Finite Element Analysis of Damage Evolution of Solid Lubrication Film in Rolling–Sliding Contact

Abstract

1. Introduction

2. Materials and Methods

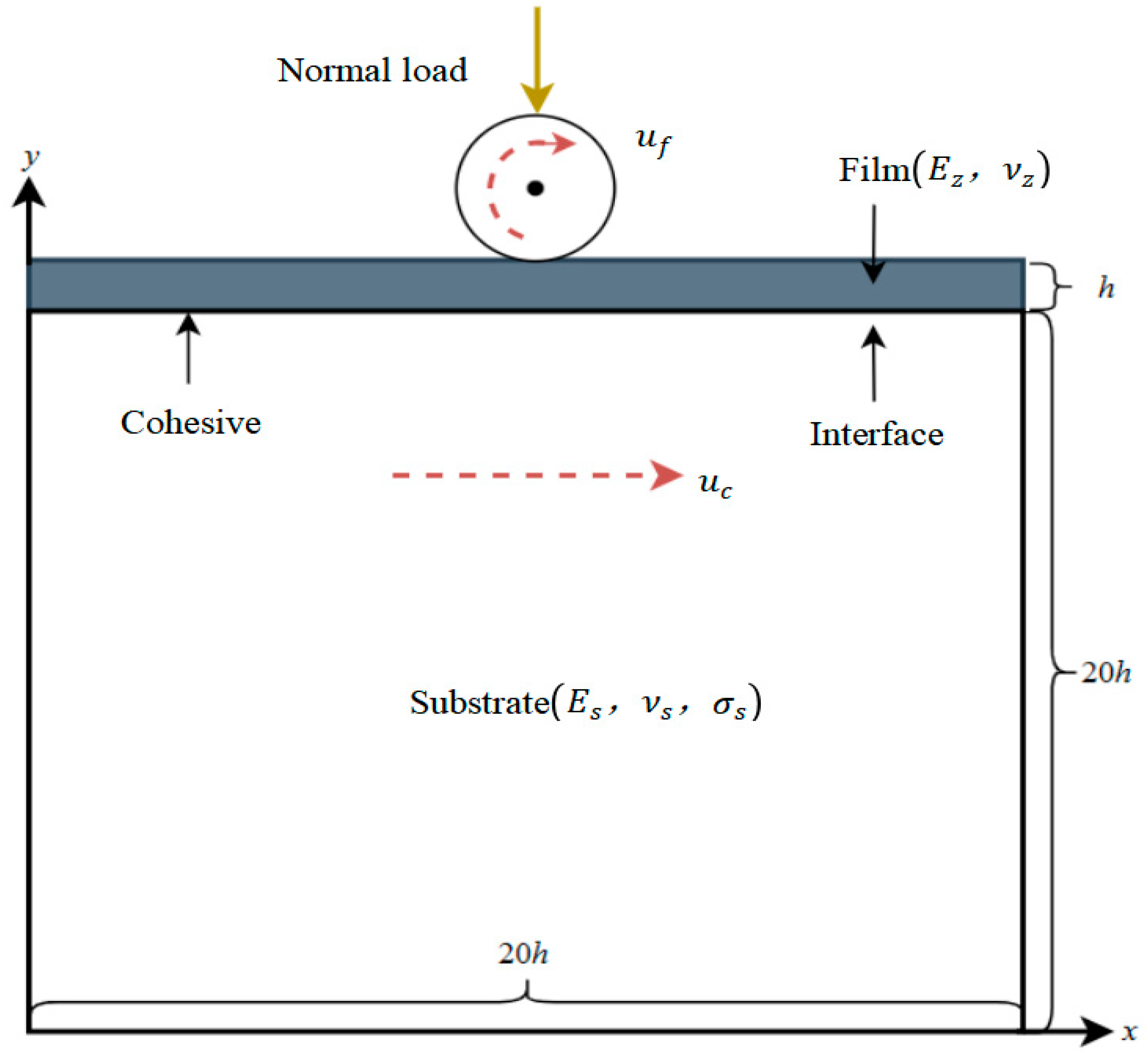

2.1. Geometric Model

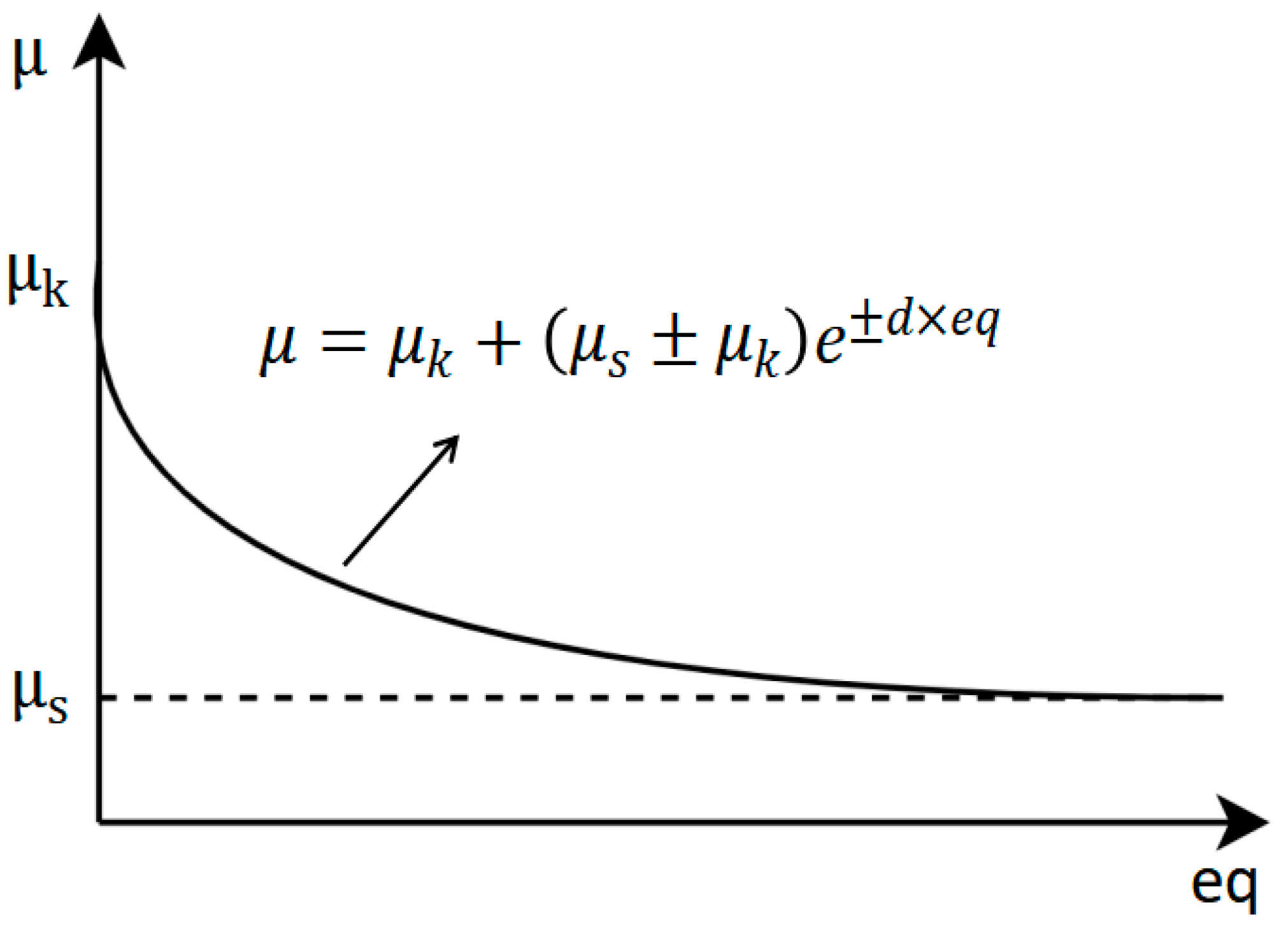

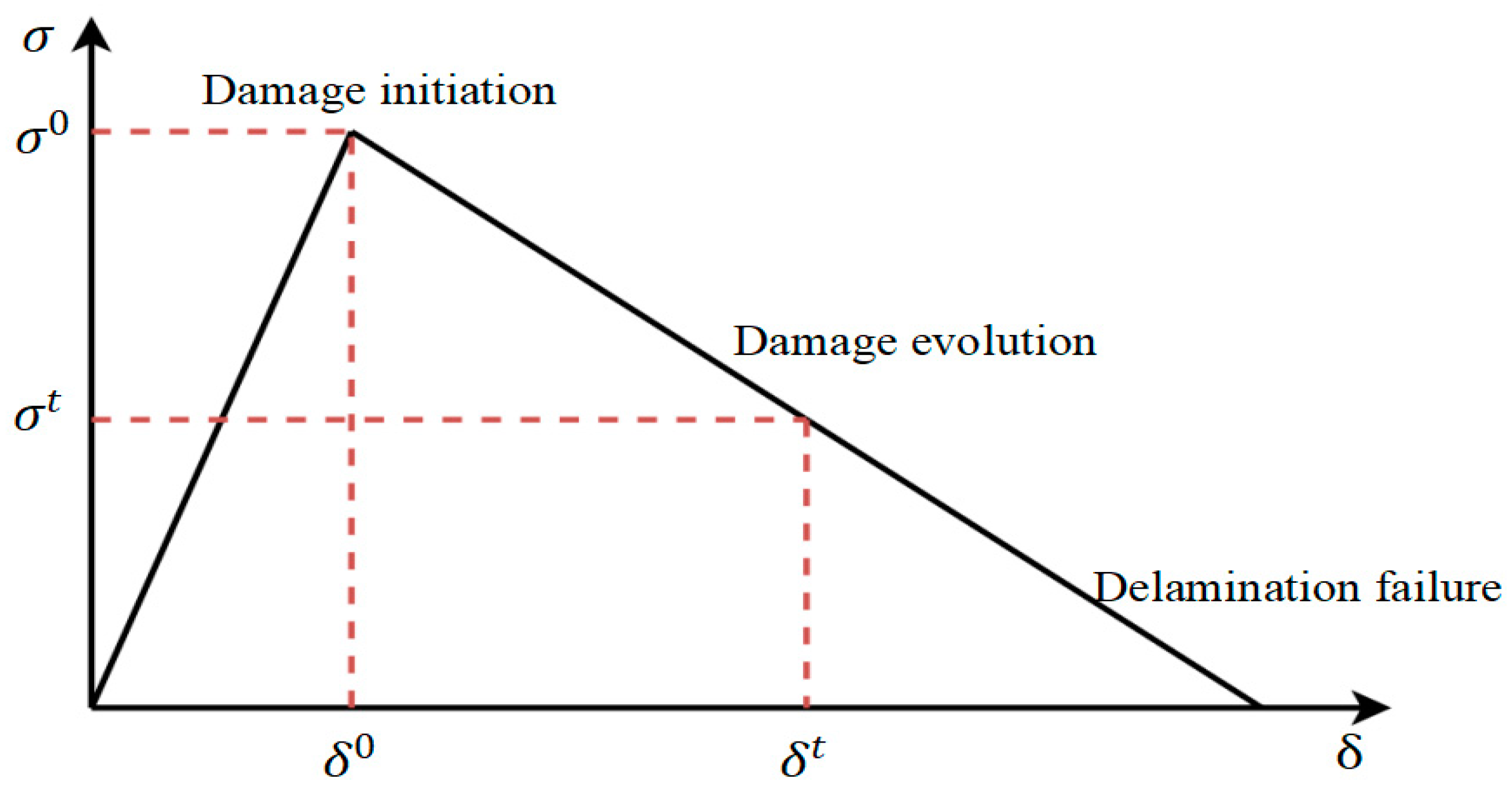

2.2. Cohesive Zone Model

2.3. Finite Element Model

- (1)

- To improve the computational efficiency, the simplified model is a two-dimensional plane model, in which the simplified film is a linear–elastic material, and the substrate is a completely elastic–plastic material.

- (2)

- The effects of loading rate and inertial load are not considered, the film–substrate interface is assumed to be smooth, and the effects of residual stress are not considered.

