1. Introduction

Brake noise and vibration phenomena occurring during brake engagement are commonly referred to as squeal, groan, moan, and similar terms. Among these, squeal is typically defined as a high-frequency noise problem occurring above 1 kHz during low-speed operations. Due to its high frequency, squeal is widely recognised as the most annoying issue for passengers. Squeal manifests intermittently or even randomly, making it difficult to capture repeatable signals under identical test conditions [

1,

2,

3,

4]. Microscopic aspects, such as wear and contact debris, are potential contributors to the intermittency of squeal occurrence, as they alter the friction coefficient at the brake contact interface and its friction–velocity slope [

5,

6,

7].

Brake squeal presents a significant challenge for the automotive industry and has been extensively investigated through finite element (FE) analysis, analytical modelling, and experimental studies. The onset of brake squeal is commonly assumed to be caused by the linear instability of the linearised equations of motion at equilibrium [

1,

2,

3,

4]. The complex eigenvalues of the system, derived from analytical approaches, have provided comprehensive explanations of the squeal mechanism [

8,

9,

10,

11]. Experimental investigations have also been widely conducted to analyse brake squeal behaviour [

12,

13,

14,

15,

16,

17,

18].

In analytical models, the disc brake system is often represented as a symmetric circular plate subjected to frictional stresses [

9,

10,

11]. The rotation of the disc introduces velocity-dependent gyroscopic and friction-damping matrices. Kang’s comprehensive model [

11] demonstrated that gyroscopic destabilisation is a critical mechanism for point contact, while mode-coupling becomes predominant for distributed contact areas. The relative contributions of mode-coupling and gyroscopic effects to dynamic instability are summarised in

Table 1 of reference [

11].

Most analytical models assume a brake disc subjected to stationary friction loads over the brake pad contact area. While friction is generated as the disc rotates, the rotation effect is often neglected in brake squeal simulations, as squeal primarily occurs at low speeds. Neglecting the rotation of the disc introduces two major limitations:

(1) Velocity-dependent terms, including gyroscopic destabilisation and friction damping, cannot be investigated [

19].

(2) Rotation angle-dependent terms, including the frequency split of the disc, cannot be analysed [

20,

21,

22], which is the central focus of this paper.

The frequency split effect associated with disc rotation may reveal rich insights into nonlinear brake squeal signals, which can exhibit time-periodic and chaotic characteristics. Despite its potential importance, accurate models that account for disc rotation and frequency split are rare. This paper aims to derive these rotational effects, including gyroscopic actions and geometric asymmetry, in the equations of motion.

Geometric asymmetry, a related factor, has drawn attention for its impact on the dynamic behaviour of symmetric-like vibrating structures [

23,

24,

25]. Asymmetry in non-rotating brake components, such as hub bolts, can also contribute to frequency splitting [

26]. One significant outcome of geometric asymmetry is the frequency split between doublet modes in symmetric-like structures. The frequency split effects in stationary brake discs have been widely studied, with previous models showing that mode-coupling instability increases as the frequency split between two adjacent modes decreases [

9,

10]. The frequency split of doublet mode pairs is of particular interest, as it is typically very small or even zero. In principle, this split exists only when axis-symmetry is broken and is always present in automotive brake discs due to geometric imperfections or bolt assemblies disrupting rotational symmetry [

1]. However, the effect of slight frequency split on doublet modes in rotating discs remains underexplored.

To address this, the solution approach for rotating discs must consider the rotation of phase angles. For perfectly symmetric rotating discs with zero frequency split between doublet modes, stationary mode shape functions satisfying boundary conditions can describe compact solutions as the number of modes approaches infinity. However, for asymmetric rotating discs, frequency splitting between doublet modes necessitates incorporating the disc phase angle during rotation into the compact solution form. In this context, the moving mode shape function approach provides an accurate solution for mode discretisation. Recently, this approach has been developed using finite element and analytical methods [

21,

22]. Notably, periodic time-varying squeal phenomena can be captured using the moving mode shape approach in both linear and nonlinear models [

21].

