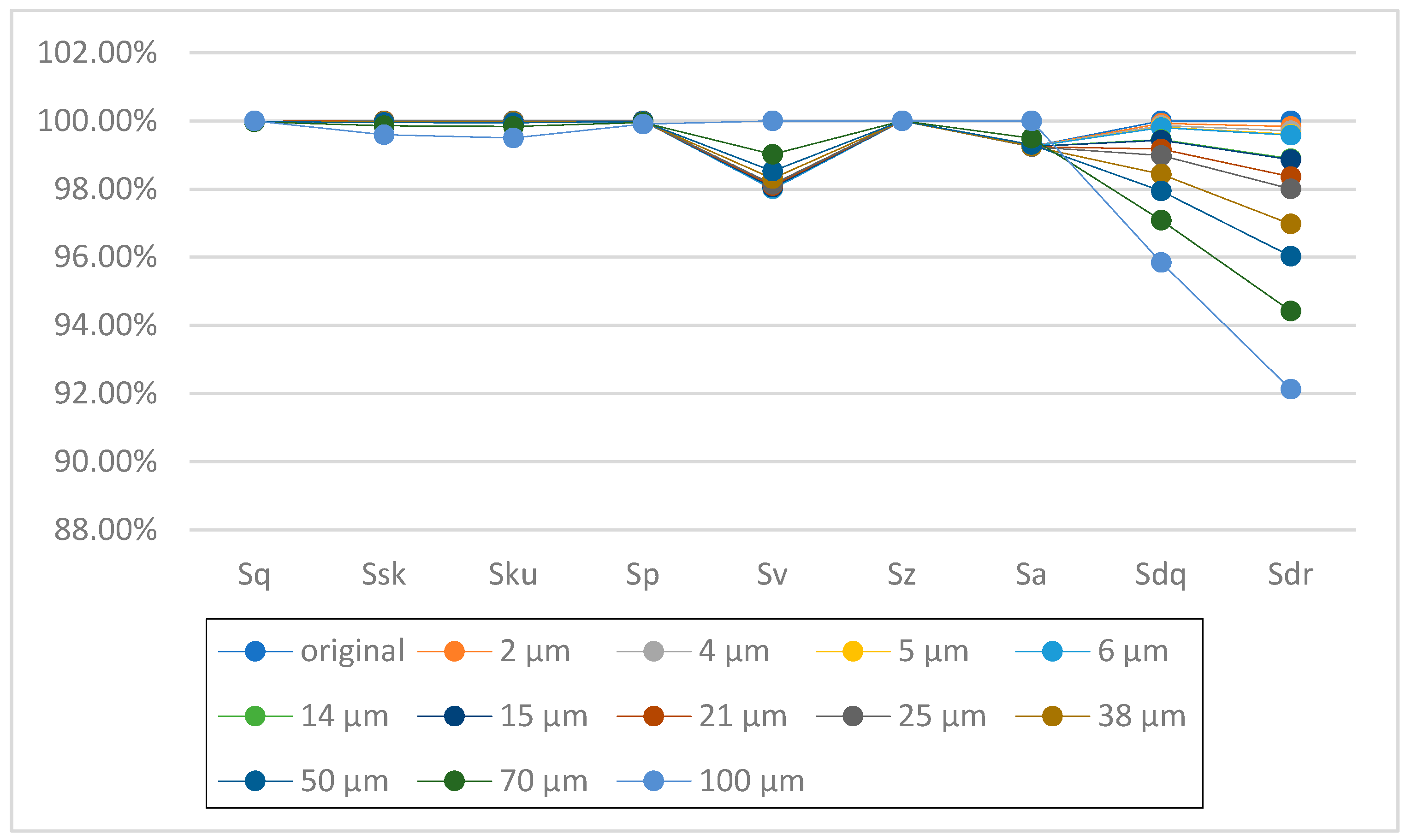

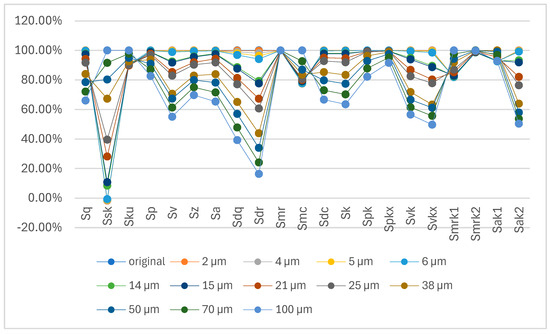

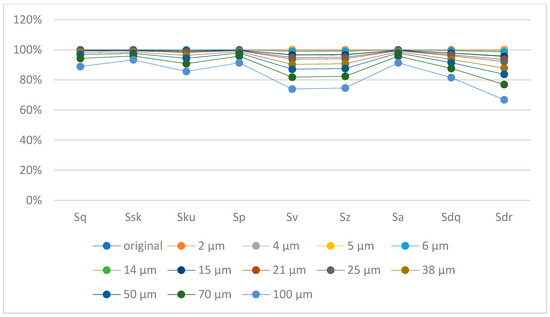

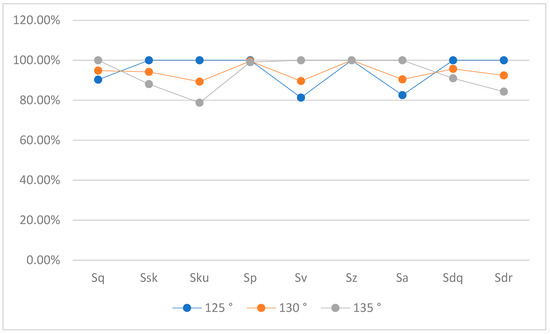

In Figure 12, the evolution of each areal roughness parameter is observed with the filter size increasing.

Figure 12.

Graph of the variation in results between original and filtered point clouds.

3.2. Evaluation for Profile

For the evaluation of the profile roughness parameters, the first profile after removing all data affected by the end effect was used. This profile corresponds to 1002 of the original random surface. This evaluation could have been performed with any of the profiles. For the evaluation of the profile parameters, a disc of the same diameter as the particle has been used instead of a sphere, since we are working in two dimensions and not in three.

Table 5 and Table 6 contain the results of the calculation of the profile roughness parameters of the original and filtered profiles.

Table 5.

Results of the profile roughness of the original and filtered clouds (2–15 µm).

Table 6.

Results of the profile roughness parameters of the filtered clouds (21–100 µm).

The parameter with the greatest variation is Rdr, which starts at 4.2369% and ends with a value of 0.9790%. The Rkvx parameter also shows significant evolution, changing from 2.4678 µm to 0.7963 µm. Rak2 starts at 69.9784 µm2/mm and ends at 30.0181 µm2/mm; this may seem like a large change, but it is due to the unit of this parameter. Rvk also has considerable evolution, exceeding 50%, starting at 1.4236 µm and ending at 0.6862 µm. Rdq also varies significantly, from 0.2986 rad to 0.1406 rad.

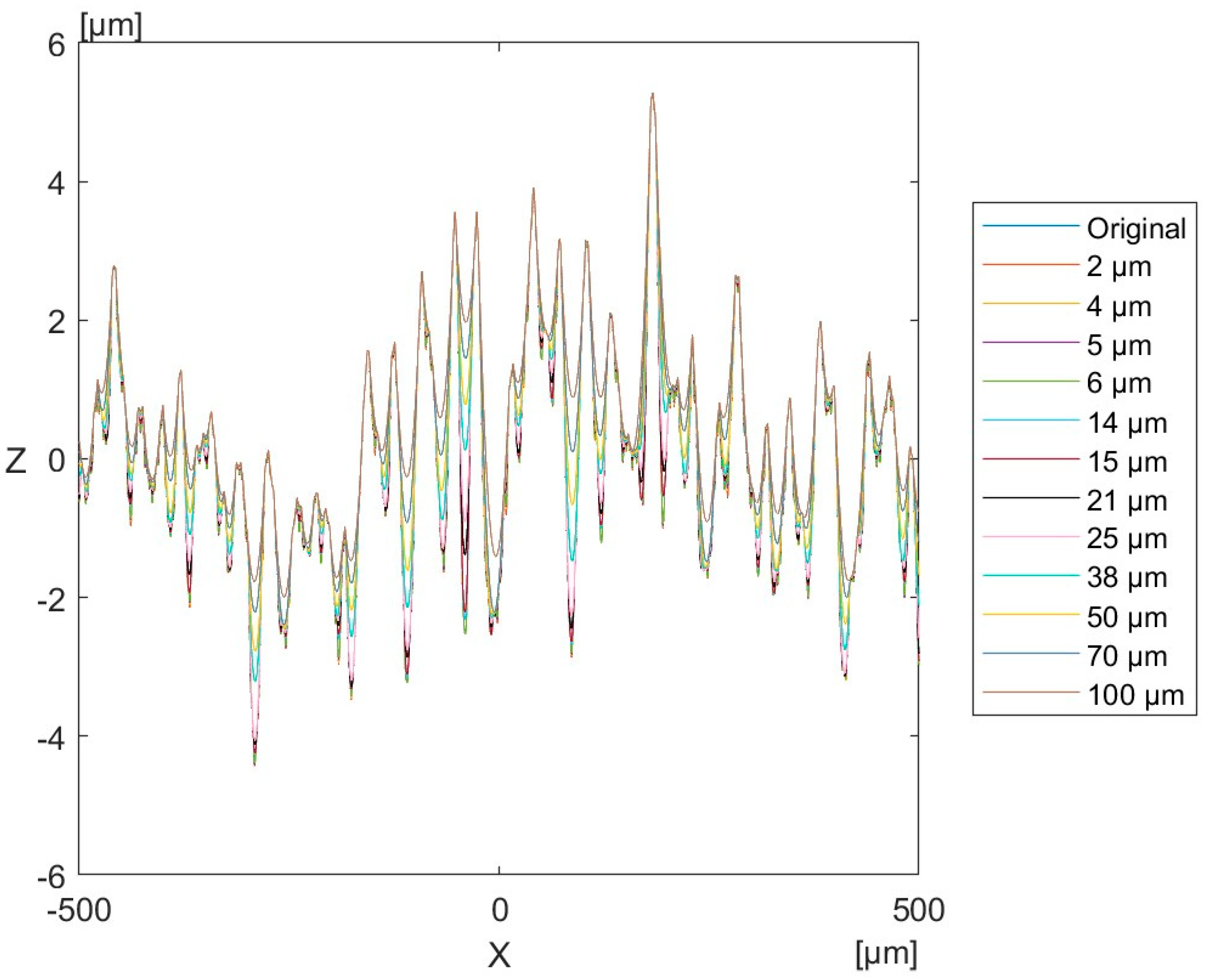

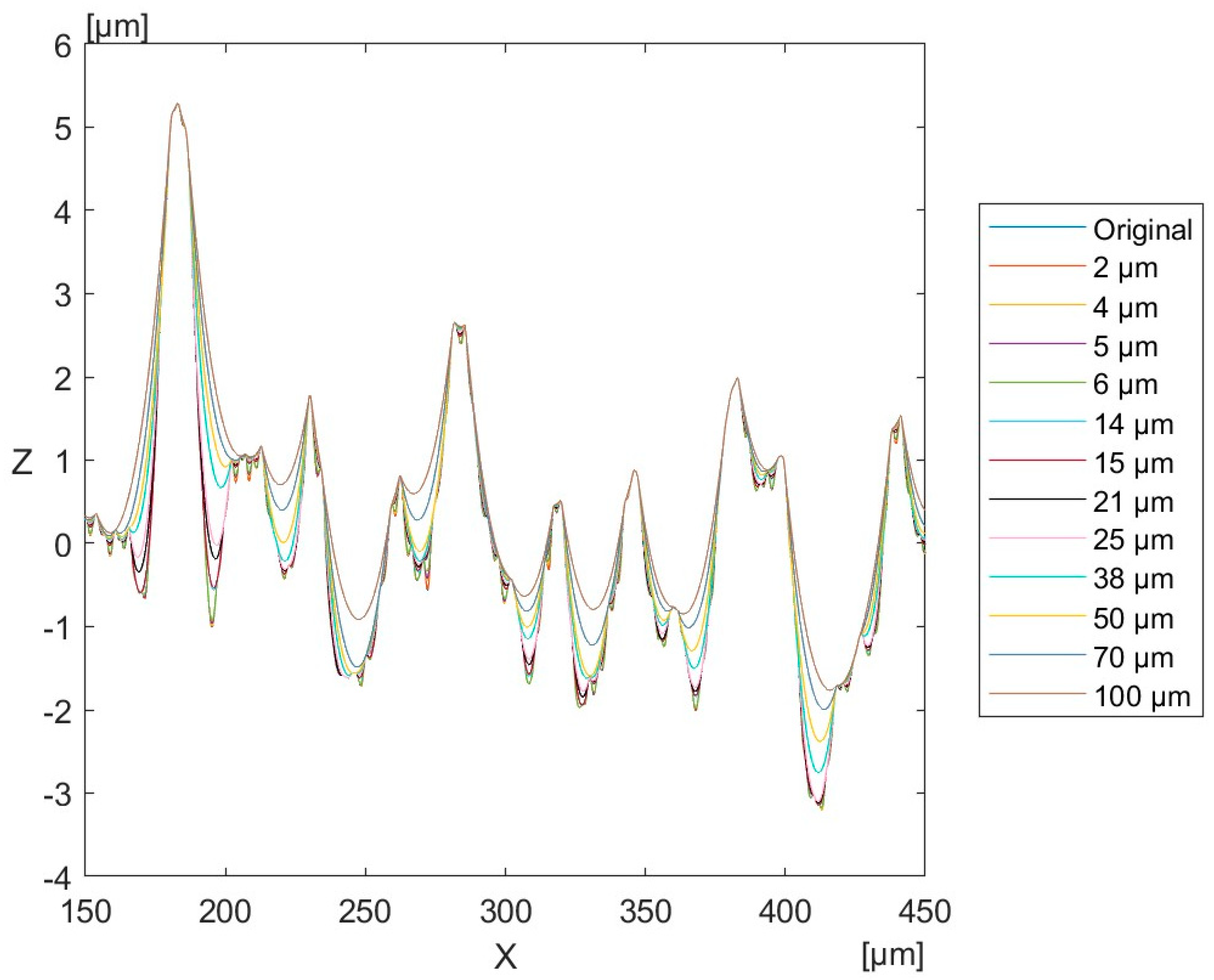

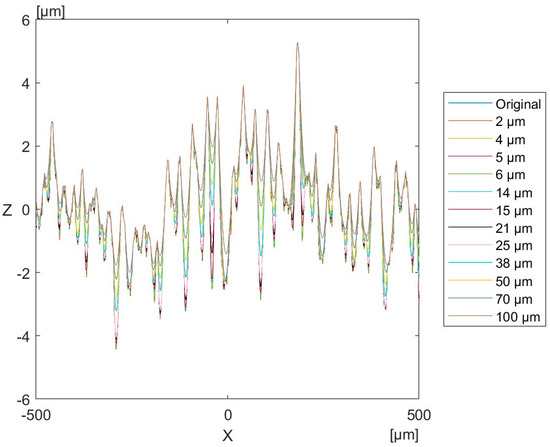

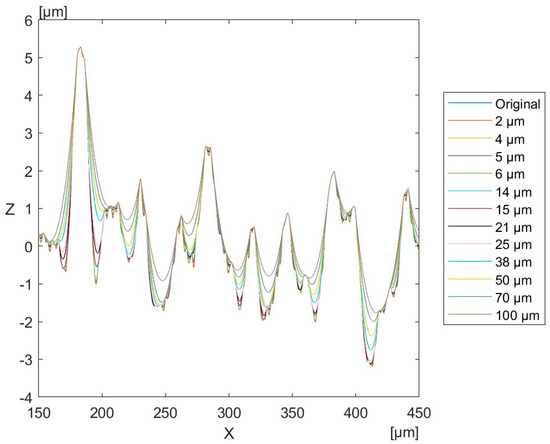

The results obtained from the profile filtering of the original point cloud profile 1002 (which is the first profile after removing the end effect of the biggest FAMCB filter used in the paper) and the calculation of roughness parameters for the profile are shown below. Figure 13 shows the selected and fitted profile with all the selected stylus sizes. Figure 14 shows a part of this profile, which has been trimmed so that the behaviour of the FPMCD filter for the peaks and dales of the profile can be observed.

Figure 13.

Original profile and filtered profile with different sizes. Z (height in µm) and X (horizontal displacement in µm).

Figure 14.

Original and filtered profiles expanded. Z (height in µm) and X (horizontal displacement in µm).

Figure 14 shows the profile expanded to better appreciate the differences between different particle sizes.

