Prediction of Lubrication Performances of Vegetable Oils by Genetic Functional Approximation Algorithm

Abstract

1. Introduction

2. Materials and Methods

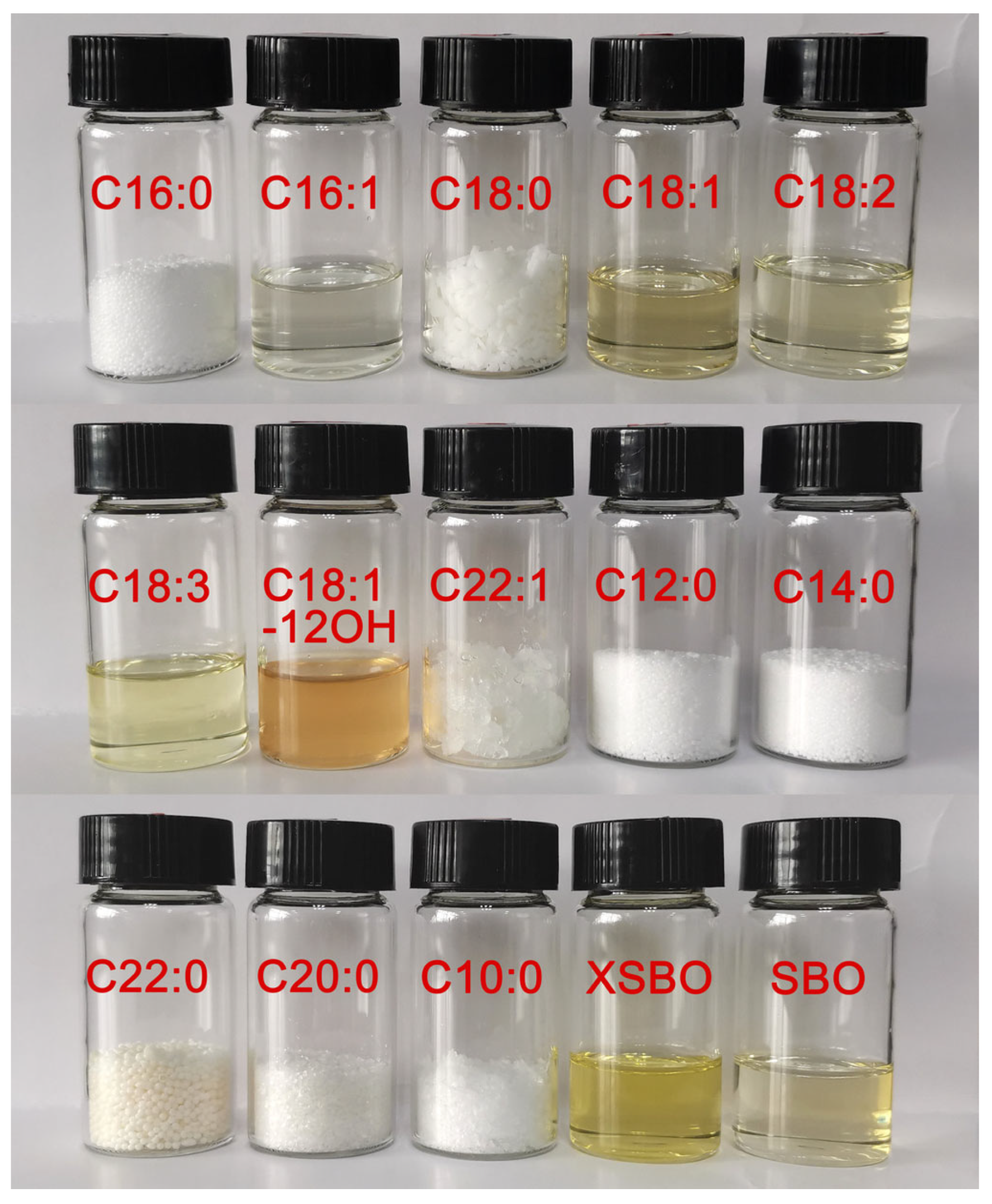

2.1. Raw Materials

2.2. Tests on Lubrication Performances

2.3. Fatty Acid Composition Analysis Method

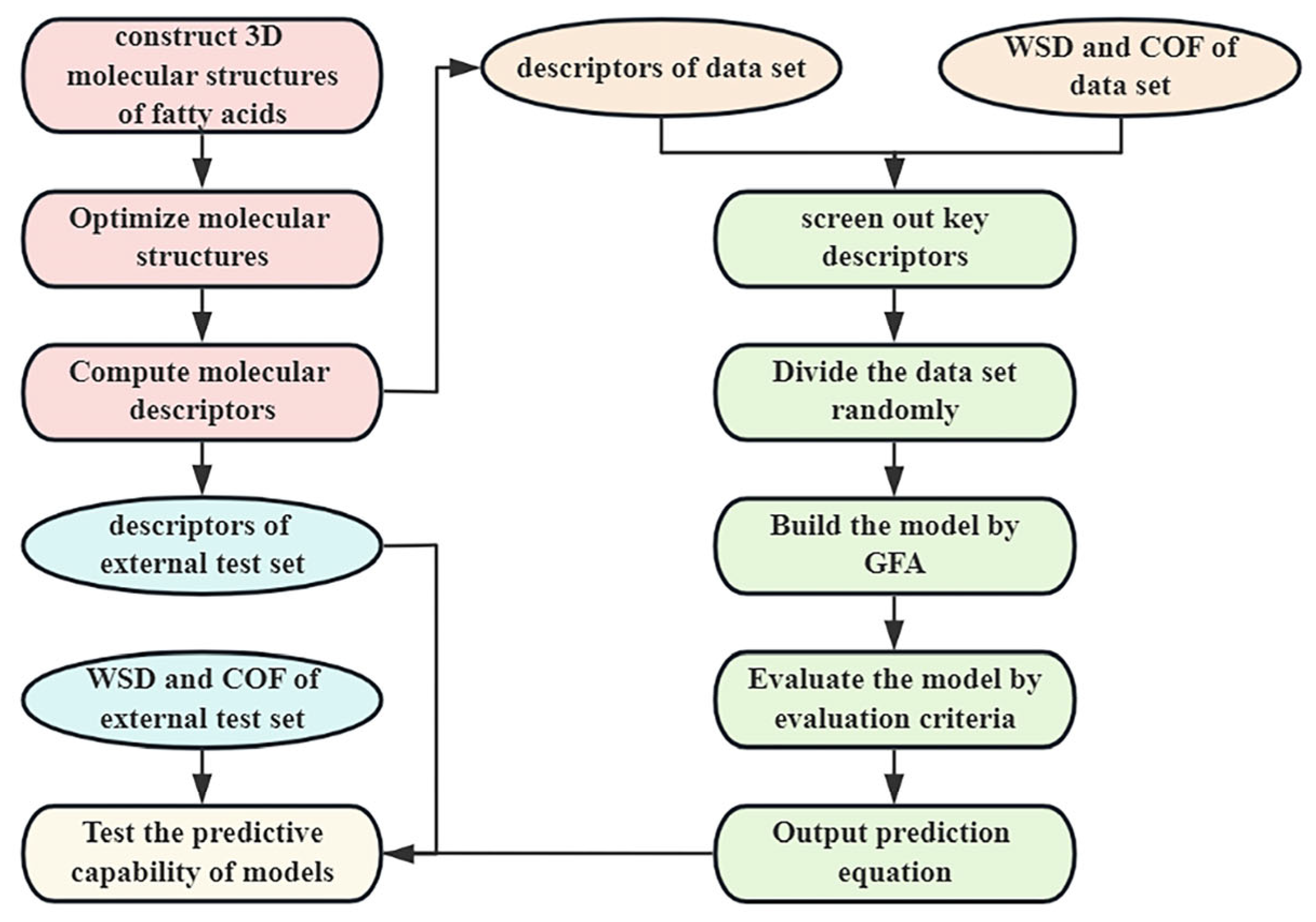

2.4. Modeling and Calculation Methods

3. Results and Discussion

3.1. Friction Test Results and Fatty Acid Compositions

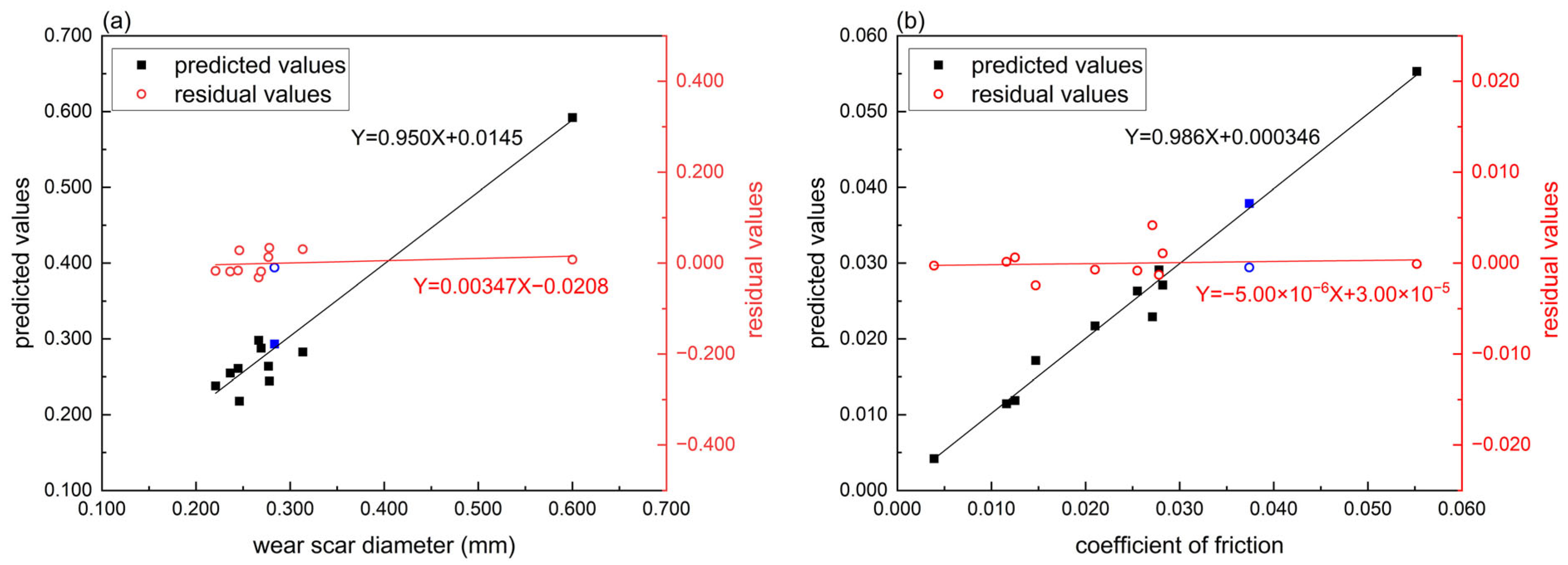

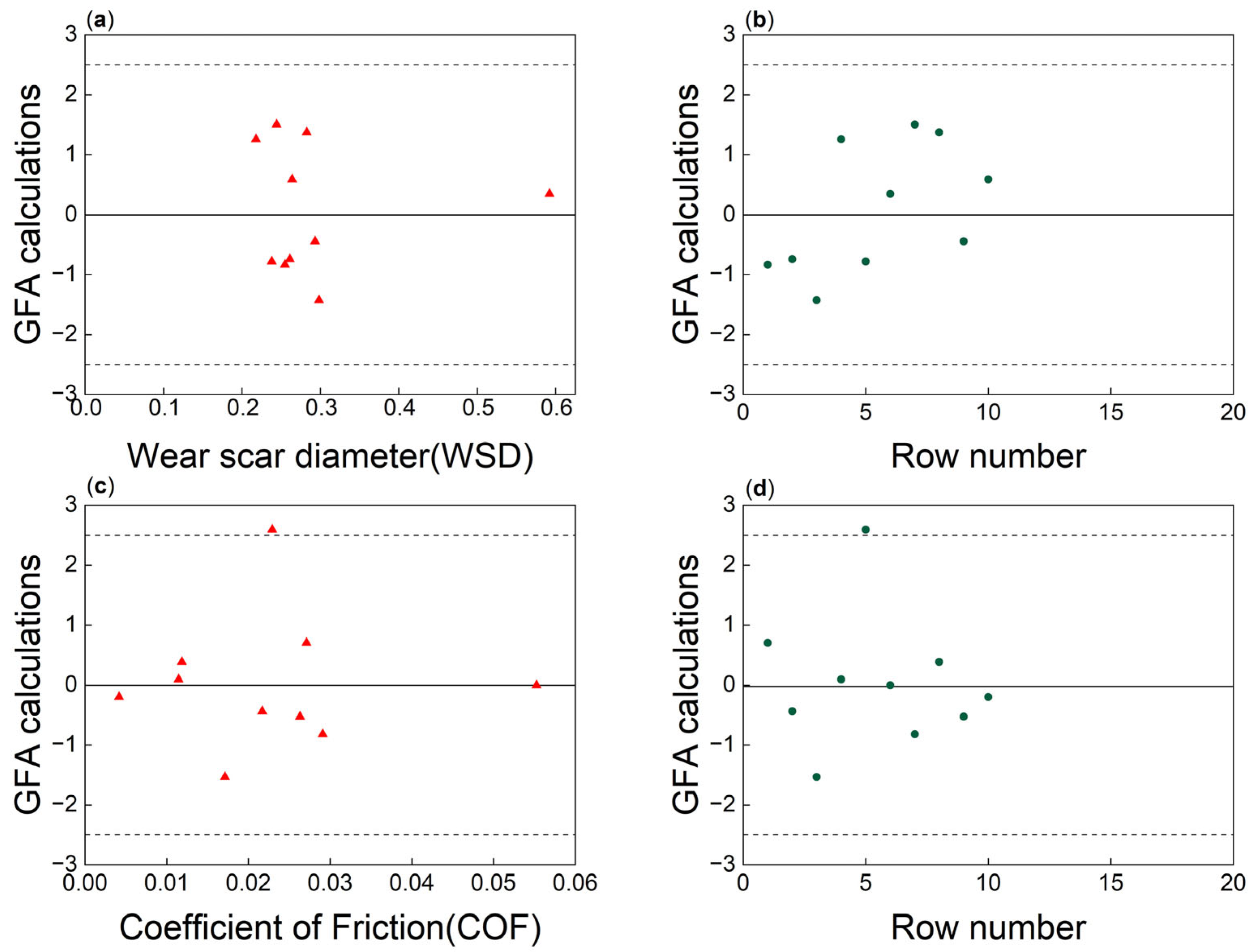

3.2. Prediction Model for Lubrication Properties of Fatty Acids

3.3. The Descriptors in QSPR Models

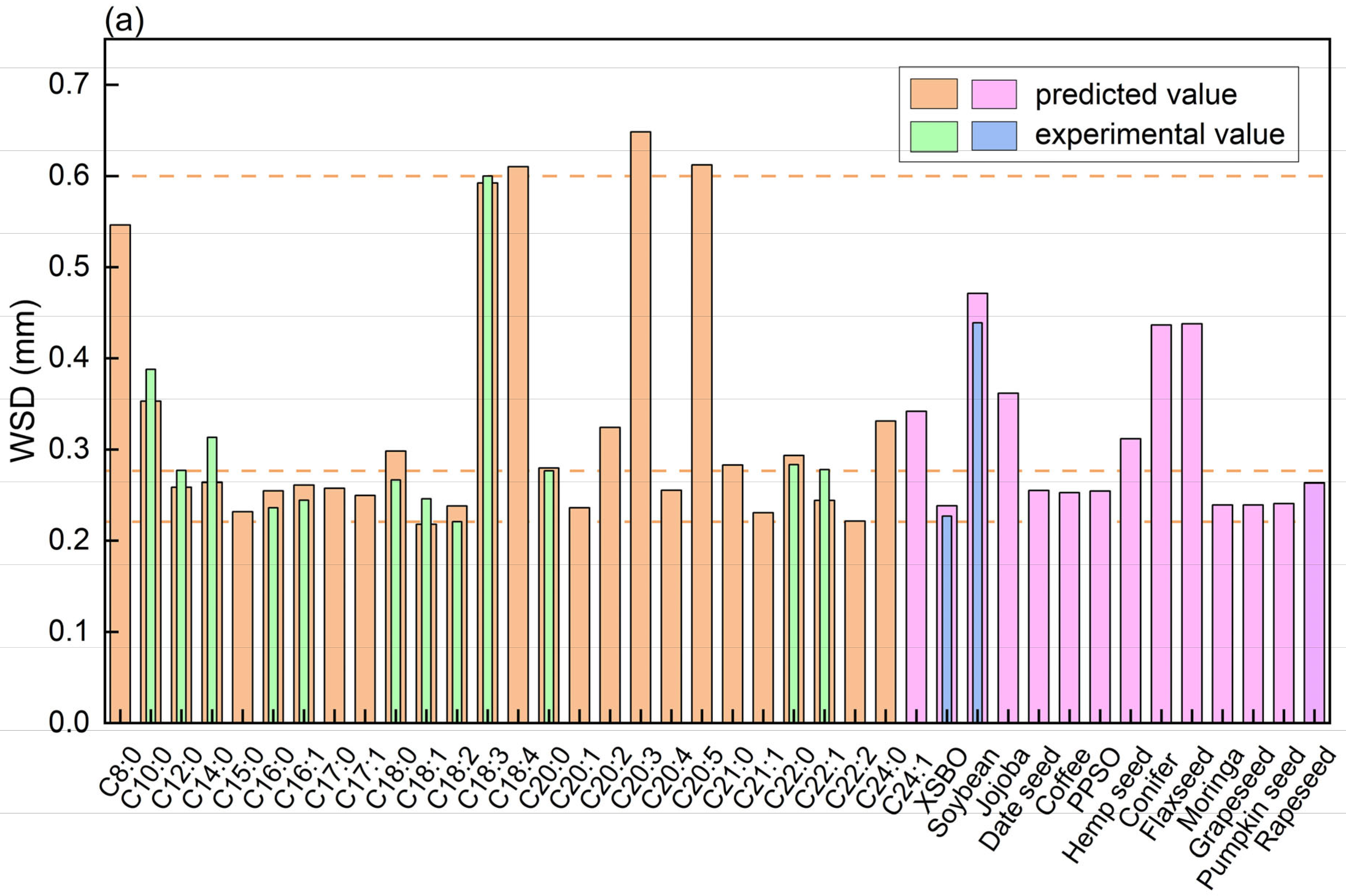

3.4. Predicting Lubrication Performance

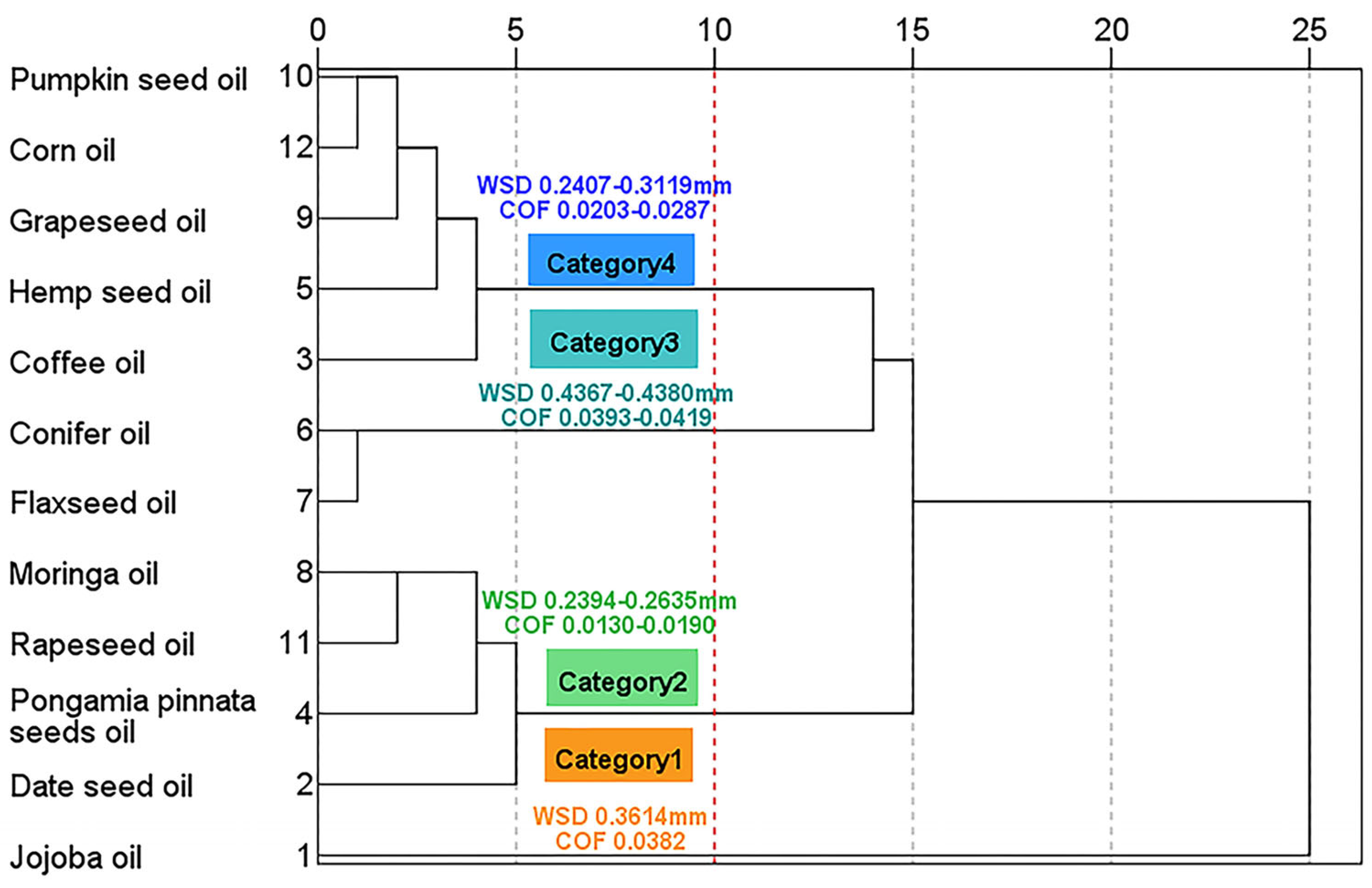

3.5. Cluster Analysis of Vegetable Oils

