Enabling Ultra-Stable Bearing Performance: Design of a Self-Lubricating PI Composite Retainer

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Main Experimental Equipment

2.3. Bearing Retainer Preparation

2.4. Bearing Properties Tests

3. Results and Discussion

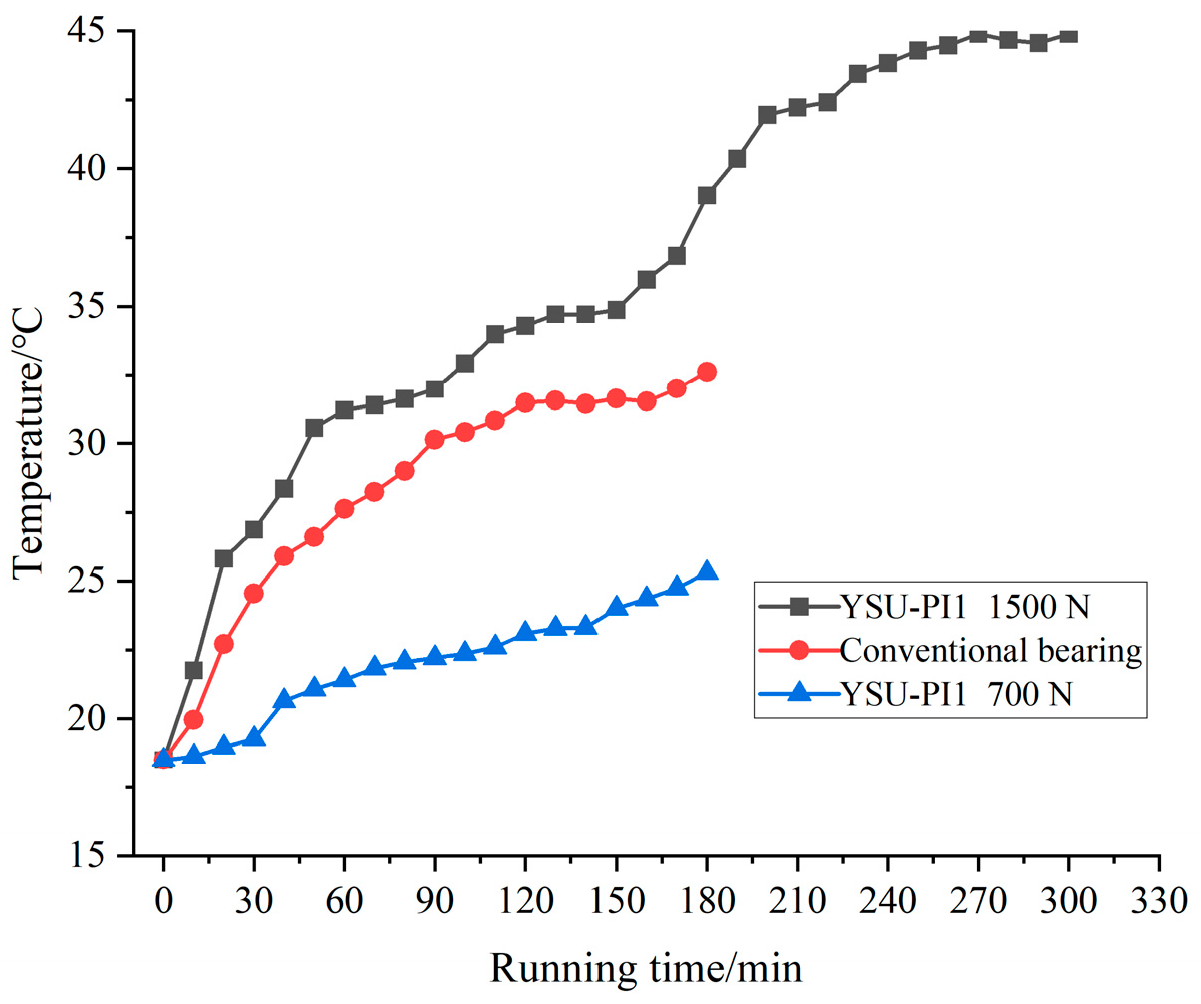

