3.1. Theoretical Overview of the Research Model

The performance and longevity of an internal combustion engine are heavily reliant on the efficacy of the lubricating oil. Among the critical parameters influencing its lubricating performance, viscosity stands out prominently. While lowering viscosity can diminish frictional losses and enhance fuel efficiency, it can also precipitate issues like heightened wear on engine components and accelerated degradation of the lubricant. The Navier–Stokes equations are fundamental principles governing fluid dynamics and are of pivotal significance in understanding the flow characteristics of lubricating oil among engine components and in investigating its transport. The general expression of the Navier–Stokes equation is:

where

is the density of the fluid,

u is the velocity field,

p is the pressure, the constant

is the dynamic viscosity, and

f is the external force on the fluid per unit volume (if only gravity is considered,

f =

g).

In internal combustion engines, the main role of lubricating oil is to form an oil film between the piston group and the cylinder liner to reduce friction and wear. According to the viscosity term in the Navier–Stokes equation, a reduction in viscosity will weaken the viscous resistance, resulting in a reduction in the thickness of the oil film. Reduced film thickness may not effectively isolate moving parts, increasing the risk of direct contact and wear.

In the actual working conditions of internal combustion engines, operations typically occur under high-speed, high-temperature, and high-pressure settings, resulting in a highly intricate flow pattern of the lubricating oil. Due to the significant disparity between the length of the piston skirt and the clearance width between the piston and cylinder wall, the transport mechanism of lubricating oil at the interface between the cylinder liner and piston can be simplified into two primary physical models [

23]. Firstly, the interplay between viscous and inertial forces governs the flow, predominantly describing the shear flow induced by piston movement, known as Couette flow. Secondly, pressure gradient dominance characterizes the flow under pressure-driven conditions, typifying Poiseuille flow, which is a typical laminar flow.

Assuming laminar flow of the lubricating oil between the piston assembly and the cylinder liner, the Navier–Stokes equation can be approximated and suitably simplified by neglecting the nonlinear and inertial terms, resulting in the Reynolds equation. To systematically investigate the impact of inertia and viscous forces in the oil film lubrication process, a set of dimensionless numbers can be employed to delineate the influence of different forces [

24], with the Reynolds number serving to characterize the relative significance of inertia and viscous forces.

where

h represents the gap width between the piston skirt and the cylinder liner wall,

l denotes the relative motion length between the piston and the cylinder liner, and

η signifies the characteristic dynamic viscosity.

From the expression of the Reynolds number, it is evident that the Reynolds number escalates with an increase in the characteristic velocity, indicating a proportional rise in inertial force with velocity augmentation. Conversely, the Reynolds number dwindles as the characteristic dynamic viscosity rises, signifying a decline in the influence of viscous forces as dynamic viscosity increases. The interplay between inertial and viscous forces profoundly impacts the formation mechanism and stability of the oil film in low-viscosity lubricants. In such lubricants, the lower viscosity implies a potentially more pronounced role of inertial forces in the flow dynamics. As velocity increases, inertial forces induce alterations in oil acceleration, thereby influencing the formation and stability of the oil film. Furthermore, the lower viscosity of low-viscosity lubricants renders them more prone to discharge during Poiseuille flow, posing challenges to the establishment and sustenance of the oil film.

With the reciprocating motion of the piston, both the piston ring and the piston ring bank induce scratching and redistribution of the oil film, among other intricate physical phenomena. Variations in the topology of the piston ring and the physical morphology of the ring bank lead to fluctuating oil film patterns around them, thereby amplifying the complexity of the lubrication scenario [

25]. Moreover, during the operation of the internal combustion engine, inadequate lubricating oil supply to the piston skirt can lead to the formation of a very thin oil film in select areas of the skirt [

26,

27].

The intricacies of internal combustion engine lubrication extend beyond the challenge of reducing lubricating oil viscosity; they also encompass the heightened complexity of free surface lubrication [

28]. These challenges entail multiphase flow, surface tension effects, and substantial fluid structure deformations, particularly evident in the contact zone between the piston ring and cylinder liner. Interactions between gas and lubricating oil lead to accumulation or separation of the lubricant in these regions, significantly influencing the state of the oil film and the engine’s load-bearing capacity. Classical lubrication theory encounters numerous numerical hurdles when addressing these intricate free surface phenomena, making accurate predictions challenging.

In conclusion, analysis based on the Navier–Stokes equations underscores the significant impact of reducing lubricating oil viscosity on the transport and combustion processes within internal combustion engines. While low-viscosity lubricants can enhance fuel economy and delivery efficiency, they may also result in diminished film thickness, increased wear, incomplete combustion, and heightened emissions. These factors can contribute to accelerated aging and potential failure of the reprocessing system. In the pursuit of low-viscosity lubricating oil technology, a comprehensive engineering approach is essential. This involves assessing the reliability of low-viscosity lubricant application across the entire vehicle engine, encompassing macro-verification against regulatory emission limits and micro-level analysis of post-treatment system performance.

3.2. Actual Road-Testing Environment

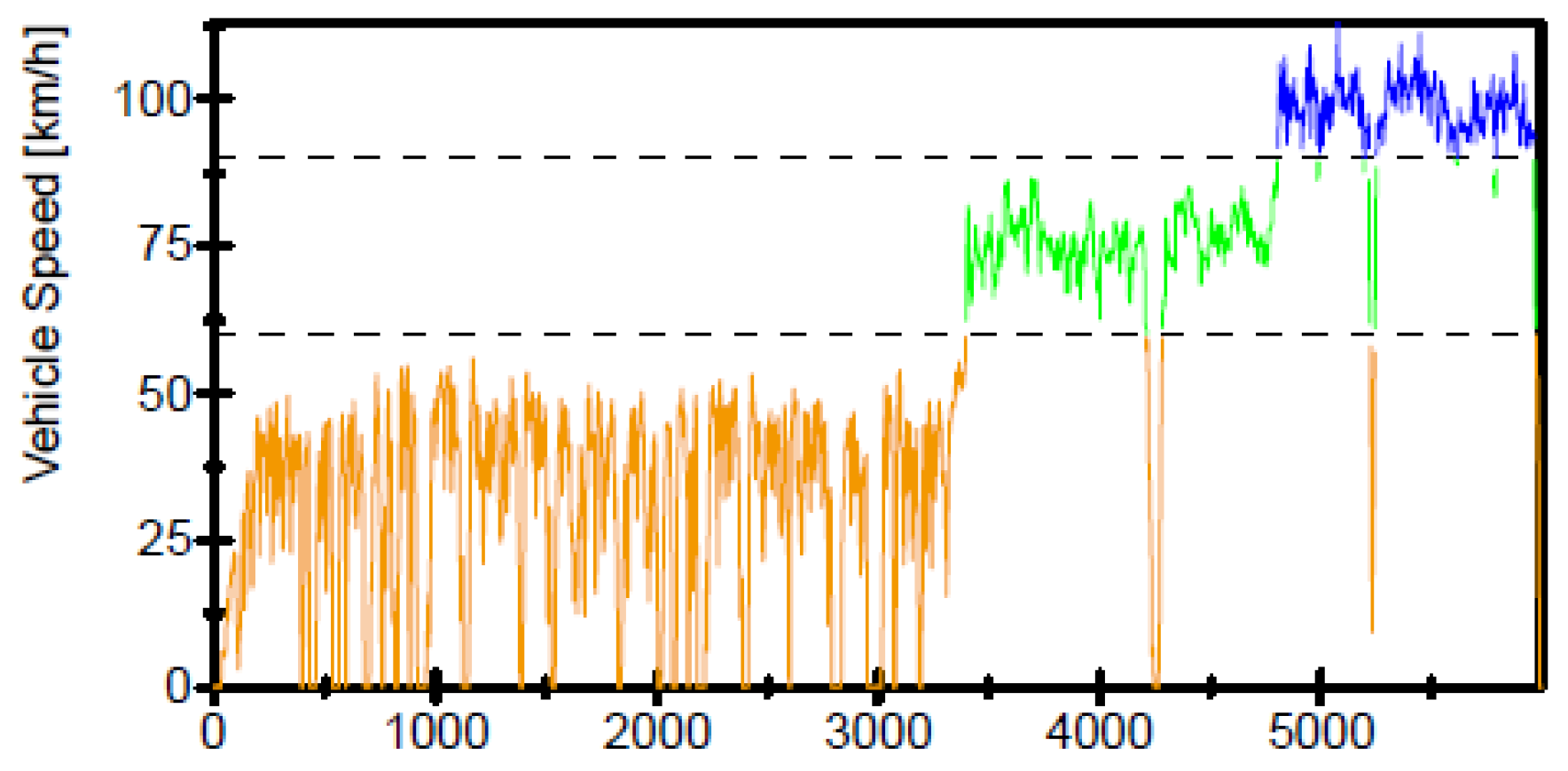

The 120,000 km endurance test covered four challenging environments. During the low-temperature endurance test, the lowest test temperature recorded was −38 °C. In the high-humidity endurance test, the maximum ambient relative humidity recorded at the test location was 99.2%. The high-temperature endurance test reached a maximum test temperature of 48 °C, and during the high-altitude endurance test, the highest altitude reached was 4731 m. The calculated results of the environmental data for each phase are shown in

Table 6, and the temperature variation throughout the entire cycle is illustrated in

Figure 4. During the 120,000 km test period, the maximum temperature difference reached 86 °C, the maximum absolute humidity difference was 20.1 g/m

3, and the maximum altitude difference was 4741 m. The actual road-testing was conducted under representative climatic conditions in China, providing important data support for the formation of the test vehicle sample and valuable reference for related testing within the industry.