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ermakov, C.F.; Chmykhova, T.G.; Timoshenko, A.V.; Shershnev, E.B. Tribological Features of Environmentally Safe Lubricant Compositions Based on Rapeseed Oil. J. Frict. Wear 2019, 40, 194–199. [Google Scholar] [CrossRef]

- Dong, L.; Li, C.H.; Zhou, F.M.; Bai, X.F.; Gao, W.; Duan, Z.J.; Li, X.P.; Lv, X.J.; Zhang, F.B. Temperature of the 45 steel in the minimum quantity lubricant milling with different biolubricants. Int. J. Adv. Manuf. Technol. 2021, 113, 2779–2790. [Google Scholar] [CrossRef]

- Birleanu, C.; Pustan, M.; Cioaza, M.; Molea, A.; Popa, F.; Contiu, G. Effect of TiO2 nanoparticles on the tribological properties of lubricating oil: An experimental investigation. Sci. Rep. 2022, 12, 5201. [Google Scholar] [CrossRef] [PubMed]

- Sulima, S.I.; Bakun, V.G.; Chistyakova, N.S.; Larina, M.V.; Yakovenko, R.E.; Savost’yanov, A.P. Prospects for Technologies in the Production of Synthetic Base Stocks for Engine Oils (A Review). Pet. Chem. 2021, 61, 1178–1189. [Google Scholar] [CrossRef]

- Nowak, P.; Kucharska, K.; Kaminski, M. Ecological and Health Effects of Lubricant Oils Emitted into the Environment. Int. J. Environ. Res. Public Health 2019, 16, 3002. [Google Scholar] [CrossRef] [PubMed]

- Attia, N.K.; El-Mekkawi, S.A.; Elardy, O.A.; Abdelkader, E.A. Chemical and rheological assessment of produced biolubricants from different vegetable oils. Fuel 2020, 271, 117578. [Google Scholar] [CrossRef]

- Fathurrahman, N.A.; Auzani, A.S.; Zaelani, R.; Anggarani, R.; Aisyah, L.; Maymuchar; Wibowo, C.S. Lubricity Properties of Palm Oil Biodiesel Blends with Petroleum Diesel and Hydrogenated Vegetable Oil. Lubricants 2023, 11, 176. [Google Scholar] [CrossRef]