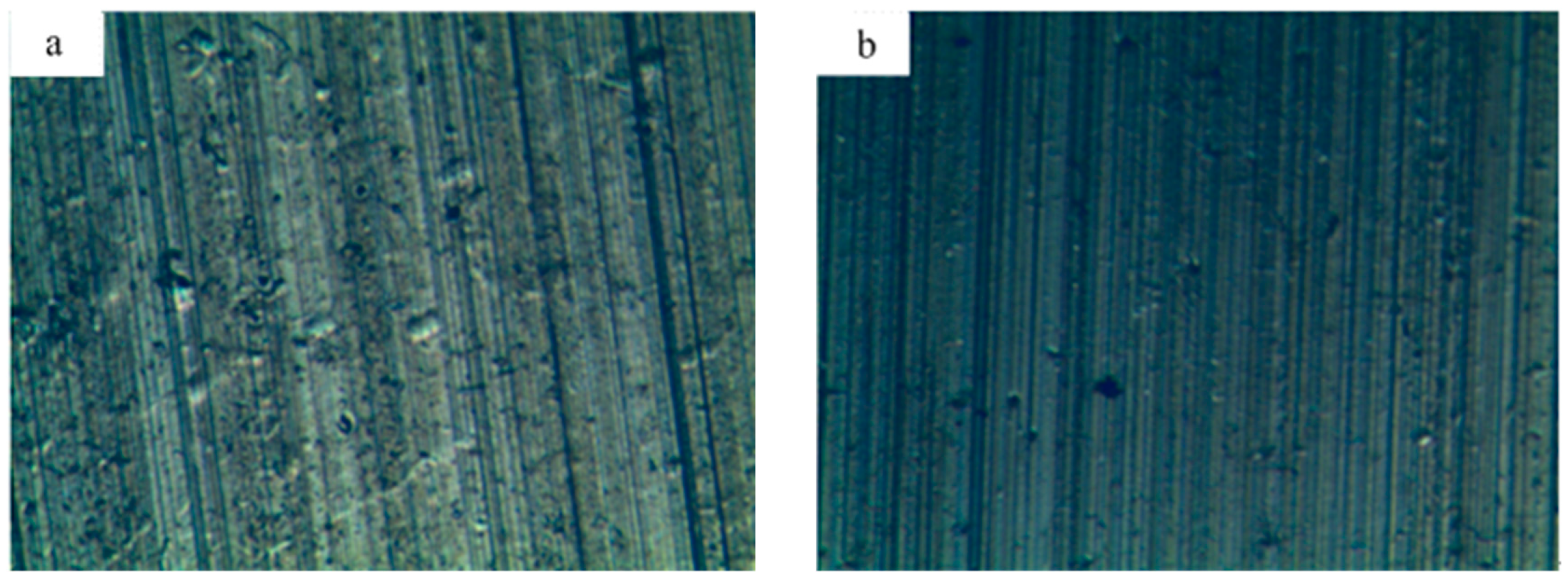

3.1. Comparison of Solid Retainer Bearings

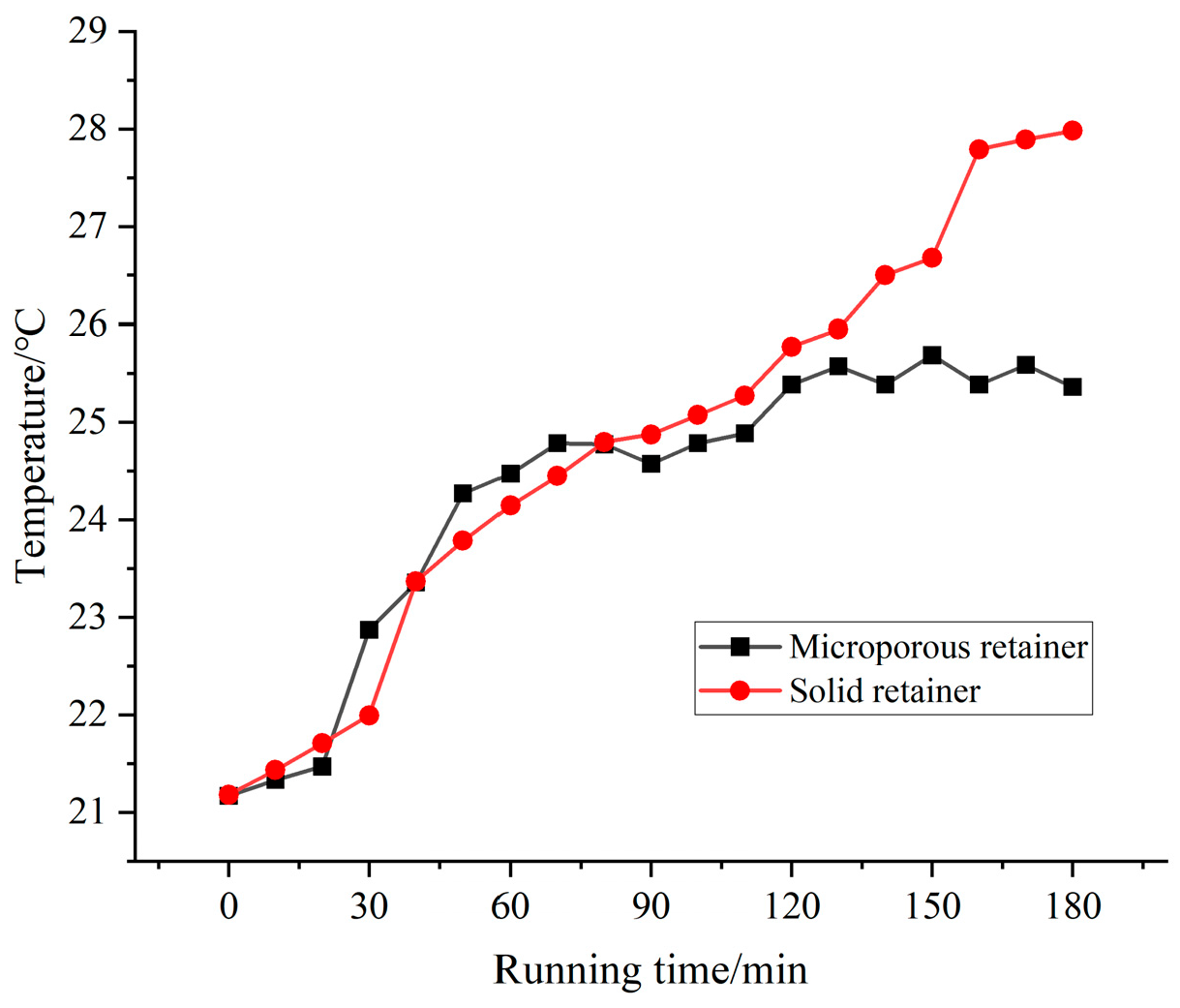

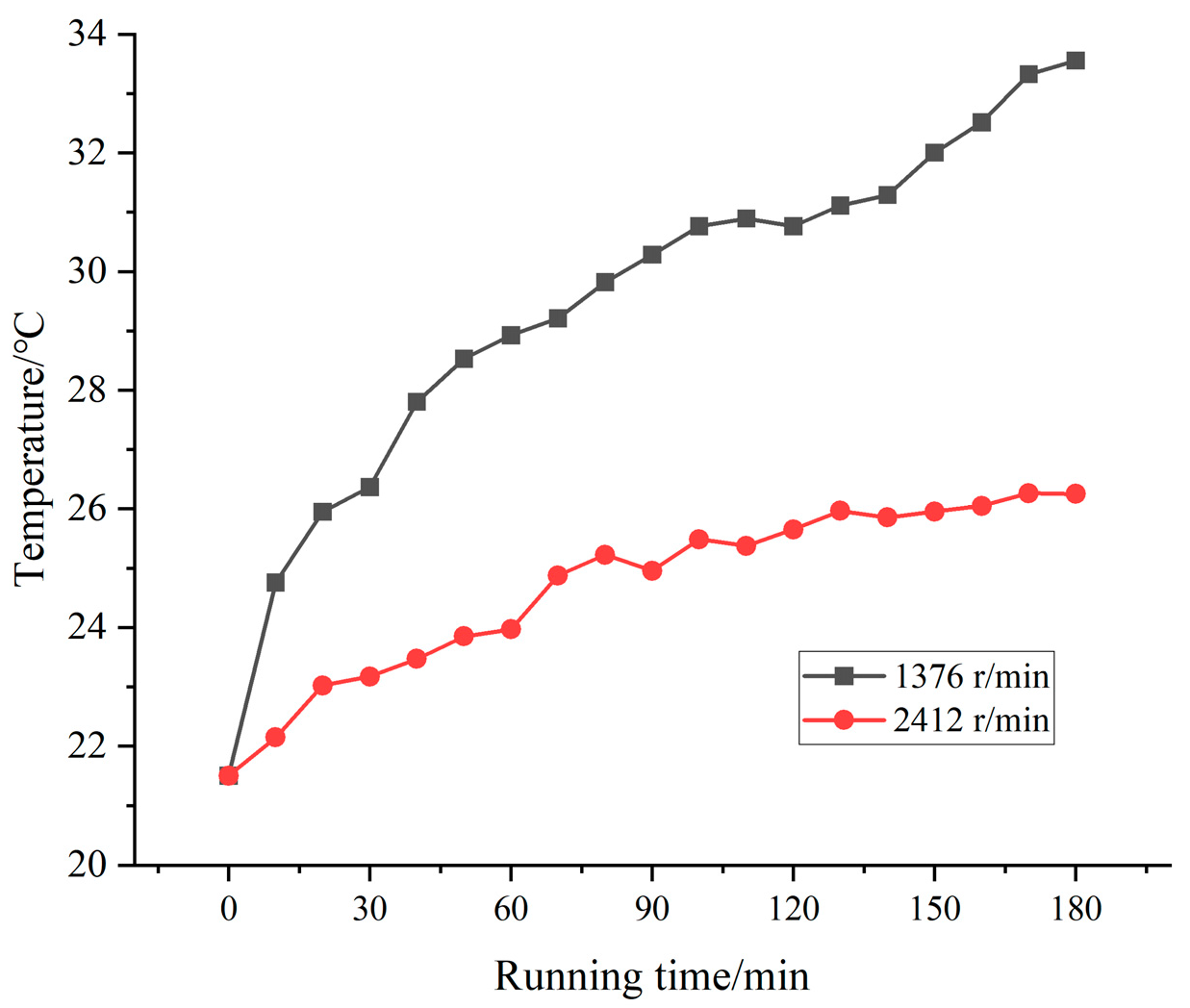

3.2. Performance of Bearings with Porous Oil-Containing Retainers

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Harris, T.A.; Kotzalas, M.N. Rolling Bearing Analysis, 5th ed.; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Davim, J.P. Tribology for Engineers: A Practical Guide; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Davim, J.P. Tribology: A bibliometric Analysis. Int. J. Surf. Sci. Eng. 2025, 19, 1–3. [Google Scholar]

- Bhushan, B. Principles and Applications of Tribology, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Jiang, T.H.; Zhou, S.; Pan, A.X.; Che, Y.-H.; Li, G.-Q.; Xu, H.-J.; Gong, Y.; Yang, Z.-G. Failure Analysis of the Abnormal Wear of Rolling Bearing in the Centrifugal Fan for Nuclear Power Plant. Eng. Fail. Anal. 2025, 171, 109353. [Google Scholar] [CrossRef]