The subsequent 80,000 km of testing took place in Suzhou, Jiangsu Province, China. The city has a mild climate, with an average annual temperature of 18.1 °C in the urban area. Over the entire durability testing period (200,000 km), the real-road durability testing for the six vehicles lasted for one year and ten months.

3.3. Whole-Vehicle Emission Results

This study aims to evaluate the impact of different oil formulations on the overall vehicle emission performance under varying endurance conditions. As China’s new attempt in controlling automotive emissions, the WLTC test standard sets higher emission requirements and simulates real driving conditions more accurately by including four different speed zones and driving characteristics from suburban to urban areas. In this study, vehicles #1 and #4 were selected as the research subjects, and WLTC tests were conducted at three endurance mileages: 0 km, 120,000 km, and 210,000 km. As shown in

Figure 5, the emission results of both vehicles at different endurance mileages are well below the corresponding emission limits specified in CN6b. Furthermore, there is no significant increase in emissions after endurance testing compared to the initial values. For vehicle #1, the emission variation rate of all gas pollutants, except N

2O, is less than 20% after endurance testing, while for vehicle #4, the emission variation rate of all gas pollutants, except NO

x, is less than 25%. Although vehicle #4 shows a relatively large variation rate in NO

x emissions after endurance testing due to its initially low level of 9.65 mg/km in WLTC at 0 km, the overall value remains at a low level.

The results demonstrate that low-viscosity lubricating oils play a significant role in engine protection and emission control over long endurance periods, showcasing their suitability for hybrid platforms. These test results are of great significance for assessing the overall vehicle emission performance under long-term use with different oil formulations and provide valuable references for the application of hybrid platforms.

The viscosity of a lubricating oil has a complex and significant impact on the overall vehicle performance in WLTC testing. Therefore, for the lubricating oil selection, it is necessary to consider both the microscopic lubrication effect and the macroscopic overall vehicle performance to ensure the best comprehensive performance of the vehicle in WLTC testing. Some studies [

29,

30,

31] have shown that comparisons of overall vehicle emission results can be made for turbocharged engines with the same displacement.

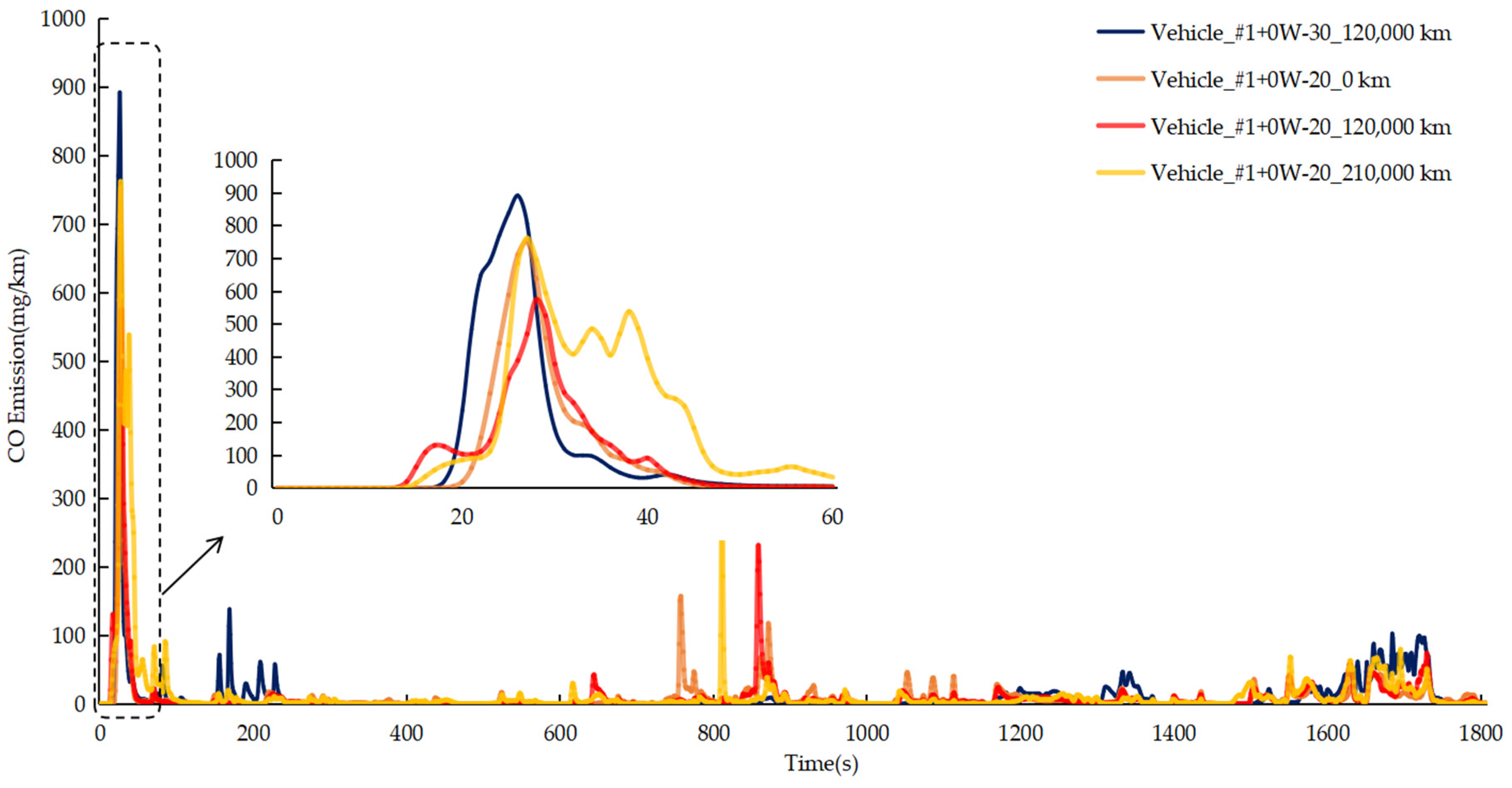

This study compared the overall vehicle WLTC emission results of vehicle #1 using a lubricating oil with relatively high viscosity (0W-30). As shown in

Figure 6, the emission results indicate that the peak CO emission during the cold start phase differs by approximately 18.5% between vehicles using different viscosity oils, while the average CO emission in the first two minutes of cold start is reduced by approximately 31.1% when using low-viscosity lubricating oil. Low-viscosity engine lubricating oil reduces internal friction during engine startup, ensuring lower engine operating resistance, shortening the engine’s warm-up time, and allowing the engine to reach the optimal operating range more quickly. Combined with the assistance of the BSG motor, the tested vehicles in this study maintain lower CO emissions during the cold start phase of WLTC. Additionally, as shown in

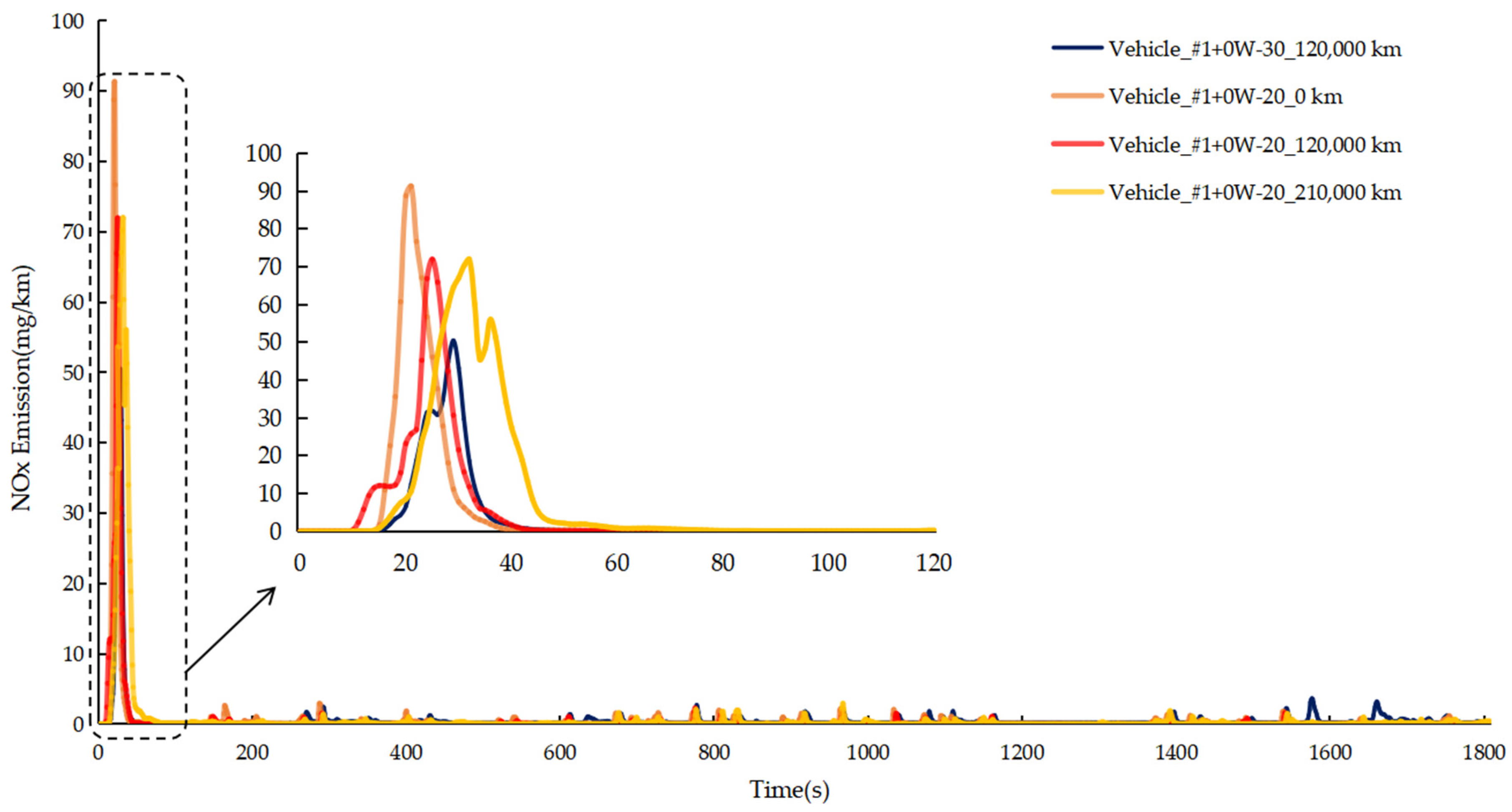

Figure 7, vehicles using low-viscosity lubricating oil exhibit varying degrees of increase in NO

x during the cold start phase of WLTC compared to high-viscosity oils. However, from the perspective of the complete WLTC testing cycle, this level of increase is within an acceptable range.