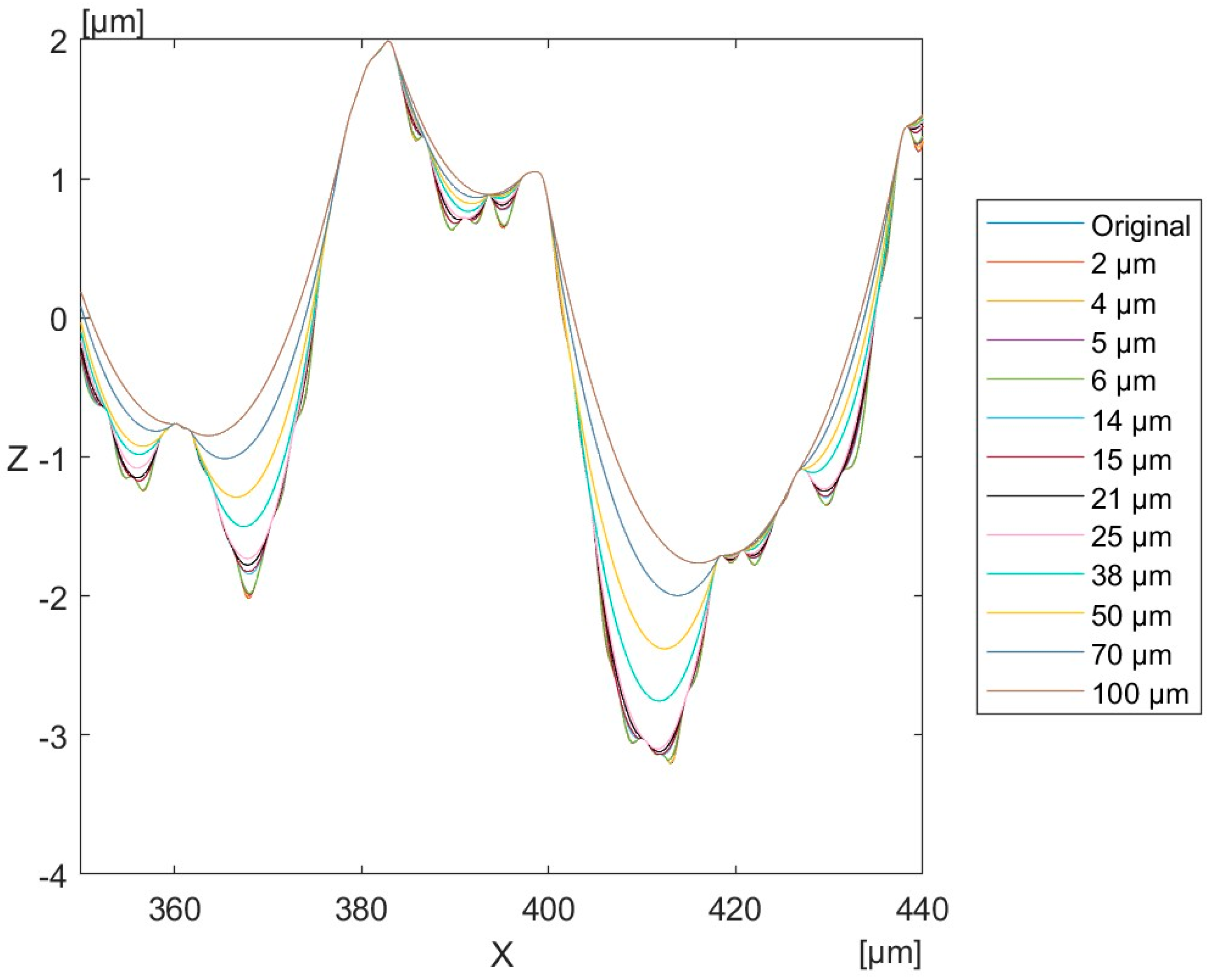

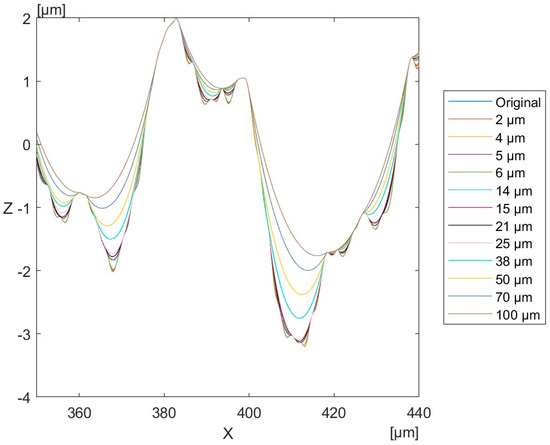

Figure 15 shows a detailed enlargement in the 340–440 um range of the X order.

Figure 15.

Original and filtered profiles greatly expanded. Z (height in µm) and X (horizontal displacement in µm).

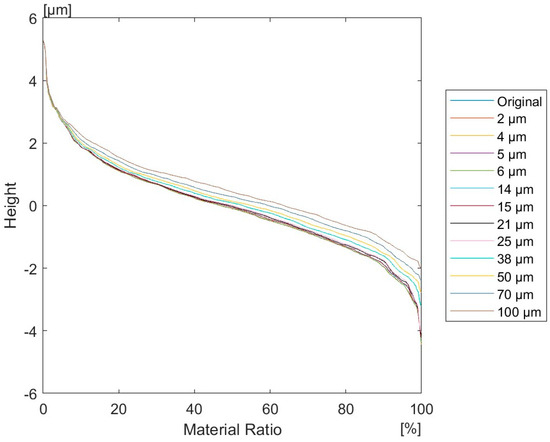

Figure 16 shows the evolution of the material ratio curve with an increasing stylus size and the comparison with the original profile. With the increase in the filter size, a clear reduction in the profile dales can be seen on the right side of the curve, reducing the depth of the dales by about 2 µm for the 100 µm filter.

Figure 16.

Comparison of the material ratio curve of the original and filtered profiles. Vertical axis (height in µm) and horizontal axis (Material ratio in %).

Comparing this curve with the one in Figure 11, it can be seen that it has a more irregular shape; this is due to the fact that as it is only a profile, and not the complete surface, many fewer points are used to generate it and it has some small undulations.

Reviewing the filtering of the dales, it can be seen that up to 25 µm, it only filters the small dales, but from 38 µm onwards, it starts to reduce larger dales.

A notable reduction in the dales is observed in the bearing capacity curve, as the dales decrease by at least 2 µm. A reduction in the minimum secant of the curve is also observed, which could lead to an increase in the Rmrk2 parameter and a reduction in the core (Rk) of the profile.

The reduction in the minimum secant with an increasing particle size is smaller than that at the surface.

In the original profile for a height of 0 µm, a bearing rate of 46.8106% is observed, and in the filtered profile curve with a particle size of 100 µm, a bearing rate of 63.6873% is observed.

The difference between the two material rate curves for the surface is greater than in the case of the profile.

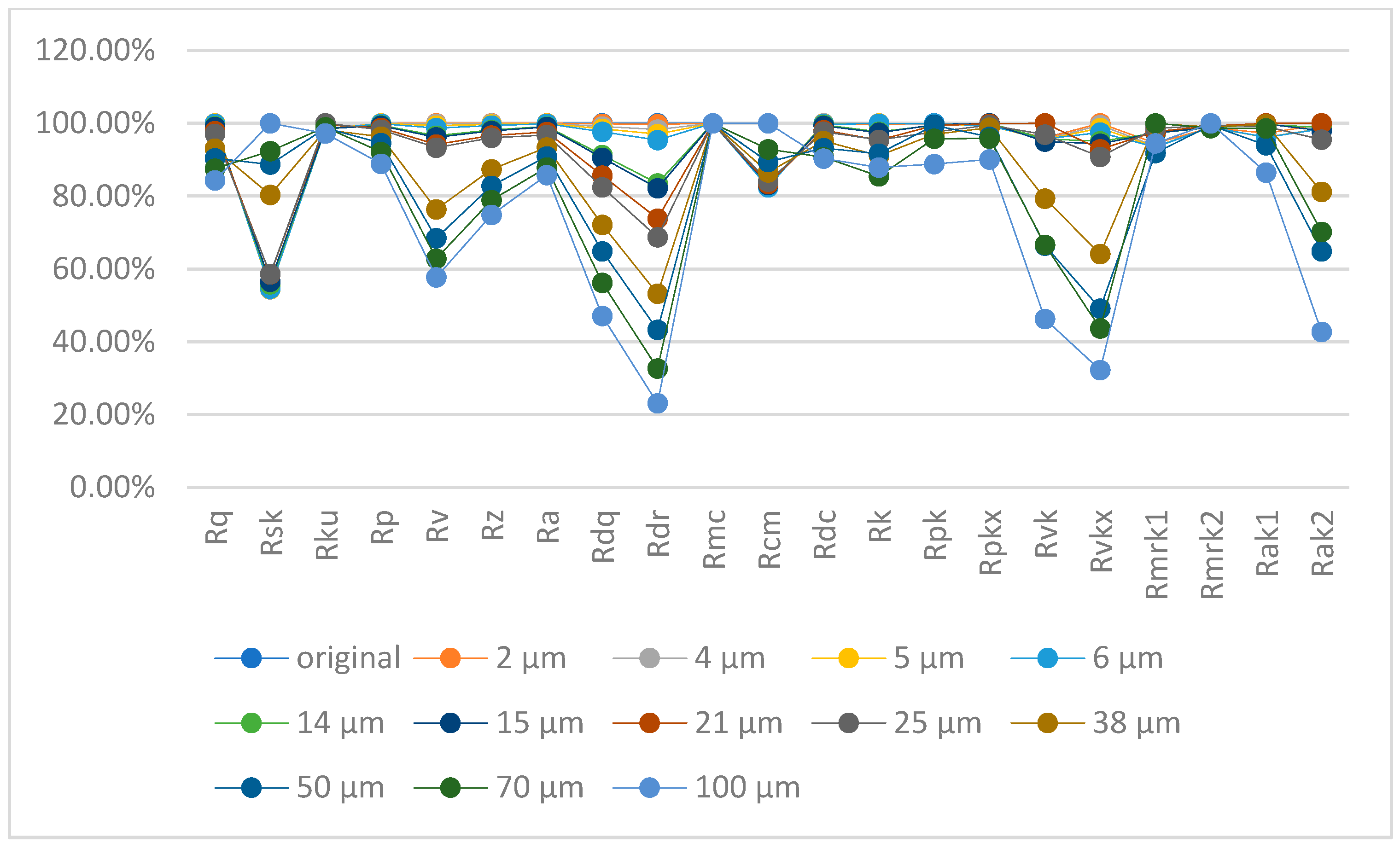

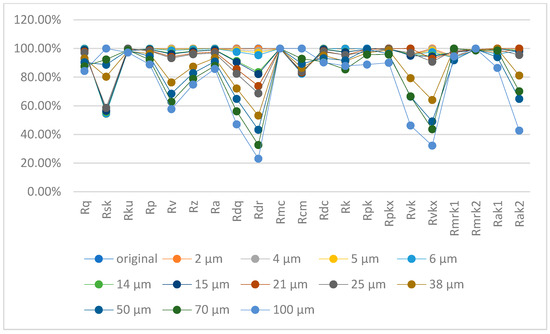

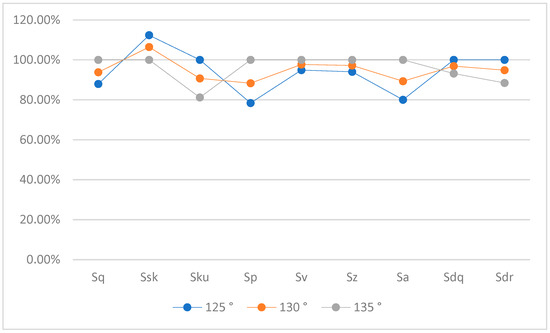

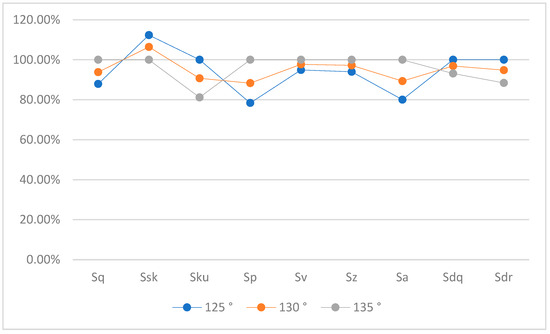

Figure 17 shows the evolution of each profile roughness parameter as a percentage for each of the filter sizes analysed.

Figure 17.

Graphical representation of the evolution of the areal roughness parameters in the surface for each analysed filter.

This graph presents a similar aspect to that of Figure 12, although in this case the Rsk parameter does not present such a severe variation graphically, as occurs with Ssk. This is due to the fact that in the case of the random surface, the Ssk parameter changes sign, and graphically, it seems that the change is much greater.

The previous graph shows a great evolution in the results of the parameters Rdr, Rvkx, Rvk, Rak2, and Rdq. The variation in Rdr is almost 80%.

3.3. Evaluation for Groove and Peak Standard

As explained above, in addition to the random surface, groove and peak standards have also been generated in order to clearly appreciate the effect of the filtering on the peaks and dales.

3.3.1. Comparison of Results of Standard with α = 130°

In this section, the variation in the surface roughness parameter results for the peak and groove standards is analysed.

Table 7 and Table 8 contain the results of the calculation of the surface roughness parameters of the original and filtered groove standard.

Table 7.

Results of the areal roughness parameters of the original and filtered groove standard (2–15 µm).

Table 8.

Results of the areal roughness parameters of the filtered groove standard (21–100 µm).

There is a large difference in the results obtained for the Sdr parameter, ranging from 0.8842 µm to 0.5906 µm. the Sz parameter also has a considerable difference in its value, which is originally 20 µm, and ends up being 14.9345 µm. The Sv parameter has a variation similar to that of Sz, starting at 19.1335 µm and ending at 14.1429 µm.

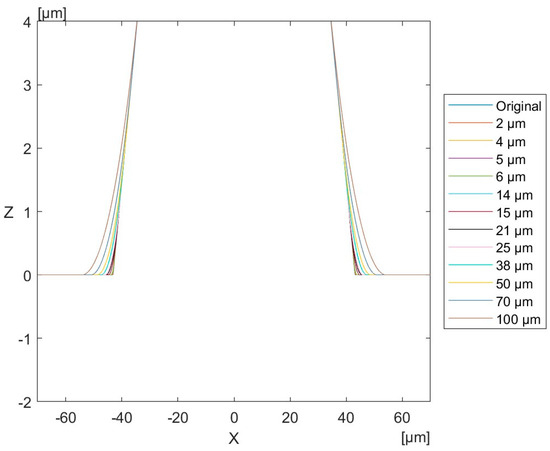

Figure 18 shows the evolution of the groove with an increasing particle size. A reduction in the dale size of around 25% is observed for a filter size of 100 µm.

Figure 18.

Graphical comparison of the shape of the original and filtered groove standard. Z (height in µm) and X (horizontal displacement in µm).

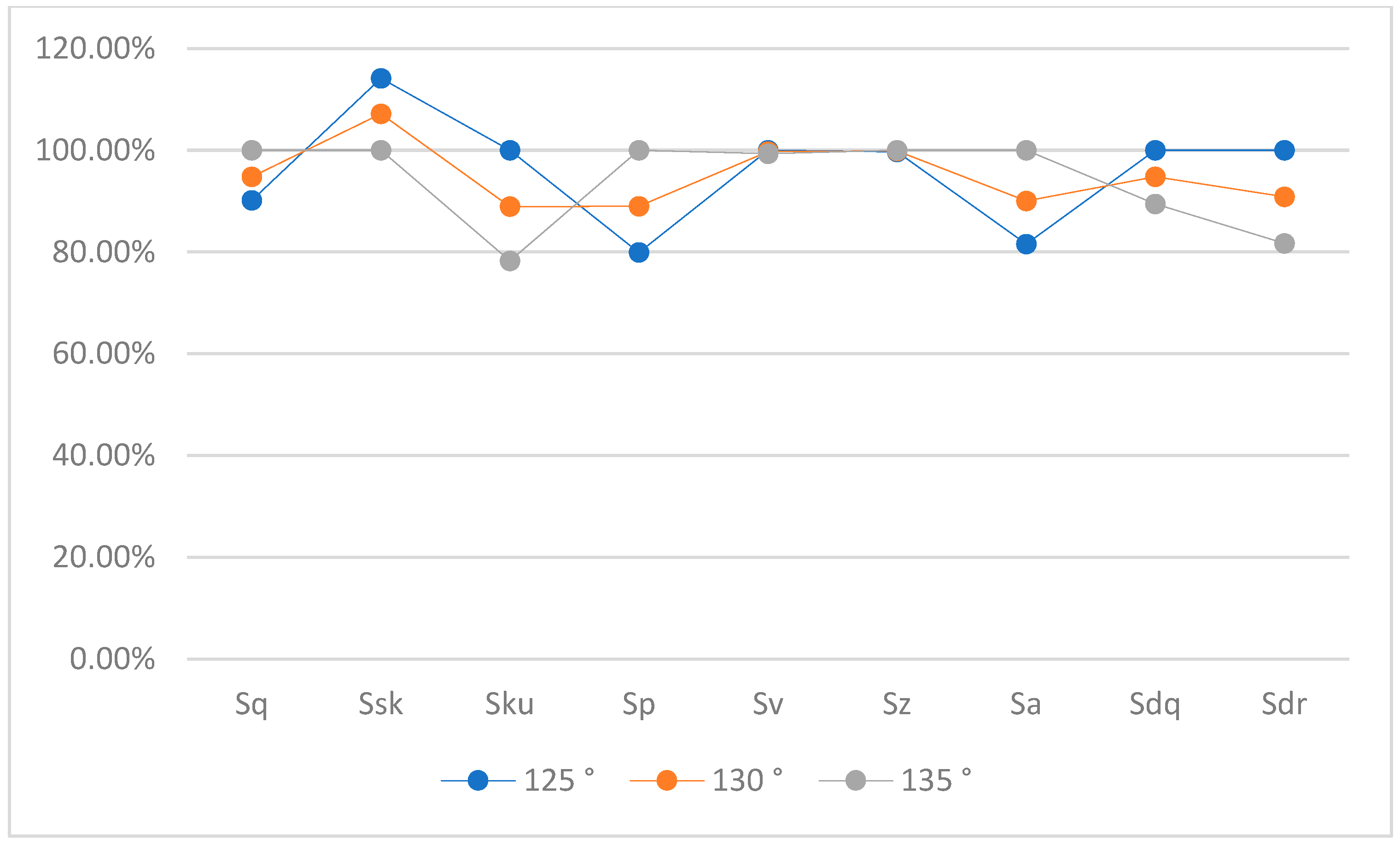

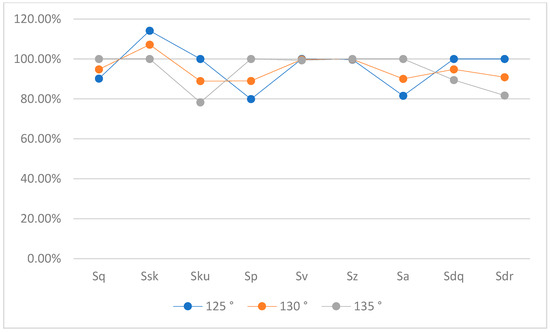

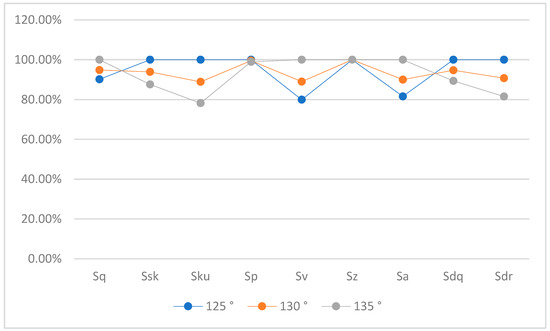

Figure 19 shows the evolution of each surface roughness parameter as a percentage for each of the filter sizes analysed for the groove standard.

