A Mechanics Model for Contact with Rough Surface Considering the Interaction of Micro-Asperity Bodies

Abstract

1. Introduction

2. The Establishment of the Contact Characteristic Model

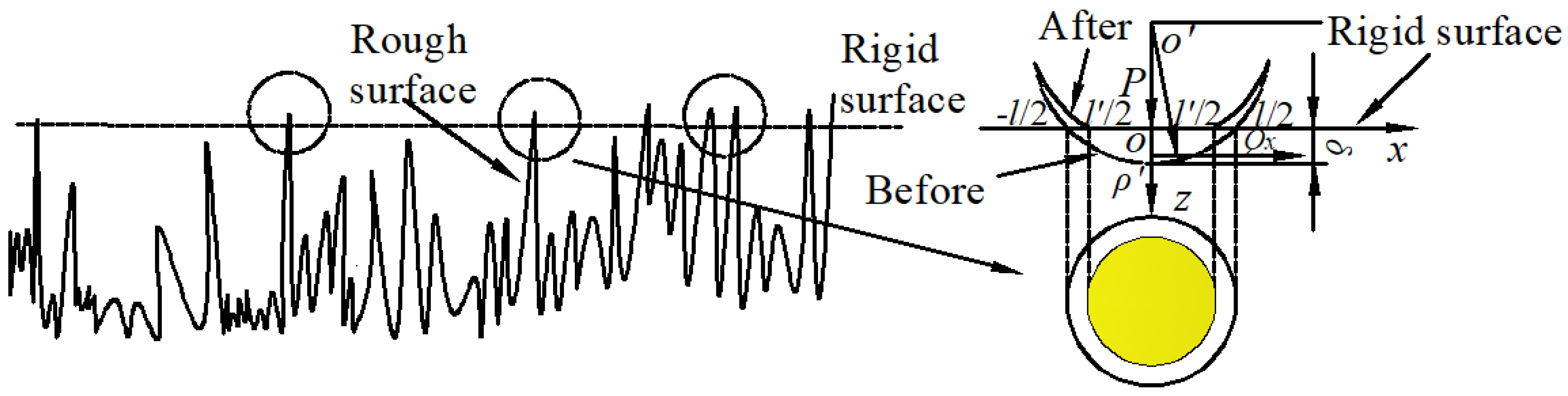

2.1. Contact Characterization of Micro-Asperity Bodies

