Abstract

Activated carbons are commonly used for adsorption/depollution applications, but only a few studies are related to their lubricating properties. In order to investigate a new family of friction reducers, the tribological properties of biochars and derived activated carbons obtained from sugar cane bagasse are investigated. Activated carbons are obtained from either a physical (steam water) or chemical (with phosphoric acid) activation process. The tribological tests show that the activated carbons present very low friction coefficients, close to 0.08. The correlation of textural and tribological investigations shows that the specific surface area of the compounds as well as the microporous and mesoporous domain extensions are key parameters to optimize the friction reduction properties of activated carbons. The friction properties of the compounds are improved if the mesoporous domain extension is above 40% of the total porous volume. This study shows that local biomass waste valorization is possible and that sugar cane bagasse-derived activated carbons appear as interesting new friction reduction additives for lubricants.

1. Introduction

Friction and wear are two of the major modes of energy dissipation and material losses in moving mechanical systems. It is estimated that approximately one third of the fuel used in automobiles is spent to overcome friction, while wear limits mechanical component life. Lubrication is one of the most effective ways to reduce energy waste and to improve mechanical durability. Most of the conventional lubricants are in liquid and/or solid forms, even if gases may be used. Liquid lubricants are composed of synthetic or mineral oil (base oil) and additives used to confer to the lubricant specific characteristics, such as friction and wear reduction, viscosity improvement, anti-oxidizing effect and anti-corrosive properties [1,2]. Lubricants reduce friction by preventing sliding contact interfaces from surface-to-surface contacts. Depending on the lubrication regimes associated to sliding speed and operating conditions, base oils can effectively separate the sliding surfaces and, thereby, reduce friction and wear. This process is not possible in the boundary lubrication regime, where the oil film thickness is not sufficient to prevent surface-to-surface contacts. In this case, the lubricant additives form a low-shear and protective boundary film, also called tribofilm, resulting in friction and wear reduction.

Among the wide range of candidates for lubricant additives, carbon materials have been intensively studied because of their good mechanical, thermal and intrinsic friction properties. Diamond, diamond-like carbons (DLC) and graphite are well-known for tribological applications, but more and more attention has been paid to the use of carbon nanoparticles in order to improve the energy efficiency of the tribological systems [3]. Carbon blacks [4], carbon onions [5], fullerenes [6], carbon nanotubes [7] and carbon nanofibers [8,9] present interesting tribological properties. We showed in previous works that friction reduction mechanisms depend on the morphology of the nanocarbons involving size or bulk effects and that the functionalization of the nanoparticles strongly affects their tribological performances [10].

For several years, biomass has received strong attention to synthetize biochars and derived activated carbons, but the research has been mainly focused on adsorption/depollution applications [11,12,13,14,15] or energy storage systems [16,17,18,19,20,21,22] because of their high specific surface areas, adjustable porous structures and the presence of heteroatoms that facilitate ion transfer and diffusion. Only few data can be found in the literature concerning porous carbons for tribological applications. Baik et al. investigated the tribological performances of ordered mesoporous carbons as lubricant additives in mineral oil [23]. It was found that there was little difference in the frictional forces and wear amounts of the oils with and without additives. However, the scuffing time of the lubricant was improved, showing the beneficial role of ordered mesoporous carbons to protect the sliding surfaces. In the case of biomass-derived activated carbons, such compounds were mainly studied as reinforcements in polymer composites [24,25]. It was observed that reinforcement of activated nanocarbons in epoxy composites enhanced the wear resistance. Both the friction coefficient and wear rate of the composite increased with operating temperatures [26]. Few studies reported on the friction properties of activated carbons as solid additives in oils. The tribological study of nonedible nanofluid added with activated carbon nanoparticles showed improved friction and wear performances of the nanofluid [27]. The beneficial effect of the addition of activated carbons on the tribological properties of palm and mineral oils was also evidenced [28,29]. Recently, the addition of activated carbon nanoparticles in bio greases was studied, showing improved tribological properties [30,31].

In this work, the friction properties of biochars and derived activated carbons obtained from sugar cane bagasse have been investigated. The aim of this study is to contribute to local biomass waste valorization by developing new friction reducing additives for lubricants. The friction mechanisms of porous carbons have not yet been explained. The influence of the pyrolysis temperature on the friction properties of bagasse-derived biochars is investigated in order to select the optimal synthesis conditions. Biochars are then activated either by a chemical or physical method. The friction reduction properties as well as the anti-wear performances of the bagasse-derived activated carbons are evaluated in correlation with structural and textural characterization. The objective of this work is to point out key parameters leading to improved lubricating properties of porous carbons.

2. Materials and Methods

2.1. Materials

Sugar cane bagasse was collected in Moule (Guadeloupe, French West Indies) and then dried at 105 °C for 48 h using a drying oven, ground and sieved. A fraction of the raw material with a particle size ranging between 0,4 and 1 mm was used for biochars and activated carbon synthesis.