Figure 19.

Graphical representation of the evolution of the areal roughness parameters in the groove standard for each analysed filter.

It is curious that, being a groove standard, all the parameters are reduced with the increase in the particle size.

Table 9 and Table 10 contain the results of the calculation of the surface roughness parameters of the original and filtered peak standard.

Table 9.

Results of the areal roughness parameters of the original and filtered peak standard (2–15 µm).

Table 10.

Results of the areal roughness parameters of the filtered peak standard (21–100 µm).

There is a large difference in the results obtained for the Sdr parameter, ranging from 0.8842 µm to 0.8146 µm.

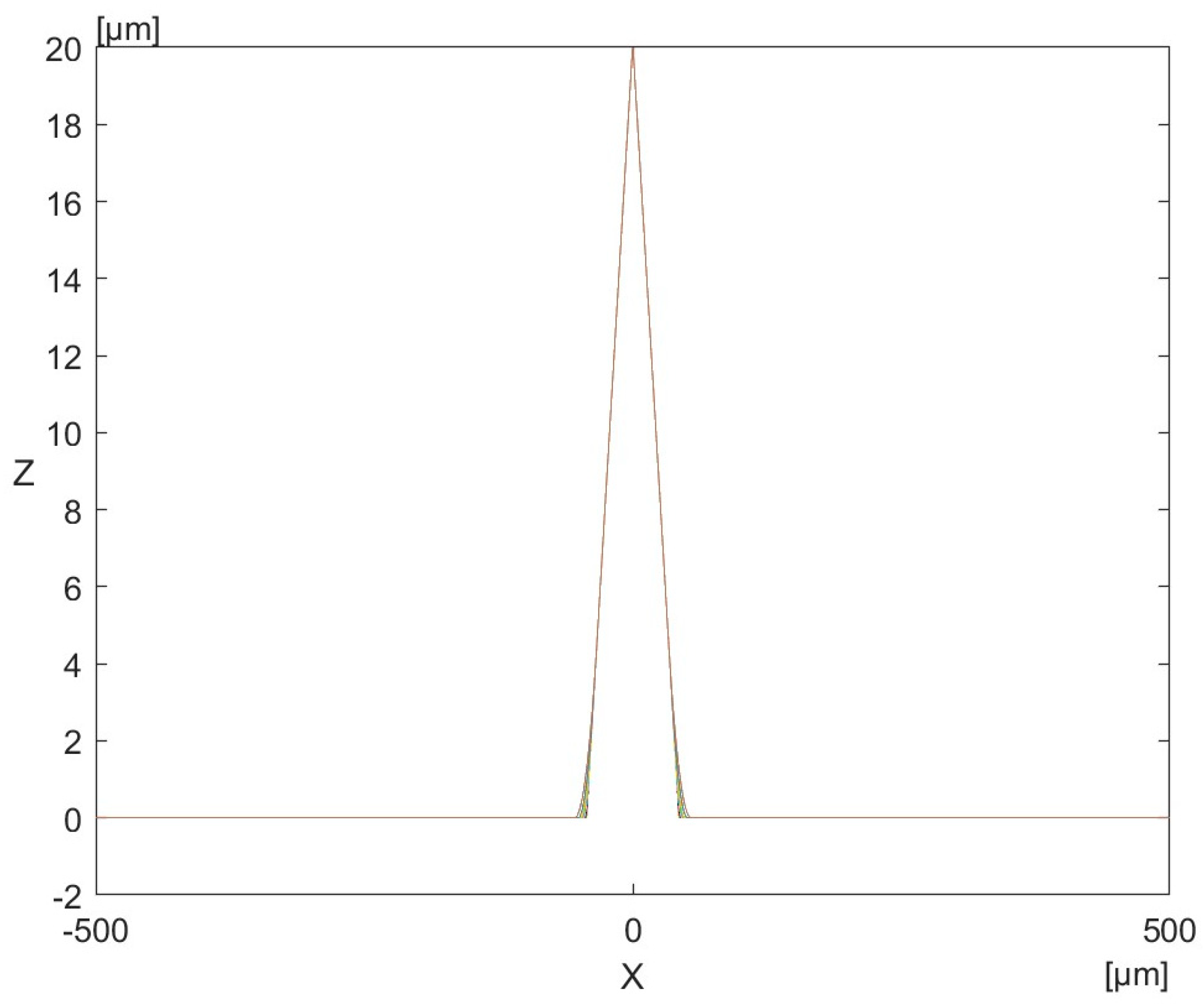

Figure 20 shows the graphical comparison of the shape of the original and filtered peak standard. The variations are only seen at the lower rounding radii. As this is a morphological closing filter, as is the case with the random surface and the profile, the peak is not affected.

Figure 20.

Graphical comparison of the shape of the original and filtered peak standard. Z (height in µm) and X (horizontal displacement in µm).

Figure 21 shows an expansion of Figure 20, where the increase in the roundness radius with the particle size increase can be seen.

Figure 21.

The original and filtered peak standard expanded. Z (height in µm) and X (horizontal displacement in µm).

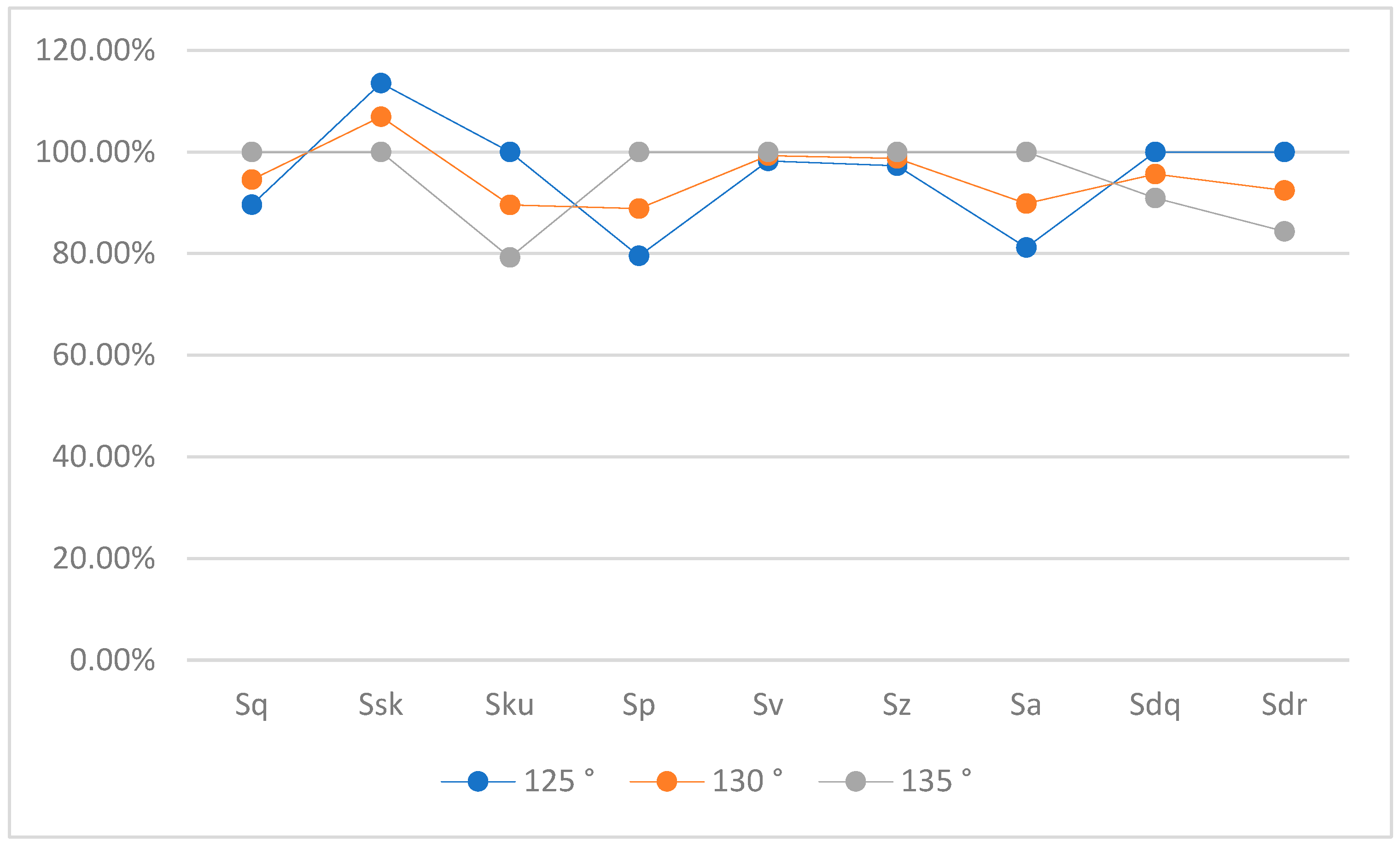

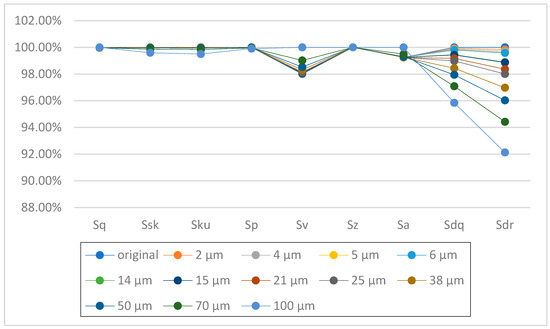

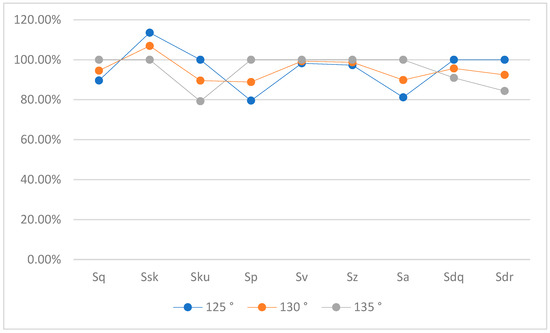

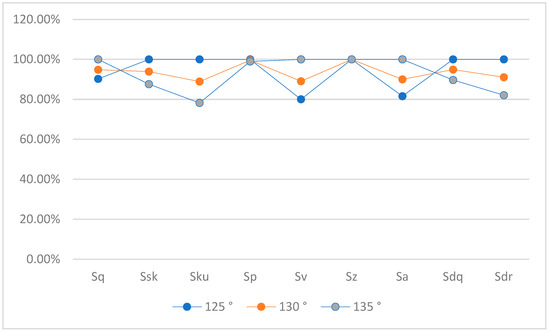

Figure 22 shows the evolution of each surface roughness parameter as a percentage for each of the filter sizes analysed for the peak standard.

Figure 22.

Graphical representation of the evolution of the areal roughness parameters in the peak standard for each analysed filter.

An important evolution is observed in the results of the parameters Sdr and Sdq.

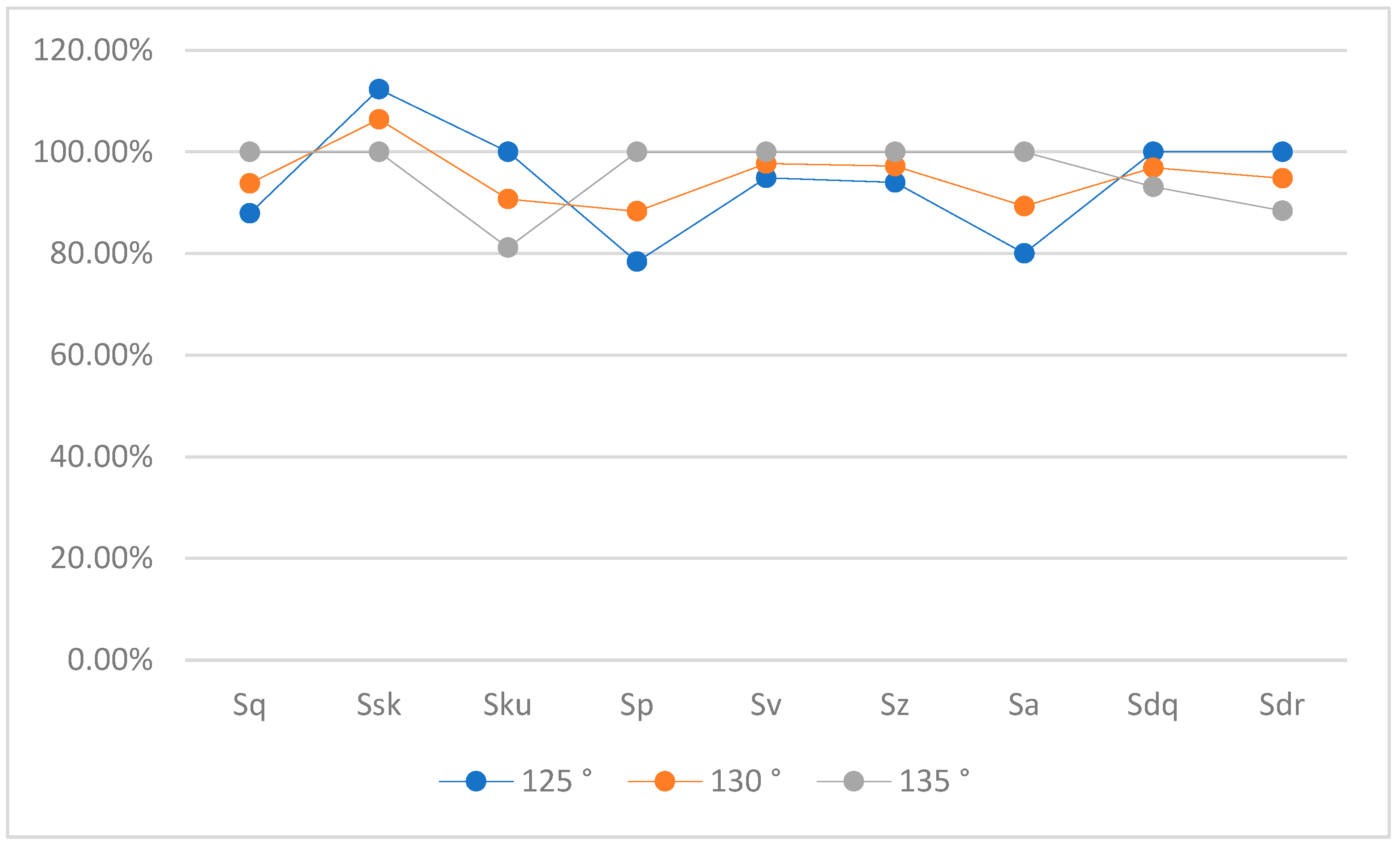

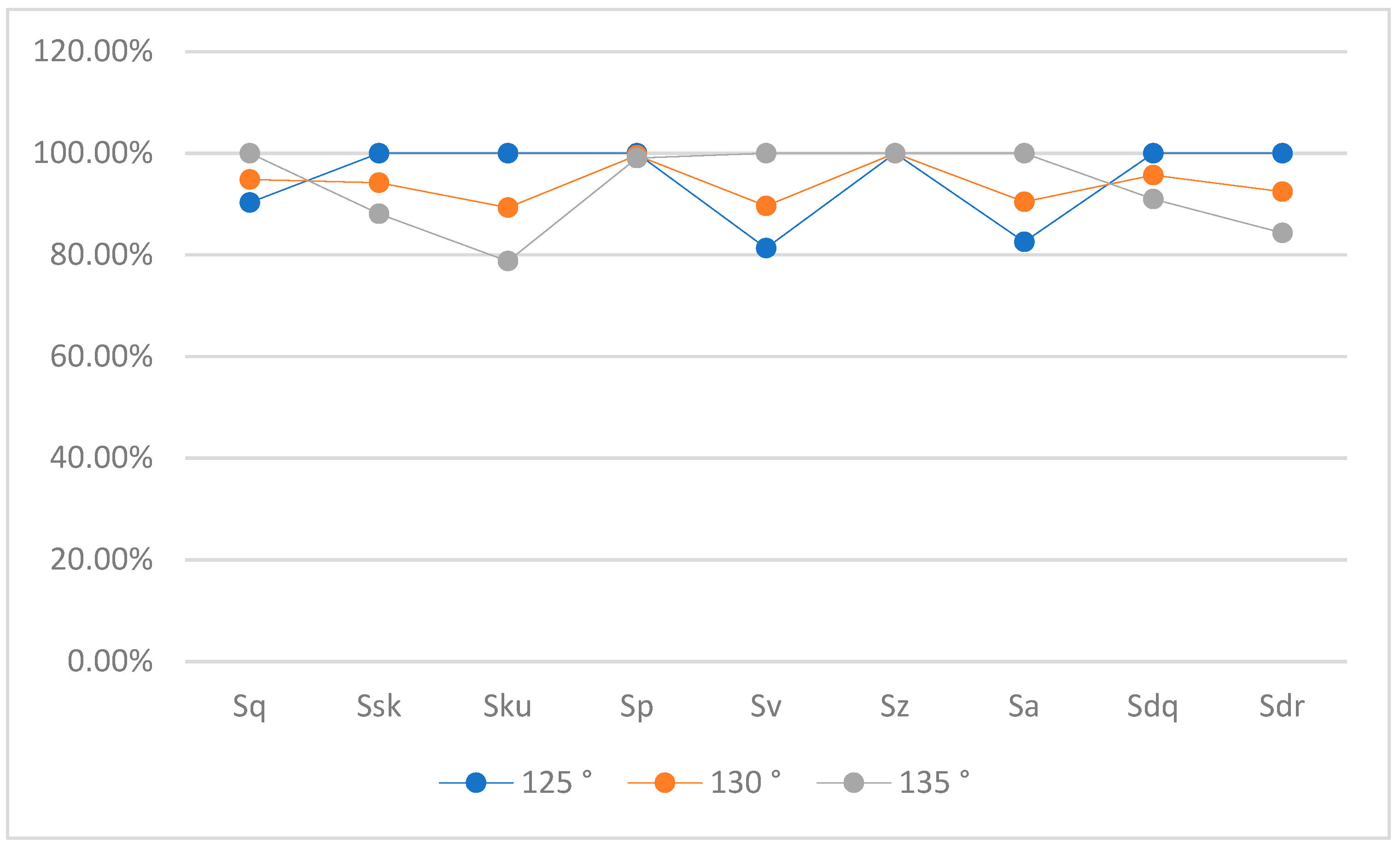

3.3.2. Comparison of Results with Variations of ±5° of α

This section shows the evolution of the results for an alpha variation of ±5° of the groove and peak standards. It has been decided to consider ±5°, because it is a total variation of 10° and it is considered to be a large variation.

