Deep Eutectic Solvents as Green and Novel Lubricant Additives for Castor Oil with High Tribological Performance

Abstract

1. Introduction

2. Materials and Methods

2.1. Base Oil and Additives

2.2. Lubricant Formulation

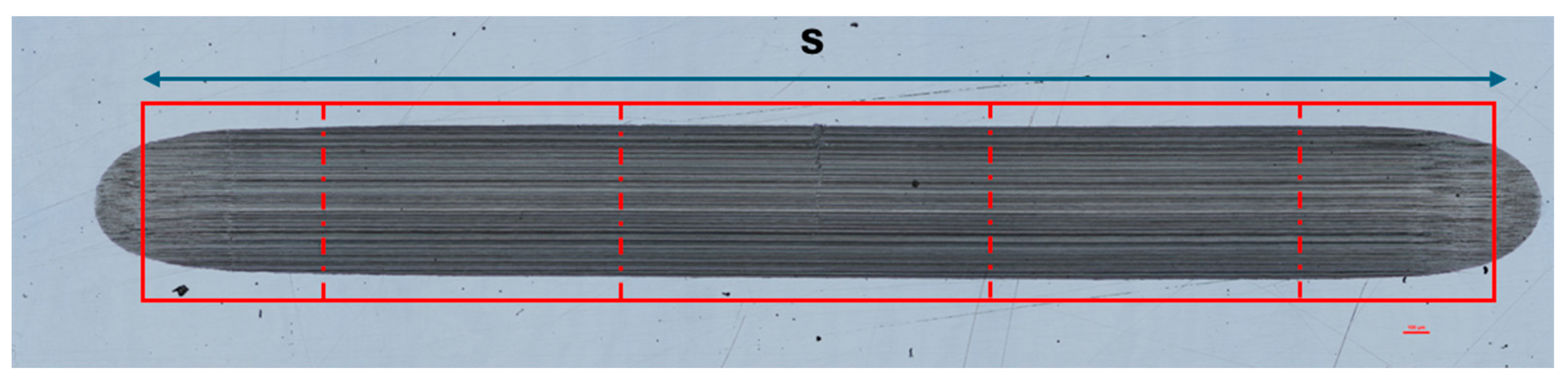

2.3. Tribological Tests: Pure Sliding

3. Results

3.1. Characterization of Lubricant Components: Base Oil and Deep Eutectic Solvent

3.2. Friction and Wear Results in Tribological Tests

4. Conclusions

- -

- The deep eutectic solvent (DES1), formed by DL-menthol as an HBA and dodecanoic acid as an HBD, was successfully prepared by a one-step route, forming a halogen-free, eco-friendly, and economical lubricant additive.

- -

- The formulation of lubricants composed of a castor oil base and DES1 as an additive was completed observing good miscibility.

- -

- DES1 lubricants have better antifriction performance than castor oil, with the maximum friction reduction observed for the 0.1 wt% DES1 lubricant (4%).

