Comparative Study of the Tribological Properties of MoSe2 Coatings Under Dry and Oil-Lubricated Sliding Conditions

Abstract

1. Introduction

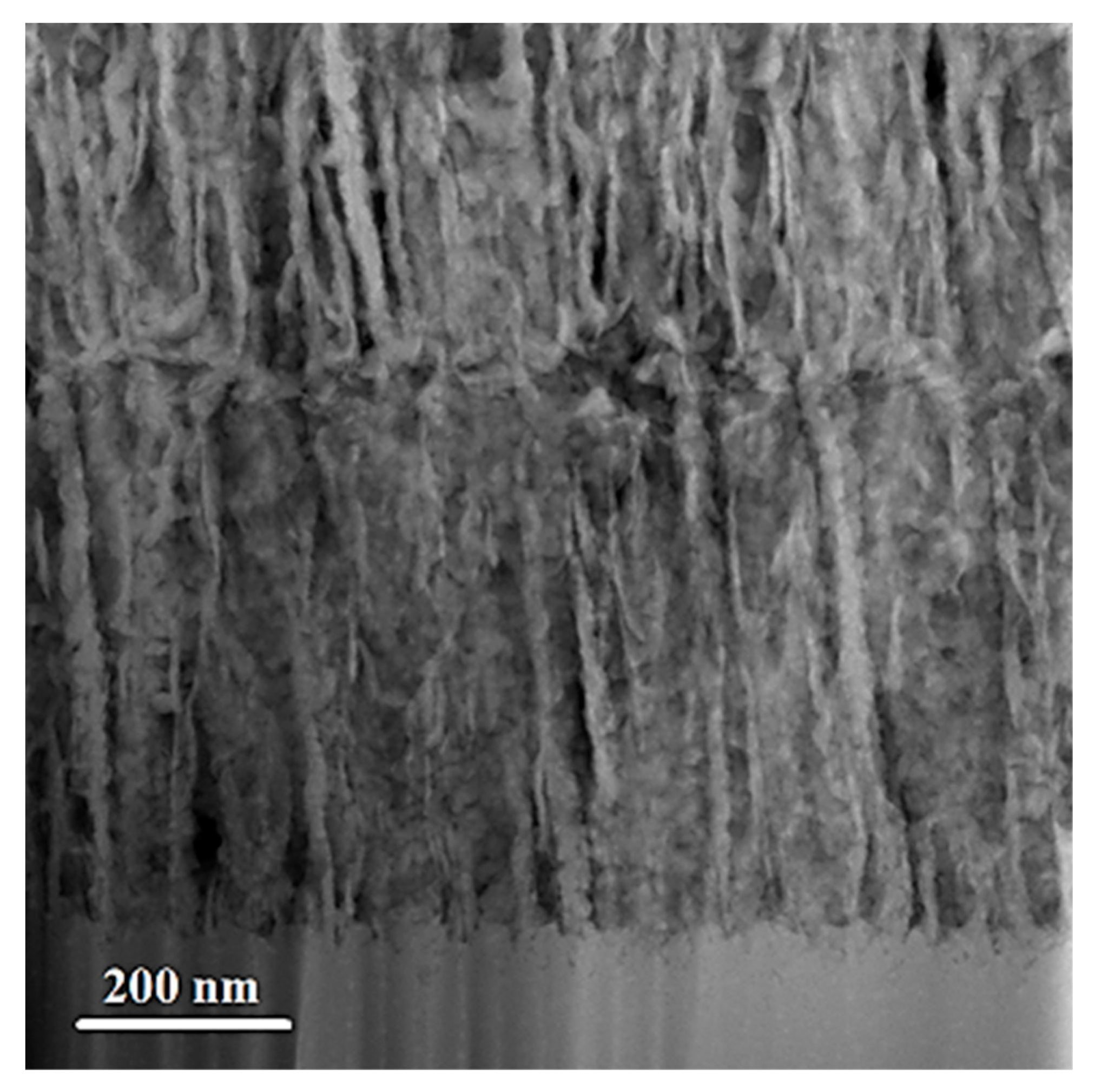

2. Materials and Methods

3. Results

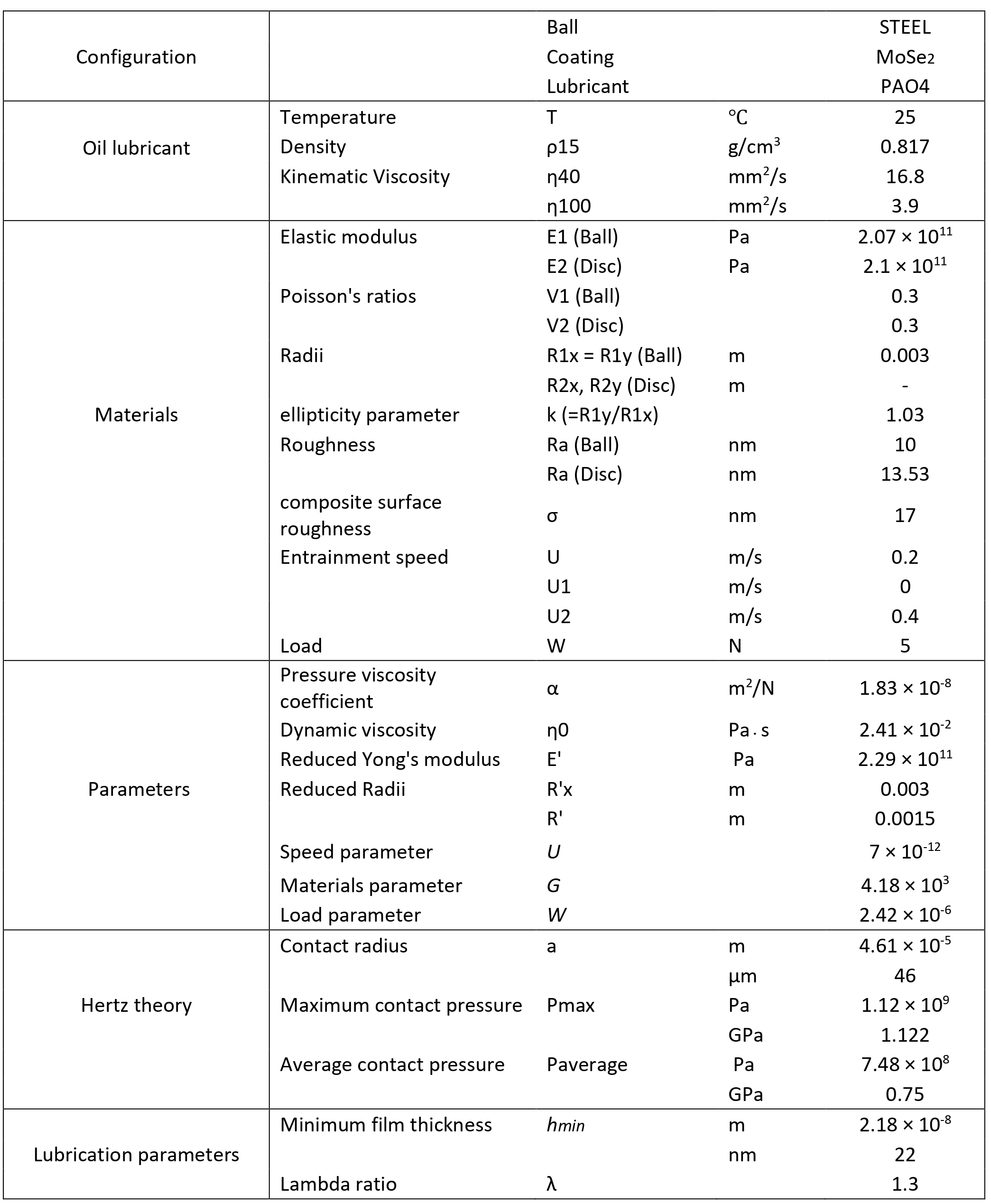

3.1. Crystalline Structure

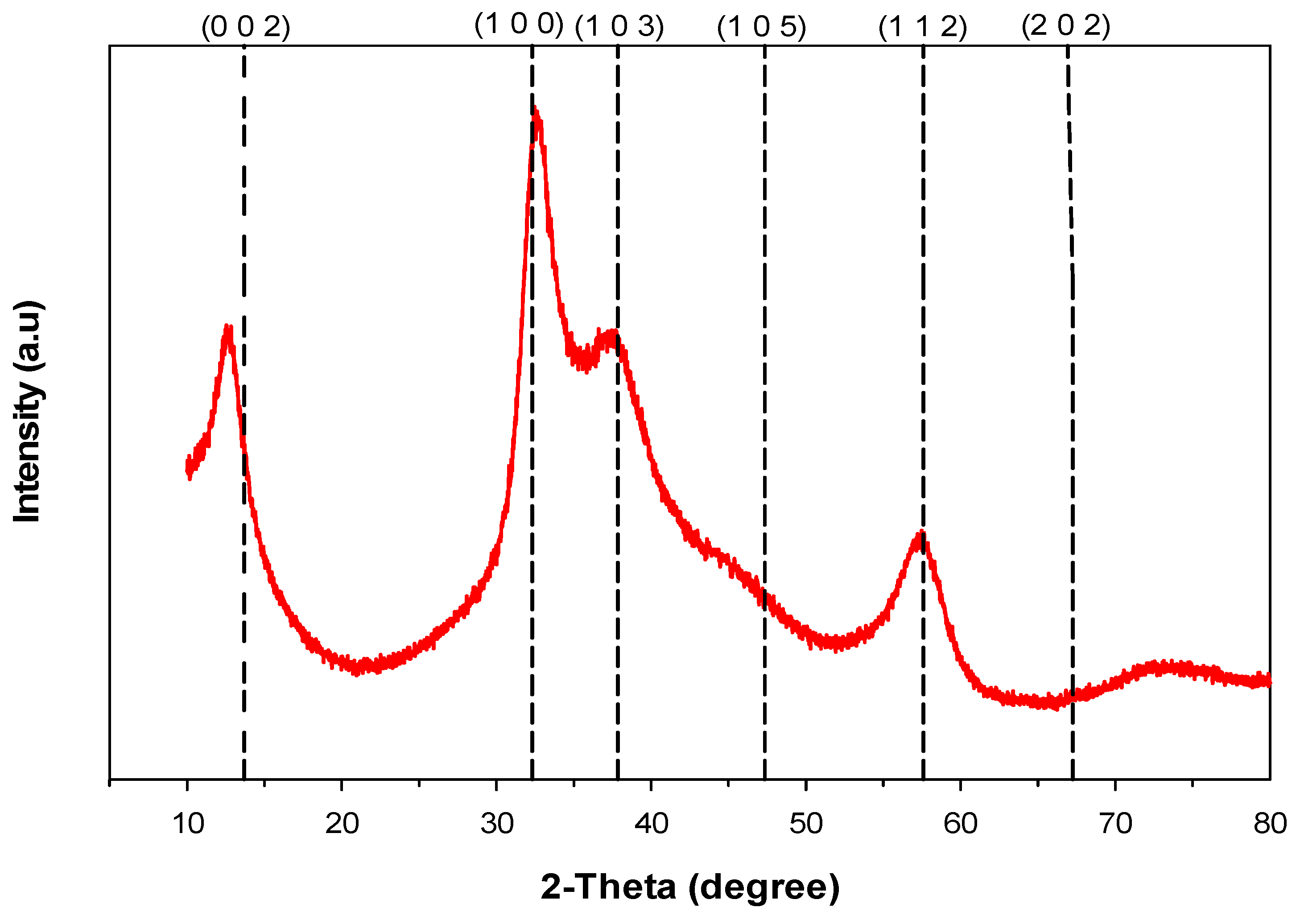

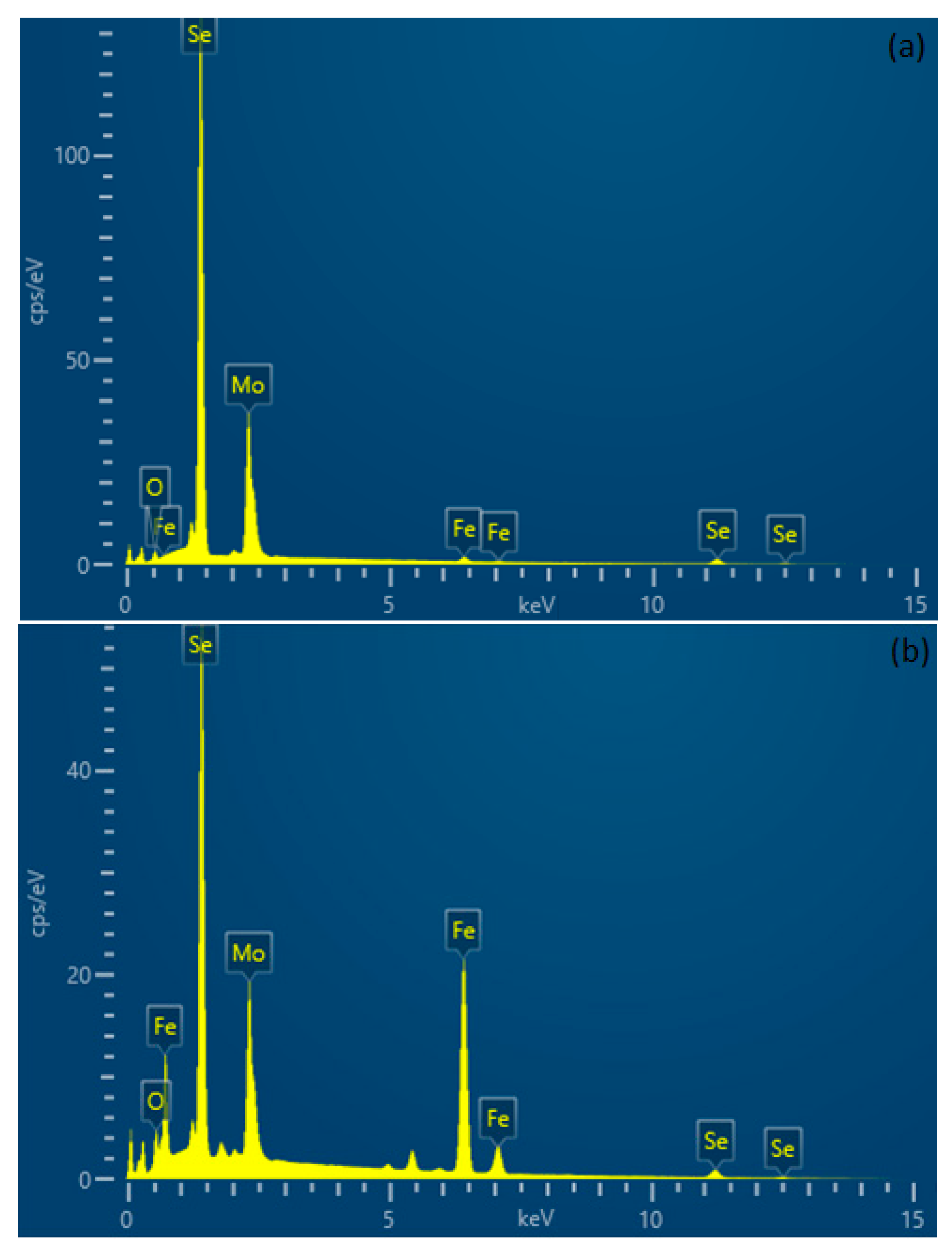

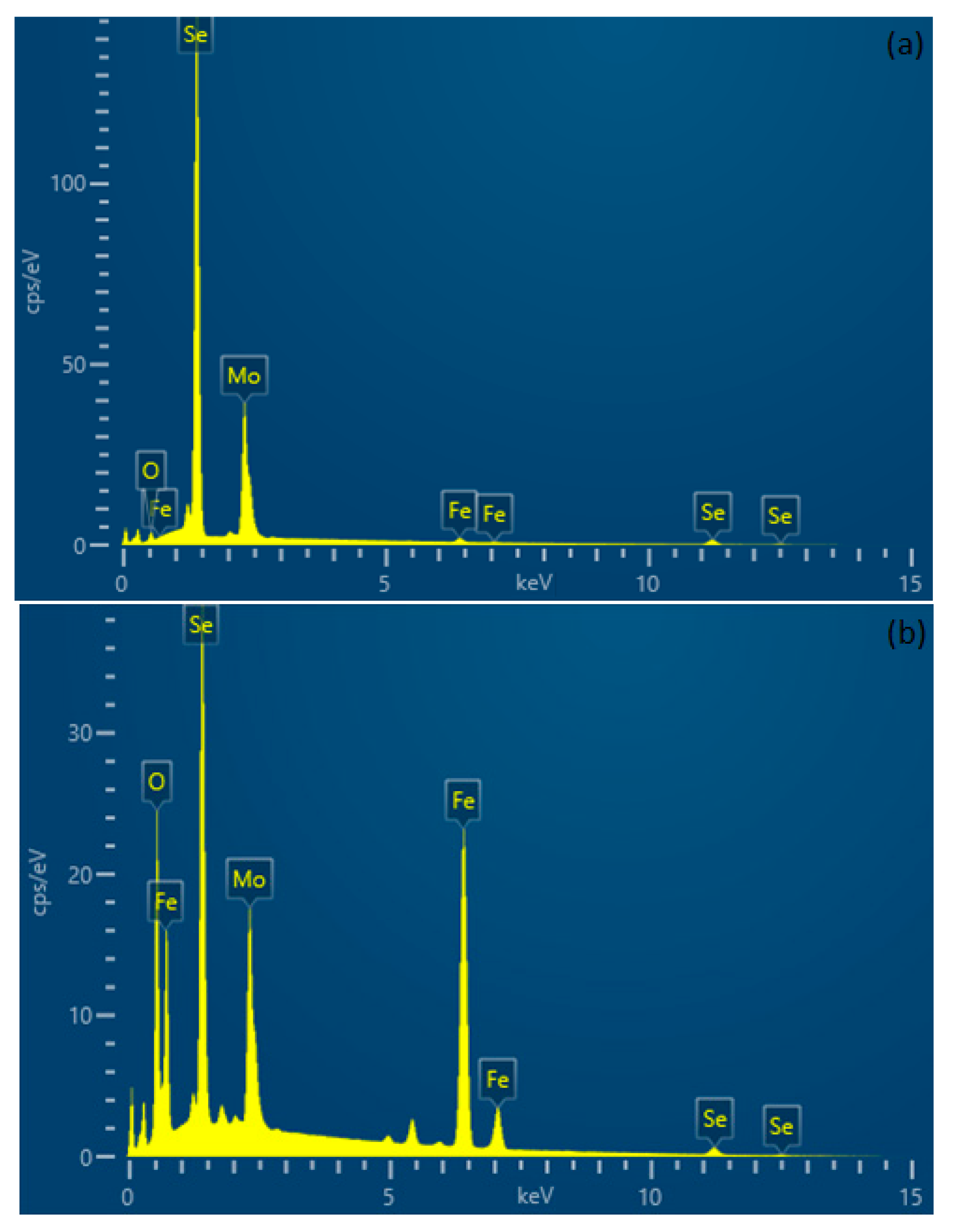

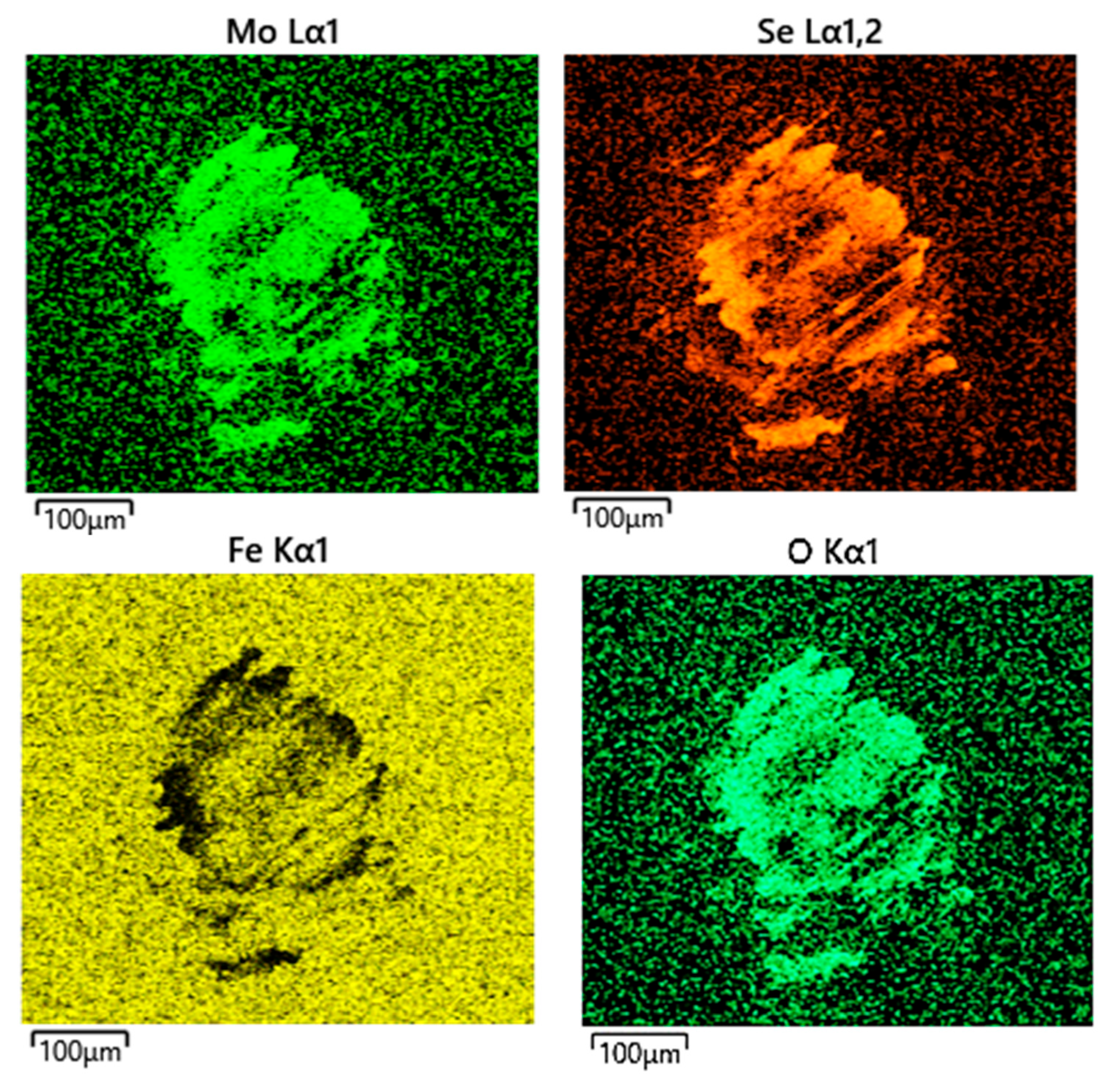

3.2. Chemical Composition, Mechanical Properties, and Cross-Sectional Morphology