- Zhou, Y.Z.; Wang, C.J.; Lu, Z. On the Free Vibration of High-Speed Ball Bearing Retainer. J. Beijing Univ. Aeronaut. Astronaut. 2001, 27, 596–599. (In Chinese) [Google Scholar]

- Sathyan, K.; Gopinath, K.; Lee, S.H.; Hsu, H.Y. Bearing Retainer Designs and Retainer Instability Failures in Spacecraft Moving Mechanical SSystems. Tribol. Trans. 2012, 55, 503–511. [Google Scholar] [CrossRef]

- Chen, W.B.; Wang, W.Z.; Zhu, P.Z.; Ge, X. Effects of Pore Size on the Lubrication Properties of Porous Polyimide Retainer Material. Friction 2023, 11, 1419–1429. [Google Scholar] [CrossRef]

- Sahinkaya, M.N.; Abulrub, A.H.G.; Keogh, P.S.; Burrows, C.R. Multiple Sliding and Rolling Contact Dynamics for a Flexible Rotor/Magnetic Bearing System. IEEE/ASME Trans. Mechatron. 2007, 12, 179–189. [Google Scholar] [CrossRef]

- Muzakkir, S.M.; Hirani, H. Experimental Investigation on Effect of Grinding Direction on Wear Under Heavy Load and Slow Speed Conditions with Molybdenum Disulphide (MoS2) as Additive in Commercial Lubricant. Int. J. Eng. Res. 2015, 4, 102–104. [Google Scholar] [CrossRef]

- Hu, J.; Xun, B.; Zhang, X.M.; Zhang, Q.-Y.; Li, G.-W. Design and Research of New-type Nozzle Structure Based on Oil–air Lubrication. Mecc. J. Ital. Assoc. Theor. Appl. Mech. 2024, 59, 18. [Google Scholar] [CrossRef]

- Meheux, M.; Minfray, C.; Ville, F.; Mogne, T.L.; Lubrecht, A.A.; Martin, J.M.; Lieurade, H.P.; Thoquenne, G. Effect of Lubricant Additives in Rolling Contact Fatigue. Proc. Inst. Mech. Eng. 2010, 947, 947–955. [Google Scholar] [CrossRef]

- Milewski, K.; Madej, M. DIamond-like Carbon (DLC) Coatings on Roller Bearing Elements of Belt Conveyors. Metalurgija 2022, 61, 835–837. [Google Scholar]

- Saharudin, M.F.; Zulkifli, N.W.M.; Goh, Y.; Ibrahim, M.Z.; Morina, A.; Mehtab, R. Investigation of the Tribological and Mechanical Properties of FeCrMoCB Coating on AISI 52100 Bearing Steel. Tribol. Int. 2025, 203, 1110401. [Google Scholar] [CrossRef]

- Wang, P.F.; Li, S.H.; Wu, Y.H.; Zhao, J. Research on Calculation of Allowable Radial Load of Silicon Nitride Full Ceramic Ball Bearing. J. Mech. Sci. Technol. 2024, 38, 6757–6767. [Google Scholar] [CrossRef]

- Alshorman, O.; Irfan, M.; Saad, N.; Zhen, D.; Haider, N.; Glowacz, A.; Alshorman, A. A Review of Artificial Intelligence Methods for Condition Monitoring and Fault Diagnosis of Rolling Element Bearings for Induction Motor. Shock. Vib. 2020, 2020, 8843759. [Google Scholar] [CrossRef]

- Jin, X.Y.; Li, X.M.; Liu, Y.; Gao, J.; Bai, L. Experimental Study of Lubricant Distribution and Lubrication Enhancement Induced by Ball Bearing Cage. J. Tribol. 2024, 146, 11. [Google Scholar] [CrossRef]