2.2. Contact Deformation of Micro-Asperity Bodies

2.3. Actual Contact Area

2.4. The Relationship Between Total Actual Contact Area and External Loads

2.5. Friction and Wear

2.5.1. Running-In Wear

2.5.2. Abrasive Wear

3. Results and Discussion

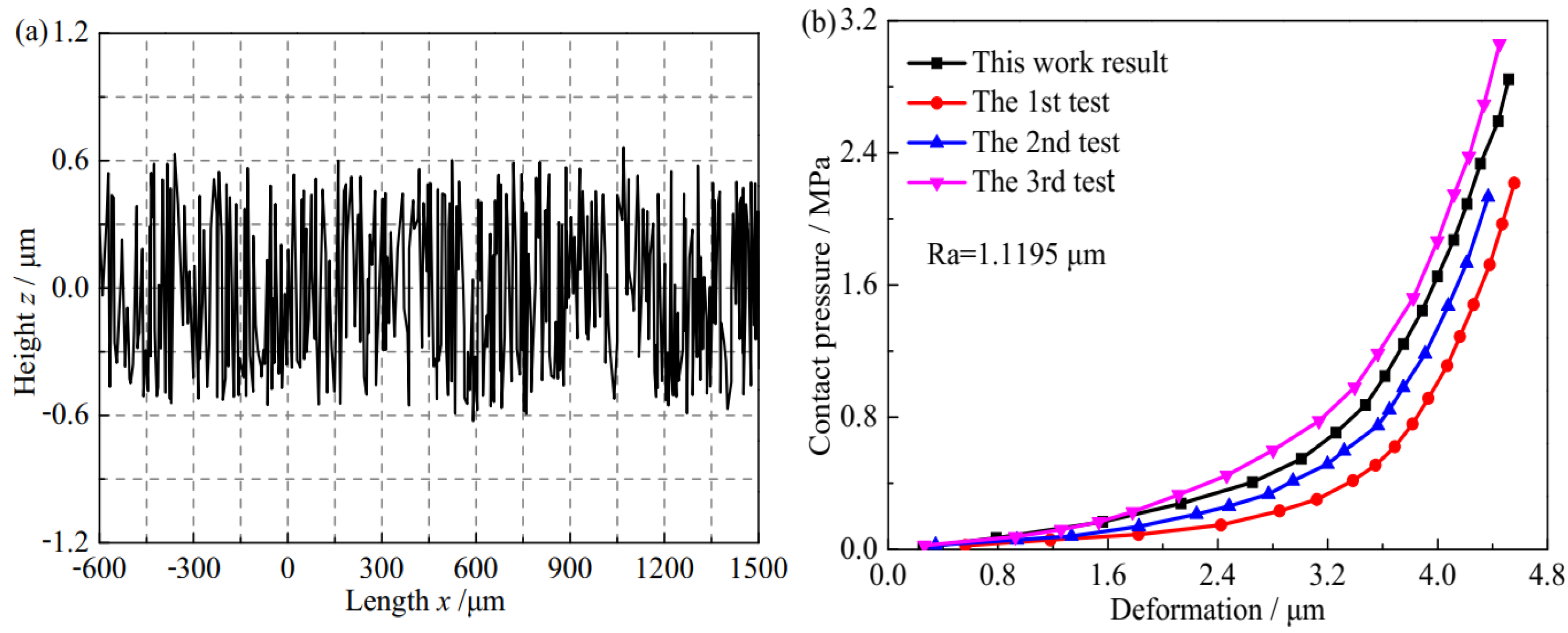

3.1. Model Results and Validation

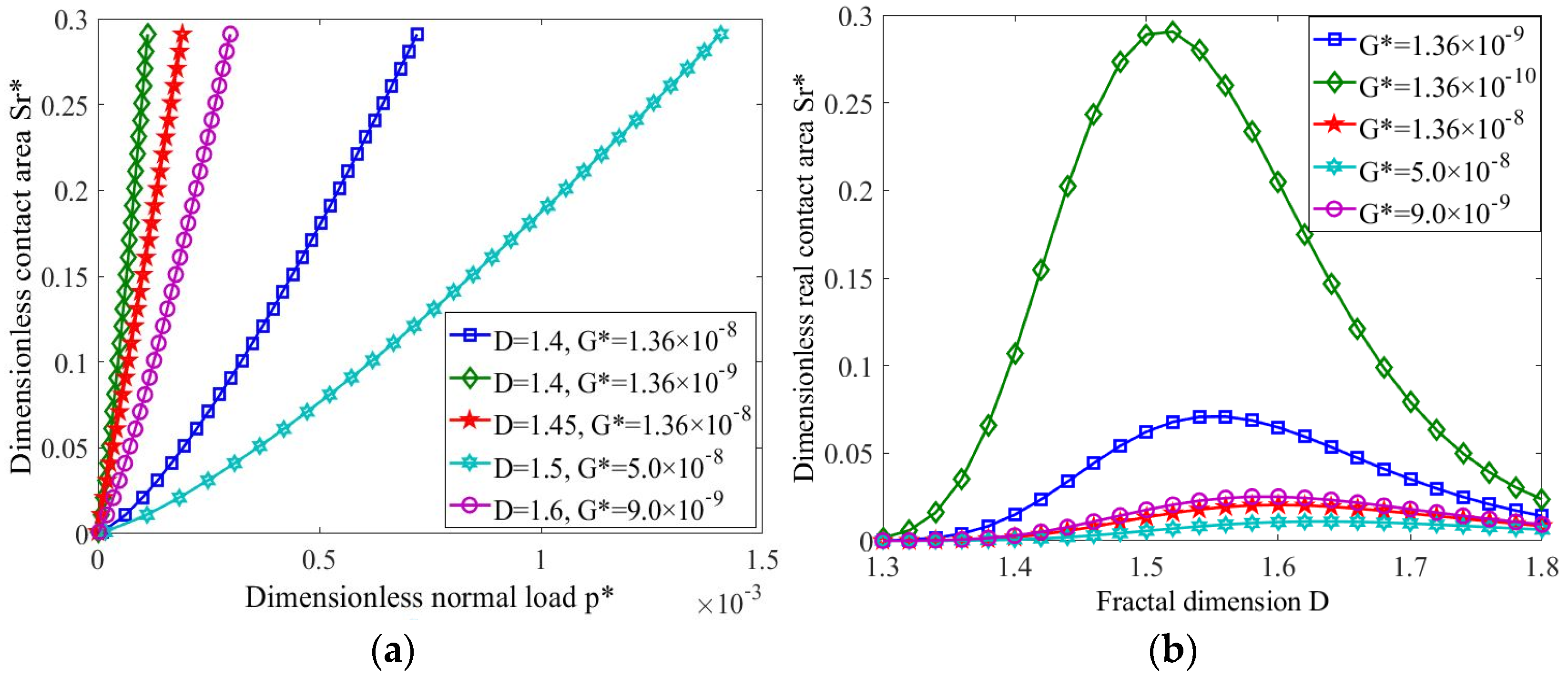

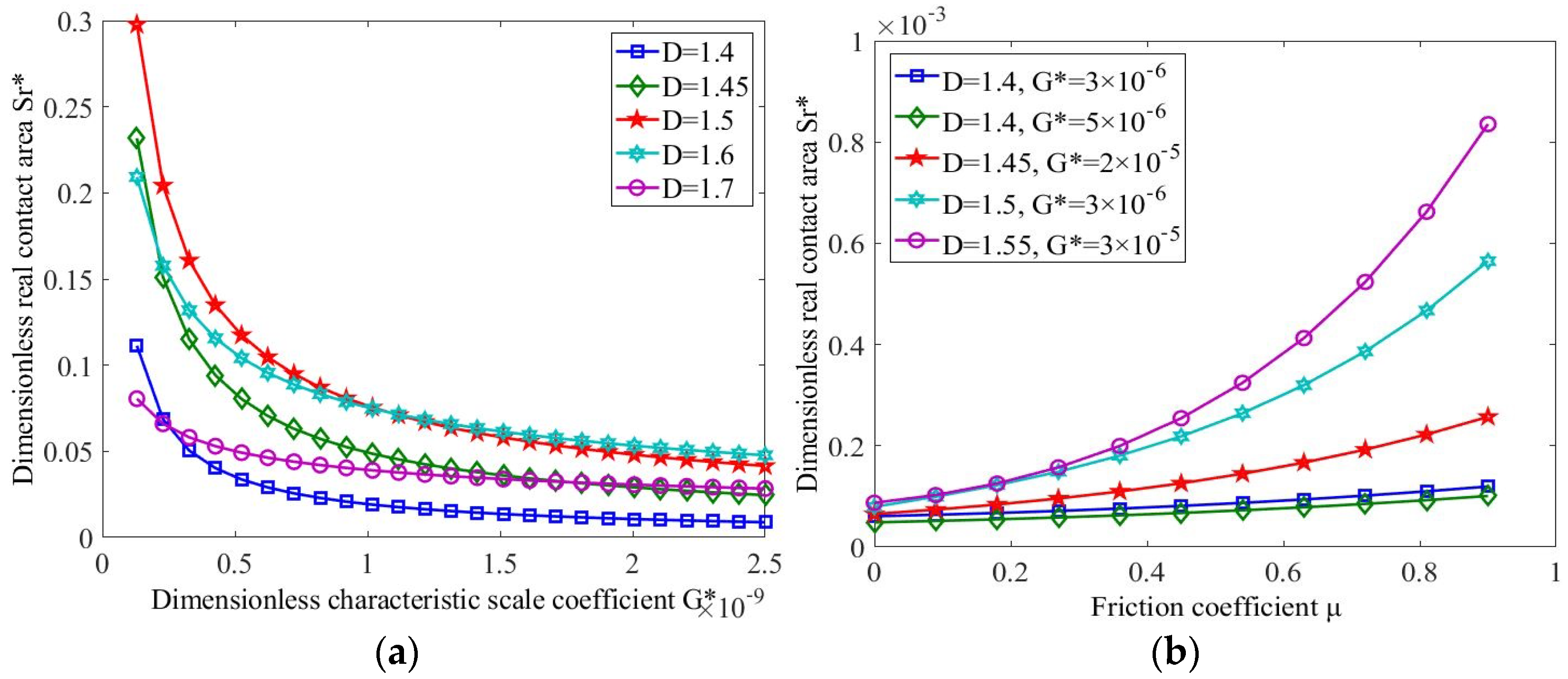

3.2. The Variation in Contact Area with Load, Fractal Coefficient and Friction Coefficient

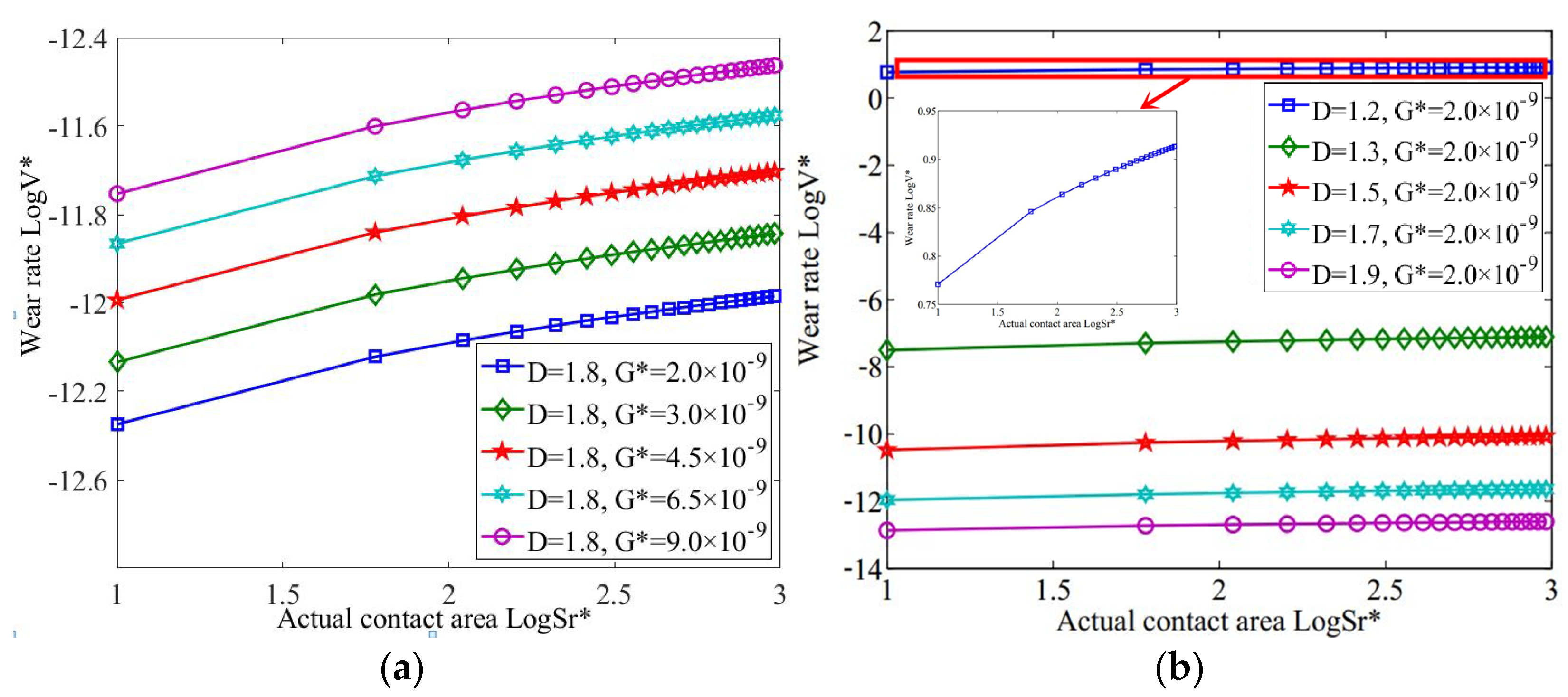