3.3. Tribological Behaviour

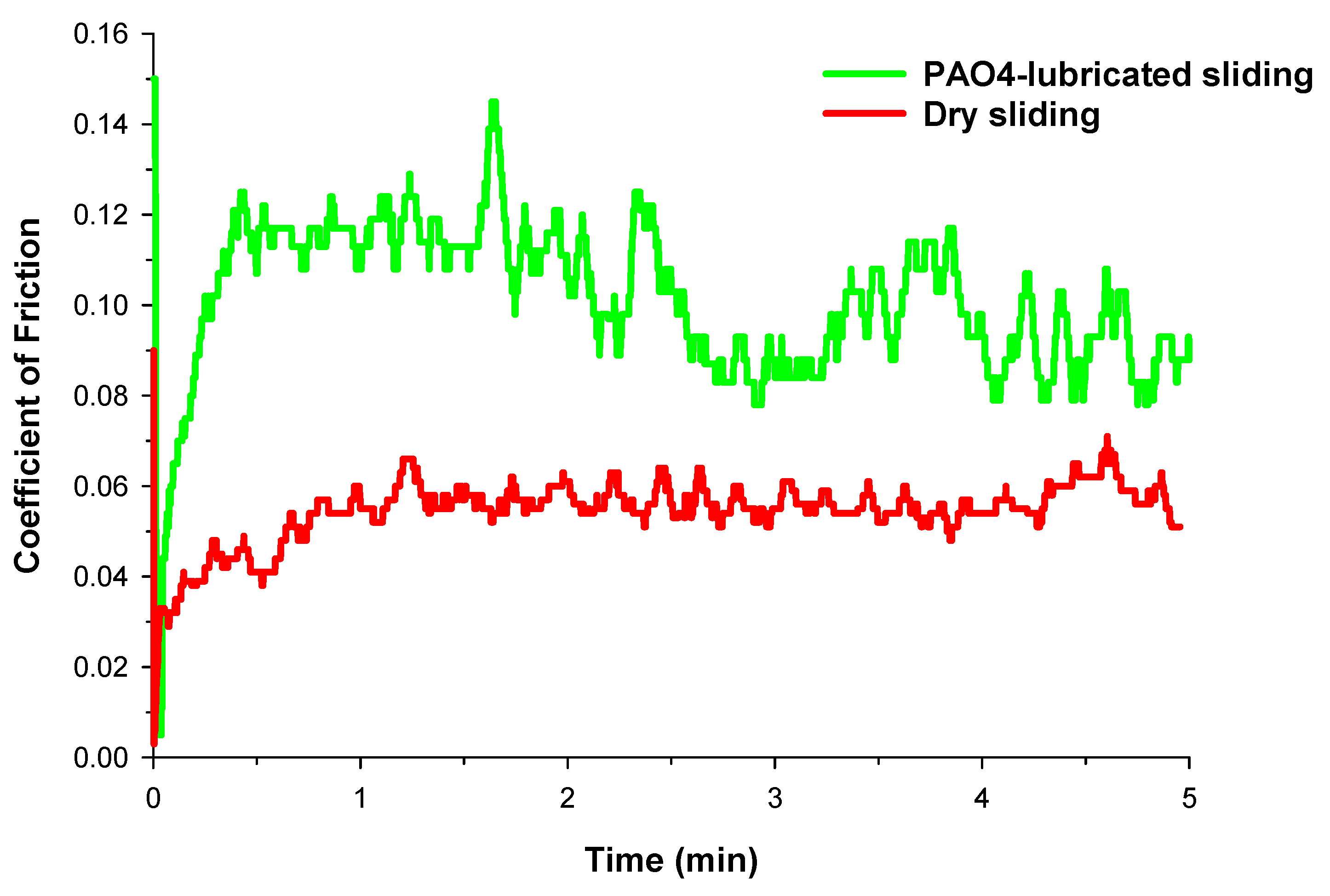

3.3.1. Friction Behaviour

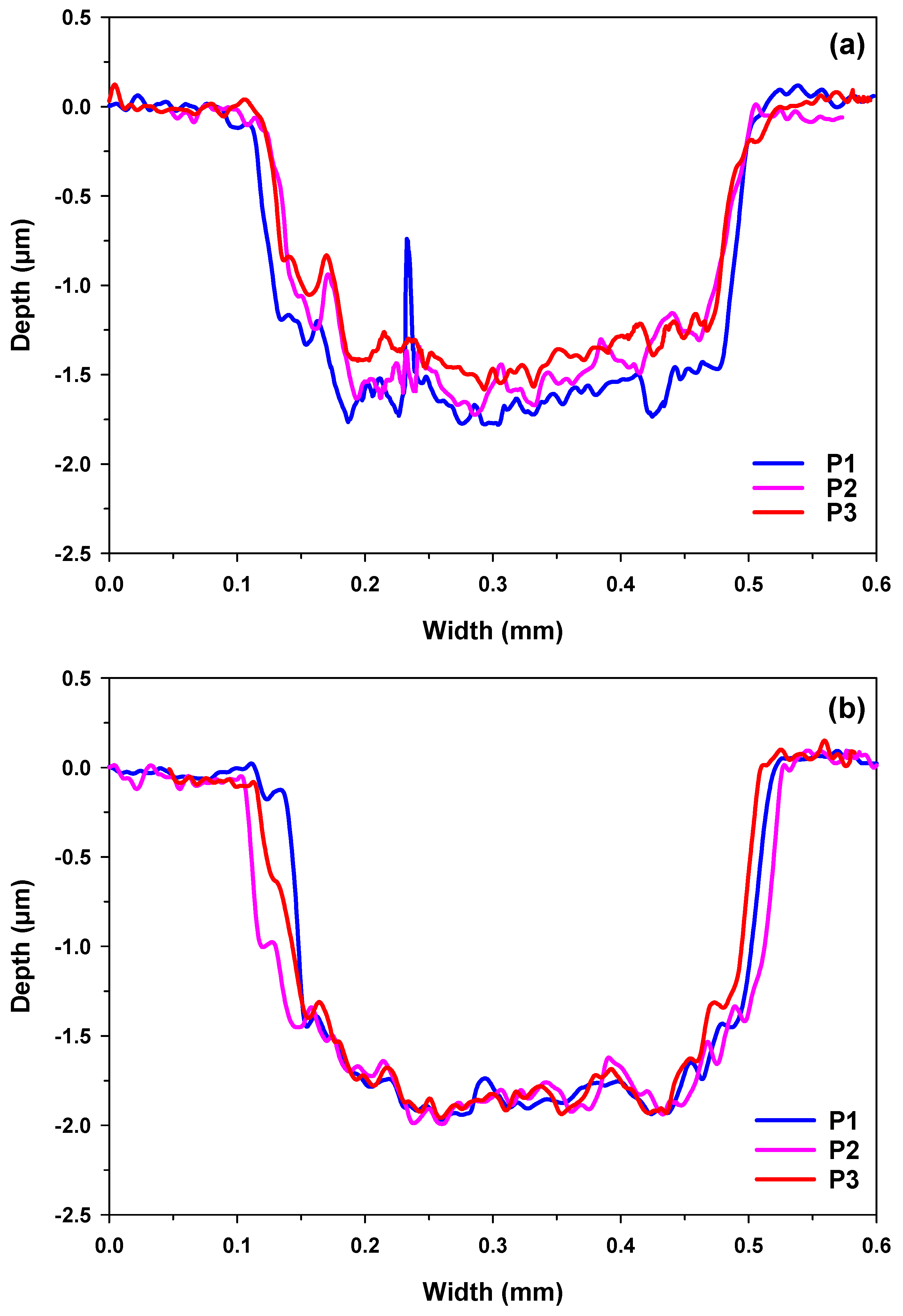

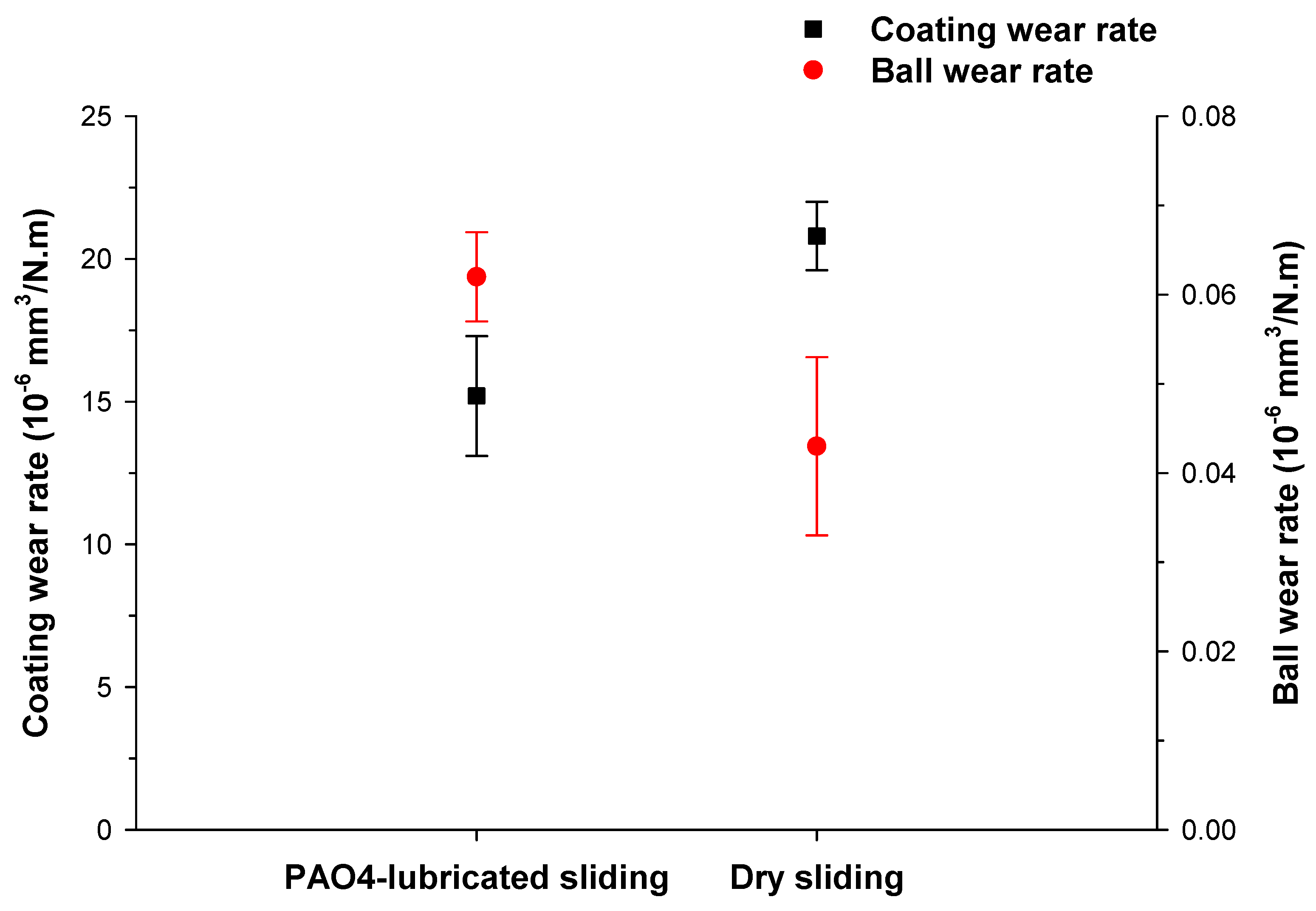

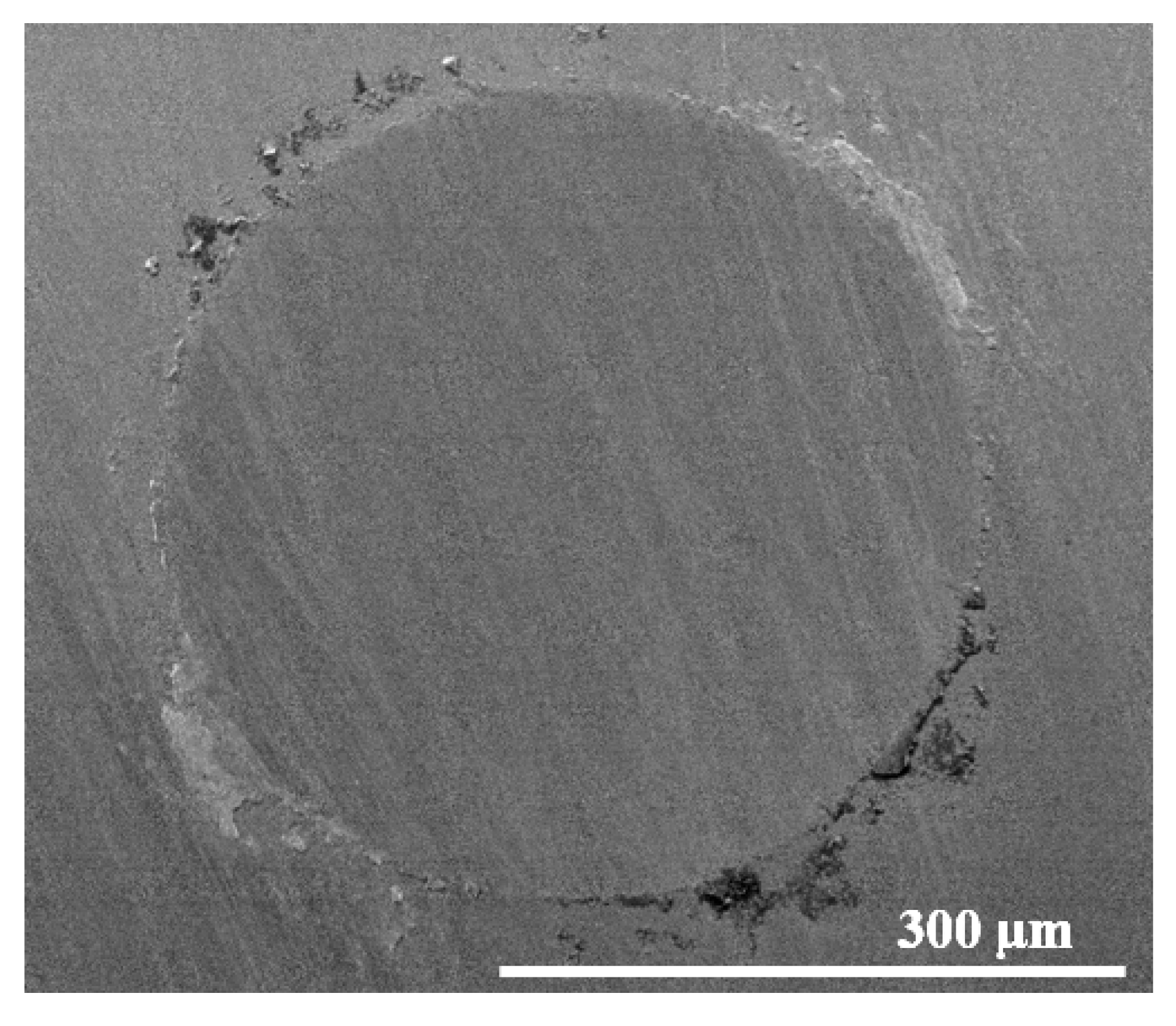

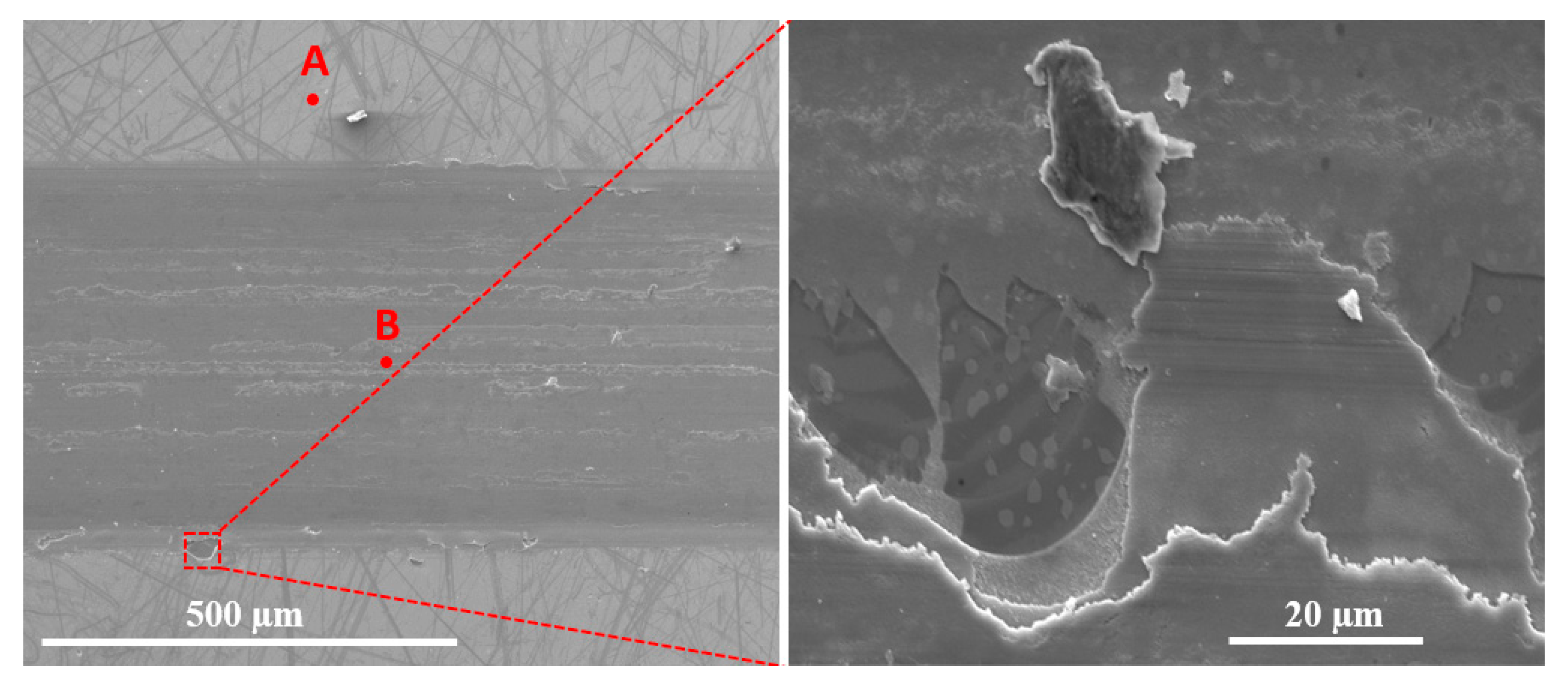

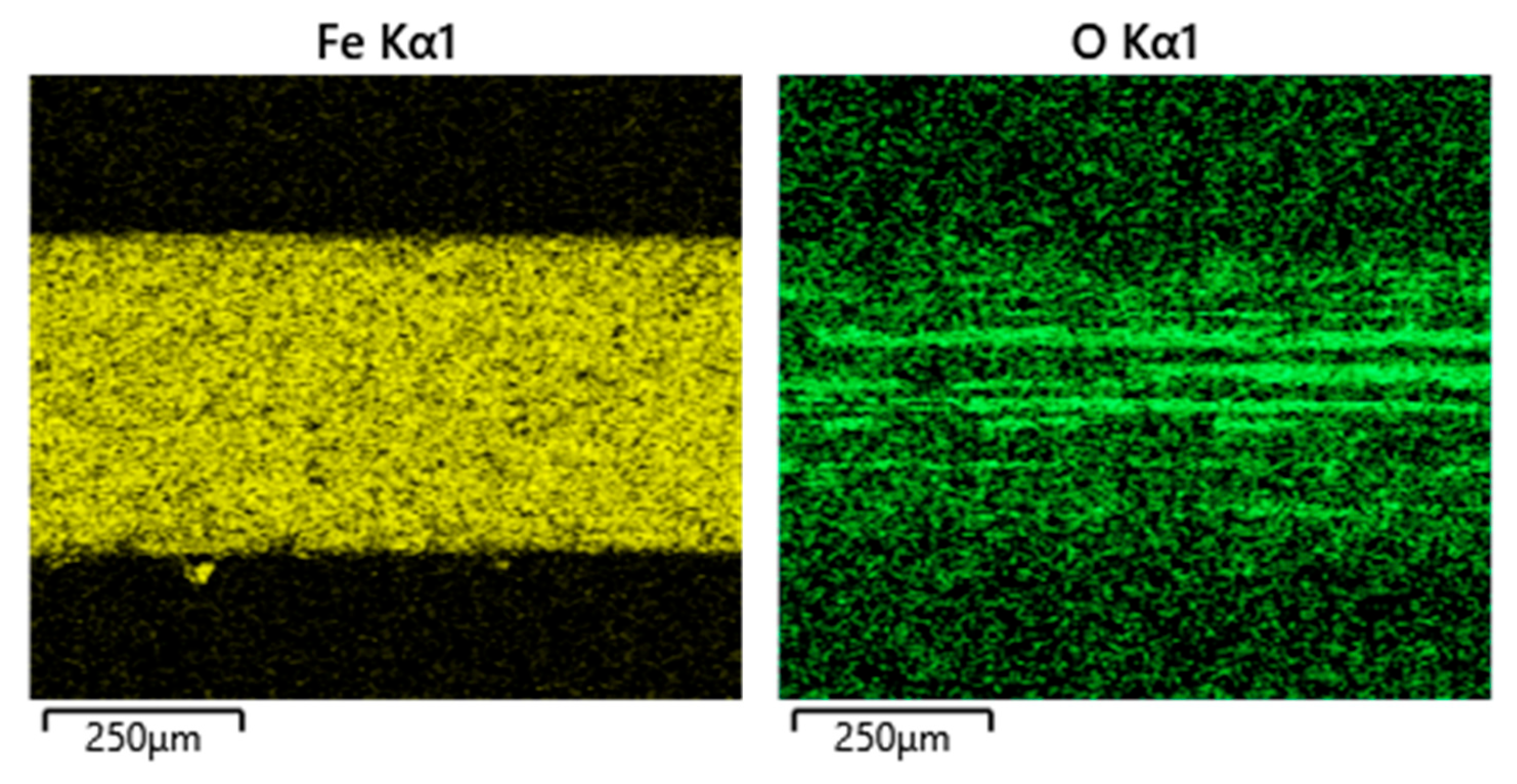

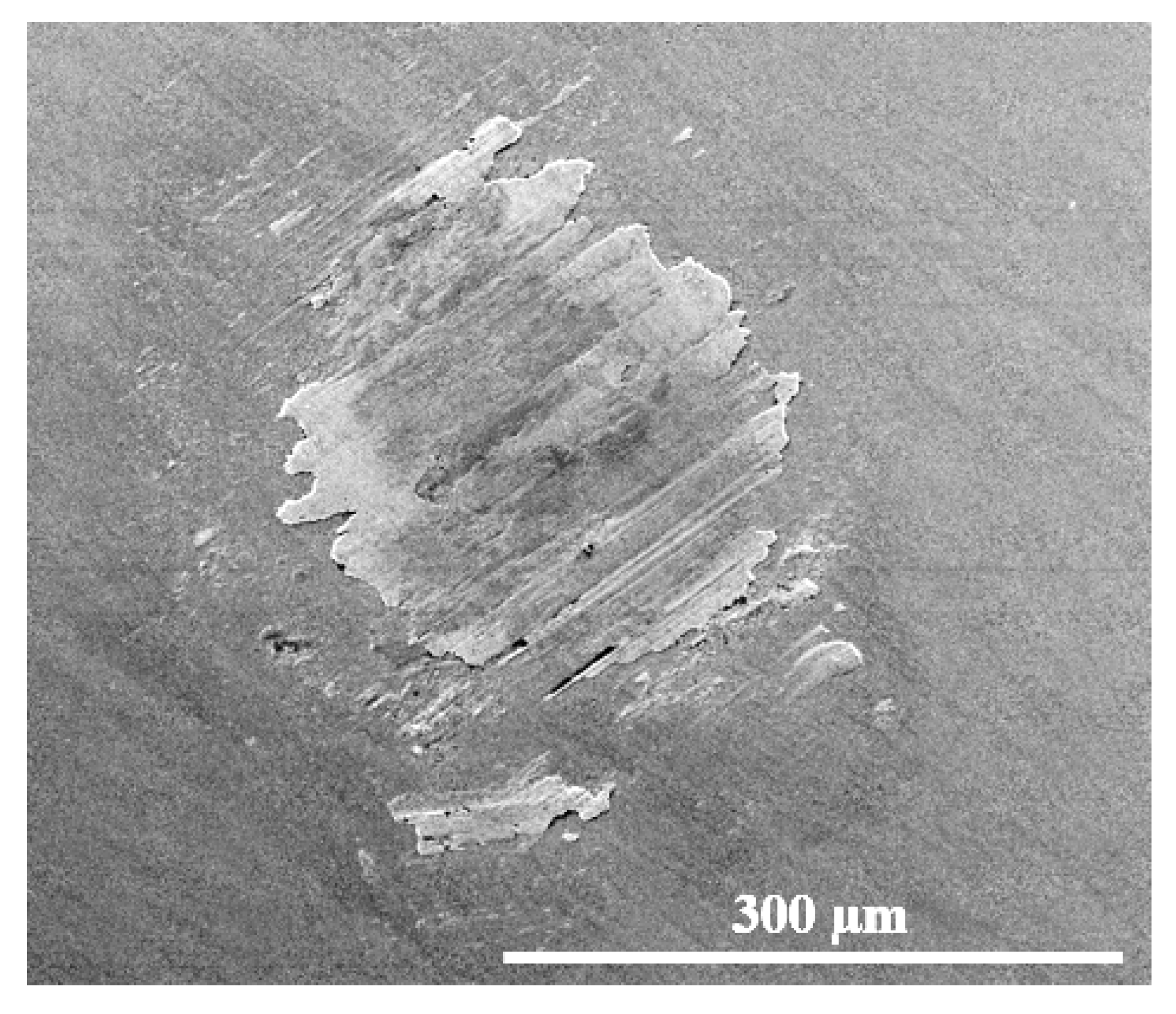

3.3.2. Wear Behaviour

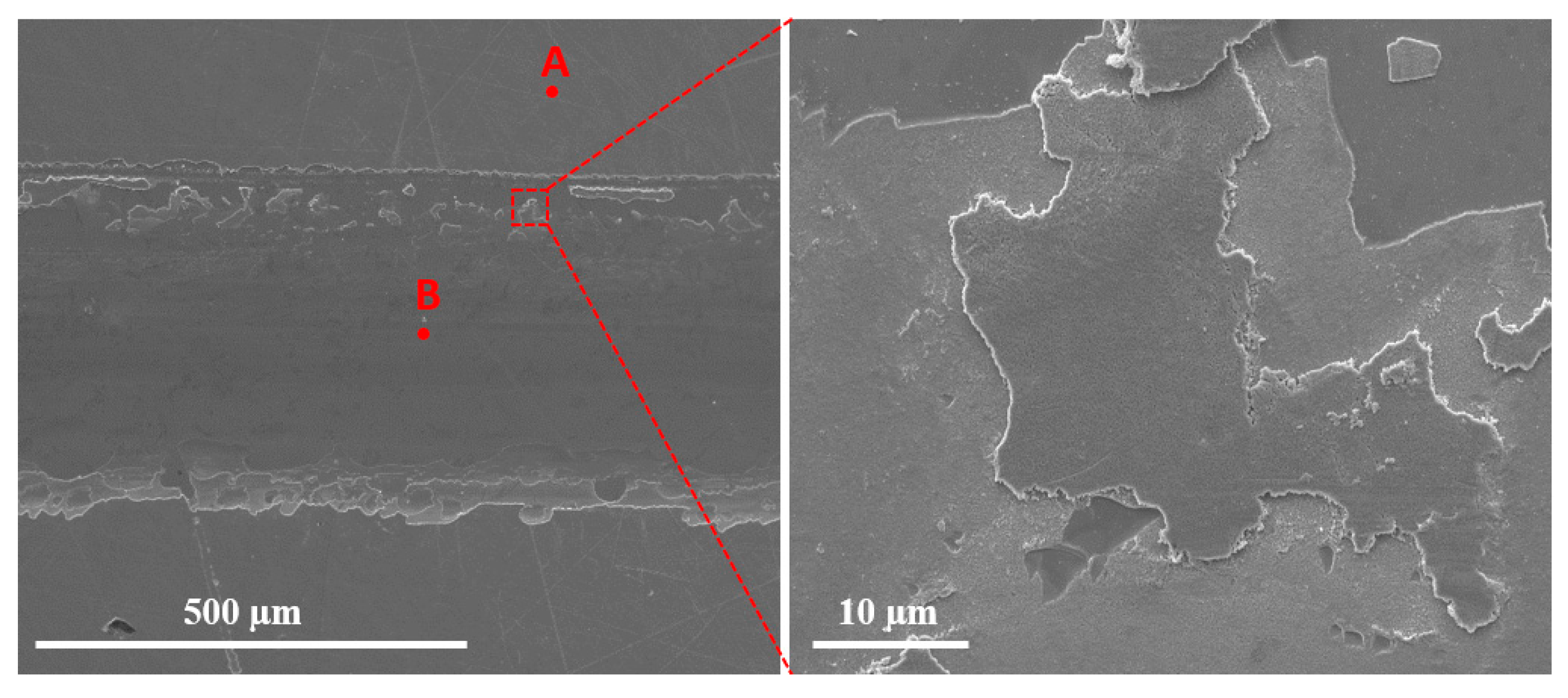

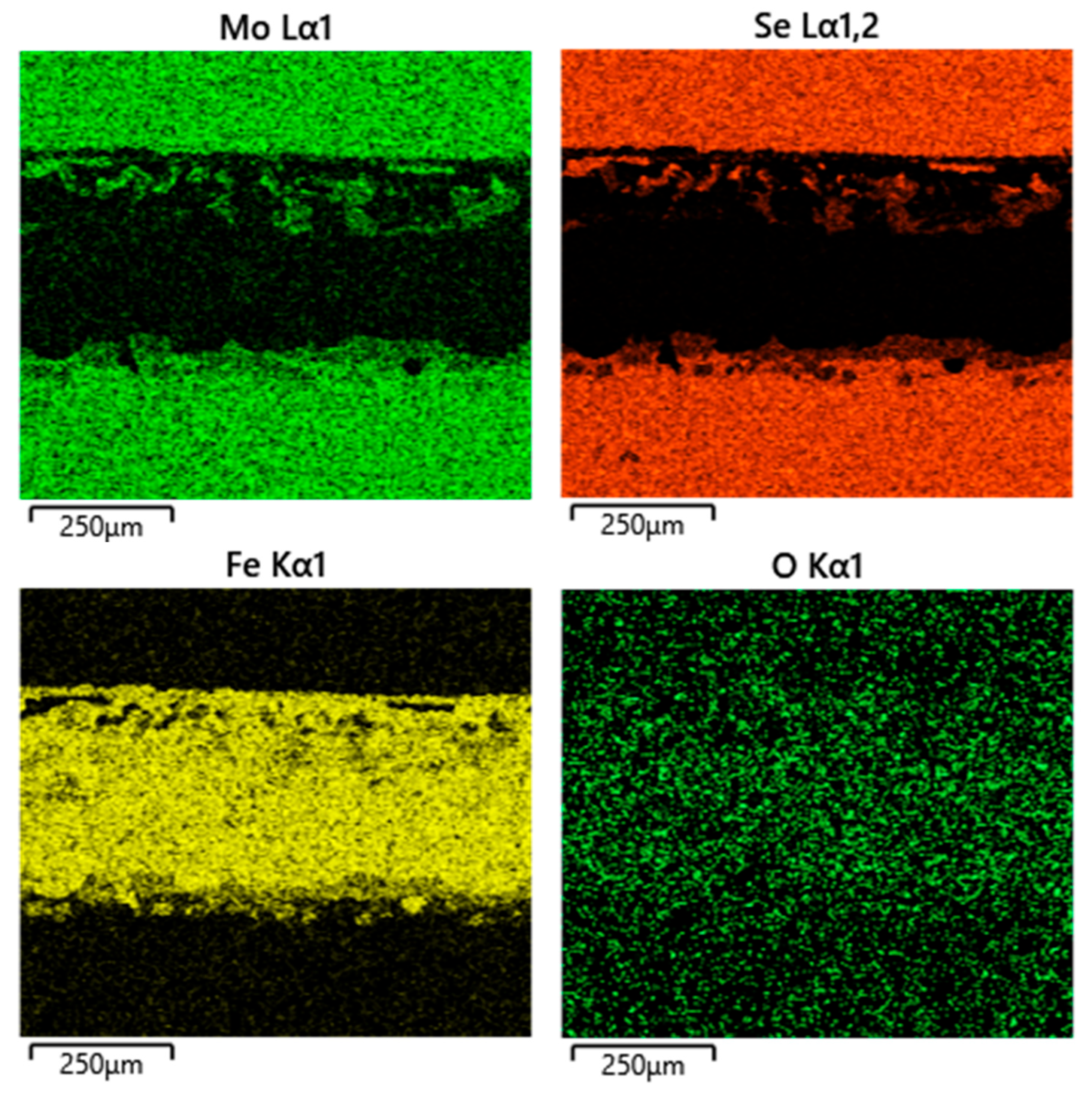

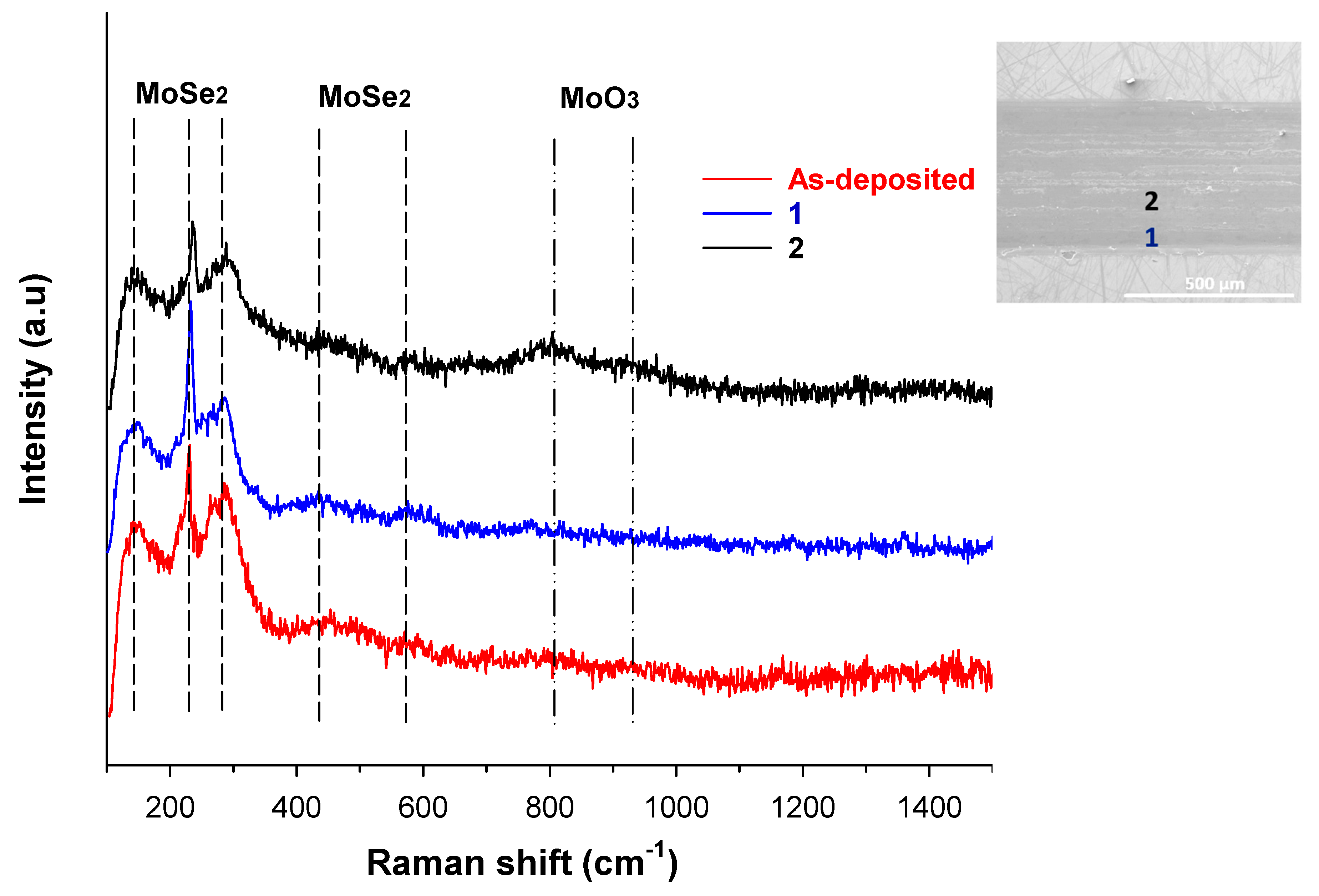