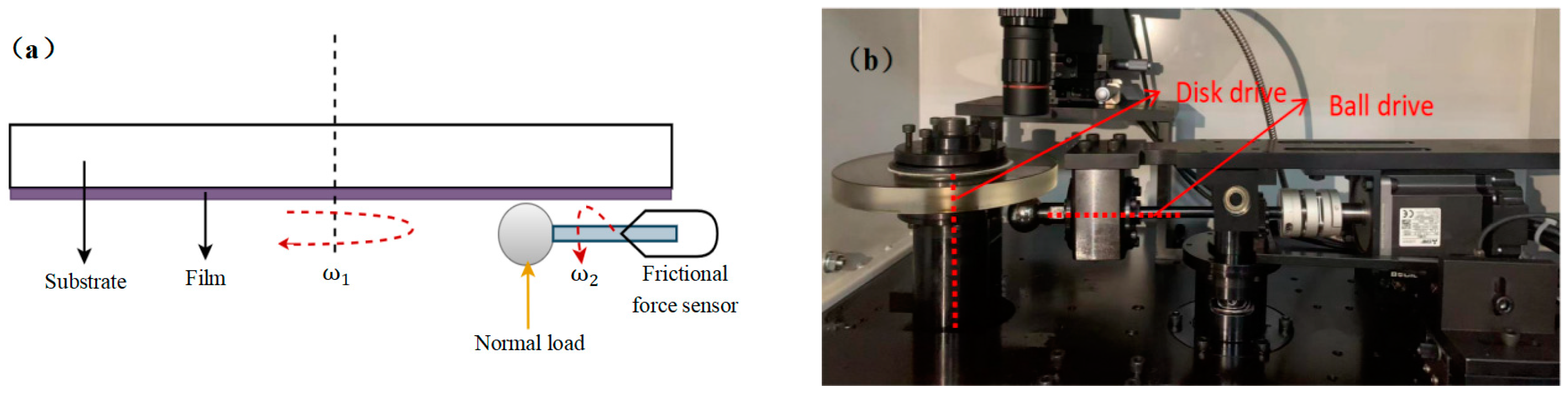

2.4. Model Validation

3. Results and Discussion

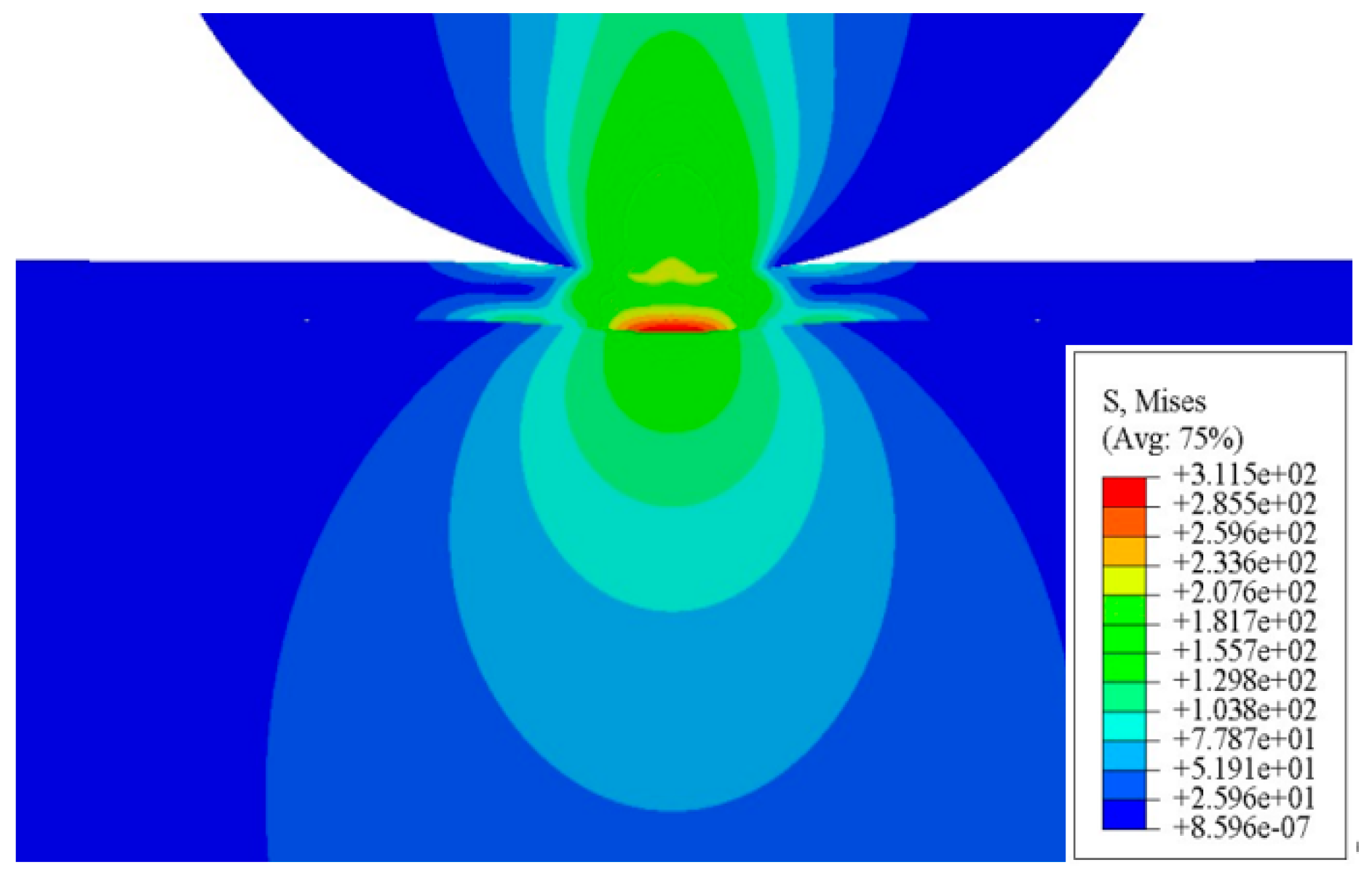

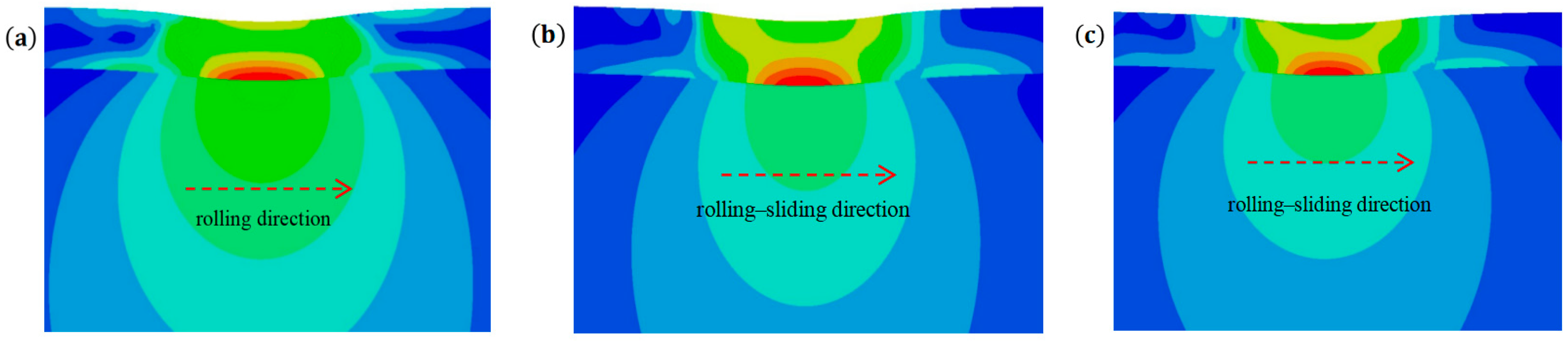

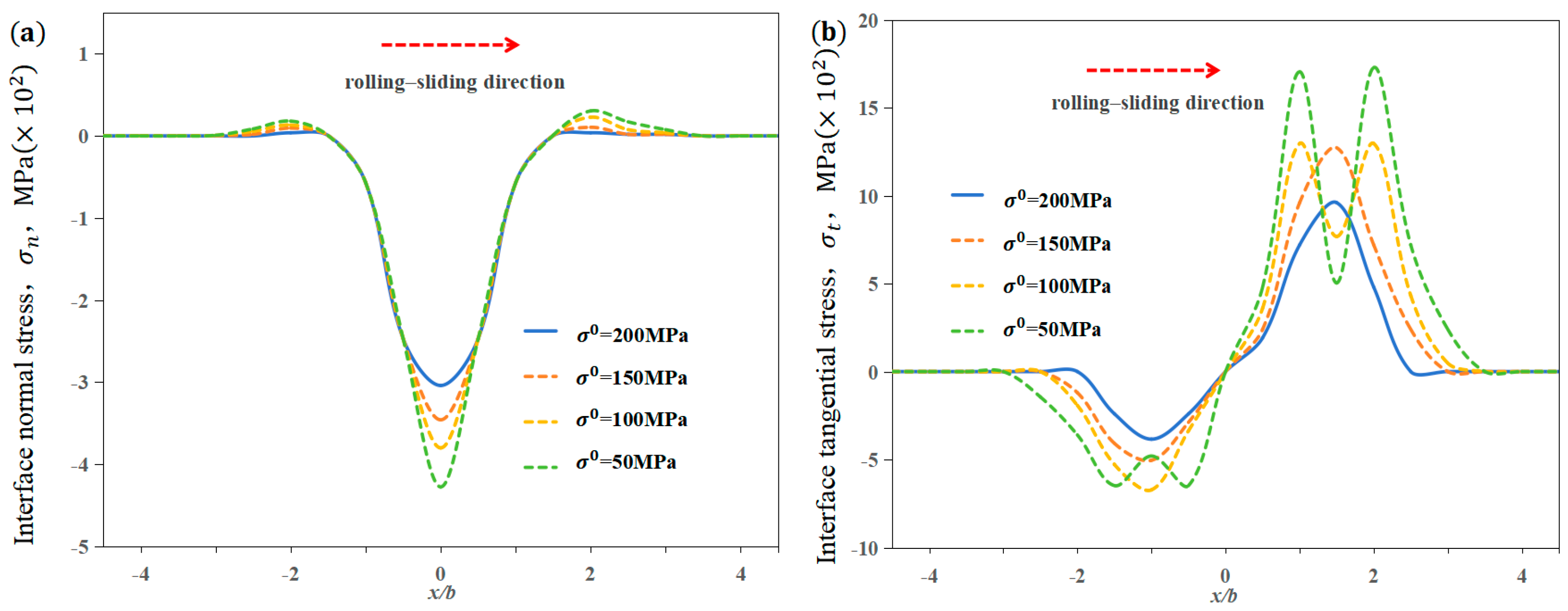

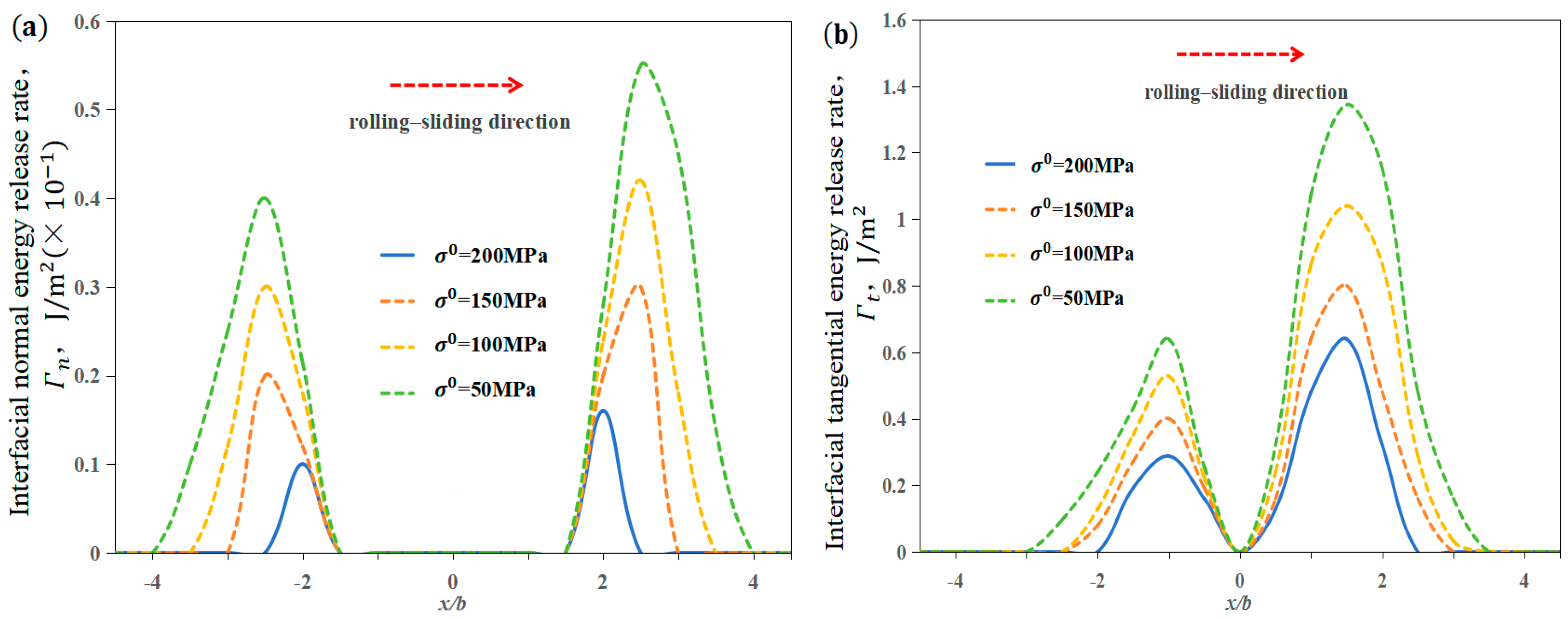