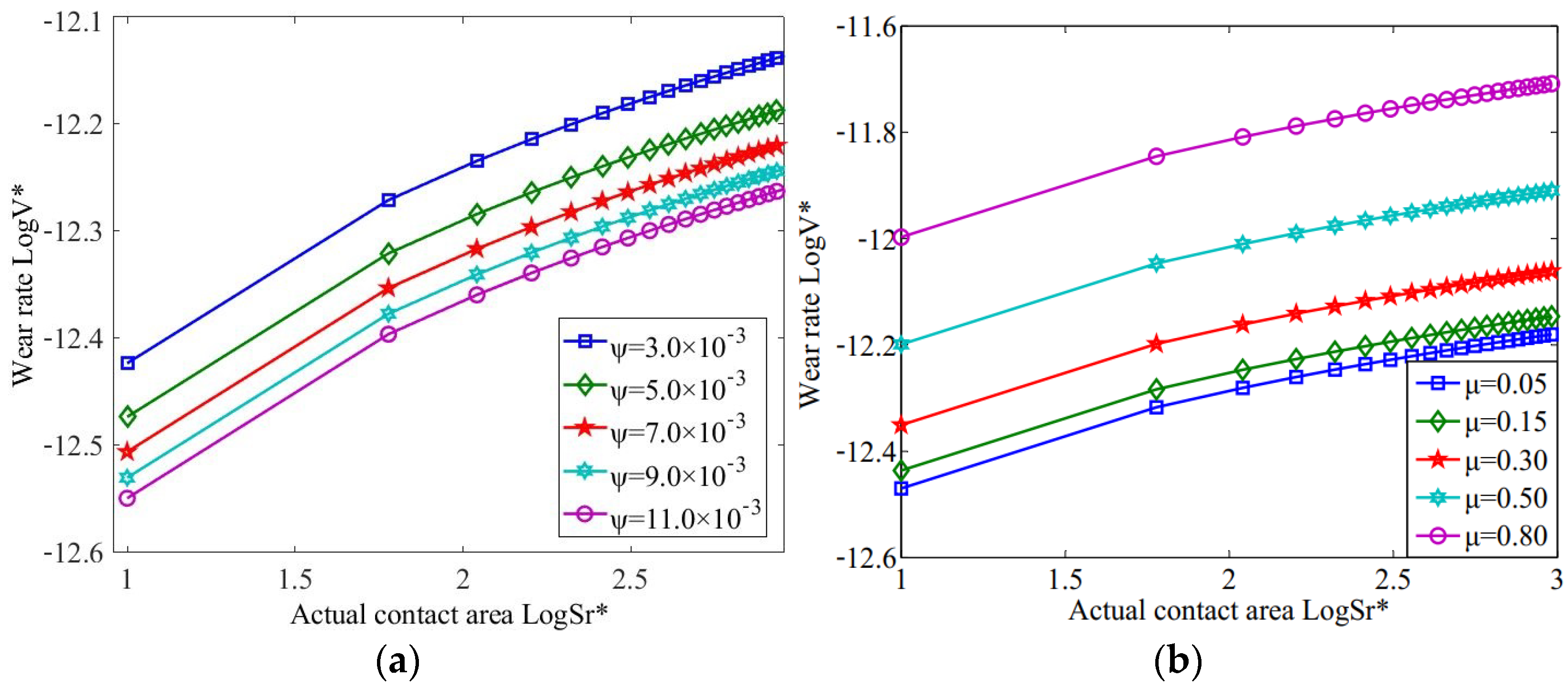

3.3. The Variation in Wear Rate with Contact Area Under Running-In Wear Condition

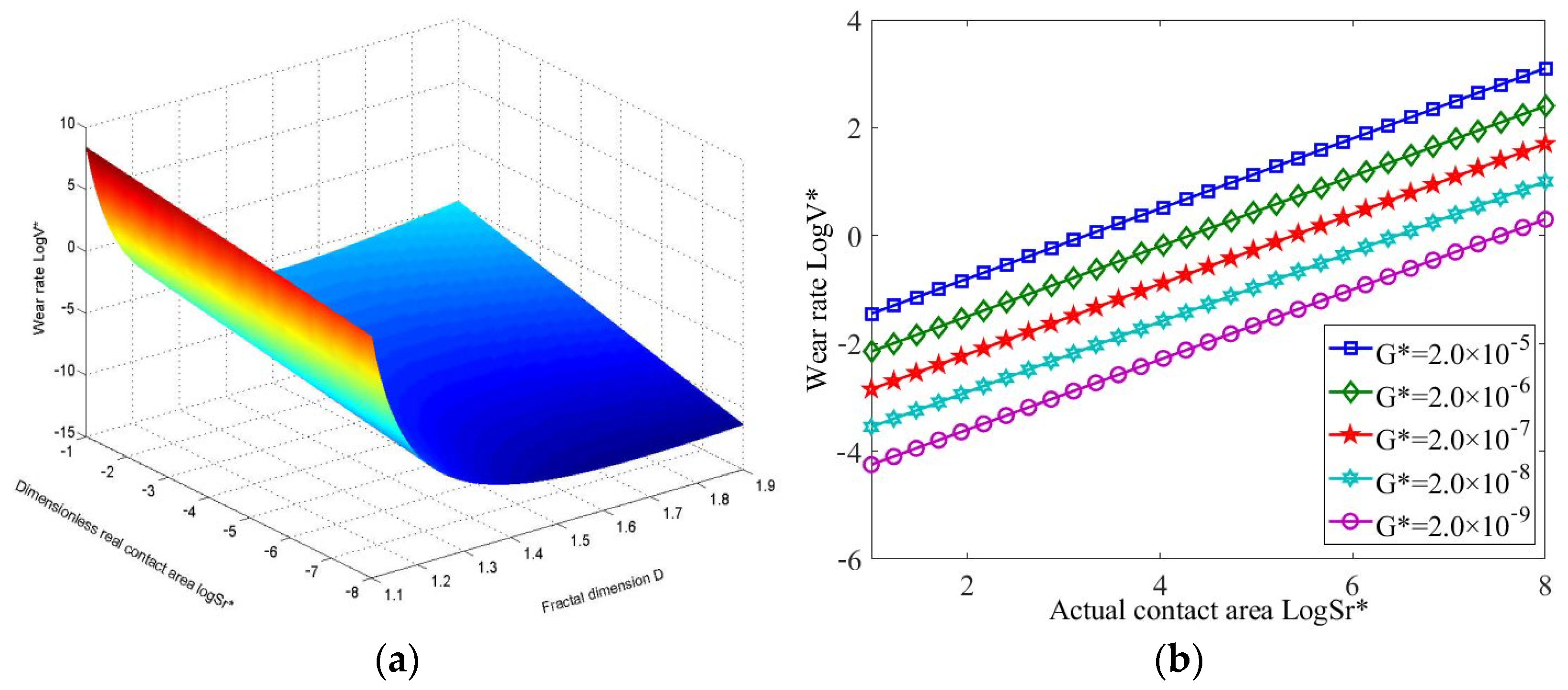

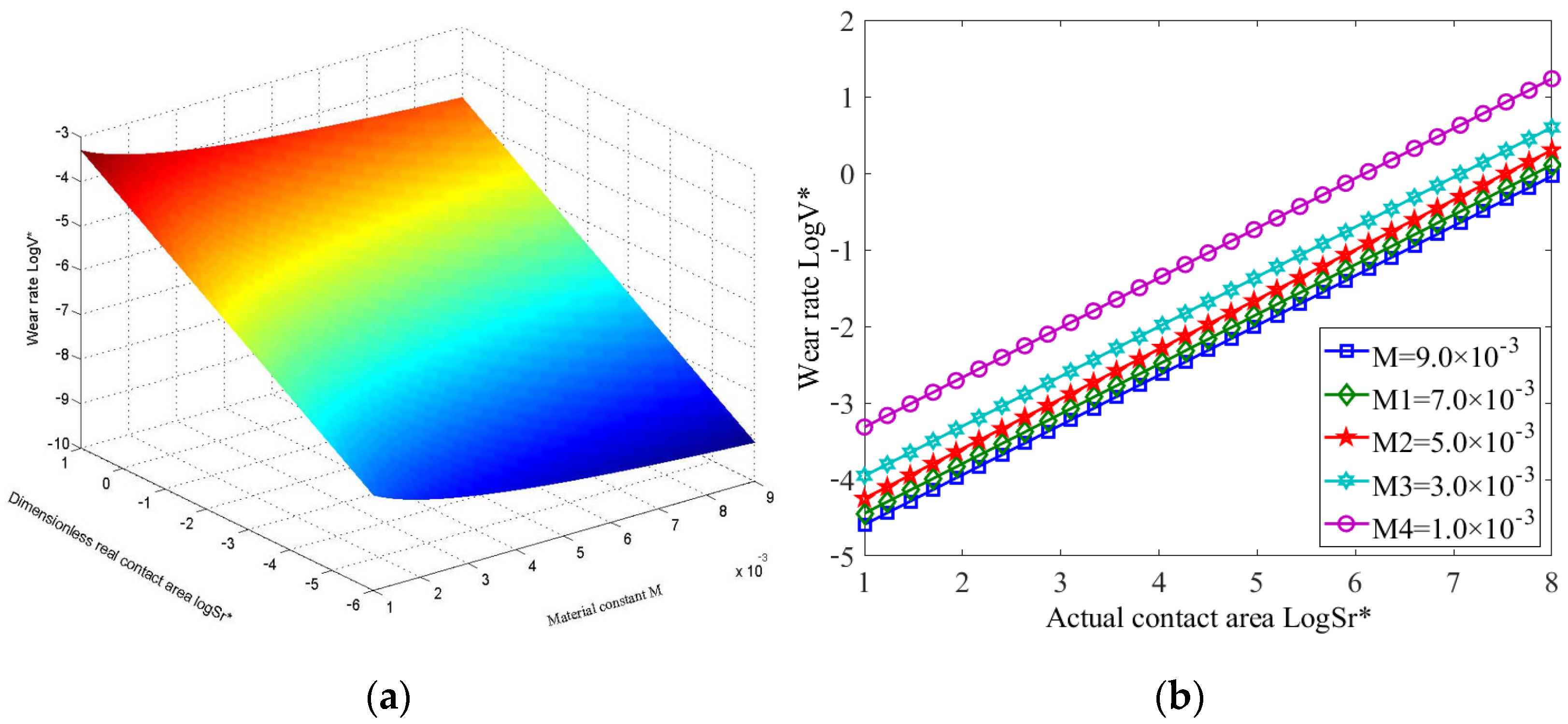

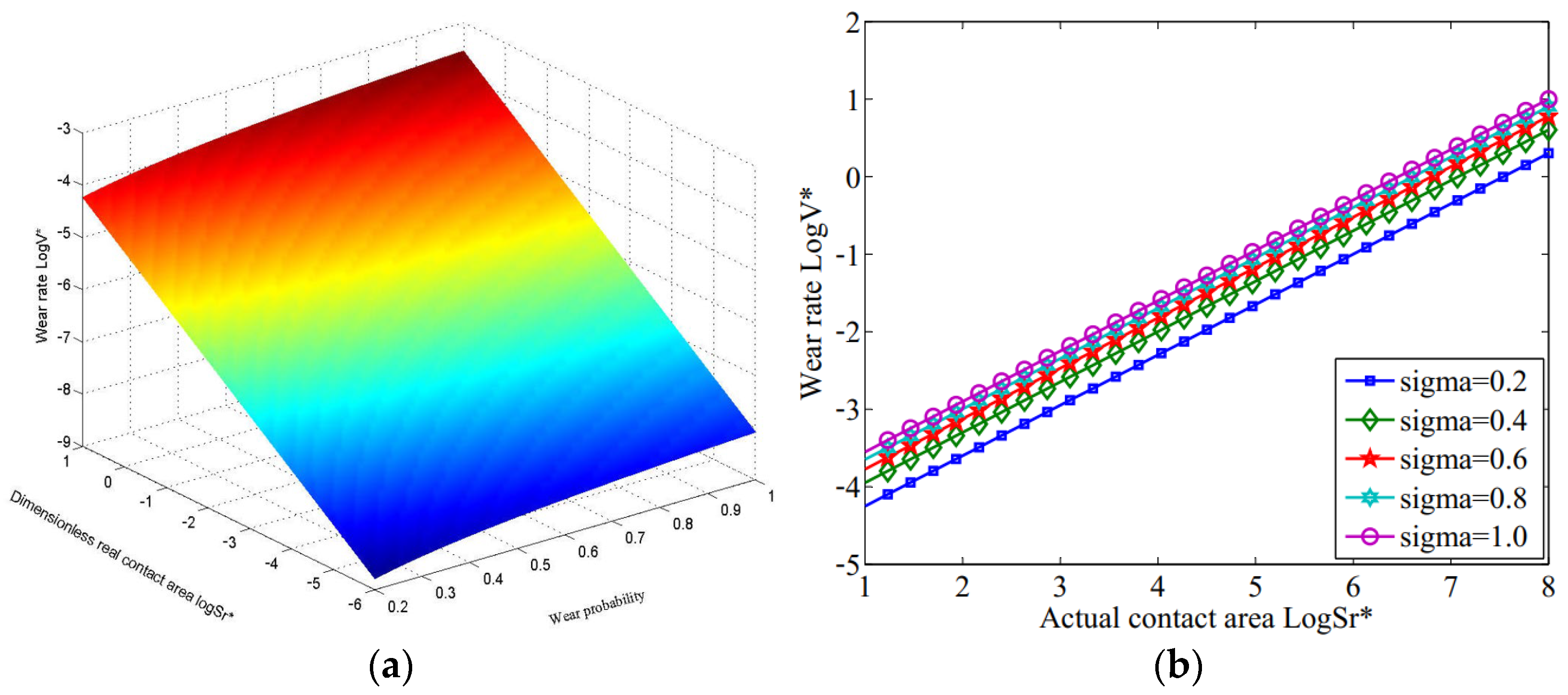

3.4. The Variation in Wear Rate with Contact Area Under Abrasive Wear Condition

4. Conclusions

- (1)

- The actual contact area increased with the increase in external load when the surface morphology was constant. The actual contact area decreased with the increase in characteristic scale coefficient and increased first and then decreased with the increase in fractal dimension when the load was constant. Meanwhile, the actual contact area decreased with the increase in the characteristic scale coefficient when the fractal dimension was constant.