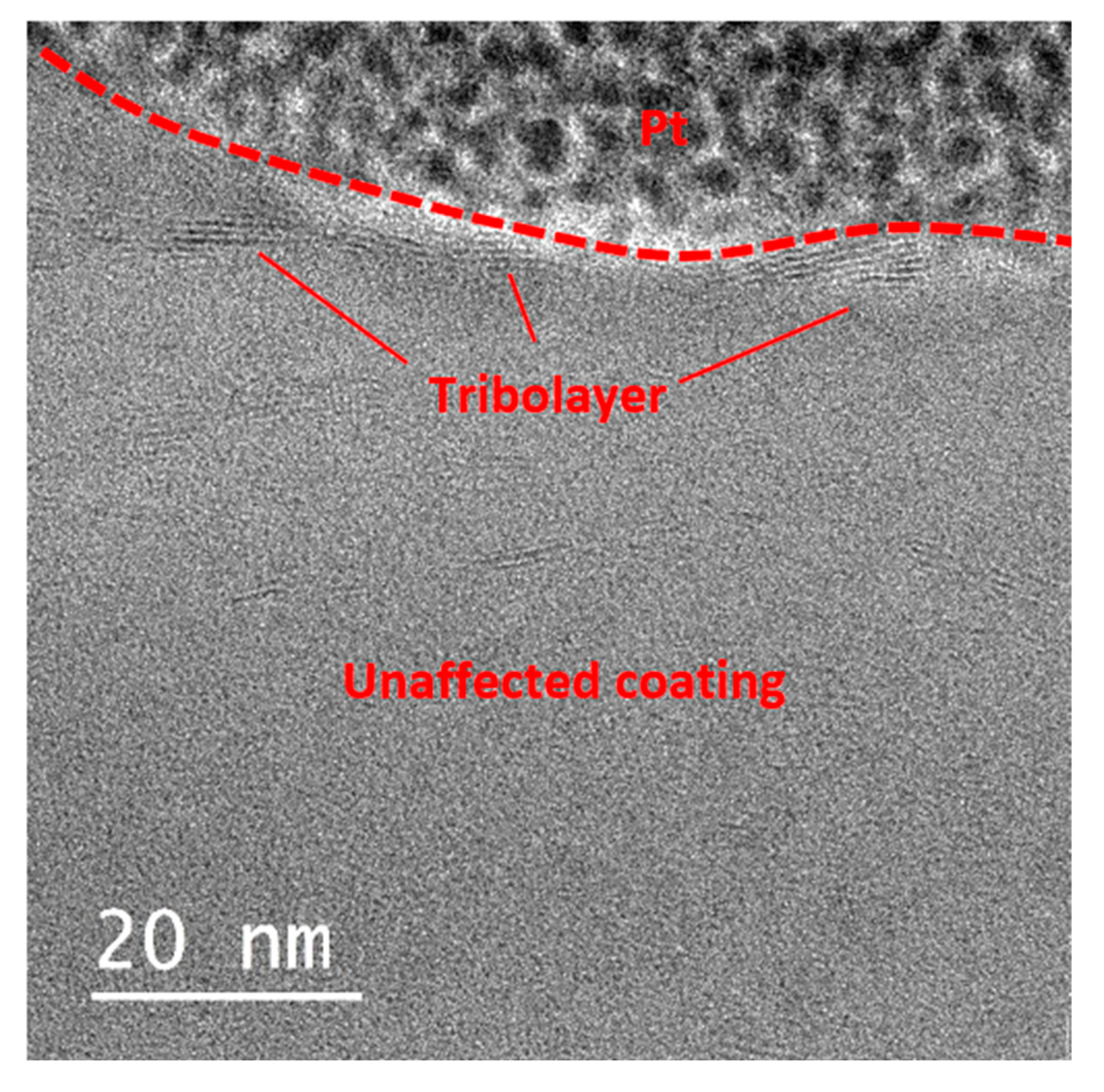

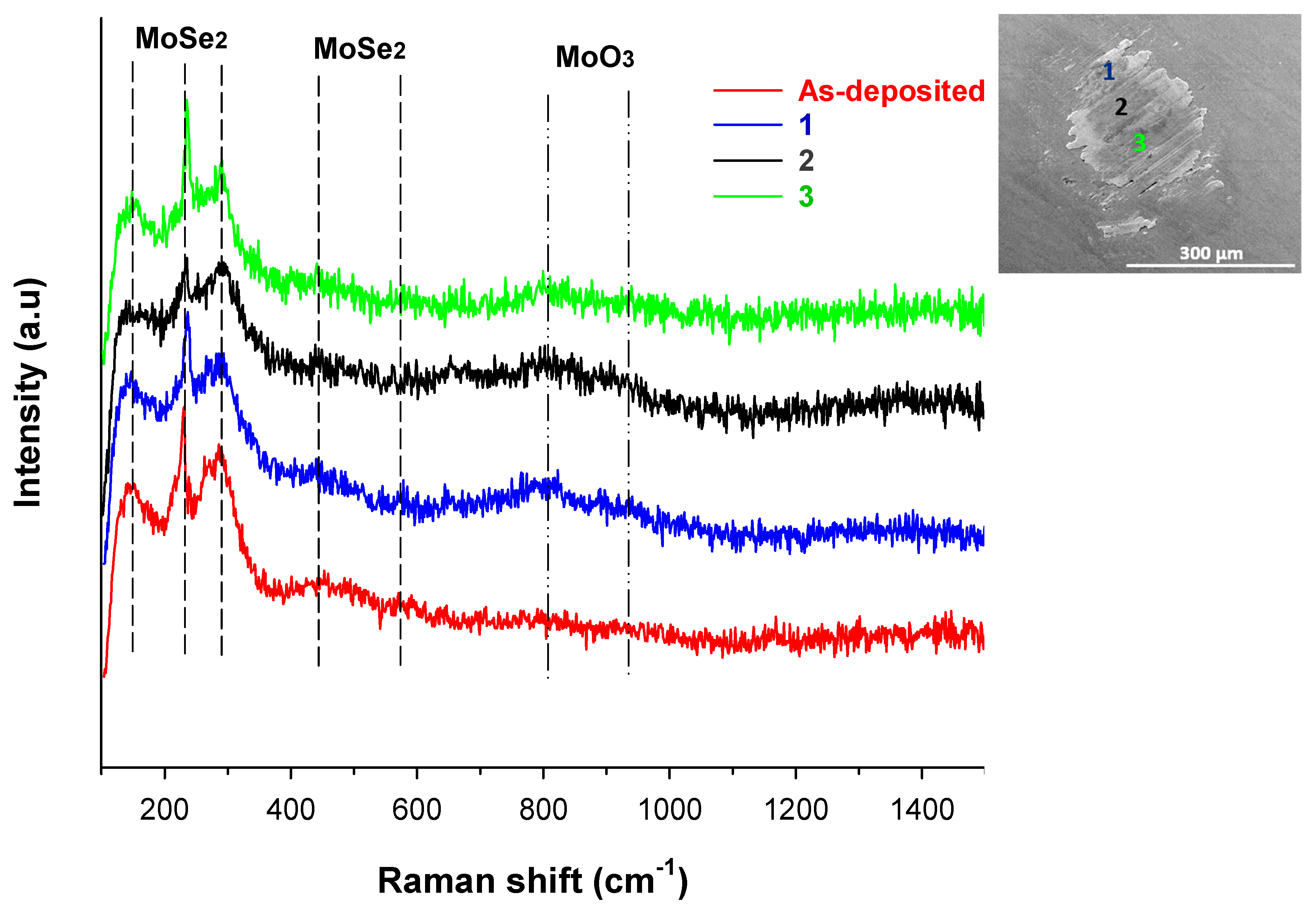

3.3.3. Analysis of Worn Surfaces

PAO4-Lubricated Sliding

Dry Sliding

4. Discussion

4.1. Friction Performance

4.2. Wear Performance

5. Conclusions

- •

- Evaluation of the coating during PAO4-lubricated sliding revealed a coefficient of friction that was double the value recorded in dry sliding.

- •

- Characterization of the worn surfaces from the PAO4-lubricated sliding test showed that a crystalline MoSe2 tribolayer, with MoSe2 basal planes perfectly aligned parallel to the sliding direction, did not form in the coating wear track. Similarly, no beneficial transfer layer formed on the coating’s sliding counterpart. The combined effects of these two factors contributed to the higher coefficient of friction when compared to dry sliding.

- •

- Despite the higher coefficient of friction, the coating exhibited enhanced wear resistance in PAO4-lubricated sliding, with a wear rate 27% lower than that observed in dry sliding. This improvement in the wear resistance of the coating was due to the presence of PAO4 at the sliding interface, which acted as a sealant and protected the coating from the formation of abrasive metal oxides.

- •

- The coating demonstrated better friction performance in dry sliding due to two major factors. The first was the formation of a uniform and compact transfer layer on the counterpart surface, which effectively prevented direct contact between sliding surfaces. The second was the presence of a crystalline MoSe2 tribolayer in the topmost surface of the wear track with perfect alignment of the basal planes parallel to the sliding direction, which led to low interfacial shear strength at the sliding interface.

- •

- The coating inevitably oxidized during dry sliding, resulting in the formation of MoO3 particles. These newly formed particles with abrasive properties deteriorated the wear resistance of the coating and led to the higher coating wear rate when compared to PAO4-lubricated sliding.