Biochars were obtained by pyrolyzing dried bagasse in a tubular furnace (Thermolyne, Thermo Fischer Scientific, Waltham, MA, USA)) under nitrogen flow at temperatures of 600, 800 and 900 °C for 1h. The obtained biochars were named BagPyr600, BagPyr800 and BagPyr900.

Activated carbons were obtained from chemical and physical activation methods. In the case of chemical activation, the raw material was impregnated in phosphoric acid (H3PO4 85%, Sigma Aldrich, St. Louis, MO, USA) for 24 h and then dried at 110 °C during 4 h. Impregnation ratios (g H3PO4/g precursor) were equal to 1 and 1.5. After impregnation, the samples were pyrolyzed under a nitrogen flow at 600 °C for 1h. In relation to the initial impregnation ratios, the resulting activated carbons were washed with deionized water until pH stabilization and dried at 110 °C. The samples were named BagP1 and BagP1.5. H3PO4 impregnation ratios were chosen based on previous studies [11], leading to activated carbons presenting high surface areas and high mesoporous volumes in comparison to biochar and physically activated materials. As such, the influence of textural properties on the friction properties of the samples could be herein evaluated. In the case of physical activation, BagPyr800 biochar was activated with steam under a nitrogen atmosphere at 800 °C for 8 h as previously described [11]. The resulting activated carbon was named BagH2O.

2.2. Tribological Tests

A homemade reciprocating ball-on-plane tribometer was used to determine the tribological behavior of the tested materials. The experiments were carried out at room temperature (25 °C) under air atmosphere (relative humidity: 50 ± 5%).

The balls (AISI 52100, with a diameter of 1 cm, Vickers hardness 850) did not undergo treatment, whereas the planes (AISI 52100, 1 cm diameter, 1 cm height, initial average roughness of 10 nm, Vickers hardness 850) were roughened with abrasive paper to generate multidirectional scratches, leading to better adherence of the compounds. The final average roughness was 100 nm. After ultrasonically cleaning both balls and planes in acetone and ethanol baths (for pollutants and remaining abrasive particle removal), the tested materials were deposited on the plane surface. After ball-on-plane contact, a normal load FN = 10 N was applied. The alternative motion of the ball was performed with a sliding speed of 3 mm·s−1 and a frequency of 1 Hz. Those conditions were chosen in order to perform the tribological tests in boundary lubrication. A computer-based data acquisition system allowed for us to measure the tangential force FT and to calculate the friction coefficient μ = FT/FN. A total of 10 friction tests were repeated for each tested compound. According to Hertz’s theory, our experimental conditions lead to a maximum contact pressure of 1 GPa and a contact diameter of 140 μm. Thus, the measurement of the width of the wear scars (on the planes) or of the contact diameters (on the balls) after the tribological tests allowed for us to estimate the anti-wear properties of the compounds by comparison with the theoretical characteristics of the contact.

2.3. Physico-Chemical Investigations

Raman spectroscopy investigations were carried out with an HR 800 Horiba multi-channel spectrometer (Horiba Scientific, Montpellier, France) equipped with a Peltier-cooled CCD detector. A green laser exciting light (532 nm) was used to record Raman spectra on the initial compounds and on the tribofilms at the end of the friction tests. The Raman spectrometer ran with a notch filter pre-monochromator and a 300 lines/mm holographic grating monochromator. Our experimental conditions lead to a probe diameter of 5 µm and a wavenumber resolution of 1.5 cm−1. In order to prevent the carbon materials from irradiation damages, the laser power was 30 mW with an acquisition time in the 10 to 60 s range.

Scanning electron microscopy investigations were performed with an FEI Quanta 250 FEG microscope (FEI, Eindhoven, The Netherlands)using secondary electron and backscattered electron detectors. EDXS analyses were performed with an EDX Silicon Drift Detector.

The textural characterization of the samples was carried out by N2 adsorption at 77 K using a Micromeritics ASAP-2020 analyzer (Micromeritics France, Merignac, France). The Brunauer–Emmett–Teller (BET) equation was used to determine the specific surface area. The t-plot method was used for the calculation of total pore volume (VT) and micropore volume (Vmi). The Barrett–Joyner–Halenda (BJH) method was used for estimating the mesopore volume (Vme) [13].