When the mode shape function rotates, the linearised system matrices become time-varying. Due to the periodic nature of rotation, these matrices exhibit time-periodicity. Consequently, the stability of squeal propensity is determined by solving the eigenvalues of the linear time-periodic system. Floquet theory is used to assess stability via characteristic multipliers [

27,

28,

29,

30,

31,

32,

33].

In references [

21,

22], mathematical and finite element model developments using the moving mode shape function approach were introduced, and some insights into squeal propensity due to frequency splitting were discussed. However, the detailed effects of frequency splitting on squeal propensity have not been fully explored using the exact solution form of the moving mode shape functions.

The primary objective of this study is to formulate and investigate the modal instability of doublet mode pairs in rotating asymmetric discs. The frequency split between doublet modes is described analytically, and the friction-engaged system equations are reduced to a time-periodic doublet mode model using the moving mode shape function approach. The modal instability is then determined by the eigenvalues of the transition matrix via Floquet theory. Subsequently, the stability of various doublet mode pairs is numerically evaluated. This study focuses on the parametric stability analysis of frequency split effects, addressing a topic that has been rarely explored in the literature.

2. Materials and Methods

The stability of a time-varying annular disc under distributed frictional contact is investigated using a reduced-order model that considers a doublet mode pair of the disc. When the frequencies of two modes are closely spaced, the eigenvalues of the friction-coupled system are dominated by these two mode shapes. The influence of other mode shapes is found to be negligible, as demonstrated in Equations (38) and (39) of the eigenvalue perturbation method [

10]. For a symmetric disc, the doublet mode pair has identical frequencies. Even in a slightly asymmetric disc, the frequency split between the doublet modes remains very small. Consequently, the reduced-order model, incorporating the closely spaced frequencies of the doublet mode pair, can effectively approximate the stability of the doublet mode pair in a full-order model with a sufficiently large number of mode shapes.