- Matsubayashi, S.; Watanabe, Y.; Kida, K. Wear Failure of PEEK-Alumina Ball Bearings in Dry Rolling Contact at 600 rpm/Part 2: Observation of Wear on Retainer. In Materials Science Forum; Trans Tech Publications Ltd.: Bäch, Switzerland, 2023; Volume 1101, pp. 47–53. [Google Scholar]

- Maslavi, A.; Ünal, H.; Yetgin, S. Determination of the Effect of Sliding Speed on Tribological Performances of Carbon Fiber Reinforced, Graphite and PTFE Filled Poly-ether-ether-ketone (PEEK) Polymer Composite. Konya J. Eng. Sci. 2022, 10, 457–467. [Google Scholar] [CrossRef]

- Zhao, X.C.; Wang, W.W.; Liu, J.; Tang, C.; Liu, P. Study on Effect of Heat Treatment Modification on Tribological Properties of PTFE/PEEK Porous Cage Materials. Plast. Sci. Technol. 2025, 53, 21–26. [Google Scholar]

- Chen, J.X.; Qin, H.L.; Xu, X.; Zeng, Y.; Chen, K. Study on the Performance of Porous Polyimide Bearing Cage Material Modified with Molybdenum Disulfide and Glass fiber. J. Phys. Conf. Ser. 2024, 2760, 012035. [Google Scholar] [CrossRef]

- Jiang, Y.Y.; Chen, L.; Chen, X.; Zhou, N.; Qing, T.; Qian, L. Friction and Wear Behaviors of Steel Ball Against Polyimide-PTFE Composite under Rolling-Sliding Motion. Tribol. Lett. 2021, 69, 100. [Google Scholar] [CrossRef]

- Daniel, N.; Liu, H. Comparative Study on Tribological Behavior of Graphene/Polyimide and Carbon Fibers/ Polyimide Composites: A Review. World J. Eng. Technol. 2021, 9, 26–50. [Google Scholar] [CrossRef]

- Hu, H.J.; He, Y.; Wang, Q.H.; Tao, L. In-situ Research on Formation Mechanisms of Transfer Films of A Polyimide-MoS2 Composite in Vacuum. Tribol. Int. 2023, 180, 1108211. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Zhang, H.; Wang, J.H.; Qin, S.; Duan, X.; Duan, M. Study on Mechanics and High Temperature Tribological Properties of Porous Bearing Cage Material. J. Reinf. Plast. Compos. 2024, 43, 1165–1178. [Google Scholar] [CrossRef]

- Zhang, H.; Duan, M.D.; Qin, S.K.; Zhang, Z. Preparation and Modification of Porous Polyetheretherketone (PEEK) Cage Material Based on Fused Deposition Modeling (FDM). Polymers 2022, 14, 5403. [Google Scholar] [CrossRef] [PubMed]

- Yin, Y.; Shi, P.F.; Zhang, S.H.; Qing, T.; Zhou, N.; Qian, L.; Chen, L. Lubrication Failure Mechanism of Rolling-sliding Steel Ball against Oil-impregnated Porous Polyimide and Bearing Steel in Double Friction Pair. Eng. Fail. Anal. 2024, 164, 108622. [Google Scholar] [CrossRef]

- Pu, Y.P.; Lu, G.S.; Li, X.J.; Xiao, H.C. Tribological Property of Polyimide Porous Materials. J. Beijing Inst. Technol. 2006, 15, 483–487. [Google Scholar]

- Burda, E.A.; Zusman, G.V.; Nicoletti, N.R. An Overview of Vibration Analysis Techniques for the Fault Diagnostics of Rolling Bearings in Machinery. Shock. Vib. 2022, 2022, 6136231. [Google Scholar] [CrossRef]

