Abstract

In the quest for sustainable lubrication solutions, the present research explored the potential of five organic compounds as additives in castor oil (CO) to improve its lubricating properties. The compounds tested were curcumin, eugenol, 1,3-Diphenyl-2-propanone, 1,3-Diphenyl-2-propenone, and 1,3-Diphenyl-1,3-propanedione. The main results showed that each additive enhanced at least one characteristic of CO. Most of the additives lowered the density of the castor oil but increased the viscosity by up to 20%. Curcumin and eugenol were particularly effective in creating thicker lubricant films and higher film thickness ratios. Eugenol and 1,3-Diphenyl-2-propanone significantly reduced the friction coefficient by up to 25%. Wear rate and wear mechanisms were significantly reduced with all the additives, achieving a reduction in wear rate of up to 50% (CO+curcumin). All the additives, except the 1,3-Diphenyl-1,3-propanedione, enhanced the oxidation onset temperature up to 8 °C. The influence of chemical structure was also addressed. The optimal additive combination for a specific application that demands minimal friction and wear, as well as strong oxidation stability, was eugenol, followed by curcumin and 1,3-Diphenyl-2-propanone. Overall, the research contributes to the development of eco-friendly lubricants, aligning with the growing demand for green industrial applications, and highlights the significant tribological benefits of these substances as sustainable additives in biolubricant formulations.

1. Introduction

Continuing investigations to mitigate the environmental impact of human activities have turned the attention of the industry towards the development of biodegradable lubricants, marking a significant milestone in sustainability and environmental preservation [1,2,3]. Lubricants play a crucial role in various sectors, from the automotive industry to manufacturing and heavy machinery. However, most conventional petroleum-based lubricants present considerable environmental challenges due to their resistance to natural degradation [1,2]. In this context, biodegradable lubricants, especially those derived from vegetable oils, emerge as promising alternatives [1,2,3,4,5]. These lubricants are formulated with renewable raw materials, offering a solution to dependence on non-renewable resources and reducing the carbon footprint associated with the production and use of conventional lubricants. The integration of additives becomes an essential component to improve the lubricating performance of bio-based lubricants, addressing critical issues such as friction, wear, and oxidation-reduction.

Friction and wear are inevitable phenomena in machinery and mechanical systems, but their minimization is necessary to extend the useful life of components and improve energy efficiency [3]. The incorporation of specific additives in biodegradable lubricants can play a fundamental role in reducing these adverse effects. Anti-friction additives, such as friction modifiers, allow smoother sliding between contact surfaces, reducing the energy dissipated as heat, and improving system efficiency. In the area of oxidation, vegetable oils as lubricants can be susceptible to chemical degradation processes due to exposure to high temperatures and adverse conditions [3]. Antioxidant additives are needed to counteract this phenomenon, protecting oils against the formation of deposits and loss of viscosity. Oxidation not only affects the effectiveness of the lubricant but can also generate byproducts such as aldehydes, acids, esters, alcohols, and hydroxyl acids that are harmful to the environment and human health. These substances can pollute air, water, and soil, posing risks to all living beings on Earth. Aldehydes, for example, have the potential to harm aquatic organisms and contribute to atmospheric smog formation [6]. Acids can cause water bodies to become more acidic, disrupting aquatic ecosystems [7]. The sludge resulting from oil oxidation can also lead to soil and water contamination, threatening plant and animal life.

When considering vegetable oils as a base for biodegradable lubricants, their renewable origin and their ability to be produced more sustainably compared to petroleum derivatives are highlighted. Castor oil, extracted from the seeds of the castor bean plant (Ricinus communis), has historically been used for various applications, including as a lubricant [4,5]. Its viscosity and ability to adhere to metal surfaces make castor oil suitable for certain types of machinery and equipment. Castor oil contains fatty acids, especially ricinoleic (88.07%), linoleic (4.82%), and oleic (3.37%) [8], which allow it to provide a protective layer between moving parts, reducing friction and wear, enhancing efficiency, and extending equipment life. Moreover, castor oil stands out as an environmentally friendly option due to its biodegradability, renewability, and abundant availability; it is also economically viable and can be simply obtained from castor beans [9]. The seeds of the castor bean plant are notably oleaginous, containing up to 50% oil by weight [10]. In terms of production, castor plants are prodigious oil producers, yielding anywhere from 350 to 650 kg per hectare in low-rainfall areas, while in optimal growing conditions, this figure can surge to 950 kg per hectare [11]. Those characteristics make it an attractive option for contributing to the lubricant market’s growth and transformation toward sustainability. However, despite its beneficial properties, castor oil may have limitations in terms of thermal stability and oxidation resistance compared to some synthetic lubricants. Therefore, the novelty of lubrication research of castor oil lies in the optimization of its performance by addressing the intrinsic limitations of vegetable oils, such as their lower thermal stability and tendency to oxidize. The incorporation of specific additives offers a comprehensive solution to these challenges.

The following research marks recent insights into the experimental investigation of various additives in castor oil and their impact on tribological properties. In 2018, R.N. Gupta and A.P. Harsha [12] used CeO2 and polytetrafluoroethylene nanoparticles as additives in castor oil. The nanoparticles were optimized for concentration based on their tribological performance. The addition of nanoparticles significantly improved the antiwear, anti-friction, and extreme pressure properties of castor oil, as observed in the wear scar diameter and weld load measurements. Also in 2018, S. Qian et al. [13] modified carbon nanotubes with oleic acid and added this to castor oil. The tribological properties were studied using a four-ball testing rig. The results indicated better dispersion of the modified carbon nanotubes in castor oil. The addition of a small amount of modified carbon nanotubes improved the properties of the castor oil, with an optimum concentration observed for a minimum coefficient of friction and wear scar diameter. Later, in 2020, Yashvir Singh et al. [14] added TiO2 nanoparticles to castor oil, and the friction and wear characteristics were investigated. The study revealed that the concentration of 0.2% nanoparticles resulted in the minimum coefficient of friction (COF) and wear rate. Higher sliding speeds contributed to reduced COF and wear. In 2021, Tiancheng Ouyang et al. [15] analyzed the incorporation of IF–WS2 nanoparticles as additives in castor oil, resulting in improved lubrication performance. The friction coefficient and worn volume decreased significantly under certain conditions. The unique pressure-bearing structure and dispersion stability of modified IF–WS2 were identified as contributing factors. In that year, K.J. Moreno et al. [4] explored xanthophylls as additives for green lubricant applications in castor oil. The study focused on their impact on friction, wear, and oxidation properties. Xanthophylls demonstrated better wear protection, reducing the wear rate compared to the neat oil. Astaxanthin was identified as the most effective additive, and the oxidation of castor oil was significantly improved. More recently, in 2022, M.T. Hernández et al. [5], in the same research group, underscored the potential of curcumin to contribute to the creation of sustainable lubricants, aligning with the growing demand for eco-friendly and biodegradable solutions in various industrial applications. The study reveals that incorporating curcumin into the oil results in increased viscosity (up to 46%), a significant decrease in friction coefficient (up to 70%), and a substantial reduction in wear (up to 96%), even under boundary lubrication conditions. Furthermore, the addition of curcumin notably enhanced the oxidative stability of the lubricants.