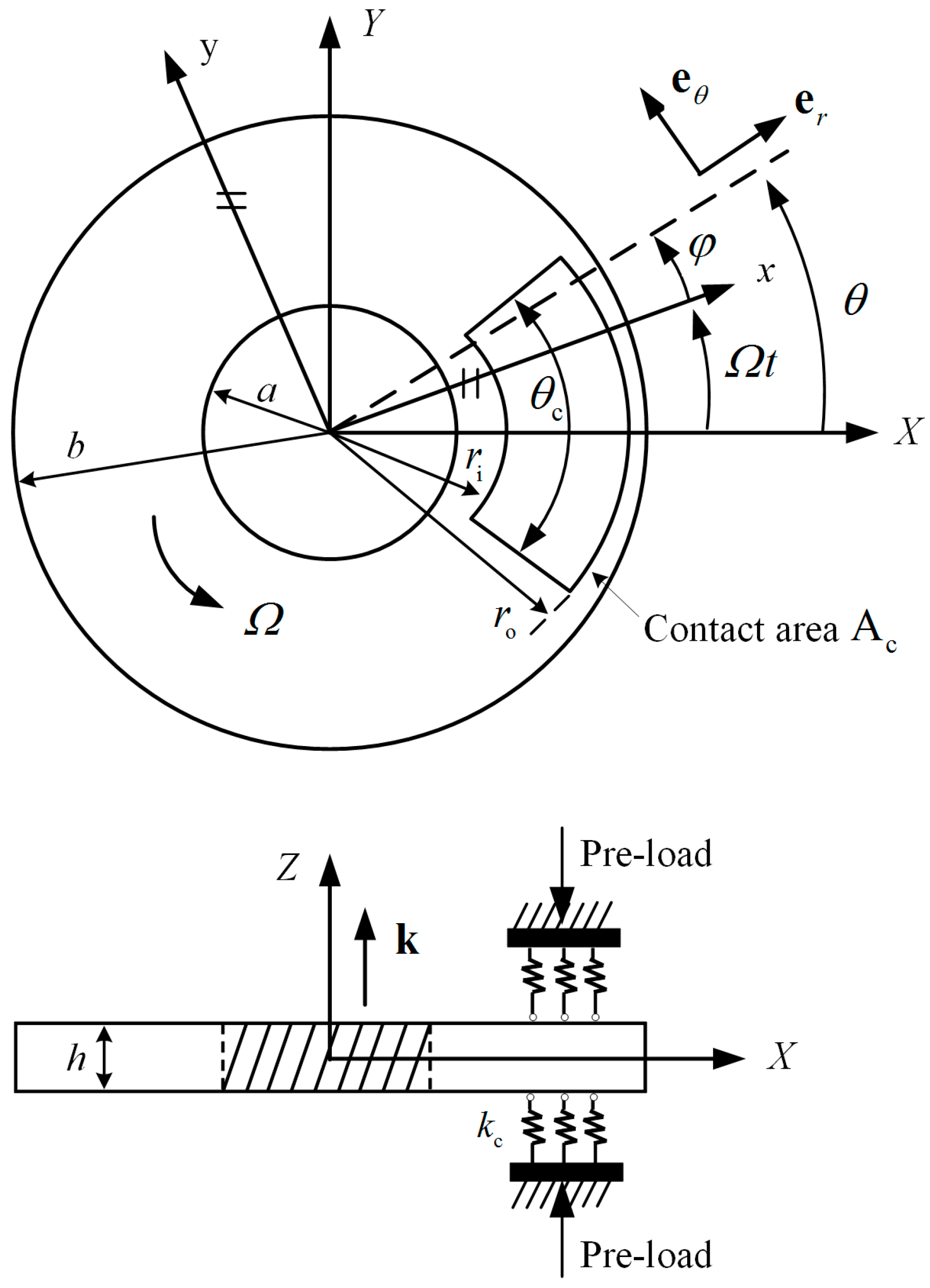

The annular disc is clamped at the inner radius and free at the outer radius. It rotates at a constant speed and is subjected to an annular sector-shaped frictional contact, as illustrated in

Figure 1.

In automotive brake applications, the disc doublet pair typically exhibits a slight frequency split due to axis asymmetry arising from factors such as bolt assembly or geometric imperfections. The accurate mode shapes of each doublet mode pair can be obtained through Fourier series analysis or finite element analysis. However, for simplification, the mode shape functions used in the slightly asymmetric disc problem are approximated by those of the axis-symmetric annular disc [

23,

24,

25].

The trial functions used in the assumed mode method should be the basic functions satisfying the boundary conditions and the following equation of motion in the rotating axis-symmetric annular plate in the local

-frame:

where

is the flexural rigidity and the solution can be expressed in the modal expansion form of the basic function with

nodal circles and

nodal diameters satisfying Equation (1) as follows:

where

is the linear combination of Bessel functions for the axis-symmetric plate. Superscript C and S denote the cosine and sine functions, respectively. Alternatively, Equation (1) can be written in the reference

XYZ-frame as follows:

where

Here, the basic functions satisfying Equation (4) must take the form of

In the case of the slightly asymmetric disc, the mode shape functions and the corresponding eigenvalues for a rotating disc with a small imperfection

can be written as follows:

where the eigenvalues of the mode pair are given by the following:

where

is the eigenvalue of the axis-symmetric disc, and

is the circular natural frequency. In the perfectly axis-symmetric disc,

. Thus,

in Equation (10) is related to the frequency split and included in the asymmetric disc model. But

of the mode shape functions in Equation (8) is assumed to be negligible.

The mode shape functions obtained in Equations (8) and (9) are applied to the Hamilton principle of the friction-coupled system:

where

where

and B stand for the contact area and the volume of the body, and

and

are the radial and tangential contact displacements, respectively. Here,

,

, and

are the generalised force induced by the contact stresses in the

,

, and

directions, respectively, to be derived as follows. It is noted that the in-plane stress distribution due to rotation is neglected by the assumption of the slow rotation of the brake disc application.