3. Results and Discussion

3.1. Influence of the Pyrolysis Temperature on the Friction Properties of Biochars Derived from Sugar Cane Bagasse

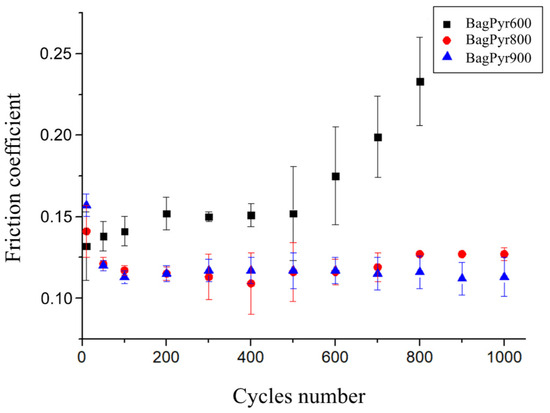

Biochars were prepared by pyrolysis of local sugar cane bagasse at 600 °C (BagPyr600), 800 °C (BagPyr800) and 900 °C (BagPyr900). Figure 1 shows the corresponding evolutions of the friction coefficient as a function of cycles number. The tribological properties of the biochars are improved by increasing the pyrolysis temperature from 600 °C to 800 °C and 900 °C, as the stabilized friction coefficients (200 cycles) are μ = 0.15 ± 0.01 for BagPyr600 and μ = 0.115 ± 0.004 for both BagPyr800 and BagPyr900.

Figure 1.

Evolution of the friction coefficient as a function of cycles number for biochars obtained from sugar cane bagasse at pyrolysis temperatures of 600 °C (BagPyr600), 800 °C (BagPyr800) and 900 °C (BagPyr900).

Figure 1 also shows a decrease in the friction coefficient during the first 100 cycles, corresponding to the so-called induction period, i.e., the tribofilm formation period. The friction coefficient drastically increases after 400 cycles for BagPyr600, whereas the tribological performances are more stable for BagPyr800 and BagPyr900. This behavior is attributed to a deterioration of the tribofilm in the case of BagPyr600. The increase in the pyrolysis temperature leads to a better stability of the tribofilm.

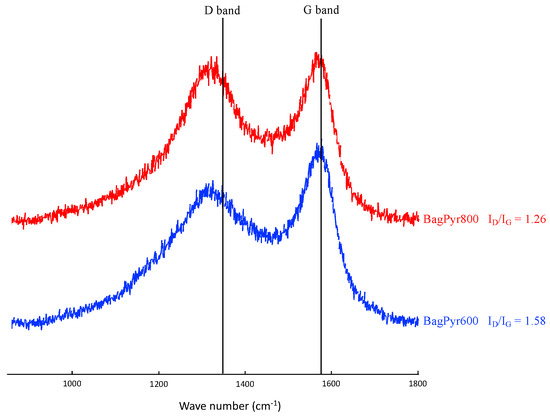

In order to explain the beneficial effect of the increase in the pyrolysis temperature on the friction performances of the biochars, the structures of the compounds have to be considered. Figure 2 shows the Raman spectra recorded on the initial BagPyr600 and BagPyr800 particles. The spectra exhibit the characteristic D and G bands associated with the presence of graphitic domains. The G band (1580 cm−1) is attributed to the E2g vibration mode of the graphitic lattice, while the D band (1350 cm−1) is associated with disorder [32,33]. The determination of the relative intensities of the D and G bands (ID/IG ratio) allows for us to point out the structural evolution of the biochar with the increase in the pyrolysis temperature. The ID/IG ratios of the BagPyr600 and BagPyr800 samples are, respectively, equal to 1.58 ± 0.01 and 1.26 ± 0.01. As expected and already observed for carbon materials, the increase in the pyrolysis temperature leads to a decrease in structural disorder and, in consequence, to an improvement of the friction properties.

Figure 2.

Raman spectra recorded on initial BagPyr600 and BagPyr800 particles and corresponding IDIG ratios.

The D/G intensities ratio can be related to the La coherence length, i.e., the graphitic domains extension perpendicularly to the c-axis by the relation of Tuinstra and Koenig [34]:

where is the laser line wavelength ( = 532 nm in our experimental conditions).

The graphitic domains are estimated to be close to 12 nm for BagPyr600 and 15 nm for BagPyr800.

According to these results, BagPyr800 biochar has been selected for the synthesis of activated carbons using the physical activation method.

3.2. Structural and Textural Characterization of Activated Carbons Prepared from Sugar Cane Bagasse

The morphology of the BagPyr800 biochar particles is presented in Figure 3. SEM investigations show that the particles size ranges from 0.4 to 1 mm, and we can observe the presence of closed or partially closed pores of approximately 25 microns in length all along the particles.

Figure 3.

SEM micrographs recorded on BagPyr800 biochar.

Figure 4 shows SEM micrographs recorded on both physically and chemically activated carbons. After physical activation, the presence of channels presenting diameters in the 15–20 μm range is evidenced (Figure 4b), and by zooming on the BagH2O particles, macropores are observed with diameters close to 1 μm (Figure 4c). When sugarcane bagasse is activated by the chemical way (BagP1 and BagP1.5 samples), the presence of channels and macropores is also detected (see micrographs of Figure 4d–f). However, if we compare the BagP1 and BagP1.5 particles, we can observe that the increase in the impregnating ratio, that is the increase in phosphoric acid amount, leads to a smoothing of the particle’s surface (Figure 4g,h).