- -

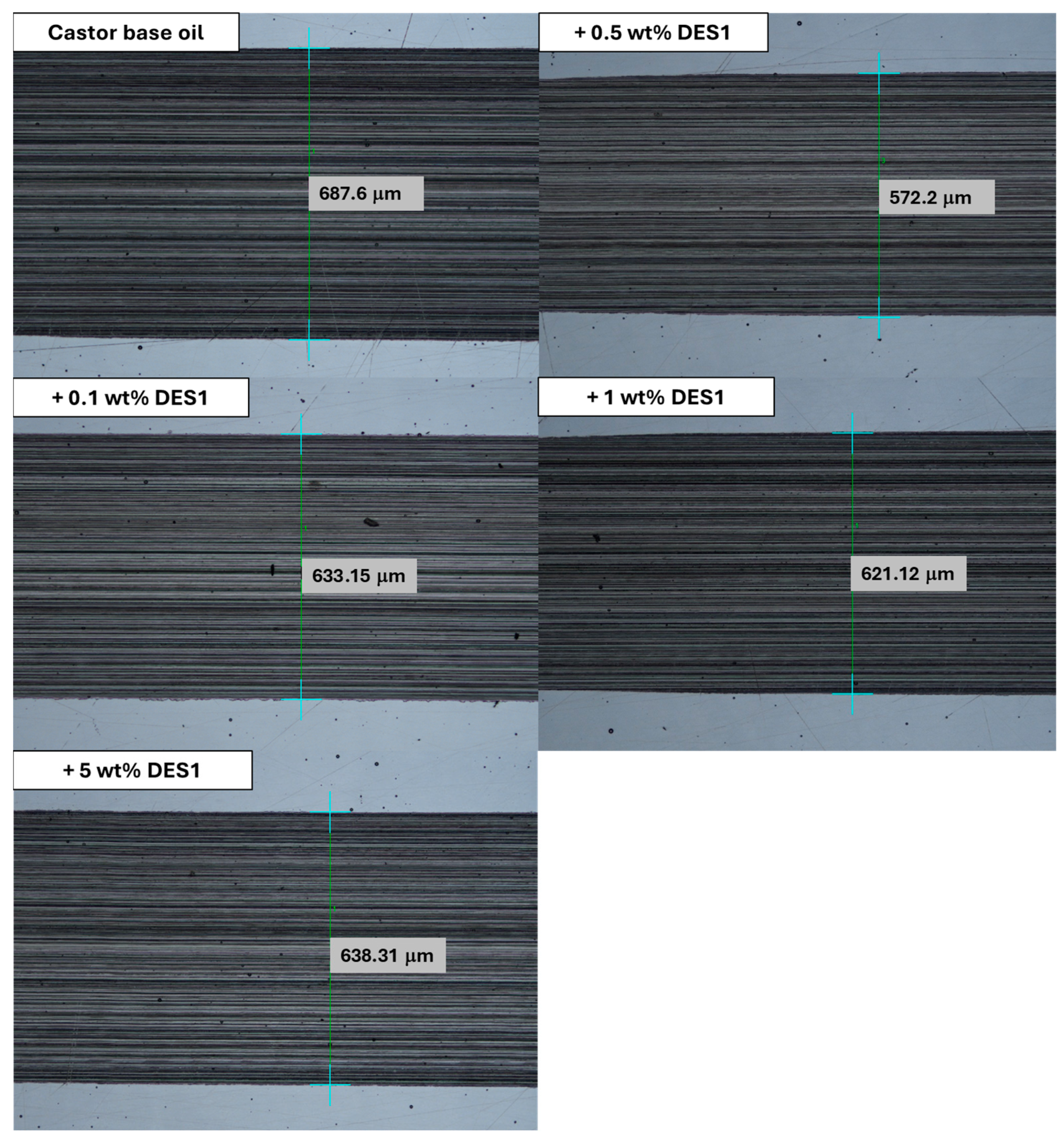

- DES1 lubricants have better antiwear performance than castor oil. In particular, the castor oil + 0.5 wt% DES1 lubricant achieved the best antiwear performance with reductions up to 17% in wear track width.

- -

- The ASTM D7755-11 standard was utilized to obtain the worn volumes, observing volume reductions up to 36% for the castor oil + 0.5 wt% DES1 lubricant.

- -

- Steel surfaces are particularly smooth with reduced furrows when DESs are added to a base oil, indicating a clear tribological improvement in comparison with steel surfaces lubricated with castor oil.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Benedicto, E.; Rubio, E.M.; Aubouy, L.; Sáenz-Nuño, M.A. Sustainable Lubrication/Cooling Systems for Efficient Turning Operations of γ-TiAl Parts from the Aeronautic Industry. Int. J. Precis. Eng. Manuf.-Green Technol. 2023, 10, 709–728. [Google Scholar] [CrossRef]

- Kumar, D.B. Oil and Lubricant Hazard Effects on Human Health. Int. J. Innov. Sci. Eng. Technol. 2017, 4, 315–322. [Google Scholar]

- Zheng, T.; Fang, J.; Xie, Q.; Wu, Z.; Lu, M.; Xia, F.; Deng, D.; Nie, Y.; Ji, J. Measurement and correlation of the density, viscosity and vapor pressure of fatty acid 2-ethyhexyl esters. J. Chem. Thermodyn. 2019, 130, 243–250. [Google Scholar] [CrossRef]

- Yadav, A.; Singh, Y.; Negi, P. A review on the characterization of bio based lubricants from vegetable oils and role of nanoparticles as additives. Mater. Today Proc. 2021, 46, 10513–10517. [Google Scholar] [CrossRef]

- Liñeira del Río, J.M.; Fernandes, C.M.C.G.; Gonçalves, D.E.P.; Seabra, J.H.O. Tribological performance of green nanolubricants using functionalized CaCO3 nanoparticles. Tribol. Int. 2024, 199, 110007. [Google Scholar] [CrossRef]