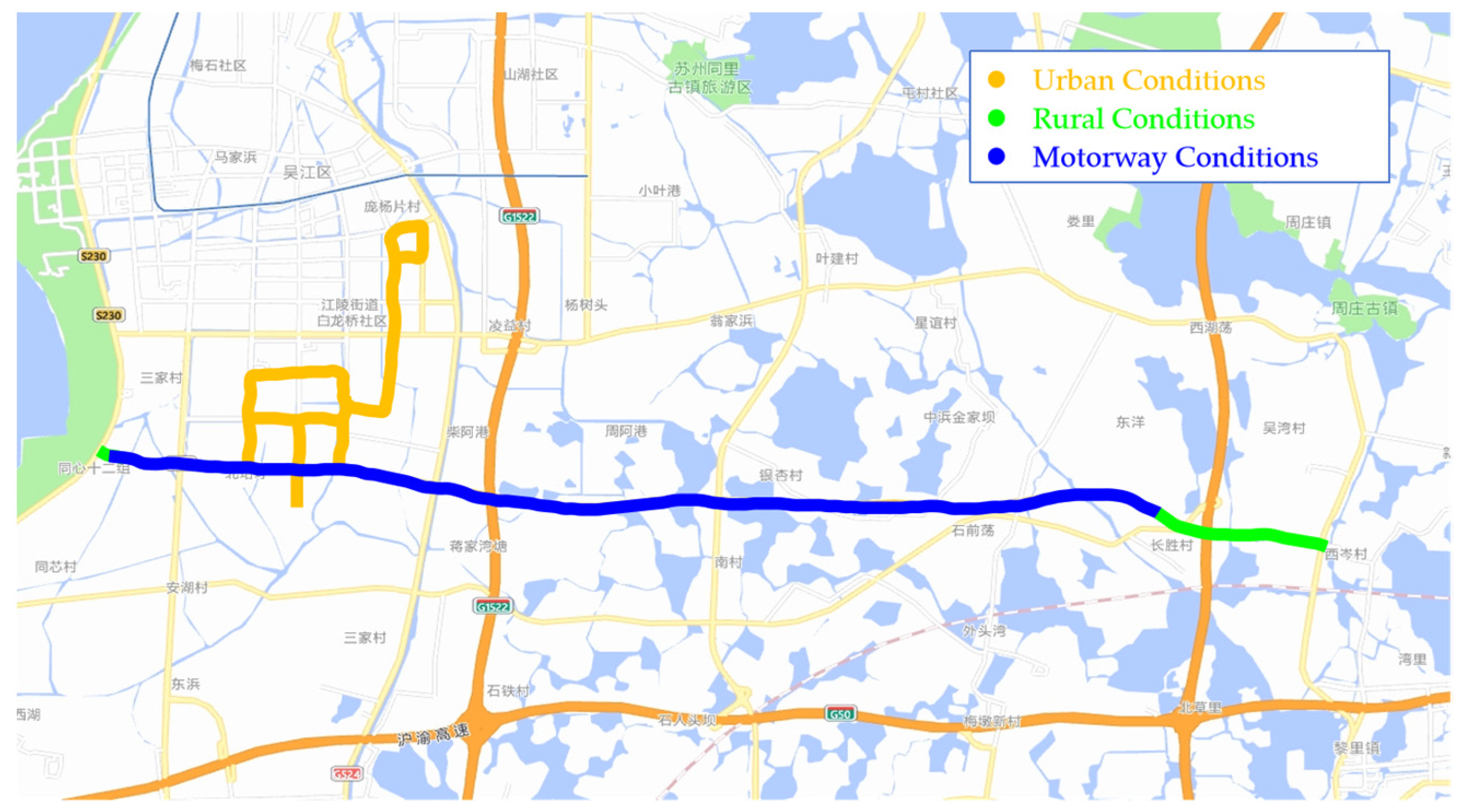

In addition, this study also conducted RDE testing on vehicle #1. RDE testing has now become a global trend and direction in automotive emission regulations. Regions such as the European Union and the United States have already incorporated it into regulatory requirements. In China, the application scope, timing, and calculation methods of RDE testing have been specified in the China Stage 6 Light-duty Vehicle Pollutant Emission Standard. Unlike laboratory-based drum tests, RDE testing emphasizes data collection from real-world scenarios, enhancing the authenticity and reliability of environmental simulation and facilitating to better evaluate a vehicle’s real-world environmental performance. In the study, the RDE test route was carried out near a certain urban area in Suzhou City, China. The specific route is shown in

Figure 8, and the test information is shown in

Table 7 and

Figure 9 below.

Based on the CN6b emission limit requirements and their corresponding conformity factors, the results shown in

Figure 10 indicate that after 210,000 km of endurance testing, the actual pollutant emissions from the tested vehicles comply with the limit requirements for both urban and total driving cycles. This demonstrates that low-viscosity lubricating oil exhibits good compatibility and reliability in terms of hybrid engine technology and overall vehicle emissions performance during long-distance on-road testing. It should be noted that the emission results covering cold-start requirements are similar to those for hot start, further confirming the excellent performance of low-viscosity lubricating oil under various operating conditions. From a macro perspective, these test results provide strong support for the application of low-viscosity lubricating oil in the automotive industry. Although further research and testing are needed, these results indicate that the use of low-viscosity lubricating oil can effectively reduce vehicle emissions without adversely affecting hybrid powertrain technology and aftertreatment system performance. Moreover, considering future stricter regulatory limits and lower conformity factors, the application of low-viscosity lubricating oil becomes necessary.