Figure 4.

SEM micrographs recorded on (a–c) BagH2O activated carbon (physical activation); (d,e) BagP1 activated carbon (chemical activation); and (f–h) BagP1.5 activated carbon (chemical activation).

In parallel to morphology characterization, EDX analyses were performed. Figure 5 presents the X-ray spectrum recorded on the BagPyr800 particle and associated carbon, silicon and oxygen element mappings. As in the case of the initial sugarcane bagasse, the presence of silicon is detected. It is interesting to note that the silica particles are localized near the closed or partially closed pores (Figure 5d,e). Similar analyses were performed on physically activated BagH2O carbon and chemically activated BagP1 and BagP1.5 materials. The corresponding atomic concentrations in carbon, silicon, oxygen and phosphorus are reported in Table 1. Physical or chemical activation leads to partial silica elimination. The atomic phosphorus concentration is higher for the BagP1 and BagP1.5 compounds due to the activation method. Phosphorus element mapping shows that it is homogeneously distributed on the particle’s surface (see Figure 6 in the case of BagP1.5 activated carbon).

Figure 5.

EDX analyses showing (a) SEM micrograph recorded on analyzed BagH2O particle; (b) associated EDX spectrum; corresponding (c) carbon element mapping; (d) silicon element mapping; and (e) oxygen element mapping.

Table 1.

Atomic concentrations in carbon, oxygen, silicon and phosphorus deduced from EDX analyses for BagPyr800 biochar, BagH2O activated carbon (physical activation) and BagP1 and BagP1.5 activated carbons (chemical activation).

Figure 6.

EDX analyses showing (a) SEM micrograph recorded on analyzed BagP1.5 particle; (b) corresponding carbon element mapping and (c) corresponding phosphorus element mapping.

The textural properties of the compounds were determined via N2 adsorption–desorption analysis. The associated isotherms presented in Figure 7 show a type IV shape with a hysteresis loop for BagP1 and BagP1.5 activated carbons (chemical activation), characteristic of mesoporous materials. In the case of BagH2O activated carbon (physical activation), a type I shape isotherm is observed, corresponding to microporous material. The BET surface area, microporous volume (Vmi), mesoporous volume (Vme) and total porous volume (Vtot) were then calculated. The extensions of the microporous (Vmi/Vtot) and mesoporous domains (Vme/Vtot) were also estimated. The results are reported in Table 2.

Figure 7.

Isotherms obtained from N2 adsorption–desorption analysis for BagH2O (physical activation), BagP1 and BagP1.5 (chemical activation) activated carbons.

Table 2.

BET surface area (SBET), microporous volume (Vmi), mesoporous volume (Vme), total porous volume (Vtot) and microporous (Vmi/Vtot) and mesoporous extensions (Vme/Vtot) determined for BagPyr800 biochar and BagH2O (physical activation), BagP1 and BagP1.5 activated carbons (chemical activation).

BagP1.5 exhibits the higher surface area and contains a majority of mesopores, while BagPyr800 presents the lowest surface area and a majority of micropores. An interesting surface area value higher than 1000 m2/g is obtained for BagH2O and BagP1, which present both micropores and mesopores.

In order to evaluate the influence of activation on the structure of the carbon materials, Raman spectroscopy experiments were performed on bagasse-derived activated carbons. Figure 8 presents the Raman spectra recorded for the BagH2O, BagP1 and BagP1.5 samples. As in the case of the biochar, the Raman spectra of the activated carbons exhibit the D and G bands. Figure 8 shows an increase in the ID/IG ratio for the activated carbons compared to the biochar one: ID/IG = 1,28 ± 0.01 for BagPyr800, whereas the ID/IG ratios of BagH2O, BagP1 and BagP1.5 are 1.66, 1.81 and 1.96 ± 0.01, respectively. This increase in disorder is not surprising and probably attributed to the development of the porous domains.

Figure 8.

Raman spectra recorded for BagH2O, BagP1 and BagP1.5 activated carbons and associated ID/IG ratios.

Figure 9 shows the correlation between the microporous and mesoporous extensions and the Raman results. It is interesting to note that the structural disorder (estimated as the ID/IG ratio) increases as far as the microporous domain extension (Vmi/Vtot) decreases. The opposite behavior is observed with the extension of the mesoporous domain: ID/IG increases with Vme/Vtot. Such results suggest that the microporous and mesoporous domains extensions should be key parameters determining the tribological properties of activated carbons.

Figure 9.

Evolution of ID/IG ratios with (a) the microporous domain extension (Vmi/Vtot) and (b) the mesoporous domain extension (Vme/Vtot) for BagPyr800 biochar and BagH2O, BagP1 and BagP1.5 activated carbons.