- Zhou, Y.; Qu, J. Ionic Liquids as Lubricant Additives: A Review. ACS Appl. Mater. Interfaces 2017, 9, 3209–3222. [Google Scholar] [CrossRef]

- Mariño, F.; Liñeira del Río, J.M.; López, E.R.; Fernández, J. Chemically modified nanomaterials as lubricant additive: Time stability, friction, and wear. J. Mol. Liq. 2023, 382, 121913. [Google Scholar] [CrossRef]

- Smith, E.L.; Abbott, A.P.; Ryder, K.S. Deep Eutectic Solvents (DESs) and Their Applications. Chem. Rev. 2014, 114, 11060–11082. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; De Oliveira Vigier, K.; Royer, S.; Jérôme, F. Deep eutectic solvents: Syntheses, properties and applications. Chem. Soc. Rev. 2012, 41, 7108–7146. [Google Scholar] [CrossRef] [PubMed]

- Lawes, S.D.A.; Hainsworth, S.V.; Blake, P.; Ryder, K.S.; Abbott, A.P. Lubrication of Steel/Steel Contacts by Choline Chloride Ionic Liquids. Tribol. Lett. 2010, 37, 103–110. [Google Scholar] [CrossRef]

- Li, Y.; Li, H.; Fan, X.; Cai, M.; Xu, X.; Zhu, M. Green and Economical Bet-Based Natural Deep Eutectic Solvents: A Novel High-Performance Lubricant. ACS Sustain. Chem. Eng. 2022, 10, 7253–7264. [Google Scholar] [CrossRef]

- Li, Y.; Li, H.; Fan, X.; Xu, X.; Zhu, M. Oil-soluble deep eutectic solvent as high-performance green lubricant additives for PAO 40 and PEG 200. Tribol. Int. 2023, 186, 108602. [Google Scholar] [CrossRef]

- Khan, A.; Singh, R.; Gupta, P.; Gupta, K.; Khatri, O.P. Aminoguanidine-based deep eutectic solvents as environmentally-friendly and high-performance lubricant additives. J. Mol. Liq. 2021, 339, 116829. [Google Scholar] [CrossRef]

- Li, T.; Chen, Y.; Han, Z.; Wang, J.; Li, X.; Zhang, L.; Yu, Y. Deep Eutectic Solvent-Modified MXene as Nonpolar Lubricant Additives. ACS Appl. Nano Mater. 2025, 8, 4470–4483. [Google Scholar] [CrossRef]

- Nagendramma, P.; Khatri, P.K.; Goyal, S.; Jain, S.L. Novel polyol-based deep eutectic solvent: A potential candidate for bio-lubricant and additive for tribological performance. Biomass Convers. Biorefinery 2023, 13, 5701–5708. [Google Scholar] [CrossRef]

- Cañadas, R.; González-Miquel, M.; González, E.J.; Prado, A.N.d.; Díaz, I.; Rodríguez, M. Sustainable Recovery of High Added-Value Vanilla Compounds From Wastewater Using Green Solvents. ACS Sustain. Chem. Eng. 2021, 9, 4850–4862. [Google Scholar] [CrossRef]

- Vallejo, J.P.; Liñeira del Río, J.M.; Fernández, J.; Lugo, L. Tribological performance of silicon nitride and carbon black Ionanofluids based on 1-ethyl-3-methylimidazolium methanesulfonate. J. Mol. Liq. 2020, 319, 114335. [Google Scholar] [CrossRef]

- Li, Y.; Cao, C.; Cai, M.; Li, H.; Fan, X.; Gao, Y.; Lu, Z.; Zhu, M. Green hydrophobic deep eutectic solvents as low-viscosity and efficient lubricants. Tribol. Int. 2023, 185, 108531. [Google Scholar] [CrossRef]

- Mirghani, M.E.S.; Che Man, Y.B. Determination of hexane residues in vegetable oils with FTIR spectroscopy. J. Am. Oil Chem. Soc. 2003, 80, 619–623. [Google Scholar] [CrossRef]

- Boey, P.-L.; Saleh, M.I.; Sapawe, N.; Ganesan, S.; Maniam, G.P.; Ali, D.M.H. Pyrolysis of residual palm oil in spent bleaching clay by modified tubular furnace and analysis of the products by GC–MS. J. Anal. Appl. Pyrolysis 2011, 91, 199–204. [Google Scholar] [CrossRef]