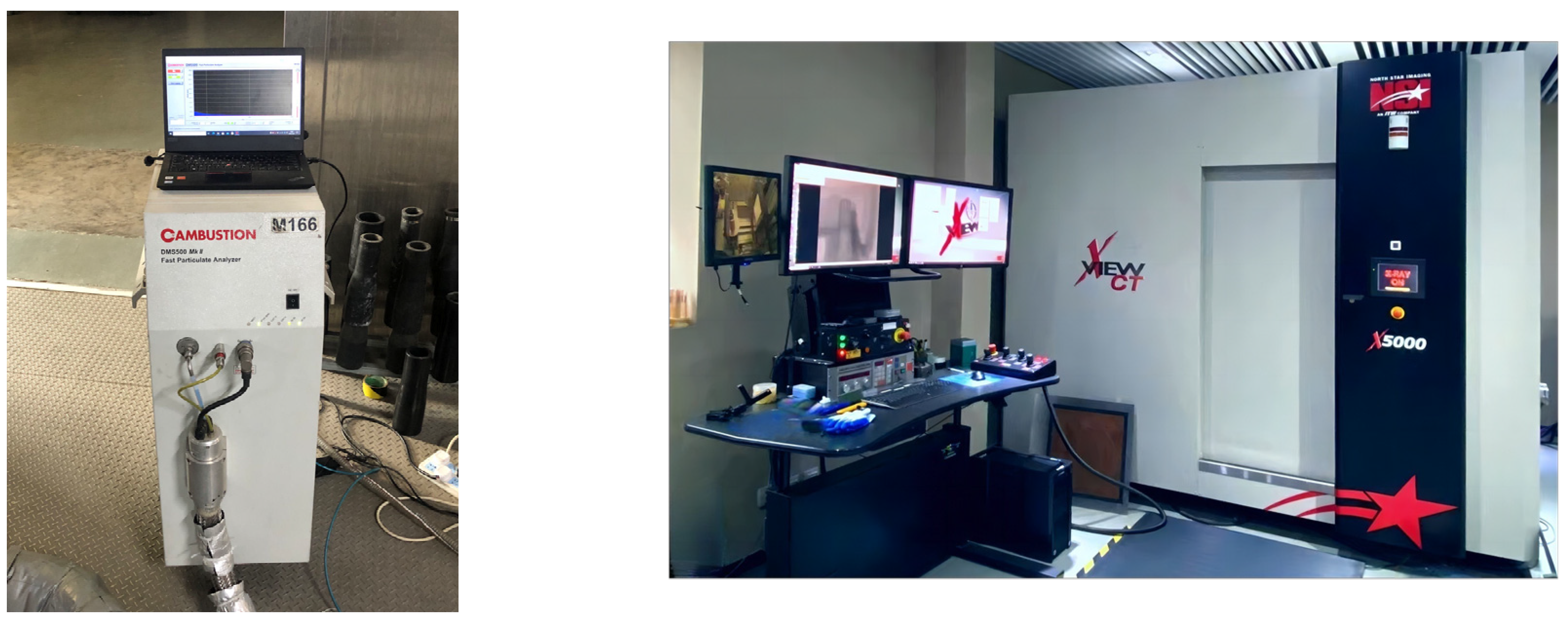

3.4. TWC Performance Test Results

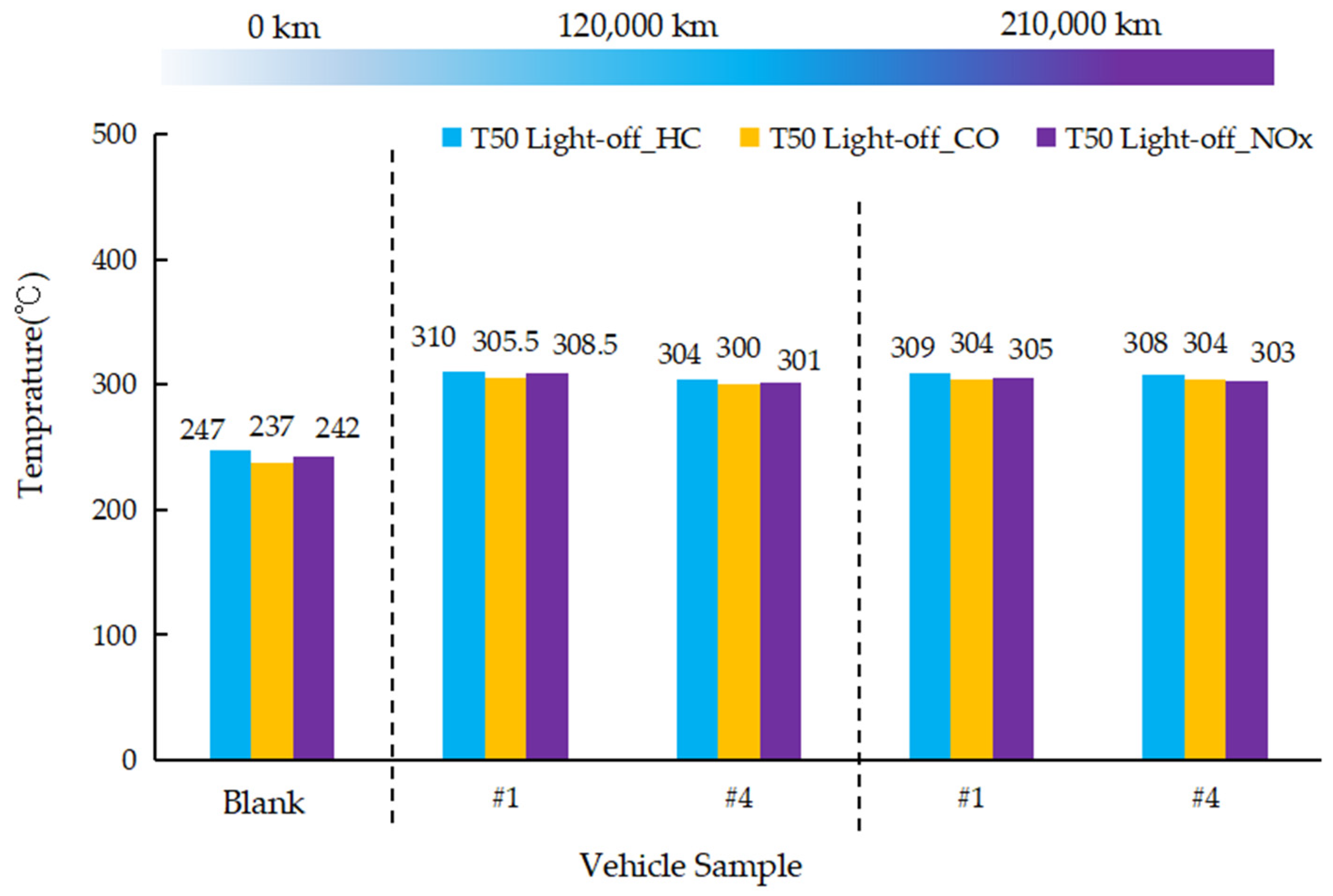

Based on a 4.8 L V 8-cylinder engine test bench, this study conducted light-off temperature tests and oxygen storage capacity tests on aged TWC at different mileage intervals. The light-off temperature test is used to study the substrate temperature index (T50 Light-off) at which the conversion efficiency of different gas pollutants in the TWC reaches 50%, thus characterizing the filtration performance of the TWC. The ignition temperature directly determines whether the catalytic converter can rapidly and effectively transform harmful gases under actual operating conditions, achieving the anticipated reduction in emissions. This characterizes the particulate filtration performance of the TWC.

Figure 11 illustrates the light-off temperature test results of the TWC for the tested vehicles at the 120,000 km endurance mileage. As shown in

Figure 11, comparing the results of vehicles #2 and #3, it can be observed that different vehicles of the same model using the same lubricating oil exhibit good consistency under the same endurance mileage. The differences in light-off temperature for the three gases between different vehicles are only 1.30%, 1.65%, and 1.61%. This conclusion is further confirmed in the comparison of results for vehicles #5 and #6.

Based on the above conclusion, the average light-off temperature results for vehicles #2 and #3, as well as #5 and #6, can be calculated, and these results serve as the equivalent results for vehicles #1 and #4 at the 120,000 km endurance mileage.

Figure 12 presents the light-off temperature performance results of the TWC for vehicles #1 and #4 at different levels of aging. The results indicate that the fresh samples with zero kilometers of aging maintain the best performance and have the lowest light-off temperature.

At the 120,000 km endurance mileage, the equivalent results for vehicles #1 and #4 indicate that compared to fresh substrates, the T50 light-off temperatures of the samples decreased by approximately 60 °C. As mileage accumulates, the catalyst inside the TWC is affected by ash accumulation, which can block the catalyst’s gaps, reduce the contact area between the catalyst and reactants, lower the catalyst’s oxidation efficiency, and thus impact the TWC’s performance. However, after 120,000 km of aging, the light-off temperatures of the TWC only decreased by around 60 °C, which is a relatively small and acceptable temperature reduction.

At the 210,000 km endurance mileage, the samples aged for longer mileage did not show a significant deterioration in light-off temperature characteristics compared to the samples at the 120,000 km mileage. In severe environments, including the engine, vehicles face more challenging conditions, especially frequent cold starts in extremely low temperatures. Using low-viscosity lubricating oil may increase the risk of engine component wear, leading to more ash and impurities entering the TWC substrate, which can affect its performance or reduce its lifespan. However, the experimental results demonstrate that the increase in endurance mileage did not further deteriorate the TWC’s performance. Low-viscosity lubricating oil can effectively protect the engine in long-distance driving, and its impact on TWC performance can be considered negligible.

Additionally, at the 120,000 km mileage, the samples aged using oil A showed a more pronounced increase in light-off temperature compared to the samples using oil B. However, after longer mileage endurance aging, there was no significant difference in performance between the two. (The cause of this phenomenon may be attributed to the formulation difference in oil A, which deviates from the full calcium (Ca2+) formulation present in oil B.) Different from the fully calcium-based formulation in oil B, oil A partially replaced part of calcium with magnesium ions. Due to the stronger oxidative properties of magnesium ions, the combustion products of magnesium ions in the consumed ash during endurance have stable properties and are less prone to further oxidation, thus exacerbating the negative impact of ash accumulation on TWC performance. Moreover, using partial magnesium ion substitution for calcium ions does not significantly affect or alter the filtration performance of the TWC for HC, CO, and NOx.