Previous research reflects a shared interest in developing more sustainable and environmentally friendly castor oil-based lubricants. In all the research, an improvement in the tribological properties of lubricants was observed after the incorporation of additives. These improvements include reducing the coefficient of friction and wear, as well as increasing the load capacity and resistance to extreme pressure. Although the additives used in the aforementioned studies have shown significant improvements in the tribological properties of castor oil, it is important to recognize that they may also have some limitations. The effectiveness of nanoparticles depends largely on their ability to disperse homogeneously in the lubricant; then, problems with agglomeration or sedimentation can affect the long-term stability and effectiveness of the additive. Additionally, some additives only improve a single property, either friction or wear, which can be limiting for some applications. Likewise, not all the additives indicated are completely biodegradable, which limits their use in applications where they may come into contact with the environment.

Although it is difficult to make a comparison, of the aforementioned additives, to our knowledge, curcumin is the natural additive to date that has shown the greatest benefit in the tribological systems studied. It is recognized that the chemical nature of the additives plays a very important role. Curcumin is a natural polyphenol; it contains two phenolic groups in its structure. These phenolic groups give it antioxidant properties and contribute to its ability to neutralize free radicals. Its chemical structure also includes two methoxy groups (–OCH3), and two carbonyl groups (C=O) in a specific arrangement.

Eugenol, 1,3-Diphenyl-2-propanone, 1,3-Diphenyl-2-propenone, and 1,3-Diphenyl-1,3-propanedione are also aromantic organic compounds that share certain structural characteristics of curcumin (benzene rings and carbonyl groups). Eugenol is an aromatic natural compound found in essential oils such as clove oil. It is known for its pleasant spicy aroma and is commonly used as a flavoring agent and fragrance. It has garnered significant attention in recent research due to its diverse applications and beneficial properties. Several studies have highlighted eugenol’s potent antioxidant properties; clove oil and eugenol have been shown to effectively inhibit oxidation in various applications such as lubricating oils [16,17,18], cutting fluids [19], and biofuels [20]. The antioxidant activity of eugenol contributes to improved oxidative stability, reducing degradation and extending the lifespan of these products. The current literature provides valuable insights into the use of eugenol in lubricants [5,12,13,14,15]; nevertheless, the tribological or mechanical behavior of eugenol has not been reported. On the other hand, 1,3-Diphenyl-2-propanone, 1,3-Diphenyl-2-propenone, and 1,3-Diphenyl-1,3-propanedione are aromatic ketone compounds commonly employed as precursors for the synthesis of other aromatic hydrocarbons and polymers. Although the specific use of these three compounds as lubricant additives is not commonly documented, as with other aromatic ketones, they could play a role in improving lubricant properties.

In the present study, five organic compounds (curcumin, eugenol, 1,3-Diphenyl-2-propanone, 1,3-Diphenyl-2-propenone, and 1,3-Diphenyl-1,3-propanedione) were investigated as lubricant additives in castor oil, to explore new biolubricant formulations and analyze the influence of chemical structure on the friction, wear, and oxidation performance. The present research includes the study of the physical properties of the formulated lubricants, such as density and viscosity, the study of friction and wear using a standardized method in accordance with ASTM G99 [21], and the analysis of the oxidation onset temperature.

2. Materials and Methods

2.1. Additives

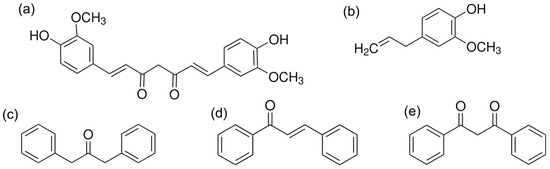

This article explores curcumin (96.4%, CAS number: 458-37-7), eugenol (99%, CAS number: 97-53-0), 1,3-Diphenyl-2-propanone (99%, CAS number: 102-04-5), 1,3-Diphenyl-2-propenone (98%, CAS number: 614-47-1), and 1,3-Diphenyl-1,3-propanedione (98%, CAS number: 20-46-7) as additives in a green lubricant. All the substances were acquired from Sigma-Aldrich (St. Louis, MO, USA) and were used without further modification. Figure 1 illustrates the molecular structure of the additives. Curcumin is a polyphenolic compound that has two aromatic rings, each with one hydroxy (–OH) and one methoxy (–OCH3) group, and these rings are connected by a seven-carbon linker that includes a 1,3-diketone structure. On the other hand, eugenol features a methoxy group (–OCH3) attached to the phenol group, 1,3-Diphenyl-2-propanone is an organic ketone with two benzene rings attached, 1,3-Diphenyl-2-propenone contains a double bond between the two benzene rings, and 1,3-Diphenyl-1,3-propanedione is a compound that has two benzene rings attached to a central carbon atom, forming a diketone structure. Some characteristics and properties of these additives are identified in Table 1.

Figure 1.

Molecular structures of the additives: curcumin (a), eugenol (b), 1,3-Diphenyl-2-propanone (c), 1,3-Diphenyl-2-propenone (d), and 1,3-Diphenyl-1,3-propanedione (e).

Table 1.

Characteristics and properties of the additives.

2.2. Chemical Characterization of Additives

The additives were characterized by attenuated total reflection–Fourier transform infrared spectroscopy (ATR–FTIR) using a Spectrum 100 spectrometer from Perkin Elmer (Waltham, MA, USA). This equipment has a LiTa03 detector, a KBr beam splitter, and a ZnSe-attenuated total reflectance device. The additives were analyzed in a wavenumber range of 4000 to 500 cm−1, with a resolution of 4.0 cm−1 and four scans per sample.