- Basiron, J.; Abdollah, M.F.B.; Abdullah, M.; Amiruddin, H. Formulation and tribological performance of engine oil blended with various non-edible vegetable oils. Lubr. Sci. 2023, 35, 480–497. [Google Scholar] [CrossRef]

- Rubio-Valle, J.F.; Valencia, C.; Sánchez, M.; Martín-Alfonso, J.E.; Franco, J.M. Oil structuring properties of electrospun Kraft lignin/cellulose acetate nanofibers for lubricating applications: Influence of lignin source and lignin/cellulose acetate ratio. Cellulose 2023, 30, 1553–1566. [Google Scholar] [CrossRef]

- Yin, Q.G.; Li, C.H.; Dong, L.; Bai, X.F.; Zhang, Y.B.; Yang, M.; Jia, D.Z.; Li, R.Z.; Liu, Z.Q. Effects of Physicochemical Properties of Different Base Oils on Friction Coefficient and Surface Roughness in MQL Milling AISI 1045. Int. J. Precis. Eng. Manuf. Technol. 2021, 8, 1629–1647. [Google Scholar] [CrossRef]

- Reeves, C.J.; Menezes, P.L.; Jen, T.C.; Lovell, M.R. The influence of fatty acids on tribological and thermal properties of natural oils as sustainable biolubricants. Tribol. Int. 2015, 90, 123–134. [Google Scholar] [CrossRef]

- Sajeeb, A.; Rajendrakumar, P.K. Comparative evaluation of lubricant properties of biodegradable blend of coconut and mustard oil. J. Clean. Prod. 2019, 240, 118255. [Google Scholar] [CrossRef]

- Zulhanafi, P.; Syahrullail, S.; Hamid, M.K.A.; Chong, W.W.F. The effect of saturated and unsaturated fatty acid composition in bio-based lubricant to the tribological performances using four-ball tribotester. J. Oil Palm Res. 2021, 33, 653–667. [Google Scholar] [CrossRef]