3.3. Tribological Properties of Activated Carbons

3.3.1. Friction Properties

The evolution of the friction coefficient of BagPyr800 biochar and BagH2O, BagP1 and BagP1.5 activated carbons is presented in Figure 10 as a function of cycles number. Activation strongly improves the friction reduction performances of the carbon materials, as very low friction coefficients (close to 0.08) are obtained for activated carbons (compared to μ = 0.115 for the biochar). Figure 10 does not evidence a significant influence of the activation method on the friction properties of the materials: μ = 0.085 ± 0.002 at 400 cycles (corresponding to the stabilization of μ after the induction period) for both the BagH2O (physical activation) and BagP1.5 (chemical activation) compounds. In the case of chemical activation, similar friction coefficients are obtained at 400 cycles for the BagP1 and BagP1.5 materials (μ = 0.085 ± 0.002 for BagP1.5 and μ = 0.09 ± 0.005 for BagP1), indicating that the impregnation ratio (g H3PO4/g precursor) does not play a key role on the friction properties.

Figure 10.

Evolution of the friction coefficient as a function of cycles number for BagPyr800 biochar and BagH2O, BagP1 and BagP1.5 activated carbons.

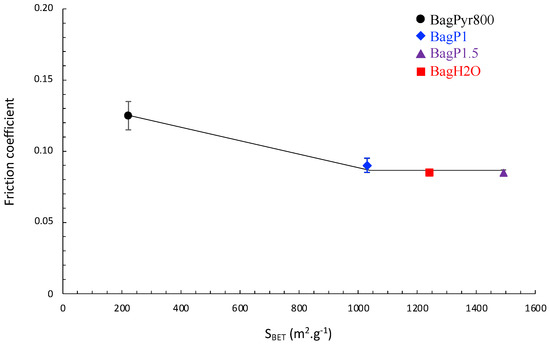

In order to evidence key parameters for the optimization of the tribological properties, the friction results were correlated to textural parameters. Figure 11 and Figure 12 show the evolution of the stabilized friction coefficient (recorded at 400 cycles) of BagPyr800 biochar and BagH2O, BagP1 and BagP1.5 activated carbons as a function of the specific surface area (SBET) and the microporous and mesoporous domains extensions, expressed respectively as Vmi/Vtot and Vme/Vtot. Figure 11 clearly shows that the increase in the specific surface area leads to a decrease in the friction coefficient to raise an asymptotic value for SBET higher than 1000 m2·g−1. The microporous and mesoporous domains extensions appear as parameters that affect the friction properties of activated carbons. The development of the microporous domain above 60% of the total porous volume leads to a deterioration of the tribological performances (Figure 12a). On the other hand, the friction reduction performances of activated carbons are improved when the mesoporous domain extension is superior to 40% of the total porous volume (Figure 12b). Our results show that bagasse-derived activated carbons can be used as new friction reduction additives for lubricants and that it is possible to tune the friction properties of porous carbons by selecting the synthesis conditions.

Figure 11.

Evolution of the friction coefficient (recorded at 400 cycles) as a function specific surface area (SBET) for BagPyr800 biochar and BagH2O, BagP1 and BagP1.5 activated carbons.

Figure 12.

Evolution of the friction coefficient (recorded at 400 cycles) of BagPyr800 biochar and BagH2O, BagP1 and BagP1.5 activated carbons as a function of (a) the microporous domain extension Vmi/Vtot and (b) the mesoporous domain extension Vme/Vtot.

3.3.2. Estimation of the Anti-Wear Properties of Activated Carbons

The anti-wear properties of the compounds were estimated from SEM investigations of the associated tribofilms by measuring the width of the wear scar observed on the plane in comparison with the theoretical value of 140 μm determined from Hertz theory. Figure 13a shows the wear scars observed in the case of BagH2O and BagP1.5 activated carbons after 1000 cycles of friction. The width of the track corresponds to the width of the high-pressure zone without taking into account the Hertz penombra (associated to the low-pressure zone). The measured widths obtained for BagPyr800 biochar and BagH2O, BagP1 and BagP1.5 activated carbons are reported in Figure 13b in comparison with steel–steel contact, that is without lubricant, leading to a width superior to 500 μm. The width of the wear track corresponding to pyrolyzed bagasse is close to 250 μm. Figure 13b clearly shows that activation improves the anti-wear properties of the carbon materials, as we obtain widths close to 170 μm for activated carbons, pointing out a rather slight wear of the planes during the friction tests associated with interesting anti-wear properties of sugar cane-derived activated carbons. This is confirmed in Figure 13a, as the SEM characterizations reveal the presence of the initial scratches of the planes, which are still visible under the tribofilms after 1000 cycles of friction. This improvement of the anti-wear properties is probably due to the presence of pores in the structure of the compounds. AFM investigations will be performed in order to determine the structure and the compactness of the tribofilms.