2.3. Lubricants Formulation

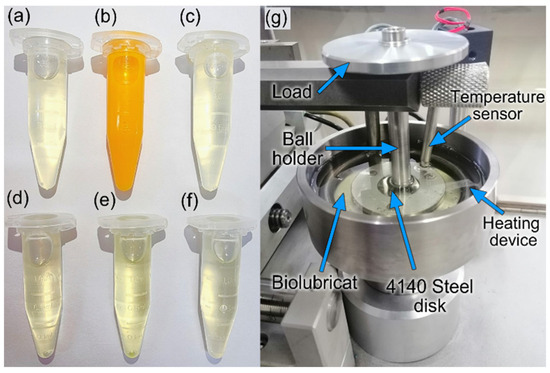

The lubricants analyzed in this study were obtained by mixing 0.5% by weight of each additive in pure castor oil purchased in the local market. The concentration of additives employed in this study aligns with common industry standards, where the additive concentration can vary from a mere 0.01% to over 30%, designed for specific applications [22]. The mixing process was carried out with constant magnetic stirring at 100 rpm while maintaining a temperature of 70 °C for 10 min. The lubricant formulations resulted in completely homogeneous mixtures, and no precipitation or phase separation was observed. Figure 2a–f shows a photograph of the lubricant samples studied. It can be seen that the formulations are completely homogeneous, and in the case of curcumin, it produced a notable color change in the castor oil.

Figure 2.

Photograph of the lubricant samples studied: CO (a), CO+curcumin (b), CO+eugenol (c), CO+1,3-Diphenyl-2-propanone (d), CO+1,3-Diphenyl-2-propenone (e), and CO+1,3-Diphenyl-1,3-propanedione (f); configuration of lubricated friction tests (g).

2.4. Physical Properties of Lubricants

The physical properties, such as density and viscosity, of the biolubricants were studied at 40 °C and 100 °C. The density was determined using a pycnometer Cannon Instrument (State College, PA, USA) (ASTM D 891 [23]), whereas the kinematic viscosity was measured using different glass capillary viscometers from Cannon Instrument (State College, PA, USA) (ASTM D445 [24]), respectively.

2.5. Lubricating Regime Estimation

The lubricating regime determination is a key aspect of estimating the efficiency of a mechanical system. This process involves the determination of which of the main regimes (boundary, mixed, or elastohydrodynamic/hydrodynamic) is present in a lubricated contact. The lubricating regime depends on factors such as load, speed, temperature, and lubricant properties, among others. In this study, the lubrication regime of each system was considered by calculating the dimensionless parameter known as the lambda ratio (λ), which is the ratio of the lubricant film thickness to the combined surface roughness of the two surfaces in contact. One value λ < 1 corresponds to boundary lubrication, 1 < λ < 3 to mixed lubrication, and λ > 3 to elastohydrodynamic/hydrodynamic lubrication. For this purpose, the thickness of the lubricant film was determined by employing the theory of Hamrock and Dowson [25], developing the method described in [26].

2.6. Tribological Performance Evaluation

The tribological performance of the biolubricants was evaluated through sliding friction tests based on the ASTM G-99 standard [21]. To this end, the biolubricants were analyzed under boundary lubricating conditions in a tribosystem of AISI 4140 steel vs. tungsten carbide (WC). For these tests, a standard tribometer (TRB) from CSM Instruments (Needham, MA, USA) with a ball-on-disk configuration was used. The steel disks of 25.4 mm and 5 mm in diameter and thickness, respectively, were cut from a commercial steel bar and subjected to a heat treatment that consisted of hardening and tempering until obtaining a hardness of 45 HRC. Subsequently, these samples were prepared metallographically to a surface roughness of 0.03 µm in Ra. The WC balls were already stated at the same commercial roughness. The tests were performed at 1 N of normal load, generating a contact pressure of 0.9 GPa. The counterpart (WC) was positioned at a fixed distance of 2 mm from the center of the disk, which rotated at a linear speed of 25 mm/s. Each test was carried out until completing 30,000 cycles with a duration of approximately 15,000 s. For each test, 60 mL of lubricant at a constant temperature of 100 °C was employed. In this study, the 100 °C test temperature selection aims to emulate one characteristic operation condition of mechanical systems where biolubricants can be employed, particularly within oil splash lubrication systems of various gear types. The pin-on-disk configuration, heating device, temperature sensor, and lubricant container are indicated in Figure 2g. Before and after the tribological tests, the materials were cleaned with methanol and a soft tissue to remove any contamination and properly analyze the worn surfaces. Three experiments were performed for each system, of which the average value of the measurements is reported.

Friction was evaluated through the coefficient of friction (COF), which was recorded during the tests using the tribometer software Tribox 4.5 R (accessed on 12 May 2024). On the other hand, immediately after the experiments, the worn surfaces were cleaned and analyzed with a Carl Zeiss Axio Imager.A1m microscope (ZEISS, Göttingen, Germany). In all the cases, due to the difference in the hardness of the materials, it was observed that the wear of the balls was negligible when measured according to ASTM G 99 [21]; therefore, only the wear of the steel discs was reported. To determine wear, volume loss (mm3) and wear rate (mm3/Nm) were calculated with Equations (1) and (2), respectively. Only the wear rate is reported in this work.

V = πRd3/6r

K = V/FS

In the previous equations, R represents the wear track radius (mm), d the wear track width (mm), r the ball radius (mm), F the normal load (N), and S the total sliding distance (m).

2.7. Oxidation Performance Evaluation

The oxidation onset temperature (OOT) is a critical parameter that indicates, under certain conditions, the temperature at which a lubricant begins to significantly oxidize. This temperature is important because it helps to predict the thermo-oxidative stability of the lubricants, which is essential for their performance and longevity. A higher OOT suggests better resistance to oxidation, which is desirable in lubricants, as it can lead to longer service life and better performance. In this work, the OOT was determined through differential scanning calorimetry (DSC) according to the ASTM E 2009 standard [27] in a Simultaneous Thermal Analyzer STA 8000 from PerkinElmer. For the evaluation of the OTT of the lubricants, 3 ± 0.5 mg of each lubricant was placed in an open ceramic crucible, and dry air was flowed (50 mL/min) at atmospheric pressure. The heating rate was 10 °C/min, and the samples were studied in a temperature range of 30 °C to 500 °C. When plotting the DSC thermogram, the OOT is determined by measuring the start temperature of the exothermic reaction extrapolated.