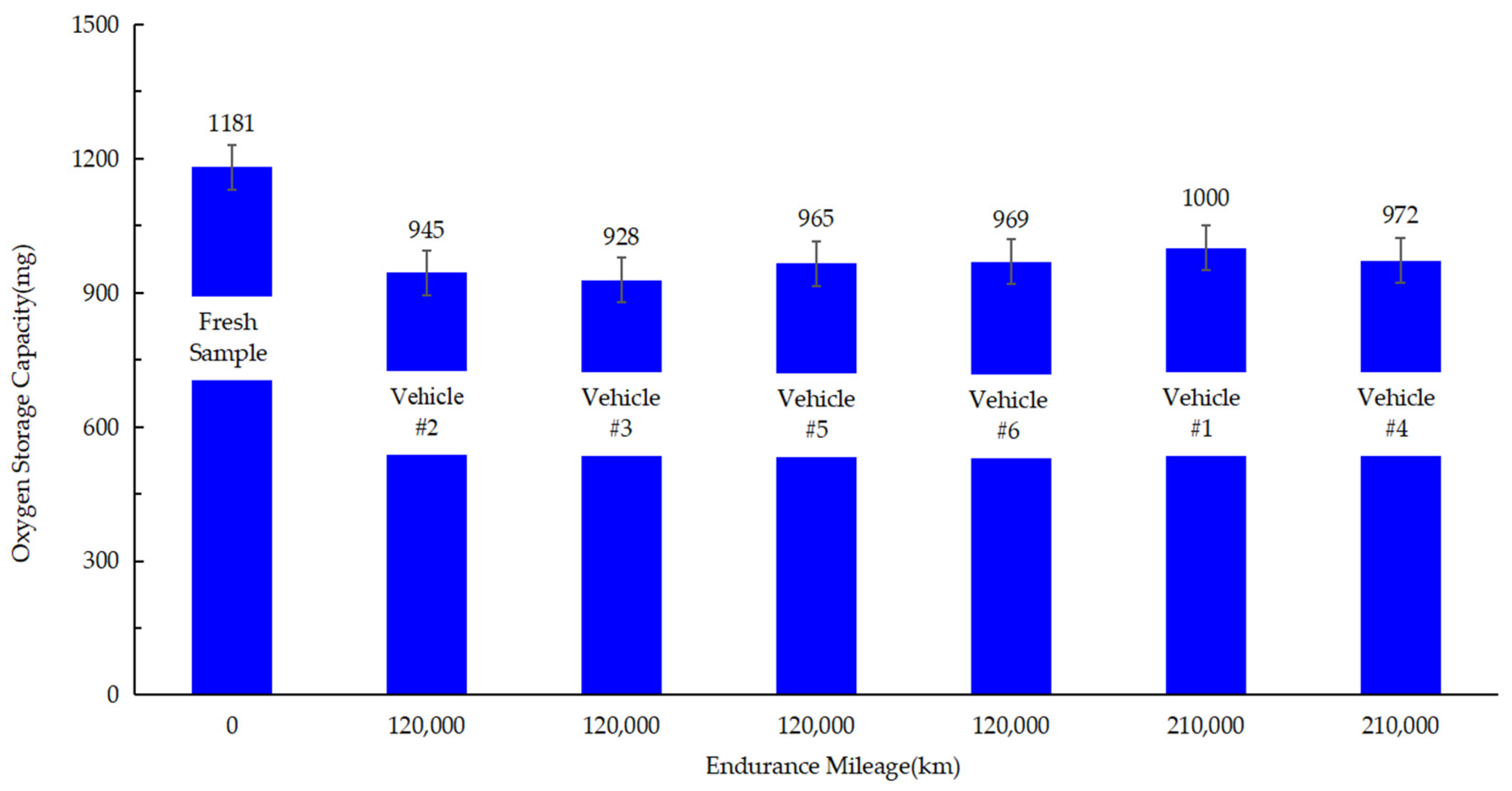

The results of the oxygen storage capacity (OSC) tests for the aged TWC samples are shown in

Figure 13, with the fresh sample at zero kilometers used as the control group. Compared to fresh samples (zero km), the accumulated actual on-road durability mileage leads to varying degrees of reduction in the oxygen storage capacity (oxygen storage capacity, OSC) of the aged catalytic converter, and the carriers’ OSC experiences an approximate 19% degradation before and after the endurance testing for different vehicles. Compared to the fresh samples, the accumulated real-world endurance mileage caused varying degrees of thermal aging and resulted in a reduction in the samples’ oxygen storage capacity. Without considering test fluctuations, there was an average degradation of approximately 18.44% in OSC before and after endurance. However, for the 210,000 km endurance mileage, this degree of decline is entirely acceptable. There was no significant difference in OSC performance between the samples at 120,000 and 210,000 km of endurance. Increasing the endurance mileage did not lead to sustained degradation in the samples’ oxygen storage capacity.

The oxygen storage capacity (OSC) of the Three-Way Catalyst (TWC) is achieved through oxygen vacancies on the catalyst’s surface. During endurance testing, as the engine operates, the high temperatures in the exhaust gases conduct to the TWC, exposing it to prolonged periods of elevated temperatures. This high-temperature environment can result in physical degradation of the OSC material within the catalyst, such as fracture and grain growth, disrupting the continuity of the OSC material and reducing the number of oxygen vacancies, leading to a decrease in OSC. Furthermore, harmful components and additives in the lubricating oil may form high-temperature deposits, potentially reacting with or blocking the catalyst, altering its structure. This can further reduce the number of oxygen vacancies or hinder their formation and availability, directly impeding the catalyst’s ability to effectively adsorb and release oxygen.

Catalyst thermal aging is not an indefinitely continuous process; when the catalyst reaches a certain level of aging, its performance tends to stabilize. High-quality catalysts exhibit better thermal stability and durability, thus providing a longer service life. Therefore, when evaluating catalyst performance over extended durability mileage, especially in the context of extended oil change intervals in the future, lubricating oil becomes a critical influencing factor. High-quality lubricating oil can effectively reduce the entry of harmful elements, and its excellent antioxidation and cleaning-dispersant properties can inhibit deposit formation, thereby better preserving the catalyst’s oxygen storage capacity. This also explains the absence of a significant decrease in OSC for the tested vehicles at 120,000 and 210,000 km in this study.

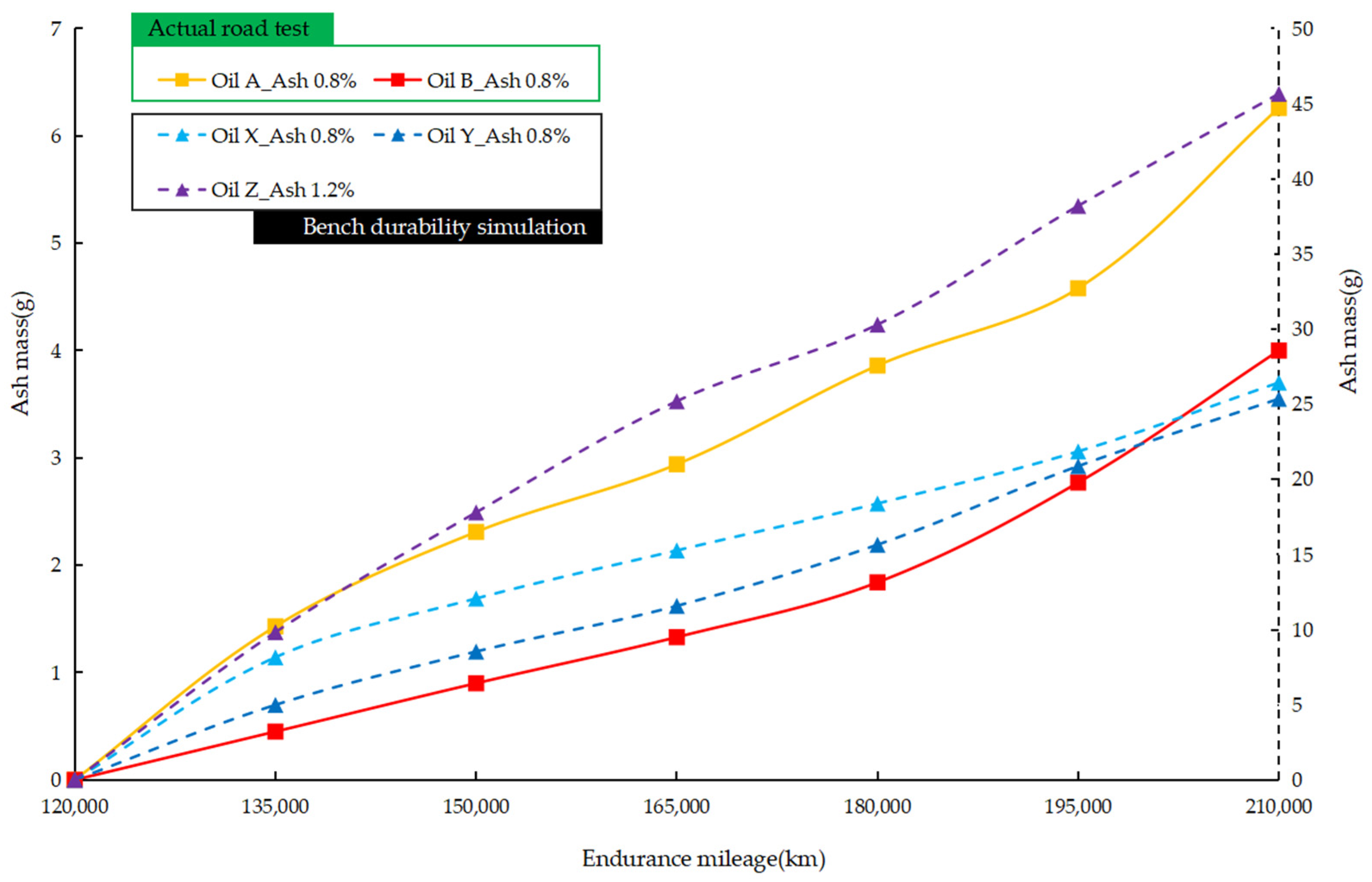

3.5. GPF Performance Test Results

The additives of friction modifiers and anti-wear agents added to low-viscosity lubricating oil can decompose under high temperature and high pressure, generating harmful substances such as carbon and sulfides that deposit inside the substrate. This deposition can lead to pore blockage and substrate aging, especially for substrates with catalytic coatings. The deposits can also reduce the effective contact area between the coating and pollutants, increase backpressure, deteriorate emissions, and thus affect its filtration performance and cleaning efficiency. The addition of friction reducers and anti-wear agents in low-viscosity lubricating oils can lead to their decomposition under high-temperature and -pressure conditions [

32], generating harmful substances such as carbon and sulfides that deposit inside the carrier. This deposition can result in pore blockage and carrier aging, especially in carriers with catalytic coatings. Furthermore, the deposits can reduce the effective contact area between the coating and pollutants, increasing backpressure and worsening emissions [

33,

34], thereby affecting their filtration performance and cleaning effectiveness. Additionally, low-viscosity lubricating oil may also cause oil fouling and carbon buildup on the surface of the particulate filter after long-term use, further reducing its performance. To better compare the impact of different oils on GPF performance after endurance, different GPFs obtained after endurance testing with oil A and oil B were installed on the same vehicle for WLTC testing. The results of gas pollutant emissions are shown in

Figure 14.

The results show that the gas pollutant emissions of the vehicles under different samples all meet the requirements of China VI emission standards, and there is no significant difference in the filtration performance of the aftertreatment system between the two types of oils.

Figure 15 shows the data for particle pollutant emissions. As shown in

Figure 15, compared to the fresh substrate (0 km), the particle emissions of the vehicle after endurance testing did not show significant deterioration and were well below the limits. After 210,000 km, the whole-vehicle GPF showed an approximately 92% improvement in PN filtration efficiency. The results demonstrate the protective and sustainable performance of low-viscosity lubricating oils with mid to low ash content after long-distance endurance with GPFs.