Figure 13.

(a) Wear scars observed in the case of BagH2O and BagP1.5 activated carbons after 1000 cycles of friction; (b) Widths of the wear scars measured on the tribofilms associated to BagPyr biochar and BagH2O, BagP1 and BagP1.5 activated carbons in comparison with steel–steel contact.

From the SEM characterization of the wear scars, it is also possible to estimate the thickness of the tribofilms by scratching the track with a razor blade. Figure 14 present the case of the BagP1 compound. By zooming in on the scratched area, a tribofilm thickness close to 0.2 μm was measured. A similar thickness value was obtained for the BagPyr, BagH2O and BagP1.5 tribofilms. We can also note the very smooth aspect of the tribofilms compared to the initial shape of the particles. Figure 13 and Figure 14 show that there is no correlation between the width of the wear scars and the thickness of the tribofilms.

Figure 14.

Estimation of the thickness of the tribofilm corresponding to BagP1 activated carbon by scratching the wear scar with a razor blade.

In order to study the influence of the friction process on the structure of the compounds, Raman analyses of the tribofilms were performed after 1000 cycles of friction. The ID/IG ratios were determined and compared to those of the initial particles (before friction). The results are reported in Table 3. An increase in the ID/IG ratio is evidenced after friction for all the tested materials. As already observed for other carbon materials [12], the friction process leads to an increase in structural disorder for activated carbons. This phenomenon is generally attributed to a reduction in the size of the graphitic domains induced by the friction process. This is confirmed by the calculation of the La coherence length using the Tuinstra and Koenig relation [34]. The graphitic domains extensions are reported in Table 3 before and after the friction tests.

Table 3.

ID/IG ratios and La coherence lengths determined from Raman spectra for initial BagPyr800 biochar and BagH2O, BagP1 and BagP1.5 activated carbons and for corresponding tribofilms after 1000 friction cycles.

4. Conclusions

The study of the tribological properties of biochars and derived activated carbons obtained from sugar cane bagasse shows promising performances.

In the case of the biochar, the increase in the pyrolysis temperature above 800 °C leads to an improvement of the friction properties due to the increase in the structural order of the carbon material.

The tribological performances of the biochars are improved by physical or chemical activation, as very low friction coefficients, close to 0.08, are obtained. Our results show that activated carbons appear as interesting friction reducers compared to conventional graphitic carbons.

The correlation of structural and tribological characterizations allows for us to point out key parameters to optimize the friction properties of porous carbons. The best results are obtained for compounds presenting specific surface areas higher than 1000 m2·g−1. The microporous and mesoporous domains extensions also appear as parameters that affect the friction properties of activated carbons. The lowest friction coefficients are observed for materials presenting a highly developed mesoporous domain, whereas the development of the microporous domain leads to a deterioration of the tribological performances. This could be explained by the fact that mesoporous materials that are prepared by phosphoric acid activation may contain more water inside the mesopores due to the presence of acidic groups at their surface. These water molecules could play a role on the wettability of the tribofilm, which may decrease the friction coefficient.

Accordingly, activation of the biochar, leading to higher porosity, also improves the anti-wear properties of the compounds. The width of the wear scars points out a rather slight wear of the planes during the friction tests. The tribofilm thickness is close to 0.2 μm for the biochar and derived activated carbons, independently of the activation process. There is no correlation between the width of the wear scars and the thickness of the tribofilms. AFM investigations will be performed in order to study the structure and the compactness of the tribofilms.

Our results show that it is possible to tune the friction properties of porous carbons by selecting the synthesis conditions. However, further work is necessary to evaluate the best compromise between the porous volume extension and the graphitic domains extension. In the field of local biomass waste valorization, sugar cane bagasse-derived activated carbons appear as interesting new friction reduction additives for lubricants.

5. Patents

This section is not mandatory but may be added if there are patents resulting from the work reported in this manuscript.

Author Contributions

Conceptualization, P.T.; methodology, P.T., A.M., T.C., P.B., N.N.-M., C.Y. and S.G.; software, P.B.; validation, P.T.; formal analysis, P.T., C.Y. and S.G.; investigation, P.T.; writing—original draft preparation, P.T. and S.G.; writing—review and editing, P.T.; supervision, P.T.; project administration, P.T.; funding acquisition, P.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the EUROPEAN REGIONAL DEVELOPMENT FUND, grant number GP0009623.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Booser, E.R. Tribology Data Handbook; CRC Press: New York, NY, USA, 1997. [Google Scholar]

- Georges, J.M. Frottement, Usure et Lubrification: La Tribologie ou Science des Surfaces; CNRS Editions: Paris, France, 2000. [Google Scholar]