3. Results and Discussion

3.1. Chemical Characterization of Additives

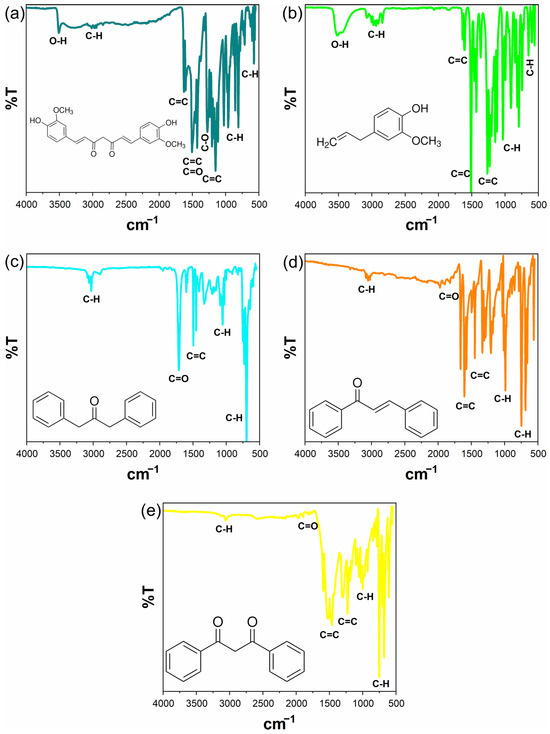

Figure 3 illustrates the FTIR spectra of the additives employed. As mentioned above, the four additives maintain similar characteristics as benzene rings and carbonyl groups which are also observed in the FTIR spectra. The signals corresponding to the aromatic ring are the =C–H stretching vibration which is observed slightly higher than 3000 cm−1, the stretching vibrations associated with the aromatic C=C bond are observed in the regions 1600–1585 cm−1 and 1500–1400 cm−1, and the C–H bending vibrations in-plane and out-of-plane are located in the regions of 1250–1000 cm−1 and 900–675 cm−1, respectively. In the case of curcumin and eugenol, they exhibit a peak at about 3450 cm−1, which is due to the stretching vibration of the hydroxyl group O–H. Finally, the stretching vibration band of the carbonyl group (C=O), which is present in the curcumin, 1,3-Diphenyl-2-propanone, 1,3-Diphenyl-2-propenone, and 1,3-Diphenyl-1,3-propanedione, is shown at about 1715 cm−1. All the spectra are in good agreement with those reported by the supplier and the literature [28,29,30,31].

Figure 3.

FTIR spectra of the additives: curcumin (a), eugenol (b), 1,3-Diphenyl-2-propanone (c), 1,3-Diphenyl-2-propenone (d), and 1,3-Diphenyl-1,3-propanedione (e).

3.2. Physical Properties of Biolubricants

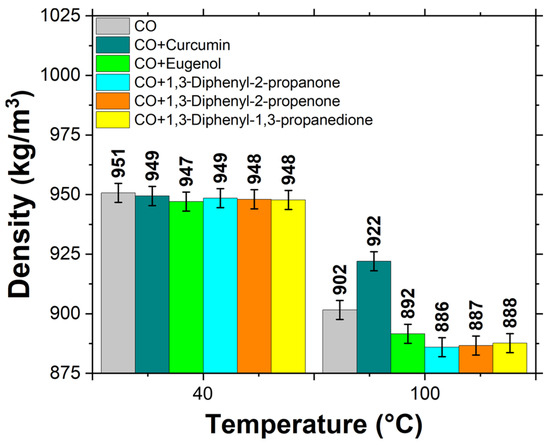

The density of a lubricant is a crucial factor in its performance, especially in various temperature conditions. Understanding how additives affect density can provide insights into the potential applications of these lubricant compositions. In this regard, Figure 4 provides information on the density of lubricants at different temperatures. Firstly, it can be observed that the density of biolubricants decreases as temperature increases, which is a common behavior for liquids, where higher temperatures generally lead to lower densities. Comparing the different lubricant compositions, variations in density can be observed at both 40 °C and 100 °C. All the additives produced lubricants with lower density than CO at both temperatures, with the exception of curcumin at 100 °C, which increased the density to 922. Furthermore, some lubricant compositions (CO+1,3-Diphenyl-2-propanone, CO+1,3-Diphenyl-2-propenone, and CO+1,3-Diphenyl-1,3-propanedione) show a more significant decrease in density as temperature increases, while CO+eugenol exhibits a less pronounced change. This reflects the temperature sensitivity of these compositions.

Figure 4.

The density of biolubricants.

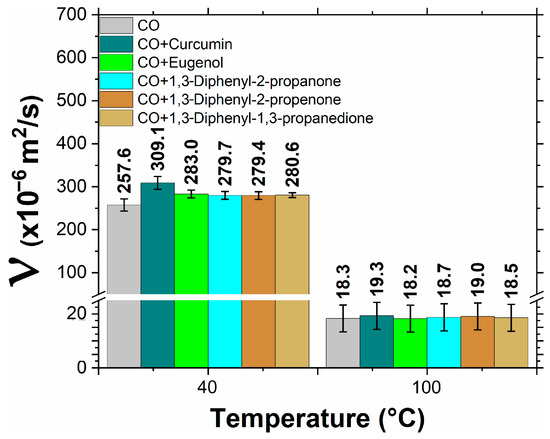

The viscosity data is crucial for understanding the flow properties of lubricants. Higher viscosity may be desirable in certain applications where better adherence and resistance to flow are needed. Figure 5 shows the viscosity of the biolubricants. It can be observed that similar to the density data, the viscosity of the lubricants decreases as temperature increases. Higher temperatures generally result in lower viscosity, allowing the lubricant to flow more easily but reducing the thickness of the layer. It can be observed that the incorporation of the additives increased the viscosity of CO at both temperatures, up to 20% (curcumin) at 40 °C and up to 6% (curcumin) at 100 °C. While for the rest, it increased between 8.4% and 9.8% at 40 °C and less than 4% at 100 °C. This behavior indicates that the additives contribute to higher resistance to flow and suggests that they contribute to a thicker and more resistant lubricant. The change in viscosity with temperature varies among the additives. The viscosity index from the mixtures is shown in Figure 5.

Figure 5.

The viscosity of biolubricants.

3.3. Lubricating Regime Estimation

The lubricant film thickness represents the separation between the surfaces being lubricated. A thicker film generally provides better protection against friction and wear. Table 2 shows the central and minimum lubricating film and the lambda ratio of the AISI 4140 steel/WC tribosystem lubricated with the biolubricants. CO+curcumin and CO+eugenol had the thickest lubricant films, suggesting that these additives could contribute to a more substantial separation between the surfaces. CO+1,3-Diphenyl-2-propanone and CO+1,3-Diphenyl-2-propenone had similar film thicknesses to CO, while CO+1,3-Diphenyl-1,3-propanedione had slightly thinner films. The lambda ratio (λ) provides information about the effectiveness of the lubricant in filling surface asperities. In this study, due to the high temperature of the tribological tests, all the systems had λ lower than 1, which indicates the lubricating regime is a boundary lubricating condition. CO+curcumin and CO+eugenol had the highest lambda ratio, while CO+1,3-Diphenyl-2-propanone and CO+1,3-Diphenyl-2-propenone had the same λ as CO. CO+1,3-Diphenyl-1,3-propanedione had a slightly lower ratio in comparison to the studied lubricants. Lubricant film thickness and λ are critical for determining the ability of the lubricant to provide effective separation and reduce friction. Curcumin and eugenol appear to contribute to the formation of a thicker film and higher lambda ratio, indicating promising improvements in lubrication performance.