The results are presented for particle or stylus sizes of 5 µm, 25 µm, 50 µm, and 100 µm. It is considered that these four sizes are sufficient to be able to appreciate an evolution in the calculated parameters. Parameters have been calculated for all particle sizes considered in the article and are presented in Appendix B.

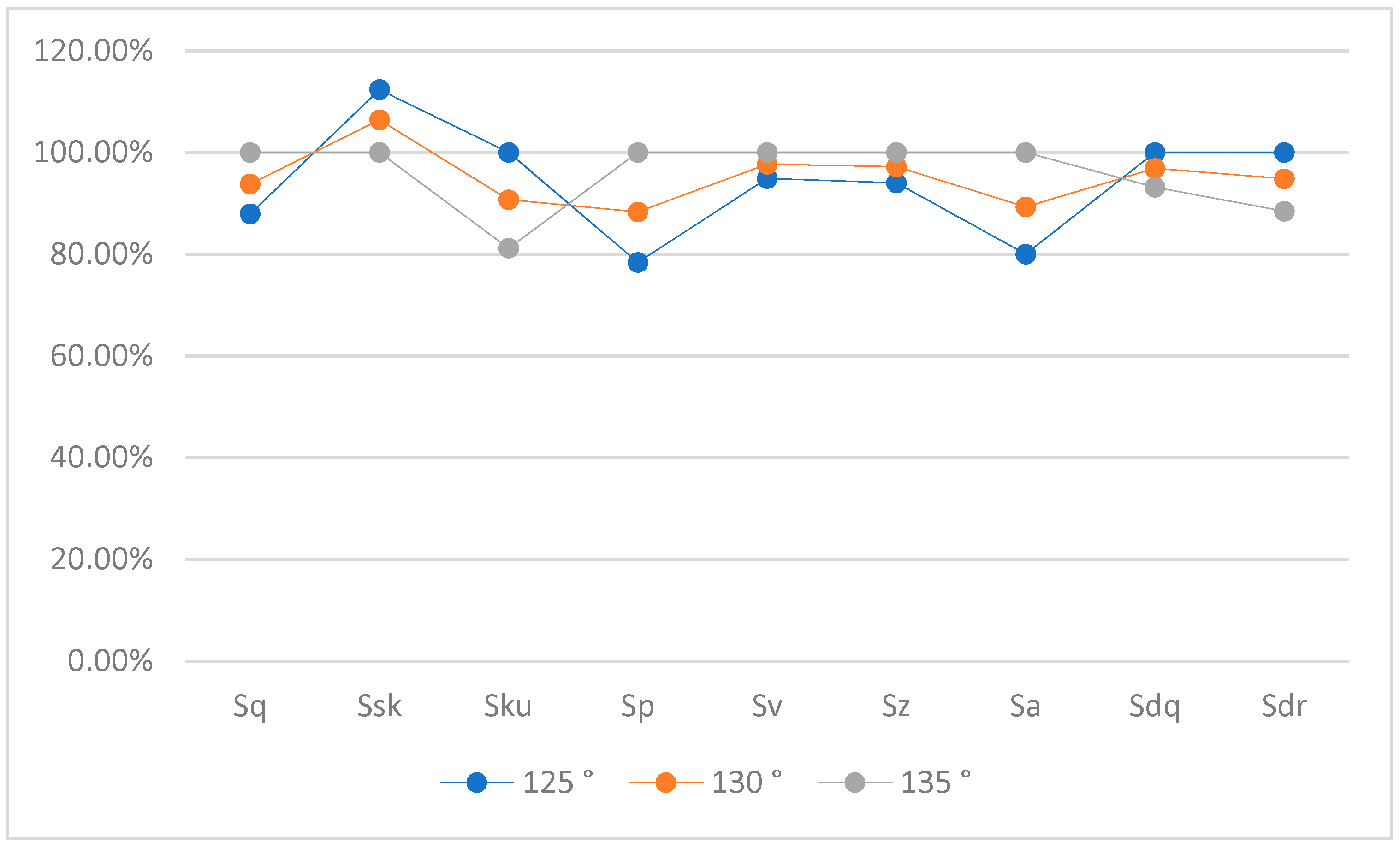

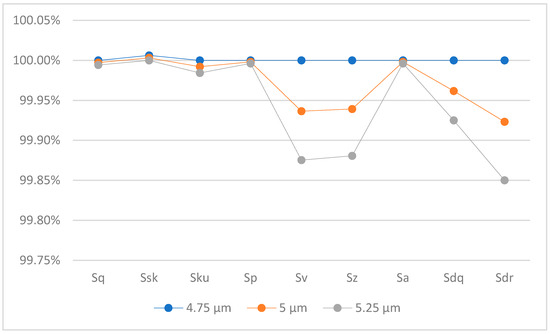

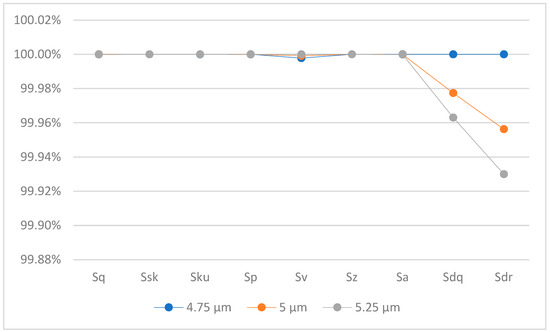

Table 11 and Figure 23 show the results of areal parameters for the variation in the groove standard for the 5 µm particle size.

Table 11.

Results of applying a 5 µm filter and a ±5° variation in α for a groove standard.

Figure 23.

Graphical comparison of applying a 5 µm filter and a ±5° alpha variation in a groove standard.

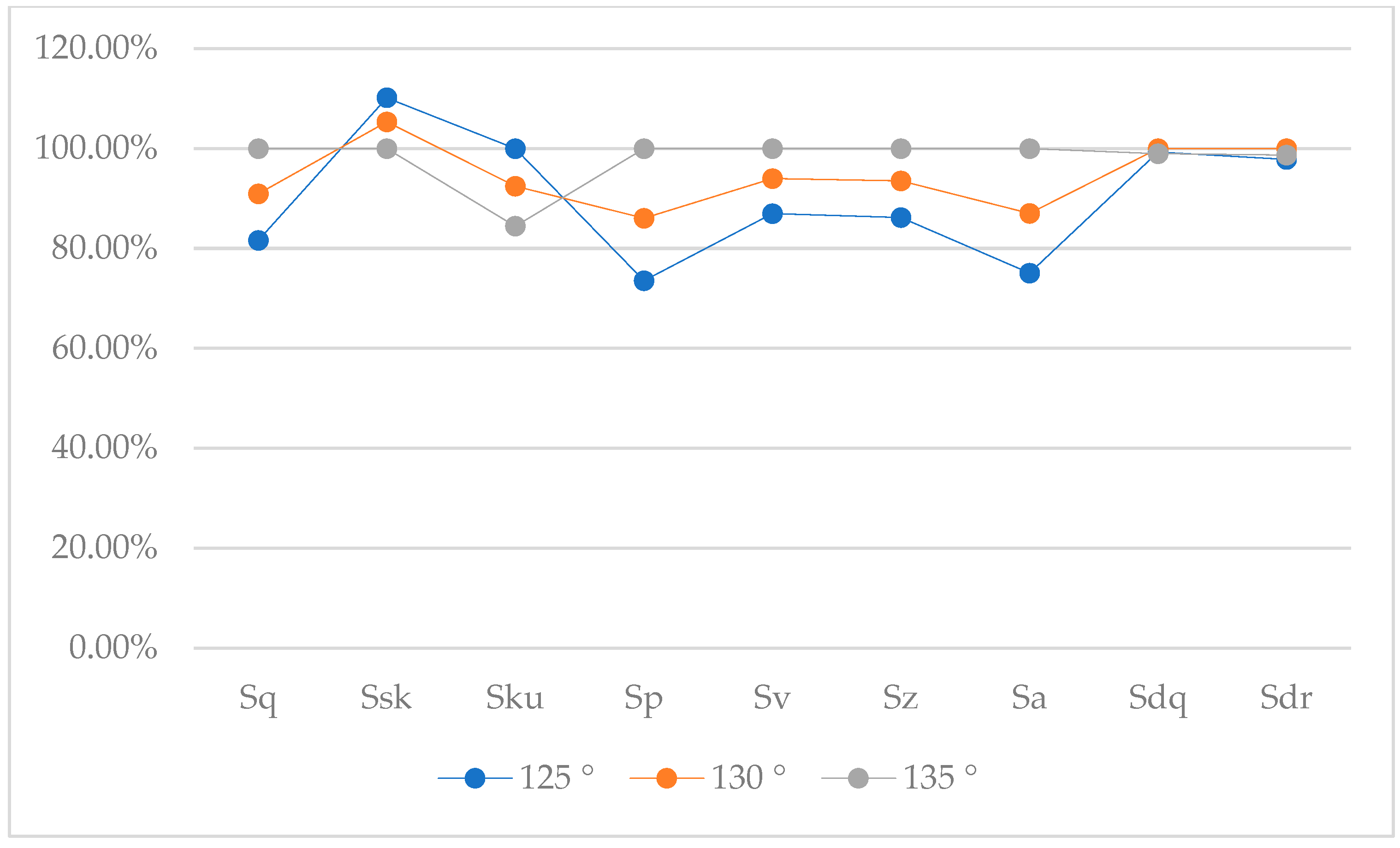

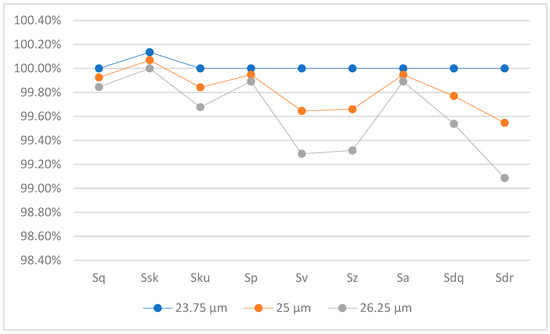

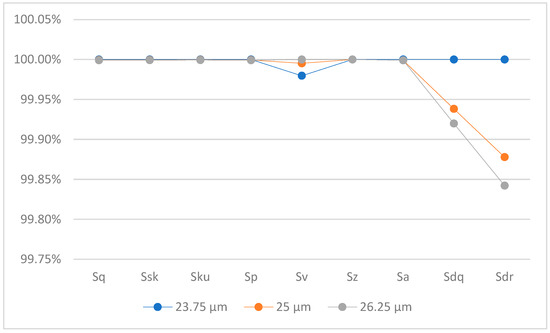

Table 12 and Figure 24 show the results of areal parameters for the variation in the groove standard for the 25 µm particle size.

Table 12.

Results of applying a 25 µm filter and a ±5° variation in α for a groove standard.

Figure 24.

Graphical comparison of applying a 25 µm filter and a ±5° alpha variation in a groove standard.