- Liu, P.; Wang, X.; Wu, J.; Lin, W.; Feng, Y.H.; Chen, B.S.; Fang, J.H.; Jiang, Z.Q. Effect of boron-nitrogen modified soybean oil additive on biodegradability, anti-oxidation property, and lubricity of rapeseed oil. Proc. Inst. Mech. Eng. Part J-J. Eng. Tribol. 2020, 234, 282–291. [Google Scholar] [CrossRef]

- Liu, P.; Fang, J.H.; Wang, X.; Wu, J.; Chen, B.S. A novel boron-nitrogen modified castor oil as an ecofriendly and efficient lubricant additive. J. Dispers. Sci. Technol. 2021, 42, 180–189. [Google Scholar] [CrossRef]

- Weinebeck, A.; Kaminski, S.; Murrenhoff, H.; Leonhard, K. A new QSPR-based prediction model for biofuel lubricity. Tribol. Int. 2017, 115, 274–284. [Google Scholar] [CrossRef]

- Liu, J.; Yi, C.; Zhang, Y.; Yang, S.; Liu, T.; Zhang, R.; Jia, D.; Peng, S.; Yang, Q. Structure–activity relationship study of anti-wear additives in rapeseed oil based on machine learning and logistic regression. RSC Adv. 2024, 14, 8464–8480. [Google Scholar] [CrossRef]

- Wan, Z.Y.; Wang, Q.D.; Liu, D.C.; Liang, J.H. Discovery of ester lubricants with low coefficient of friction on material surface via machine learning. Chem. Phys. Lett. 2021, 773, 138589. [Google Scholar] [CrossRef]

- Rogers, D.; Hopfinger, A.J. Application of Genetic Function Approximation to Quantitative Structure-Activity Relationships and Quantitative Structure-Property Relationships. J. Chem. Inf. Comput. Sci. 1994, 34, 854–866. [Google Scholar] [CrossRef]

- Abdulfatai, U.; Uzairu, A.; Uba, S.; Shallangwa, G.A. Molecular design of antioxidant lubricating oil additives via QSPR and analysis dynamic simulation method. Heliyon 2019, 5, e02880. [Google Scholar] [CrossRef] [PubMed]

- Nasab, S.G.; Semnani, A.; Marini, F.; Biancolillo, A. Prediction of viscosity index and pour point in ester lubricants using quantitative structure-property relationship (QSPR). Chemom. Intell. Lab. Syst. 2018, 183, 59–78. [Google Scholar] [CrossRef]

- Liu, J.F.; Zhang, R.R.; Yang, S.C.; Liu, T.; Yi, C.L.Z.; Zhang, Y.Y.; Jia, D. Evaluation of Anti-wear Properties of Different Vegetable Oils Based on QSPR Model. Tribol. Lett. 2023, 71, 35. [Google Scholar] [CrossRef]

- ASTM D4172-21; Standard Test Method for Wear Preventive Characteristics of Lubricating Fluid (Four-Ball Method). American Society for Testing and Materials: West Conshohocken Borough, PA, USA, 2021.

- Al Jabri, H.; Khan, S.; Das, P.; Thaher, M.I.; Quadir, M.A. Effect of ethylene-vinyl acetate copolymer on kinematic viscosity and thermal stability of jojoba, date seed, and waste cooking oils in lubricant applications. Iran. Polym. J. 2022, 31, 261–273. [Google Scholar] [CrossRef]

- Budryn, G.; Nebesny, E.; Zyzelewicz, D.; Oracz, J.; Miskiewicz, K.; Rosicka-Kaczmarek, J. Influence of roasting conditions on fatty acids and oxidative changes of Robusta coffee oil. Eur. J. Lipid Sci. Technol. 2012, 114, 1052–1061. [Google Scholar] [CrossRef]

- Bala, M.; Nag, T.N.; Kumar, S.; Vyas, M.; Kumar, A.; Bhogal, N.S. Proximate Composition and Fatty Acid Profile of Pongamia pinnata, a Potential Biodiesel Crop. J. Am. Oil Chem. Soc. 2011, 88, 559–562. [Google Scholar] [CrossRef]

- Borriello, A.; Miele, N.A.; Masi, P.; Aiello, A.; Cavella, S. Effect of fatty acid composition of vegetable oils on crystallization and gelation kinetics of oleogels based on natural wax. Food Chem. 2022, 375, 131805. [Google Scholar] [CrossRef] [PubMed]

- Gutierrez-Luna, K.; Ansorena, D.; Astiasaran, I. Fatty acid profile, sterols, and squalene content comparison between two conventional (olive oil and linseed oil) and three non-conventional vegetable oils (echium oil, hempseed oil, and moringa oil). J. Food Sci. 2022, 87, 1489–1499. [Google Scholar] [CrossRef] [PubMed]

- Paragi, G.; Gyémánt, I.K.; VanDoren, V.E. Investigation of exchange-correlation potentials in ensemble density functional theory: Parameter fitting and excitation energy. J. Mol. Struct.-Theochem. 2001, 571, 153–161. [Google Scholar] [CrossRef]

- Liu, J.F.; Zhang, Y.Y.; Yi, C.L.Z.; Zhang, R.R.; Yang, S.C.; Liu, T.; Jia, D.; Yang, Q.; Peng, S. Evaluation of Antioxidant Properties and Molecular Design of Lubricant Antioxidants Based on QSPR Model. Lubricants 2024, 12, 3. [Google Scholar] [CrossRef]