Table 2.

Lubricating film thickness and lambda ratios of the AISI 4140 steel/WC tribosystem.

3.4. Tribological Performance

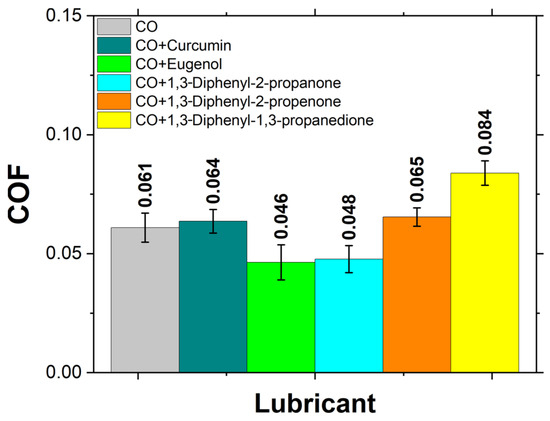

The mean friction coefficient of the AISI 4140 vs. WC tribosystem is depicted in Figure 6. It can be observed that the friction coefficient for the base lubricant CO is 0.061. This value represents the inherent friction resistance of the base lubricant. The addition of eugenol reduced the friction coefficient to 0.046 (25% lower than CO), indicating that eugenol contributes to a lower frictional behavior. The 1,3-Diphenyl-2-propanone also produced a reduction of 21% in the friction coefficient, suggesting improved lubricating properties. However, with the addition of curcumin and 1,3-Diphenyl-2-propenone, the friction coefficients slightly increased to 0.064 and 0.065, respectively. The lubricant with 1,3-Diphenyl-1,3-propanedione showed the highest friction coefficient, reaching a mean value of 0.084 (38% higher than CO). In general, in this tribosystem, eugenol appears to be the most effective in reducing friction, followed by 1,3–Diphenyl–2–propanone. On the other hand, curcumin, 1,3-Diphenyl-2-propenone, and 1,3-Diphenyl-1,3-propanedione produced poor friction performance, leading to higher friction coefficients compared to the base lubricant; the friction coefficients increased by 5%, 6%, and 38%, respectively. Lower friction coefficients are generally desirable in lubrication applications, as they indicate smoother and more efficient operation. Lubricants with additives like eugenol and 1,3-Diphenyl-2-propanone may be suitable for applications where minimizing friction is crucial.

Figure 6.

The mean friction coefficients in the AISI 4140 steel/WC tribosystem.

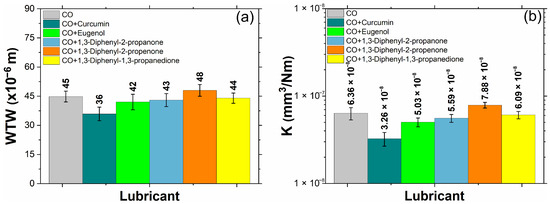

Figure 7 shows the wear track width (WTW) and wear rate (K) of the AISI 4140 steel/WC tribosystem. The wear track width represents the width of the area where wear occurs on the material surfaces; smaller wear track widths generally indicate better wear resistance. It can be observed that all the samples had similar behavior with little variation. CO+curcumin exhibited the most significant improvement in wear resistance, with a wear track width reduction of 9 µm compared to CO alone. This suggests that curcumin is highly effective as an antiwear additive for castor oil. CO+eugenol and CO+1,3-Diphenyl-2-propanone showed moderate improvements, with reductions of 3 µm and 2 µm, respectively. These additives appear to provide some wear protection but are not as effective as curcumin. On the other hand, CO+1,3-Diphenyl-2-propenone presented an increase in wear track width by 3 µm, and CO+1,3-Diphenyl-1,3-propanedione displayed a slight decrease in wear track width compared to CO alone. On the other hand, similar behavior was observed in the wear rate, as it represents the volume of material worn away per unit force and distance; lower wear rates indicate better wear protection. CO+curcumin resulted in the lowest wear rate, which is approximately half of the wear rate of CO without additives. CO+eugenol and CO+1,3-Diphenyl-2-propanone also demonstrated a significantly reduced wear rate, indicating good wear resistance. CO+1,3-Diphenyl-1,3-propanedione presented a moderate reduction in wear rate compared to neat CO, suggesting it also contributes to improved wear resistance but to a lesser extent. CO+1,3-Diphenyl-2-propenone has a higher wear rate than CO and is the least effective among the additives tested. The lubricant compositions with smaller wear track widths and lower wear rates are generally preferred for applications where wear protection is crucial, such as in machinery components. The results suggest that the additives curcumin, eugenol, 1,3-Diphenyl-2-propanone, and 1,3-Diphenyl-1,3-propanedione contribute to improved wear protection, while 1,3-Diphenyl-2-propenone may have undesirable effects on wear performance.

Figure 7.

Wear track width (a) and wear rate (b) of the AISI 4140 steel/WC tribosystem.

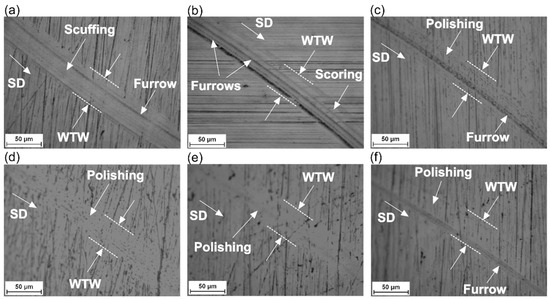

Exploring the wear mechanism of mechanical components is an important step to understanding their response and thereby improving their efficiency and extending their useful life. The wear results obtained in this work were quite small and similar to each other due to the great resistance of the hardened and tempered AISI 4140 steel. Figure 8 presents optical micrographs of a region of the wear mark of the steel lubricated with the different media. It can be seen that the samples were worn mainly by the abrasion mechanism; all of them have one or more groove marks, which can be produced by abrasive particles. Likewise, it can be observed that the sample lubricated with CO was worn mainly by the phenomenon of scuffing wear, the one lubricated with CO+curcumin exhibited damage by scoring, while the rest of the samples showed only polishing characteristics. Scoring involves the creation of deep, distinct furrows on a surface, typically caused by the movement of hard particles or rough edges under pressure. This action often leads to considerable loss of material and notable surface damage. Scuffing resembles scoring but usually affects a broader surface area and is marked by grooves or marks that are less sharp and clear-cut. In contrast, polishing is the mildest type of wear among these, leading to a refined surface texture. Often, polishing is referred to as “zero wear” [32,33] because the material loss is so minimal that it falls within the micro-topography of the component’s surface, often at the asperity level. This negligible volume loss is challenging to quantify due to its subtlety and the resolution limits of measurement techniques. It suggests that the wear process does not significantly alter the original surface characteristics, maintaining the integrity of the component within its operational specifications. It can enhance the efficiency of the mechanism by lowering friction and is sometimes not perceived negatively [33]. This can be why the sample lubricated with CO+1,3-Diphenyl-2-propanone suffered lesser friction than other samples. In this context, it can be observed that, in this system, although curcumin helped to decrease the size of the wear track width, the intensity of damage could be considered larger than that produced by CO, whereas the newly studied molecules exhibited better protection against wear.