- Vennapusa, J.R.; Singh, J.; Chattopadhyay, S. Curding of milk in incubator utilizing latent heat of lauric acid in winter. Energy Storage 2022, 4, e307. [Google Scholar] [CrossRef]

- Al-Akayleh, F.; Mohammed Ali, H.H.; Ghareeb, M.M.; Al-Remawi, M. Therapeutic deep eutectic system of capric acid and menthol: Characterization and pharmaceutical application. J. Drug Deliv. Sci. Technol. 2019, 53, 101159. [Google Scholar] [CrossRef]

- Ribeiro, B.D.; Florindo, C.; Iff, L.C.; Coelho, M.A.Z.; Marrucho, I.M. Menthol-based Eutectic Mixtures: Hydrophobic Low Viscosity Solvents. ACS Sustain. Chem. Eng. 2015, 3, 2469–2477. [Google Scholar] [CrossRef]

- Zarei, A.R.; Nedaei, M.; Ghorbanian, S.A. Ferrofluid of magnetic clay and menthol based deep eutectic solvent: Application in directly suspended droplet microextraction for enrichment of some emerging contaminant explosives in water and soil samples. J. Chromatogr. A 2018, 1553, 32–42. [Google Scholar] [CrossRef]

- Khan, A.; Yasa, S.R.; Gusain, R.; Khatri, O.P. Oil-miscible, halogen-free, and surface-active lauryl sulphate-derived ionic liquids for enhancement of tribological properties. J. Mol. Liq. 2020, 318, 114005. [Google Scholar] [CrossRef]

- Ayerdi, J.J.; Aginagalde, A.; Llavori, I.; Bonse, J.; Spaltmann, D.; Zabala, A. Ball-on-flat linear reciprocating tests: Critical assessment of wear volume determination methods and suggested improvements for ASTM D7755 standard. Wear 2021, 470–471, 203620. [Google Scholar] [CrossRef]

- Hallett, J.E.; Hayler, H.J.; Perkin, S. Nanolubrication in deep eutectic solvents. Phys. Chem. Chem. Phys. 2020, 22, 20253–20264. [Google Scholar] [CrossRef]

| Lubricant | COF | σ | WTW/μm | σ/μm | WTD/μm | σ/μm | Volume/103 μm3 | σ/103 μm3 |

|---|---|---|---|---|---|---|---|---|

| Castor Oil | 0.1497 | 0.0035 | 687.6 | 16 | 60.5 | 3.5 | 207,999 | 20 |

| +0.1 wt% DES1 | 0.1434 | 0.0018 | 633.2 | 12 | 58.6 | 2.3 | 182,559 | 14 |

| +0.5 wt% DES1 | 0.1495 | 0.0019 | 572.2 | 11 | 47.5 | 2.4 | 133,451 | 11 |

| +1 wt% DES1 | 0.1481 | 0.0033 | 621.1 | 13 | 59.2 | 2.8 | 183,110 | 15 |

| +5 wt% DES1 | 0.1485 | 0.0037 | 638.3 | 14 | 59.6 | 1.8 | 188,539 | 17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liñeira del Río, J.M.; Aourdou, A.; García-Marquínez, G.; Amado, J.M.; Tobar, M.J. Deep Eutectic Solvents as Green and Novel Lubricant Additives for Castor Oil with High Tribological Performance. Lubricants 2025, 13, 456. https://doi.org/10.3390/lubricants13100456

Liñeira del Río JM, Aourdou A, García-Marquínez G, Amado JM, Tobar MJ. Deep Eutectic Solvents as Green and Novel Lubricant Additives for Castor Oil with High Tribological Performance. Lubricants. 2025; 13(10):456. https://doi.org/10.3390/lubricants13100456

Chicago/Turabian StyleLiñeira del Río, José M., A. Aourdou, G. García-Marquínez, J. M. Amado, and M. J. Tobar. 2025. "Deep Eutectic Solvents as Green and Novel Lubricant Additives for Castor Oil with High Tribological Performance" Lubricants 13, no. 10: 456. https://doi.org/10.3390/lubricants13100456

APA StyleLiñeira del Río, J. M., Aourdou, A., García-Marquínez, G., Amado, J. M., & Tobar, M. J. (2025). Deep Eutectic Solvents as Green and Novel Lubricant Additives for Castor Oil with High Tribological Performance. Lubricants, 13(10), 456. https://doi.org/10.3390/lubricants13100456