For the formulation of the contact kinematics, the position vector of the upper contact location is described on the un-deformed state of the disc surface as follows:

where

is the contact displacement vector and

In the two-mode model with the

th disc doublet mode, the displacement functions on the upper contact surface are reduced to the summation of the mode shape functions of the mode pair in Equation (8):

where the radial and tangential mode shape functions are obtained from the thin plate theory as follows:

It is noted that the mode shape functions are time-varying with respect to the stationary contact locations and they are referred to as the moving mode shape function [

21,

22]. At a contact location (

) fixed to the reference frame, the time-derivative of the moving mode shape functions can be taken as the reference [

21,

22]:

Therefore, the velocity vector at the contact location

can be written in the form of two mode discretisation as follows:

The friction force vector at the contact location is expressed by the Coulomb’s friction law as follows:

where

is the friction coefficient and the normal contact stress

is obtained from the summation of the pre-stress

and the normal load variation, such as

The contact stresses on the lower contact can be derived in a similar manner.

Therefore, the generalised force is obtained from the work performed by the friction and normal forces over both contact surfaces, such that

where

is the inner vector product and

denotes the lower contact.

By linearising Equation (11) at the equilibrium, taking the integration as

and applying the two mode expansion form of Equations (17)–(19), the doublet-mode model can be written in the

matrix form:

where the internal structural damping is not included in the model.

is the circular natural frequency of the

th disc doublet mode,

is the slightly detuned frequency of

as

, and

It is noted that Equation (27) represents the analytical formulation for the two closely spaced frequency doublet mode pairs of the brake disc. This formulation significantly simplifies the stability analysis of the full vibration mode system presented in [

22] while also providing valuable physical insights into the friction-engaged modal instability. The off-diagonal elements in the system matrices, specifically within the gyroscopic matrix and friction-coupled matrices, are known to contribute to system destabilisation in the eigenvalue analyses. Notably, the off-diagonal elements in

S2 of the friction-coupled system matrices exhibit time-periodic behaviour. Consequently, this paper focuses on analysing the brake squeal propensity associated with the doublet mode pair in a brake disc with slightly asymmetric geometry.

It is also noteworthy that Equation (27) represents the homogeneous differential equations of motion for a self-excited vibration problem. When the pre-stress

is not constant but oscillates with the brake cylinder, parametric excitation can be introduced into the brake system. This parametric excitation may induce dither, potentially affecting the system’s stability. However, the investigation of parametric excitation lies beyond the scope of this paper and is referenced in [

34].

Here, the ratio of frequency split

is set to be less than one percentile of the natural frequency as follows:

It is noted that the damping and stiffness matrices in EOM (27) are time-periodic with a period

. But, the period of the system matrices is set to be a period per revolution as

for any modes, which does not change the results. For determining the stability of the periodic time-varying system by the Floquet theory, EOM is written in the state-space form of

of Equation (27) as follows:

where

The periodic time-varying system of Equation (35) is discretised by the time step

(

), and the transition matrix of each time step is calculated in the discretisation method [

23,

24,

25,

26], such that

The system is unstable if the largest modulus of the eigenvalues of the transition matrix in Equation (38) is larger than one and stable otherwise.

3. Results

The nominal values of the system parameters in the numerical calculation are brought from the automotive brake application. The geometry and material properties of the annular disc with a free boundary condition at the outer radius and clamped boundary condition at the inner radius used in the analysis are shown as

Table 1. The operating condition is chosen to be 8 [bar] braking pressure and

rotating speed. The natural frequencies of the freely stationary annular disc can be obtained by the boundary value analysis [

9] as in

Table 2, and the corresponding mode shapes are illustrated in

Figure 2. From the assumption of the slightly asymmetric disc, the mode shape functions with small imperfections approximate those of the symmetric annular disc in

Figure 2.