3.1. Stress State of Film–Substrate System

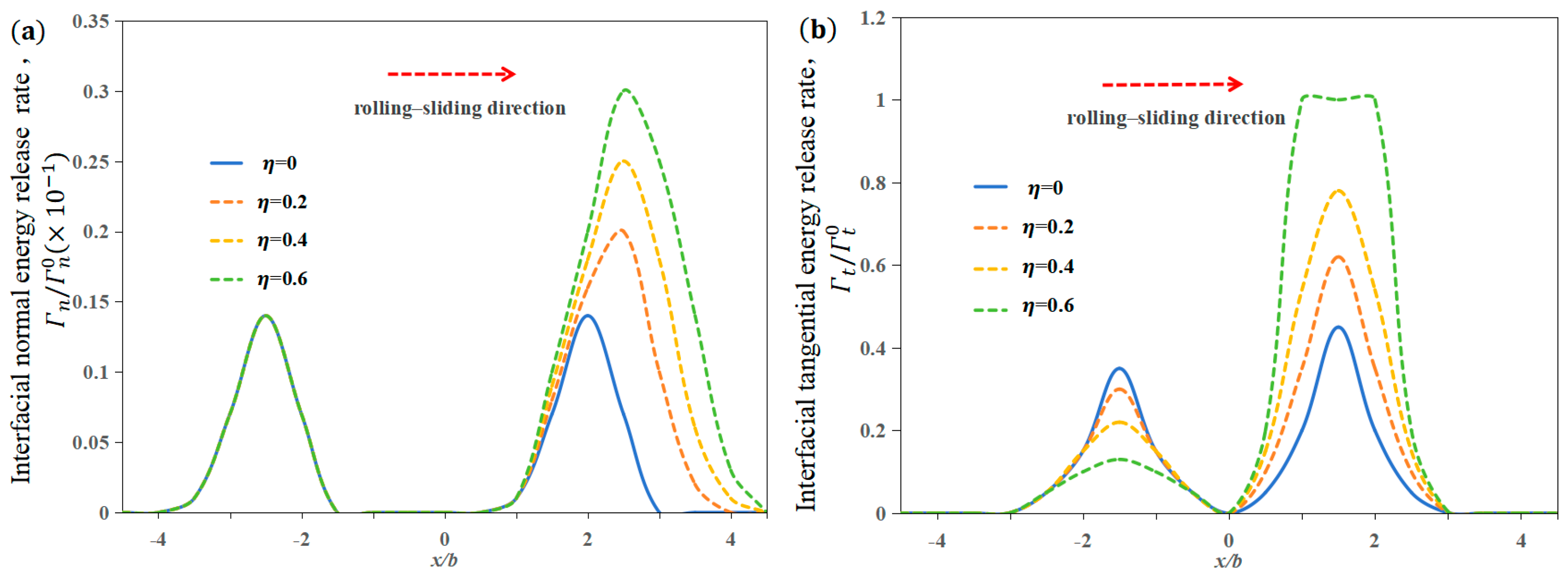

3.2. Influence of Sliding–Rolling Ratio on Interface Delamination

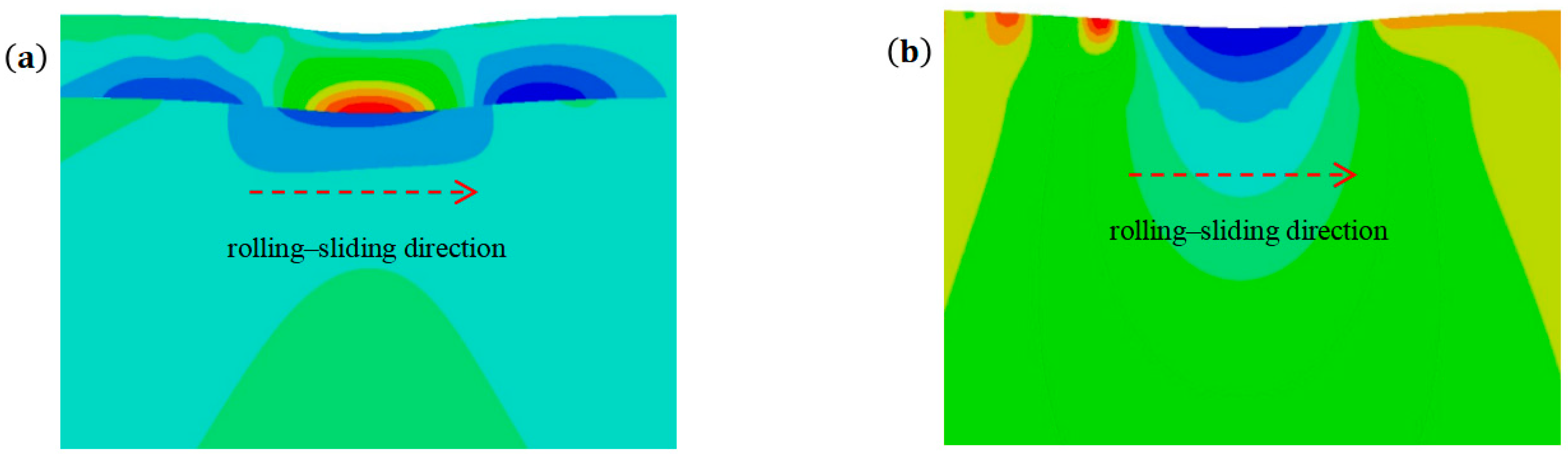

3.3. Influence of Adhesion Strength on Interface Delamination

4. Conclusions

- (1)

- In rolling contact, the film–substrate system shows almost symmetric stress distribution at both sides of the contact zone, and the rolling friction has less effect on the shear instability of the film. In the rolling–sliding contact, the film–substrate system has obvious asymmetric stress distribution at both sides of the contact zone; an obvious shear flow along the rolling–sliding direction is observed along the front of the contact zone.