- •

- Under both sliding conditions, the coatings exhibited a combination of three wear mechanisms: abrasion, adhesion, and delamination.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| DLC | Diamond-like Carbon |

| EDS | Energy Dispersive X-ray Spectroscopy |

| PAO | Polyalphaolefin |

| RF | Radio Frequency |

| SEM | Scanning Electron Microscopy |

| TEM | Transition Electron Microscopy |

| TMD | Transition Metal Dichalcogenide |

Appendix A

References

- Polcar, T.; Cavaleiro, A. Review on self-lubricant transition metal dichalcogenide nanocomposite coatings alloyed with carbon. Surf. Coat. Technol. 2011, 206, 686–695. [Google Scholar] [CrossRef]

- Menezes, P.L.; Rohatgi, P.K.; Omrani, E. Self-Lubricating Composites; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Nyberg, H.; Sundberg, J.; Särhammar, E.; Gustavsson, F.; Kubart, T.; Nyberg, T.; Jansson, U.; Jacobson, S. Extreme friction reductions during initial running-in of W-S-C-Ti low-friction coatings. Wear 2013, 302, 987–997. [Google Scholar] [CrossRef]

- Quan, X.; Zhang, S.; Hu, M.; Gao, X.; Jiang, D.; Sun, J. Tribological properties of WS2/MoS2-Ag composite films lubricated with ionic liquids under vacuum conditions. Tribol. Int. 2017, 115, 389–396. [Google Scholar] [CrossRef]

- Vuchkov, T.; Yaqub, T.B.; Evaristo, M.; Cavaleiro, A. Synthesis, microstructural and mechanical properties of self-lubricating Mo-Se-C coatings deposited by closed-field unbalanced magnetron sputtering. Surf. Coat. Technol. 2020, 394, 125889. [Google Scholar] [CrossRef]

- Spalvins, T. Lubrication with sputtered MoS2 films: Principles, operation, and limitations. J. Mater. Eng. Perform. 1992, 1, 347–351. [Google Scholar] [CrossRef]

- Fleischauer, P.D. Fundamental aspects of the electronic structure, materials properties and lubrication performance of sputtered MoS2 films. Thin Solid Film. 1987, 154, 309–322. [Google Scholar] [CrossRef]

- Scharf, T.W.; Prasad, S.V. Solid lubricants: A review. J. Mater. Sci. 2013, 48, 511–531. [Google Scholar] [CrossRef]

- Manu, B.R.; Gupta, A.; Jayatissa, A.H. Tribological properties of 2D materials and composites—A review of recent advances. Materials 2021, 14, 1630. [Google Scholar] [CrossRef]

- Cizaire, L.; Vacher, B.; Le Mogne, T.; Martin, J.; Rapoport, L.; Margolin, A.; Tenne, R. Mechanisms of ultra-low friction by hollow inorganic fullerene-like MoS2 nanoparticles. Surf. Coat. Technol. 2002, 160, 282–287. [Google Scholar] [CrossRef]

- Caessa, J.; Vuchkov, T.; Yaqub, T.B.; Cavaleiro, A. On the microstructural, mechanical and tribological properties of Mo-Se-C coatings and their potential for friction reduction against rubber. Materials 2021, 14, 1336. [Google Scholar] [CrossRef]

- Gustavsson, F.; Jacobson, S. Diverse mechanisms of friction induced self-organisation into a low-friction material—An overview of WS2 tribofilm formation. Tribol. Int. 2016, 101, 340–347. [Google Scholar] [CrossRef]

- Fayeulle, S.; Ehni, P.D.; Singer, I.L. Paper V (ii) Role of transfer films in wear of MoS2 coatings. Tribol. Ser. 1990, 17, 129–138. [Google Scholar] [CrossRef]

- Lince, J.R.; Kim, H.I.; Adams, P.M.; Dickrell, D.J.; Dugger, M.T. Nanostructural, electrical, and tribological properties of composite Au–MoS2 coatings. Thin Solid Film. 2009, 517, 5516–5522. [Google Scholar] [CrossRef]

- Polcar, T.; Cavaleiro, A. Self-adaptive low friction coatings based on transition metal dichalcogenides. Thin Solid Film. 2011, 519, 4037–4044. [Google Scholar] [CrossRef]

- Ju, H.; Wang, R.; Ding, N.; Yu, L.; Xu, J.; Ahmed, F.; Zuo, B.; Geng, Y. Improvement on the oxidation resistance and tribological properties of molybdenum disulfide film by doping nitrogen. Mater. Des. 2020, 186, 108300. [Google Scholar] [CrossRef]

- Lansdown, A.R. Molybdenum Disulphide Lubrication; Elsevier Science S.A.: Amsterdam, The Netherlands, 1999. [Google Scholar]

- Xiao, H.; Liu, S. 2D nanomaterials as lubricant additive: A review. Mater. Des. 2017, 135, 319–332. [Google Scholar] [CrossRef]

- Kogovšek, J.; Kalin, M. Various MoS2-, WS2- and C-based micro- and nanoparticles in boundary lubrication. Tribol. Lett. 2014, 53, 585–597. [Google Scholar] [CrossRef]

- Rabaso, P.; Ville, F.; Dassenoy, F.; Diaby, M.; Afanasiev, P.; Cavoret, J.; Vacher, B.; Le Mogne, T. Boundary lubrication: Influence of the size and structure of inorganic fullerene-like MoS2 nanoparticles on friction and wear reduction. Wear 2014, 320, 161–178. [Google Scholar] [CrossRef]

- Kalin, M.; Kogovšek, J.; Remškar, M. Mechanisms and improvements in the friction and wear behavior using MoS 2 nanotubes as potential oil additives. Wear 2012, 280–281, 36–45. [Google Scholar] [CrossRef]

- Martin, J.M.; Donnet, C.; Le Mogne, T.; Epicier, T. Superlubricity of molybdenum disulphide. Phys. Rev. B 1993, 48, 10583–10586. [Google Scholar] [CrossRef]

- Donnet, C.; Le Mogne, T.; Martin, J.M. Superlow friction of oxygen-free MoS2 coatings in ultrahigh vacuum. Surf. Coat. Technol. 1993, 62, 406–411. [Google Scholar] [CrossRef]

- Donnet, C.; Erdemir, A. Solid lubricant coatings: Recent developments and future trends. Tribol. Lett. 2004, 17, 389–397. [Google Scholar] [CrossRef]

- Renevier, N.M.; Fox, V.C.; Teer, D.G.; Hampshire, J. Coating characteristics and tribological properties of sputter-deposited MoS2/metal composite coatings deposited by closed field unbalanced magnetron sputter ion plating. Surf. Coat. Technol. 2000, 127, 24–37. [Google Scholar] [CrossRef]

- Arslan, E.; Bülbül, F.; Efeoglu, I. The Structural and Tribological Properties of MoS2-Ti Composite Solid Lubricants. Tribol. Trans. 2010, 47, 218–226. [Google Scholar] [CrossRef]

- Holbery, J.D.; Pflueger, E.; Savan, A.; Gerbig, Y.; Luo, Q.; Lewis, D.; Munz, W.-D. Alloying MoS2 with Al and Au: Structure and tribological performance. Surf. Coat. Technol. 2003, 169–170, 716–720. [Google Scholar] [CrossRef]

- Wahl, K.J.; Dunn, D.N.; Singer, I.L. Wear behavior of Pb-Mo-S solid lubricating coatings. Wear 1999, 230, 175–183. [Google Scholar] [CrossRef]

- Pimentel, J.V.; Polcar, T.; Cavaleiro, A. Structural, mechanical and tribological properties of Mo-S-C solid lubricant coating. Surf. Coat. Technol. 2011, 205, 3274–3279. [Google Scholar] [CrossRef]

- Rho, B.H.; Kim, K.W. Tribological behaviour and wear mechanism of MoS2-Cr coatings sliding against various counterbody. Tribol. Int. 2003, 36, 11–23. [Google Scholar] [CrossRef]

- Hudec, T.; Mikula, M.; Satrapinskyy, L.; Roch, T.; Truchlý, M.; Švec, P.; Huminiuc, T.; Polcar, T. Structure, mechanical and tribological properties of Mo-S-N solid lubricant coatings. Appl. Surf. Sci. 2019, 486, 1–14. [Google Scholar] [CrossRef]

- Zhang, X.; Qiao, L.; Chai, L.; Xu, J.; Shi, L.; Wang, P. Structural, mechanical and tribological properties of Mo-S-N solid lubricant films. Surf. Coat. Technol. 2016, 296, 185–191. [Google Scholar] [CrossRef]

- Kubart, T.; Polcar, T.; Kopecký, L.; Novák, R.; Nováková, D. Temperature dependence of tribological properties of MoS2 and MoSe2 coatings. Surf. Coat. Technol. 2005, 193, 230–233. [Google Scholar] [CrossRef]

- Johnson, R.L.; Sliney, H.E. Fundamental Considerations for Future Solid Lubricants; NASA TM X-52659; NASA: Sandusky, OH, USA, 1969. [Google Scholar]

- Brainard, W.A. The Thermal Stability and Friction of the Disulfides, Diselenides, and Ditellurides of Molybdenum and Tungsten in Vaccum (10-9 to 10-6 TORR); NASA Tech Note D-5141; NASA: Sandusky, OH, USA, 1968; pp. 1–26. Available online: http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19690013627.pdf%5Cnhttp://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19690013627.pdf%5Cnpapers3://publication/uuid/CFE5E80B-C183-4052-96FE-0CA1EB625F73 (accessed on 3 July 2025).

- Tomala, A.; Ripoll, M.R.; Kogovšek, J.; Kalin, M.; Bednarska, A.; Michalczewski, R.; Szczerek, M. Synergisms and antagonisms between MoS2 nanotubes and representative oil additives under various contact conditions. Tribol. Int. 2019, 129, 137–150. [Google Scholar] [CrossRef]

- Rabaso, P.; Dassenoy, F.; Ville, F.; Diaby, M.; Vacher, B.; Le Mogne, T.; Belin, M.; Cavoret, J. An investigation on the reduced ability of IF-MoS2 nanoparticles to reduce friction and wear in the presence of dispersants. Tribol. Lett. 2014, 55, 503–516. [Google Scholar] [CrossRef]

- An, V.; Irtegov, Y.; de Izarra, C. Study of Tribological Properties of Nanolamellar WS2 and MoS2 as Additives to Lubricants. J. Nanomater. 2014, 2014, 1–8. [Google Scholar] [CrossRef]

- Dong, J.; Li, C.; Yang, J.; Chen, B.; Song, H.; Chen, J.; Peng, W. Facile synthesis of ultrathin NbTe2 nanosheets for enhanced tribological properties as a lubricant additive. Cryst. Res. Technol. 2016, 51, 671–680. [Google Scholar] [CrossRef]

- Chng, E.L.K.; Sofer, Z.; Pumera, M. MoS2 exhibits stronger toxicity with increased exfoliation. Nanoscale 2014, 6, 14412–14418. [Google Scholar] [CrossRef] [PubMed]

- Tan, E.; Li, B.L.; Ariga, K.; Lim, C.T.; Garaj, S.; Leong, D.T. Toxicity of Two-Dimensional Layered Materials and Their Heterostructures. Bioconjugate Chem. 2019, 30, 2287–2299. [Google Scholar] [CrossRef] [PubMed]

- Teo, W.Z.; Chng, E.L.K.; Sofer, Z.; Pumera, M. Cytotoxicity of exfoliated transition-metal dichalcogenides (MoS2, WS2, and WSe2) is lower than that of graphene and its analogues. Chem.—A Eur. J. 2014, 20, 9627–9632. [Google Scholar] [CrossRef]

- Rodrigues, S.P.; Polcar, T.; Carvalho, S.; Cavaleiro, A. The wettability and tribological behaviour of thin F-doped WS2 films deposited by magnetron sputtering. Surf. Coat. Technol. 2019, 378, 125033. [Google Scholar] [CrossRef]

- Hovsepian, P.E.; Mandal, P.; Ehiasarian, A.P.; Sáfrán, G.; Tietema, R.; Doerwald, D. Friction and wear behaviour of Mo-W doped carbon-based coating during boundary lubricated sliding. Appl. Surf. Sci. 2016, 366, 260–274. [Google Scholar] [CrossRef]

- Gustavsson, F.; Forsberg, P.; Jacobson, S. Friction and wear behaviour of low-friction coatings in conventional and alternative fuels. Tribol. Int. 2012, 48, 22–28. [Google Scholar] [CrossRef]

- Alshammari, S. Tribological Characterisation of MoSe2 and MoSe2/DLC-W Coatings Under Oil-Lubricated Sliding Conditions. Ph.D. Thesis, University of Southampton, Hampshire, UK, July 2023. Available online: https://eprints.soton.ac.uk/478798/ (accessed on 8 June 2025).