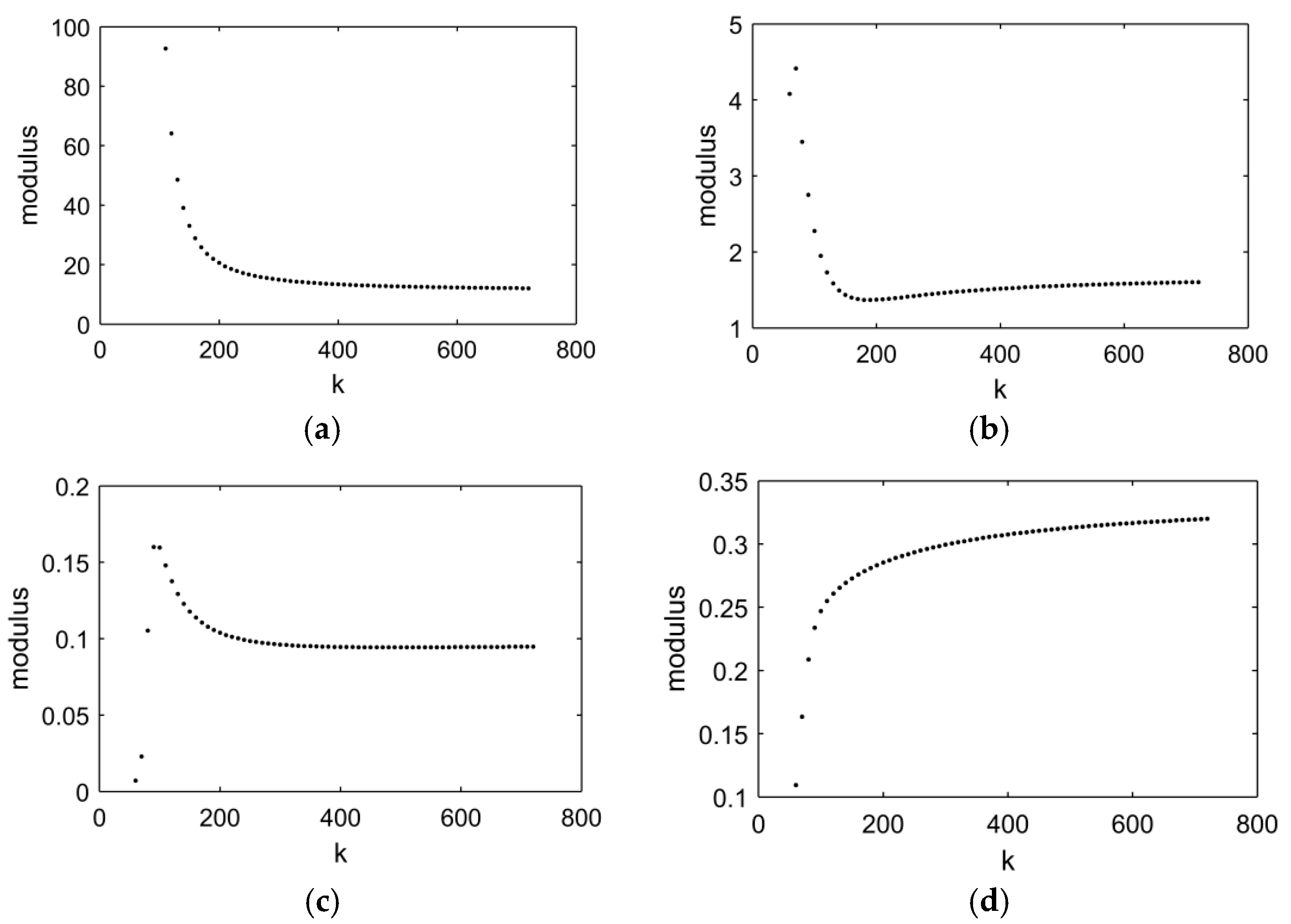

For the numerical calculation of the transition matrix, the period over one revolution is discretised by the equally spacing time interval as

. The number

of the discretisation interval is chosen by the convergence check, as illustrated in

Figure 3. For the unstable mode pairs, the modulus of critical eigenvalues is calculated with respect to

. It is shown that the modulus converges to a fixed value as

. Hereafter,

is set to be 720 in the Floquet stability analysis.

The analysis focuses on the effect of the mode splitting between the doublet mode pair on the stability of the time-periodic system. For this, the stability boundary is calculated with respect to the frequency split and one of the other important parameters such as the friction coefficient, the contact angle, and the contact stiffness. From the stability analysis, the mode pairs with are found to be stable at , so their results are excluded from this study.