- Zhao, L.J.; Xie, T.; Wei, Y.H.; Liu, Y.; Qin, Y. Overview of Digital Twin-driven Rotating Machinery Fault Diagnosis: Status and Trends. Meas. Sci. Technol. 2025, 36, 052001. [Google Scholar] [CrossRef]

- Liao, H.; Xie, P.F.; Deng, S.E.; Zhang, W.; Shi, L.; Zhao, S. Investigation of Dynamic Characteristics Experiments and Stability Evaluation Criterion of Space Ball Bearing Cage. Tribol. Trans. 2023, 66, 453–465. [Google Scholar] [CrossRef]

- Yan, J.Y.; Zhang, X.L.; Wang, Y.M. Review of Tribological Properties of Polyimide-based Composite. Ind. Lubr. Tribol. 2023, 75, 883–894. [Google Scholar] [CrossRef]

- Yan, Y.H.; Yang, C.W.; Zhou, Y.F.; Dong, W.; Yan, P.; Jia, Z. Study on Preparation Process Parameters and Tribological Properties of Porous PI Materials. Ind. Lubr. Tribol. 2022, 74, 205–210. [Google Scholar] [CrossRef]

- Yan, Y.H.; Yang, Y.L.; Jia, Z.N.; Song, X. Friction and Wear Behaviors of Hybrid PI/PTFE Nanocomposites Enhanced with Nanoparticles. J. Balk. Tribol. Assoc. 2017, 49, 948–954. [Google Scholar]

- Jia, Z.N.; Hao, C.Z. Thermal-Tribological Synergy in PTFE-Based Self-Lubricating Retainers for Ball Bearings Under Oil-Depleted Conditions. Lubricants 2025, 13, 280. [Google Scholar] [CrossRef]

- Panin, S.V.; Kornienko, L.A.; Anh, N.D.; Alexenko, V.O.; Buslovich, D.G.; Bochkareva, S.A. Three-component Wear-resistant PEEK-based Composites Filled with PTFE and MoS2: Composition Optimization, Structure Homogenization, and Self-lubricating Effect. In Multiscale Biomechanics and Tribology of Inorganic and Organic Systems; Springer Nature: Cham, Switzerland, 2021. [Google Scholar]

- Kamga, L.S.; Emrich, S.; Merz, R.; Oehler, M.; Gedan-Smolka, M.-S.; Kopnarski, M.; Sauer, B.; Koch, O. Influence of PTFE-based Dry Lubricants on Friction and Wear Behavior in Dry Lubricated Steel–Bronze Contact. J. Tribol. 2023, 145, 121703. [Google Scholar] [CrossRef]

- Duan, L.; Jian, L.I.; Duan, H. Nanomaterials for Lubricating Oil Application: A review. Friction 2023, 11, 647–684. [Google Scholar] [CrossRef]

- Paula, P.B.D.; Gutiérrez, A.R.; García-Contreras, R. Influence of Al2O3 Nanoparticles in A Lubricating Oil for Reciprocating Engines. J. Eng. Tribol. (Part J) 2023, 237, 178–189. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, Z.; Hao, C. Enabling Ultra-Stable Bearing Performance: Design of a Self-Lubricating PI Composite Retainer. Lubricants 2025, 13, 465. https://doi.org/10.3390/lubricants13110465

Jia Z, Hao C. Enabling Ultra-Stable Bearing Performance: Design of a Self-Lubricating PI Composite Retainer. Lubricants. 2025; 13(11):465. https://doi.org/10.3390/lubricants13110465

Chicago/Turabian StyleJia, Zhining, and Caizhe Hao. 2025. "Enabling Ultra-Stable Bearing Performance: Design of a Self-Lubricating PI Composite Retainer" Lubricants 13, no. 11: 465. https://doi.org/10.3390/lubricants13110465

APA StyleJia, Z., & Hao, C. (2025). Enabling Ultra-Stable Bearing Performance: Design of a Self-Lubricating PI Composite Retainer. Lubricants, 13(11), 465. https://doi.org/10.3390/lubricants13110465