Figure 8.

Optical micrographs at 500X of a region of the wear mark of the steel lubricated with CO (a), CO+curcumin (b), CO+eugenol (c), CO+1,3-Diphenyl-2-propanone (d), CO+1,3-Diphenyl-2-propenone (e), and CO+1,3-Diphenyl-1,3-propanedione (f).

3.5. OOT of Biolubricants

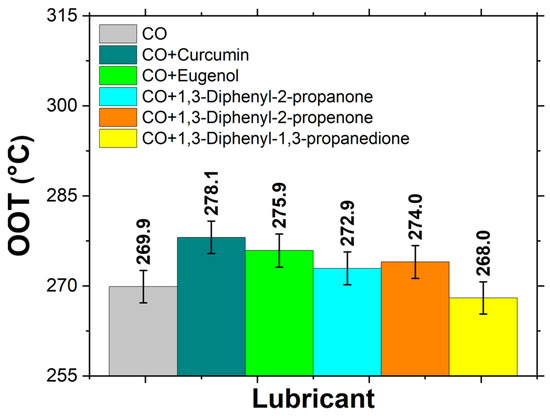

Figure 9 indicates the OOT of the biolubricants. Curcumin seemed to be the most effective additive for increasing the OOT of CO, raising it by 8 °C compared to the base oil. This suggests that curcumin could be a potent antioxidant for castor oil, potentially improving its stability and performance as a lubricant. Eugenol also demonstrated a significant increase in OOT, with a 6 °C improvement over the base oil. Curcumin and eugenol are known for their antioxidant properties, which could explain the enhanced thermal stability. The additives 1,3-Diphenyl-2-propanone and 1,3-Diphenyl-2-propenone showed moderate improvements in OOT, with increases of 3 °C and 4 °C, respectively. This indicates that they may also contribute antioxidant effects to the castor oil, although to a lesser extent than curcumin and eugenol. Interestingly, 1,3-Diphenyl-1,3-propanedione resulted in a decrease in OOT by 2 °C. This could suggest that the 1,3-Diphenyl-1,3-propanedione additive did not synergize well with castor oil in terms of oxidative stability, or it may even have pro-oxidant effects under the conditions tested. Curcumin stands out as the most promising additive, followed by eugenol. It is important to note that while OOT provides a good indication of the initial resistance to oxidation, other factors such as long-term stability, mechanical properties, and compatibility with other materials should also be considered when selecting additives for lubricants.

Figure 9.

OOT of biolubricants.

4. Complementary Discussion

As can be seen from the results, some additives may be excellent in some properties but not so good in others. This is due to their set of properties and chemical characteristics. In the boundary lubricating regime, the lubricating film thickness can be minimal, often just a few molecules in depth (ranging from 1 to 10 nanometers) [34]. At such a scale, the physical and chemical properties of lubricants and additives play a crucial role in determining friction and wear effects. It has been recognized, as per reference [35], that molecules featuring elongated and polar structures are conducive to a thicker adsorbed film, thereby fostering better surface interactions and diminishing friction. This principle explains the reduced friction observed when using eugenol in CO, which is a polar molecule. The hydroxyl group presented in curcumin and eugenol could be also a key point in the observed performance of the lubricant formulations since this group creates a van der Waals bond with the triglyceride in CO, as stated by [20]. Van der Waals bonds are stronger than the London force movement of the molecule of triglycerides in CO.

On the other hand, regarding the oxidation behavior, curcumin and eugenol have at least one phenolic group, and these substances serve as fundamental antioxidants, either by transferring hydrogen atoms to reactive entities or by preventing the formation of free radicals. They enhance the resistance to oxidation by directly interacting with free radicals, transforming them into non-radical entities, and halting the oxidative process [5,18]. The study suggests that the presence of two phenyl rings in curcumin is likely the reason for the improved oxidation onset temperature (OOT) in the CO+curcumin lubricant.

Lubricants are generally formulated to meet specific performance requirements, and trade-offs are often made between different properties to achieve the best performance in a particular application. The selection of a lubricant should be based on a clear understanding of the demands of the application and a balance between different properties to ensure optimal performance. To do this, the different alternatives must be evaluated according to multiple criteria before making a decision. In this study, and as a preliminary step for the selection of some of the additives analyzed for a specific application, an example of a decision matrix for the selection of an additive in castor oil is shown.

A decision matrix is an objective decision method that is used to help decide which option is best using various decision criteria. To do this, each of the alternatives in each criterion is indicated according to its characteristics, and all the scores received are subsequently added. Thus, the option that has obtained the highest score is the best alternative according to the decision factors used.

The first step is to define the objective of the decision matrix: in this case, which additive is best to use in castor oil to improve its performance. Next is to identify the alternatives: in this study none, curcumin, eugenol, 1,3-Diphenyl-2-propanone, 1,3-Diphenyl-2-propenone or 1,3-Diphenyl-1,3-propanedione as an additive. The third step is to stabilize the decision criteria: for the present example, the suggested properties or characteristics to evaluate are:

- Viscosity: Essential for the formation of the lubricant film and affects the resistance to flow of the lubricant.

- Friction Coefficient: Indicates the efficiency of the lubricant to reduce friction between surfaces.

- Wear Rate: A key indicator of the durability and useful life of the mechanical system.

- Wear Mechanism: Helps understand how and why wear occurs, which can influence lubricant selection.

- Oxidation Onset Temperature (OOT): Affects the chemical stability and useful life of the lubricant.