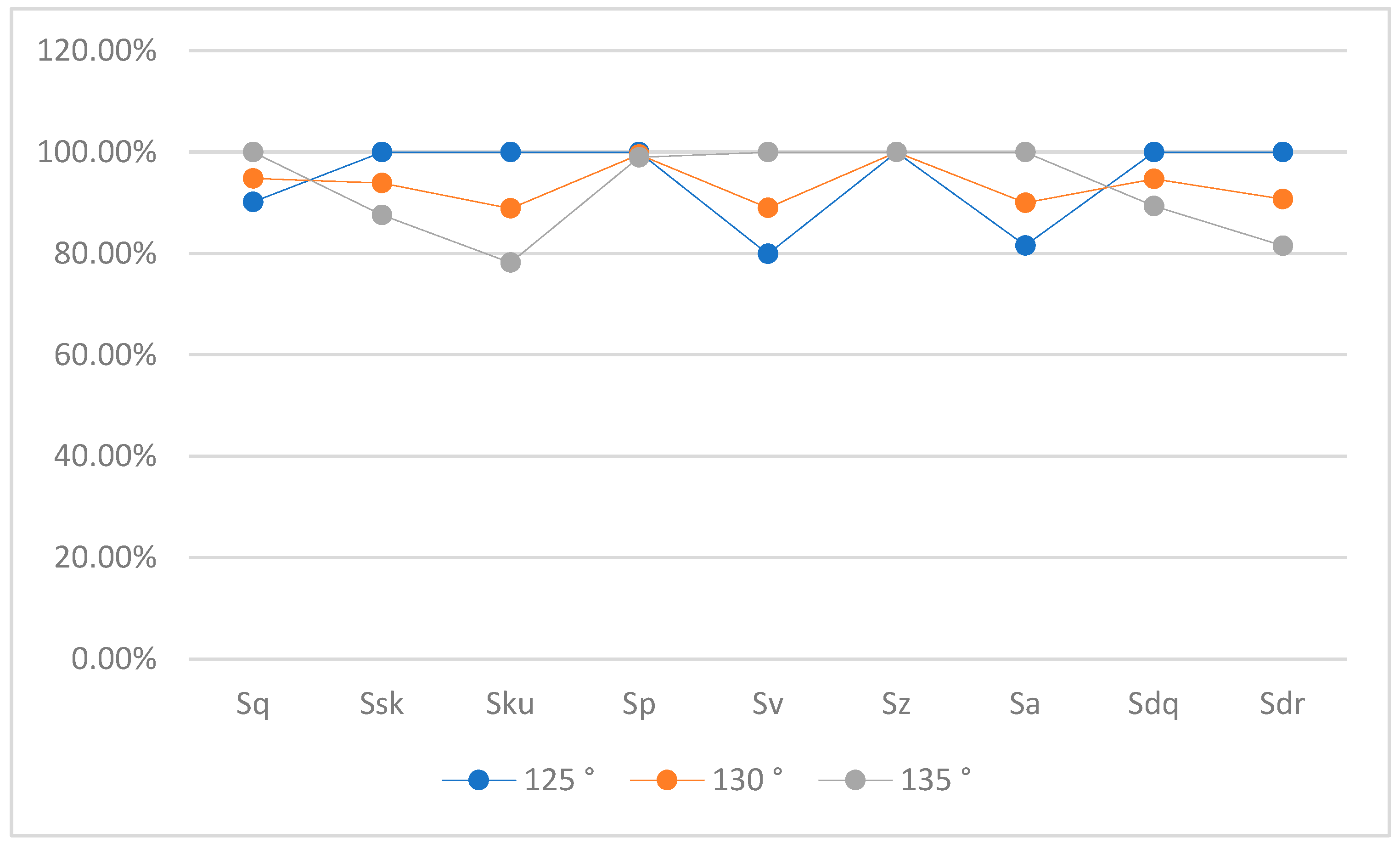

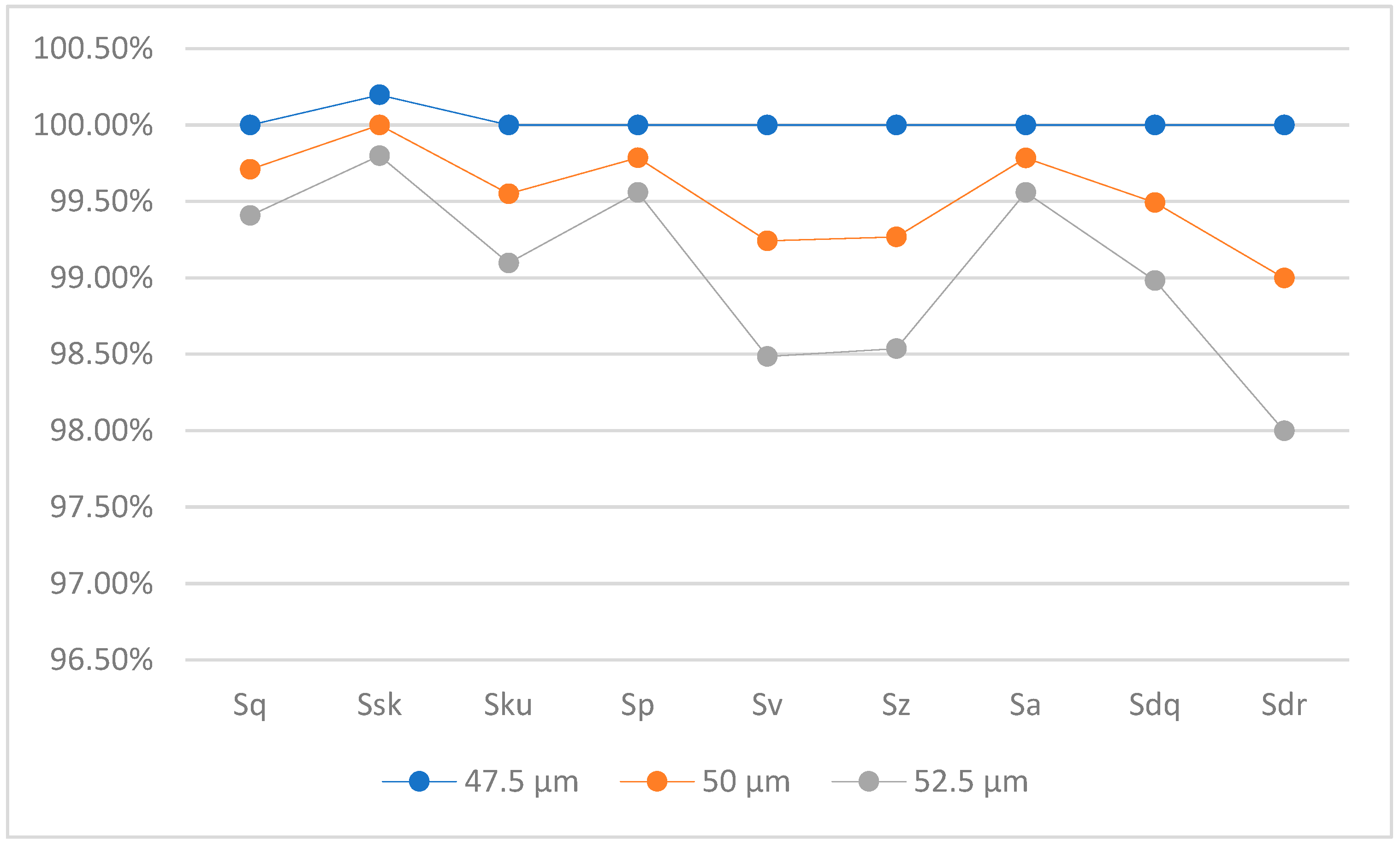

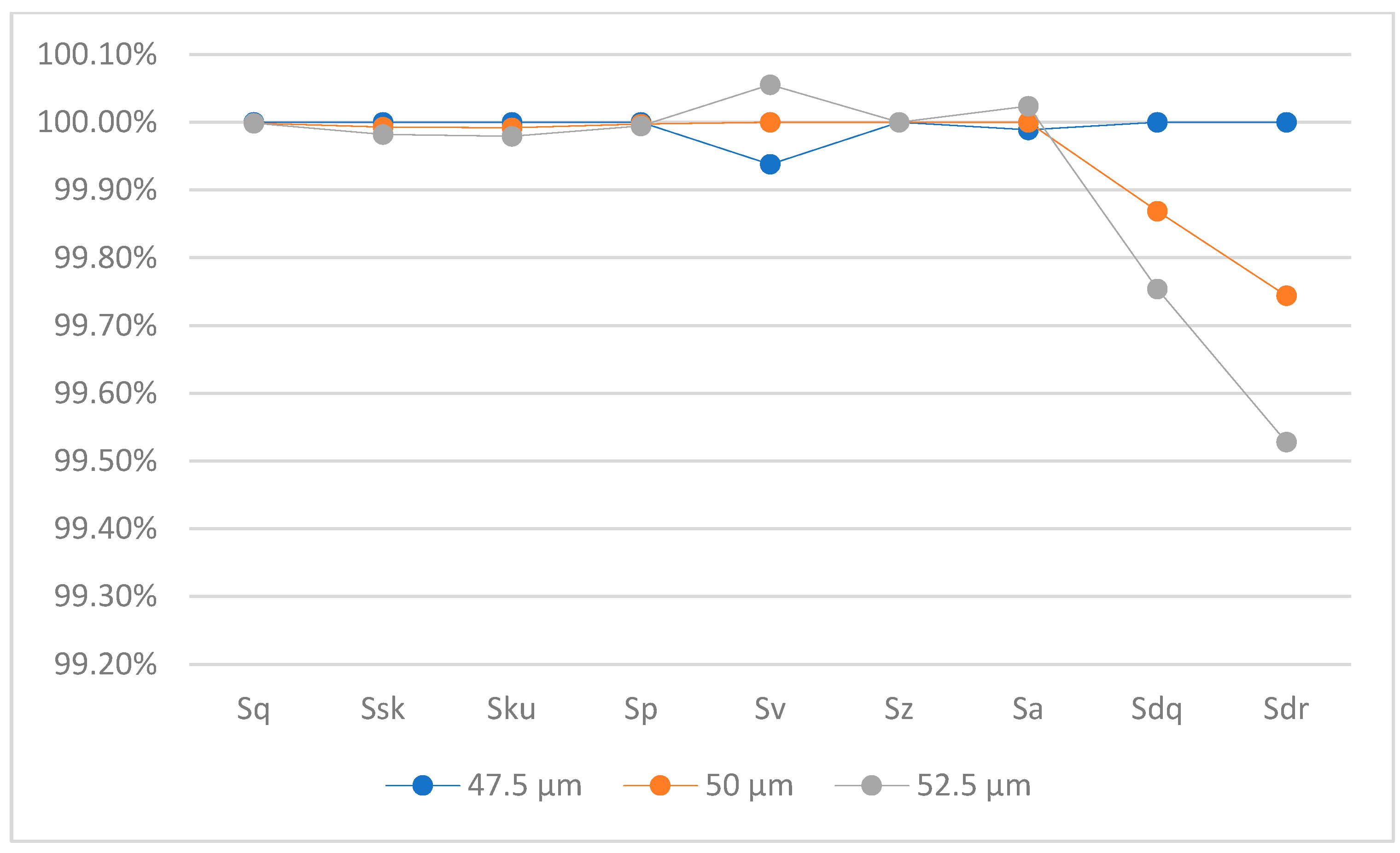

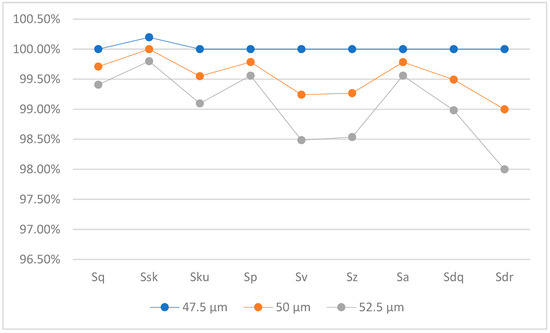

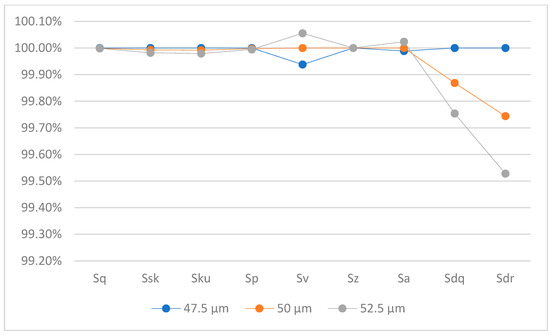

Table 13 and Figure 25 show the results of areal parameters for the variation in the groove standard for the 50 µm particle size.

Table 13.

Results of applying a 50 µm filter and a ±5° variation in α for a groove standard.

Figure 25.

Graphical comparison of applying a 50 µm filter and a ±5° alpha variation in a groove standard.

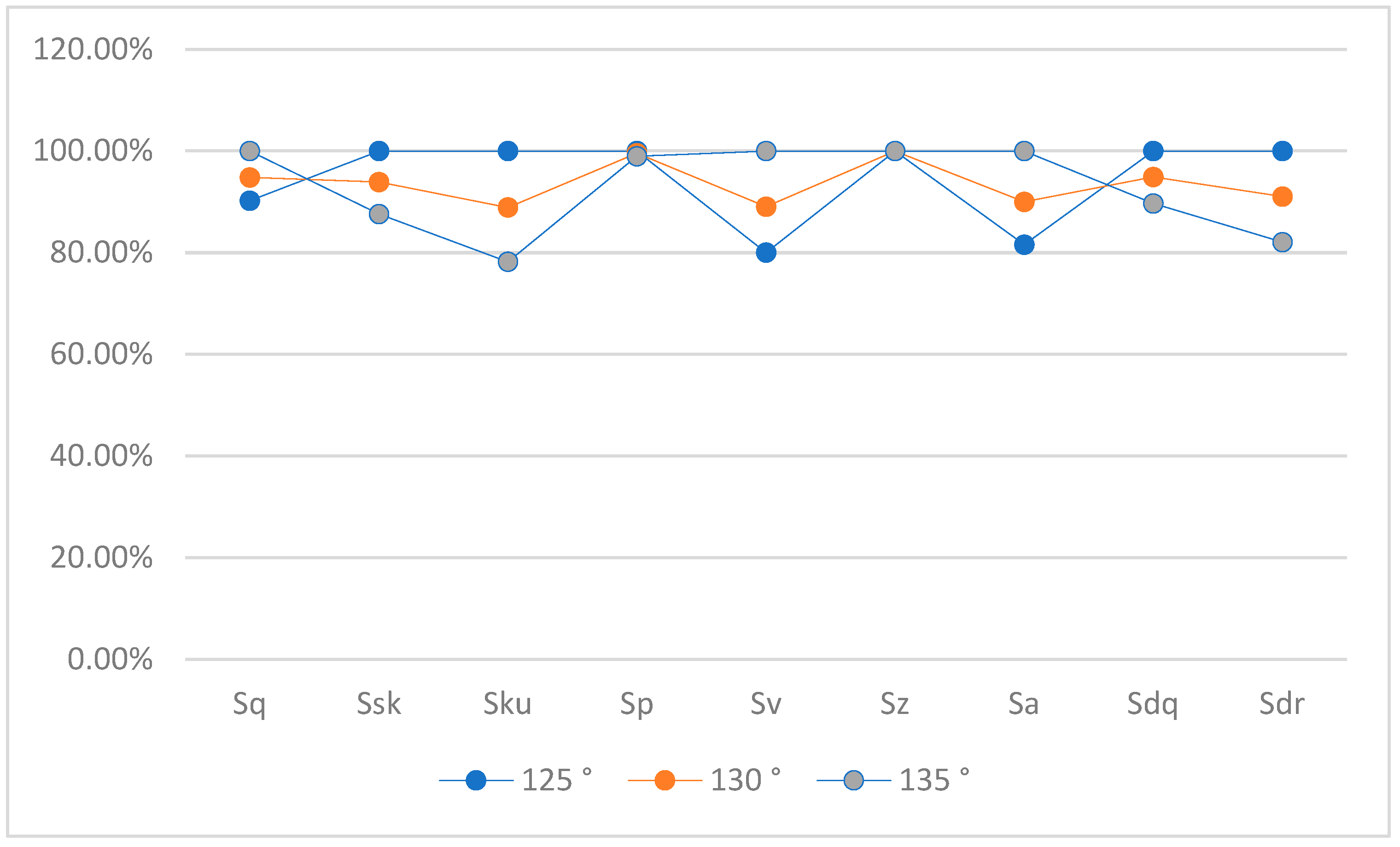

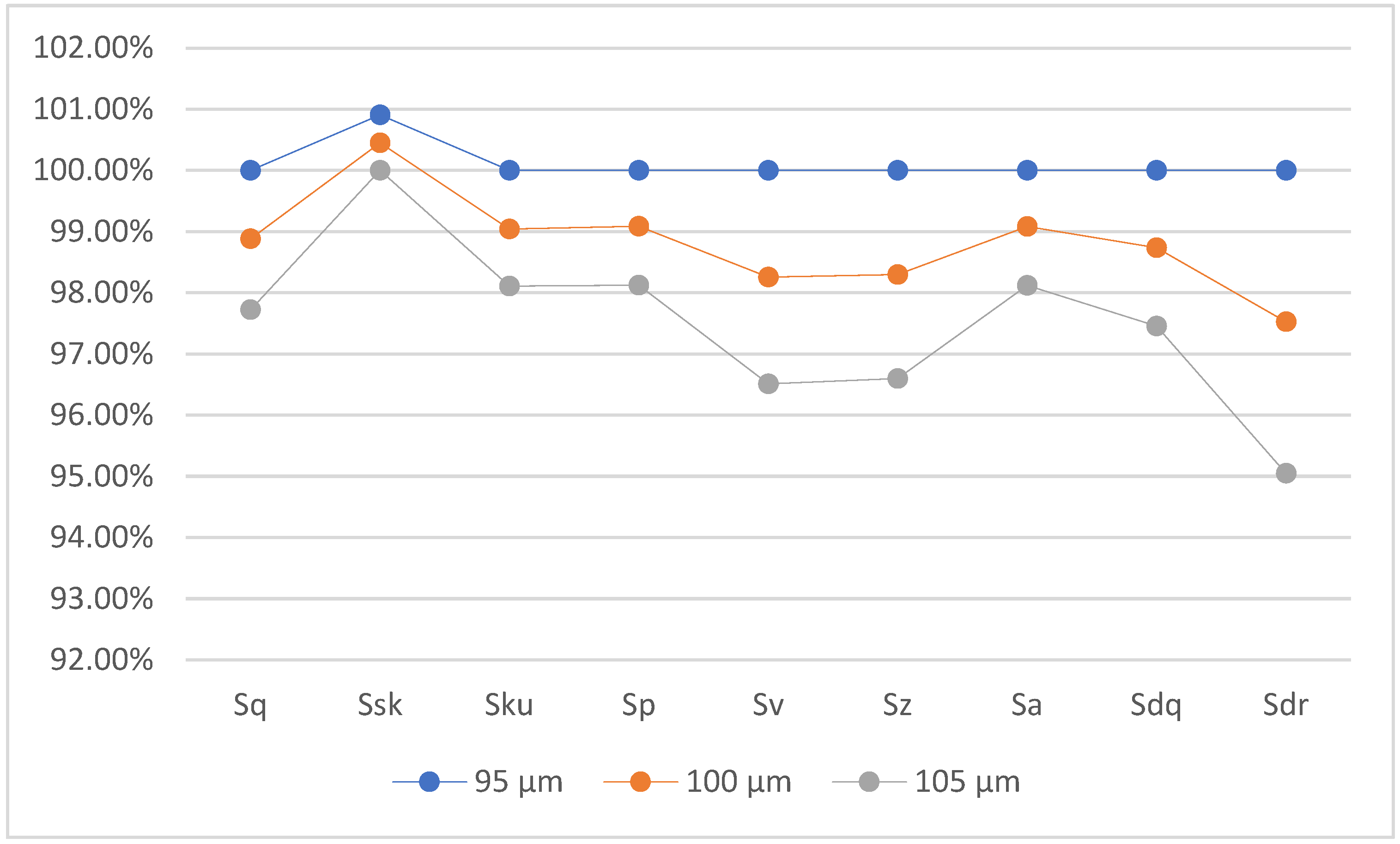

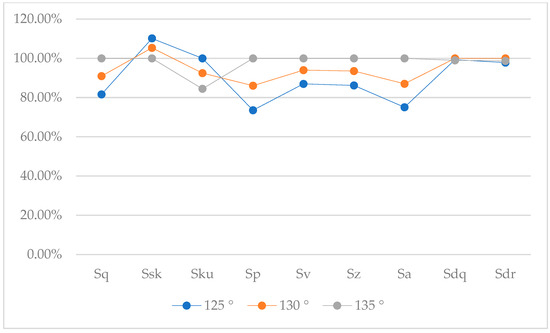

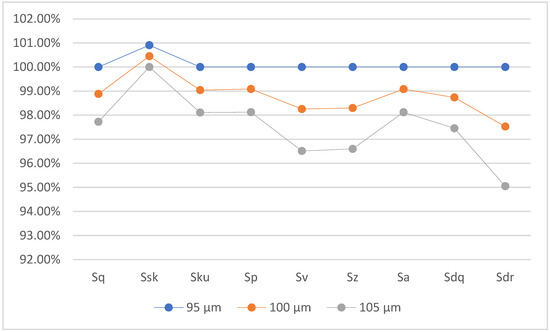

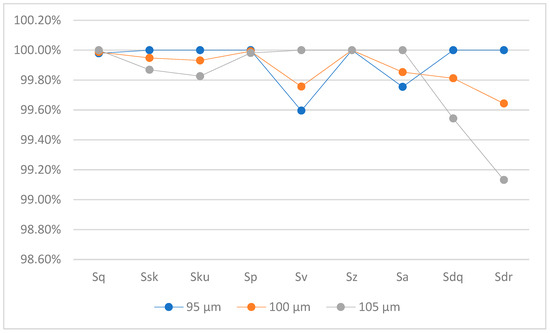

Table 14 and Figure 26 show the results of areal parameters for the variation in the groove standard for the 100 µm particle size.

Table 14.

Results of applying a 100 µm filter and a ±5° variation in α for a groove standard.

Figure 26.

Graphical comparison of applying a 100 µm filter and a ±5° alpha variation in a groove standard.

Comparing the four graphs, the larger the particle size, the less dependent the Sdr and Sdq parameter are on the angle of the standard.

Table 15 and Figure 27 show the results of areal parameters for the variation in the peak standard for the 5 µm particle size.

Table 15.

Results of applying a 5 µm filter and a ±5° variation in α for a peak standard.

Figure 27.

Graphical comparison of applying a 5 µm filter and a ±5° alpha variation in a peak standard.

The parameters with the highest variability are Sku, Sv, Sdr, and Sa, all of which are around 20%.

Table 16 and Figure 28 show the results of areal parameters for the variation in the peak standard for the 25 µm particle size.

Table 16.

Results of applying a 25 µm filter and a ±5° variation in α for a peak standard.

Figure 28.

Graphical comparison of applying a 25 µm filter and a ±5° alpha variation in a peak standard.