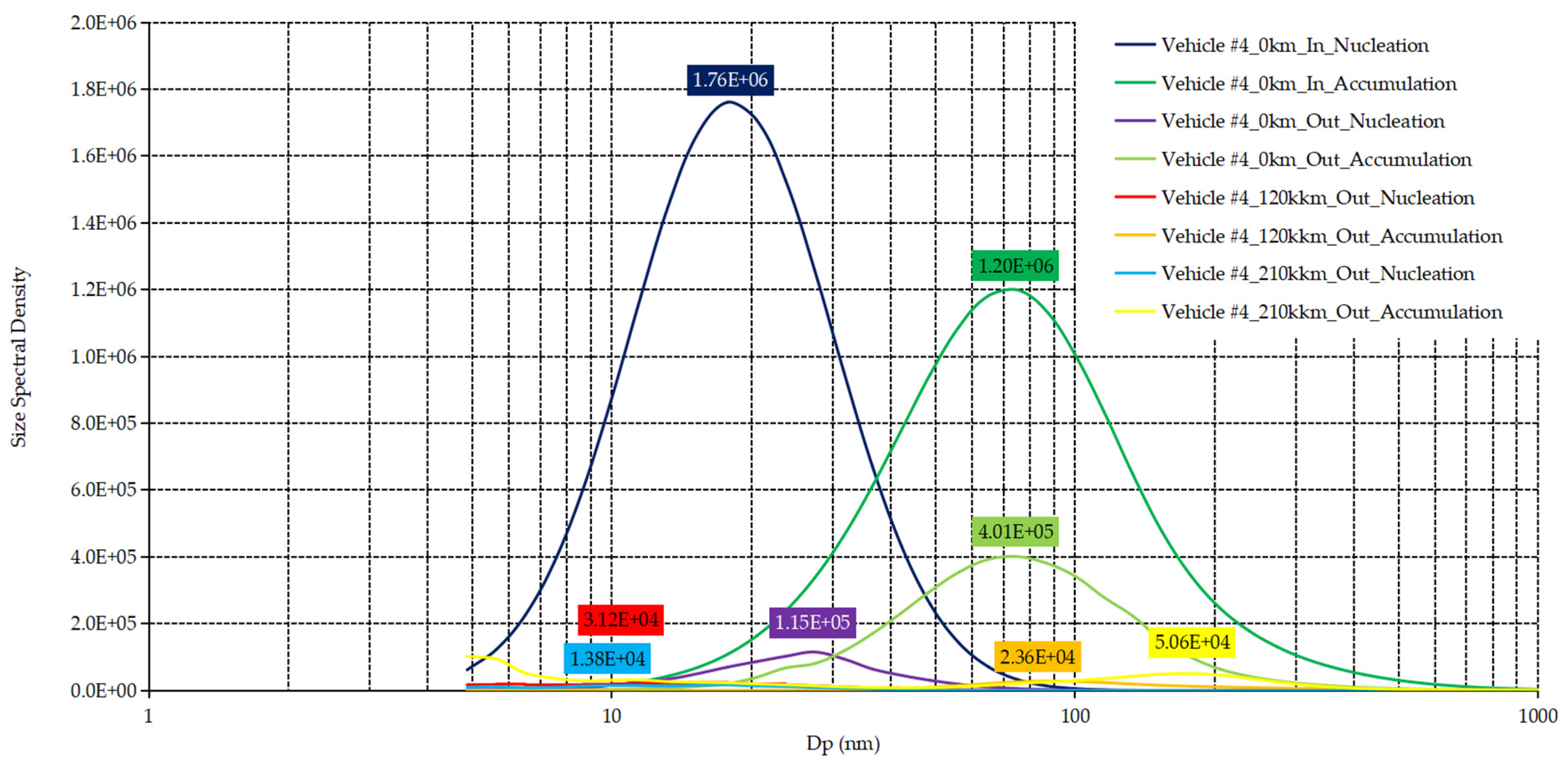

Based on the above experiments, this study also monitored the particle concentrations and size distributions of the GPF inlet (In) and outlet (Out) of vehicle #4 during emission tests at different mileage intervals, aiming to explore the variation in and distribution patterns of particle concentrations. The particle size results in

Figure 16 indicate that the whole-vehicle particle emissions of vehicle #4 before the aging of the aftertreatment system exhibited a bimodal distribution, with both nucleation mode particles and accumulation mode particles at relatively high levels. As the mileage increased, the accumulated ash in the aftertreatment system led to a gradual improvement in the GPF’s particle filtration performance, resulting in a significant decrease in particle concentrations. The concentration decrease was particularly prominent for the nucleation mode particles with smaller sizes, reaching a filtration efficiency of approximately 99.2%.

Due to the structural characteristics of the particulate filter, when exhaust gas passes through the filter, the gas undergoes continuous changes in direction inside the substrate. Particles with smaller sizes exhibit molecular motion characteristics and are more prone to Brownian motion due to molecular thermal motion. As a result, these small particles are more likely to aggregate into larger particles due to interception by pores or gravity settling within the substrate, or they can be captured by the inner wall of the substrate channels due to changes in concentration gradients caused by their aggregation.

By observing the heat map of particle concentration distribution, the concentration decrease can be visualized more intuitively.

Figure 17 presents the concentration changes of sample gas at the inlet and outlet of the GPF substrate in vehicle #4 at different mileage based on WLTC. The results indicate that a GPF substrate without ash content can effectively reduce the particle concentration during the middle and later stages of the WLTC. Only at 120,000 km, a small amount of ash significantly reduces the particle concentration during the cold start stage and throughout the entire cycle of the WLTC. As ash accumulates, there is no significant change in the level of whole-vehicle particle emissions at the 210,000 km mileage, but the particle distribution differs from the earlier stages, transitioning from a more uniform distribution to one dominated by larger particle sizes.

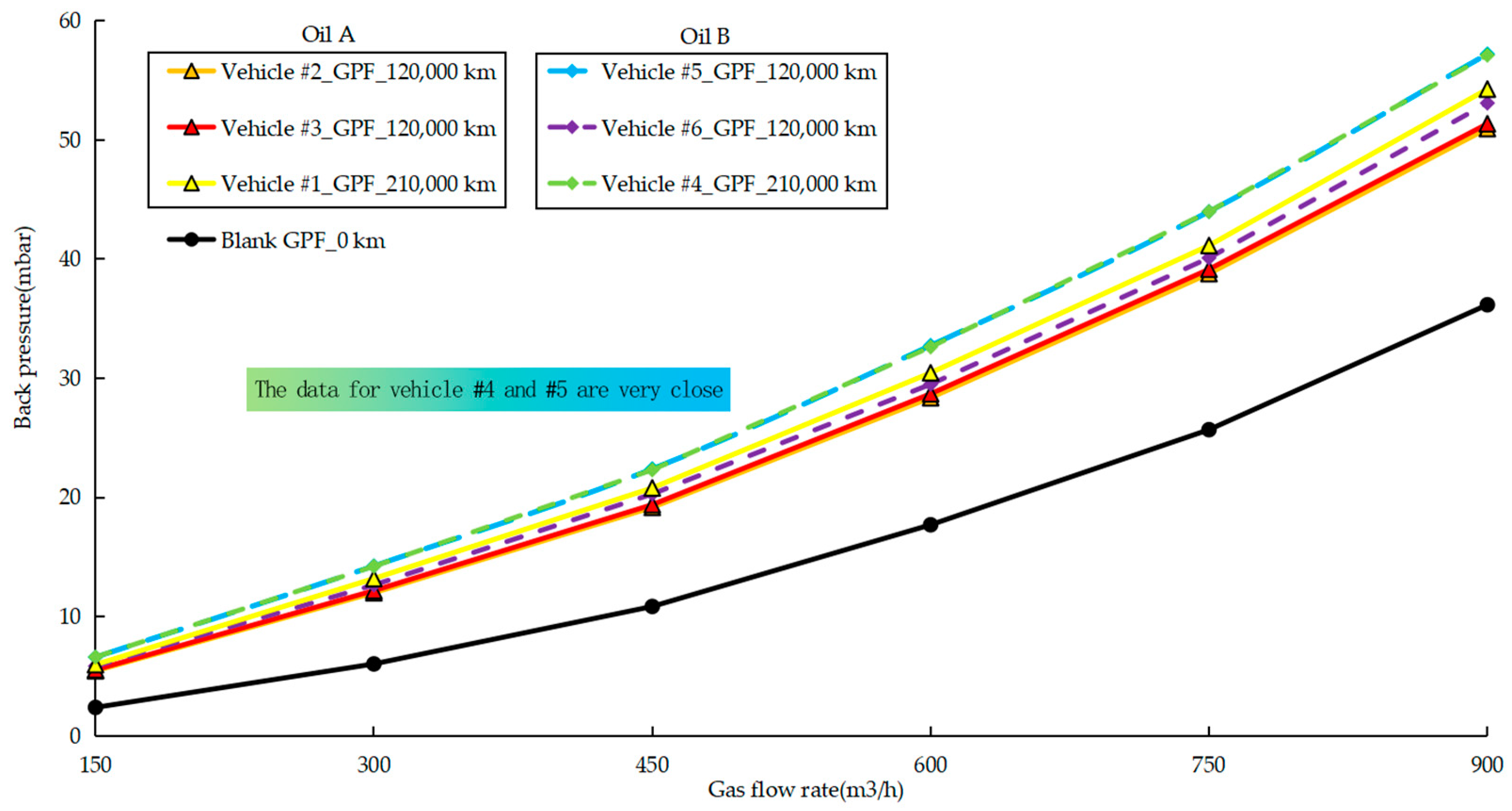

Although the increase in ash content caused by mileage accumulation can improve the particle filtration efficiency of the GPF, the accompanying increase in backpressure due to ash accumulation may result in increased fuel consumption or changes in vehicle performance. In this study, a cold flow (23 °C) backpressure test platform was used to conduct six sets of backpressure tests at different flow rates on GPF substrates with different endurance mileages. The test data results are shown in

Figure 18.