Likewise, once the different decision factors have been defined, they must be weighted according to the importance of each one. A weighting of 1 to 5 is given to each criterion based on its relevance, with 1 meaning not important and 5 meaning very important. The order of importance of the properties of a lubricant may vary depending on the specific application and operating conditions. In this study, to use an example, we considered the particular application for oil splash lubrication used for helical, spur, and bevel gearboxes, where low friction, good oxidation resistance, and low wear are required; the order of importance is assigned as follows:

- Viscosity = 1

- Friction coefficient = 5

- Wear rate = 3

- Wear mechanism = 4

- Oxidation Onset Temperature (OOT) = 5

A score of 1 was assigned to the additive with which a minimum desired value was observed and 5 to the additive with the maximum desired value. In the case of quantitative parameters, the highest score of 5 was given to the maximum value found in those parameters in which a higher value is desired (viscosity and OOT), or the minimum value found in which a lower value is desired (friction coefficient and wear rate) (see Table 3). In the case of the wear mechanism, being a qualitative parameter, where less superficial damage to the elements is desired, the assignment proposed by K.G. Budinski and S.T. Budinski (2015) [36] was used as a reference. Nevertheless, for this study, it was considered the lowest damage had the highest score of 5, and the highest damage had the lowest score of 1. Table 3 summarizes the score for each decision criterion.

Table 3.

Score of each decision criterion for the suitability of additives in CO.

Finally, each score is multiplied by the weighting of each criterion, and all the scores are added to find out which is the best alternative. Therefore, the best option is the one that has achieved the highest score. Table 4 shows the scores obtained, where each color refers to the level of criticality based on the improvement of the criteria. In the example presented, the highest total score was found with eugenol as an additive, followed by curcumin and 1,3-Diphenyl-2-propanone. This suggests that these additives have a better synergy of properties to improve the performance of castor oil as a completely environmentally friendly lubricant.

Table 4.

Scores of the decision matrix for the suitability of additives in CO.

5. Conclusions

The present study investigated five organic compounds (curcumin, eugenol, 1,3-Diphenyl-2-propanone, 1,3-Diphenyl-2-propenone, and 1,3-Diphenyl-1,3-propanedione) as potential lubricant additives in castor oil. The research included analyzing the physical properties such as the density and viscosity of the formulated lubricants, conducting friction and wear tests following the standardized ASTM G99 method, and determining the oxidation onset temperature of lubricants. The main results can be summarized as follows:

- All the additives, except for the curcumin at 100 °C, resulted in lower density compared to the castor oil (CO), whereas the additives increased the viscosity of CO, with curcumin showing an up to 20% increase at 40 °C.

- CO+curcumin and CO+eugenol produced the thickest lubricant films and the highest λ compared to the neat CO.

- Eugenol and 1,3-Diphenyl-2-propanone reduced the friction coefficient of CO significantly, while curcumin and other additives slightly increased it.

- Curcumin greatly improved wear track width and wear rate. However, eugenol, 1,3-Diphenyl-2-propanone, 1,3-Diphenyl-2-propenone, and 1,3-Diphenyl-1,3-propanedione notably enhanced the wear mechanism.

- All the studied additives, except for 1,3-Diphenyl-1,3-propanedione, increased the oxidation onset temperature (OOT), improving the oxidative stability of the CO.

- Through a decision matrix, it was observed that in situations where it is essential to have reduced friction, strong oxidation resistance, and minimal wear, the most effective additive for CO is eugenol, followed by curcumin, and then 1,3-Diphenyl-2-propanone.

Overall, in this study, all the additives improved to some extent one or more properties of castor oil. This means that, depending on the application, a particular additive could be used or a synergy between several of these additives could be sought. The use and study of these biodegradable additives provide important points in the emerging issues of tribology and lubrication topics on the formulation of biodegradable lubricants to improve efficiency without compromising sustainability.

Author Contributions

Conceptualization, M.T.H.-S., J.E.B. and K.J.M.; formal analysis, L.D.A.-C. and J.S.G.-M.; investigation, M.T.H.-S., L.D.A.-C. and J.S.G.-M.; supervision, J.E.B. and K.J.M.; validation, J.E.B. and K.J.M.; writing—original draft, M.T.H.-S.; writing—review and editing, M.T.H.-S. and K.J.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Tecnológico Nacional de México (TecNM), grant numbers 13781.22-P (2022) and 16722.23-P (2023).

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Acknowledgments

The authors acknowledge Tecnológico Nacional de México (TecNM) and Universidad de Guanajuato for their support.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Shah, R.; Woydt, M.; Zhang, S. The Economic and Environmental Significance of Sustainable Lubricants. Lubricants 2021, 9, 21. [Google Scholar] [CrossRef]

- Granja, V.; Jogesh, K.; Taha-Tijerina, J.; Higgs, C.F., III. Tribological Properties of h-BN, Ag and MgO Nanostructures as Lubricant Additives in Vegetable Oils. Lubricants 2024, 12, 66. [Google Scholar] [CrossRef]

- Freschi, M.; Paniz, A.; Cerqueni, E.; Colella, G.; Dotelli, G. The Twelve Principles of Green Tribology: Studies, Research, and Case Studies—A Brief Anthology. Lubricants 2022, 10, 129. [Google Scholar] [CrossRef]

- Moreno, K.J.; Hernández-Sierra, M.T.; Báez, J.E.; Rodríguez-deLeón, E.; Aguilera-Camacho, L.D.; García-Miranda, J.S. On the Tribological and Oxidation Study of Xanthophylls as Natural Additives in Castor Oil for Green Lubrication. Materials 2021, 14, 5431. [Google Scholar] [CrossRef]

- Hernández-Sierra, M.T.; Báez, J.E.; Aguilera-Camacho, L.D.; García-Miranda, J.S.; Moreno, K.J. Friction and wear improvement by using Curcumin as a natural additive in green lubricants. Proc. Inst. Mech. Eng. Part J 2023, 237, 578–588. [Google Scholar] [CrossRef]

- Liu, Z.; Liang, Z.; Li, K.; Huang, T.; Ma, J.; Wen, G. Degradation of Micropollutants and Formation of Oxidation By-Products during the Ozone/Peroxymonosulfate System: A Critical Review. Water 2021, 13, 3126. [Google Scholar] [CrossRef]

- Wu, T. Byproduct formation in heterogeneous catalytic ozonation processes. Environ. Sci. Adv. 2023, 2, 558–569. [Google Scholar] [CrossRef]

- Giakoumis, E.G. Analysis of 22 vegetable oils’ physico-chemical properties and fatty acid composition on a statistical basis, and correlation with the degree of unsaturation. Renew. Energy 2018, 126, 403–419. [Google Scholar] [CrossRef]

- Martín-Alfonso, M.A.; Rubio-Valle, J.F.; Hinestroza, J.P.; Martín-Alfonso, J.E.; Franco, J.M. Environmentally friendly tailor-made oleo-dispersions of electrospun cellulose acetate propionate nanostructures in castor oil for lubricant applications. Nano Mater. Sci. 2024. [Google Scholar] [CrossRef]

- Mubofu, E.B. Castor oil as a potential renewable resource for the production of functional materials. Sustain. Chem. Process. 2016, 4, 11. [Google Scholar] [CrossRef]

- Dubyne, D. Castor Bean. Available online: https://www.oilseedcrops.org/castor-bean/ (accessed on 1 July 2024).