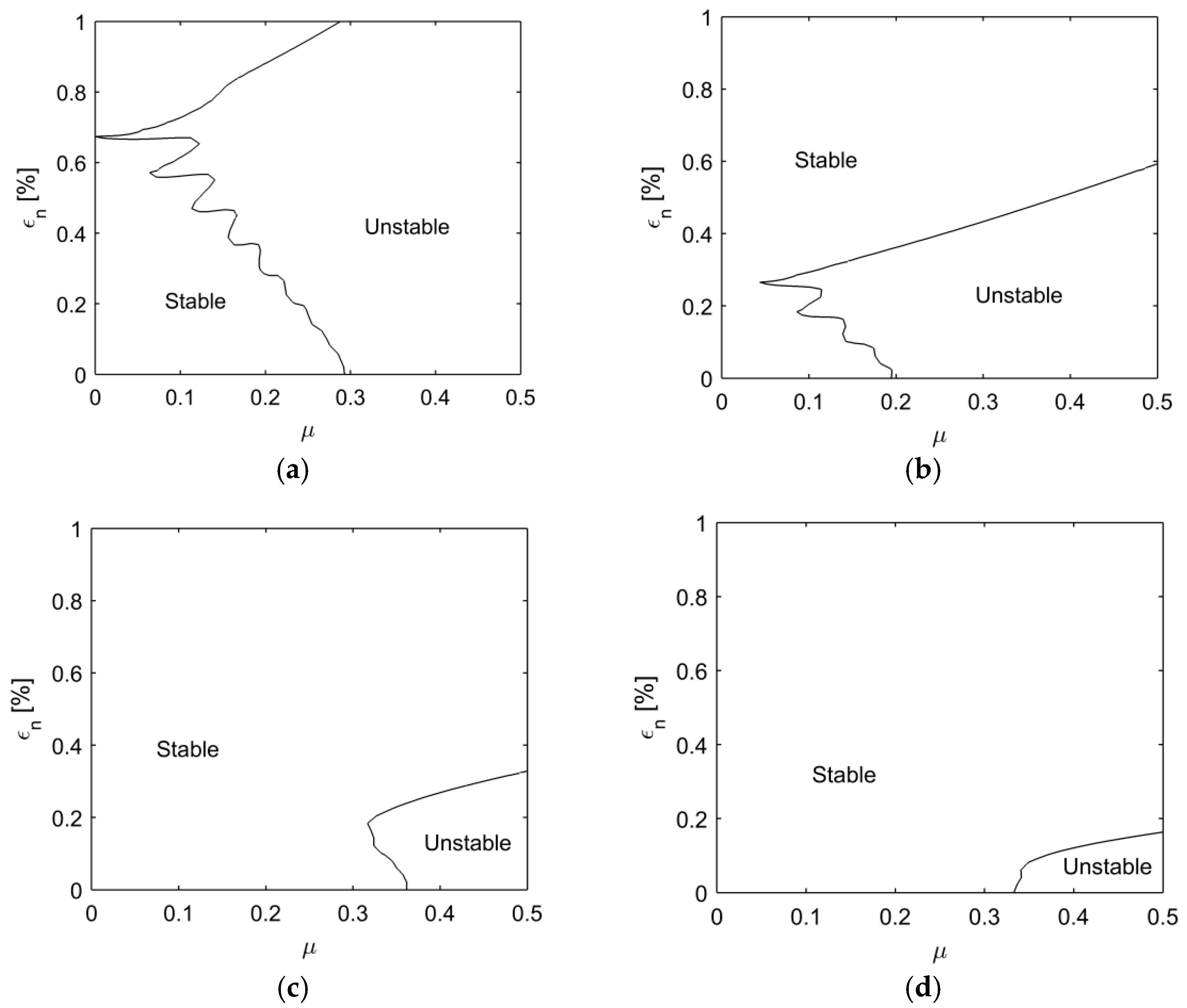

Figure 4 illustrates the stability boundaries for the mode number

in the

and

domain. For

, 5, and 6, the minimum friction coefficient for the instability arises near

, 0.3%, and 0.2%, respectively. For

, the unstable region appears below

. This reveals that the stability of the mode pair is highly dependent on the frequency split. Particularly, it is noted that the specific frequency split exists for the minimum friction coefficient generating the instability. It is interesting that zero frequency split does not maximise the squeal propensity. However, it is seen in

Figure 4 that the mode pair under friction loading becomes more stable as the frequency split increases.