The results show that GPF samples from different vehicles obtained after the same oil endurance exhibit good consistency in the trend of backpressure changes (such as vehicle #2_GPF_120kkm and vehicle #3_GPF_120kkm). Based on the type of GPF (non-coated type) used in this study, the contribution of the two oil types to the backpressure of the samples after actual driving to 210,000 km (after the actual endurance test up to 210,000 km for both oil formulations) reached 100% and 80% compared to the 0 km samples, respectively. The increase in backpressure is much higher than that of conventional non-coated GPF endurance results (based on commonly used test flow rates of 300 m3/h and 600 m3/h). The backpressure of fresh substrates of the same specifications as the tested GPF, after catalyst coating, was 19.4 mbar at 300 m3/h and 42 mbar at 600 m3/h. Therefore, compared to conventional coated GPFs, the absolute value of backpressure after 210,000 km in this study is slightly lower than that of fresh coated GPFs, within an acceptable range.

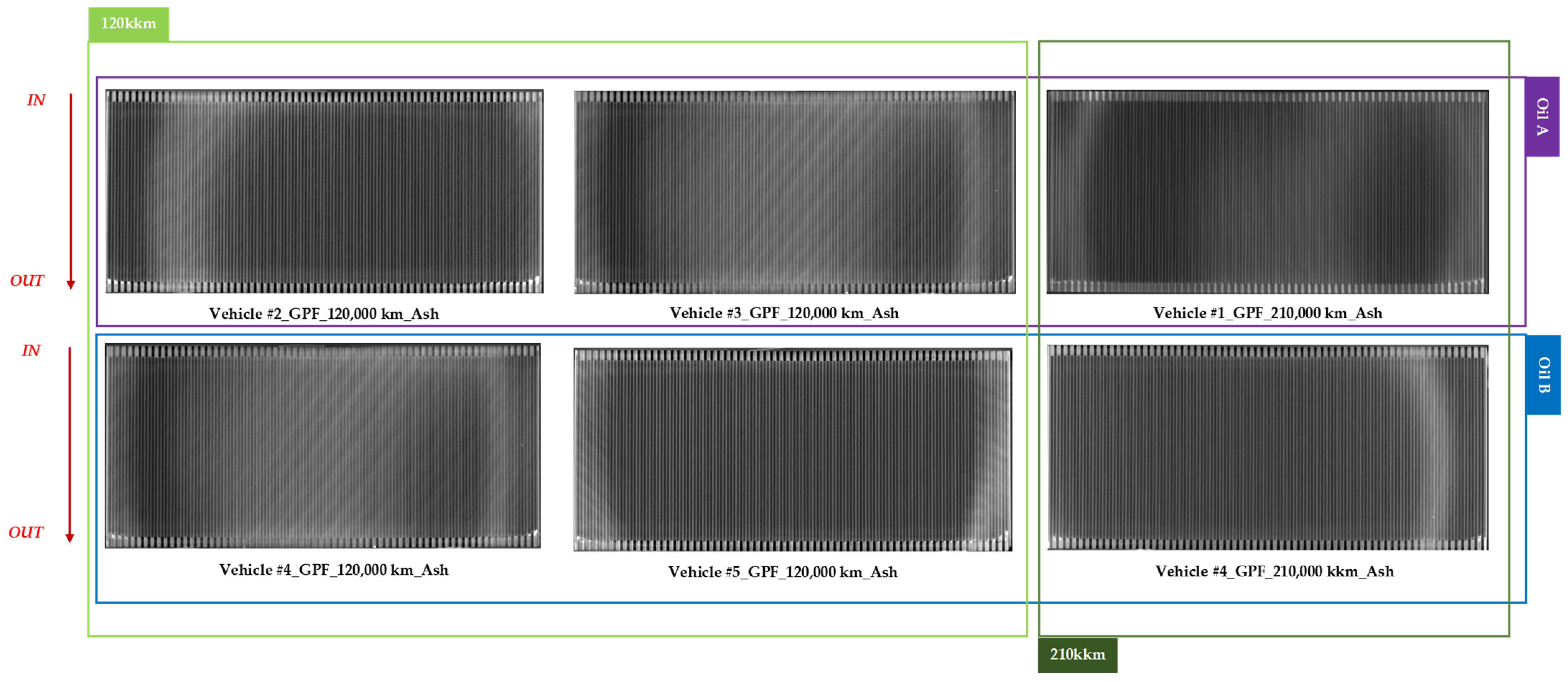

There was no significant increase observed in the backpressure of samples with the same oil type after 210,000 km compared to 120,000 km. This is because the ash content in the GPF after 210,000 km of endurance is lower relative to the ash content in the substrate obtained using traditional high-ash lubricating oil. Additionally, there was no significant change in the form and deposition mode of ash content in the substrate after long-distance endurance compared to 120,000 km. Even at 210,000 km, the impact of mid-to-low-ash-content lubricating oil on GPF backpressure is minimal in actual application. This observation was further validated by analyzing the CT scan results of aged samples, as shown in

Figure 19. No significant increase in ash content was observed in samples with different endurance mileages, and the number of ash deposits at the bottom did not show a significant increase.In order to define the deposition results more intuitively, the scanning results of other vehicles after 200,000 km can be compared, and the comparison samples are shown in

Figure 20.

Lubricating oils with excessively low viscosity are more prone to penetrate through component clearances into the combustion chamber, leading to the phenomenon of lubricating oil dilution. Additionally, due to the potential lack of sufficient anti-wear properties, these oils may contribute to increased wear in component clearances, exacerbating the issue of oil dilution. Shell’s low-viscosity lubricating oil demonstrates outstanding performance in ash control. In actual endurance testing, there were no observed abnormal accumulations of ash caused by excessive oil dilution. Due to the low ash content of this lubricating oil, ash accumulation is relatively minimal during the post-treatment phase, contributing to a further mitigation of the tendency for lubricating oil dilution.

In addition, compared to oil A, oil B contributes more to the increase in backpressure after long-distance endurance. This may be due to the different additive compositions of the two oils, resulting in differences in the composition of the generated ash content, which affects the ash morphology and micro-scale deposition, thereby leading to differences in the magnitude of backpressure.

This study investigated the influence of different carbon loadings on the backpressure of GPFs before and after endurance. During actual vehicle operation, the engine operating conditions and the working temperature of the GPF constantly change, leading to changes in the carbon loading inside the substrate. Different carbon loadings result in different GPF backpressures, directly affecting the overall emission reduction performance and power output of the vehicle. Examining the backpressure of GPFs under different carbon loadings is of great significance for optimizing GPF design and operation strategies, as well as improving engine output power and fuel economy.

Figure 21 shows the backpressure variation of the substrate under different carbon loadings at a gas flow rate of 250 kg/h and a temperature of 240 °C. As the carbon loading increases, the backpressure of the GPF significantly increases, and the contribution of soot particles to the backpressure increase is much greater than that of ash content, especially for GPF samples with low ash content. The fresh substrate at 0 km, without ash-formed filter cake, has larger soot particle sizes. After entering the substrate, the soot quickly reaches the deep layers, adhering to the pore periphery and reducing the pore area, resulting in a rapid increase in backpressure. Compared to the G0 sample, the remaining samples with a small amount of ash content have an ash-formed filter cake in the substrate. The deposition morphology and distribution of soot particles in the substrate differ from those without ash, resulting in different trends in backpressure changes. A small amount of ash content in the substrate can effectively prevent a rapid increase in backpressure caused by continuous soot accumulation, and this effect is more pronounced at lower carbon loadings.

For carbon loadings below 0.2 g/L, the ash layer is the main factor affecting the backpressure, and the sample using oil B shows a slightly faster increase in backpressure compared to oil A. However, when the carbon loading exceeds 0.2 g/L, the filter layer formed by soot particles plays a dominant role, and the backpressure trends of the fresh sample (without ash) and the aged sample (with ash) tend to align.