- (2)

- The increase in the sliding–rolling ratio leads to a significant increase in the shear stress at the interface at the front edge of the contact zone, which increases the risk of interfacial damage and delamination failure. The rolling–sliding motion also causes the normal tensile stress concentration along the surface of the film at the rear edge of the contact zone, which very easily causes the emergence and expansion of film surface cracks.

- (3)

- The increase in the adhesion strength of the film–substrate system can raise the bearing capacity of the interface. Whether in the rolling or the rolling–sliding contact state, the degree of delamination damage of the film–substrate system interface in the tangential direction is obviously greater than that in the normal direction. The tangential adhesion strength of the film–substrate system should be enhanced to improve the bearing capacity of the interface.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fan, X.; Xue, Q.; Wang, L. Carbon-based solid-liquid lubricating coatings for space applications—A review. Friction 2015, 3, 191–207. [Google Scholar] [CrossRef]

- Li, H.; Zhang, G.; Wang, L. The role of tribo-pairs in modifying the tribological behavior of the MoS2/Ti composite coating. Phys. D Appl. Phys. 2016, 49, 095501. [Google Scholar] [CrossRef]

- Xiao, Y.; Shi, W.; Wan, Q. Evaluation of failure properties of a DLC/steel system using combined nanoindentation and finite element approach. Diam. Relat. Mater. 2019, 93, 159–167. [Google Scholar] [CrossRef]

- Bakoglidis, K.D.; Nedelcu, I.; Ivanov, I.G. Rolling performance of carbon nitride-coated bearing components in different lubrication regimes. Tribol. Int. 2017, 114, 141–151. [Google Scholar] [CrossRef]

- Zhu, W.; Zhou, Y.C.; Guo, J.W. Quantitative characterization of the interfacial adhesion of Ni thin film on steel substrate: A compression-induced buckling delamination test. J. Mech. Phys. Solids 2015, 74, 19–37. [Google Scholar] [CrossRef]

- Xiao, Y.; Shi, W.; Luo, J. Indentation for evaluating cracking and delamination of thin coatings using finite element analysis. Vacuum 2015, 122, 17–30. [Google Scholar] [CrossRef]

- Sun, W.D.; Wang, J.; Wang, K.W.; Pan, J.J.; Wang, R.; Wen, M.; Zhang, K. Turbulence-like Cu/MoS2 films: Structure, mechanical and tribological properties. Surf. Coat. Technol. 2021, 422, 127490. [Google Scholar] [CrossRef]

- Zhou, Y.; Xu, Y.; Gong, H.; Wang, C. Prediction and Regulation of Delamination at Flexible Film/Finite-Thickness-Substrate Structure Interfaces. Acta Mech. Solida Sin. 2024, 37, 238–251. [Google Scholar] [CrossRef]

- Ferguen, N.; Leclerc, W.; Lamini, E.S. Numerical investigation of thermal stresses induced interface delamination in plasma-sprayed thermal barrier coatings. Surf. Coat. Technol. 2023, 461, 129449. [Google Scholar] [CrossRef]

- Hu, P.; Li, X.; Lubineau, G. Prediction of a complex delamination front using a general cohesive model. Compos. Sci. Technol. 2023, 233, 109911. [Google Scholar] [CrossRef]

- Hameed, M.A.; Ibrahim, G.R.; Albarbar, A. Effect of friction and shear strength enhancement on delamination prediction. J. Compos. Mater. 2020, 54, 3329–3342. [Google Scholar] [CrossRef]

- Liu, J.; Wang, X.; Li, H. Delamination mechanism maps for coatings/substrates system subjected to adhesive contact loads. Thin Solid Film. 2017, 626, 159–167. [Google Scholar] [CrossRef]

- Chen, L.; Yeap, K.B.; She, C.M. A computational and experimental investigation of three-dimensional micro-wedge indentation-induced interfacial delamination in a soft-film-on-hard-substrate system. Eng. Struct. 2011, 33, 3269–3278. [Google Scholar] [CrossRef]

- Liu, P.; Zhang, Y.W.; Zeng, K.Y. Finite element analysis of interface delamination and buckling in thin film systems by wedge indentation. Eng. Fract. Mech. 2007, 74, 1118–1125. [Google Scholar] [CrossRef]

- Wang, Z.; Zhong, X.; Jiang, L. Effect of interfacial delamination on coating crack in thick diamond-like carbon coatings under indentation. Acta Mech. Sin. 2020, 36, 524–535. [Google Scholar] [CrossRef]

- Xia, S.M.; Gao, Y.F.; Bower, A.F. Delamination mechanism maps for a strong elastic coating on an elastic–plastic substrate subjected to contact loading. Int. J. Solids Struct. 2007, 44, 3685–3699. [Google Scholar] [CrossRef][Green Version]

- Lofaj, F.; Németh, D. The effects of tip sharpness and coating thick ness on nanoindentation measurements in hard coatings on softer substrates by FEM. Thin Solid Film. 2017, 644, 173–181. [Google Scholar] [CrossRef]

- Kot, M.; Rakowski, W.; Lackner, J.M. Analysis of spherical indentations of coating-substrate systems: Experiments and finite element modeling. Mater. Des. 2013, 43, 99–111. [Google Scholar] [CrossRef]