Figure 5 shows the stability of the split mode pair (

) for the contact angle variation. In

Figure 5a, the instability for

occurs nearly above

, but the stable region appears between

and

below

. In

Figure 5b for

, the stability boundary lies near

for

, but the instability that occurs as

is increased above

. In

Figure 4c,d, the instability arises for the smaller

and the larger

for

and 7. It is notable that the critical contact span angle is much more susceptible as the mode number increases. For example, in

, squeal occurs at 23 degrees for zero frequency split, but it disappears if a small amount of frequency split exists. In contrast, squeal does not disappear even if frequency split exists for

.

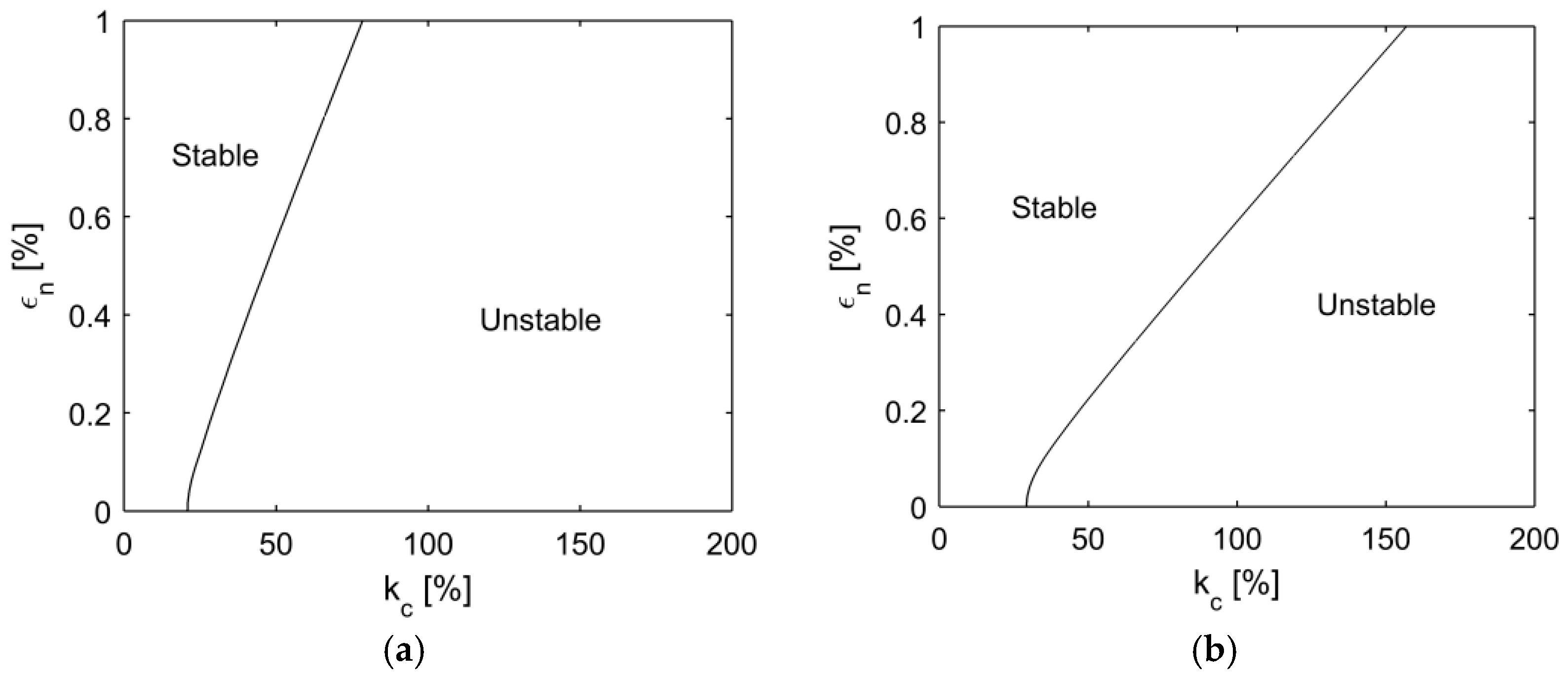

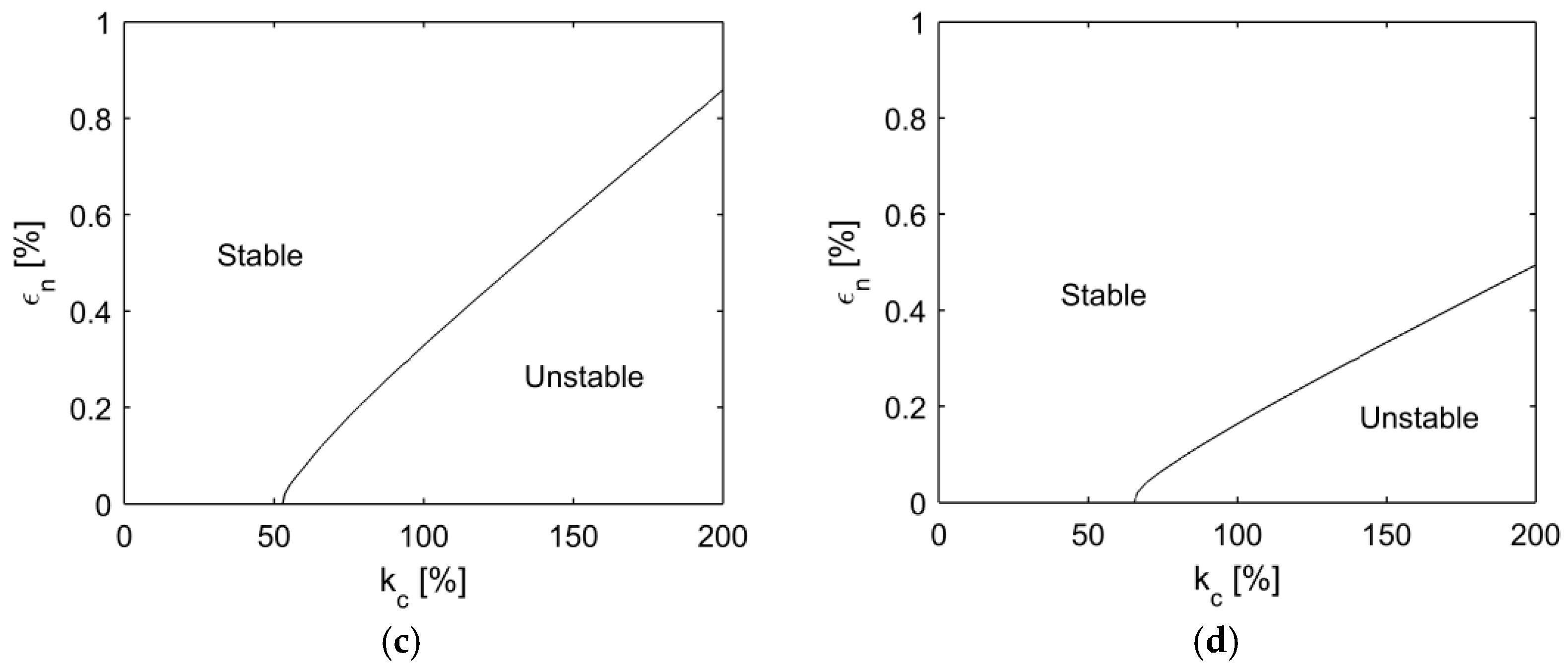

Similarly,

Figure 6 demonstrates the instability of the split doublet mode with respect to the contact stiffness

. The instability that occurs as

increases and

decreases for all of

, 5, 6, and 7. This implies that the higher contact stiffness produces the higher propensity of the instability in the split mode pair under friction contact. The rate of change in critical contact stiffness over frequency split is increased as the mode number increases. Therefore, it is noted from

Figure 4,

Figure 5 and

Figure 6 that the susceptibility of the frequency split on squeal is seen to increase as the mode number decreases.