- Yang, Z.Z.; Liang, Y.J.; Huang, Q.; Wang, X.W.; Zhou, C.Y.; Wang, R.Z.; Yan, X.Y.; Yu, B.; Yu, Q.L.; Cai, M.R.; et al. Tribological performance study of oil-soluble ILs as lubricant additives by the four-ball method. Lubr. Sci. 2023, 35, 183–192. [Google Scholar] [CrossRef]

- Baumgart, P.; Canzi, G.; Hanashiro, T.; Doezema, L.A.; Siniawski, M.T. Influence of fatty acid additives on the tribological performance of sunflower oil. Lubr. Sci. 2010, 22, 393–403. [Google Scholar] [CrossRef]

- Elsamman, A.; Khaled, K.F.; Halim, S.A.; Abdelshafi, N.S. Development of QSAR based GFA predictive model for the effective design of a new bispyrazole derivative corrosion inhibitor. J. Mol. Struct. 2023, 1293, 136230. [Google Scholar] [CrossRef]

- Leach, A.R. Molecular Modelling: Principles and Applications; Pearson Education: London, UK, 2001. [Google Scholar]

- Xiong, S.; Wu, H.; Liu, Z.Y.; Zhang, B.S. QSAR Models for the Prediction of the Relationship Among Corrosion Inhibition Efficiency, Friction Coefficient and Oil Film Strength of Lubricants. Polycycl. Aromat. Compd. 2022, 42, 3780–3791. [Google Scholar] [CrossRef]

- Gao, X.L.; Wang, Z.; Wang, T.T.; Song, Z.; Dai, K.; Chen, H. BPNN-QSTR Modeling to Develop Isosteres as Sulfur-Free, Anti-Wear Lubricant Additives. J. Tribol.-Trans. Asme 2019, 141, 011801. [Google Scholar] [CrossRef]

- Hall, L.H.; Kier, L.B. Electrotopological State Indices for Atom Types: A Novel Combination of Electronic, Topological, and Valence State Information. J. Chem. Inf. Comput. Sci. 1995, 35, 1039–1045. [Google Scholar] [CrossRef]

- Wang, Y.B.; Sun, C.F.; Su, Q.; Wang, R.M. Tribological Properties of MACs-APS Films. J. Macromol. Sci. Part B-Phys. 2012, 51, 2064–2074. [Google Scholar] [CrossRef]

- Gao, X.L.; Wang, Z.; Dai, K.; Wang, T.T. A Quantitative Structure Tribo-Ability Relationship Model for Ester Lubricant Base Oils. J. Tribol.-Trans. Asme 2015, 137, 021801. [Google Scholar] [CrossRef]

- Wang, R.Z.; Sun, C.F.; Yan, X.Y.; Guo, T.T.; Xiang, W.J.; Yang, Z.Z.; Yu, Q.L.; Yu, B.; Cai, M.R.; Zhou, F. Influence of the molecular structure on the tribological properties of choline-based ionic liquids as water-based additives under current-carrying lubrication. J. Mol. Liq. 2023, 369, 120868. [Google Scholar] [CrossRef]

| No | Name | Melting Point /Pour Point * | WSD (mm) | COF | |||

|---|---|---|---|---|---|---|---|

| Experimental | Error | Experimental | Error | ||||

| 1 | Palmitic acid | C16:0 | 62 | 0.2363 | 0.0170 | 0.0282 | 0.0026 |

| 2 | Palmitoleic acid | C16:1 | 0.5 | 0.2446 | 0.0102 | 0.0210 | 0.0028 |

| 3 | Stearic acid | C18:0 | 67–72 | 0.2665 | 0.0310 | 0.0147 | 0.0015 |

| 4 | Oleic acid | C18:1 | 13–14 | 0.2461 | 0.0270 | 0.0116 | 0.0046 |

| 5 | Linoleic acid | C18:2 | −5 | 0.2208 | 0.0059 | 0.0271 | 0.0010 |

| 6 | Linolenic acid | C18:3 | −11 | 0.6000 | 0.0240 | 0.0552 | 0.0186 |

| 7 | Ricinoleic acid | C18:1-12OH | 22.5–24.5 | 0.2692 | 0.0023 | 0.0278 | 0.0027 |