- Chen, X.; Shaw, C.; Gelman, L. Advances in test and measurement of the interface adhesion and bond strengths in coating-substrate systems, emphasising blister and bulk techniques. Measurement 2019, 139, 387–402. [Google Scholar] [CrossRef]

- Lu, P.; Xiao, X.; Chou, Y.K. Interface delamination study of diamond-coated carbide tools considering coating fractures. Surf. Coat. Technol. 2014, 260, 239–245. [Google Scholar] [CrossRef]

- Qiu, L.S.; Zhu, X.D.; Lu, S. Quantitative evaluation of bonding strength for hard coatings by interfacial fatigue strength under cyclic indentation. Surf. Coat. Technol. 2017, 315, 303–313. [Google Scholar] [CrossRef]

- Hu, J.; Chou, Y.K.; Thompson, R.G. Cohesive zone effects on coating failure evaluations of diamond-coated tools. Surf. Coat. Technol. 2008, 203, 730–735. [Google Scholar] [CrossRef]

- Zhang, S.; Spiryagin, M.; Lin, Q.; Ding, H.; Wu, Q.; Guo, J.; Liu, Q.; Wang, W. Study on wear and rolling contact fatigue behaviors of defective rail under different slip ratio and contact stress conditions. Tribol. Int. 2022, 169, 107491. [Google Scholar] [CrossRef]

- Zawischa, M.; Makowski, S.; Schwarzer, N. Scratch resistance of superhard carbon coatings–A new approach to failure and adhesion evaluation. Surf. Coat. Technol. 2016, 308, 341–348. [Google Scholar] [CrossRef]

- Zhao, B.; Zhang, S.; Keer, L.M. Spherical Elastic–Plastic Contact Model for Power-Law Hardening Materials Under Combined Normal and Tangential Loads. J. Tribol. 2017, 139, 021401. [Google Scholar] [CrossRef]

- Jamison, R.D.; Shen, Y.L. Delamination analysis of metal–ceramic multilayer coatings subject to nanoindentation. Surf. Coat. Technol. 2016, 303, 3–11. [Google Scholar] [CrossRef]

- Yuan, H.; Li, X. Critical remarks to cohesive zone modeling for three-dimensional elastoplastic fatigue crack propagation. Eng. Fract. Mech. 2018, 202, 311–331. [Google Scholar] [CrossRef]

- Fu, K.; Chang, L.; Ye, L. Indentation stress-based models to predict fracture properties of brittle thin film on a ductile substrate. Surf. Coat. Technol. 2016, 296, 46–57. [Google Scholar] [CrossRef]

- Shu, K.; Zhang, C.; Sun, D.; Wu, B.; Li, Z.; Wu, J.; Zheng, D.; Gu, L. Contact cracking and delamination of thin solid lubricating films on deformable substrates. Tribol. Int. 2021, 163, 107181. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Film elastic modulus, | 90 GPa |

| Substrate elastic modulus, | 210 GPa |

| Rolling element elastic modulus, | 210 GPa |

| Film Poisson’s ratio, | 0.3 |

| Substrate Poisson’s ratio, | 0.3 |

| Rolling element Poisson’s ratio, | 0.3 |

| Substrate yield strength, | 1 GPa |

| Film thickness, | 1 µm |

| Contact half width, | 1.3 µm |

| Interfacial adhesion strength, | 200 MPa |

| Interfacial critical energy release rate, | 6 J/m2 |

| Characteristic length, | 0.0004 µm |

| Separation displacement, | 0.04 µm |

| Interfacial stiffness, | 107 MPa/mm |

| Interface Mesh Size | 0.0785h | 0.0675h | 0.0565h | 0.0455h |

|---|---|---|---|---|

| Inaccuracies | 1.67% | 0% | 0.41% | 0.36% |

| Sliding–Rolling Ratio, | 0.1 | 0.2 |

|---|---|---|

| Test disk linear velocity (mm/s) | 1000 | 1000 |

| Test ball linear velocity (mm/s) | 904.76 | 818.18 |

| Simulation rolling element linear velocity (µm/s) | 20 | 20 |

| Simulation substrate linear velocity (µm/s) | 18.09 | 16.36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, P.; Tian, C.; Xue, Y.; Yu, Y.; Cai, H.; Yin, Y. Finite Element Analysis of Damage Evolution of Solid Lubrication Film in Rolling–Sliding Contact. Lubricants 2024, 12, 258. https://doi.org/10.3390/lubricants12070258

Lv P, Tian C, Xue Y, Yu Y, Cai H, Yin Y. Finite Element Analysis of Damage Evolution of Solid Lubrication Film in Rolling–Sliding Contact. Lubricants. 2024; 12(7):258. https://doi.org/10.3390/lubricants12070258

Chicago/Turabian StyleLv, Peng, Changling Tian, Yujun Xue, Yongjian Yu, Haichao Cai, and Yanjing Yin. 2024. "Finite Element Analysis of Damage Evolution of Solid Lubrication Film in Rolling–Sliding Contact" Lubricants 12, no. 7: 258. https://doi.org/10.3390/lubricants12070258

APA StyleLv, P., Tian, C., Xue, Y., Yu, Y., Cai, H., & Yin, Y. (2024). Finite Element Analysis of Damage Evolution of Solid Lubrication Film in Rolling–Sliding Contact. Lubricants, 12(7), 258. https://doi.org/10.3390/lubricants12070258