- Gupta, R.N.; Harsha, A. Antiwear and extreme pressure performance of castor oil with nano-additives. Proc. Inst. Mech. Eng. Part J 2018, 232, 1055–1067. [Google Scholar] [CrossRef]

- Qian, S.; Wang, H.; Huang, C.; Zhao, Y. Experimental investigation on the tribological properties of modified carbon nanotubes as the additive in castor oil. Ind. Lubr. Tribol. 2018, 70, 499–505. [Google Scholar] [CrossRef]

- Singh, Y.; Chaudhary, V.; Pal, V. Friction and wear characteristics of the castor oil with TiO2 as an additive. Mater. Today Proc. 2020, 26, 2972–2976. [Google Scholar] [CrossRef]

- Ouyang, T.; Lei, W.; Tang, W.; Shen, Y.; Mo, C. Experimental investigation of the effect of IF-WS2 as an additive in castor oil on tribological property. Wear 2021, 486, 204070. [Google Scholar] [CrossRef]

- Adithyan, K.S.; Edla, S.; Thampi, A.D.; Kumar, S.A.; Sasidharan, B.; Arif, M.M.; Rani, S. Experimental investigation on the effects of clove oil as an anti-oxidant additive on the lubricant properties of transesterified rice bran oil. Mater. Today Proc. 2023, 72, 2892–2896. [Google Scholar] [CrossRef]

- Al-Shibli, F.S.; Al-Tamemi, R.K.; Al-Assdi, K.A. Synthesis of the Antioxidant Compounds from the Eugenol to the Lubricating Oils. J. Kufa Chem. Sci. 2022, 2, 501–518. [Google Scholar] [CrossRef]

- Sneha, E.; Karthik, G.V.S.; Thampi, A.D.; Krishna, A.; Revikumar, A.; Rani, S. Experimental and quantum chemical investigation of bio-fuels/lubricants for its oxidative stability. J. Mol. Liq. 2021, 340, 117292. [Google Scholar] [CrossRef]

- Edla, S.; Thampi, A.D.; Pillai, A.B.; Sivan, V.V.; Arif, M.M.; Sasidharan, B. Formulation of rice bran oil-based green cutting fluid with holy basil oil and clove oil as bio-additives. Biomass Convers. Biorefin. 2022, 13, 16877–16886. [Google Scholar] [CrossRef]

- Gamayel, A.; Mohammed, M.; Al-Zubaidi, S.; Yusuf, E. Characterization and physicochemical properties of biofuel from mixed crude jatropha oil and clove oil. Sys. Rev. Pharm. 2020, 11, 910–916. [Google Scholar]

- ASTM G99; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus, Annual Book of Standards. ASTM International: West Conshohocken, PA, USA, 2017.

- Pirro, D.M.; Webster, M.; Daschner, E. Lubrication Fundamentals, 3rd ed.; Taylor & Francis Group: New York, NY, USA, 2016; pp. 35–67. [Google Scholar]

- ASTM D 891; Standard Test Methods for Specific Gravity, Apparent, of Liquid Industrial Chemicals. ASTM International: West Conshohocken, PA, USA, 1993.

- ASTM D 445; Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (the Calculation of Dynamic Viscosity). ASTM International: West Conshohocken, PA, USA, 2024.

- Hamrock, B.J.; Dowson, D. Isothermal elastohydrodynamic lubrication of point contacts: Part III—Fully flooded results. J Lubr. Technol. 1977, 99, 264–275. [Google Scholar] [CrossRef]

- Hernández-Sierra, M.T.; Bravo-Sánchez, M.G.; Báez, J.E.; Aguilera-Camacho, L.D.; García-Miranda, J.S.; Moreno, K.J. Improvement effect of green lubricants on the tribological and mechanical performance of 4140 steel. Appl. Sci. 2019, 9, 4896. [Google Scholar] [CrossRef]

- ASTM E 2009; Standard Test Method for Oxidation Onset Temperature of Hydrocarbons by Differential Scanning Calorimetry. ASTM International: West Conshohocken, PA, USA, 2008.

- Fugita, R.A.; Gálico, D.A.; Guerra, R.B.; Perpétuo, G.L.; Treu-Filho, O.; Galhiane, M.S.; Mendes, R.A.; Bannach, G. Thermal behaviour of curcumin. Braz. J. Therm. Anal. 2012, 1, 19–23. [Google Scholar]

- Pramod, K.; Suneesh, C.V.; Shanavas, S.; Ansari, S.H.; Ali, J. Unveiling the compatibility of eugenol with formulation excipients by systematic drug-excipient compatibility studies. J. Anal. Sci. Technol. 2015, 6, 34. [Google Scholar] [CrossRef]

- de Sousa, A.S.; Silva, R.; Tay, F.H.; Simplício, A.L.; Kazarian, S.G.; Duarte, C.M. Solubility enhancement of trans-chalcone using lipid carriers and supercritical CO2 processing. J. Supercrit. Fluids. 2009, 48, 120–125. [Google Scholar] [CrossRef]

- Horozić, E.; Suljagić, J.; Husejnagić, D.; Hasić, N.; Bratovčić, A. Synthesis, characterization and in vitro biological evaluation of the Schiff base derived from benzidine and 1,3-diphenyl-1,3-propanedione. J. Eng. Process. Manag. 2019, 11, 112–116. [Google Scholar] [CrossRef]

- Krzyzak, Z.; Pawlus, P. ‘Zero-wear’ of piston skirt surface topography. Wear 2006, 260, 554–561. [Google Scholar] [CrossRef]

- Kim, I.J. (Ed.) Wear Behaviours and Mechanisms. In Engineering Metrology for Pedestrian Falls Prevention and Protection; Springer Nature: Cham, Switzerland, 2022; pp. 153–191. [Google Scholar] [CrossRef]

- Jabbarzadeh, A. Tribological Properties of Interfacial Molecular Films. In Encyclopedia of Interfacial Chemistry; Wandelt, K., Ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2018; pp. 864–874. [Google Scholar]

- Cyriac, F.; Akchurin, A. Thin Film Lubrication, Lubricants and Additives. In Tribology in Materials and Applications; Katiyar, J.K., Ramkumar, P., Rao, T.V.V.L.N., Davim, J.P., Eds.; Springer Nature: Geneva, Switzerland, 2020; pp. 33–76. [Google Scholar]

- Budinski, K.G.; Budinski, S.T. Interpretation of galling tests. Wear 2015, 332, 1185–1192. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).