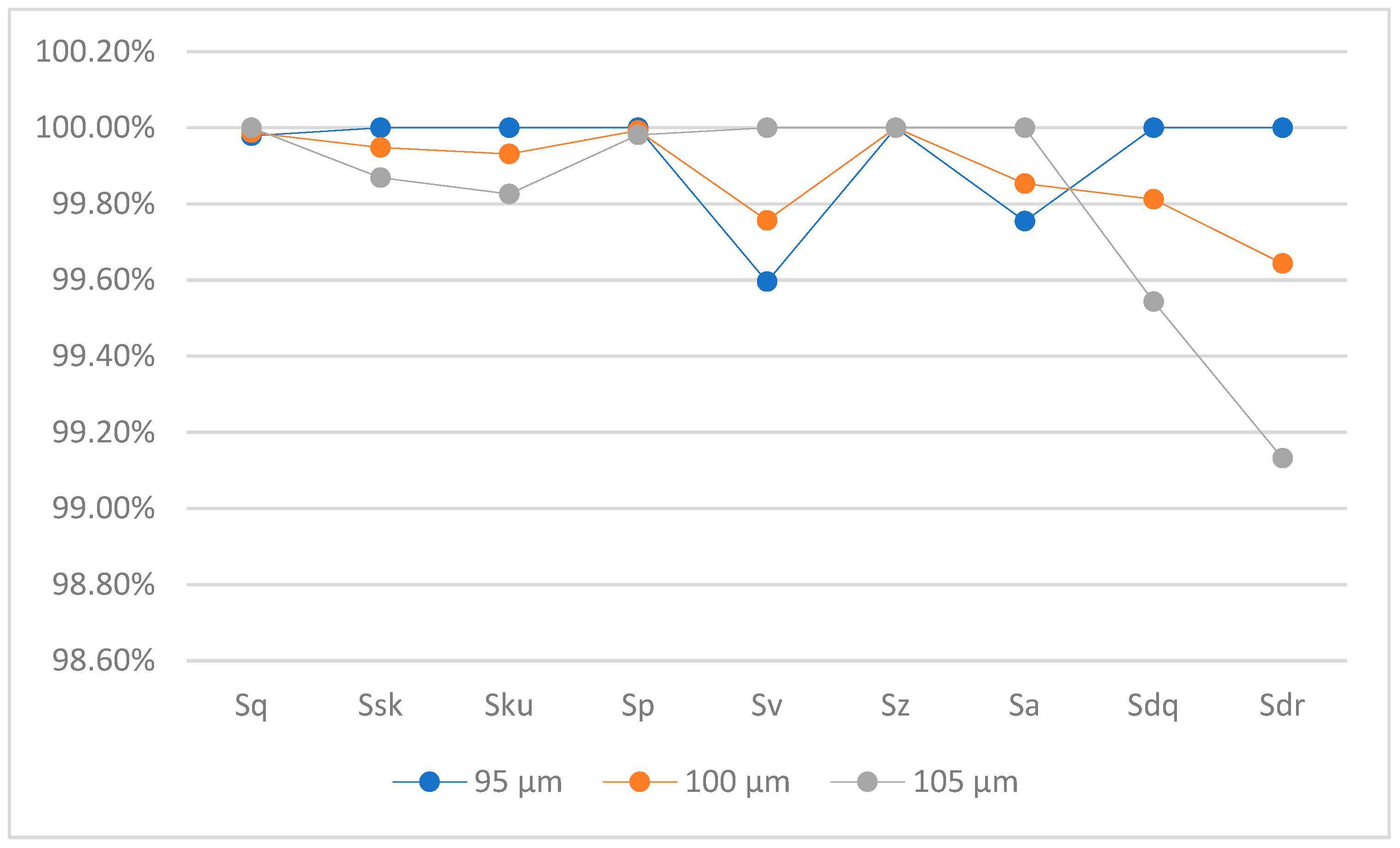

Table 17 and Figure 29 show the results of areal parameters for the variation in the peak standard for the 50 µm particle size.

Table 17.

Results of applying a 50 µm filter and a ±5° variation in α for a peak standard.

Figure 29.

Graphical comparison of applying a 50 µm filter and a ±5° alpha variation in a peak standard.

Table 18 and Figure 30 show the results of areal parameters for the variation in the peak standard for the 100 µm particle size.

Table 18.

Results of applying a 100 µm filter and a ±5° variation in α for a peak standard.

Figure 30.

Graphical comparison of applying a 100 µm filter and a ±5° alpha variation in a peak standard.

A variation of up to 20% of the value is observed for all particle sizes. It is reasonable that it remains similar because the change is in the angle of the standard and not in the particle size.

The parameter Sku seems to be the one that varies the most in the numbers, but it has a variability of approximately 20% in all cases.

In the case of the peak standard, the variation between the parameters seems to be more constant and not so dependent on the particle size. In the case of the groove standard, the difference between values increases with increasing particle size, i.e., at the 5 µm size there is less variability than at the 100 µm size.

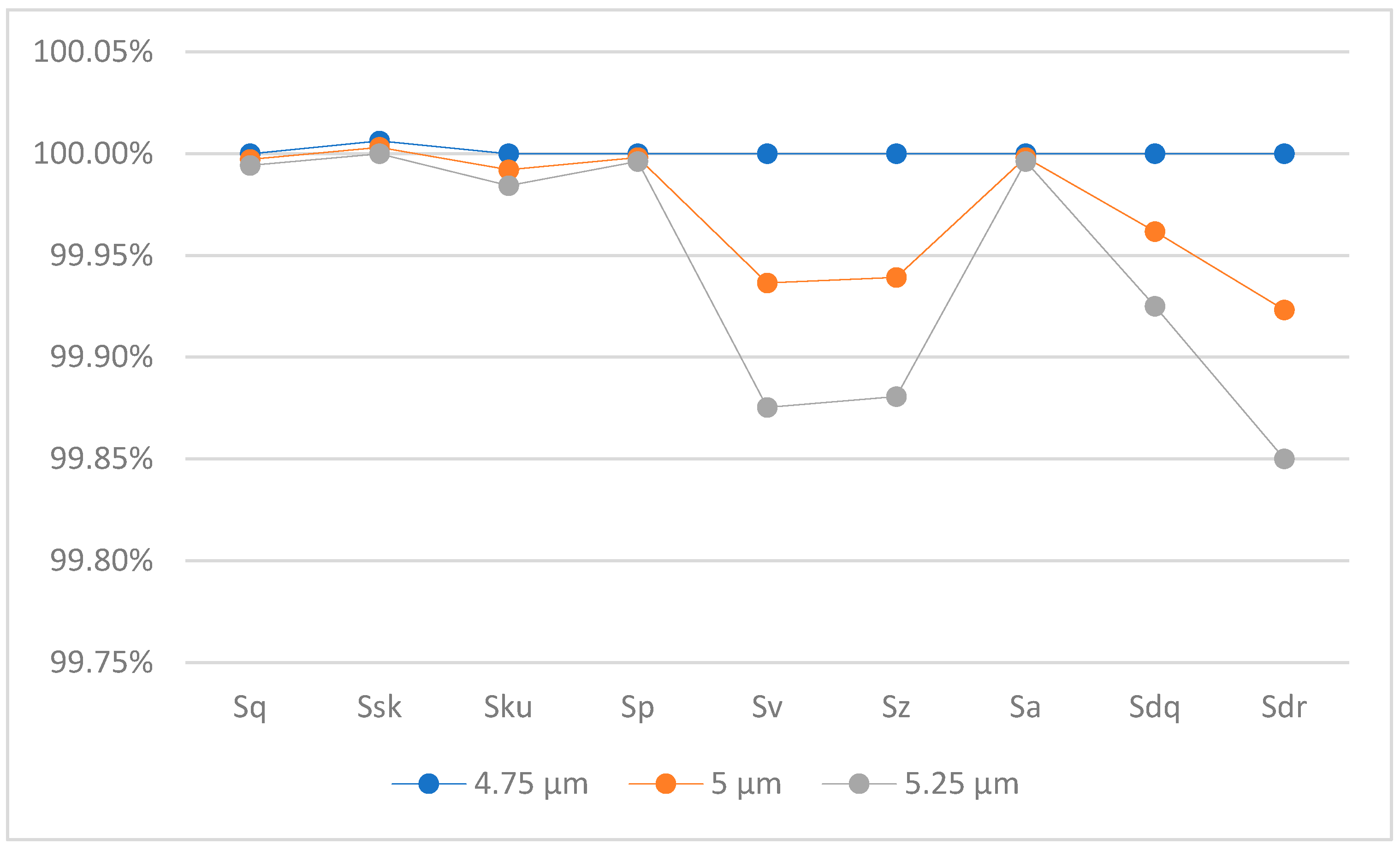

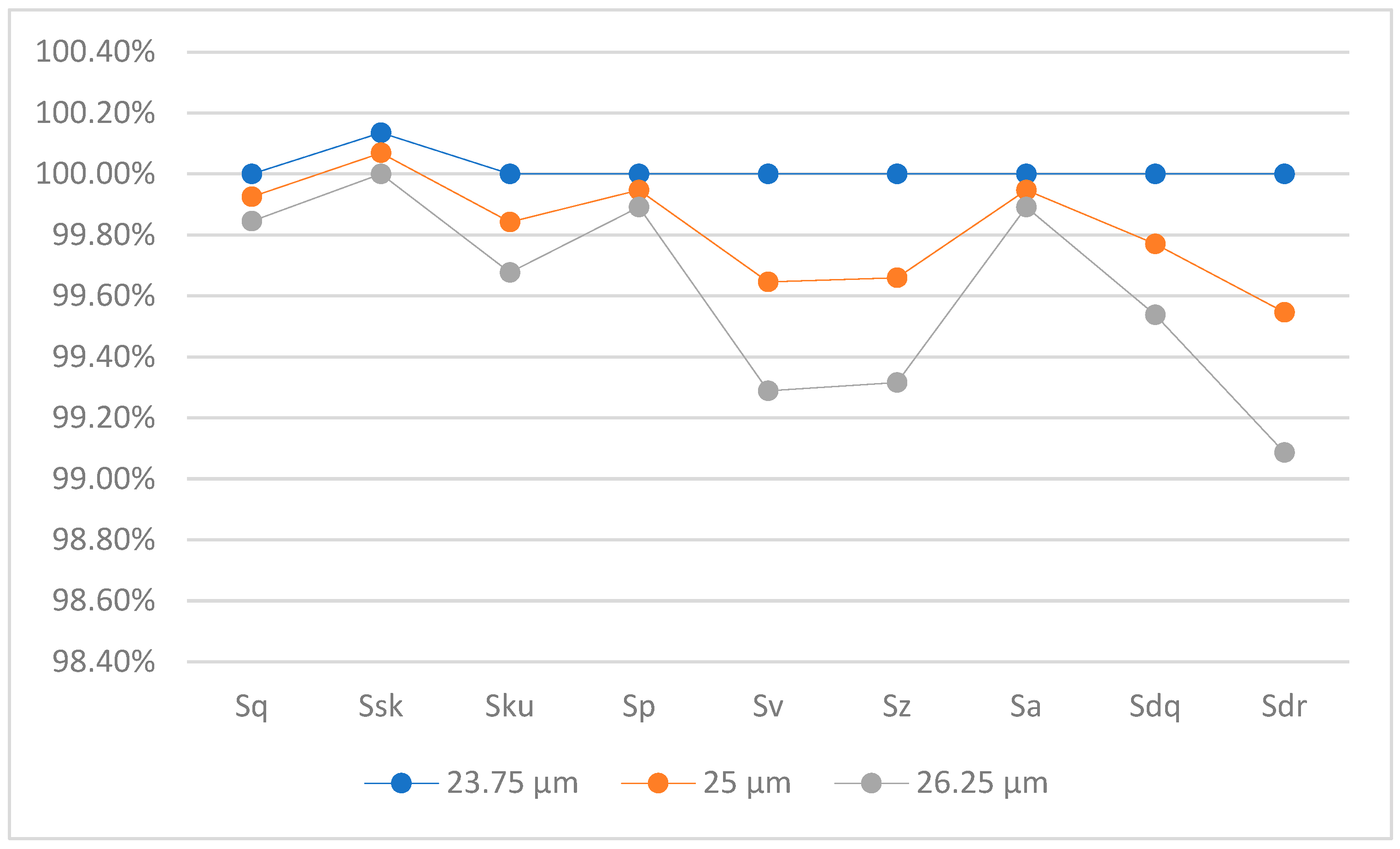

3.3.3. Comparison of Results for ±5% Variations in Stylus Size

The size of the stylus varies by 5% for the groove and peak standards with α = 130° and the following results are obtained. It has been decided to consider ±5% because it is a total variation of 10% and when a stylus shows a wear of 5%, it is discarded.

In this section, as in the previous one, the results are presented for particle or stylus sizes of 5 µm, 25 µm, 50 µm, and 100 µm. It is considered that these four sizes are sufficient to be able to appreciate an evolution in the calculated parameters. Parameters have been calculated for all particle sizes considered in the article and are presented in Appendix B.

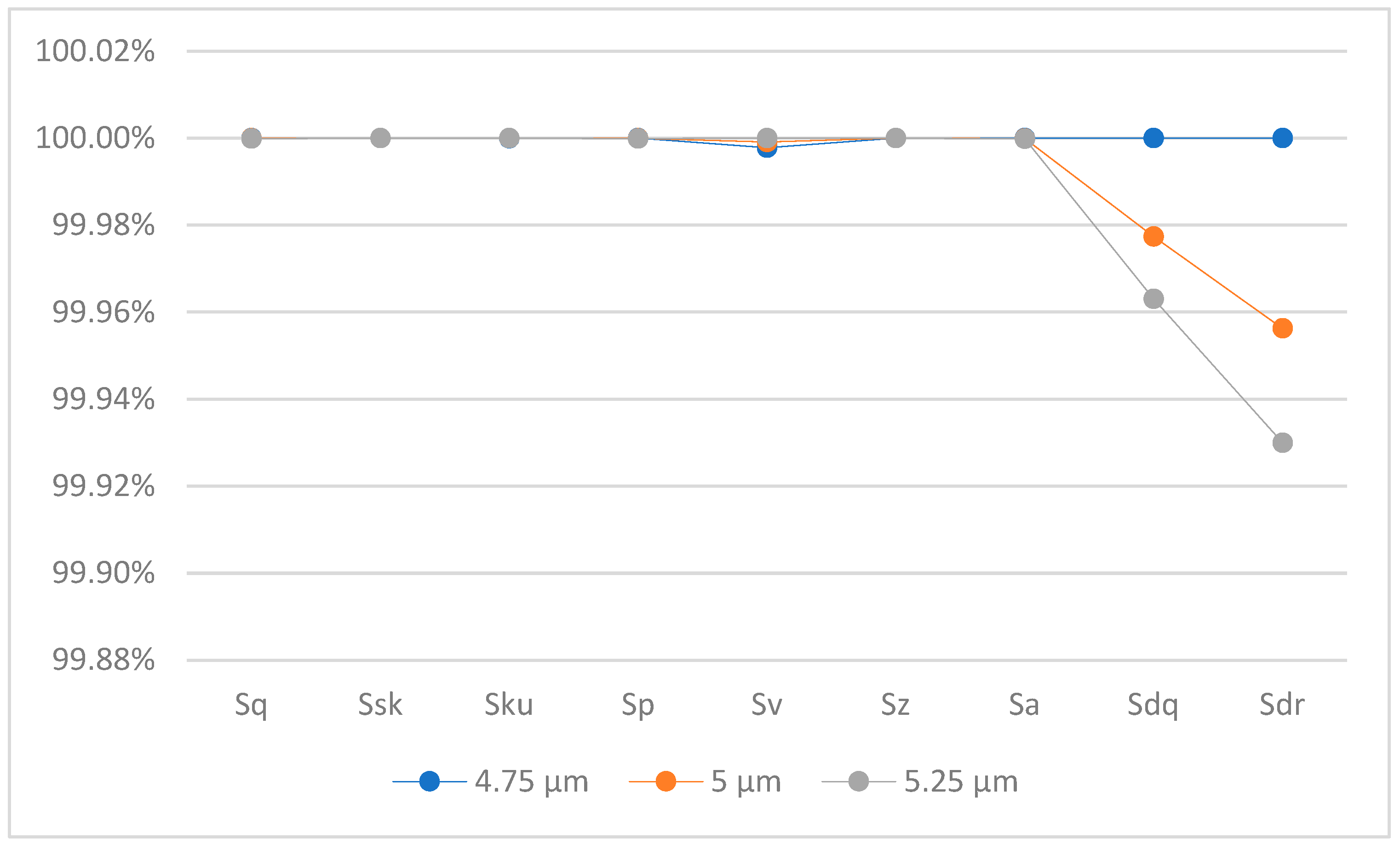

Table 19 and Figure 31 show the results of areal parameters for the 5 µm particle size variation for the groove standard.

Table 19.

Results of applying a stylus size variation of ±5% to the 5 µm stylus for the groove standard with α = 130°.

Figure 31.

Graphical representation of the variation in results of applying a ±5% stylus size variation to the 5 µm stylus for the groove standard with α = 130°.

The parameters have a minimum variation of only 0.15% of the maximum value.

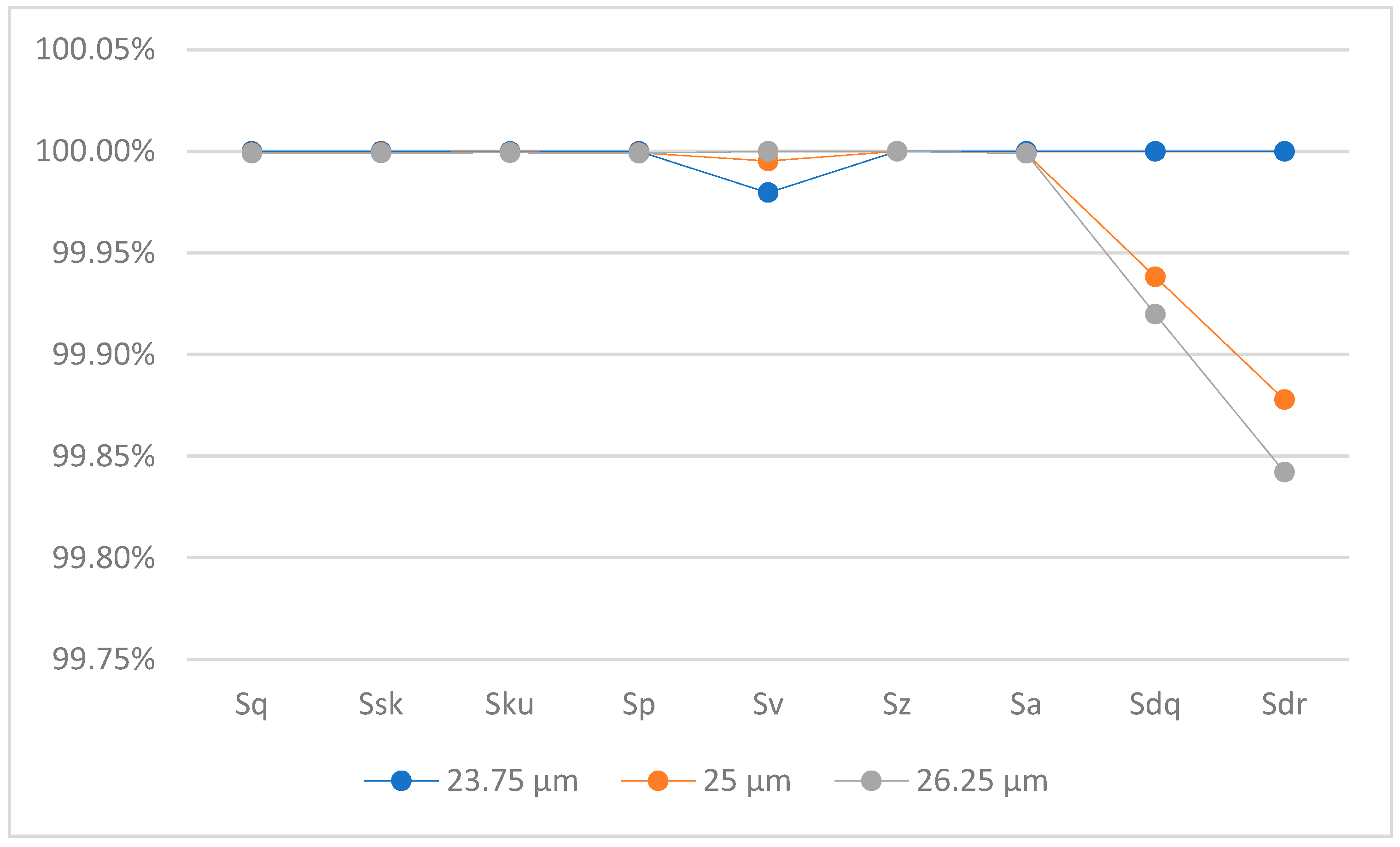

Table 20 and Figure 32 show the results of areal parameters for the 25 µm particle size variation for the groove standard.