- Zhai, W.; Srikanth, N.; Kong, L.B.; Zhou, K. Carbon nanomaterials in tribology. Carbon 2017, 119, 150–171. [Google Scholar] [CrossRef]

- Pan, Y.; Wang, Z.; Han, S.; Bian, H. Effect of Adding Pyrolysis Carbon Black (CBp) on Soft Friction and Metal Wear during Mixing. Polymers 2022, 14, 1319. [Google Scholar] [CrossRef] [PubMed]

- Joly-Pottuz, L.; Ohmae, N. Carbon-based Nanolubricants. In Nanolubricants; Martin, J.M., Ohmae, N., Eds.; John Wiley & Sons: Chichester, UK, 2008; Chapter 3; pp. 93–147. [Google Scholar]

- Lee, J.; Cho, S.; Hwang, Y.; Lee, C.; Kim, S.H. Enhancement of lubrication properties of nano-oil by controlling the amount of fullerene nanoparticle additives. Tribol. Lett. 2007, 28, 203–208. [Google Scholar] [CrossRef]

- Baik, S.; Lee, G.S.; Yoon, D.K.; Lee, Y.Z. Tribological Performance of Multi-Walled Carbon Nanotubes in Mineral Oils under Boundary Lubricated Sliding. Key Eng. Mater. 2006, 321, 694–698. [Google Scholar]

- Chen, W.X.; Tu, J.P.; Wang, L.Y.; Gan, H.Y.; Xu, Z.D.; Zhang, X.B. Tribological Application of Carbon Nanotubes in a Metal-Based Composite Coating and Composites. Carbon 2003, 41, 215–222. [Google Scholar] [CrossRef]

- Hwang, Y.; Lee, C.; Choi, Y.; Cheong, S.; Kim, D.; Lee, K.; Lee, J.; Kim, S.H. Effect of the size and morphology of particles dispersed in nano-oil friction performance between rotating discs. J. Mech. Sci. Technol. 2011, 25, 2853–2857. [Google Scholar] [CrossRef]

- Thomas, P.; Bilas, P.; Molza, A.; Legras, L.; Mansot, J.L.; Guerin, K.; Dubois, M. Fluorinated nanocarbons for lubrication. In New Fluorinated Carbons: Fundamentals and Applications; Progress in Fluorine Science Series; Botalina, O., Nakajima, T., Tressaud, A., Eds.; Elsevier Inc.: Amsterdam, The Netherlands, 2016; pp. 325–360. [Google Scholar]

- Gaspard, S.; Passé-Coutrin, N.; Durimel, A.; Cesaire, T.; Jeanne-Rose, V.R. Activated carbon from biomass for water treatment. RSC Green Chem. 2014, 46–105. [Google Scholar] [CrossRef]

- Yacou, C.; Altenor, S.; Carene, B.; Gaspard, S. Chemical structure investigation of tropical Turbinaria turbinata seaweeds and its derived carbon sorbents applied to the removal of hexavalent chromium in water. Algal Res. 2018, 34, 25–36. [Google Scholar] [CrossRef]

- Ranguin, R.; Delannoy, M.; Yacou, C.; Jean-Marius, C.; Feidt, C.; Rychen, G.; Gaspard, S. Biochar and activated carbons preparation from invasive algae Sargassum spp. for Chlordecone availability reduction in contaminated soils. J. Environ. Chem. Eng. 2021, 9, 105280. [Google Scholar] [CrossRef]

- Abuelnoor, N.; AlHajaj, A.; Khaleel, M.; Vega, L.F.; Abuzahra, M.R.M. Activated carbons from biomass-based sources for CO2 capture applications. Chemosphere 2021, 282, 131111. [Google Scholar] [CrossRef]

- Khuong, D.A.; Nguyen, H.N.; Tsubota, T. Activated carbon produced from bamboo and solid residue by CO2 activation utilized as CO2 adsorbents. Biomass Bioenergy 2021, 148, 106039. [Google Scholar] [CrossRef]

- Suarez-Guevara, J.; Ruiz, V.; Gomez-Romero, P. Hybrid energy storage: High voltage aqueous supercapacitors based on activated carbon-phosphotungstate hybrid materials. J. Mater. Chem. A 2014, 2, 1014–1021. [Google Scholar] [CrossRef]

- Sevilla, M.; Mokaya, R. Energy storage applications of activated carbons: Supercapacitors and hydrogen storage. Energy Environ. Sci. 2014, 7, 1250–1280. [Google Scholar] [CrossRef]

- Tan, X.F.; Liu, S.B.; Liu, Y.G.; Gu, Y.L.; Zeng, G.M.; Hu, X.J.; Wang, X.; Liu, S.H.; Jiang, L.H. Biochar as potential sustainable precursors for activated carbon production: Multiple applications in environmental protection and energy storage. Bioresour. Technol. 2017, 227, 359–372. [Google Scholar] [CrossRef]