3.6. Rapid Aging on the Test Bench and Real-World Endurance Verification

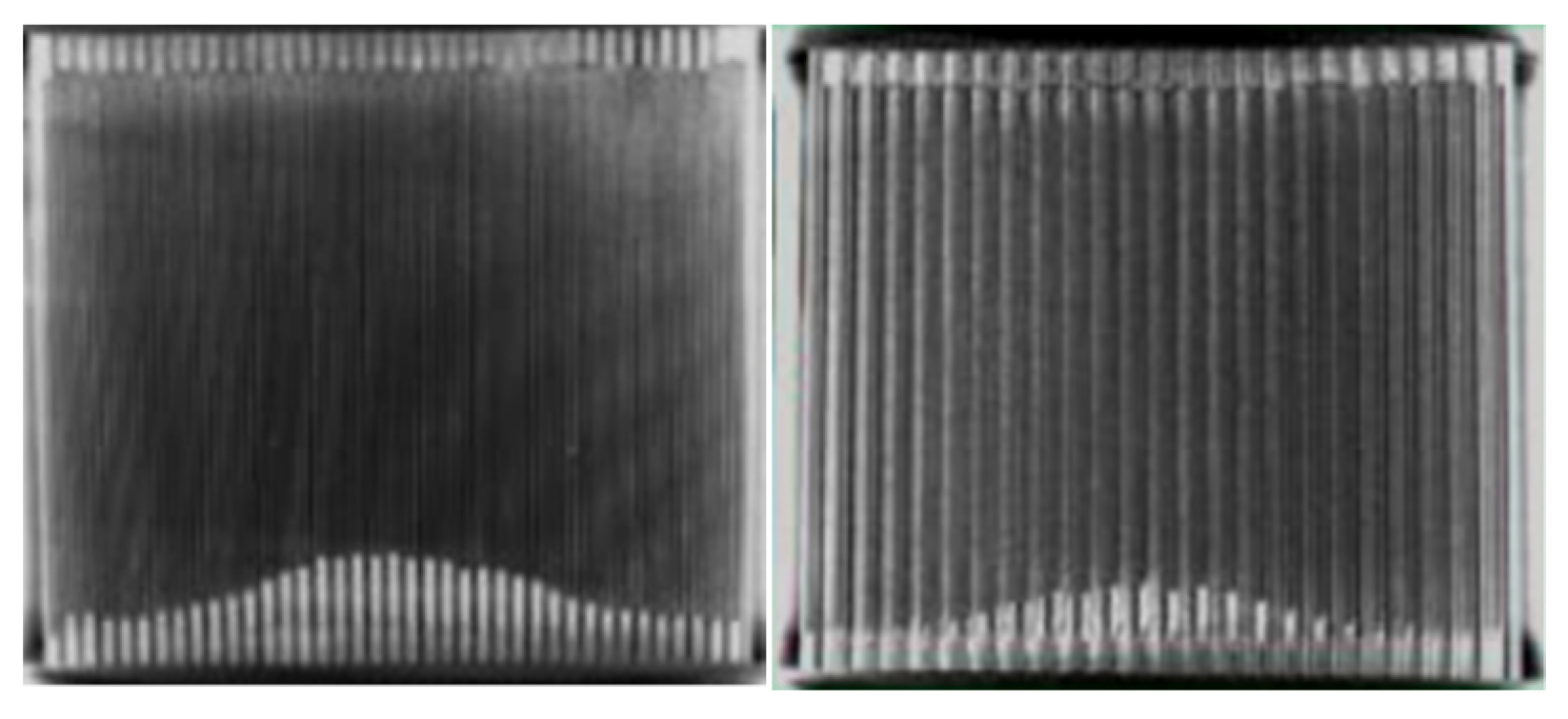

The rate of ash accumulation in the GPF is highly related to its structure and material (cordierite or silicon carbide), while the total weight of ash in the carrier is highly related to the engine’s combustion strategy and the ash level of the lubricant additives. In the method of evaluating the aftertreatment system, based on the engine test bench platform, the aftertreatment system’s aging degree at different durability mileages is equivalently tested by using gasoline mixed with lubricating oil as fuel and calculating the lubricating oil consumption per 100 km. This testing method is frequently used in product development for evaluating the aging of aftertreatment systems because it can significantly reduce testing costs and shorten testing periods. However, whether the ash accumulation rate in the bench rapid aging evaluation method conforms to actual patterns (especially over long engine mileages) largely remains theoretical.

Although the vehicle engine used in this study is different from the one used in the previous rapid ash accumulation tests (which leads to different combustion strategies), our research verifies the theoretical hypothesis of the ash accumulation rate by comparing the aging results of actual road durability and the test bench simulation of rapid aging. Based on this, the authors noted the different engines and the varying ash levels resulting from the added lubricants but did not elaborate on other information about the lubricant additives.

Based on an engine test bench, rapid aging of the aftertreatment system can be achieved by blending burning lubricating oil. Three sets of the same fuel (gasoline) were mixed with lubricating oils of different ash levels in proportion. Two of the mixed oils were mid-to-low-ash-content lubricating oils, X and Y (ash = 0.8%), and one was a high-ash lubricating oil, Z (ash = 1.2%). Based on the lubricating oil consumption per 100 km provided by the OEM for the test engine, the amount of blended lubricating oil in the fuel was measured, allowing the calculation of the equivalent endurance mileage of the engine and thus achieving rapid aging of the aftertreatment system.

In this study, the lubricating oil consumption during each oil change cycle was measured during actual road endurance testing. The ash content of GPF in vehicles #1 and #4 was also weighed after 120,000 km, with weighing performed every 15,000 km until the endurance reached 210,000 km. Vehicle #1 consumed approximately 2003.1 g of oil between 120,000 and 210,000 km, while vehicle #4 consumed approximately 1527.5 g of oil. The accumulated ash content in the GPF substrates during the 90,000 km endurance was 6.26 g and 4.0 g, respectively.

Figure 22 shows the ash mass results in the respective substrates after 120,000 km using the two testing methods. The results indicate that although the differences in testing platforms and endurance conditions can lead to variations in ash content between the two methods, the trends in ash content variation in the substrates during GPF aging are similar. The testing method of blending burning lubricating oil to achieve rapid aging of the aftertreatment system has reference value. However, to improve the accuracy of the test bench rapid aging evaluation results, it is necessary to enhance the accuracy of lubricating oil consumption during actual engine operation. Additionally, the consistency between the endurance conditions selected for engine test bench rapid aging and the real-world driving conditions is also an important factor affecting the reliability of the results.

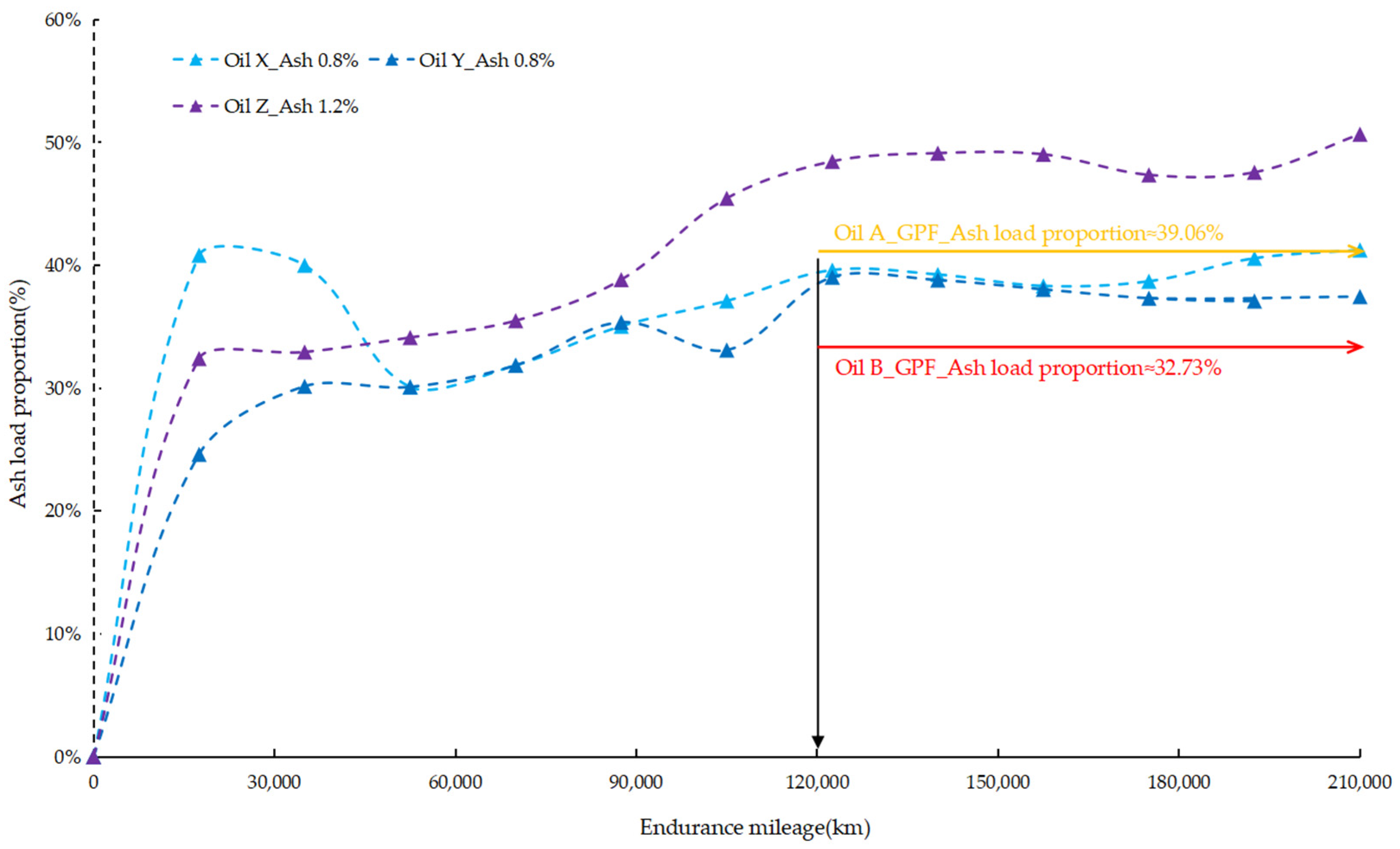

Figure 23 shows the ash collection efficiency at different equivalent endurance stages during test bench rapid aging. The ash collection efficiency of GPF stabilizes at approximately 120,000 km, with average ash collection efficiencies of approximately 39.62% for oil P and 37.96% for oil Z. During the 120,000 to 210,000 km stage of actual road endurance testing, the ash collection efficiencies for GPF substrates in vehicles #1 and #4 are 39.06% and 32.73%, respectively. Since the two evaluation methods discussed in this study use different engine platforms, further research and analysis are needed to understand the impact of ash grade on ash collection efficiency during GPF aging. However, the results indicate good consistency in the GPF ash collection efficiency obtained from the two evaluation methods.

Furthermore, although actual road endurance testing is more realistic, accurately measuring and calculating the lubricating oil consumption of the entire vehicle system on the road is challenging. Additionally, the actual road vehicle system is complex. Therefore, based on the engine test bench, rapid aging simulation of the aftertreatment system allows for more accurate and controlled quantitative analysis.