- Oliver, W.; Pharr, G. An improved technique for determining hardness and elastic modulus using load and displacement-sensing indentation systems. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Hamrock, B.J.; Schmid, S.R.; Jacobson, B.O. Fundamentals of Fluid Film Lubrication; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar] [CrossRef]

- Dunn, D.N.; Seitzman, L.E.; Singer, I.L. The origin of an anomalous, low 2θ peak in x-ray diffraction spectra of MoS2 films grown by ion beam assisted deposition. J. Mater. Res. 1997, 12, 1191–1194. [Google Scholar] [CrossRef]

- Yaqub, T.B.; Vuchkov, T.; Sanguino, P.; Polcar, T.; Cavaleiro, A. Comparative Study of DC and RF Sputtered MoSe2 Coatings Containing Carbon—An Approach to Optimize Stoichiometry, Microstructure, Crystallinity and Hardness. Coatings 2020, 10, 133. [Google Scholar] [CrossRef]

- Hudec, T.; Izai, V.; Satrapinskyy, L.; Huminiuc, T.; Roch, T.; Gregor, M.; Grančič, B.; Mikula, M.; Polcar, T. Structure, mechanical and tribological properties of MoSe2 and Mo-Se-N solid lubricant coatings. Surf. Coat. Technol. 2021, 405, 126536. [Google Scholar] [CrossRef]

- Xu, S.; Sun, J.; Weng, L.; Hua, Y.; Liu, W.; Neville, A.; Hu, M.; Gao, X. In-situ friction and wear responses of WS2 films to space environment: Vacuum and atomic oxygen. Appl. Surf. Sci. 2018, 447, 368–373. [Google Scholar] [CrossRef]

- Yaqub, T.B.; Al-Rjoub, A.; Cavaleiro, A.; Fernandes, F. Exploring the industrial implementation of W–S–N coatings: A detailed study of the synthesis, compositional, structural, mechanical and multi-environment lubrication properties. J. Mater. Res. Technol. 2022, 18, 547–563. [Google Scholar] [CrossRef]

- Koch, T.; Evaristo, M.; Pauschitz, A.; Roy, M.; Cavaleiro, A. Nanoindentation and nanoscratch behaviour of reactive sputtered deposited W-S-C film. Thin Solid Film. 2009, 518, 185–193. [Google Scholar] [CrossRef]

- Gustavsson, F.; Jacobson, S.; Cavaleiro, A.; Polcar, T. Frictional behavior of self-adaptive nanostructural Mo–Se–C coatings in different sliding conditions. Wear 2013, 303, 286–296. [Google Scholar] [CrossRef]

- Weise, G.; Mattern, N.; Hermann, H.; Teresiak, A.; Ba, I.; Bru, W. Preparation, structure and properties of MoS x films. Thin Solid Film. 1997, 298, 98–106. [Google Scholar] [CrossRef]

- Gao, X.; Fu, Y.; Jiang, D.; Wang, D.; Xu, S.; Liu, W.; Weng, L.; Yang, J.; Sun, J.; Hu, M. Constructing WS2/MoS2 nano-scale multilayer film and understanding its positive response to space environment. Surf. Coat. Technol. 2018, 353, 8–17. [Google Scholar] [CrossRef]

- Yaqub, T.B.; Hebbar Kannur, K.; Vuchkov, T.; Pupier, C.; Héau, C.; Cavaleiro, A. Molybdenum diselenide coatings as universal dry lubricants for terrestrial and aerospace applications. Mater. Lett. 2020, 275, 128035. [Google Scholar] [CrossRef]

- Bondarev, A.V.; Kiryukhantsev-Korneev, P.V.; Sheveyko, A.N.; Shtansky, D.V. Structure, tribological and electrochemical properties of low friction TiAlSiCN/MoSeC coatings. Appl. Surf. Sci. 2015, 327, 253–261. [Google Scholar] [CrossRef]

- Yaqub, T.B.; Bruyere, S.; Pierson, J.F.; Vuchkov, T.; Cavaleiro, A. Insights into the wear track evolution with sliding cycles of carbon-alloyed transition metal dichalcogenide coatings. Surf. Coat. Technol. 2020, 403, 126360. [Google Scholar] [CrossRef]

- Yang, Y.; Li, X.; Wen, M.; Hacopian, E.; Chen, W.; Gong, Y.; Zhang, J.; Li, B.; Zhou, W.; Ajayan, P.M.; et al. Brittle Fracture of 2D MoSe2. Adv. Mater. 2017, 29, 1604201. [Google Scholar] [CrossRef] [PubMed]

- Colas, G.; Serles, P.; Saulot, A.; Filleter, T. Strength measurement and rupture mechanisms of a micron thick nanocrystalline MoS2 coating using AFM based micro-bending tests. J. Mech. Phys. Solids. 2019, 128, 151–161. [Google Scholar] [CrossRef]

- Nam, D.; Lee, J.-U.; Cheong, H. Excitation energy dependent Raman spectrum of MoSe2. Sci. Rep. 2015, 5, 17113. [Google Scholar] [CrossRef]

- Vitu, T.; Huminiuc, T.; Doll, G.; Bousser, E.; Polcar, T. Tribological properties of Mo-S-C coating deposited by pulsed d.c. magnetron sputtering. Wear 2021, 480, 1–10. [Google Scholar] [CrossRef]

- Banerji, A.; Bhowmick, S.; Alpas, A.T. Role of temperature on tribological behaviour of Ti containing MoS2 coating against aluminum alloys. Surf. Coat. Technol. 2017, 314, 2–12. [Google Scholar] [CrossRef]

- Windom, B.C.; Sawyer, W.G.; Hahn, D.W. A raman spectroscopic study of MoS2 and MoO3: Applications to tribological systems. Tribol. Lett. 2011, 42, 301–310. [Google Scholar] [CrossRef]

- Hudec, T.; Bondarev, A.; Izai, V.; Šroba, V.; Satrapinskyy, L.; Roch, T.; Turiničová, V.; Grančič, B.; Polcar, T.; Mikula, M. Titanium doped MoSe2 coatings—Synthesis, structure, mechanical and tribological properties investigation. Appl. Surf. Sci. 2021, 568, 150990. [Google Scholar] [CrossRef]

- Polcar, T.; Evaristo, M.; Stuebeur, M.; Cavaleiro, A. Mechanical and tribological properties of sputtered Mo–Se–C coatings. Wear 2009, 266, 393–397. [Google Scholar] [CrossRef]

- Goikhman, A.; Fominski, D.; Gritskevich, M.; Romanov, R.; Fominski, V.; Smirnov, N. Features of pulsed laser ablation of MoS2 and MoSe2 targets and their influence on the tribological properties of the deposited low friction films. J. Phys. Conf. Ser. 2020, 1686, 012044. [Google Scholar] [CrossRef]

- Yaqub, T.B.; Vuchkov, T.; Bruyère, S.; Pierson, J.F.; Cavaleiro, A. A revised interpretation of the mechanisms governing low friction tribolayer formation in alloyed-TMD self-lubricating coatings. Appl. Surf. Sci. 2022, 571, 151302. [Google Scholar] [CrossRef]

- Spalvins, T. A review of recent advances in solid film lubrication. J. Vac. Sci. Technol. A Vac. Surf. Film. 1987, 5, 212–219. [Google Scholar] [CrossRef]

- Polcar, T.; Evaristo, M.; Cavaleiro, A. Comparative study of the tribological behavior of self-lubricating W-S-C and Mo-Se-C sputtered coatings. Wear 2009, 266, 388–392. [Google Scholar] [CrossRef]

- Sundberg, J.; Nyberg, H.; Särhammar, E.; Gustavsson, F.; Kubart, T.; Nyberg, T.; Jacobson, S.; Jansson, U. Influence of Ti addition on the structure and properties of low-friction W-S-C coatings. Surf. Coat. Technol. 2013, 232, 340–348. [Google Scholar] [CrossRef]

- Cai, S.; Guo, P.; Liu, J.; Zhang, D.; Ke, P.; Wang, A.; Zhu, Y. Friction and Wear Mechanism of MoS2/C Composite Coatings Under Atmospheric Environment. Tribol. Lett. 2017, 65, 1–12. [Google Scholar] [CrossRef]

- Scharf, T.W.; Kotula, P.G.; Prasad, S.V. Friction and wear mechanisms in MoS2/Sb2O3/Au nanocomposite coatings. Acta Mater. 2010, 58, 4100–4109. [Google Scholar] [CrossRef]

- Xu, J.; He, T.F.; Chai, L.Q.; Qiao, L.; Zhang, X.Q.; Wang, P.; Liu, W.M. Selective-releasing-affected lubricant mechanism of a self-assembled MoS2/Mo-S-C nanoperiod multilayer film sliding in diverse atmospheres. Phys. Chem. Chem. Phys. 2017, 19, 8161–8173. [Google Scholar] [CrossRef]

- Grossiord, C.; Varlot, K.; Martin, J.; Mogne TLe Esnouf, C. MoS2 single sheet lubrication by molybdenum. Tribol. Int. 1999, 31, 737–743. [Google Scholar] [CrossRef]

- Savan, A.; Pflüger, E.; Voumard, P.; Schröer, A.; Simmonds, M. Modern solid lubrication: Recent developments and applications of MoS2. Lubr. Sci. 2000, 12, 185–203. [Google Scholar] [CrossRef]

- Fleischauer, P.D.; Lince, J.R. Comparison of oxidation and oxygen substitution in MoS2 solid film lubricants. Tribol. Int. 1999, 32, 627–636. [Google Scholar] [CrossRef]

- Li, H.; Li, X.; Zhang, G.; Wang, L.; Wu, G. Exploring the Tribophysics and Tribochemistry of MoS2 by Sliding MoS2/Ti Composite Coating Under Different Humidity. Tribol. Lett. 2017, 65, 1–10. [Google Scholar] [CrossRef]

- Wang, D.Y.; Chang, C.L.; Ho, W.Y. Microstructure analysis of MoS2 deposited on diamond-like carbon films for wear improvement. Surf. Coat. Technol. 1999, 111, 123–127. [Google Scholar] [CrossRef]

| Chemical Composition (at.%) | |

| Mo | 32.51 ± 0.2 |

| Se | 65.08 ± 0.1 |

| O | 2.41 ± 0.2 |

| Mechanical Properties (GPa) | |

| Hardness (H) | 0.83 ± 0.07 |

| Reduced elastic modulus (Er) | 27.86 ± 1.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alshammari, S.; Harvey, T.; Wang, S. Comparative Study of the Tribological Properties of MoSe2 Coatings Under Dry and Oil-Lubricated Sliding Conditions. Lubricants 2025, 13, 467. https://doi.org/10.3390/lubricants13110467

Alshammari S, Harvey T, Wang S. Comparative Study of the Tribological Properties of MoSe2 Coatings Under Dry and Oil-Lubricated Sliding Conditions. Lubricants. 2025; 13(11):467. https://doi.org/10.3390/lubricants13110467

Chicago/Turabian StyleAlshammari, Saad, Terence Harvey, and Shuncai Wang. 2025. "Comparative Study of the Tribological Properties of MoSe2 Coatings Under Dry and Oil-Lubricated Sliding Conditions" Lubricants 13, no. 11: 467. https://doi.org/10.3390/lubricants13110467

APA StyleAlshammari, S., Harvey, T., & Wang, S. (2025). Comparative Study of the Tribological Properties of MoSe2 Coatings Under Dry and Oil-Lubricated Sliding Conditions. Lubricants, 13(11), 467. https://doi.org/10.3390/lubricants13110467