- Ayinla, R.T.; Dennis, J.O.; Zaid, H.M.; Sanusi, Y.K.; Usman, F.; Adebayo, L.L. A review of technical advances of recent palm bio-waste conversion to activated carbon for energy storage. J. Clean. Prod. 2019, 229, 1427–1442. [Google Scholar] [CrossRef]

- Baig, M.M.; Gul, I.H. Conversion of wheat husk to high surface area activated carbon for energy storage in high performance supercapacitors. Biomass Bioenergy 2021, 144, 105909. [Google Scholar] [CrossRef]

- Chen, Y.; Guo, X.; Liu, A.; Zhu, H.; Ma, T. Recent progress in biomass-derived carbon materials used for secondary batteries. Sustain. Energy Fuels 2021, 5, 3017–3038. [Google Scholar] [CrossRef]

- Jayachandran, M.; Kishore Babu, S.; Maiyalagan, T.; Rajadurai, N.; Vijayakumar, T. Activated carbon derived from bamboo-leaf with effect of various aqueous electrolytes as electrode material for supercapacitor applications. Mater. Lett. 2021, 301, 130335. [Google Scholar] [CrossRef]

- Baik, S.; Kim, J.M.; Lee, K.S.; Yoon, D.K. Tribological Performance of Ordered Mesoporous Carbons in Mineral Oils Under Boundary Lubricated Sliding. Key Eng. Mater. 2006, 326, 353–356. [Google Scholar]

- Om Prakash, M.; Raghavendra, G.; Ojha, S.; Panchal, M.; Kumae, D. Investigation of tribological properties of biomass developed porous nano activated carbon composites. Wear 2021, 466–467, 203523. [Google Scholar] [CrossRef]

- Om Prakash, M.; Gujjala, R.; Ojha, S.; Panchal, M. Mechanical characterization of arhar biomass based porous nano activated carbon polymer composites. Polym. Compos. 2020, 1–11. [Google Scholar] [CrossRef]

- Noor Ayuma, M.T.; Mohd Fadzli, B.A.; Radifah, H.; Hilmi, A. The effect of temperature on the tribological properties of palm kernel activated carbon-epoxy composite. Tribol. Online 2015, 10, 428–433. [Google Scholar]

- Talib, N.; Jamaluddin, N.A.; Sheng, T.K.; Kiow, L.W.; Abdullah, H.; Ahmad, S.; Saleh, A. Tribological study of activated carbon nanoparticle in nonedible nanofluid for machining application. Evergr. Jt. J. Nov. Carbon Resour. Sci. Green Asia Strategy 2021, 8, 454–460. [Google Scholar] [CrossRef]

- Jumali, S.N.Q.A.; Embong, Z.; Rahim, E.A.; Mohid, Z.; Samion, S. Surface Morphology and Tribological Studies of Activated Carbon Additive Blended in RBD Palm Olein as Sustainable Machining Lubricant. In Recent Trends in Manufacturing and Materials towards Industry 4.0; Springer: Berlin/Heidelberg, Germany, 2021; pp. 257–266. [Google Scholar] [CrossRef]

- Baik, S.; Yoon, D.; Lee, H.I.; Kim, J.M.; Lee, G.S.; Lee, Y.Z. Frictional Performances of Activated Carbon and Carbon Blacks as Lubricant Additives. Tribol. Trans. 2008, 52, 133–137. [Google Scholar] [CrossRef]

- Nassef, M.G.A.; Hassan, H.S.; Nassef, G.A.; Nassef, B.G.; Soliman, M.; Elkady, M.F. Activated Carbon Nanoparticles from Recycled Polymers Waste as Novel Nano-Additive to Grease Lubrication. Lubricants 2022, 10, 214. [Google Scholar] [CrossRef]

- Abouelkasem, Z.A.; Nassef, G.A.; Abdelnaeem, M.; Nassef, M.G.A. Enhancing the Elastohydrodynamic Lubrication and Vibration Behavior of Rolling Bearings Using a Hybrid Bio-Grease Blended with Activated Carbon Nanoparticles. Tribol. Lett. 2024, 72, 46. [Google Scholar] [CrossRef]

- Dresselhaus, M.S.; Pimenta, M.A.; Ecklund, P.C.; Dresselhaus, G. Raman Scattering in Fullerenes and Related Carbon-Based Materials; Weber, W.H., Merlin, R., Eds.; Springer: New York, NY, USA, 2000; pp. 315–364. [Google Scholar]

- Merlin, R.; Pinczuk, A.; Weber, W.H. Overview of Phonon Raman Scattering in Solids; Weber, W.H., Merlin, R., Eds.; Springer: New York, NY, USA, 2000; pp. 1–29. [Google Scholar]

- Tuinstra, F.; Koenig, J.L. Raman spectrum of graphite. J. Chem. Phys. 1970, 53, 1126–1130. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).