Table 20.

Results of applying a stylus size variation of ±5% to the 25 µm stylus for the groove standard with α = 130°.

Figure 32.

Graphical representation of the variation in results of applying a ±5% stylus size variation to the 25 µm stylus for the groove standard with α = 130°.

Table 21 and Figure 33 show the results of areal parameters for the 50 µm particle size variation for the groove standard.

Table 21.

Results of applying a stylus size variation of ±5% to the 50 µm stylus for the groove standard with α = 130°.

Figure 33.

Graphical representation of the variation in results of applying a ±5% stylus size variation to the 50 µm stylus for the groove standard with α = 130°.

Table 22 and Figure 34 show the results of areal parameters for the 100 µm particle size variation for the groove standard.

Table 22.

Results of applying a stylus size variation of ±5% to the 100 µm stylus for the groove standard with α = 130°.

Figure 34.

Graphical representation of the variation in results of applying a ±5% stylus size variation to the 100 µm stylus for the groove standard with α = 130°.

Table 23 and Figure 35 show the results of areal parameters for the 5 µm particle size variation for the peak standard.

Table 23.

Results of applying a stylus size variation of ±5% to the 5 µm stylus for the peak standard with α = 130°.

Figure 35.

Graphical representation of the variation in results of applying a ±5% stylus size variation to the 5 µm stylus for the peak standard with α = 130°.

Table 24 and Figure 36 show the results of areal parameters for the 25 µm particle size variation for the peak standard.

Table 24.

Results of applying a stylus size variation of ±5% to the 25 µm stylus for the peak standard with α = 130°.

Figure 36.

Graphical representation of the variation in results of applying a ±5% stylus size variation to the 25 µm stylus for the peak standard with α = 130°.

Table 25 and Figure 37 show the results of areal parameters for the 100 µm particle size variation for the peak standard.

Table 25.

Results of applying a stylus size variation of ±5% to the 50 µm stylus for the peak standard with α = 130°.

Figure 37.

Graphical representation of the variation in results of applying a ±5% stylus size variation to the 50 µm stylus for the peak standard with α = 130°.

Table 26 and Figure 38 show the results of areal parameters for the 100 µm particle size variation for the peak standard.

Table 26.

Results of applying a stylus size variation of ±5% to the 100 µm stylus for the peak standard with α = 130°.

Figure 38.

Graphical representation of the variation in results of applying a ±5% stylus size variation to the 100 µm stylus for the peak standard with α = 130°.

There is a very small variability in the surface roughness parameters with the variation of ±5% of the stylus size. This variation does not reach 1% in any case, although it seems that the variation increases for larger particle sizes. The parameter with the greatest variability is Sdr, which exceeds 0.8% for the 100 µm particle.

4. Discussion

Comparing the point clouds and the material ratio curves in Figure 11 and Figure 16 show a significant reduction in the dales, which are represented on the right side of the curve. With the increase in the filter size, the dale of the curve is reduced and with it, the minimum secant of the curve is reduced as well. The change in the slope of the curve is more noticeable on the surface than in the profile. This reduction in the slope causes the height of the surface core to be reduced (Sk).

The parameters Smc, Rcm, Smr, and Rmc have a very slight variation, because they receive another input parameter in addition to the surface or profile. As explained above, in the case of Smc and Rcm, a constant (10%) has been used, and in the case of Smr and Rmc, the result of Smc and Rcm has been used. A value of 10% for the calculation on the left-hand side of the curve has been used.

It can be seen that in the case of the surface, the Ssk parameter changes from negative to positive as the filter size increases. The Ssk parameter shows the deviation between the data and the median line or plane. If the parameter is negative, its distribution is above the median line or plane. It is normal that when using a filtering technique that only affects the dales, this parameter may change sign.

The kurtosis (Sku and Rku) parameter increases with the filter size for the surface but decreases for the profile. This makes this parameter unsuitable for the evaluation of the critical particle size.

As for the peak standard, it is observed that there is no variation in the Sz parameter as expected, since, when using a morphological closing filter, this should only affect the dales and, being a triangle upwards, this standard does not present any dale. There is an increase in the Sv parameter and a reduction in the Sp parameter as the filter size increases. Although the Sz parameter is not affected, the surface changes on the sides of the triangle increasing the rounding radius; this causes the arithmetic mean of the plane to increase slightly. As it is the one used to define a peak and a dale, it causes a slight variation in the Sp and Sv parameters, but not in the sum of both.

A high sensitivity of the Sdr and Sdq parameters is observed in all cases, but mainly, they seem to be more sensitive to the variation in the stylus size.

In addition to the variations in Sdr and Sdq in the point cloud and in the profile, a remarkable variation in the parameters Rv, Rvk, Rvkx, and Rak2 is observed. All these parameters are relative to the dales, so this variation is to be expected.

The parameter Sa is less sensitive to changes in the point clouds due to filtering than other parameters.

5. Conclusions

Because of the results analysed in this paper, the following conclusions were drawn:

- Special attention must be paid to the wear of the stylus used to measure roughness if the Sdr and Sdq parameters are to be used.

- Sdr and Rdr are the best parameters to evaluate the damage that can be caused by the particles in the contacting surfaces or pieces.

- The parameters Svkx, Svk, Sak2, Rvkx, Rvk, and Rak2 are also to be taken into account in this analysis. They are not as sensitive as Rdr or Sdr, but a variation in their value of more than 40% of their initial value with an increasing particle size has been observed.

- The parameters Sdq and Rdq also appear to be good indicators of the problems of poor lubricant distribution that particles can cause.

- The parameters Rku and Sku are not reliable for the evaluation of the critical particle size.

- Figure 11 shows that with larger particle sizes, larger dales can be clogged, and the lubricant is not evenly distributed over the entire surface. This generates more friction between the surfaces being examined, in addition to the friction caused by the particles themselves.

- The areas that can be left without oil due to the presence of particles of considerable size can lead to poorer heat dissipation from the machine.

- In this work, it has been observed that morphological filtering has a high computational cost. Before implementing it in a commonly used surface inspection system, it is advisable to have an estimate of the time the system may need to perform the filtering and whether it is really necessary to perform it; consideration should be given to whether another technique can be used, or whether the profiles instead of the entire surface can be inspected.

- Looking at Figure 15, the original and filtered profiles greatly expanded; it is estimated that the limiting particle size is around 38 µm, as it can be seen that the larger valleys of the profile also start to be affected.

- Surface parameters are more effective in assessing particle size, as they have greater variation, in addition to having more information on the entire surface.

Future Lines

Future lines of research include the following:

- Finish the implementation of calculation algorithms for the rest of the parameters of the UNE-EN ISO 25178-2:2023 [6] and UNE-EN ISO 21920-2:2023 [33] standards.

- Implement the F operation and apply S and L filters [6], which are not being applied now.

- Implement other filters of the UNE-EN ISO 16610 standard and compare the results and processing times of each one.

- Compare results of the software created with other libraries or calculation software.

- Test morphological filters with different spacings between data; this would be interesting, because an advantage of morphological filters is that they allow irregular spacing between data.

- Generate a mathematical model that can estimate the processing time that a large morphological filter can have on a given computer, knowing the processing time of two small filters on that computer.

- Try to optimize the filter to minimize the processing time required.

- Compare the results obtained from several profiles of a surface on which end effect compensation techniques [29] have been applied with the use of a larger surface with data discarding.

- Compare a surface filtered by profiles with an area filter to estimate the possible uncertainty that may be added by profile processing compared to area processing, given the shorter processing time it has.

- Consider the surface energy of the lubricant.

- Take into account the surface material and the possible wear of the surface.

Author Contributions

Conceptualization, L.M.-E. and M.A.S.-N.; methodology, L.M.-E. and M.A.S.-N.; validation, L.M.-E., M.A.S.-N. and E.M.R.; formal analysis, L.M.-E.; investigation, L.M.-E.; resources, L.M.-E., M.A.S.-N. and E.M.R.; data curation, L.M.-E., M.A.S.-N. and E.M.R.; writing—original draft preparation, L.M.-E.; writing—review and editing, L.M.-E., M.A.S.-N. and E.M.R.; visualization, L.M.-E., M.A.S.-N. and E.M.R.; supervision, M.A.S.-N. and E.M.R.; project administration, L.M.-E., M.A.S.-N. and E.M.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to the data size is too large.

Acknowledgments

The authors are grateful for the support of the Industrial Production and Manufacturing Engineering (IPME) Research Group, the Innovation and Teaching Group for Industrial Technologies in Productive Environments (TIA Plus UNED), and the Master of Science in Metrology.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| ACFTD | Air Cleaner Fine Test Dust |

| APC | Automatic Particle Counters |

| clx | Correlation length in X axis |

| cly | Correlation length in Y axis |

| d | Depth of grooves |

| FAMCB | Filter Areal Morphological Closing Ball |

| FPMCD | Filter Profile Morphological Closing Disk |

| GOST | Gosstandard i.e., National Standard |

| GPS | Geometrical Product Specification |

| h | Root Mean Square height |

| ISO | International Organization for Standarization |

| l | distance between grooves |

| MDPI | Multidisciplinary Digital Publishing Institute |

| MTD | Medium Test Dust |

| N | Number of surface points |

| NAS | National Aerospace Standards |

| NAV AIR | Naval Air Systems Command |

| P | reference plane |

| Ra | Arithmetic mean height profile roughness parameter |

| Rak1 | Area of the hills profile roughness parameter |

| Rak2 | Area of the dales profile roughness parameter |

| Rcm | Inverse material ratio profile roughness function |

| Rdc | Material ratio height difference profile roughness function |

| Rdq | Root Mean Square gradient profile roughness parameter |

| Rdr | Developed length ratio profile roughness parameter |

| rf | groove bottom radius |

| Rk | Core height profile roughness parameter |

| Rku | Kurtosis profile roughness parameter |

| rL | The length of the surface |

| Rmc | Material ratio profile roughness function |

| Rmrk1 | Material ratio of the hills profile roughness parameter |

| Rmrk2 | Material ratio of the dales profile roughness parameter |

| RMS | Root Mean Square |

| Rp | Maximum peak height profile roughness parameter |

| Rpk | Maximum peak height profile roughness parameter |

| Rpkx | Reduced peak height profile roughness parameter |

| Rq | Root mean square height profile roughness parameter |

| Rsk | Skewness profile roughness parameter |

| Rv | Maximum pit depth profile roughness parameter |

| Rvk | Maximum pit depth profile roughness parameter |

| Rvkx | Reduced pit depth profile roughness parameter |

| Rz | Maximum height profile roughness parameter |

| Sa | Arithmetic mean height surface roughness parameter |

| SAE | Society of Automotive Engineers |

| Sak1 | Area of the hills surface roughness parameter |

| Sak2 | Area of the dales surface roughness parameter |

| Sdc | Material ratio height difference surface roughness function |

| Sdq | Root mean square gradient surface roughness parameter |

| Sdr | Developed interfacial areal ratio roughness parameter |

| Sk | Core height surface roughness parameter |

| Sku | Kurtosis surface roughness parameter |

| Smc | Inverse areal material ratio surface roughness function |

| Smr | Areal material ratio roughness function |

| Smrk1 | Material ratio of the hills surface roughness parameter |

| Smrk2 | Material ratio of the dales surface roughness parameter |

| Sp | Maximum peak height surface roughness parameter |

| Spk | Maximum peak height surface roughness parameter |

| Spkx | Reduced peak height surface roughness parameter |

| Sq | Root mean square height surface roughness parameter |

| Ssk | Skewness surface roughness parameter |

| Sv | Maximum pit depth surface roughness parameter |

| Svk | Maximum pit depth surface roughness parameter |

| Svkx | Reduced pit depth surface roughness parameter |

| Sz | Maximum height surface roughness parameter |

| TC | Technical Committee |

| α | Angle of the groove flanks |

Appendix A. Parameters for Surface Generation

Appendix A.1. Parameters for Surface Generation

The following table (Table A1) details the parameters introduced to the rsgeng2D.m script as input and the amplitude corrections made to each of the axes to obtain the final point cloud. The amplitude corrections have been implemented by multiplying them with the result obtained. The MySimLabs developer does not specify the units of the parameters rL and h, but after the application of the corrections in X, Y, and Z, the corrections implemented in X and Y are used to obtain a distance between consecutive points in both axes of 0.2 µm. After the corrections are applied to the data, the three data are measured in micrometres.

The initial surface has a length of 1400.4 µm in X and Y. A surface of that size is generated to ensure that even applying the largest filter detailed in this paper leaves a surface of 1 mm2 for the roughness parameter analysis.

Table A1 shows the parameters used to generate the point cloud.

Table A1.

Parameters used to generate the point cloud.

Table A1.

Parameters used to generate the point cloud.

| Surface | N | rL | h | clx | cly | Correction X | Correction Y | Correction Z |

|---|---|---|---|---|---|---|---|---|

| Surface 1 | 7003 | 10 | 1.5 | 0.07 | 0.07 | 140.04 | 140.04 | 1 |

| Surface 2 | 7003 | 10 | 1.5 | 0.05 | 0.05 | 140.04 | 140.04 | 5·10−1 |

| Surface 3 | 7003 | 10 | 1.5 | 0.01 | 0.01 | 140.04 | 140.04 | 1·10−1 |

| Surface 4 | 7003 | 10 | 1.5 | 0.03 | 0.03 | 140.04 | 140.04 | 2·10−2 |

| Surface 5 | 7003 | 10 | 1.5 | 0.01 | 0.01 | 140.04 | 140.04 | 2·10−2 |

The following is the header of the function used to generate the surfaces.

where f is the matrix with surface heights, x is the vector with surface points of X axis, y is the vector with surface points of Y axis, N is the number of surface points, rL is the length of surface, h is the RMS height, clx is the correlation length in X axis, and cly is the correlation length in Y axis.

[f,x,y] = rsgeng2D(N,rL,h,clx,cly),

Although these parameters are used for the generation of the surface, an identical surface to the one used here will not be obtained, although one with similar characteristics will be obtained. This is due to the fact that the tool used starts from a generation of random values and then performs a correction of them by filtering.

Appendix B. Other Results

This section shows the complete results obtained after varying the standard α angle and stylus size.

Appendix B.1. Standards with α = 125°

This section shows the complete results of areal roughness parameters for the variation in the groove and peak standards α of a 5° reduction. This is useful to estimate the variability or uncertainty of the results for standard variations such as a build-up of dust or breaking because the standard has not been stored under optimal conditions.

In Section 3.3.2, comparative tables and graphs are shown between the angles of α of 125°, 130°, and 135° for particle sizes 5 µm, 25 µm, 50 µm, and 100 µm for the peak and groove standard.

Table A2 and Table A3 show the results of height and hybrid areal roughness parameters for the groove standard with α = 125°.

Table A2.

Results for the groove standard with α = 125° of the original and filtered standard (2–15 µm).

Table A2.

Results for the groove standard with α = 125° of the original and filtered standard (2–15 µm).

| Parameters | Original | 2 µm | 4 µm | 5 µm | 6 µm | 14 µm | 15 µm |

|---|---|---|---|---|---|---|---|

| Sq [µm] | 3.1358 | 3.1358 | 3.1351 | 3.1345 | 3.1338 | 3.1242 | 3.1225 |

| Ssk | −4.3499 | −4.3499 | −4.3488 | −4.3480 | −4.3470 | −4.3338 | −4.3316 |

| Sku | 21.5411 | 21.5411 | 21.5274 | 21.5168 | 21.5044 | 21.3439 | 21.3173 |

| Sp [µm] | 0.7780 | 0.7780 | 0.7779 | 0.7778 | 0.7777 | 0.7761 | 0.7758 |

| Sv [µm] | 19.2220 | 19.2220 | 19.0969 | 19.0317 | 18.9676 | 18.4597 | 18.3966 |

| Sz [µm] | 20.0000 | 20.0000 | 19.8748 | 19.8095 | 19.7453 | 19.2358 | 19.1724 |

| Sa [µm] | 1.4381 | 1.4381 | 1.4378 | 1.4377 | 1.4375 | 1.4344 | 1.4339 |

| Sdq [rad] | 0.1440 | 0.1440 | 0.1434 | 0.1431 | 0.1428 | 0.1403 | 0.1400 |

| Sdr [%] | 0.9757 | 0.9757 | 0.9678 | 0.9636 | 0.9595 | 0.9271 | 0.9231 |

Table A3.

Results for the groove standard with α = 125° of the filtered standard (21–100 µm).

Table A3.