- (2)

- In running-in wear, the wear rate increases with the increase in surface profile parameters. However, the wear rate decreased with the increase in the fractal dimension or material characteristic coefficient under the same contact area. In abrasive wear, the wear rate was the smallest when the fractal dimension was 1.6, within the fractal dimension range (1.1 ≤ D < 1.9). Additionally, a linear relationship was present between the wear rate and the contact area. In addition, the larger the characteristic scale coefficient, the higher the wear rate; and the greater the probability constant, and the smaller the material constant, the higher the wear rate under the same contact area.

- (3)

- A modified evaluation contact model was proposed, considering the deformation characteristics of asperity bodies according to the fractal theory, which not only helped to analyze the deformation and wear conditions of the micro-asperity bodies, but also provided a theoretical basis for further study of the properties of the contact bearing (e.g., bearing design optimization, lubricant improvement, friction and wear reduction, etc.).

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| z(x) | represents asperity body height, m |

| D | represents fractal dimension |

| G | represents characteristic scale coefficient |

| l’ = 1/γn | represents cross section width (m) with frequency index n |

| Ee | represents elastic modulus, Pa |

| E1e and E2e | represent elastic modulus of contact asperity bodies, Pa |

| v1 and v2 | represent Poisson’s ratio |

| μ | represents friction correction factor; and σy represents yield strength, Pa |

| ψ | fractal extension region coefficient; Sl was the maximum contact area, mm2 |

| Sr | total actual contact area, mm2 |

| p* | dimensionless normal load value |

| G* | dimensionless characteristic dimension coefficient |

| Sc* | critical contact area of the dimensionless elastic deformation |

| Spc* | critical contact area of dimensionless plastic deformation |

| Sl* | maximum contact area of dimensionless contact micro-asperity bodies |

References

- Mao, Y.; Li, D.; Li, L.; Zheng, J. Effect of textured parameters on tribological properties of hydrodynamic journal bearing. Ind. Lubr. Tribol. 2024, 76, 107–109. [Google Scholar] [CrossRef]

- Mao, Y.Z.; Li, L.L.; Li, D.Q.; Zheng, J. Analysis of the turbulent lubrication of a textured hydrodynamic journal bearing. Lubricants 2023, 11, 362. [Google Scholar] [CrossRef]

- Mao, Y.Z.; Zhang, Y.X.; Shi, S.L.; Wang, L.; Li, Z.; Zheng, J. Study on laser textured surface machining and optimization of process parameters. Appl. Phys. B 2025, 131, 16. [Google Scholar] [CrossRef]

- Mao, Y.Z.; Yang, J.C.; Ji, J.C. Theoretical and experimental study of surface texturing with laser machining. Adv. Manuf. 2021, 9, 538–557. [Google Scholar] [CrossRef]

- Zhang, K.P.; Wu, C.H.; Shi, X.L.; Xue, Y.; Huang, Q. Investigations of tribological performance of slewing bearing raceway with bionic textured composite surface under grease lubrication. Tribol. Int. 2023, 184, 108469. [Google Scholar] [CrossRef]

- Bartkowiak, T.; Peta, K.; Królczyk, J.B.; Niesłony, P.; Bogdan-Chudy, M.; Przeszłowski, Ł.; Trych-Wildner, A.; Wojciechowska, N.; Królczyk, G.M.; Wieczorowski, M. Wetting properties of polymer additively manufactured surfaces—Multiscale and multi-technique study into the surface-measurement-function interactions. Tribol. Int. 2025, 202, 110394. [Google Scholar] [CrossRef]

- Marian, M.; Almqvist, A.; Rosenkranz, A.; Fillon, M. Numerical micro-texture optimization for lubricated contacts—A critical discussion. Friction 2022, 10, 1772–1774. [Google Scholar] [CrossRef]

- Peta, K.; Stemp, W.J.; Chen, R.; Love, G.; Brown, C.A. Multiscale characterizations of topographic measurements on lithic materials and microwear using a GelSight Max: Investigating potential archaeological applications. J. Archaeol. Sci. Rep. 2024, 57, 104637. [Google Scholar] [CrossRef]

- Shen, F.; Li, Y.H.; Ke, L.L. A novel fractal contact model based on size distribution law. Int. J. Mech. Sci. 2023, 249, 20–23. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, W.; Wang, C.; Liu, D.; Zhu, L. An accurate solution of a hemisphere contact against a rigid flat under varying elastic moduli and yield strengths and comparison with previous model. J. Mech. Sci. Tech. 2022, 36, 4615–4624. [Google Scholar] [CrossRef]

- Schewe, M.; Wilbuer, H.; Menzel, A. Simulation of wear and effective friction properties of microstructured surfaces. Wear 2021, 464–465, 203491. [Google Scholar] [CrossRef]

- Bai, C.; Zhang, W.; Zhang, Z.; Zhao, Z.; Li, Y. Modeling of running-in wear based on fractal theory. Machinery 2016, 54, 28–31. [Google Scholar]

- Zhang, C.X.; Li, X.; He, J.L.; Cheng, Y.H.; Liu, Z.F.; Li, Y. Static friction coefficient model of joint surface based on the modified fractal model and experimental investigation. Int. J. Adv. Manuf. Technol. 2023, 12, 4415–4429. [Google Scholar] [CrossRef]