| 8 | Erucic acid | C22:1 | 28–32 | 0.2779 | 0.0087 | 0.0125 | 0.0039 |

| 9 | Lauric acid | C12:0 | 44–46 | 0.2770 | 0.0082 | 0.0039 | 0.0008 |

| 10 | Myristic acid | C14:0 | 52–54 | 0.3134 | 0.0110 | 0.0255 | 0.0035 |

| 11 | Behenic acid | C22:0 | 72 | 0.2834 | 0.0118 | 0.0374 | 0.0013 |

| 12 | Arachidic acid | C20:0 | 74 | 0.2765 | 0.0135 | 0.0173 | 0.0012 |

| 13 | Decanoic acid | C10:0 | 27–32 | 0.3878 | 0.0232 | 0.0190 | 0.0016 |

| 14 | XSBO | 32%C18:1 47%C18:2 | −21 | 0.2270 | 0.0355 | 0.0263 | 0.0040 |

| 15 | SBO | 16%C18:2 65%C18:3 | −9 | 0.4390 | 0.0118 | 0.0437 | 0.0019 |

| WSD | COF | |

|---|---|---|

| Number of sample points | 11 | 11 |

| Range | 0.3790 | 0.0514 |

| Maximum | 0.6000 | 0.0552 |

| Minimum | 0.2210 | 0.0039 |

| Mean | 0.2941 | 0.0241 |

| Median | 0.2690 | 0.0255 |

| Variance | 9.95 × 10−3 | 1.804 × 10−4 |

| Standard deviation | 0.1046 | 0.0141 |

| Mean absolute deviation | 0.0591 | 0.0103 |

| Skewness | 2.2059 | 0.6517 |

| Kurtosis | 3.6898 | −0.2580 |

| Parameters | ||

| Friedman LOF | 1.54 × 10−3 | 3.3 × 10−5 |

| R-squared | 0.9501 | 0.9856 |

| Adjusted R-squared | 0.9289 | 0.9712 |

| Cross-validated R-squared (QCV2) | 0.7145 | 0.7466 |

| Significant Regression | Yes | Yes |

| Significance-of-regression F-value | 44.4719 | 68.4366 |

| Critical SOR F-value (95%) | 4.5239 | 5.1301 |

| Replicate points | 0 | 0 |

| Computed experimental error | 0.0000 | 0.0000 |

| Lack-of-fit points | 7 | 5 |

| Min expt. error for non-significant LOF (95%) | 0.0196 | 0.0016 |

| R-squared external test set (Rtest2) | 0.8682 | 0.8525 |

| No | Name | X1 | X2 | X3 | X4 | X5 | X6 | X7 | X8 |

|---|---|---|---|---|---|---|---|---|---|

| AlogP98 | E-State Keys (Sums): S_sCH3 | Shadow Area: XY Plane | Total Dipole | Atomic Composition (Total) | Shadow Area: ZX Plane | Shadow Area Fraction: YZ Plane | Propyl | ||

| 1 | Palmitic acid | 6.3930 | 2.2604 | 89.5046 | 4.9780 | 56.1928 | 85.1321 | 0.6687 | 1.0000 |

| 2 | Palmitoleic acid | 5.9484 | 2.2492 | 86.6844 | 2.9080 | 54.8715 | 85.7617 | 0.6567 | 1.0000 |

| 3 | Stearic acid | 7.3054 | 2.2700 | 96.2423 | 2.1470 | 62.0359 | 98.1686 | 0.6891 | 1.0000 |

| 4 | Oleic acid | 6.8608 | 2.2588 | 103.6651 | 2.7960 | 60.7315 | 95.1076 | 0.7387 | 1.0000 |

| 5 | Linoleic acid | 6.4162 | 2.2347 | 106.5797 | 2.8110 | 59.3642 | 94.3883 | 0.6897 | 1.0000 |

| 6 | Linolenic acid | 5.9716 | 2.1479 | 105.7513 | 2.8200 | 57.9274 | 94.8382 | 0.6877 | 0.0000 |

| 7 | Ricinoleic acid | 5.6239 | 2.1997 | 105.5990 | 4.8030 | 65.1875 | 101.9273 | 0.7271 | 1.0000 |

| 8 | Erucic acid | 8.6856 | 2.2753 | 125.8767 | 2.0470 | 72.3452 | 113.9757 | 0.7312 | 1.0000 |

| 9 | Lauric acid | 4.5682 | 2.2281 | 72.1495 | 2.1760 | 44.3626 | 66.6541 | 0.6586 | 1.0000 |

| 10 | Myristic acid | 5.4806 | 2.2471 | 76.3903 | 4.4560 | 50.3061 | 78.2255 | 0.6920 | 1.0000 |

| 11 | Behenic acid | 9.1302 | 2.2829 | 124.1960 | 2.1550 | 73.6250 | 120.8127 | 0.6712 | 1.0000 |

| 12 | Arachidic acid | 8.2178 | 2.2773 | 111.6795 | 1.5190 | 67.8444 | 109.2919 | 0.6962 | 1.0000 |

| 13 | Decanoic acid | 3.6558 | 2.1988 | 60.8896 | 4.9050 | 38.3422 | 56.8992 | 0.7017 | 1.0000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Zhang, Y.; Yang, S.; Yi, C.; Liu, T.; Zhang, R.; Jia, D.; Peng, S.; Yang, Q. Prediction of Lubrication Performances of Vegetable Oils by Genetic Functional Approximation Algorithm. Lubricants 2024, 12, 226. https://doi.org/10.3390/lubricants12060226

Liu J, Zhang Y, Yang S, Yi C, Liu T, Zhang R, Jia D, Peng S, Yang Q. Prediction of Lubrication Performances of Vegetable Oils by Genetic Functional Approximation Algorithm. Lubricants. 2024; 12(6):226. https://doi.org/10.3390/lubricants12060226

Chicago/Turabian StyleLiu, Jianfang, Yaoyun Zhang, Sicheng Yang, Chenglingzi Yi, Ting Liu, Rongrong Zhang, Dan Jia, Shuai Peng, and Qing Yang. 2024. "Prediction of Lubrication Performances of Vegetable Oils by Genetic Functional Approximation Algorithm" Lubricants 12, no. 6: 226. https://doi.org/10.3390/lubricants12060226

APA StyleLiu, J., Zhang, Y., Yang, S., Yi, C., Liu, T., Zhang, R., Jia, D., Peng, S., & Yang, Q. (2024). Prediction of Lubrication Performances of Vegetable Oils by Genetic Functional Approximation Algorithm. Lubricants, 12(6), 226. https://doi.org/10.3390/lubricants12060226