Results for the groove standard with α = 125° of the filtered standard (21–100 µm).

| Parameters | 21 µm | 25 µm | 38 µm | 50 µm | 70 µm | 100 µm |

|---|---|---|---|---|---|---|

| Sq [µm] | 3.1098 | 3.0992 | 3.0534 | 2.9966 | 2.8734 | 2.6293 |

| Ssk | −4.3160 | −4.3038 | −4.2566 | −4.2064 | −4.1167 | −3.9862 |

| Sku | 21.1325 | 20.9899 | 20.4554 | 19.9092 | 18.9815 | 17.7271 |

| Sp [µm] | 0.7736 | 0.7717 | 0.7634 | 0.7527 | 0.7283 | 0.6766 |

| Sv [µm] | 18.0164 | 17.7634 | 16.9437 | 16.1902 | 14.9407 | 13.0818 |

| Sz [µm] | 18.7900 | 18.5352 | 17.7072 | 16.9429 | 15.6690 | 13.7584 |

| Sa [µm] | 1.4298 | 1.4264 | 1.4110 | 1.3912 | 1.3461 | 1.2503 |

| Sdq [rad] | 0.1381 | 0.1368 | 0.1326 | 0.1286 | 0.1217 | 0.1104 |

| Sdr [%] | 0.8987 | 0.8824 | 0.8297 | 0.7809 | 0.6997 | 0.5779 |

Table A4 and Table A5 show the results of height and hybrid areal roughness parameters for the peak standard with α = 125°.

Table A4.

Results for the peak standard with α = 125° of the original and filtered standard (2–15 µm).

Table A4.

Results for the peak standard with α = 125° of the original and filtered standard (2–15 µm).

| Parameters | Original | 2 µm | 4 µm | 5 µm | 6 µm | 14 µm | 15 µm |

|---|---|---|---|---|---|---|---|

| Sq [µm] | 3.1358 | 3.1358 | 3.1358 | 3.1358 | 3.1358 | 3.1357 | 3.1357 |

| Ssk | 4.3499 | 4.3499 | 4.3499 | 4.3499 | 4.3499 | 4.3498 | 4.3498 |

| Sku | 21.5411 | 21.5411 | 21.5411 | 21.5412 | 21.5412 | 21.5410 | 21.5409 |

| Sp [µm] | 19.2220 | 19.2220 | 19.2219 | 19.2219 | 19.2219 | 19.2215 | 19.2214 |

| Sv [µm] | 0.7780 | 0.7780 | 0.7781 | 0.7781 | 0.7781 | 0.7785 | 0.7786 |

| Sz [µm] | 20.0000 | 20.0000 | 20.0000 | 20.0000 | 20.0000 | 20.0000 | 20.0000 |

| Sa [µm] | 1.4381 | 1.4380 | 1.4380 | 1.4380 | 1.4380 | 1.4380 | 1.4380 |

| Sdq [rad] | 0.1440 | 0.1438 | 0.1437 | 0.1436 | 0.1436 | 0.1430 | 0.1429 |

| Sdr [%] | 0.9757 | 0.9736 | 0.9721 | 0.9708 | 0.9710 | 0.9631 | 0.9614 |

Table A5.

Results for the peak standard with α = 125° of the filtered standard (21–100 µm).

Table A5.

Results for the peak standard with α = 125° of the filtered standard (21–100 µm).

| Parameters | 21 µm | 25 µm | 38 µm | 50 µm | 70 µm | 100 µm |

|---|---|---|---|---|---|---|

| Sq [µm] | 3.1356 | 3.1356 | 3.1354 | 3.1354 | 3.1359 | 3.1386 |

| Ssk | 4.3497 | 4.3494 | 4.3481 | 4.3459 | 4.3390 | 4.3178 |

| Sku | 21.5402 | 21.5388 | 21.5314 | 21.5183 | 21.4746 | 21.3328 |

| Sp [µm] | 19.2209 | 19.2204 | 19.2184 | 19.2160 | 19.2102 | 19.1978 |

| Sv [µm] | 0.7791 | 0.7796 | 0.7816 | 0.7840 | 0.7898 | 0.8022 |

| Sz [µm] | 20.0000 | 20.0000 | 20.0000 | 20.0000 | 20.0000 | 20.0000 |

| Sa [µm] | 1.4379 | 1.4380 | 1.4389 | 1.4406 | 1.4457 | 1.4599 |

| Sdq [rad] | 0.1425 | 0.1422 | 0.1412 | 0.1404 | 0.1388 | 0.1365 |

| Sdr [%] | 0.9562 | 0.9520 | 0.9397 | 0.9292 | 0.9101 | 0.8812 |

Appendix B.2. Standards with α = 135°

This section shows the complete results of areal roughness parameters for the variation in the groove standard α of a 5° ampliation. This is useful to estimate the variability or uncertainty in the results for standard variations such as breaking or wear because the standard has not been stored under optimal conditions or because it has been heavily used.

Table A6 and Table A7 show the results of height and hybrid areal roughness parameters for the groove standard with α = 135°.

Table A6.

Results for the groove standard with α = 135° of the original and filtered standard (2–15 µm).

Table A6.

Results for the groove standard with α = 135° of the original and filtered standard (2–15 µm).

| Parameters | Original | 2 µm | 4 µm | 5 µm | 6 µm | 14 µm | 15 µm |

|---|---|---|---|---|---|---|---|

| Sq [µm] | 3.4763 | 3.4763 | 3.4759 | 3.4757 | 3.4754 | 3.4708 | 3.4699 |

| Ssk | −3.8101 | −3.8101 | −3.8097 | −3.8094 | −3.8090 | −3.8036 | −3.8026 |

| Sku | 16.8466 | 16.8466 | 16.8417 | 16.8381 | 16.8337 | 16.7746 | 16.7645 |

| Sp [µm] | 0.9734 | 0.9734 | 0.9734 | 0.9733 | 0.9733 | 0.9724 | 0.9723 |

| Sv [µm] | 19.0266 | 19.0266 | 18.9446 | 18.9036 | 18.8625 | 18.5338 | 18.4926 |

| Sz [µm] | 20.0000 | 20.0000 | 19.9180 | 19.8769 | 19.8358 | 19.5062 | 19.4649 |

| Sa [µm] | 1.7627 | 1.7627 | 1.7626 | 1.7625 | 1.7624 | 1.7608 | 1.7606 |

| Sdq [rad] | 0.1285 | 0.1285 | 0.1281 | 0.1280 | 0.1278 | 0.1264 | 0.1262 |

| Sdr [%] | 0.7937 | 0.7937 | 0.7895 | 0.7874 | 0.7852 | 0.7680 | 0.7659 |

Table A7.

Results for the groove standard with α = 135°.

Table A7.

Results for the groove standard with α = 135°.

| Parameters | 21 µm | 25 µm | 38 µm | 50 µm | 70 µm | 100 µm |

|---|---|---|---|---|---|---|

| Sq [µm] | 3.4638 | 3.4587 | 3.4363 | 3.4081 | 3.3463 | 3.2214 |

| Ssk | −3.7959 | −3.7905 | −3.7687 | −3.7441 | −3.6966 | −3.6179 |

| Sku | 16.6926 | 16.6354 | 16.4094 | 16.1611 | 15.6999 | 14.9752 |

| Sp [µm] | 0.9711 | 0.9701 | 0.9657 | 0.9600 | 0.9471 | 0.9197 |

| Sv [µm] | 18.2462 | 18.0824 | 17.5514 | 17.0626 | 16.2516 | 15.0431 |

| Sz [µm] | 19.2173 | 19.0525 | 18.5171 | 18.0226 | 17.1987 | 15.9628 |

| Sa [µm] | 1.7584 | 1.7567 | 1.7487 | 1.7383 | 1.7149 | 1.6651 |

| Sdq [rad] | 0.1251 | 0.1244 | 0.1220 | 0.1198 | 0.1160 | 0.1100 |

| Sdr [%] | 0.7530 | 0.7443 | 0.7164 | 0.6906 | 0.6475 | 0.5830 |

Table A8 and Table A9 show the results of height and hybrid areal roughness parameters for the peak standard with α = 135°.

Table A8.

Results for the peak standard with α = 135° of the original and filtered standard (2–15 µm).

Table A8.

Results for the peak standard with α = 135° of the original and filtered standard (2–15 µm).

| Parameters | Original | 2 µm | 4 µm | 5 µm | 6 µm | 14 µm | 15 µm |

|---|---|---|---|---|---|---|---|

| Sq [µm] | 3.4763 | 3.4763 | 3.4763 | 3.4763 | 3.4763 | 3.4762 | 3.4762 |

| Ssk | 3.8101 | 3.8101 | 3.8101 | 3.8101 | 3.8101 | 3.8101 | 3.8101 |

| Sku | 16.8466 | 16.8466 | 16.8466 | 16.8466 | 16.8466 | 16.8467 | 16.8467 |

| Sp [µm] | 19.0266 | 19.0265 | 19.0265 | 19.0265 | 19.0265 | 19.0263 | 19.0262 |

| Sv [µm] | 0.9734 | 0.9735 | 0.9735 | 0.9735 | 0.9735 | 0.9737 | 0.9738 |

| Sz [µm] | 20.0000 | 20.0000 | 20.0000 | 20.0000 | 20.0000 | 20.0000 | 20.0000 |

| Sa [µm] | 1.7627 | 1.7627 | 1.7627 | 1.7627 | 1.7627 | 1.7627 | 1.7627 |

| Sdq [rad] | 0.1285 | 0.1284 | 0.1283 | 0.1283 | 0.1282 | 0.1279 | 0.1279 |

| Sdr [%] | 0.7937 | 0.7925 | 0.7916 | 0.7916 | 0.7906 | 0.7866 | 0.7864 |

Table A9.

Results for the peak standard with α = 135° of the filtered standard (21–100 µm).

Table A9.

Results for the peak standard with α = 135° of the filtered standard (21–100 µm).

| Parameters | 21 µm | 25 µm | 38 µm | 50 µm | 70 µm | 100 µm |

|---|---|---|---|---|---|---|

| Sq [µm] | 3.4761 | 3.4761 | 3.4759 | 3.4757 | 3.4755 | 3.4755 |

| Ssk | 3.8101 | 3.8101 | 3.8098 | 3.8092 | 3.8074 | 3.8020 |

| Sku | 16.8466 | 16.8465 | 16.8454 | 16.8428 | 16.8340 | 16.8051 |

| Sp [µm] | 19.0260 | 19.0257 | 19.0246 | 19.0232 | 19.0201 | 19.0135 |

| Sv [µm] | 0.9740 | 0.9743 | 0.9754 | 0.9768 | 0.9799 | 0.9865 |

| Sz [µm] | 20.0000 | 20.0000 | 20.0000 | 20.0000 | 20.0000 | 20.0000 |

| Sa [µm] | 1.7626 | 1.7626 | 1.7624 | 1.7626 | 1.7638 | 1.7682 |

| Sdq [rad] | 0.1276 | 0.1275 | 0.1269 | 0.1264 | 0.1255 | 0.1242 |

| Sdr [%] | 0.7833 | 0.7813 | 0.7743 | 0.7682 | 0.7580 | 0.7428 |

Appendix B.3. Results for Stylus Reduction of 5%

This section shows the complete results of areal roughness parameters for a 5% particle size reduction. This is useful to estimate the effects or uncertainty of stylus durability in areal roughness parameters.

In Section 3.3.3, comparative tables and graphs are shown between a particle size variation of ±5% for particle sizes 5 µm, 25 µm, 50 µm, and 100 µm for the peak and groove standard.

Table A10 and Table A11 show the results of height and hybrid areal roughness parameters for a 5% reduction in the particle or stylus size in the groove standard with α = 130°.

Table A10.

Results for the groove standard with α = 130° and stylus reduction of 5% of the original and filtered standard (2–15 µm).

Table A10.

Results for the groove standard with α = 130° and stylus reduction of 5% of the original and filtered standard (2–15 µm).

| Parameters | Original | 1.9 µm | 3.8 µm | 4.75 µm | 5.7 µm | 13.3 µm | 14.25 µm |

|---|---|---|---|---|---|---|---|

| Sq [µm] | 3.2957 | 3.2956 | 3.2952 | 3.2948 | 3.2944 | 3.2883 | 3.2872 |

| Ssk | −4.0838 | −4.0838 | −4.0832 | −4.0827 | −4.0821 | −4.0743 | −4.0729 |

| Sku | 19.1490 | 19.1488 | 19.1416 | 19.1359 | 19.1291 | 19.0381 | 19.0227 |

| Sp [µm] | 0.8665 | 0.8665 | 0.8664 | 0.8664 | 0.8663 | 0.8652 | 0.8650 |

| Sv [µm] | 19.1335 | 19.1335 | 19.0405 | 18.9915 | 18.9425 | 18.5507 | 18.5018 |

| Sz [µm] | 20.0000 | 20.0000 | 19.9070 | 19.8579 | 19.8088 | 19.4159 | 19.3668 |

| Sa [µm] | 1.5868 | 1.5868 | 1.5867 | 1.5866 | 1.5864 | 1.5844 | 1.5841 |

| Sdq [rad] | 0.1363 | 0.1363 | 0.1359 | 0.1357 | 0.1354 | 0.1337 | 0.1334 |

| Sdr [%] | 0.8842 | 0.8841 | 0.8789 | 0.8761 | 0.8732 | 0.8505 | 0.8477 |

Table A11.

Results for the groove standard with α = 130° and stylus reduction of 5% of the filtered standard (21–100 µm).

Table A11.

Results for the groove standard with α = 130° and stylus reduction of 5% of the filtered standard (21–100 µm).

| Parameters | 19.95 µm | 23.75 µm | 36.1 µm | 47.5 µm | 66.5 µm | 95 µm |

|---|---|---|---|---|---|---|

| Sq [µm] | 3.2791 | 3.2723 | 3.2428 | 3.2058 | 3.1251 | 2.9631 |

| Ssk | −4.0634 | −4.0558 | −4.0255 | −3.9920 | −3.9291 | −3.8293 |

| Sku | 18.9144 | 18.8292 | 18.4984 | 18.1443 | 17.5071 | 16.5542 |

| Sp [µm] | 0.8635 | 0.8623 | 0.8568 | 0.8496 | 0.8334 | 0.7989 |

| Sv [µm] | 18.2087 | 18.0135 | 17.3807 | 16.7986 | 15.8327 | 14.3941 |

| Sz [µm] | 19.0722 | 18.8758 | 18.2374 | 17.6482 | 16.6661 | 15.1930 |

| Sa [µm] | 1.5814 | 1.5791 | 1.5689 | 1.5558 | 1.5261 | 1.4628 |

| Sdq [rad] | 0.1321 | 0.1311 | 0.1281 | 0.1253 | 0.1203 | 0.1126 |

| Sdr [%] | 0.8306 | 0.8192 | 0.7822 | 0.7480 | 0.6911 | 0.6056 |

Table A12 and Table A13 show the results of height and hybrid areal roughness parameters for a 5% reduction in the particle or stylus size in the peak standard with α = 130°.

Table A12.

Results for the peak standard with α = 130° and stylus reduction of 5% of the original and filtered standard (2–15 µm).

Table A12.

Results for the peak standard with α = 130° and stylus reduction of 5% of the original and filtered standard (2–15 µm).

| Parameters | Original | 1.9 µm | 3.8 µm | 4.75 µm | 5.7 µm | 13.3 µm | 14.25 µm |

|---|---|---|---|---|---|---|---|

| Sq [µm] | 3.2957 | 3.2956 | 3.2956 | 3.2956 | 3.2956 | 3.2956 | 3.2956 |

| Ssk | 4.0838 | 4.0838 | 4.0838 | 4.0838 | 4.0838 | 4.0838 | 4.0838 |

| Sku | 19.1490 | 19.1491 | 19.1491 | 19.1491 | 19.1491 | 19.1491 | 19.1491 |

| Sp [µm] | 19.1335 | 19.1335 | 19.1335 | 19.1335 | 19.1334 | 19.1332 | 19.1331 |

| Sv [µm] | 0.8665 | 0.8665 | 0.8665 | 0.8665 | 0.8666 | 0.8668 | 0.8669 |

| Sz [µm] | 20.0000 | 20.0000 | 20.0000 | 20.0000 | 20.0000 | 20.0000 | 20.0000 |

| Sa [µm] | 1.5868 | 1.5868 | 1.5868 | 1.5868 | 1.5868 | 1.5868 | 1.5867 |

| Sdq [rad] | 0.1363 | 0.1362 | 0.1361 | 0.1361 | 0.1360 | 0.1356 | 0.1355 |

| Sdr [%] | 0.8842 | 0.8828 | 0.8816 | 0.8812 | 0.8804 | 0.8756 | 0.8742 |

Table A13.

Results for the peak standard with α = 130° and stylus reduction of 5% of the filtered standard (21–100 µm).

Table A13.

Results for the peak standard with α = 130° and stylus reduction of 5% of the filtered standard (21–100 µm).

| Parameters | 19.95 µm | 23.75 µm | 36.1 µm | 47.5 µm | 66.5 µm | 95 µm |

|---|---|---|---|---|---|---|

| Sq [µm] | 3.2955 | 3.2954 | 3.2953 | 3.2951 | 3.2951 | 3.2958 |

| Ssk | 4.0837 | 4.0836 | 4.0830 | 4.0821 | 4.0788 | 4.0694 |

| Sku | 19.1488 | 19.1484 | 19.1457 | 19.1405 | 19.1221 | 19.0663 |

| Sp [µm] | 19.1327 | 19.1324 | 19.1310 | 19.1294 | 19.1254 | 19.1173 |

| Sv [µm] | 0.8673 | 0.8676 | 0.8690 | 0.8706 | 0.8746 | 0.8827 |

| Sz [µm] | 20.0000 | 20.0000 | 20.0000 | 20.0000 | 20.0000 | 20.0000 |

| Sa [µm] | 1.5867 | 1.5867 | 1.5868 | 1.5875 | 1.5900 | 1.5972 |

| Sdq [rad] | 0.1352 | 0.1350 | 0.1343 | 0.1337 | 0.1325 | 0.1309 |

| Sdr [%] | 0.8702 | 0.8677 | 0.8588 | 0.8513 | 0.8373 | 0.8175 |

Appendix B.4. Results for Stylus Magnification of 5%

Table A14 and Table A15 show the results of height and hybrid areal roughness parameters for a 5% magnification of the particle or stylus size in the groove standard with α = 130°.

Table A14.

Results for the groove standard with α = 130° and stylus magnification of 5% of the original and filtered standard (2–15 µm).

Table A14.