- Lan, W.B.; Fan, S.W.; Fan, S. A fractal model of elastic-plastic contact between rough surfaces for a low-velocity impact process. Int. J. Comput. Methods. 2021, 18, 2150039. [Google Scholar] [CrossRef]

- Lan, G.S.; Sun, W.; Zhang, X.L.; Chen, Y.; Tan, W.; Li, X. A three-dimensional fractal model of the normal contact characteristics of two contacting rough surfaces. AIP Adv. 2021, 11, 055023. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, Z.P.; Bu, Y.B. Normal contact model of fractal surfaces considering friction and asperity interactions. Int. J. Appl. Mech. 2024, 16, 2450057. [Google Scholar] [CrossRef]

- Feng, Y.; Yang, P.; Zhang, Y.Y. Fractal model of thermal elasto-plastic contact of rough surfaces. J. Cent. South Univ. (Engl. Ed.) 2022, 29, 1500–1509. [Google Scholar] [CrossRef]

- Liang, X.M.; Wang, G.F. A friction model of fractal rough surfaces accounting for size dependence at nanoscale. Acta Mech. 2022, 233, 69–81. [Google Scholar] [CrossRef]

- Wang, H.; Cui, J.; Wu, J.; Tan, J. A fractal friction model for nanoscale rough surface contact. J. Appl. Phys. 2022, 132, 015105. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, Z.L.; Zhang, H.; Zhu, R. Fractal variation of three-dimensional surface topography during sliding wear under mixed elastohydrodynamic lubrication. Surf. Topogr. Metrol. Prop. 2021, 9, 045007. [Google Scholar] [CrossRef]

- Wei, L.; Liu, Q.H.; Zhang, P.G. Sliding friction surface contact mechanics model based on fractal theory. J. Mech. Eng. 2012, 18, 106–113. [Google Scholar] [CrossRef]

- Yu, X.; Sun, Y.Y.; Wu, S.J. Multi-stage contact model between fractal rough surfaces based on multi-scale asperity deformation. Appl. Math. Modell. 2022, 109, 229–250. [Google Scholar] [CrossRef]

- Jeng, L.L.; Jen, F.L. A modified fractal microcontact model developed for asperity heights with variable morphology parameters. Wear 2010, 268, 134–144. [Google Scholar]

- Monti, J.M.; Pastewka, L.; Robbins, M.O. Fractal geometry of contacting patches in rough elastic contacts. J. Mech. Phys. Solids. 2022, 160, 104797. [Google Scholar] [CrossRef]

- Ding, X.X.; Yan, R.Q.; Jia, Y.L. Construction and analysis of fractal contact mechanics model for rough surface based on base length. Tribol. 2014, 34, 341–347. [Google Scholar]

- Yu, X.; Sun, Y.Y.; Zhao, D.; Wu, S. A revised contact stiffness model of rough curved surfaces based on the length scale. Tribol. Int. 2021, 164, 107206. [Google Scholar] [CrossRef]

- Bhushan, B. The real area of contact in polymeric magnetic media -Ⅱ: Experimental data analysis. ASLE Trans. 1985, 28, 181–197. [Google Scholar] [CrossRef]

- Greenwood, J.A.; Williamson, J.B.P. contact of nominally flat surfaces. Proc. R. Soc. 1966, A295, 300–319. [Google Scholar]

- Majumdar, A.; Bhushan, B. Fractal model of elasticplastic contact between rough surfaces. ASME J. Tribol. 1991, 113, 1–11. [Google Scholar] [CrossRef]

- Yu, Y.; Cheng, Y.; Zhang, J. Fractal based elastoplastic mechanics model for contact with rough surface and its experimental verification. Eng. Mech. 2018, 35, 209–221. [Google Scholar]

| Style | Absolute Error/% (n = 24) | Absolute Error/% (n = 8) |

|---|---|---|

| This work’s model | / | / |

| Bhushan’s test result | 4.13 | 4.65 |

| Wei’s model | 1.13 | 0.93 |

| G–W model | 4.41 | 4.93 |

| M–B model | 4.07 | 5.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, Y.; Hu, Q.; Yu, Y.; Shi, S.; Pei, J.; Li, Z.; Wang, L. A Mechanics Model for Contact with Rough Surface Considering the Interaction of Micro-Asperity Bodies. Lubricants 2025, 13, 96. https://doi.org/10.3390/lubricants13030096

Mao Y, Hu Q, Yu Y, Shi S, Pei J, Li Z, Wang L. A Mechanics Model for Contact with Rough Surface Considering the Interaction of Micro-Asperity Bodies. Lubricants. 2025; 13(3):96. https://doi.org/10.3390/lubricants13030096

Chicago/Turabian StyleMao, Yazhou, Qingxin Hu, Yingying Yu, Shaolin Shi, Jiaming Pei, Zichen Li, and Linyuan Wang. 2025. "A Mechanics Model for Contact with Rough Surface Considering the Interaction of Micro-Asperity Bodies" Lubricants 13, no. 3: 96. https://doi.org/10.3390/lubricants13030096

APA StyleMao, Y., Hu, Q., Yu, Y., Shi, S., Pei, J., Li, Z., & Wang, L. (2025). A Mechanics Model for Contact with Rough Surface Considering the Interaction of Micro-Asperity Bodies. Lubricants, 13(3), 96. https://doi.org/10.3390/lubricants13030096